Patents

Literature

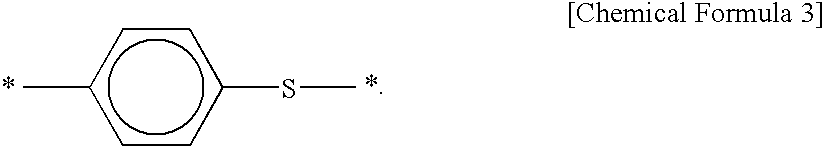

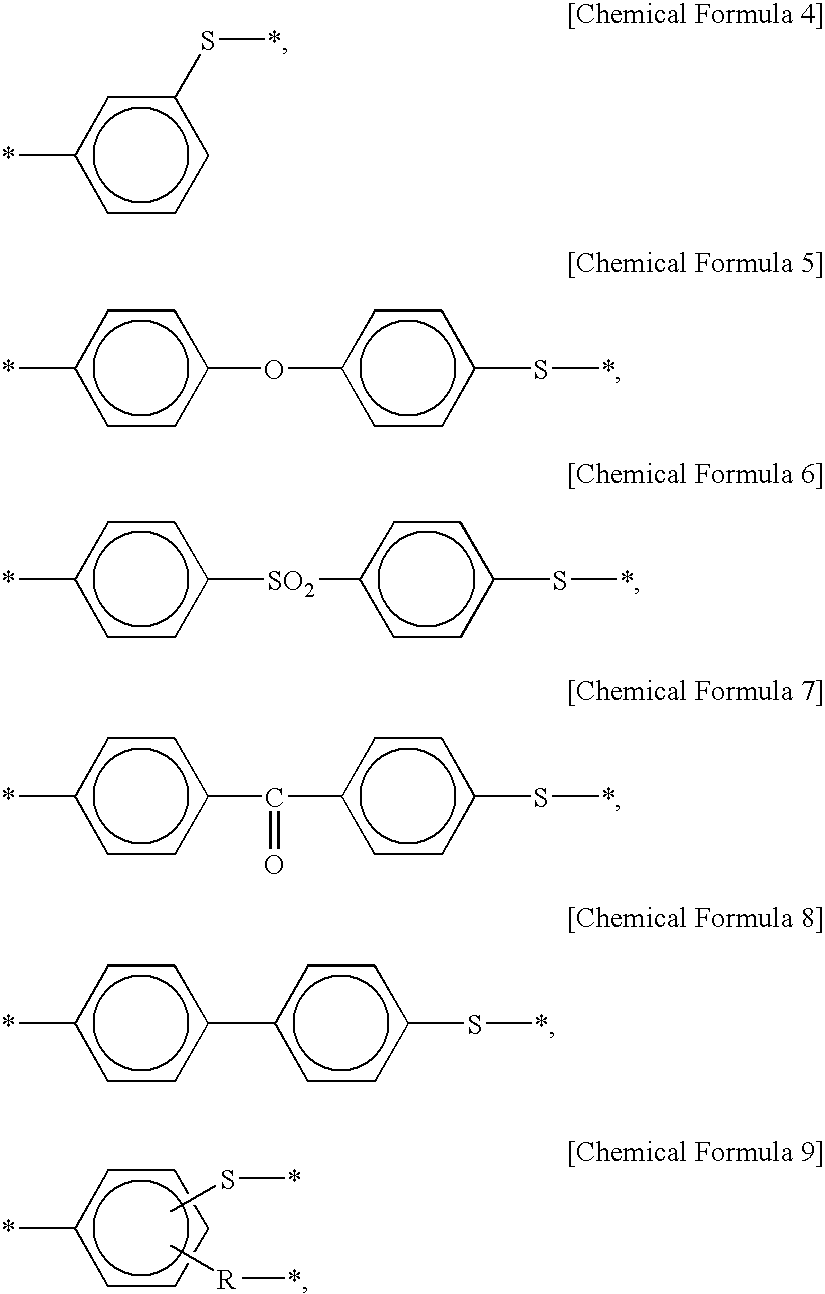

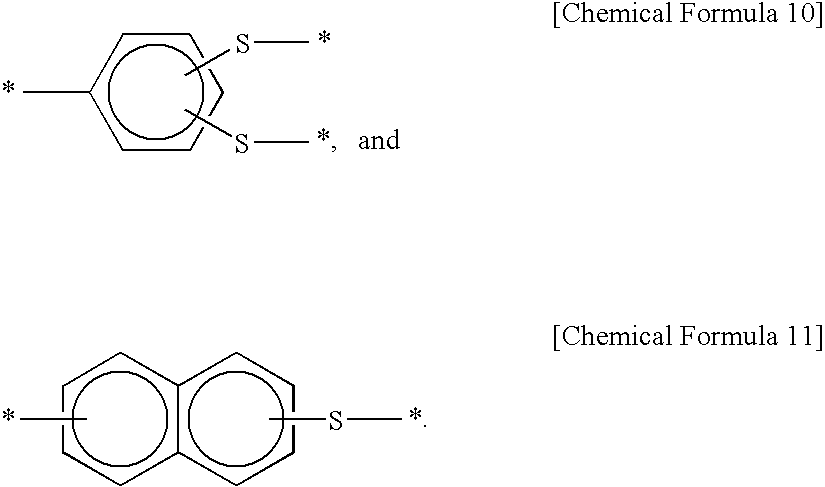

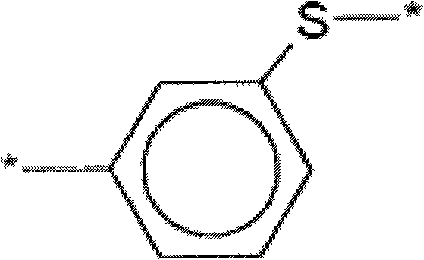

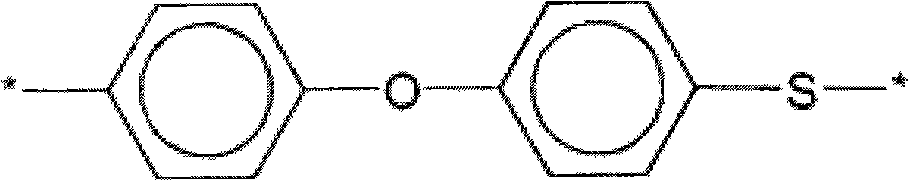

1005 results about "Phenyl sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

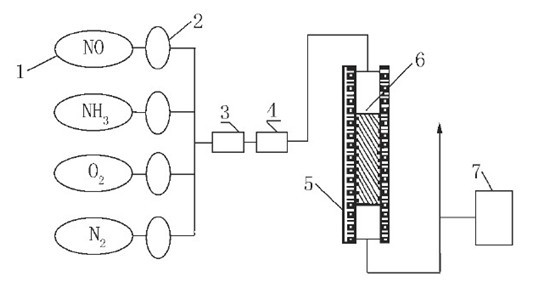

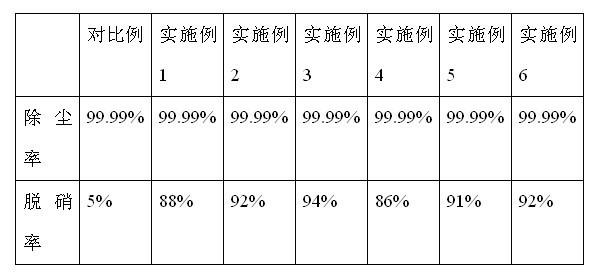

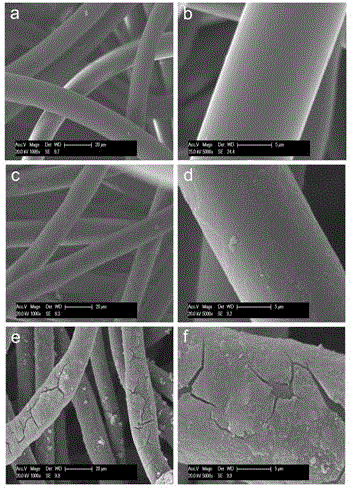

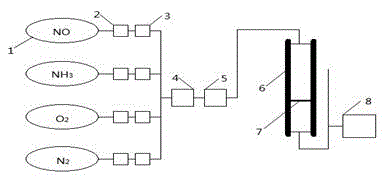

Preparation method of denitration-catalyst-supported polyphenylene sulfide (PPS) filter material

InactiveCN102145241AImprove denitrification rateImprove water resistanceDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsFiberPtru catalyst

The invention provides a supported polyphenylene sulfide (PPS) filter material which belongs to the field of filter materials. The supported PPS filter material is prepared by the following method: making a PPS fiber into a PPS filter material; performing water bath acidification in nitric acid, and washing with deionized water to neutrality; drying to obtain acidified polyphenylene sulfide nitride (PPSN); preparing a catalyst into a solution and stirring; soaking PPSN in the solution; performing water bath baking, and drying in air; and calcining in a nitrogen atmosphere to obtain the supported PPS filter material with denitration function. The denitration-catalyst-supported PPS filter material provided by the invention can be used as a dedusting agent and a denitration agent at the sametime, is prepared by simple steps, realizes dedusting and denitration functions as well, and has the advantages of high denitration rate, high temperature resistance, acid-base resistance, good waterresistance, long service life and the like; and a new application field of the filter-bag catalytic denitration is created.

