Patents

Literature

2360 results about "Polyphenyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

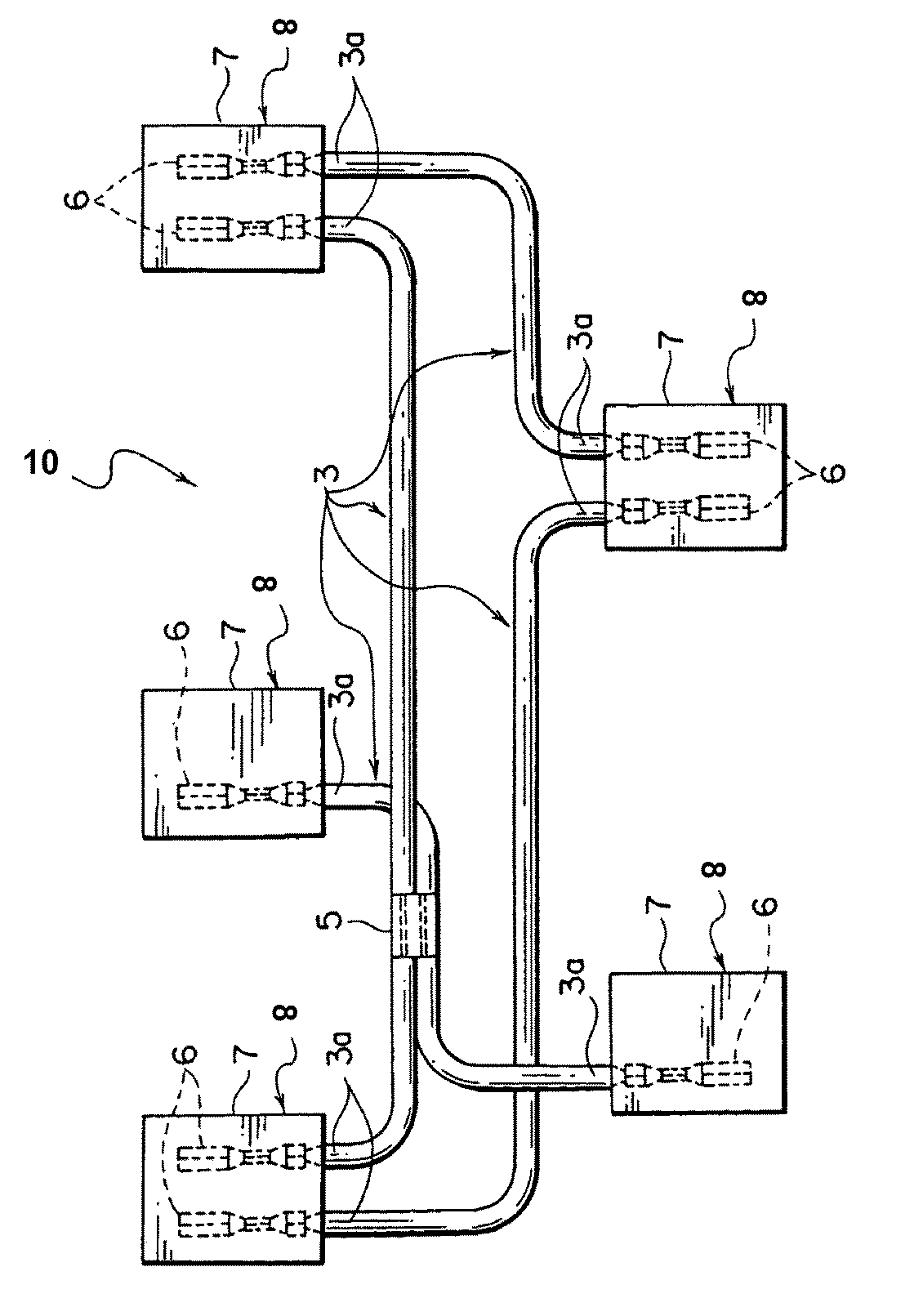

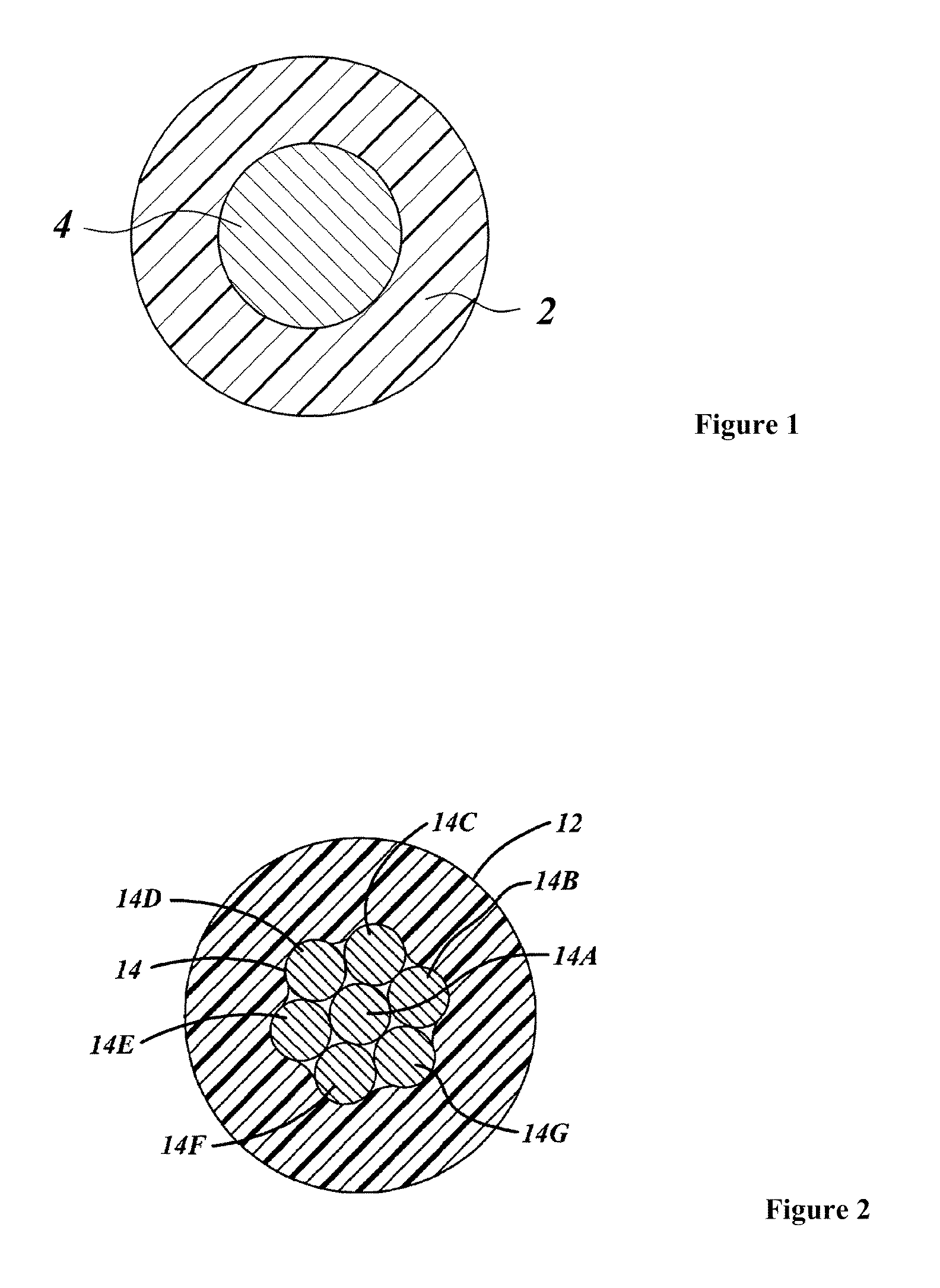

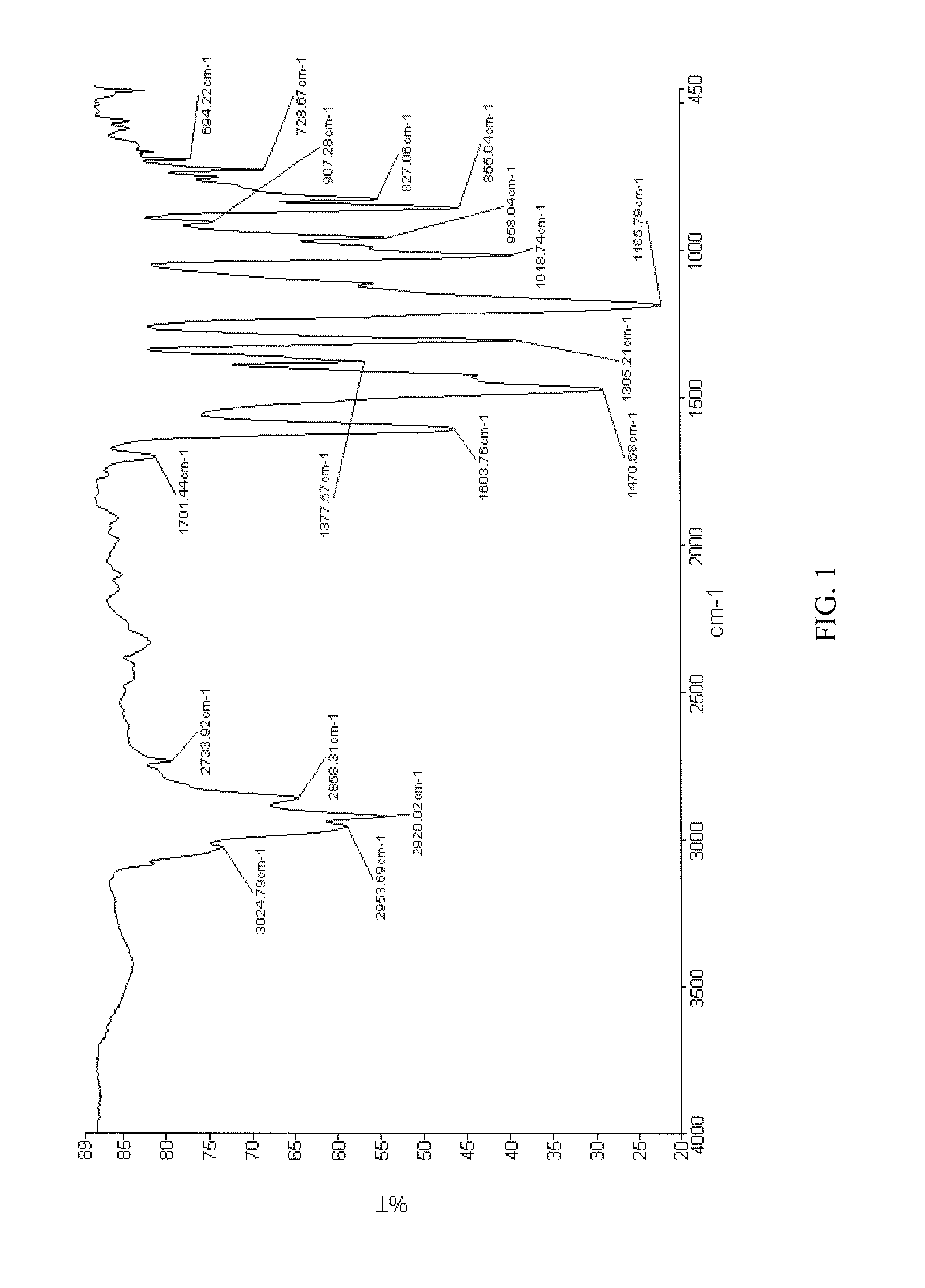

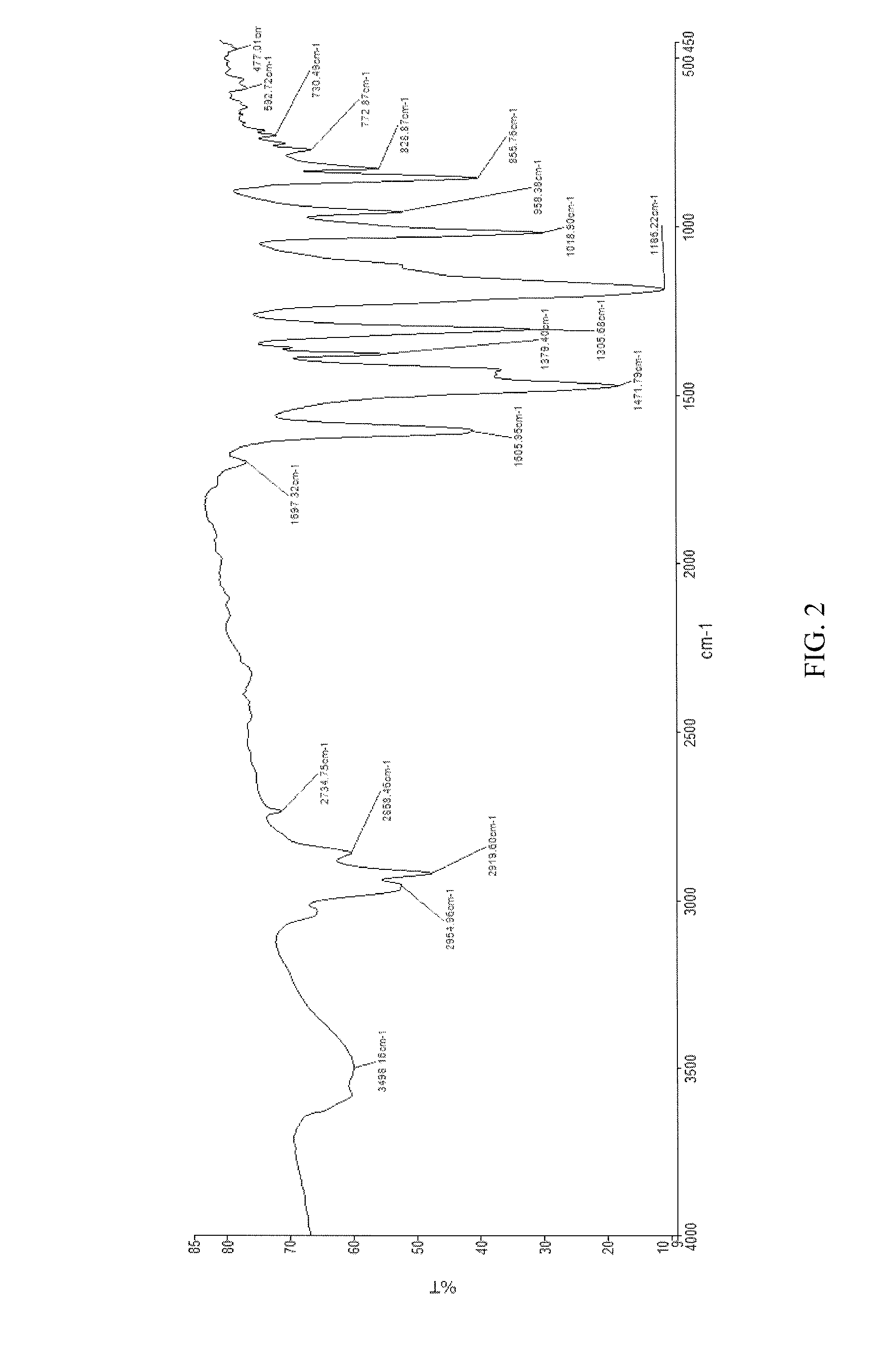

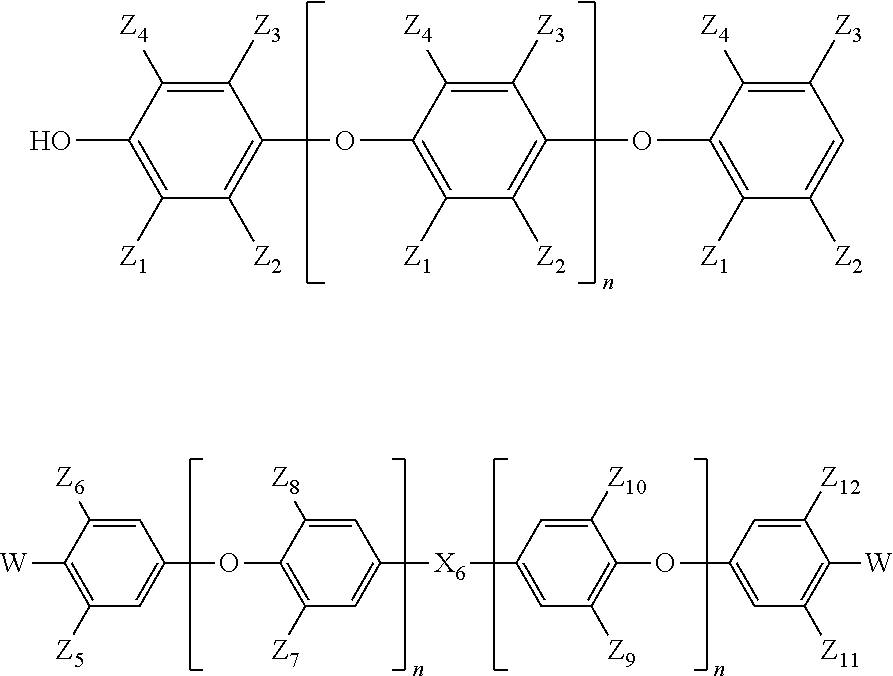

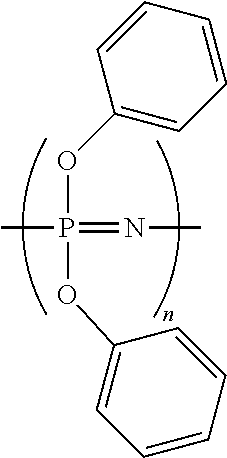

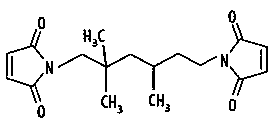

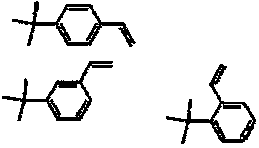

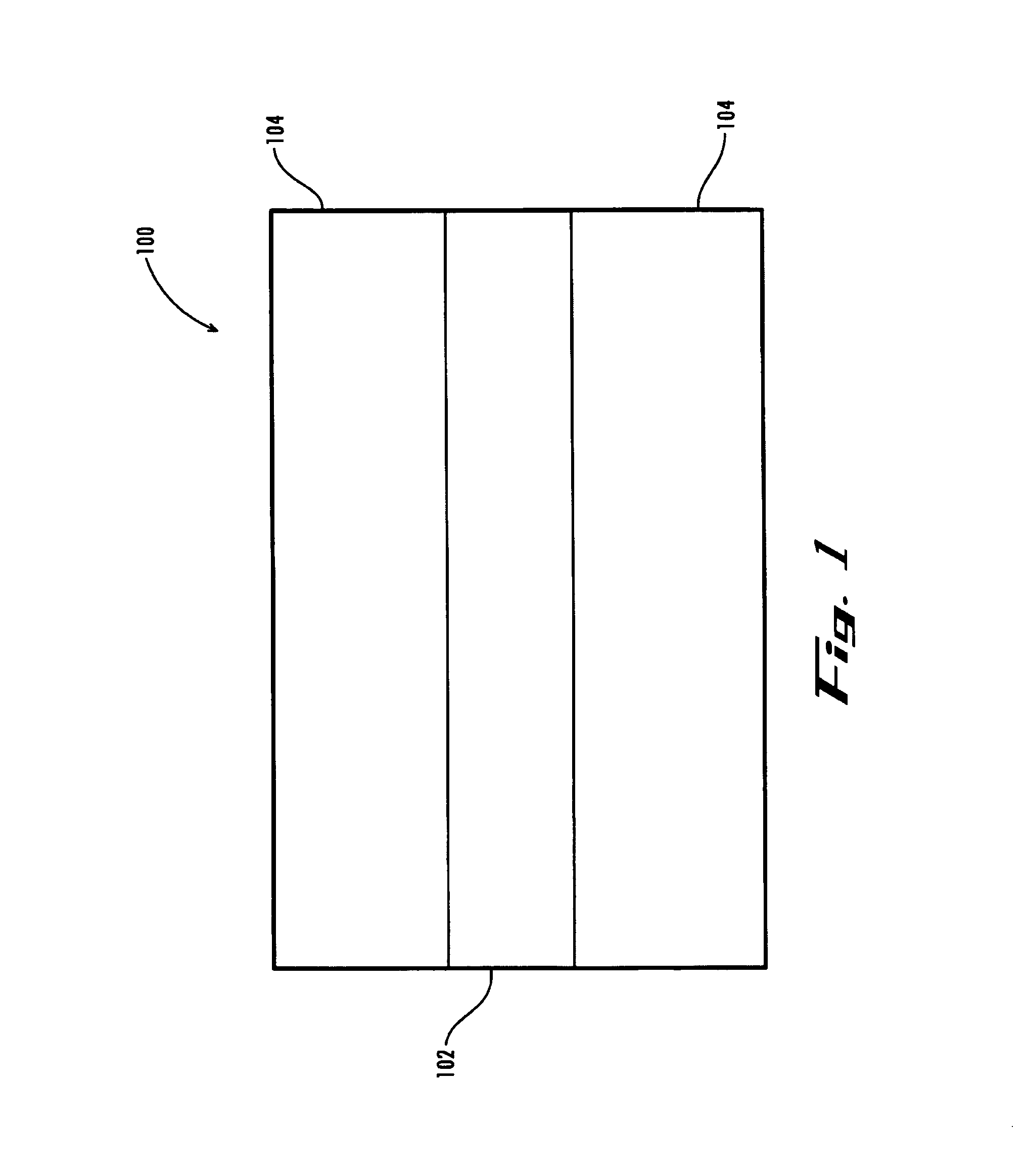

