Assembled underground structure of precast concrete planks and construction method thereof

A prefabricated concrete slab and prefabricated concrete technology, applied in underwater structures, infrastructure engineering, excavation and other directions, can solve the problems of low work efficiency, high labor cost and high engineering cost, and achieve cost saving, cost reduction, and engineering reduction. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

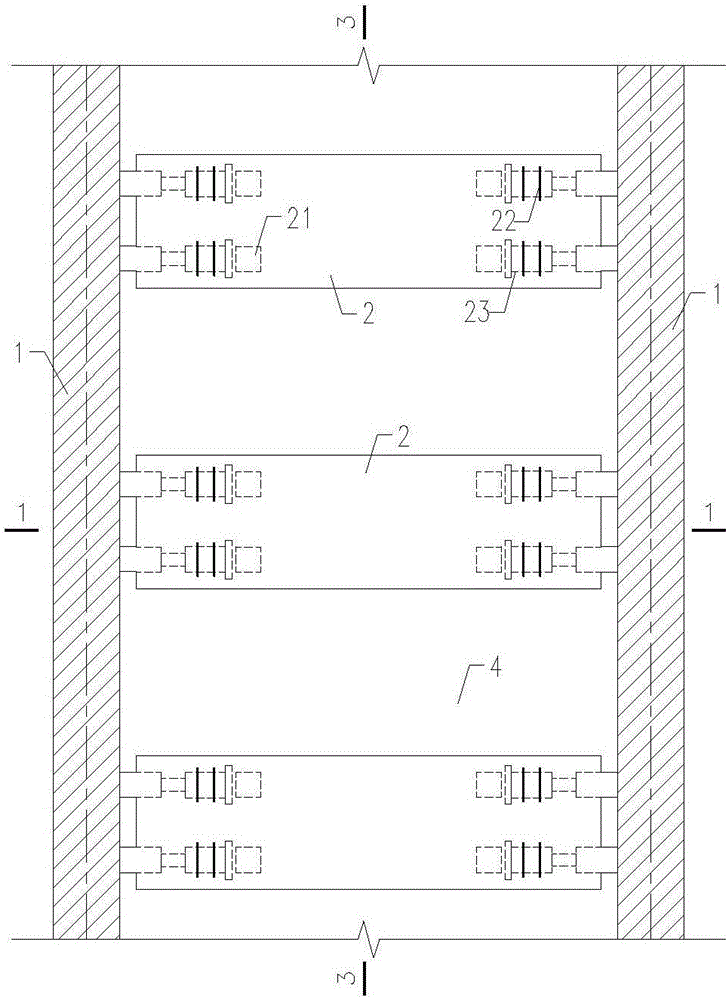

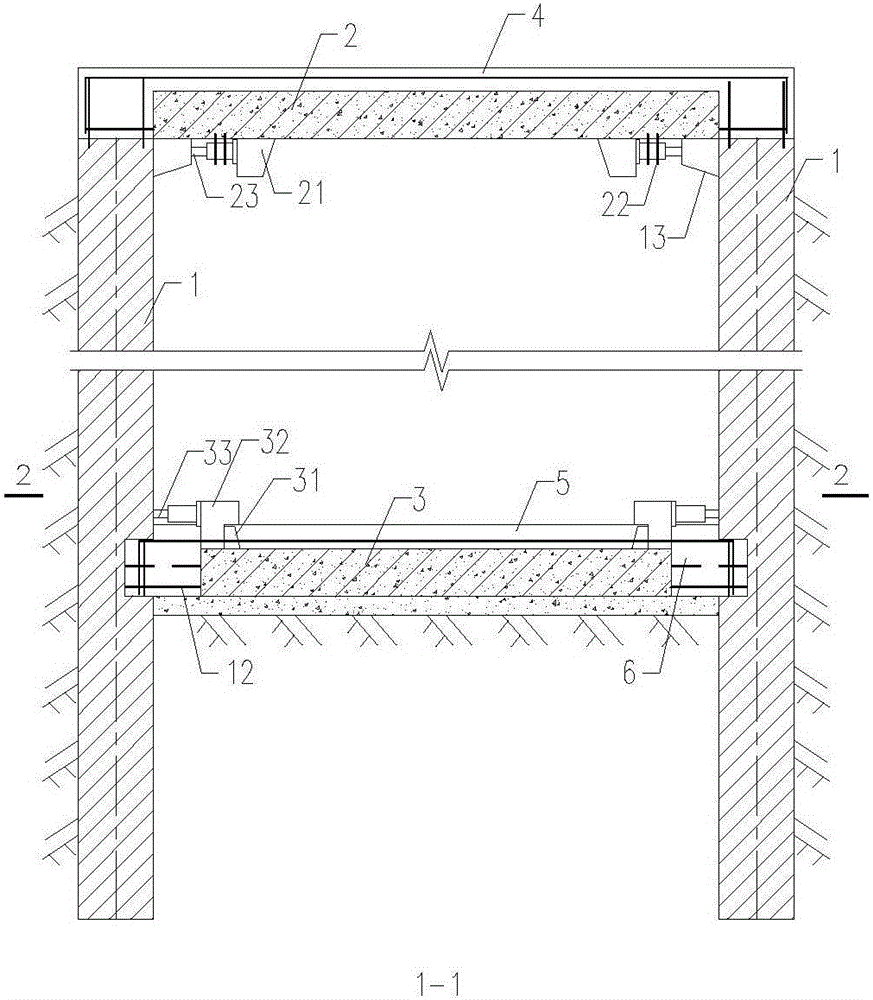

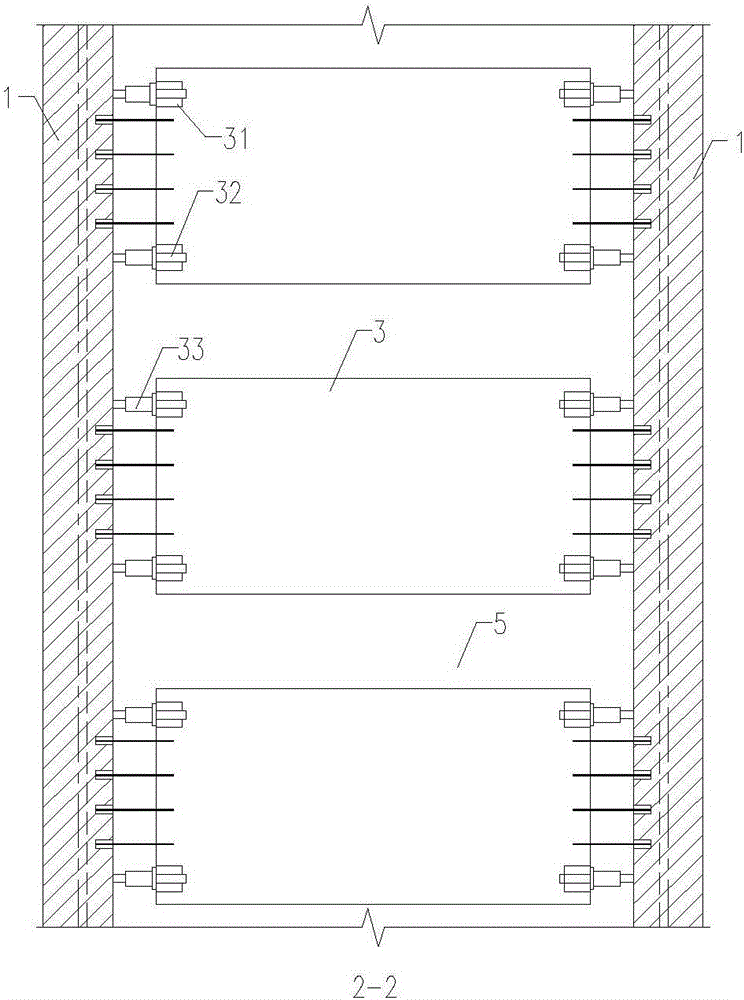

[0050] The prefabricated concrete slab-assembled underground structure of the present invention comprises a wall, a roof and a horizontal partition, the wall is formed by splicing a plurality of prefabricated concrete wall panels in the vertical and horizontal directions, and the roof is composed of spaced apart It is composed of a plurality of prefabricated concrete roofs 2 and roof cast-in-place splicing concrete 4 poured between adjacent precast concrete roofs 2, and the number and setting positions of the horizontal partitions are related to the number and setting of the prefabricated concrete slab assembled underground structure. Consistently, the horizontal partition is composed of a plurality of prefabricated concrete partitions 3 arranged at intervals and the partition cast-in-place splicing concrete 5 poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com