Owner:FUZHOU UNIV

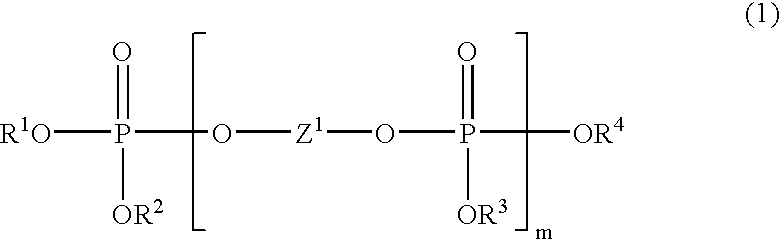

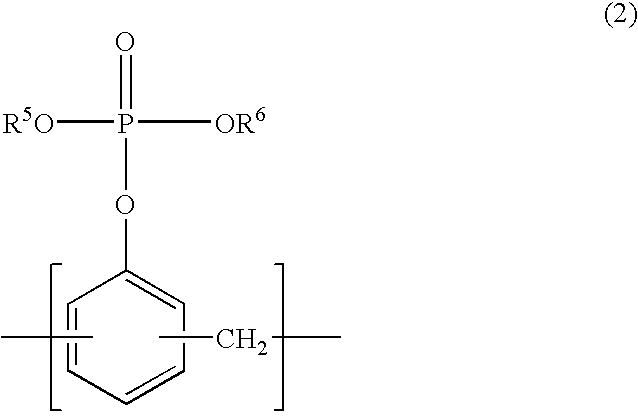

Flame-retardant resin composition

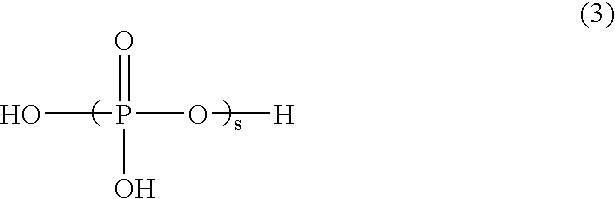

InactiveUS20050004292A1Improve flame retardant performanceSpecial tyresPolyesterPhosphoric Acid Esters

A flame-retardant resin composition comprises (A) abase resin; (B) a flame retardant comprising (B1) at least one aromatic resin selected from a pblyphenylene oxide-series resin and a polyphenylene sulfide-series resin, (B2) a phosphoric ester, and (B3) a nitrogen-containing cyclic compound; and (C) a styrenic resin having a melt flow rate of not more than 8 g / 10 minutes. The base resin may be a polyester-series resin. The styrenic resin (C) may be a styrenic resin having a melt flow rate of 0.1 g / 10 minutes to not more than 5 g / 10 minutes. The phosphoric ester (B2) may be a condensed phosphoric ester, and the nitrogen-containing cyclic compound (B3) may be a polyphosphate of an amino group-containing triazine compound, a polyphosphoric acid amide, or others. The present invention provides a flame-retardant resin composition which has been flame-retarded without using a halogen-containing flame retardant.

