Mechanical piling method for third level bottom-expanded combined pile body

A combined pile and machinery technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of unprotected construction conditions, low strength of cast-in-place concrete, large loss end bearing capacity, etc. Construction cost, good concentricity, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

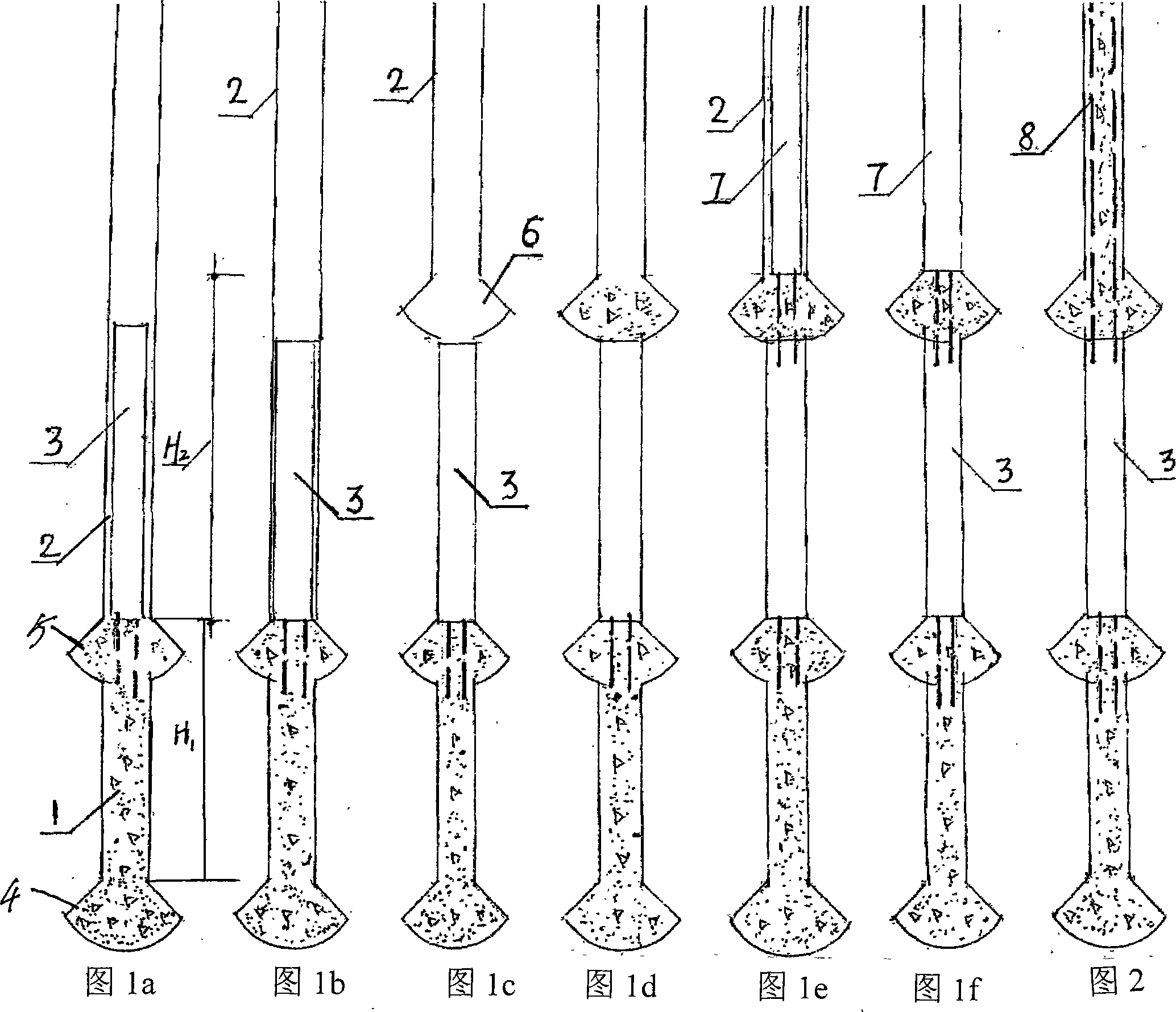

Embodiment 1

[0018] The mechanical pile-forming method of the three-stage bottom-expanding combined pile body of the present invention comprises the following process steps: a, sinking tube 2 with the metal pile head is sunk into the design elevation of the hard soil layer; b, taking out the metal pile head; c, using One of the mechanical bottom expansion equipment, explosive forming and YEJ-800 hydraulic support plate forming machine to process the lower base space 4, and pull up the immersed tube 2 to the set distance H 1 , process the middle base space 5, use immersed tube prefabricated steel concrete bottom expansion and suction equipment to clean the broken soil in the lower base space 4, lower the prefabricated hollow pile body 3 with inserted ribs at the lower end into the immersed tube 2 and pour concrete into it Inject the lower base, the lower pile body, and the middle base; d, pull up the immersed tube 2 to the set distance H 2 , inject cement slurry into the gap between the pre...

Embodiment 2

[0020] The steps a to d are the same as in the embodiment 1, step e is to lower the steel bar 8 from the immersed tube 2 and anchor it with the upper base, and pour the upper pile body with concrete; f, take out the immersed tube.

[0021] The specific steps for cleaning the broken soil in the space of the base with the soil extraction equipment in the above-mentioned process c are as follows: Use the air soil suction equipment to extract the soil, when there is only a small amount of loose soil left in the base, pour water from the mouth of the immersed tube, and pour water while pouring. Suck off until the soil is clean.

[0022] The specific steps of processing the upper and lower base spaces with mechanical bottom expansion equipment in the above-mentioned processes c and d are as follows: Align the positioning iron feet of the bottom expansion equipment with the marks on the mouth of the immersed tube and lower them into the immersed tube, and the upper end of the equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com