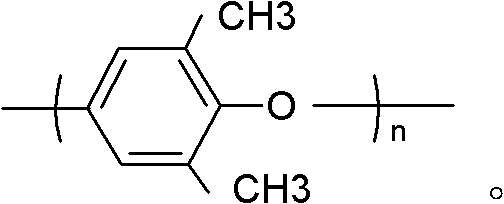

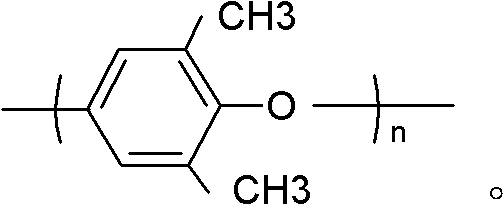

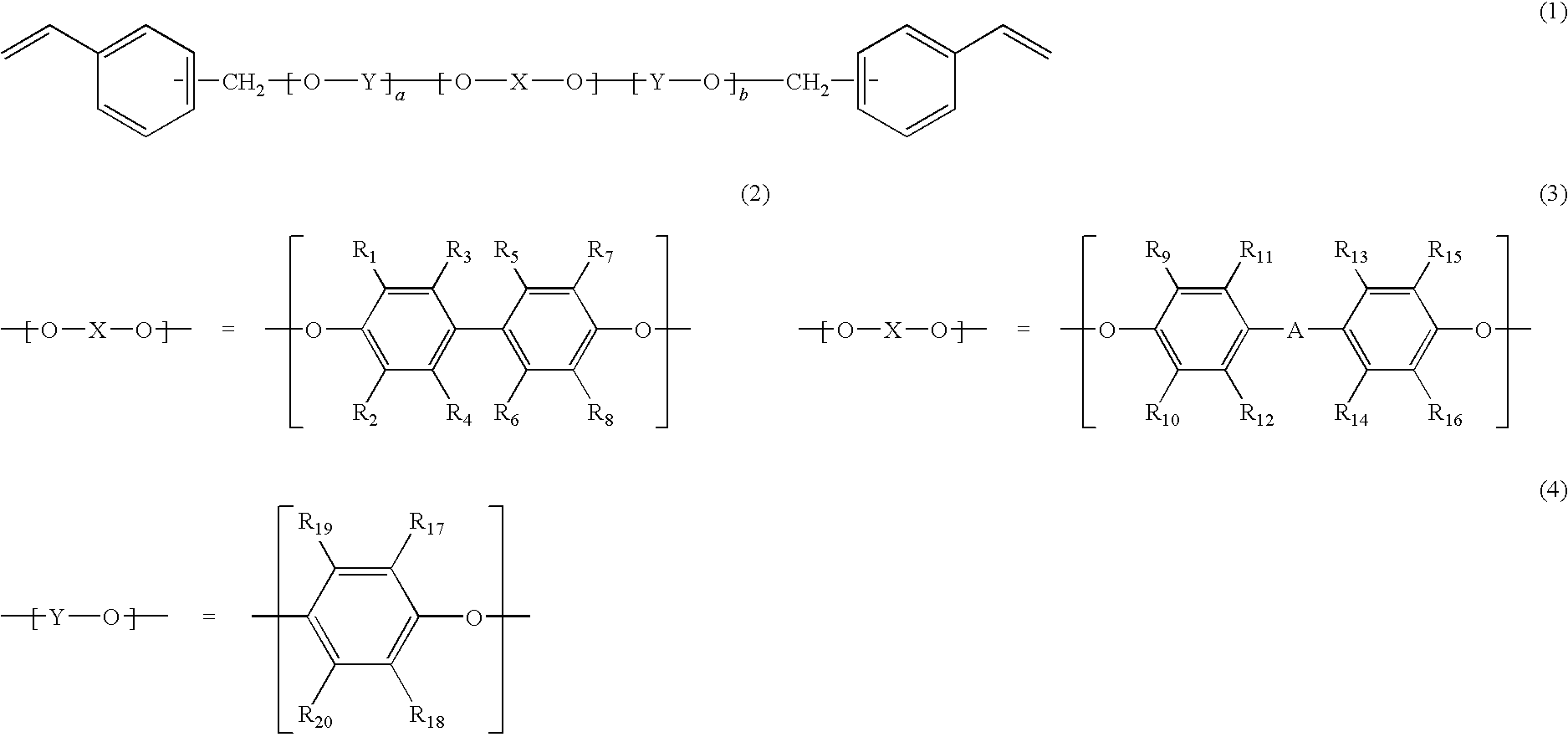

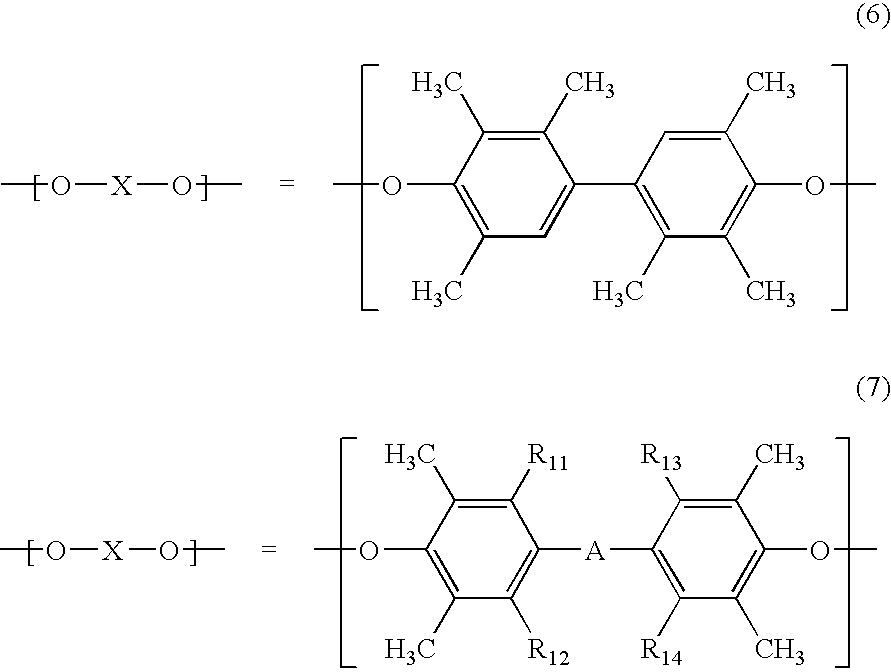

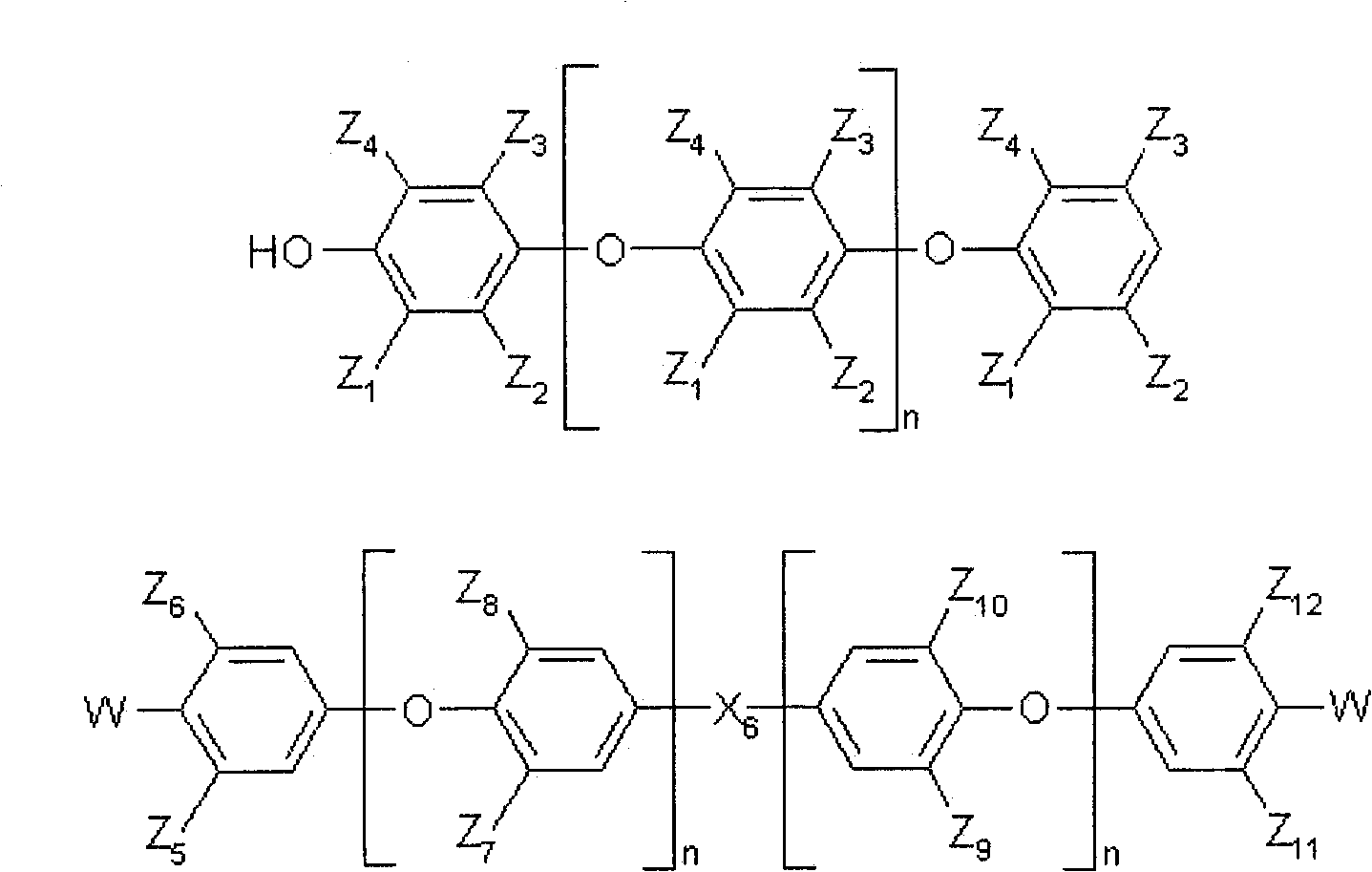

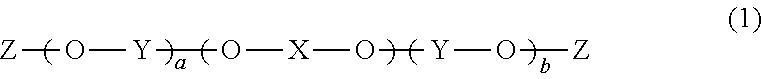

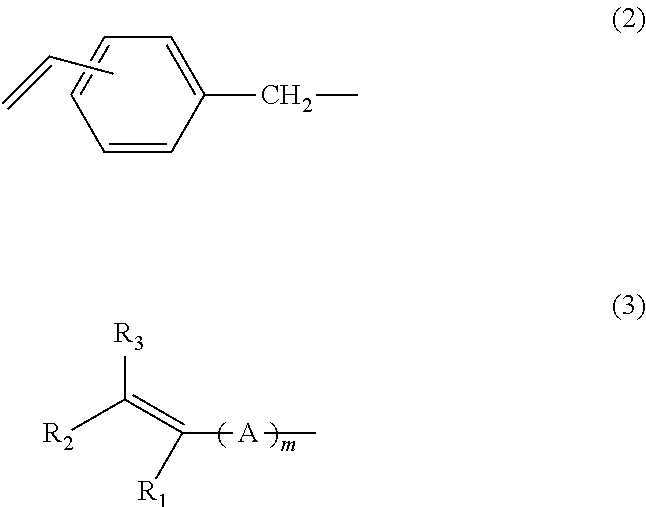

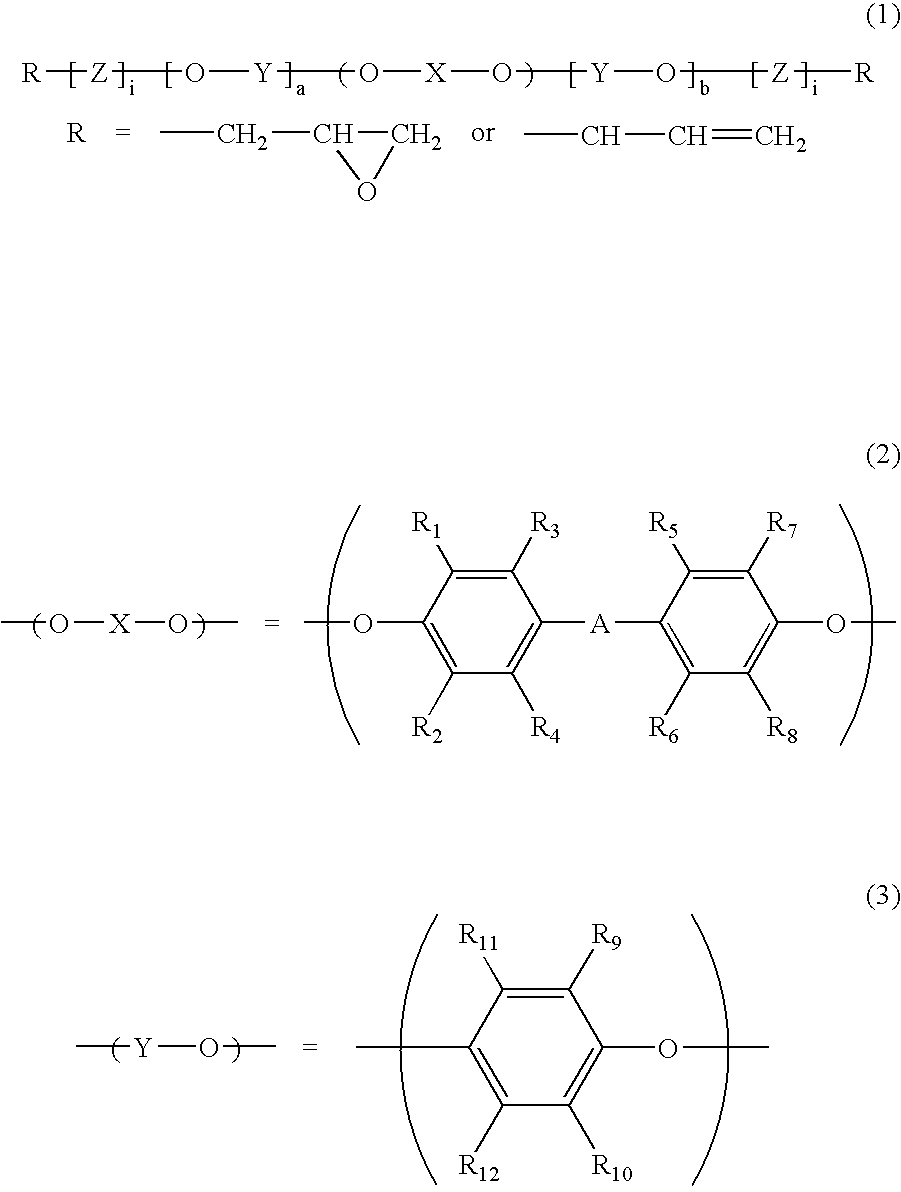

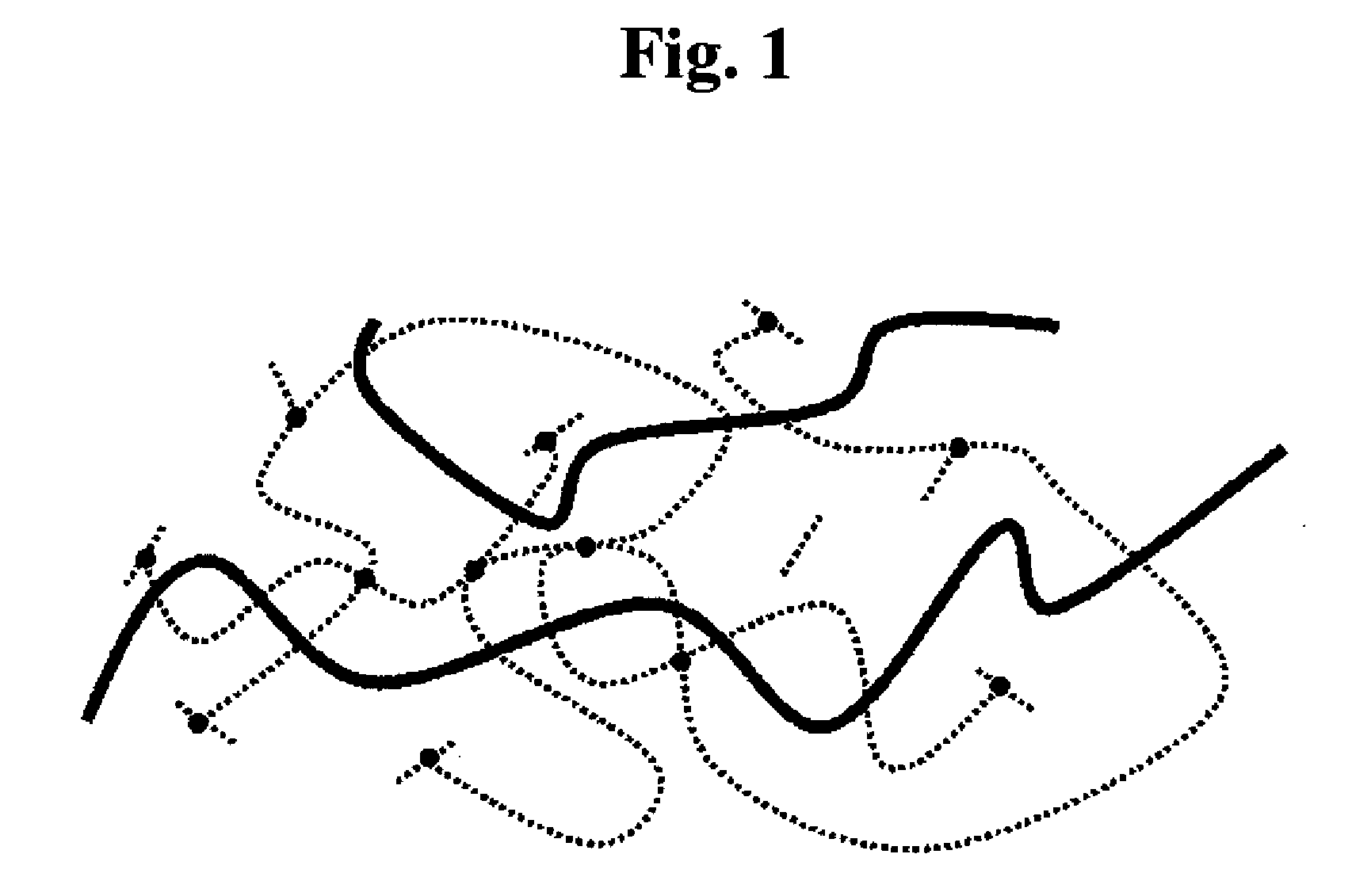

Phenyl ether polymers are a class of polymers that contain a phenoxy or a thiophenoxy group as the repeating group in ether linkages. Commercial phenyl ether polymers belong to two chemical classes: polyphenyl ethers (PPEs) and polyphenylene oxides (PPOs). The phenoxy groups in the former class of polymers do not contain any substituents whereas those in the latter class contain 2 to 4 alkyl groups on the phenyl ring. The structure of an oxygen-containing PPE is provided in Figure 1 and that of a 2, 6-xylenol derived PPO is shown in Figure 2. Either class can have the oxygen atoms attached at various positions around the rings.

