Composite hole exploration method combining drilling, Luoyang shovel and drill rod exploration

A Luoyang shovel and drill exploration technology, which is applied in the field of engineering exploration and exploration, can solve the problems of limited exploration depth, low exploration accuracy of pipelines and pipelines, and difficult exploration of complex strata, and achieves the effect of easy operation and easy control of construction risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

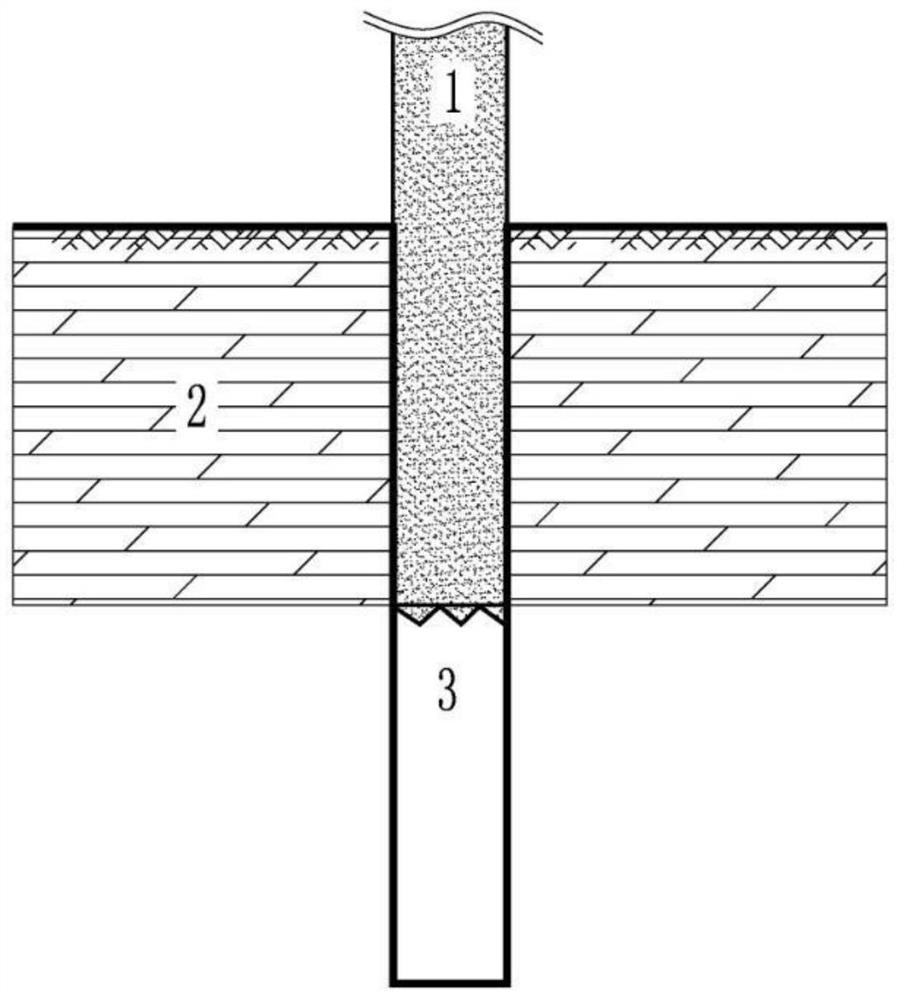

[0034] Embodiment 1, take to carry out construction on municipal road surface (comprising sidewalk) in this example, this method can be used for multiple road surface and ground; sandstone, lime soil cushion) hard surface layer 2, forming exploration drilling 3;

