Halogen-free fire-retardant polyphenyl ether composition capable of improving low-temperature toughness and preparation method thereof

A low-temperature toughness, polyphenylene ether technology, applied in the field of halogen-free flame retardant polyphenylene ether composition and its preparation, polyphenylene ether composition and its preparation field, can solve the problems of low temperature impact strength decrease, etc., achieve outstanding weather resistance, The effect of high fluidity and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

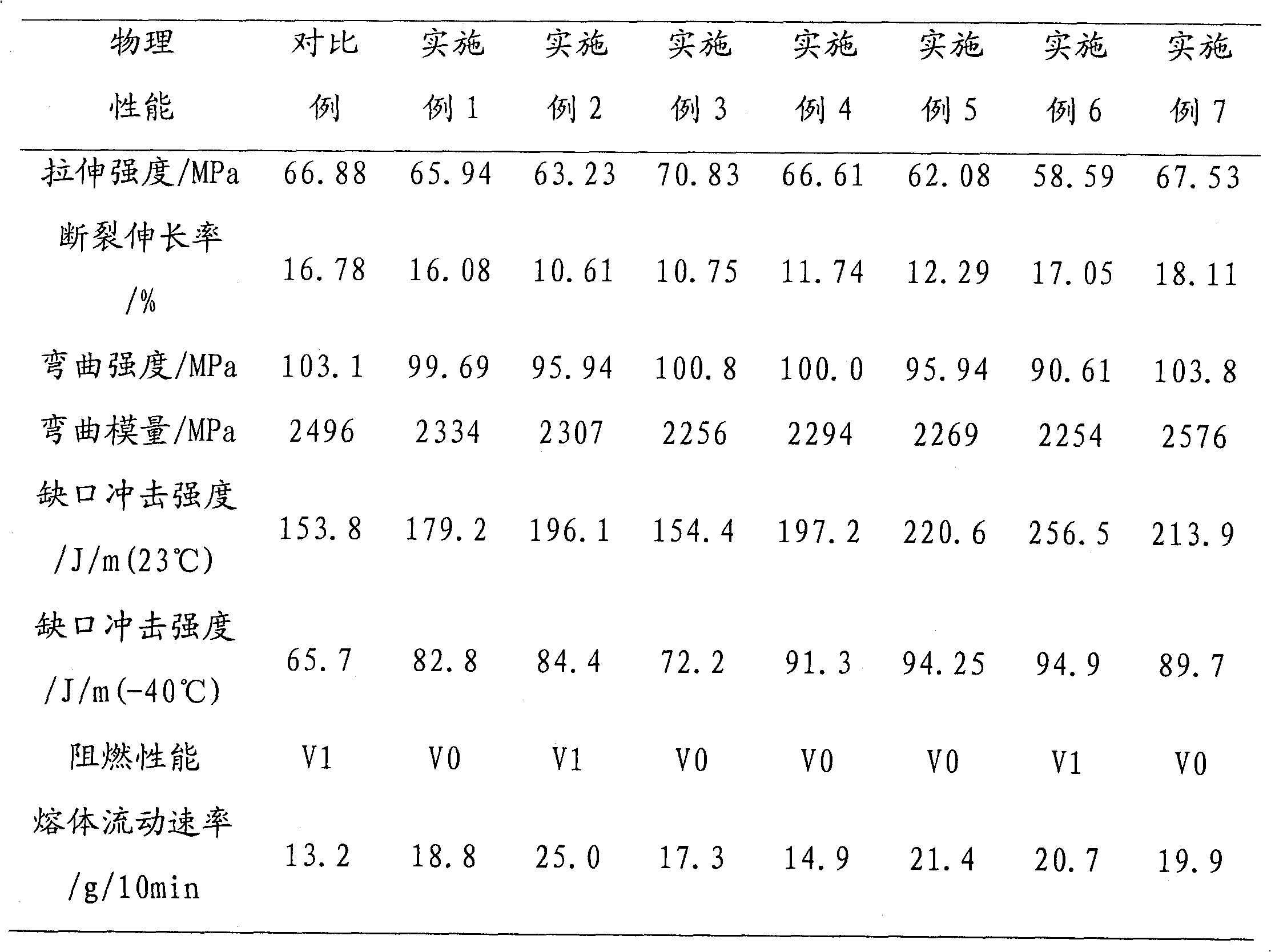

Examples

Embodiment 1

[0023] With the polyphenylene ether resin (intrinsic viscosity 0.45dL / g) of 20 weight parts, the high-impact polystyrene resin (melt flow rate 5g / 10min) of 20 weight parts, the anti-dripping agent of 0.2 weight part in high-speed mixer Mixed for 2 minutes, then added 60 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.45dL / g), 5 parts by weight of maleic anhydride grafted styrene-butadiene-styrene copolymer (domestic SEBS-g- MAH), 8 parts by weight of liquid organophosphate flame retardant (tetraphenyl bisphenol A diphosphate), 3 parts by weight of branched silicone resin with phenyl, 0.5 parts by weight of antioxidant 1010, in Stir in a high-speed mixer for 4 minutes; put the uniformly mixed material into a twin-screw extruder for melt extrusion and granulation. The aspect ratio of the twin-screw extruder is 40, the screw speed is 300rpm / min, and the feeding speed is 280rpm / min, the temperature of each section of the screw barrel is 245-290°C, and the extr...

Embodiment 2

[0025] With the polyphenylene ether resin (intrinsic viscosity 0.5dL / g) of 10 weight parts, the high-impact polystyrene resin (melt flow rate 2g / 10min) of 30 weight parts, the anti-dripping agent of 0.5 weight part in high-speed mixer Mix for 3 minutes, then add 60 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.5dL / g), 3 parts by weight of hydrogenated styrene-butadiene-styrene copolymer (SEBS YH503), 10 parts by weight of liquid Organic phosphate flame retardant (tetraphenyl bisphenol A diphosphate), 3 parts by weight of branched silicone resin with phenyl group, 0.7 part by weight of antioxidant 1010, 0.3 part by weight of antioxidant 136, Stir in a high-speed mixer for 5 minutes; put the uniformly mixed material into a twin-screw extruder for melt extrusion and granulation, the aspect ratio of the twin-screw extruder is 40, the screw speed is 300rpm / min, and the feeding speed is 280rpm / min, the temperature of each section of the screw barrel is 245-290°...

Embodiment 3

[0027]With the polyphenylene ether resin (intrinsic viscosity 0.38dL / g) of 25 weight parts, the high-impact polystyrene resin (melt flow rate 4g / 10min) of 15 weight parts, the anti-dripping agent of 0.2 weight part in high-speed mixer Mixed for 2 minutes, then added 60 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.38dL / g), 5 parts by weight of maleic anhydride grafted styrene-butadiene-styrene copolymer (SEBS- g-MAH), 8 parts by weight of liquid organophosphate flame retardant (tetraphenyl bisphenol A diphosphate), 2 parts by weight of branched silicone resin with phenyl, 0.5 parts by weight of antioxidant DLTP , stirred in a high-speed mixer for 4 minutes; put the uniformly mixed material into a twin-screw extruder for melt extrusion granulation, the aspect ratio of the twin-screw extruder is 40, the screw speed is 300rpm / min, and the feeding speed The temperature is 280rpm / min, the temperature of each section of the screw barrel is 245-290°C, and the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com