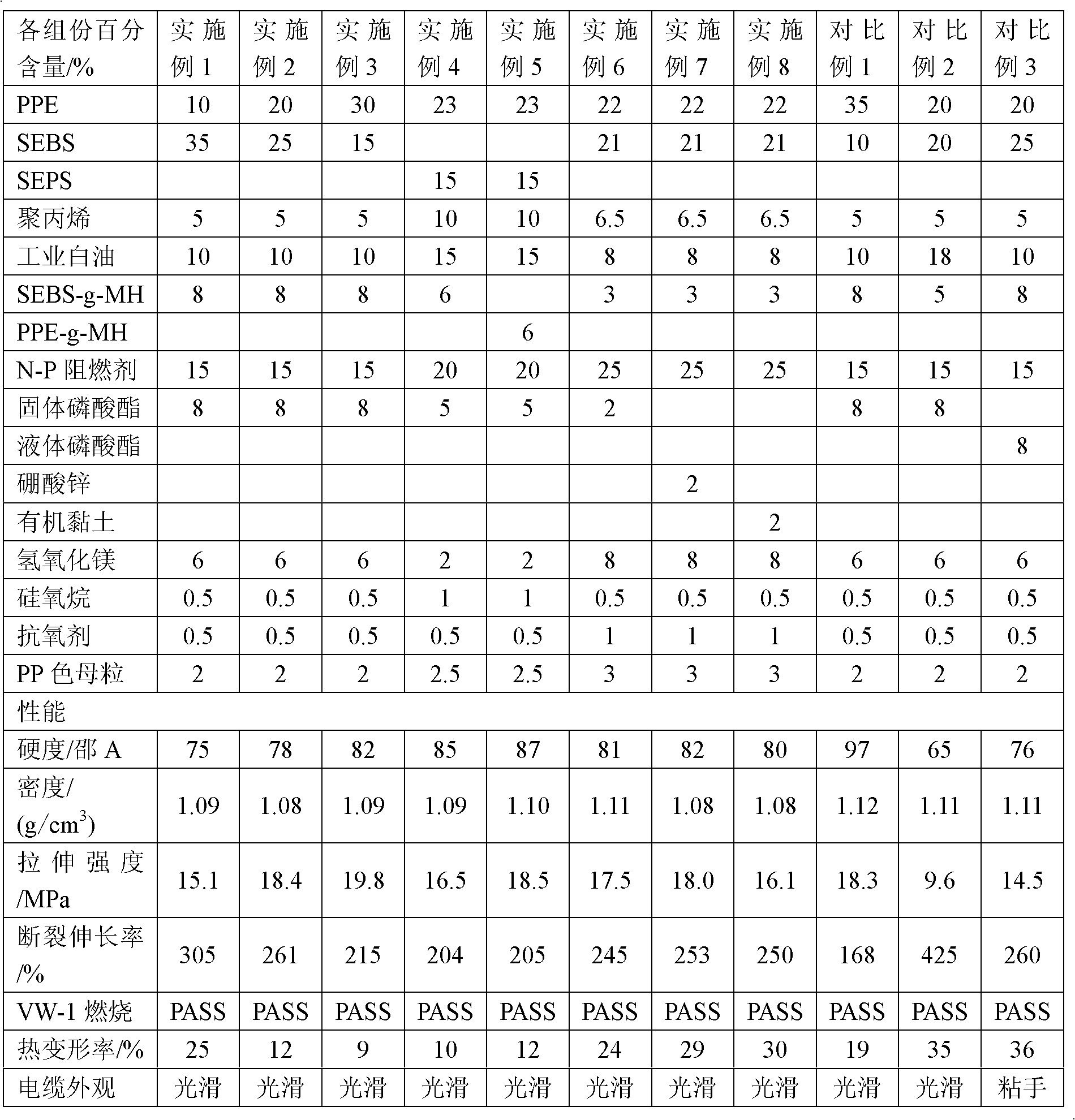

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

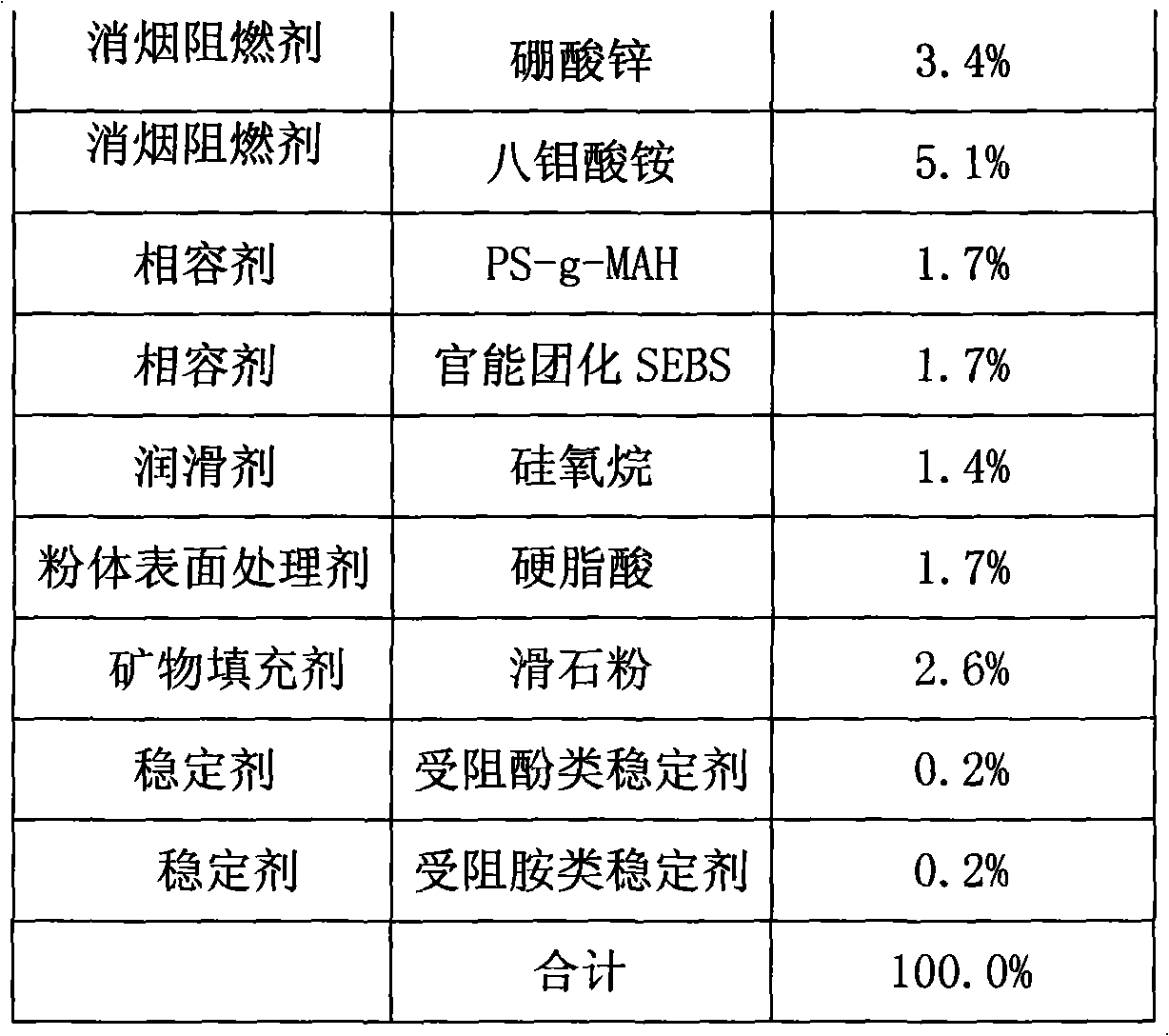

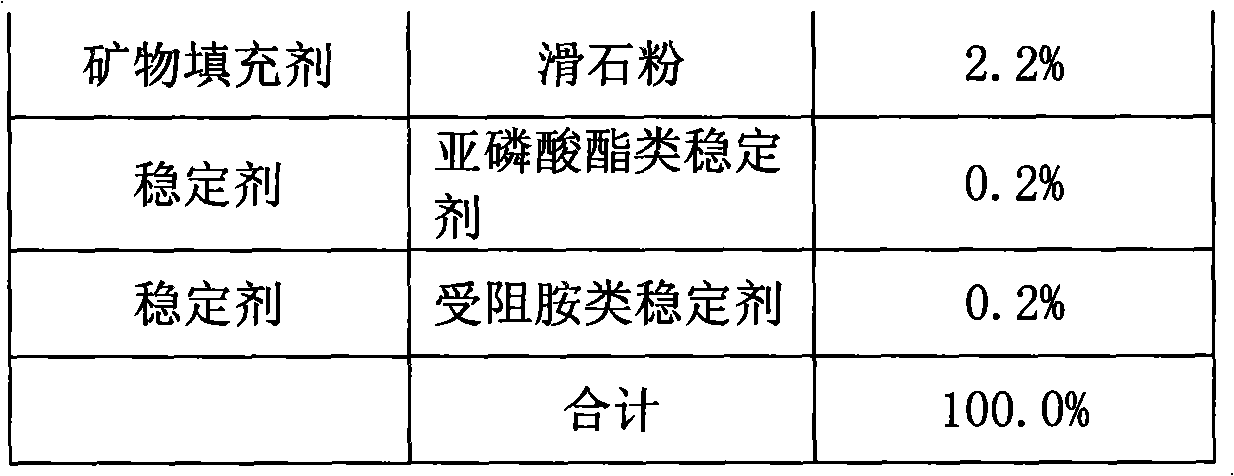

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

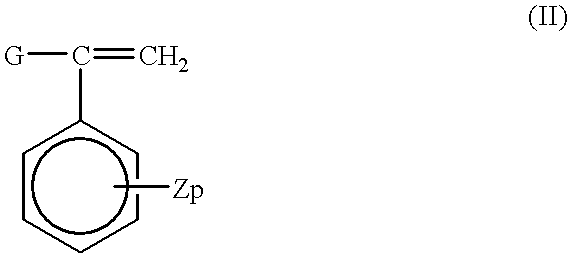

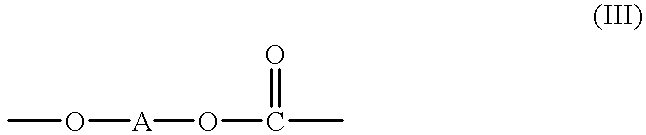

ActiveCN102161823AHigh peel strengthImprove the sticky problemPrinted circuit manufactureCircuit susbtrate materialsDouble bondCopper foil

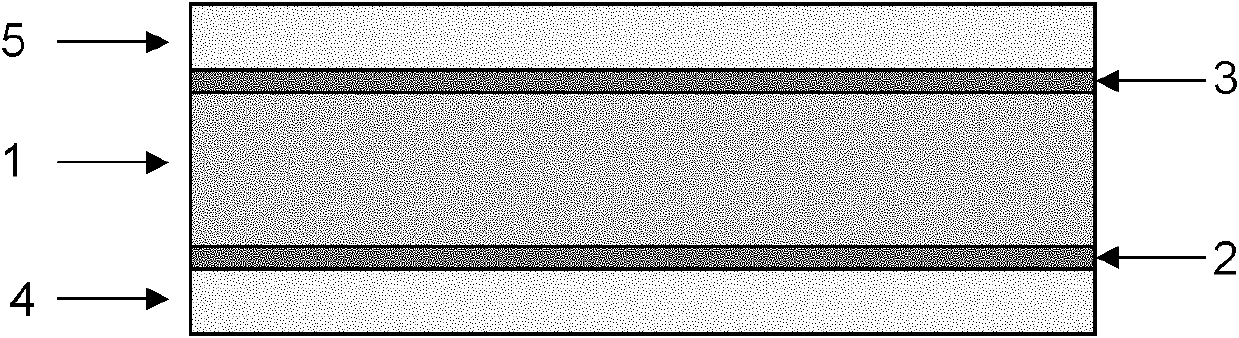

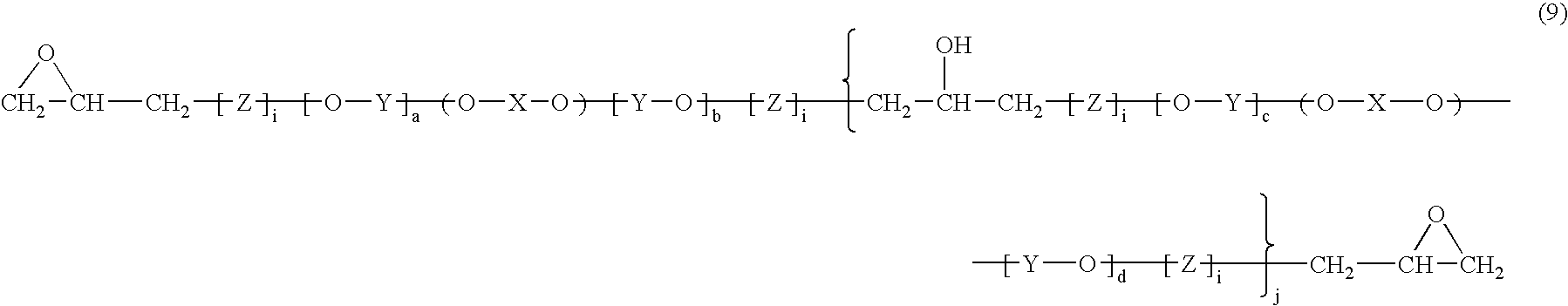

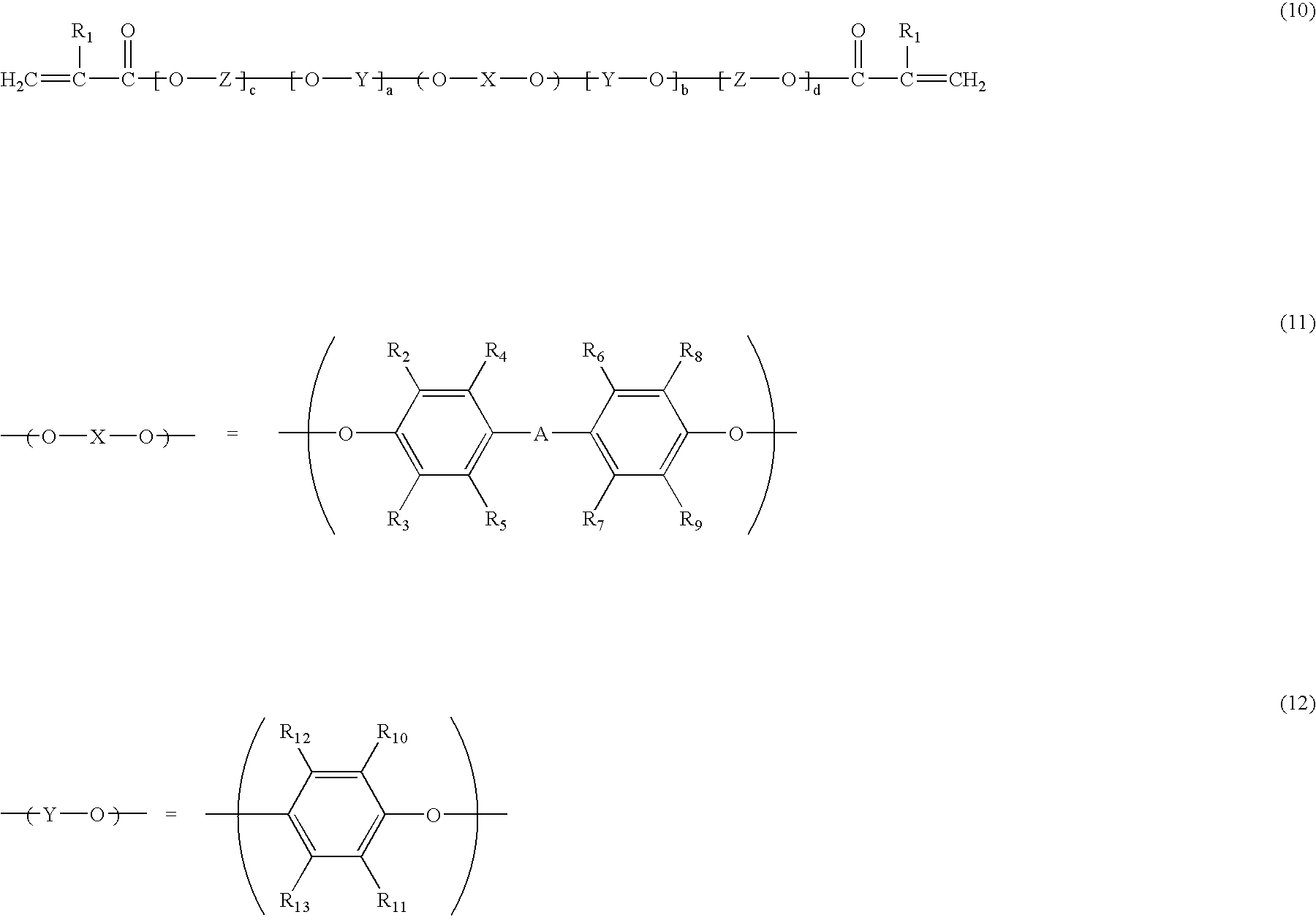

The invention relates to a composite material, a high-frequency circuit substrate therefrom and a manufacture method thereof. The composite material comprises thermoset mixture, glass fiber cloth, power filler, a fire retardant and a curing initiator, wherein the thermoset mixture comprises more than one kind of vinyl liquid resin and polyphenyl ether resin; the molecular weight of the vinyl liquid resin is below 10000, and the vinyl liquid resin is provided with a polar functional group; the molecular weight of the polyphenyl ether resin is less than 5000, and the molecular tail end of the polyphenyl ether resin is provided with unsaturated double bonds. The high-frequency circuit substrate manufactured with the composite material comprises multiple layers of semi-solidified sheets and copper foils, wherein the semi-solidified sheets are mutually overlaid, and the copper foils are respectively pressed on two sides. The composite material disclosed by the invention causes the semi-solidified sheets to be easily manufactured and have high adhesive bonding force with the copper foils. The high-frequency circuit substrate manufactured by the material has the advantages of low dielectric constant, low dielectric loss angle tangent, good heat resistance and simple technical operation. Thus, the composite material disclosed by the invention is suitable for manufacturing the circuit substrate of the high-frequency electronic equipment.

Owner:GUANGDONG SHENGYI SCI TECH

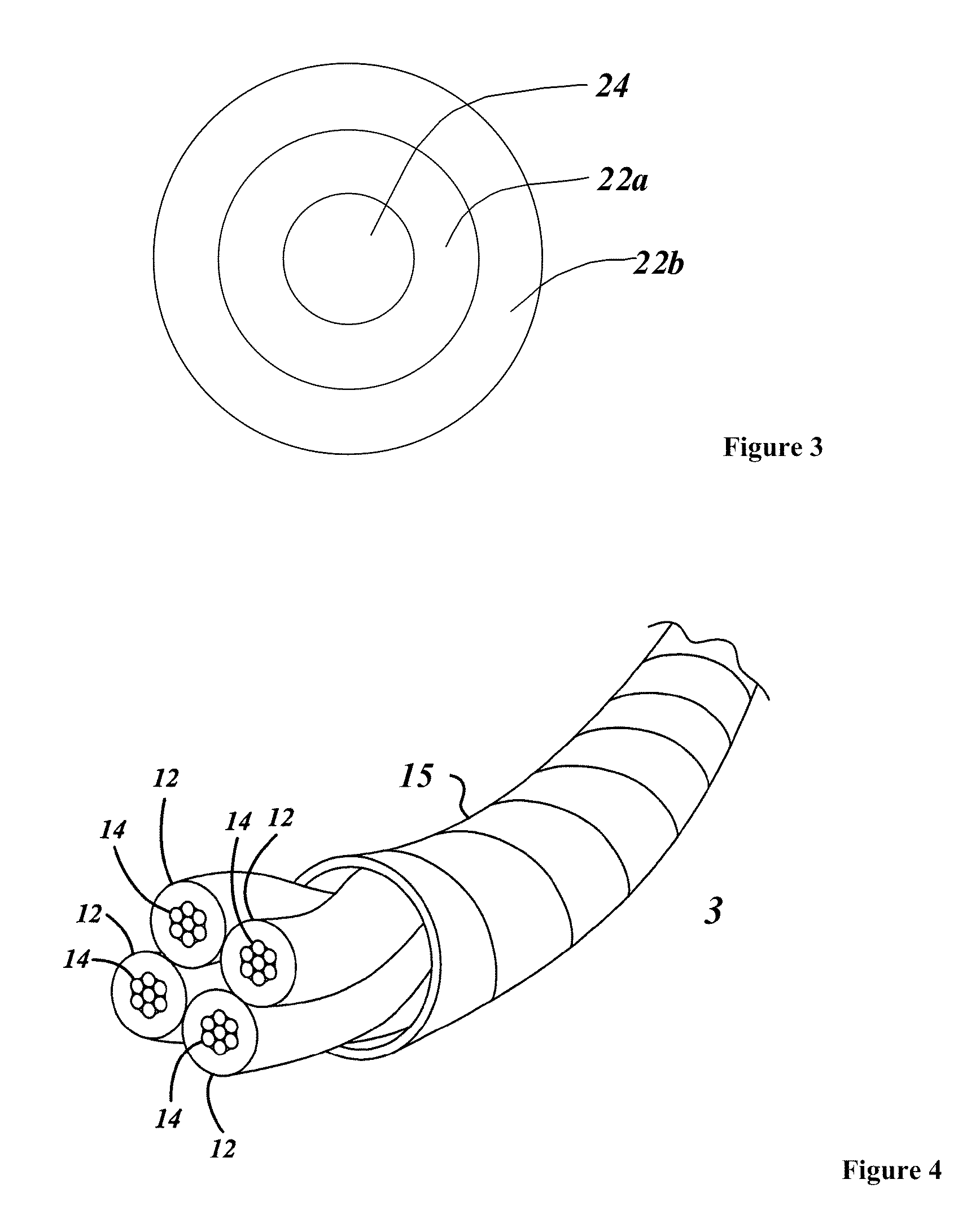

Insulated non-halogenated covered aluminum conductor and wire harness assembly

InactiveUS20110079427A1Light weightImprove connection characteristicsInsulated cablesInsulatorsNorylElectrical conductor

Disclosed herein a covered conductor comprising a conductor and a covering, wherein the covering is disposed over the conductor, wherein the conductor comprises aluminum or an alloy comprising aluminum, wherein the covering comprises a poly(arylene ether) composition, wherein optionally, the covering comprises a poly(arylene ether) composition selected from the group consisting of Noryl resins from SABIC Innovative Plastics, Xyron resins from Asahi Kasei Chemicals Corporation, Iupiace resins from Mitsubishi, Lemalloy resins from Mitsubishi, Polyphenyl Ether resins from Bluestar, Acnor resins from Aquafil Technopolymers, Ashlene resins from Ashley Polymers, Vestoran resins from Evonik Degussa. Further disclosed herein is a wire harness assembly comprising the covered conductor, and an end use equipment comprising the wire harness assembly.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Polyphenylene oxide resin, method of preparing polyphenylene oxide resin, polyphenylene oxide prepolymer and resin composition

