Organic light emitting diode device, manufacturing method thereof and display device

A light-emitting diode, organic technology, applied in the direction of diodes, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of poor light transmittance or electrical conductivity of cathode materials, and achieve the effect of enhancing conductivity and preventing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

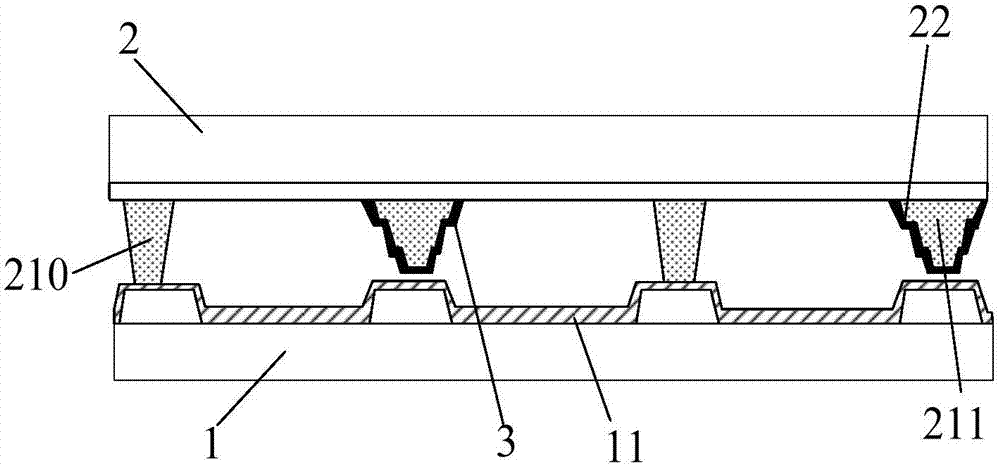

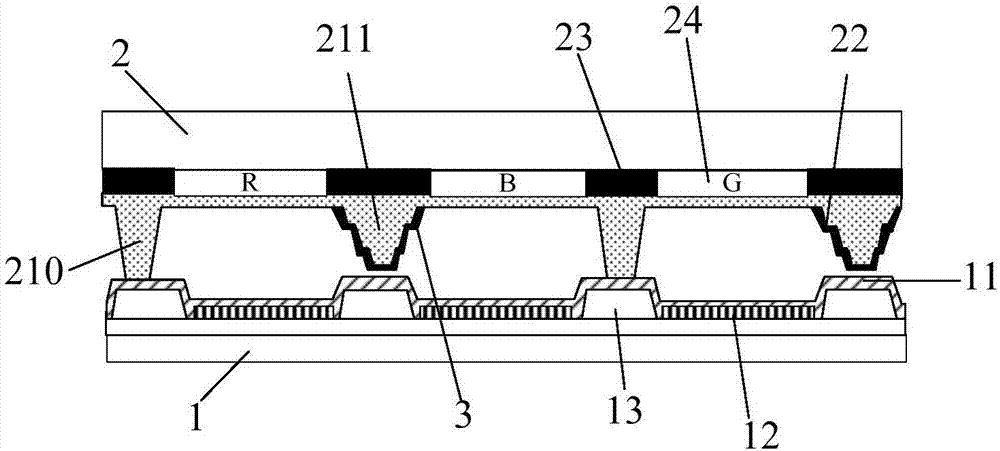

[0032] This embodiment provides an organic light emitting diode device, such as figure 1 As shown in the figure, it includes a first substrate 1 and a second substrate 2 that are arranged opposite to each other, a first electrode 11 is provided on the side of the first substrate 1 close to the second substrate 2, and the second substrate 2 is close to the first substrate One side of 1 is provided with a first spacer 211 , wherein, the outer surface of the first spacer 211 close to the first substrate 1 has an uneven structure 22 , and the first spacer 211 is close to the outer surface of the first substrate 1 . The surface is covered with an auxiliary electrode layer 3 , and at least a part of the auxiliary electrode layer 3 is connected to the first electrode 11 . It should be noted that the auxiliary electrode layer may partially or completely cover the outer surface of the first spacer, as long as it is ensured that the auxiliary electrode layer is in contact with the first...

Embodiment 2

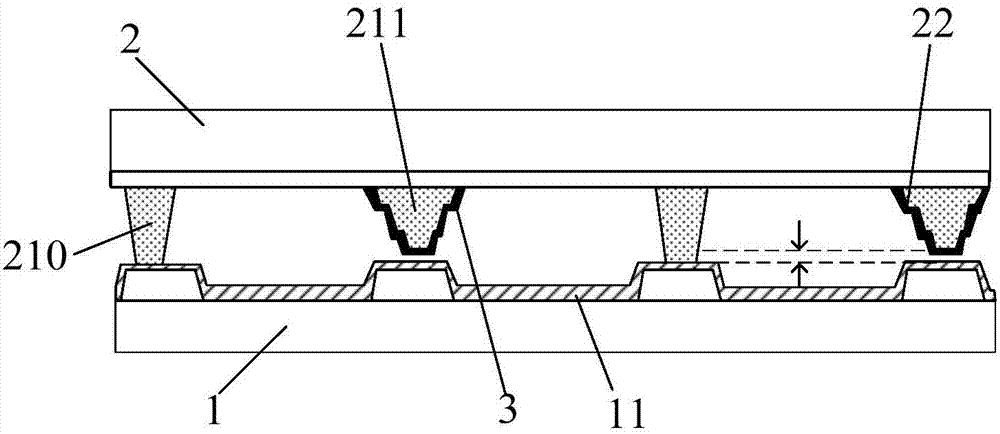

[0035] This embodiment provides an organic light emitting diode device, such as figure 2 As shown in the figure, it includes a first substrate 1 and a second substrate 2 that are oppositely arranged. A first electrode 11 is provided above the surface of the first substrate 1 close to the second substrate 2, and the second substrate 2 is close to the first substrate. 1 is provided with a main spacer 210 and a first spacer 211 ; the surface of the first spacer 211 close to the first substrate 1 has an uneven structure 22 , and the uneven structure 22 is close to the surface of the first substrate 1 . One side is covered with an auxiliary electrode layer 3 , and at least part of the auxiliary electrode layer 3 is connected to the first electrode 11 .

[0036] Among them, see Figure 5 , the uneven structure 22 of this embodiment includes but is not limited to Figure 5 The irregular surface a, the arc surface b, the rhomboid surface c, and the uneven surface d shown in the cro...

Embodiment 3

[0059] This embodiment provides a method for fabricating an organic light emitting diode device. The organic light emitting diode device in this embodiment includes a first substrate 1 and a second substrate 2. The first substrate 1 and the second substrate 2 are separately prepared and then packaged in a box. Specifically include the following steps:

[0060] S01 , forming a first electrode 11 on the first substrate 1 ; wherein, the structure on the first substrate 1 further includes a driving circuit layer, a pixel defining structure layer 13 and a light-emitting functional layer 12 . The preparation method of S01 is as follows:

[0061] S01a, cleaning the substrate of the first substrate 1; then preparing the TFT process of the driving circuit layer on the substrate of the first substrate 1;

[0062] S01b, coating a layer of photocurable material with a thickness of 1.6-2.0 microns by spin coating, and after pre-baking, exposing, developing, and post-baking, and patterning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com