Submarine pipeline laying machine and hydraulic jetting combined rotating ditcher for 500-meter deep hardpan

A technology of rotary openers and submarine pipelines, which is applied to earth movers/excavators, construction, etc., can solve the problems of difficulty in adapting to the requirements of trenching operations, small trench depth and width, and achieve social and economic benefits Significantly, the effect of deep ditching and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

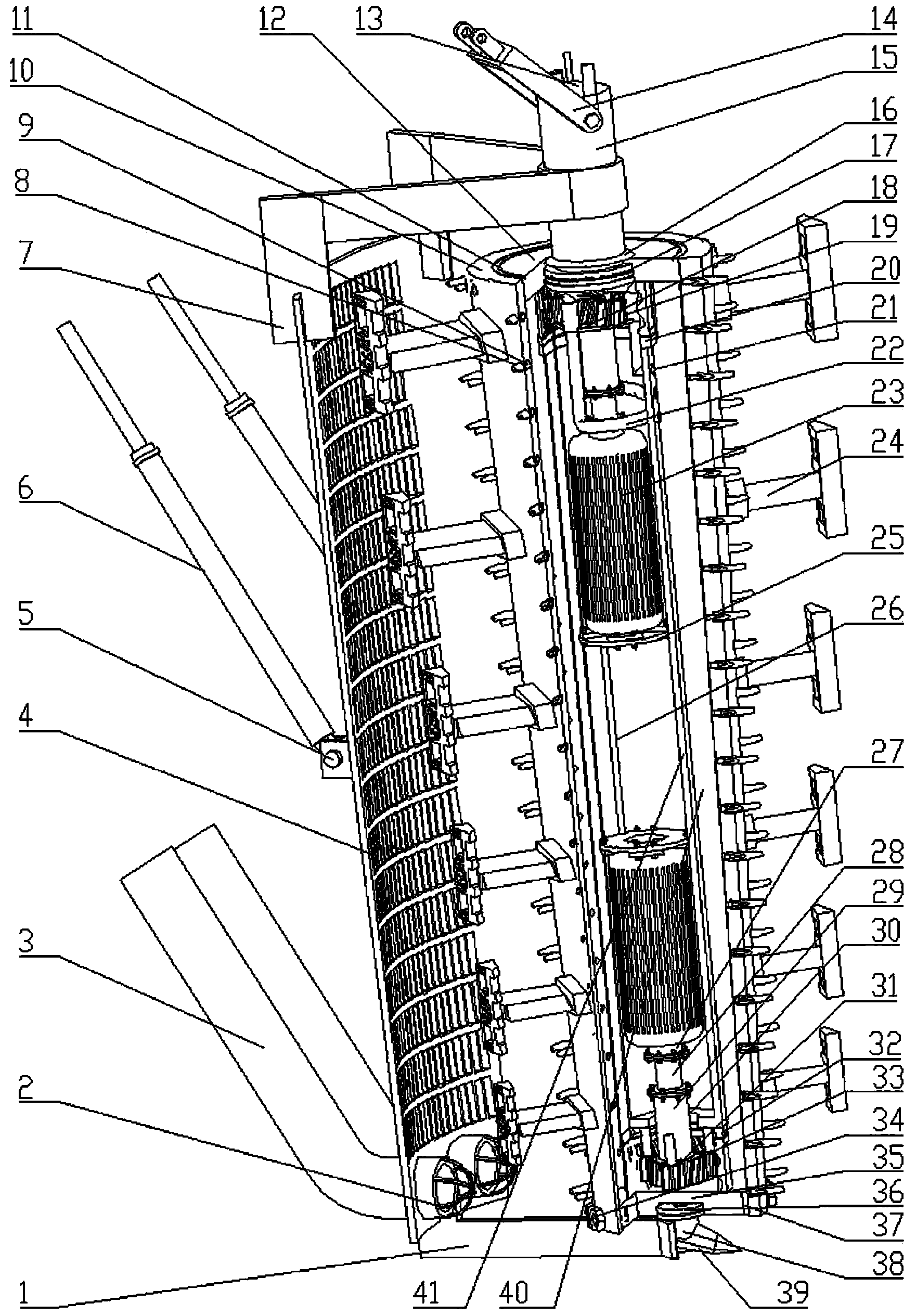