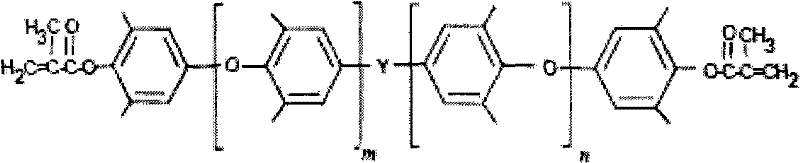

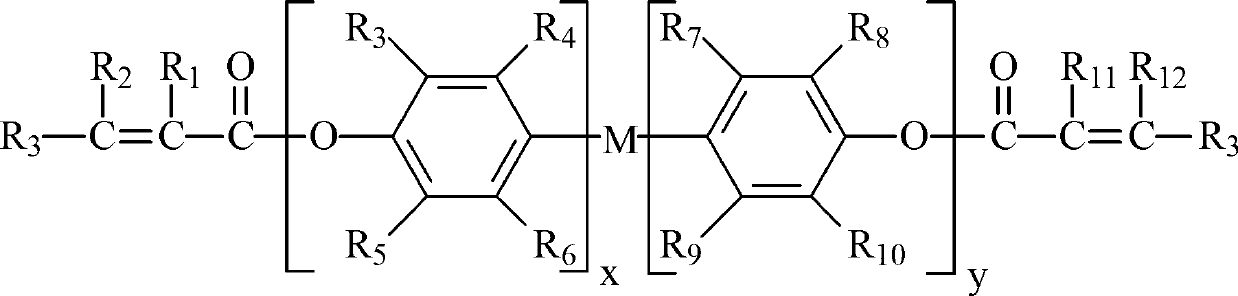

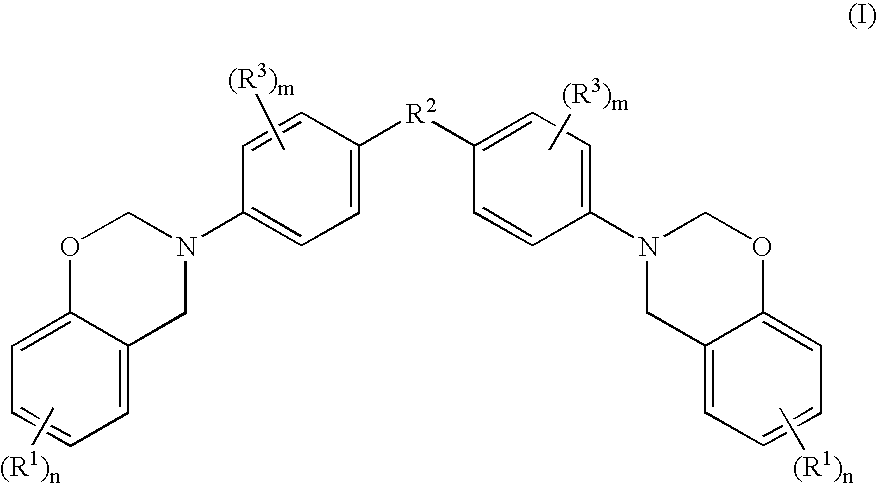

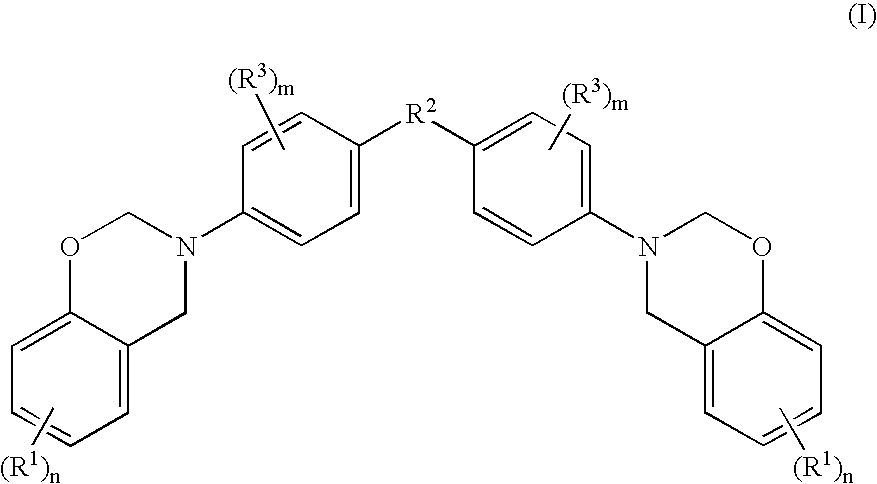

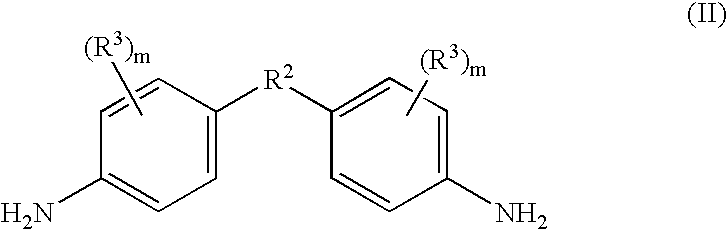

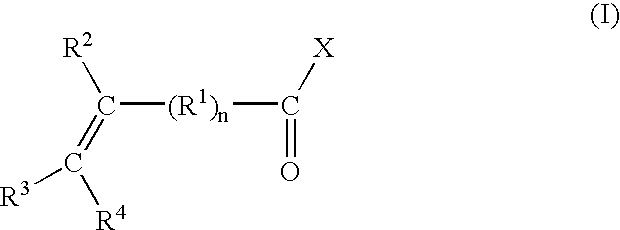

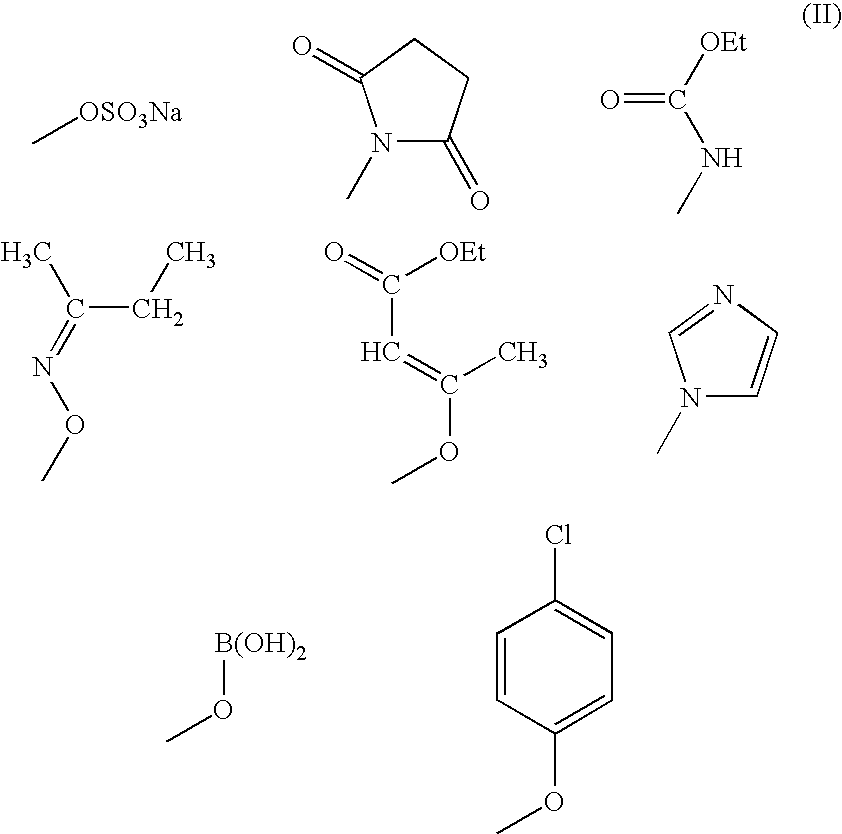

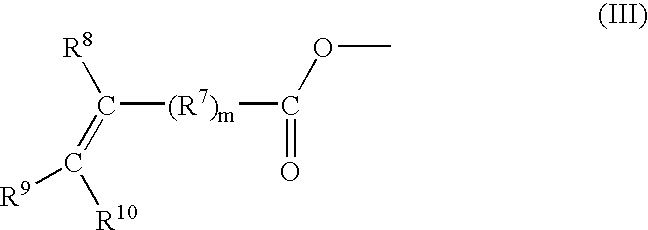

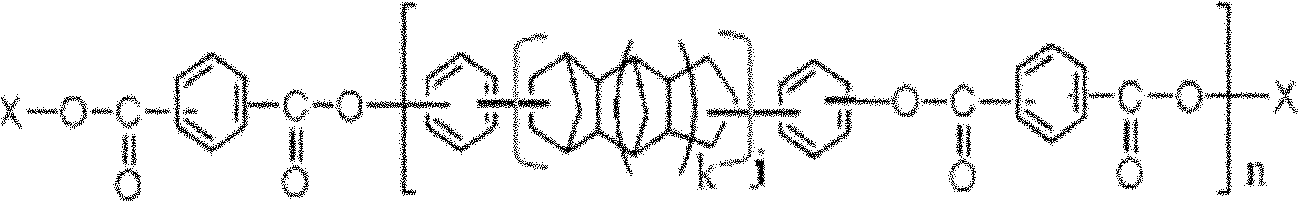

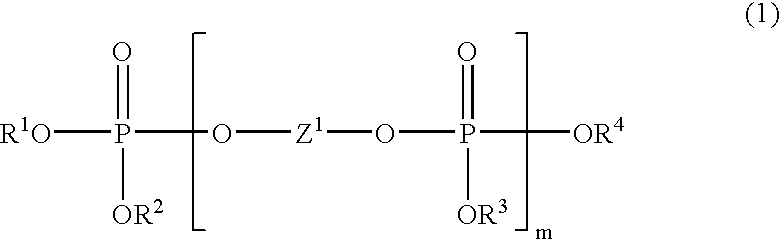

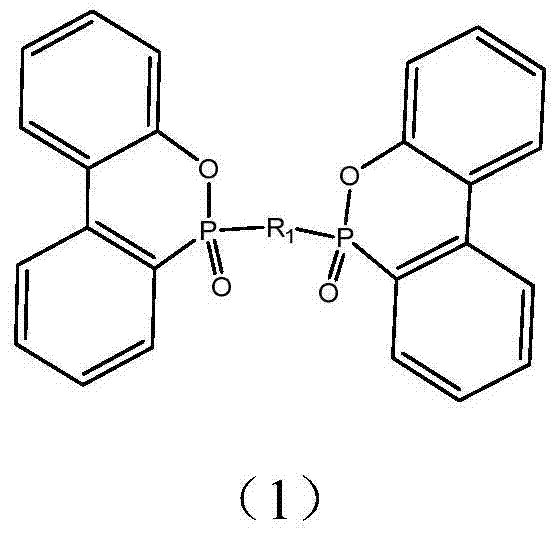

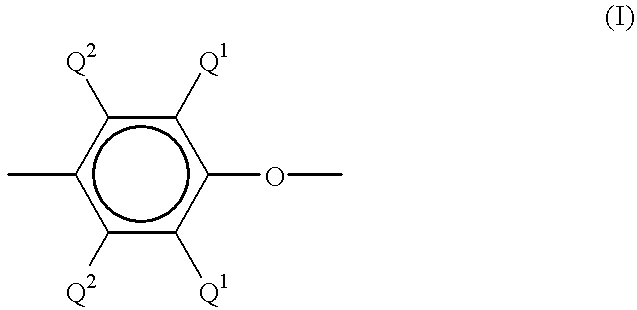

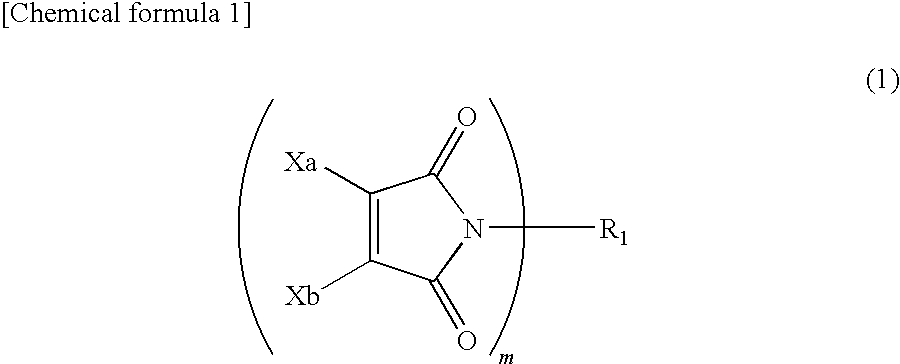

A polyphenylene oxide resin belongs to a polymerized and / or modified thermosetting polyphenylene oxide resin, having a structure represented by formula (I):The polymerized and / or modified thermosetting polyphenylene oxide resin has better flame retardancy, thermal resistance, dielectric constant, dissipation factor, toughness, reactivity, viscosity and solubility. Therefore, the polyphenylene oxide resin is suitable for producing prepregs, resin films, laminates, printed circuit boards and other articles. A method of preparing polyphenylene oxide resins, a prepolymer thereof and a resin composition containing the polyphenylene oxide resin are also provided.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

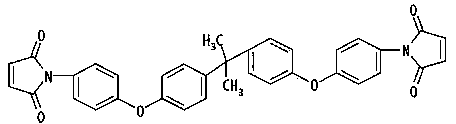

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Resin composition and use thereof

ActiveCN102993683AImprove heat resistanceIncrease crosslink densitySynthetic resin layered productsPrinted circuit aspectsVitrificationDouble bond

The invention discloses a resin composition and a use thereof. The resin composition comprises modified polyphenyl ether and organic silicon compound containing an unsaturated double bond. The invention further discloses a manufacturing method for a high frequency circuit base plate by the resin composition and a high frequency circuit base plate manufactured by the manufacturing method. The high frequency circuit base plate has a high glass transition temperature, a high thermal decomposition temperature, high interlayer bonding force, a low dielectric constant and tangent low-medium loss, and is very suitable for being used as a circuit base plate of a high frequency electronic device.

