Low-flash high-toughness good-surface polyphenylene sulfide composition as well as preparation method and application thereof

A technology of polyphenylene sulfide and composition, which is applied in the field of low flash, high toughness and good surface polyphenylene sulfide composition and its preparation, which can solve the problems of poor material surface gloss, reduced acid resistance, and large filling amount. , to achieve good appearance and surface properties, low flash, high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

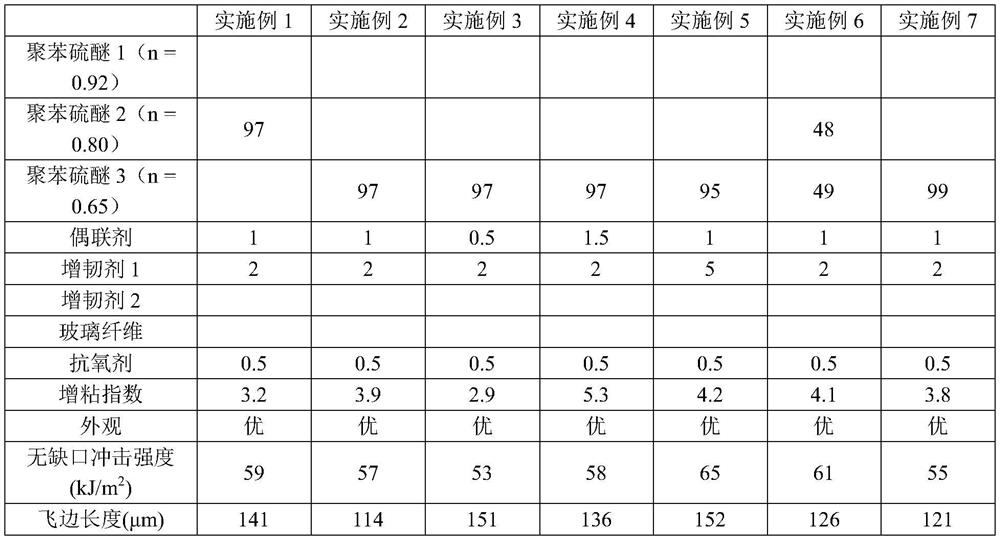

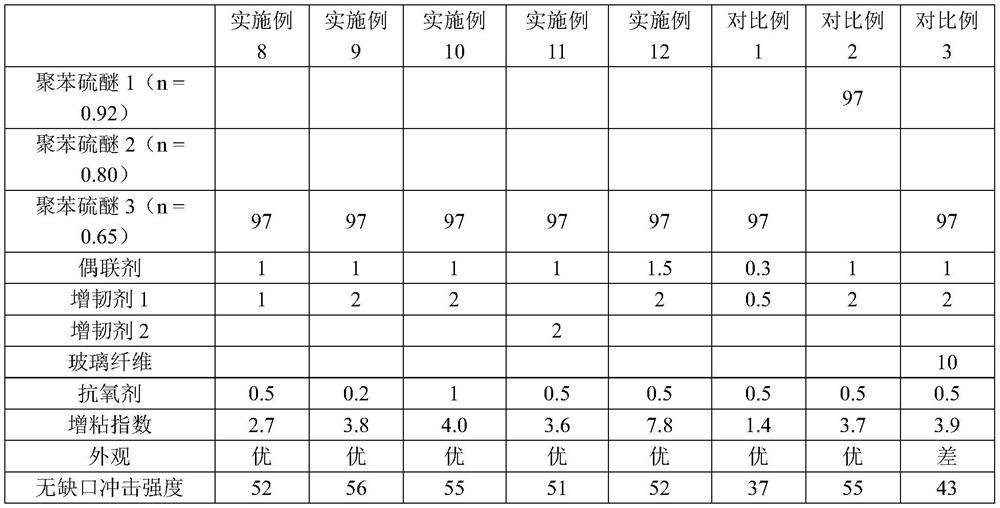

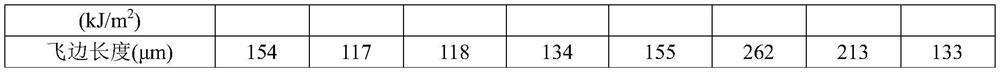

Examples

preparation example Construction

[0037] The present invention also provides the preparation method of the low-flash and high-toughness non-reinforced polyphenylene sulfide composition, which comprises the following steps: weighing each component by weight, mixing and dispersing each component by a high-speed mixer, and obtaining compound, and then pass the compound through a twin-screw extruder to obtain the polyphenylene sulfide composition.

[0038] In the present invention, the polyphenylene sulfide resin with low power law index is selected, and the interaction between the coupling agent and the reactive toughening agent is optimized. The high value makes it difficult to form flash during the pressure holding stage. At the same time, the PPS with a low power law index indicates that the pseudoplasticity of the material is stronger, and the viscosity changes greatly with the shear rate, so that the high shear viscosity of the material is conducive to mold filling. The optimization results in a low flash, hig...

Embodiment

[0040] The preparation method of the low flash high toughness non-reinforced polyphenylene sulfide composition of the present embodiment, the steps are as follows:

[0041] Weigh polyphenylene sulfide (one or two different brands), toughening agent (brand PTW), silane coupling agent (brand JH-A110), antioxidant (brand 1010, 168) by weight, First, the polyphenylene sulfide resin, coupling agent, toughening agent, antioxidant, and other additives are dispersed in a high-speed mixer according to the formula ratio, and then the mixture is passed through a twin-screw extruder; wherein, the extrusion process is: The rotating speed is 400rpm, the feeding is 450kg / h; the extrusion temperature is 280℃-290℃.

[0042] Two, the test standard used in the present invention is as follows:

[0043] (1) Izod unnotched impact strength: Tested according to standard ISO 180-2019.

[0044] (2) Flash size evaluation: use the flash assessment mold, open a 20×0.04mm opening on one side, and inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com