High-frequency thermosetting resin composition, prepreg and laminated sheet

A technology of resin composition and prepreg, which is applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of reducing the heat resistance and mechanical properties of finished products, limited flame retardant effect, leakage, etc., and achieves Excellent copper foil peel strength and heat resistance, low dielectric loss, low dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

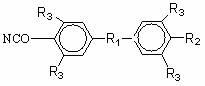

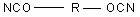

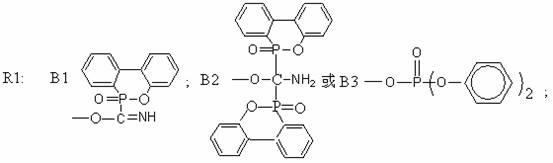

Method used

Image

Examples

Embodiment 1

[0047] Add 40g of polyphenylene ether resin (structure as formula 1, R=S1) into 40g of methyl ethyl ketone, and stir to dissolve it completely. After the polyphenylene ether resin is completely dissolved, add 30g of biphenyl epoxy resin (NC-3000, Nippon Kayaku), 15g of phosphorus cyanate resin (structure as in formula 2, R=A1), 15g of bisphenol A Type cyanate (CY-10, Wuqiao Chemical), 0.4g of 2-ethyl-4-methylimidazole and 0.4g of aluminum acetylacetonate, stirred and mixed evenly to obtain glue. Select a flat and smooth E-glass fiber cloth with a thickness of 0.1mm, evenly coat the above glue, and bake it in an oven at 150°C for 5 minutes to prepare a prepreg. Stack 8 of the above-mentioned prepregs, attach 35 μm copper foil up and down, place them in a vacuum hot press and press them for 3 hours at a pressure of 3 MPa and a temperature of 220° C. to obtain a laminate. The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 2

[0049]Add 45g of polyphenylene ether resin (structure as in Formula 1, R=S2) to 45g of butanone, and stir to dissolve it completely. After the polyphenylene ether resin is completely dissolved, add 25g of biphenyl epoxy resin (NC-3000, Nippon Kayaku), 15g of phosphorous cyanate resin (structure as in formula 4, R=A1), 15g of bisphenol A Type cyanate (CY-10, Wuqiao Chemical), 0.4g 2-ethyl-4-methylimidazole and 0.4g aluminum acetylacetonate, stir and mix evenly to obtain glue. Select a flat and smooth E-glass fiber cloth with a thickness of 0.1mm, evenly coat the above glue, and bake it in an oven at 150°C for 5 minutes to prepare a prepreg. Stack 8 of the above-mentioned prepregs, attach 35 μm copper foil up and down, place them in a vacuum hot press and press them for 3 hours at a pressure of 3 MPa and a temperature of 220° C. to obtain a laminate. The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

[0051] Add 35g of polyphenylene ether resin (structure as in Formula 1, R=S1) to 30g of butanone, and stir to dissolve it completely. After the polyphenylene ether resin is completely dissolved, add 30g of trifunctional phenolic epoxy resin (TFE1250, Changchun artificial resin), 25g of phosphorous cyanate resin (structure as in formula 5, R1=D4, R2=D5, R3= D7), 10g of dicyclopentadiene cyanate (CY-3, Wuqiao Chemical), 0.4g of 2-ethyl-4-methylimidazole and 0.4g of zinc acetylacetonate, stirred and mixed evenly to obtain a glue. Select a flat and smooth E-glass fiber cloth with a thickness of 0.1mm, evenly coat the above glue, and bake it in an oven at 150°C for 5 minutes to prepare a prepreg. Stack 8 of the above-mentioned prepregs, attach 35 μm copper foil up and down, place them in a vacuum hot press and press them for 3 hours at a pressure of 3 MPa and a temperature of 220° C. to obtain a laminate. The properties of the obtained copper-clad laminates are shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com