Owner:GUANGDONG SHENGYI SCI TECH

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

Halogen-free resin composition

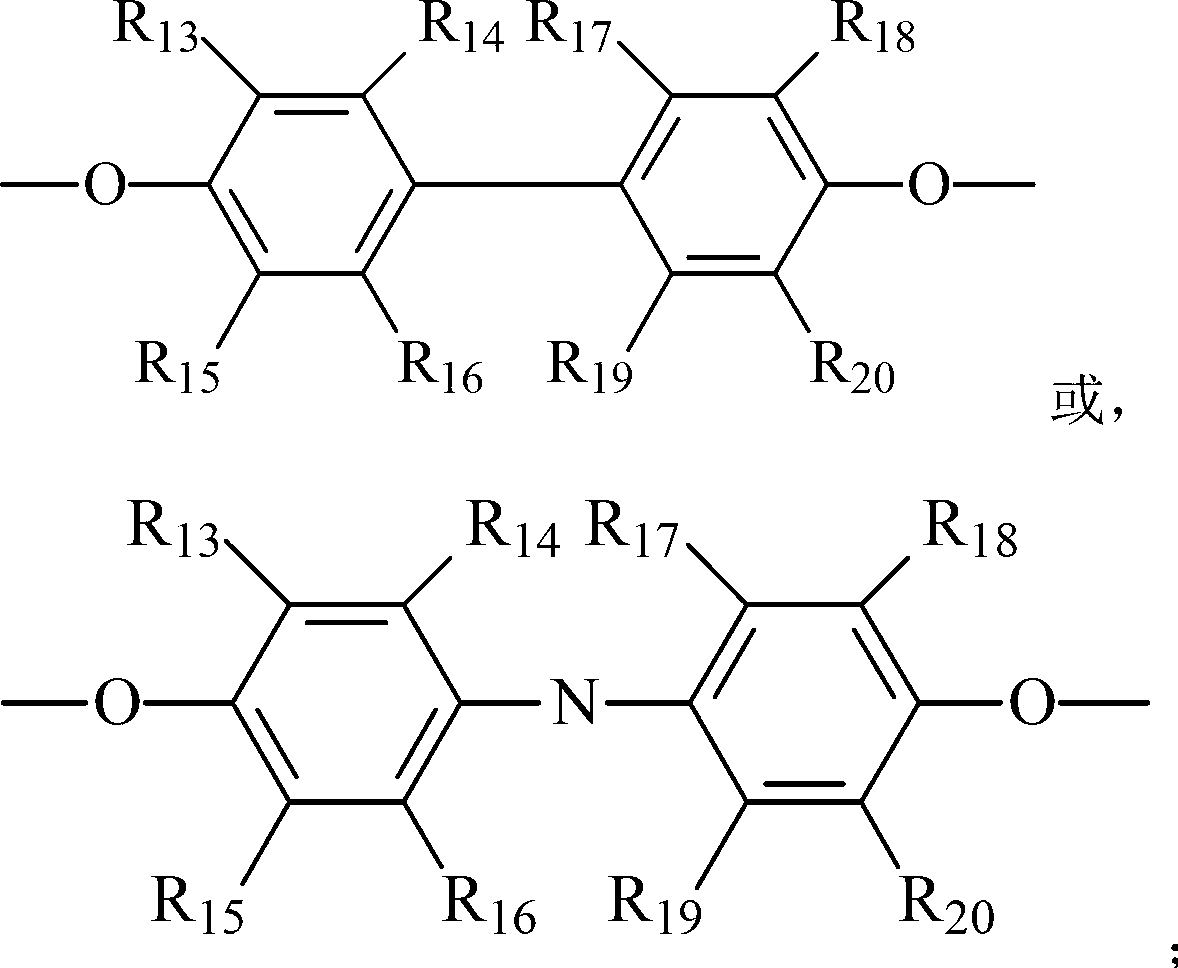

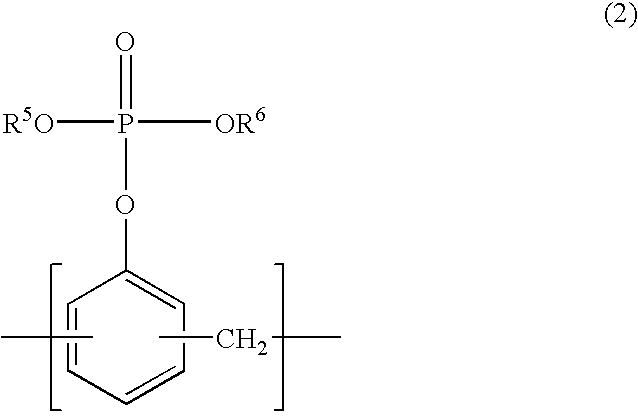

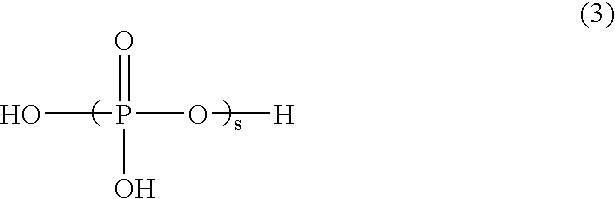

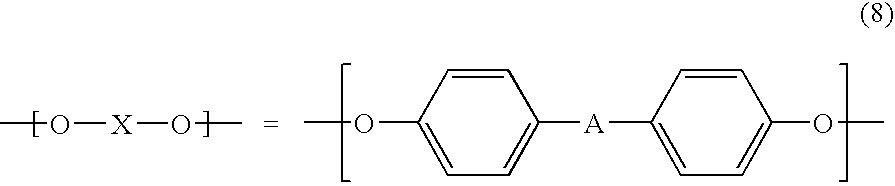

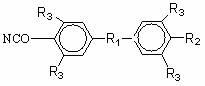

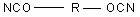

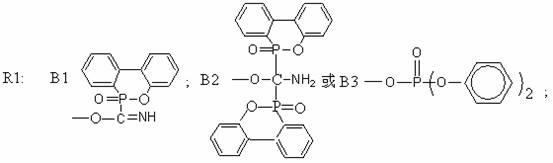

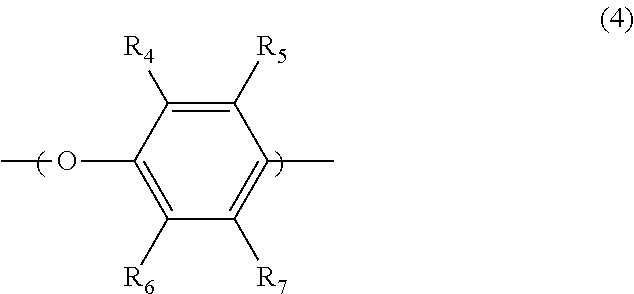

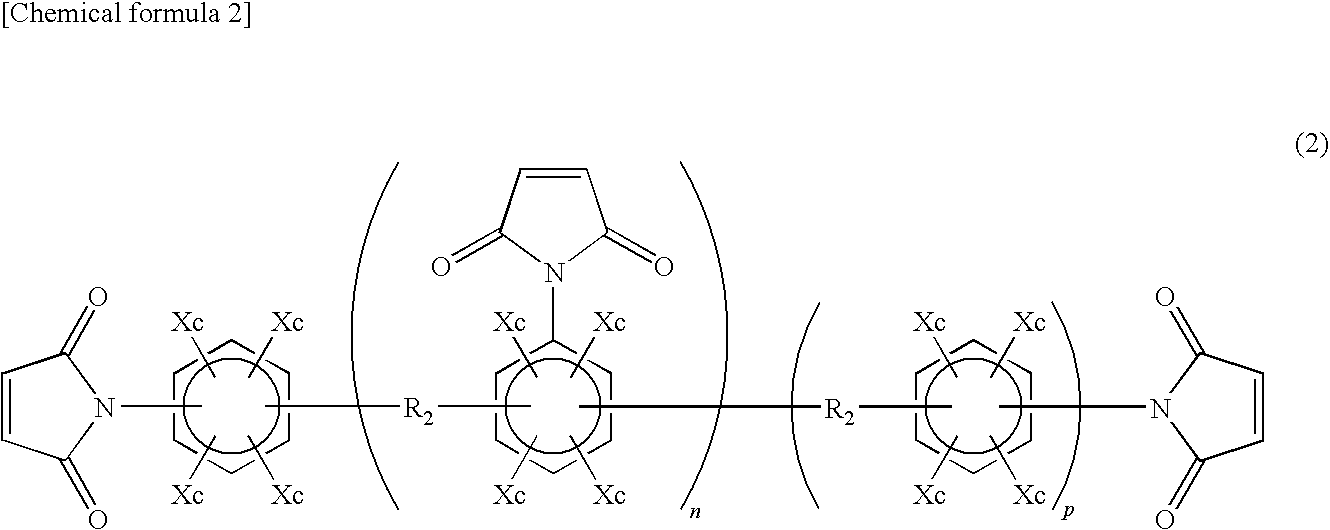

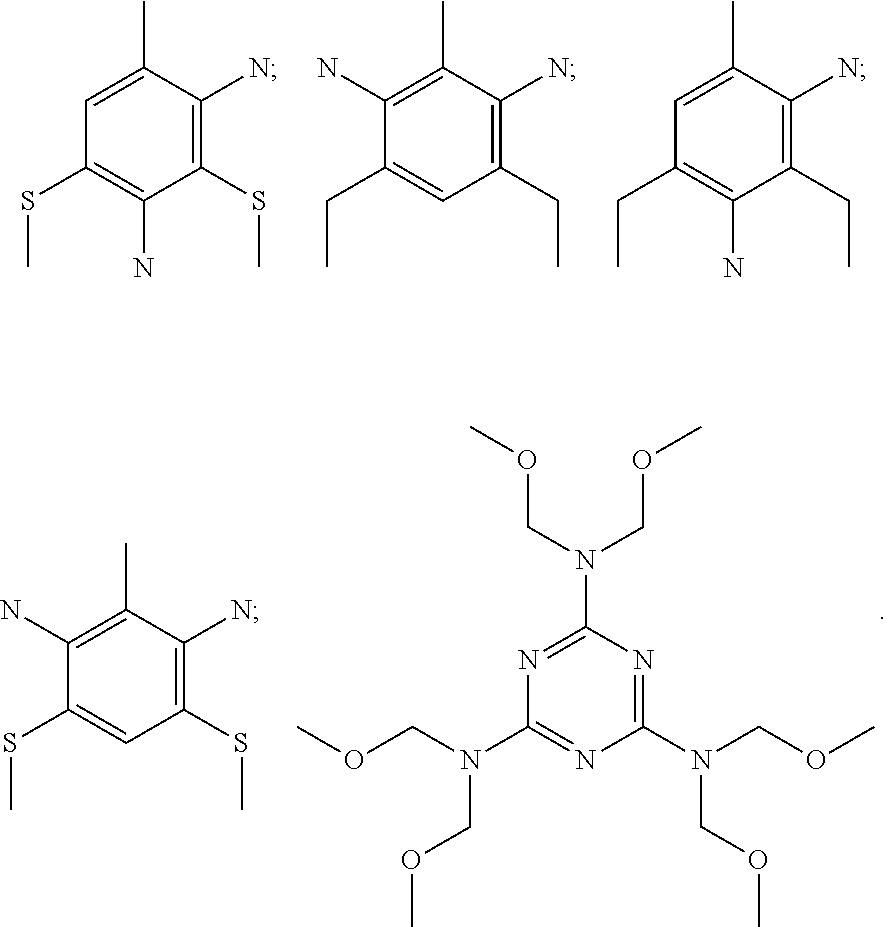

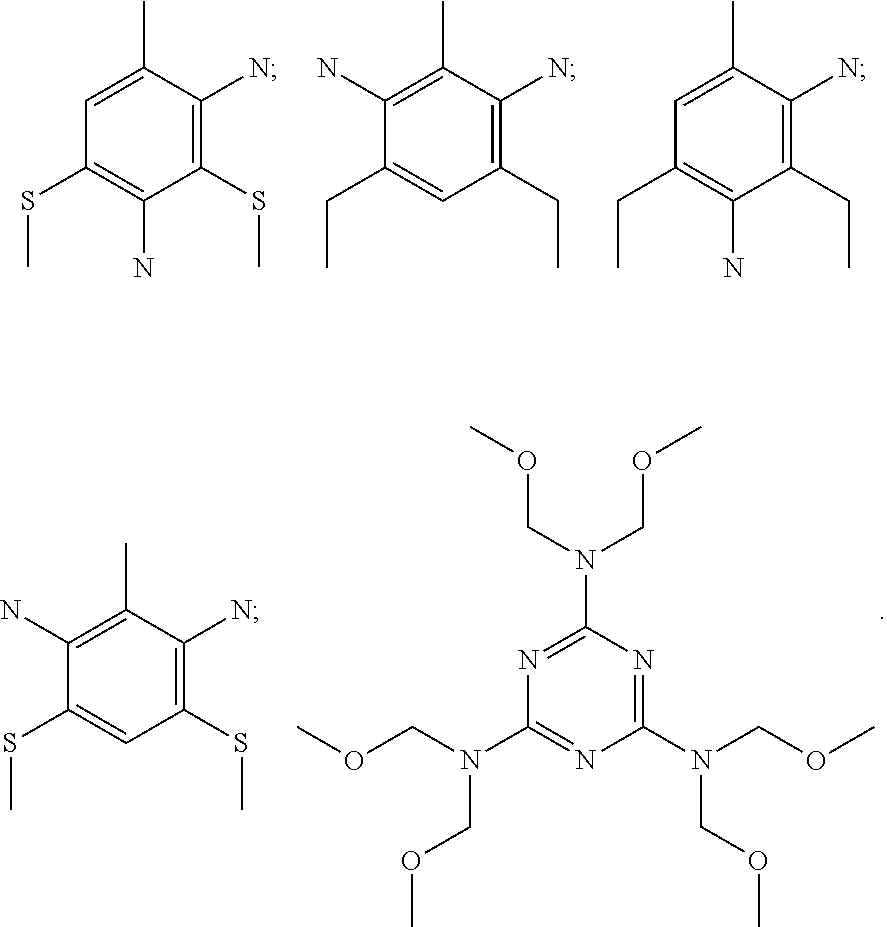

Disclosed is a halogen-free resin composition comprising: (A) one or more phosphorus-containing epoxy resins; (B) a hardener; (C) a hardening accelerator; (D) a polyphenylene oxide resin; and (E) a filling material, wherein the hardener of component B has the structure represented by the following formula (I): wherein each symbol is as defined above. The halogen-free resin composition of the present invention without adding halogen has excellent heat resistance and flame retardant property, and excellent dielectric property. The halogen-free resin composition of the present invention is particularly useful in the application of bonding sheets, composite materials, laminated plates, printed circuit boards, copper foil adhesives, inks used for build-up process, semiconductor packaging materials and the like.

Owner:CHANG CHUN PLASTICS CO LTD

Compositions comprising functionalized polyphenylene ether resins

The invention relates to a method of forming a polyphenylene ether resin containing residual aliphatic unsaturation. A polyphenylene ether is reacted with a capping agent in a solvent to form the polyphenylene ether resin containing residual aliphatic unsaturation, which is precipitated from solution by combining the solution with an antisolvent. The precipitated polyphenylene ether resin containing residual aliphatic unsaturation has lower levels of residual impurities than the same compound isolated by devolatilization.

Owner:SABIC GLOBAL TECH BV

Low dielectric material

InactiveCN103965606ASmall coefficient of thermal expansionLow water absorptionDielectric lossThermal expansion

The invention relates to a low dielectric material. The low dielectric material includes, by weight, 40-80 parts of polyphenyl ether with the number average molecular weight Mn of 1000-4000, the weight average molecular weight Mw of 1000-7000 and the Mw / Mn ratio of 1.0-1.8, 5-30 parts of bimaleimide and 5-30 parts of a polymer additive, and the Dk value and the Df value of the low dielectric material are 3.75-4.0 and 0.0025-0.0045 respectively. The low dielectric material can be applied to semi-cured films or circuit substrate insulating layers, and has the characteristics of high Tg, low thermal expansion coefficient, low water absorption rate, and excellent dielectric properties like dielectric constant (Dk) and dielectric loss (Df).

