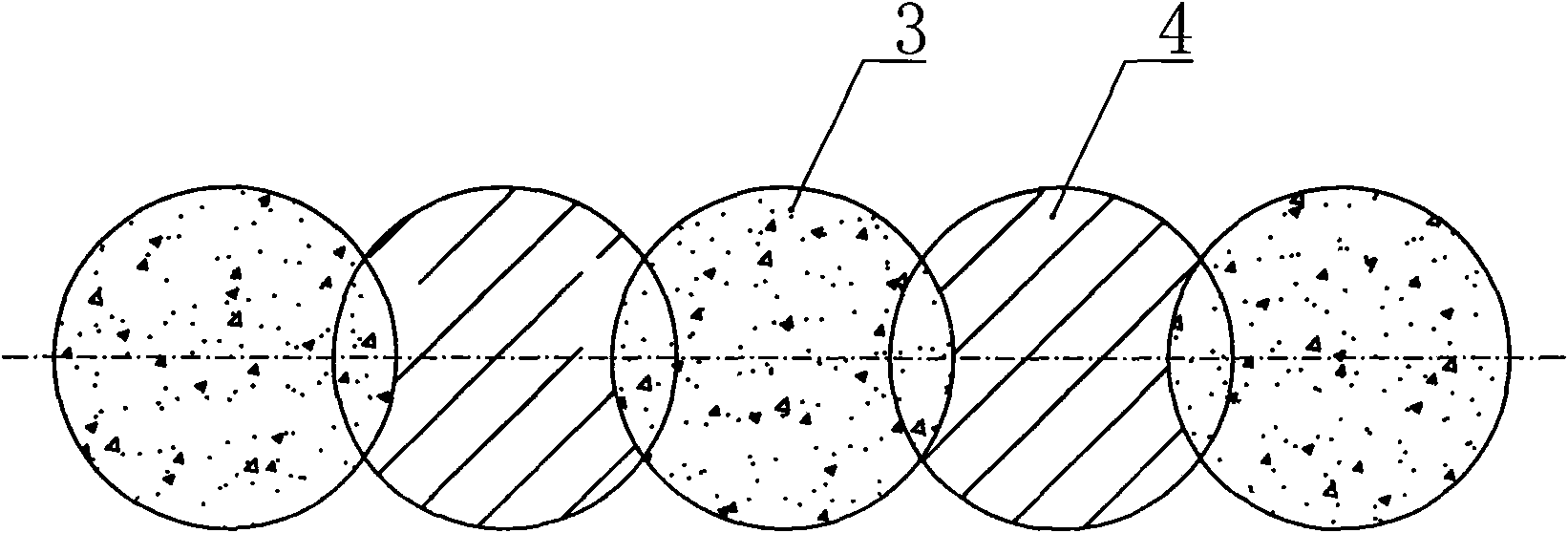

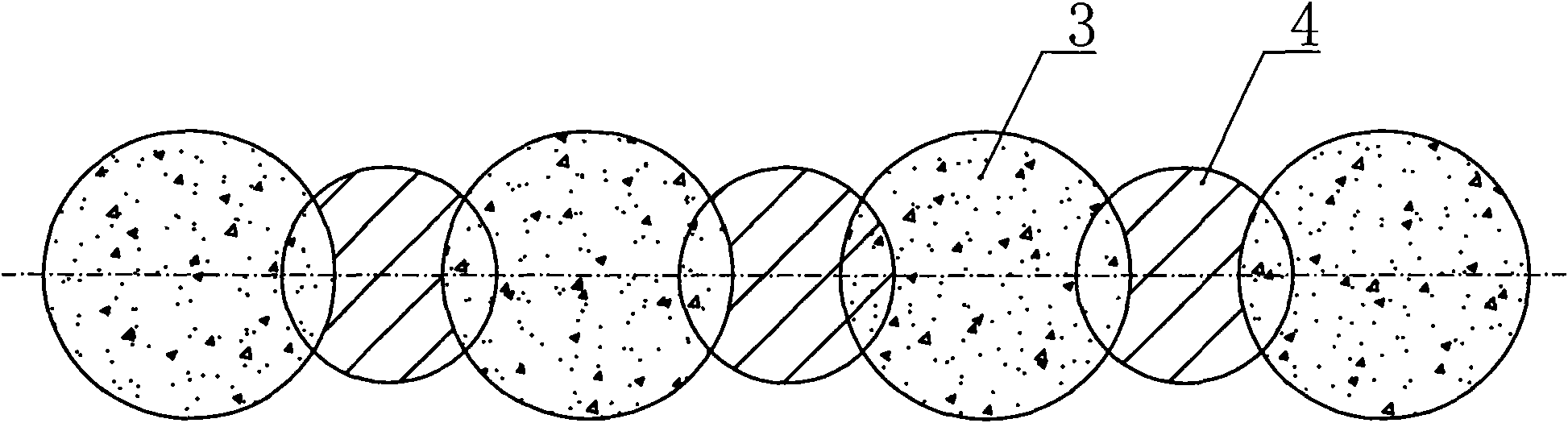

Occlusive pile of long spiral stirring water-stop curtain and construction process thereof

A technology of stirring piles and long spirals, which is applied in the field of long spiral stirring water-stop curtain occlusal piles and the construction technology of piles, which can solve the problems of difficult civilized construction, low construction efficiency, failure to reach the designed depth and designed diameter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

