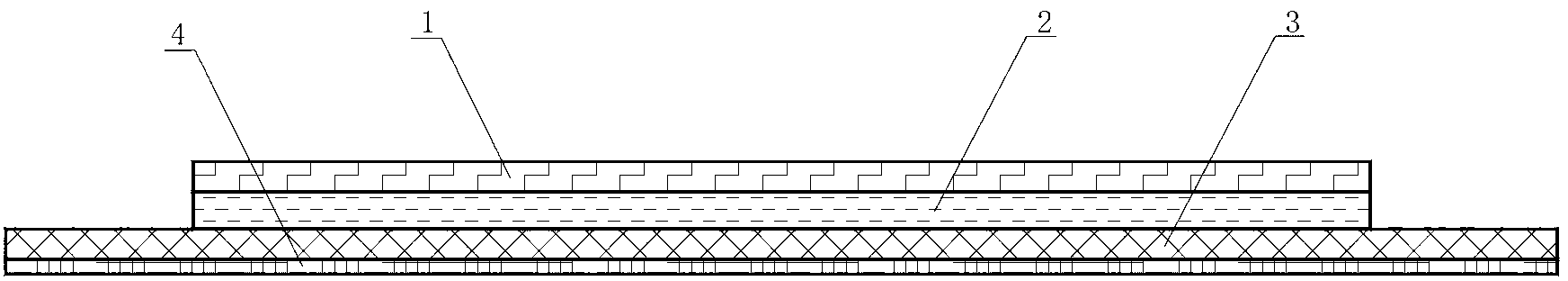

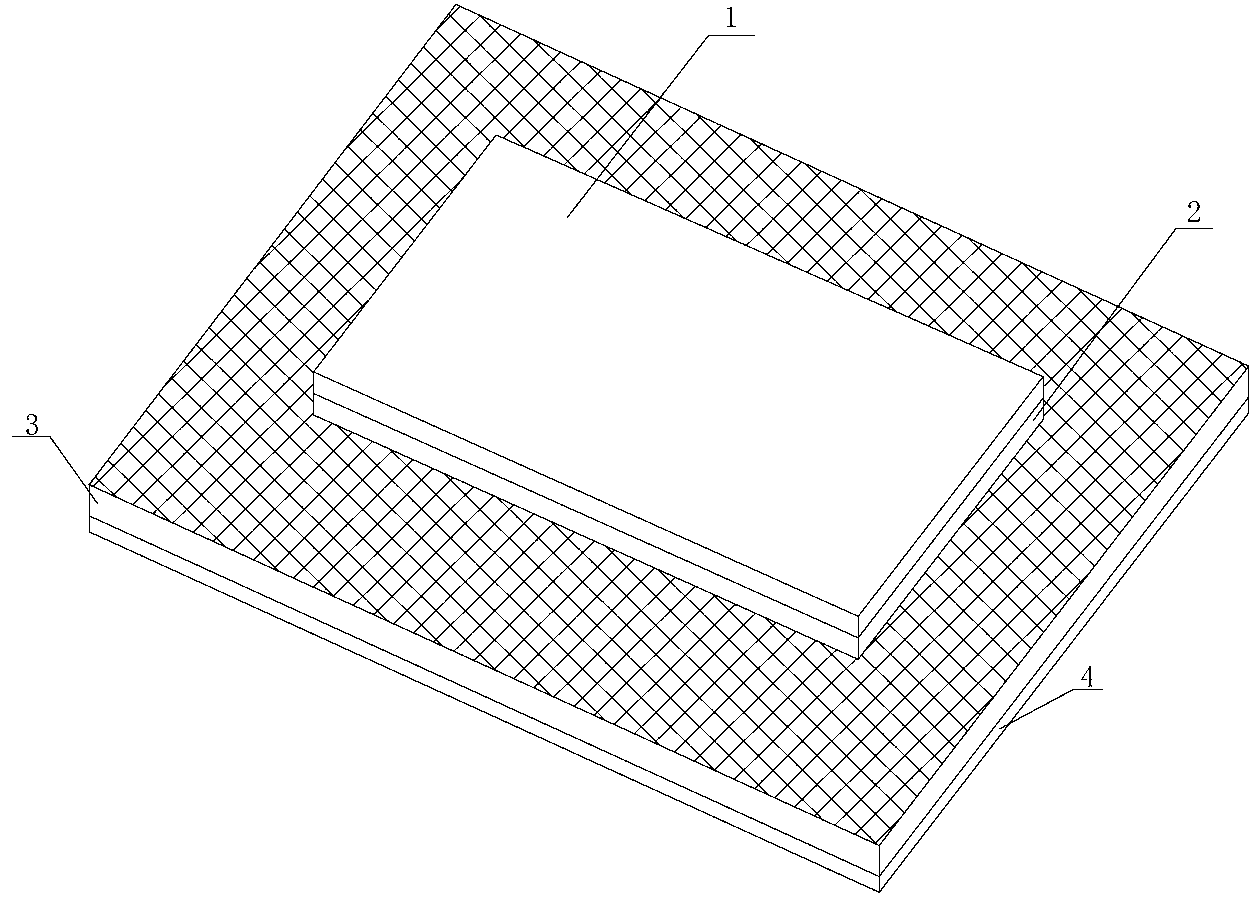

Method for preparing multi-layer composite functional surgical dressing

A multi-layer composite and functional technology, applied in viscous dressings, dressings, medical science, etc., can solve the problems of non-covering wound protection, repeated wound damage, limited bonding strength, etc., to prevent wound fluid infection, Good biocompatibility, the effect of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of described multilayer composite functional medical dressing is as follows:

[0043] (A) Prepare functional layer 1, adopt 100% chitosan fiber, the length of chitosan is 38mm, and fineness is 1.78dtex, and 1 gram weight of the obtained functional layer is 40g / m 2 , send the fiber raw materials into the cotton storage box, lay them in piles, grab them vertically and send them to the BG038 type opening equipment for loosening, dissociation, mixing and opening until uniform, the resulting opening rate is 95%, and then through BG218 type carding Machine carding and cross-lapping machine laying nets to obtain functional layer 1 fiber web, specific process parameters: carding machine feeding speed 0.35m / min, cylinder speed 600m / min, output fiber web speed 35m / min, web laying speed 38m / min min, the output speed of the bottom curtain is 2m / min, and the unevenness of the output fiber web is 2.5%.

[0044] (B) prepare water-absorbing layer 2, adopt 100% v...

Embodiment 2

[0051] The preparation method of concrete multilayer composite functional medical dressing is as follows:

[0052] (A) prepare functional layer 1, adopt 80 / 20 chitosan fiber / viscose fiber, the length 38mm of chitosan, fineness is 1.78dtex, the length 38mm of viscose fiber, fineness is 1.68dtex, the function obtained Layer 1 gram weight is 35g / m 2 , send the fiber raw materials into the cotton storage box, lay them in piles, grab them vertically and send them to the BG038 type opening equipment for loosening, dissociation, mixing and opening until uniform, the resulting opening rate is 95%, and then through BG218 type carding The web is obtained by machine carding and cross-lapper machine, functional layer 1 web, specific process parameters: carding machine feeding speed 0.40m / min, cylinder speed 700m / min, output web speed 48m / min, web laying speed 50m / min, the output speed of the bottom curtain is 5m / min, and the unevenness of the output fiber web is 2.0%.

[0053] (B) prep...

Embodiment 3

[0060] The preparation method of concrete multilayer composite functional medical dressing is as follows:

[0061] (A) prepare functional layer 1, adopt 70 / 30 chitosan fiber / viscose fiber, the length 38mm of chitosan, fineness is 1.78dtex, the length 38mm of viscose fiber, fineness is 1.68dtex, the function obtained Layer 1 gram weight is 25g / m 2 , send the fiber raw materials into the cotton storage box, lay them in piles, grab them vertically and send them to the BG038 type opening equipment for loosening, dissociation, mixing and opening until uniform, the resulting opening rate is 95%, and then through BG218 type carding Machine carding and cross-lapping machine laying nets to obtain functional layer 1 fiber web, specific process parameters: carding machine feeding speed 0.35m / min, cylinder speed 600m / min, output fiber web speed 30m / min, web laying speed 33m / min min, the output speed of the bottom curtain is 2m / min, and the unevenness of the output fiber web is 1.8%.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com