Owner:POLYPLASTICS CO LTD

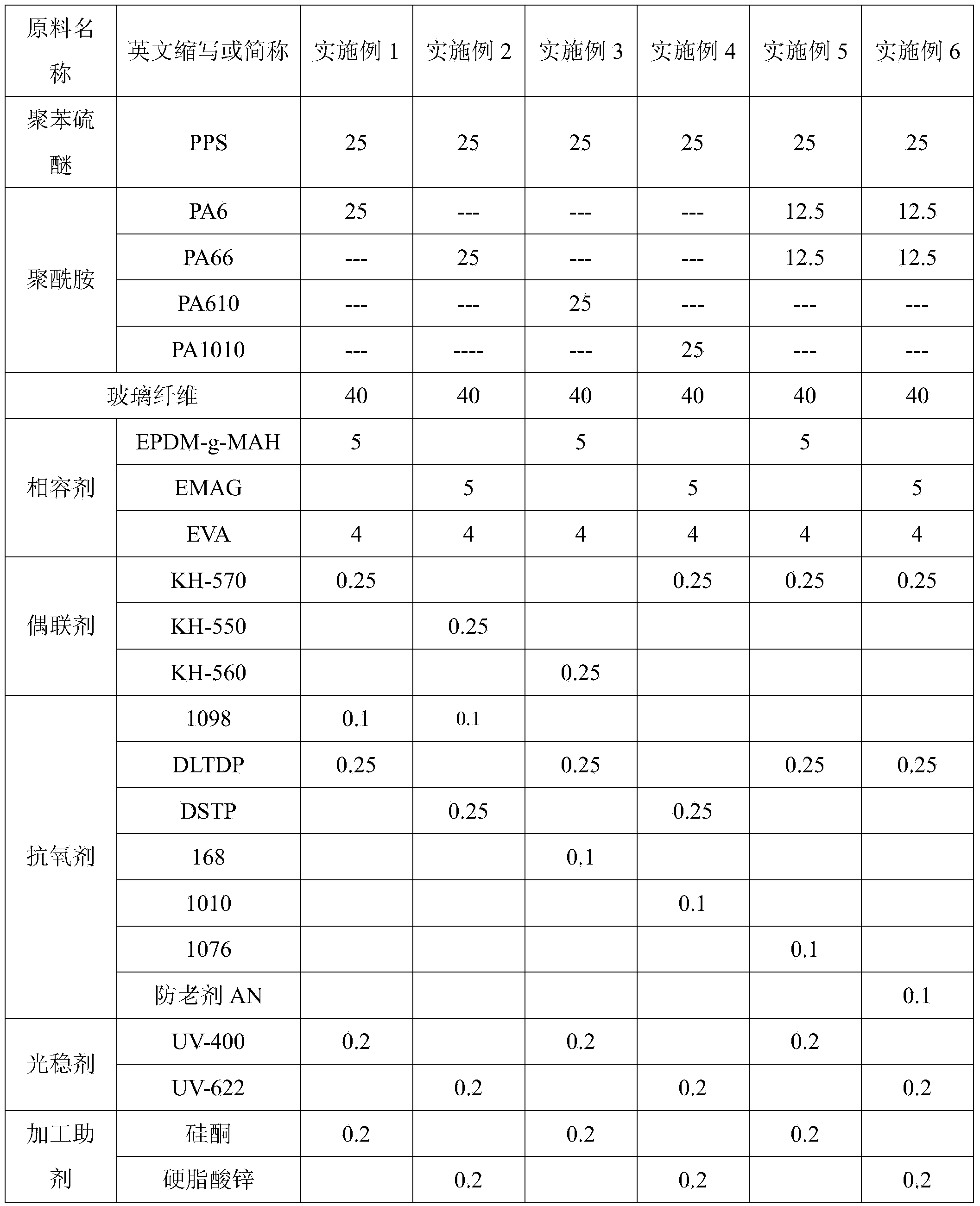

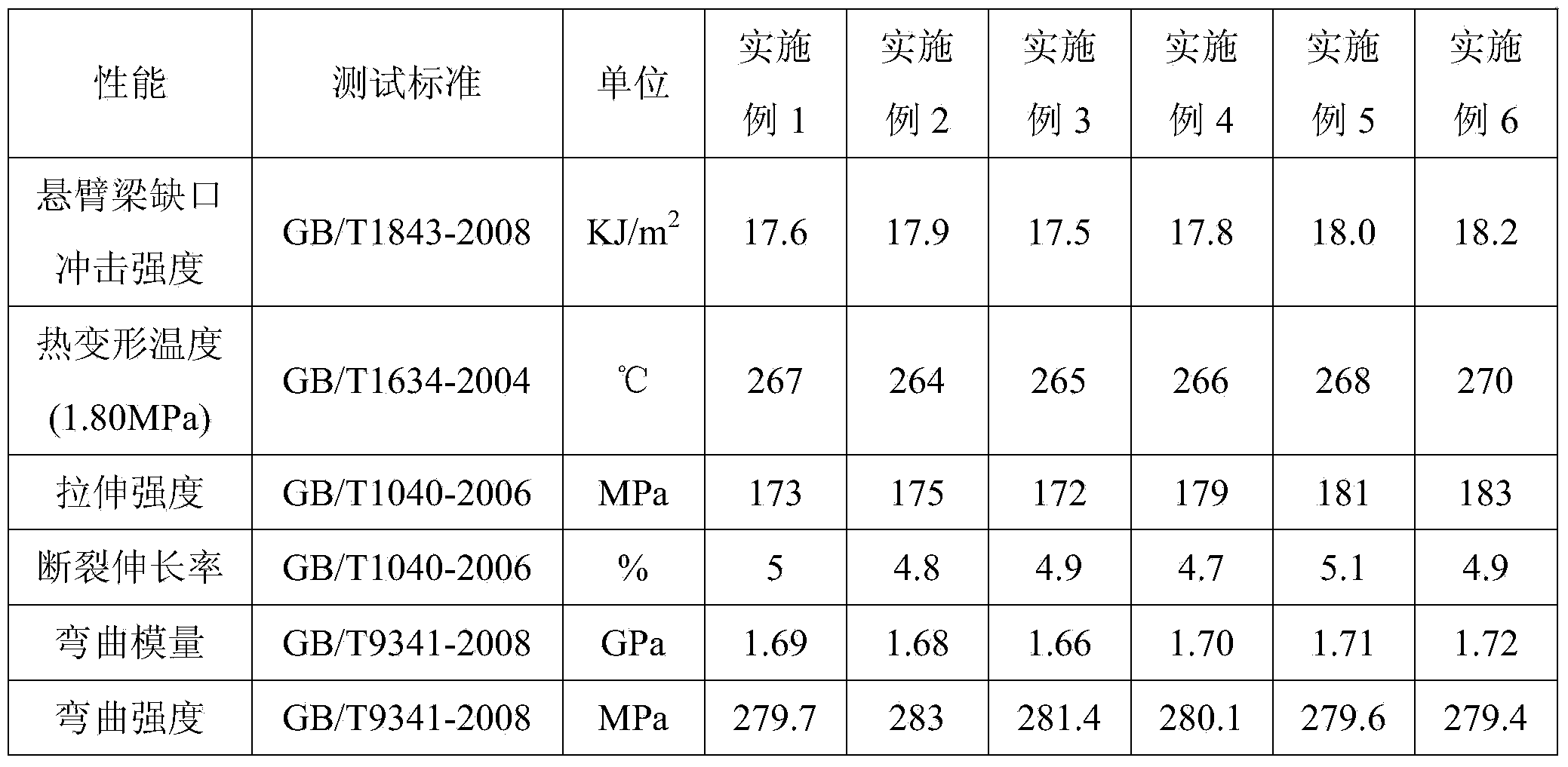

Polyphenylene sulfide composite material and preparation method thereof

The invention discloses a polyphenylene sulfide composite material which comprises the following components in percentage by weight: 10-40 percent of polyphenylene sulfide, 10-40 percent of polyamide, 5-30 percent of glass fiber, 5-20 percent of compatilizer, 0.2-1.5 percent of coupling agent, 0-1 percent of antioxidant, 0-1 percent of light stabilizer and 0-1 percent of processing aid. The method for preparing the polyphenylene sulfide composite material comprises the following steps: preparing various raw materials; sequentially adding polyphenylene sulfide, polyamide, the compatilizer, the coupling agent, the antioxidant, the light stabilizer and the processing aid into a high-speed mixer for dispersing and mixing; putting the mixed materials into an extruder after mixing is finished, independently introducing the glass fiber through a glass fiber port of the extruder during extrusion, and mixing, extruding and pelleting the materials to obtain granules of the polyphenylene sulfide composite material. The provided polyphenylene sulfide composite material has high rigidity, strength and toughness and can be widely applied to the fields of aerospace and aviation, chemical industry, electronic products, machinery, automobiles and railways.