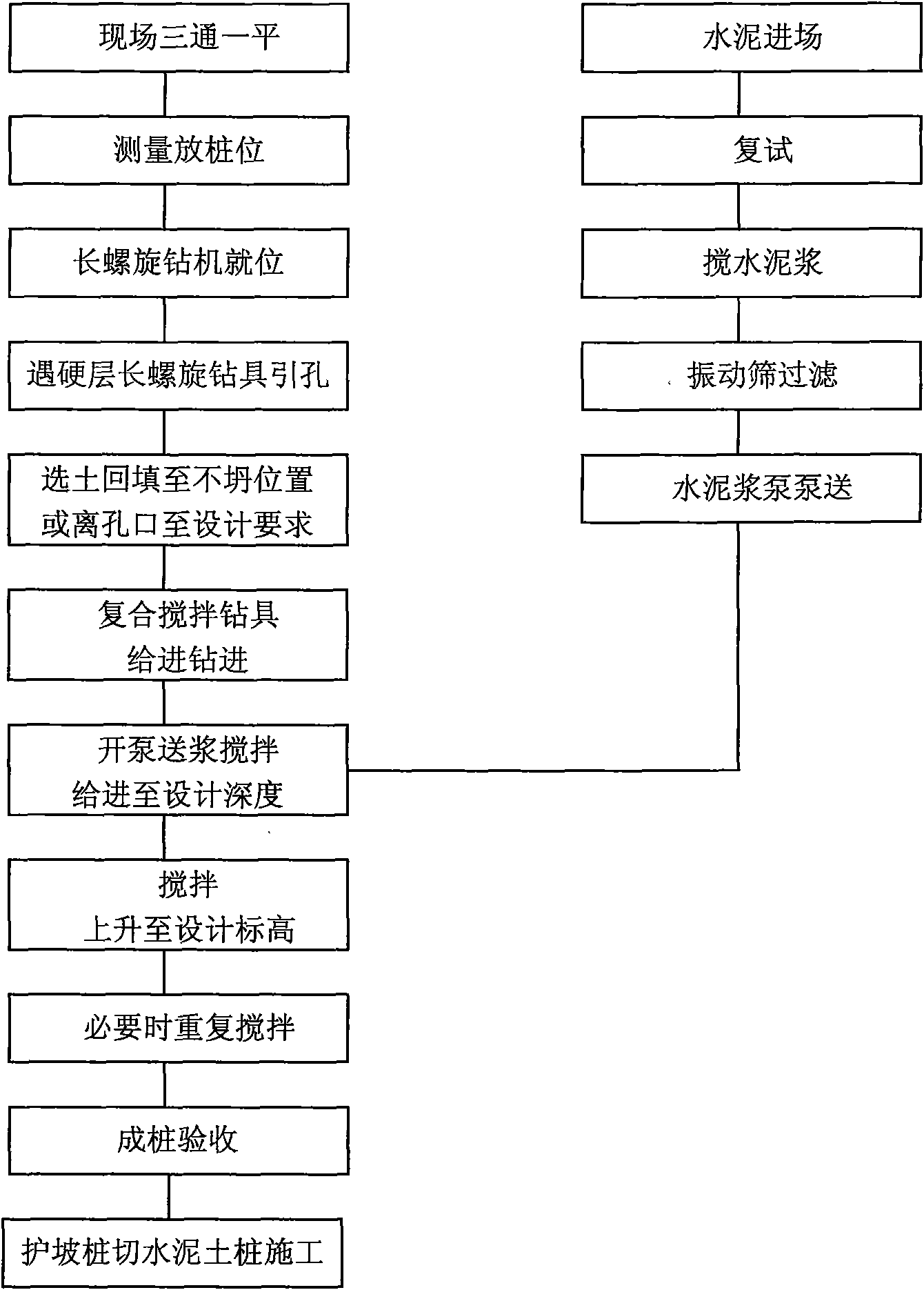

Method used

Image

Examples

Embodiment 1

[0022] Example 1 - Mafang New Village Phase II Underground Garage Foundation Pit Support Project:

[0023] 1. Project overview and geological conditions

[0024] The proposed project is located on Mafang East Road, Chaoyang District, Beijing, and is used as an underground garage with a second basement floor and 1.5m of earth covering. This project is a reinforced concrete frame structure on the second floor underground, partly out of the ground. The foundation adopts beam-slab raft foundation.

[0025] The relative elevation of this project ±0.000 is equivalent to the absolute elevation of 38.600. The elevation of the bottom of the underground garage is -13.46m (the absolute elevation is 25.14m), and the depth of the foundation pit is 12.76m.

[0026] 1.1 Engineering geological conditions of the site

[0027] According to the depositional age and genetic type, the strata in the survey area are divided into two categories: artificial accumulation layer and Quaternary sedime...

Embodiment 2

[0097] Example 2 Foundation Pit Support Engineering of Tianli Production R&D Building Project

[0098] 1 Project overview

[0099] The proposed Tianli production and R&D building project is located at No. 101 Lize Zhongyuan, Wangjing, Chaoyang District, Beijing, and is now in the courtyard of Beijing Tianli Cryogenic Equipment Co., Ltd.

[0100] According to the information provided in the "Tianli Production and R&D Building Foundation Pit Support Construction Bidding Document", this project includes the main building and the pure underground part. The main building has 13 floors above the ground, and the frame-core tube structure has a total height of 59.9m; there are 2 underground floors. The south side of the main building is a purely underground part, with a basement floor, which is mainly used for parking vehicles (partially with equipment mezzanine), frame structure, and its overlying soil is 3.90m.

[0101] The ground elevation of the basement 2 floors of the main buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com