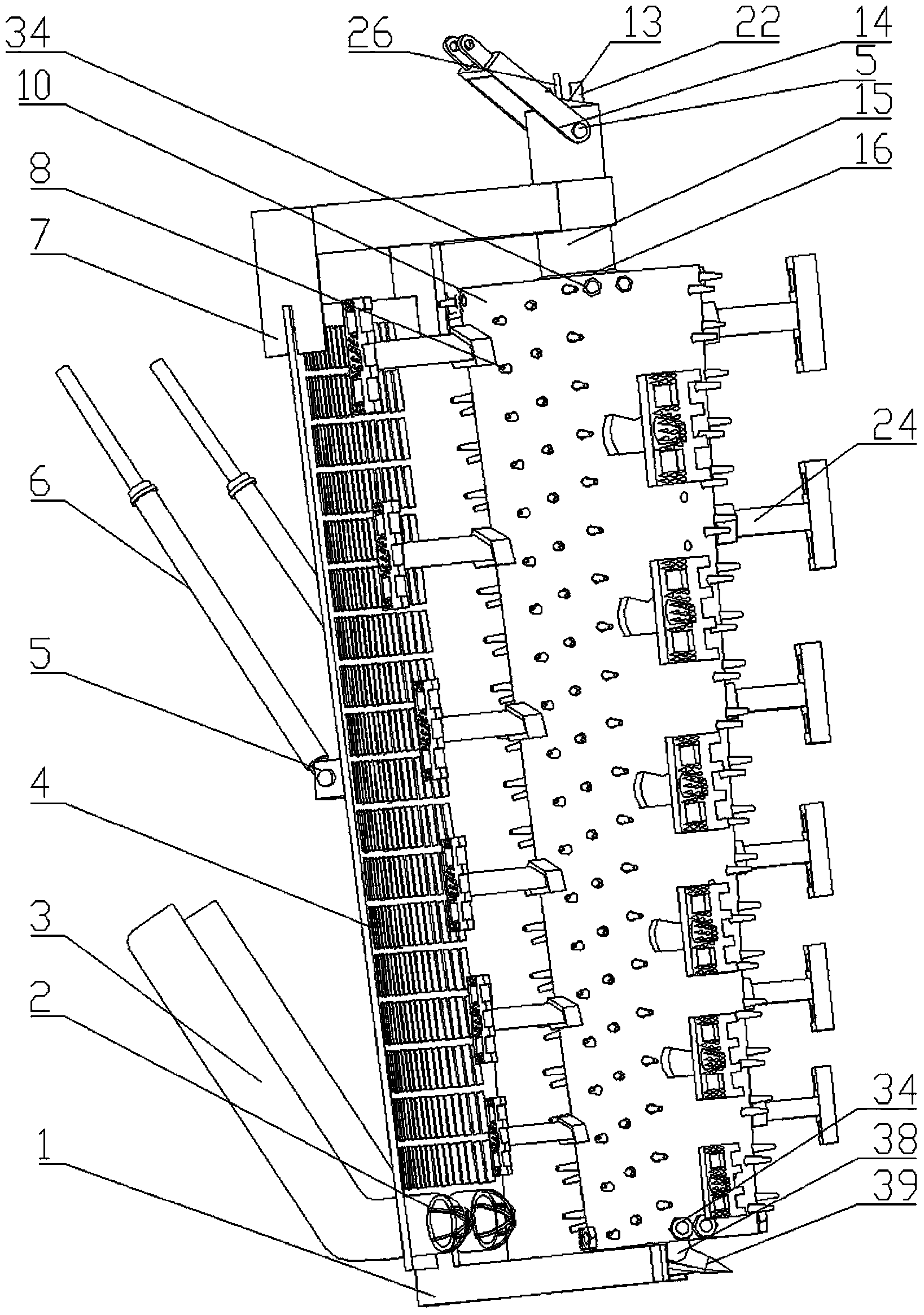

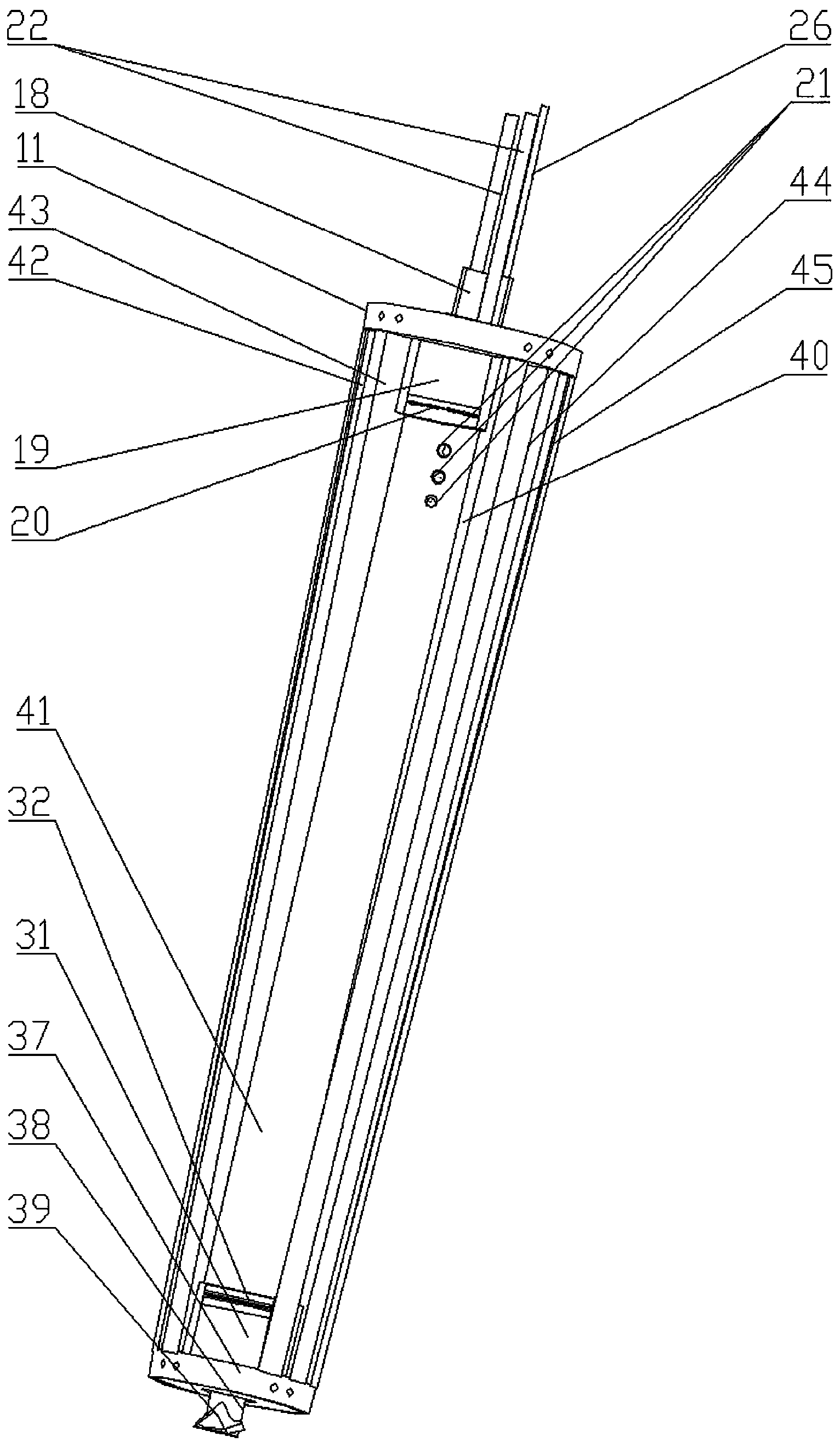

[0028] as attached figure 1 , 2, 3, and 14, a 500-meter water depth hard soil subsea pipeline laying machinery and hydraulic jet composite rotary opener, mainly composed of a hydraulic push rod 6, a pin shaft 5, a permeable shield 4, a protective cover 2, and a mud Pump suction pipe 3, bracket on shielding board 7, lower bracket on shielding board 1, upper suspension cylinder 15, lower support column 38, suspension bracket 14, rubber water-tight gasket 13, top cover 12, bottom cover 35, upper thrust cone Roller bearing 17, lower thrust tapered roller bearing 36, gasket 16, upper gasket 11, lower gasket 37, fastening bolt 34, outer rotating cylinder 10, knife teeth 24, nozzle 8, one-way flow valve 9 , upper thrust cylindrical roller bearing 20, lower plane fixed shaft gear train 31, lower thrust cylindrical roller bearing 32, motor 23, motor seat 25, motor shaft 27, coupling 28, power output shaft 29, key 33, high pressure Water pipe 22, cable 26, bracket 18, water outlet 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com