Owner:ITEQ CORP

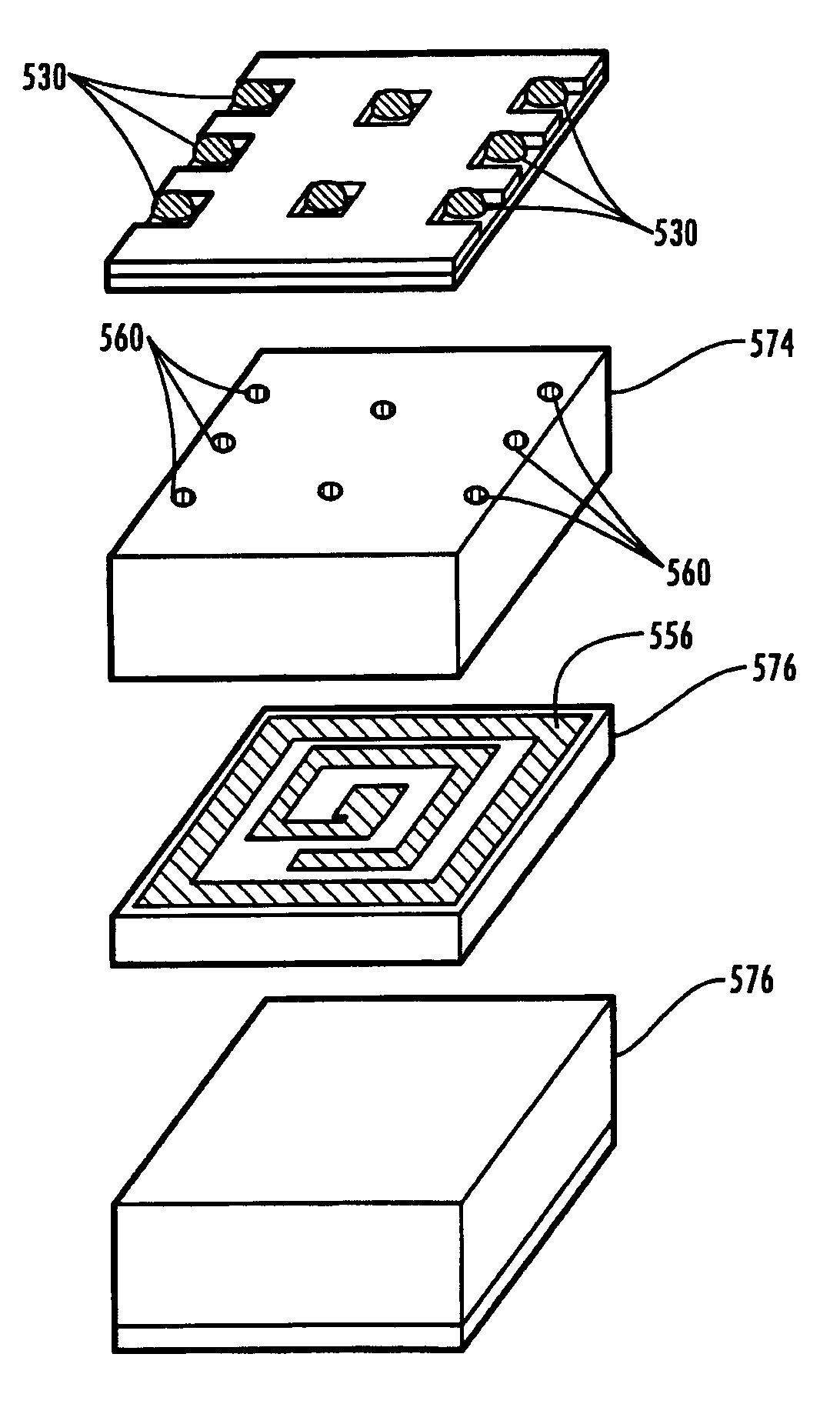

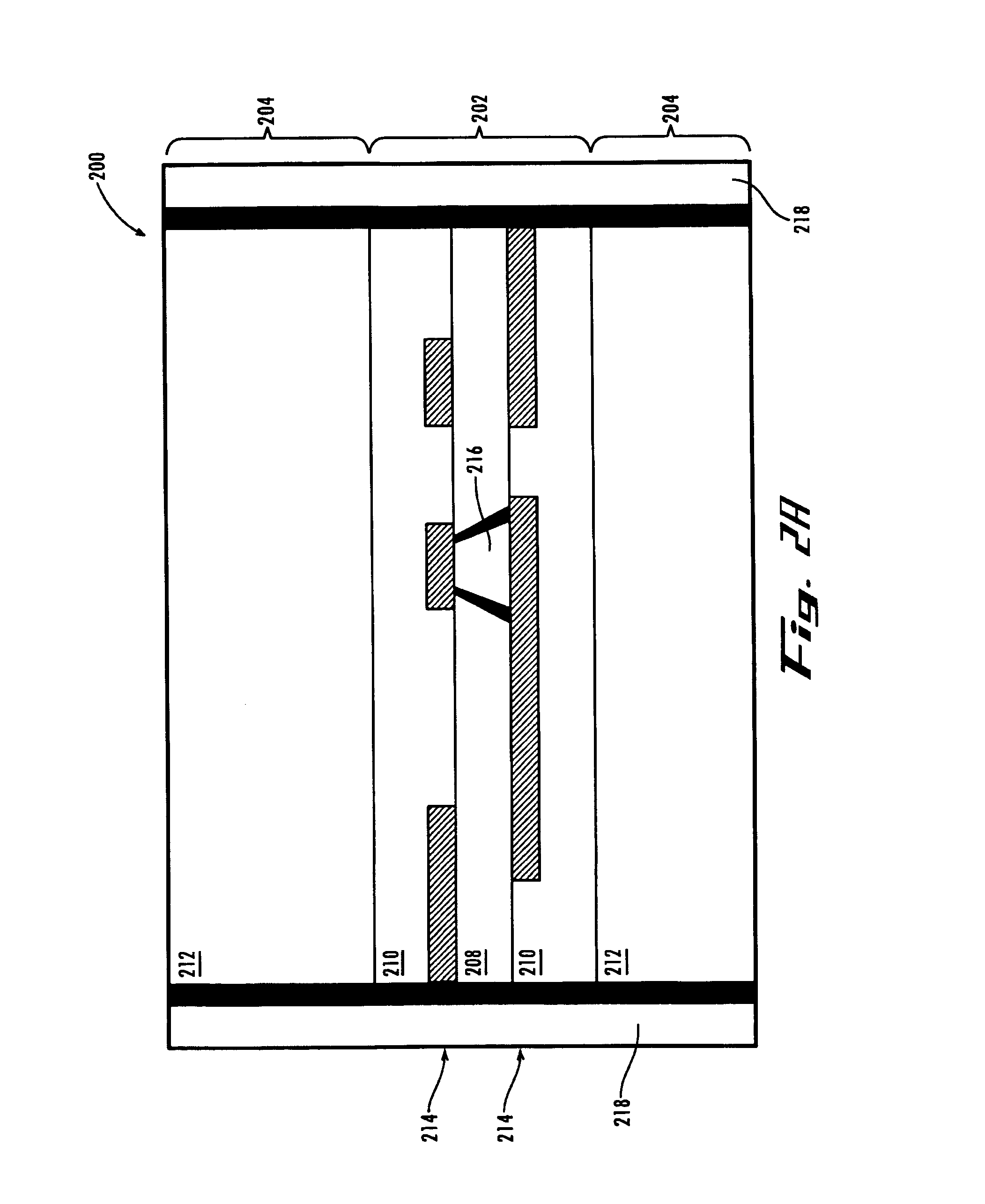

Stand-alone organic-based passive devices

InactiveUS6987307B2Low costImprove performanceMultiple-port networksSemiconductor/solid-state device detailsLiquid crystallineOrganic base

The present invention provides for low cost discrete inductor devices in an all organic platform. The inductor devices can utilize virtually any organic material that provides the desired properties, such as liquid crystalline polymer (LCP) or polyphenyl ether (PPE), in a multilayer structure, wherein the organic materials have low moisture uptake and good temperature stability. Each layer may be metalized and selectively interconnected by vias formed in respective layers so as to form winding or coiled inductors. The inductor devices may advantageously include external shielding formed by metalizing the side walls and top surface of the inductor devices on in-built shielding achieved by the utilization of the hybrid co-planar waveguide topologies. The inductor devices can be configured for either ball grid array (BGA) / chip scale package (CSP) or surface mount device (SMD) mounting to circuit boards.

Owner:GEORGIA TECH RES CORP

Epoxy resin composition as well as prepreg and laminated board made of same

InactiveCN102051022AGood heat resistanceLow water absorptionSynthetic resin layered productsCircuit susbtrate materialsDielectric lossChemistry

The invention relates to an epoxy resin composition as well as a prepreg and a laminated board made of the same. The epoxy resin composition comprises the following components in parts by weight: 1-50 parts of modified polyphenylene oxide resin, 30-80 parts of epoxy resin, 20-60 parts of active ester curing agent, 0-50 parts of filler and 1-20 parts of assistant. The prepreg made of the epoxy resin composition comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The laminated board made of the epoxy resin composition comprises a plurality of laminated prepregs, wherein each prepreg comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The invention has the advantages of high heat resistance, high fire retardancy, low dielectric constant, low dielectric loss, excellent high-frequency dielectric properties and the like, and is suitable to be used as a high frequency circuit substrate material.

Owner:GUANGDONG SHENGYI SCI TECH

Low-smoke halogen-freeflame-proof polyphenylene oxide electric wire and cable material, and method for producing the same

InactiveCN101130616AImprove flame retardant performanceImprove toughnessInsulated cablesInsulated conductorsElastomerPliability

The invention discloses a low smoke non-bitter flame-proof polyphenyl ether electric wire and cable material and preparing method, which is characterized by the following: allocating 40-80 wt polyphenyl ether PPO, 20-60 wt high impact polystyrene HIPS, 10-70 wt elastic body, 1-20 wt functional polyphenyl ether, 10-60 wt fire retardant, 5-20 wt smoke suppressor, 1-3 wt anti-oxidant and 3-5 wt environmental protection color master particle; using higher rigidity, good electrical isolation property and water resistance of the polyphenyl ether material; decreasing hardness of blending system; increasing tenacity; adding into inclusive property; increasing cohesion between the PPO and the elastic body; improving combination mechanical property of the blending material. This product is environmental protection product, which possesses good water resistance property and electrical isolation property.

Owner:SHENZHEN KEJU NEW MATERIAL

Flame-retardant resin composition

InactiveUS20050004292A1Improve flame retardant performanceSpecial tyresPolyesterPhosphoric Acid Esters

A flame-retardant resin composition comprises (A) abase resin; (B) a flame retardant comprising (B1) at least one aromatic resin selected from a pblyphenylene oxide-series resin and a polyphenylene sulfide-series resin, (B2) a phosphoric ester, and (B3) a nitrogen-containing cyclic compound; and (C) a styrenic resin having a melt flow rate of not more than 8 g / 10 minutes. The base resin may be a polyester-series resin. The styrenic resin (C) may be a styrenic resin having a melt flow rate of 0.1 g / 10 minutes to not more than 5 g / 10 minutes. The phosphoric ester (B2) may be a condensed phosphoric ester, and the nitrogen-containing cyclic compound (B3) may be a polyphosphate of an amino group-containing triazine compound, a polyphosphoric acid amide, or others. The present invention provides a flame-retardant resin composition which has been flame-retarded without using a halogen-containing flame retardant.

Owner:POLYPLASTICS CO LTD

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

Halogen-free resin composition as well as copper foil substrate and printed circuit board applying same

ActiveCN103013110AWith flame retardant functionWon't happenCircuit susbtrate materialsSheet filmCopper foil

The invention provides a halogen-free resin composition which comprises (A) 100 parts of cyanate ester resin, (B) 5-50 parts of styrene maleic anhydride, (C), 5-100 parts of polyphenyl ether resin, (D) 5-100 parts of maleimide resin, (E) 10-150 parts of nitrogenous compound, and (F) 10-1000 parts of inorganic filler. As the composition comprises components in special proportion, the halogen-free resin composition is low in dielectric constant, low in dielectric loss, high in heat resistance and high in flame resistance. The halogen-free resin composition can be prepared as a semi-cured film or a resin film, so that the composition can be applied to a copper foil substrate and a printed circuit board.

Owner:ELITE MATERIAL

High-frequency thermosetting resin composition, prepreg and laminated sheet

ActiveCN102181143ADoes not affect heat resistanceDoes not affect dielectric propertiesMetal layered productsDielectric lossCopper foil

The invention discloses a high-frequency thermosetting resin composition. The high-frequency thermosetting resin composition comprises the following components in part by weight: 10 to 60 parts of halogen-free epoxy resin, 15 to 70 parts of polyphenyl ether resin, and 5 to 60 parts of composite cyanate resin; an accelerator is 0.01 to 2 parts; and the composite cyanate resin comprises thiocyanate resin. The composition can realize halogen-free flame resistance, and does not influence the heat resistance and dielectric performance of a product; and a laminated sheet prepared from the composition has high peel strength and heat resistance of a copper foil and a low dielectric constant and low dielectric loss under the high-frequency condition.

Owner:SHENGYI TECH SUZHOU

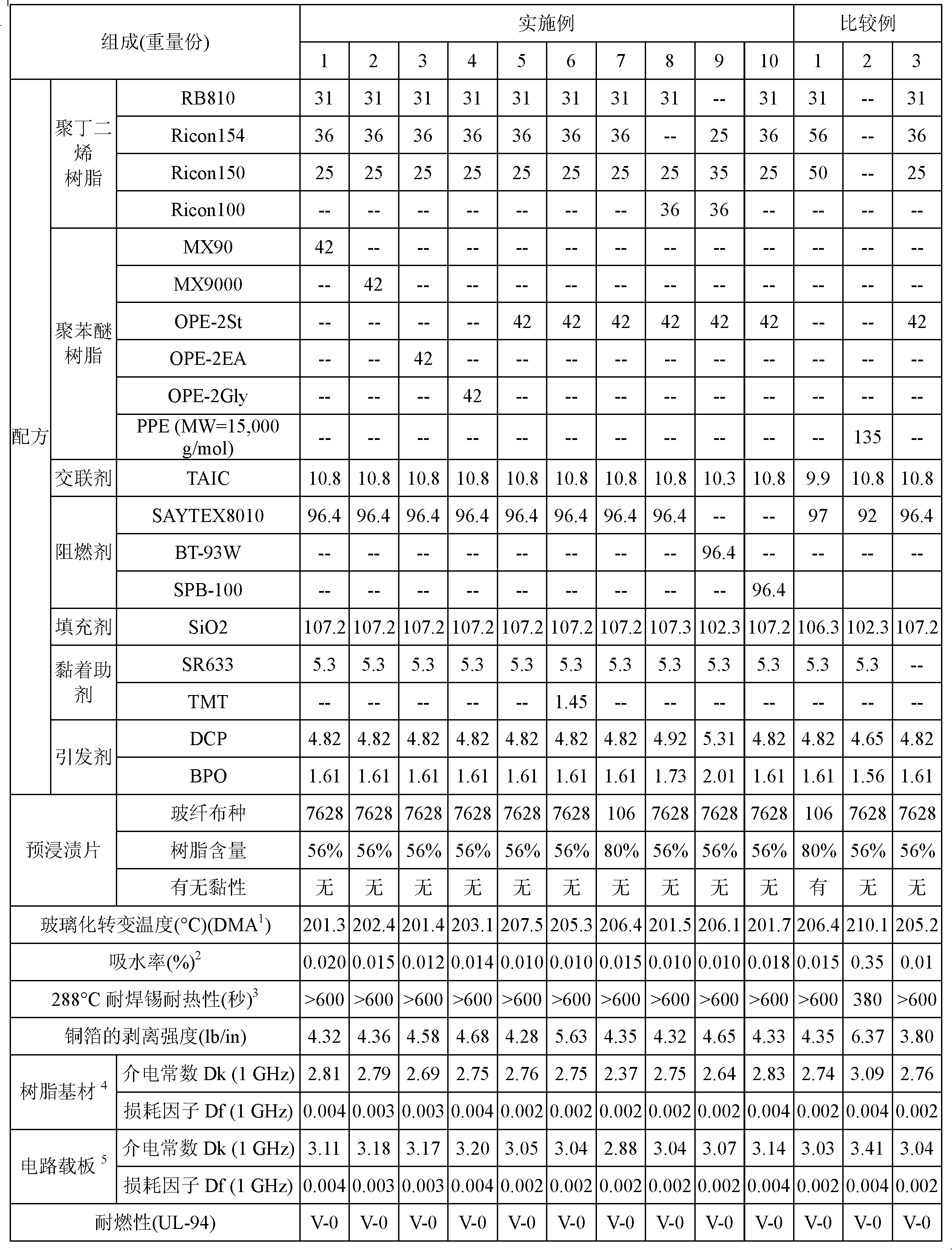

Polyphenylene ether resin composition, and a prepreg and a copper clad laminate made therefrom

ActiveUS20140044918A1Reduce molecular weightEasy to processOrganic chemistryFibre treatmentHeat resistanceEther

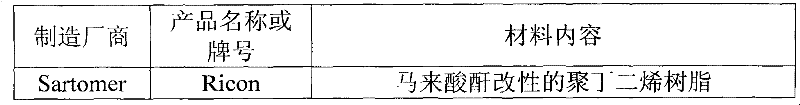

The present invention relates to a polyphenylene ether resin composition, and a prepreg and a copper dad laminate made therefrom. The polyphenylene ether resin composition comprises: (A) functionalized polyphenylene ether resin, (B) crosslinking agent, and (C) initiator; the component (A) functionalized polyphenylene ether resin is polyphenylene ether resin that has a number average molecular weight of 500-5000 and unsaturated double bonds at the molecule terminal; the component (B) crosslinking agent is olefin resin with a number average molecular weight of 500-10000, of which styrene structure comprises 10-50 wt %, and of which the molecule comprises 1,2-addition butadiene structure. The polyphenylene ether resin composition of the present invention is a composition of functionalized polyphenylene ether resin with a low molecular weight. The prepreg and copper clad laminate made from the polyphenylene ether resin composition have good dielectric properties and heat resistance.