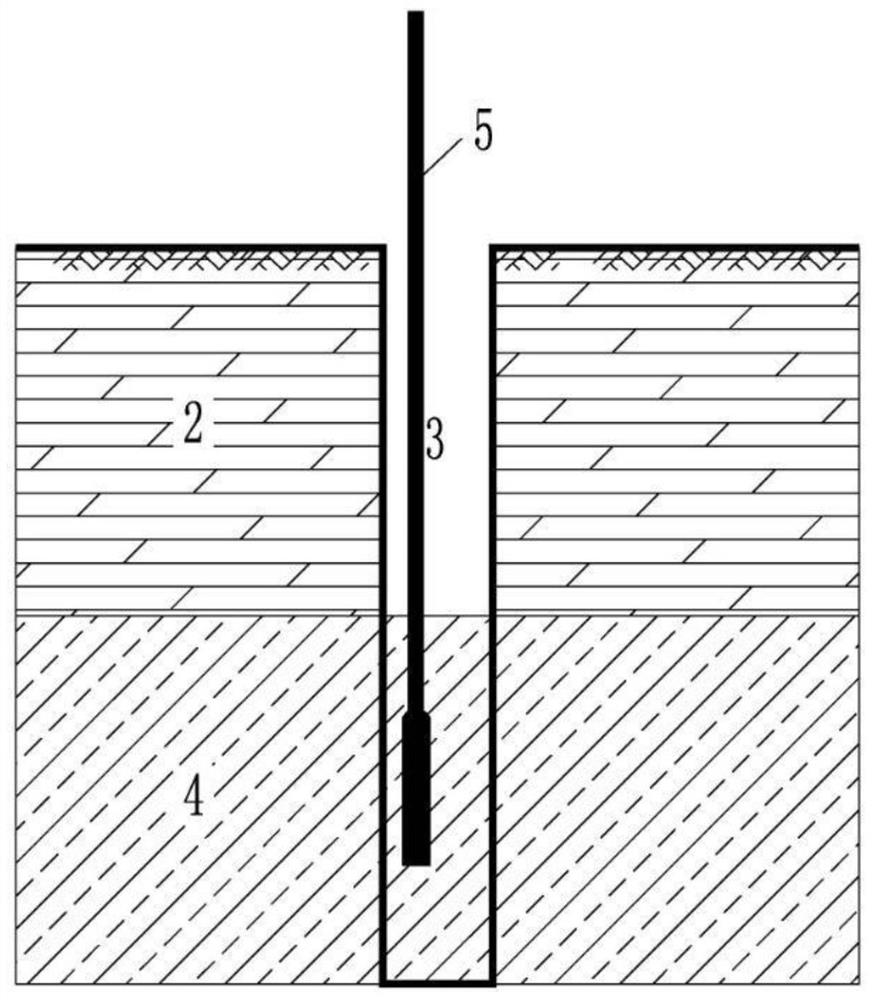

[0035] When the cohesive soil layer 4 is encountered after the drilling is completed, use Luoyang shovel 5 to manually detect, and the detection hole diameter is not smaller than the drilling diameter of the drilling rig; if the soil moisture content is small, it is not suitable to bring soil samples, and an appropriate amount of water can be injected into the detection hole for infiltration The soil is then probed with Luoyang shovel 5, and the depth of each probe is ≤0.50m; until the maximum buried depth of the known underground pipeline (road) is passed, the probe hole is completed. If meeting underground pipeline (road), then drilling rig shifts and carries out exploration work again.

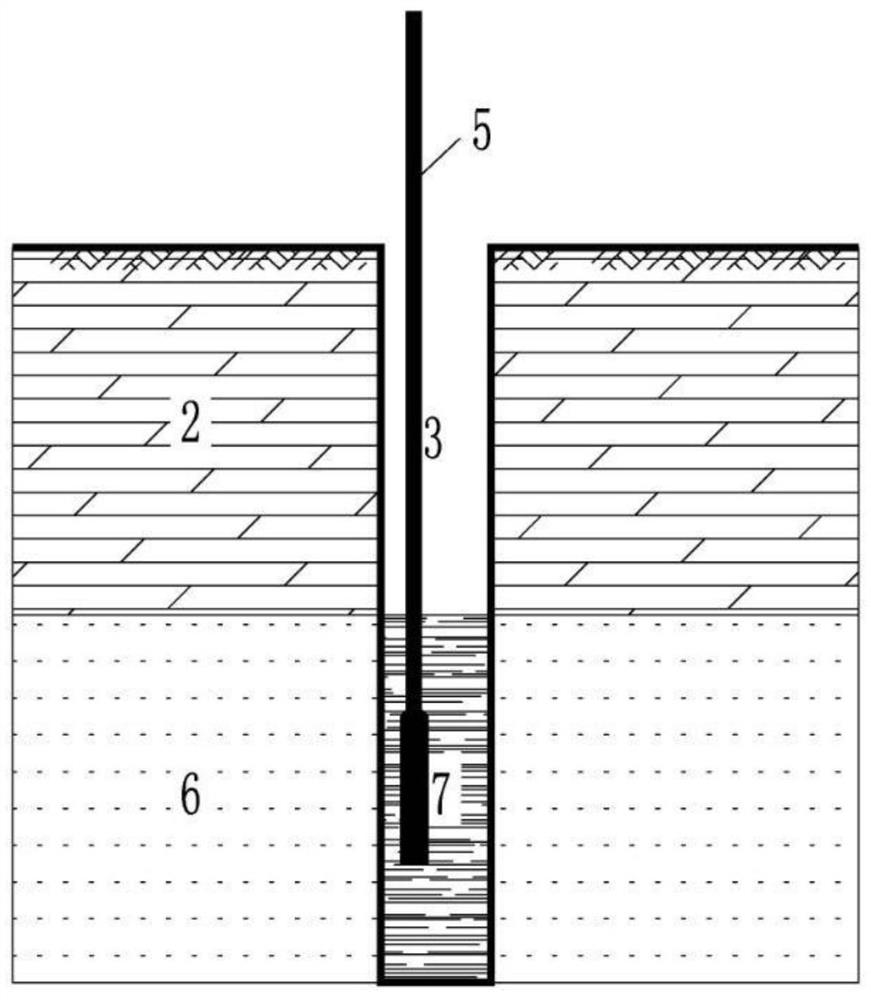

[0036] When the sandy soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com