High-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material

A polyolefin cable material, thermoplastic technology, applied in the direction of plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problem that the cable is difficult to pass the winding test and low temperature tensile test, and the material is difficult to meet the change rate of mechanical properties Requirements, intolerance to precipitation and migration resistance, etc., to achieve excellent carburization effect, lower hardness, and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

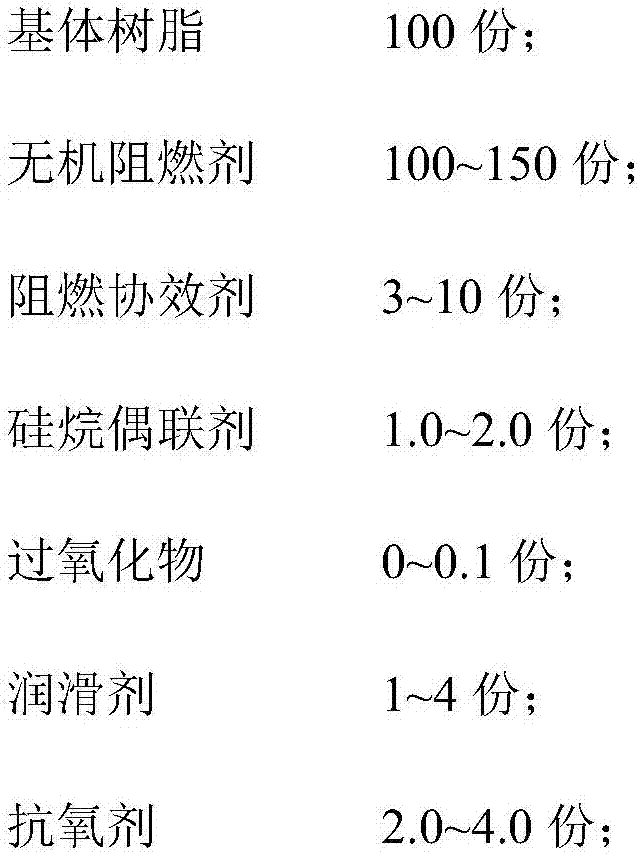

Method used

Image

Examples

Embodiment 1

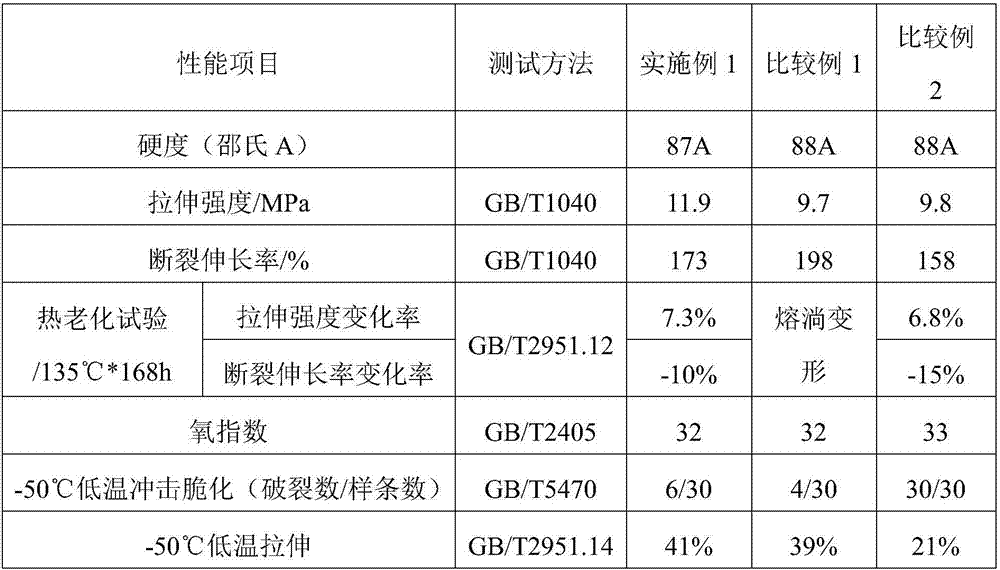

[0022] Weighing in parts by weight: 55 parts of ethylene-vinyl acetate copolymers with a mass % content of vinyl acetate monomer of 33%, 35 parts of olefin block copolymer resins with a brand name of INFUSE9010, and 1.5% of horse 10 parts of anhydride-grafted ethylene-vinyl acetate copolymer, 120 parts of aluminum hydroxide, 10 parts of organic silicon of SFR-100, 1.5 parts of vinyltrimethoxysilane, 0.07 parts of dicumyl peroxide, low Molecular weight ethylene-maleic anhydride copolymer 1 part, ethylene bis stearic acid amide 1.5 parts, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionic acid]pentaerythritol ester 1 1 part and 1 part of ditetradecyl thiodipropionate. The olefin block copolymer resin described in this example is a molecular structure with hard segment and soft segment synthesized by chain shuttling technology, wherein: the hard segment has crystallizable ethylene-octene with low comonomer content and melting temperature chain segment, the soft segment h...

Embodiment 2

[0035] Take by weight: the mass % content of methyl acrylate monomer is 45 parts of ethylene-methyl acrylate copolymer, 35 parts of olefin block copolymer resin, the maleic anhydride grafting of 1.3% graft ratio 20 parts of ethylene-octene copolymer, 90 parts of aluminum hydroxide, 35 parts of hydromagnesite powder, 5 parts of sepiolite, 1.8 parts of vinyltriethoxysilane, 3,5,5-trimethyl peroxide 0.09 parts of tert-butyl caproate, 1 part of polyhydroxymagnesium stearate, 1.5 parts of ethylene bisstearic acid amide, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) 1.5 parts of propionic acid] pentaerythritol ester and 1.0 parts of ditetradecyl thiodipropionate. The content not mentioned in this embodiment is the same as embodiment 1.

[0036] Since the preparation example of Example 2 is the same as that of Example 1, it will not be described again.

[0037] The performance test data of the high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant ...

Embodiment 3

[0040] Take by weight: the mass % content of ethyl acrylate monomer is 25 parts of ethylene-ethyl acrylate copolymer, 55 parts of olefin block copolymer resin, the maleic anhydride grafting of 1.4% graft rate 20 parts of ethylene-methyl acrylate copolymer, 100 parts of aluminum hydroxide, 50 parts of magnesium hydroxide, 7 parts of silicone, 1 part of vinyl tris(β-methoxyethoxy)silane, 1,1-bis( 0.07 parts of tert-butylperoxy)-3,5,5-trimethylcyclohexane, 2 parts of ethylene bisstearic acid amide, 2 parts of silicone, tetrakis[β-(3',5'-di-tert 1.8 parts of butyl-4'-hydroxyphenyl) propionic acid] pentaerythritol ester and 1.2 parts of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite. The content not mentioned in this embodiment is the same as embodiment 1.

[0041] Since the preparation method of Example 3 is the same as the preparation example of Example 1, it will not be repeated.

[0042] The performance test data of the high-temperature-resistant soft thermoplastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com