Owner:GUANGDONG SHENGYI SCI TECH

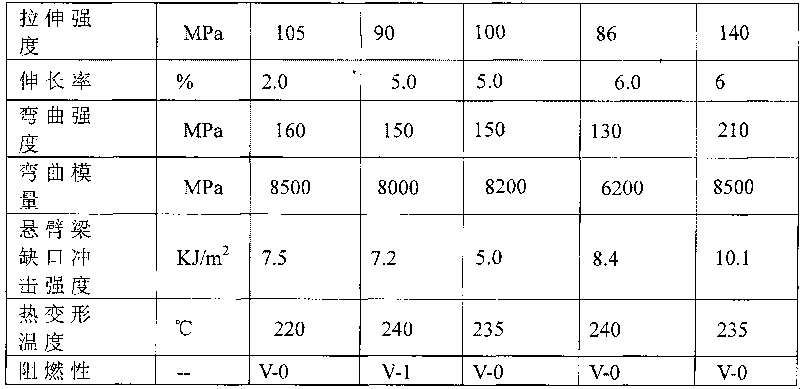

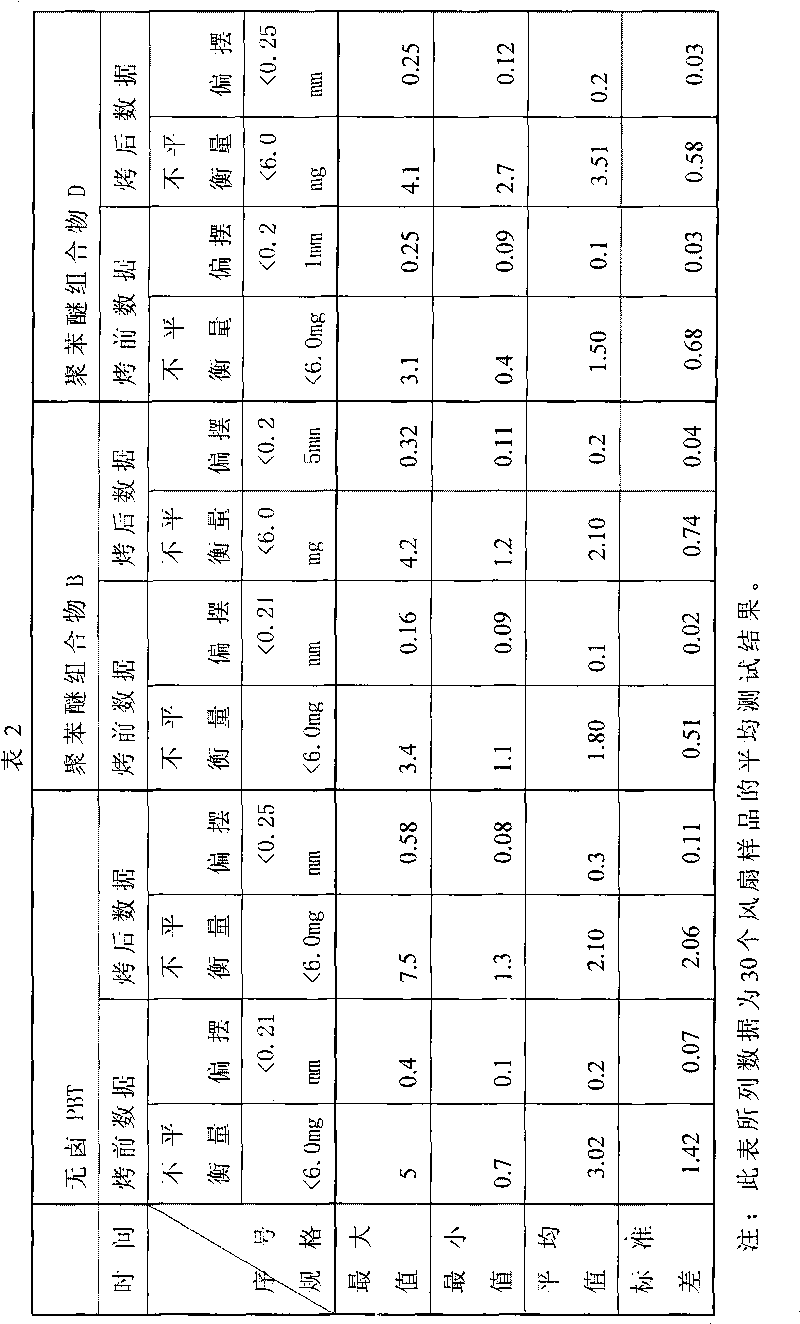

Reinforced halogen-free flame-retardant polyphenyl ether composition and preparation method and application thereof

InactiveCN101759992AImprove flame retardant performanceGood dimensional stabilityPump componentsPumpsDynamic balancePolyamide

The invention discloses a reinforced halogen-free flame-retardant polyphenyl ether composition and a preparation method and application thereof. The polyphenyl ether composition comprises the following components in part by weight: 100 to 800 parts of polyphenyl ether (PPE), 100 to 800 parts of polyamide, 100 to 600 parts of reinforcing filler, 100 to 500 parts of flame retardant, 0 to 300 parts of bulking agent, 50 to 200 parts of toughening agent, 0 to 50 parts of lubricating agent, 0 to 50 parts of coupling agent and 0 to 50 parts of other processing additives. The polyphenyl ether composition has excellent flame retardance, and can reach the flame-retardant grade V0; the polyphenyl ether composition has good size stability, and can meet the test requirement of a fan on deflection and dynamic balance; the polyphenyl ether composition has excellent mechanical properties, particularly toughness; and the polyphenyl ether composition has excellent oil resistance, and can resist the lubricant of the fan.

Owner:KINGFA SCI & TECH CO LTD +1

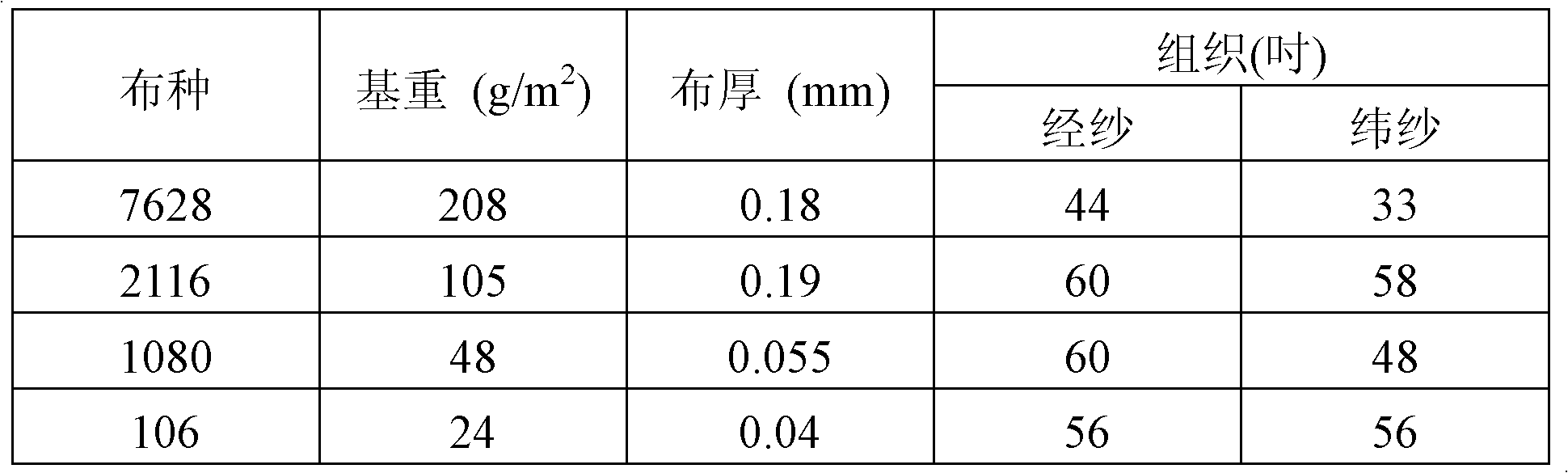

High-frequency copper foil substrate and composite material used thereby

ActiveCN102304264ALow costHigh frequencySynthetic resin layered productsCircuit susbtrate materialsCross-linkSolubility

The invention discloses a high-frequency copper foil substrate with an operating frequency of more than 1GHz, which has a dielectric constant Dk of less than 3.2 and a loss factor Df of less than 0.005 as well as high glass transition temperature, high thermostability and low moisture-absorption characteristic. The high-frequency copper foil substrate contains a special composite material and is prepared by impregnating a reinforcing material with blended resin mixture. The resin mixture of the composite material is prepared by blending the following materials: (a) high molecular weight polybutadiene resin; (b) low molecular weight polybutadiene resin; (c) modified polyphenyl ether thermosetting resin; (d) inorganic powder; (e) flame retardant; (f) cross-linking agent; (g) binding aid; and (h) hardening initiator. In the invention, the drawback of low processability of pure polybutadiene with low viscosity and the drawback of need of adding plasticizer of polyphenyl ether resin (PPE) with low solubility; particularly, the non-viscous pre-impregnated sheets made by the composite material can be processed into copper foil substrates automatically.

Owner:NANYA PLASTICS CORP

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

High-strength PPO/PA66 alloy material and preparation method thereof

The invention discloses a high-strength PPO / PA66 alloy material and a preparation method thereof. The high-strength PPO / PA66 alloy material is prepared from the following components in percentage by weight: 20-40% of polyphenyl ether resin, 20-40% of nylon 66 resin, 5-10% of compatilizer, 5-10% of toughener, 5-15% of glass fiber, 5-15% of glass microballoon, 5-15% of mica powder, 0.2-0.4% of antioxidant and 0.5-1% of other assistants. By compounding the glass fiber, the glass microballoon and the mica powder to enhance PPO / PA66 alloy, the prepared alloy material not only has excellent combination properties including high strength, good heat resistance and easy spraying, but also has excellent dimensional stability and low warpage rate. Therefore, the invention is suitable for molding large structural parts and heated components.

Owner:徐东

High performance plastic pallets

The invention relates to plastic pallets that pass the Underwriters Laboratory UL 2335 protocol for pallets wherein said pallets comprises at least one resin selected from the group consisting of: (a) polyphenylene ether resin and blends containing polyphenylene ether resin, (b) polycarbonate resin and blends containing polycarbonate resin, (c) vinyl aromatic graft copolymer resin; (d) polyetherimide resin and blends containing polyetherimide resin, and thermosetting resins. In a preferred embodiment, the plastic pallet has an open deck design. The invention also relates to a method to make pallets that pass the UL 2335 protocol.

Owner:SABIC GLOBAL TECH BV

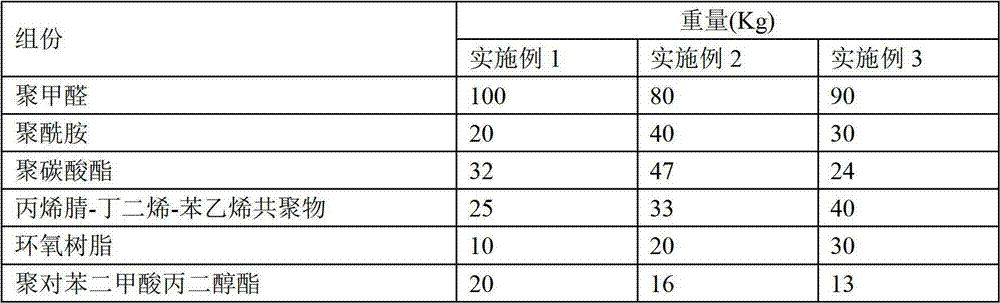

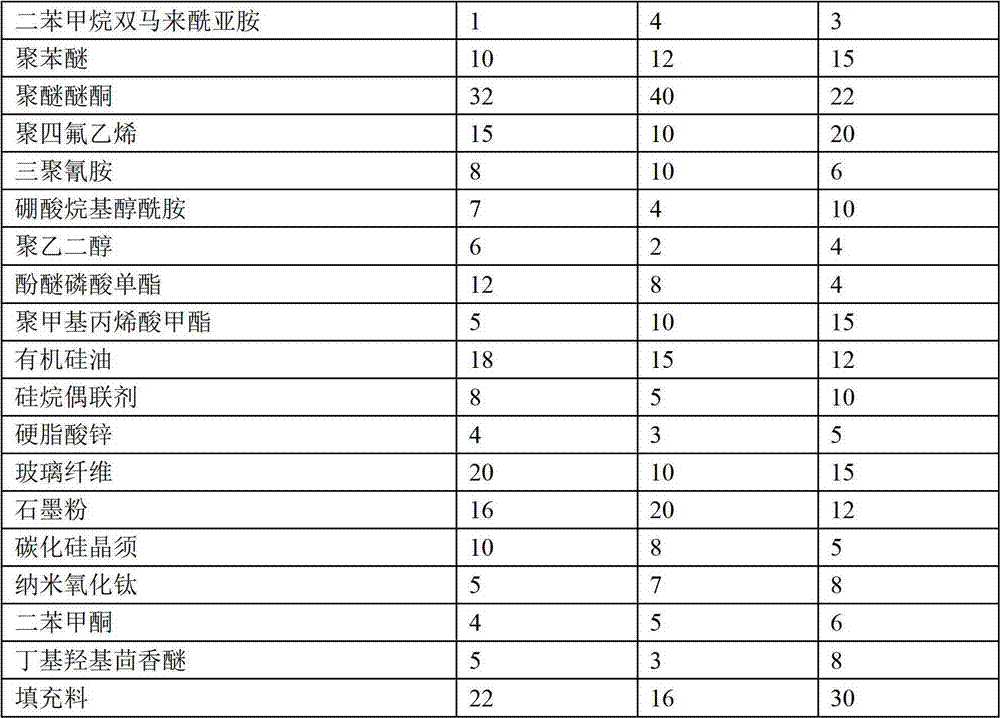

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

Polyphenylene ether oligomer compound, derivatives thereof and use thereof

InactiveUS20080033117A1Maintain good propertiesImprove compatibilityPrinted circuit aspectsPrinted circuit manufactureEpoxyOligomer

The present invention provides a bifunctional phenylene ether oligomer compound having a thermosetting functional group at each terminal, an epoxy resin containing the above oligomer compound and a use thereof. That is, it provides a sealing epoxy resin composition for sealing an electric part, an epoxy resin composition for laminates, a laminate, a printed wiring board, a curable resin composition and a photosensitive resin composition. The resins and resin compositions of the present invention are used in electronics fields in which a low dielectric constant, a low dielectric loss tangent and high toughness are required and also used for various uses such as coating, bonding and molding.

Owner:MITSUBISHI GAS CHEM CO INC

Process for producing resin varnish containing semi-ipn composite thermosetting resin and, provided using the same, resin varnish for printed wiring board, prepreg and metal-clad laminate

ActiveUS20100129676A1Maintain good propertiesPromote absorptionOther chemical processesSynthetic resin layered productsElastomerThermal dilatation

Provided is a process for producing a thermosetting resin varnish from which a printed circuit board can be produced wherein the printed circuit board has excellent dielectric properties in a high frequency band and can significantly reduce the transmission loss, and exhibits excellent heat resistance after moisture absorption and excellent thermal expansion properties and satisfies the metallic foil peeling strength.A process for producing a thermosetting resin varnish containing a thermosetting resin composition, which contains an uncured semi-IPN composite, an inorganic filler, and a saturated thermoplastic elastomer, wherein the process comprises the steps of: (i) preliminary reacting (B) a butadiene polymer which contains in the molecule thereof 40% or more of a 1,2-butadiene unit having a 1,2-vinyl group in the side chain thereof, and which is not chemically modified and (C) a crosslinking agent, in the presence of (A) a polyphenylene ether to obtain a polyphenylene ether-modified butadiene prepolymer which is an uncured semi-IPN composite; (ii) mixing together (D) an inorganic filler and (E) a saturated thermoplastic elastomer to obtain a mixture; and (iii) mixing together the obtained mixture and the polyphenylene ether-modified butadiene prepolymer, a resin varnish, a prepreg, and a metal-clad laminate provided using the same.

Owner:RESONAC CORP

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

Polyphenyl ether resin material used for processing charger case

The invention discloses a polyphenyl ether resin material used for processing a charger case, which consists of polyphenyl ether resin, polystyrene resin, an elastic body, fire retardants, polyolefin, silicone masterbatch, main antioxidants and auxiliary antioxidants. Through adding proper auxiliary agents into a polyphenyl ether resin composition, the invention improves the surface lubricating effect of manufactured elements, reduces the pressure required during welding, and solves the problems of impression, scratches and the like occurring during the ultrasonic welding of products. The products are mainly applied to the fields requiring the ultrasonic welding, such as charger cases, wiring cases and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

Resin composition for insulation film

ActiveUS20130245161A1Low dielectric constantLow DfDomestic articlesThin material handlingPolymer sciencePtru catalyst

A resin composition includes (A) 100 parts by weight of epoxy resin; (B) 20 to 100 parts by weight of polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone (DTBHQ); (D) 5 to 50 parts by weight of polyphenyl ether modified cyanate ester resin; and at least one of (E) inorganic filler, (F) chain extending sealing agent, and (G) catalyst. The resin composition is characterized by specific ingredients and proportions thereof to attain high heat resistance, low dielectric constant Dk, and low dielectric dissipation factor Df, and being halogen-free, and therefore is applicable to protective film of printed circuit boards, insulating protective film of electronic components, and resin insulation film of leadframes.

Owner:ELITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com