Owner:宁波泛龙塑料新材料有限公司

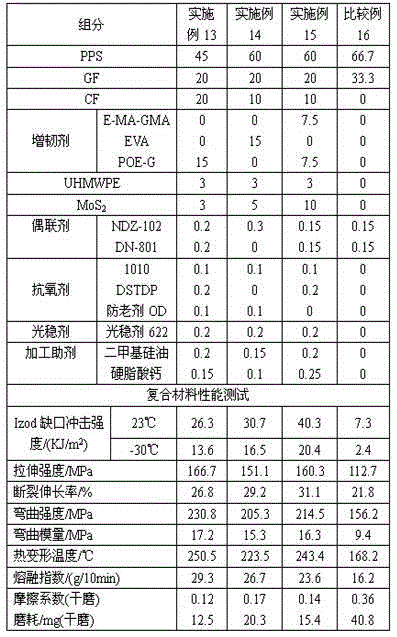

Wear-resistant and high-toughness polyphenylene sulfide composite material and preparation method thereof

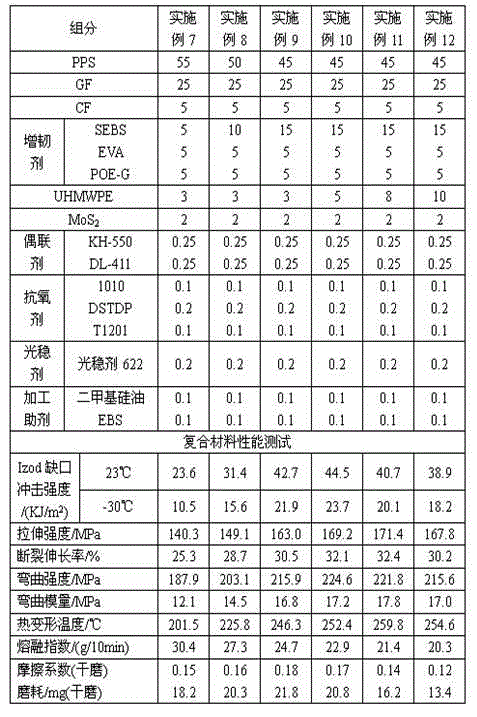

The invention discloses a wear-resistant and high-toughness polyphenylene sulfide composite material and a preparation method thereof. The composite material is composed of the following components of, by weight, 30-75 parts of polyphenylene sulfide, 20-50 parts of glass fibre, 5-20 parts of carbon fiber, 5-30 parts of a toughening agent, 0-20 parts of polytetrafluoroethylene, 0-20 parts of an ultrahigh molecular weight polyethylene, 2-10 parts of molybdenum disulfide, 0.2-1.5 parts of a coupling agent, 0.2-1 part of an antioxidant, 0.1-0.5 part of a light stability agent and 0.2-2 parts of a processing auxiliary agent. The composite material has a series of outstanding advantages of excellent low-temperature impact performance, high strength, high modulus, high heat stability, easy processing and molding, and the like, and has wide application fields such as automobiles, aeronautics and astronautics, etc.

Owner:HEFEI GENIUS NEW MATERIALS

Polyphenylene sulfide composite material and preparation method thereof

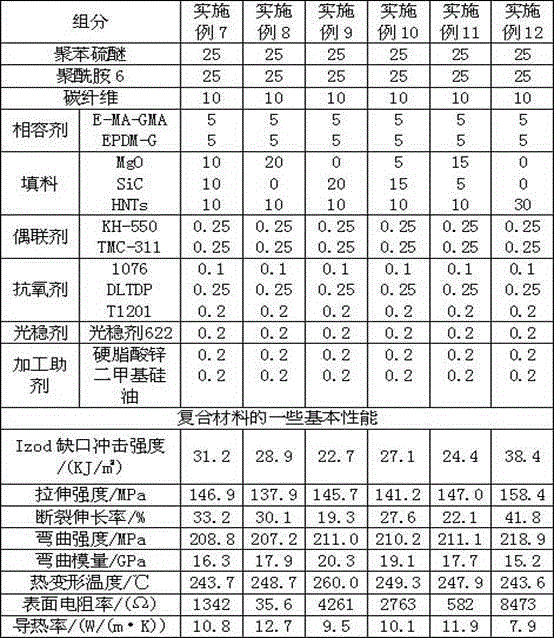

The invention discloses a polyphenylene sulfide composite material and a preparation method thereof. The polyphenylene sulfide composite material comprises, by weight, 10-40 parts of polyphenylene sulfide, 10-40 parts of polyamide, 5-25 parts of carbon fibers, 10-50 parts of packings, 5-20 parts of compatilizers, 0.2-1.5 parts of coupling agents, 0-1 part of antioxidants, 0-1 part of light stabilizers and 0-1 parts of processing additives. The polyphenylene sulfide composite material prepared by the method has advantages of excellent heat and electric conductivity, high strength, high modulus, high stability, easiness in processing and forming and the like, is wide in application range including fields of electronics and electrics, automobiles, aerospace and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Polyphenylene sulfide alloy composition

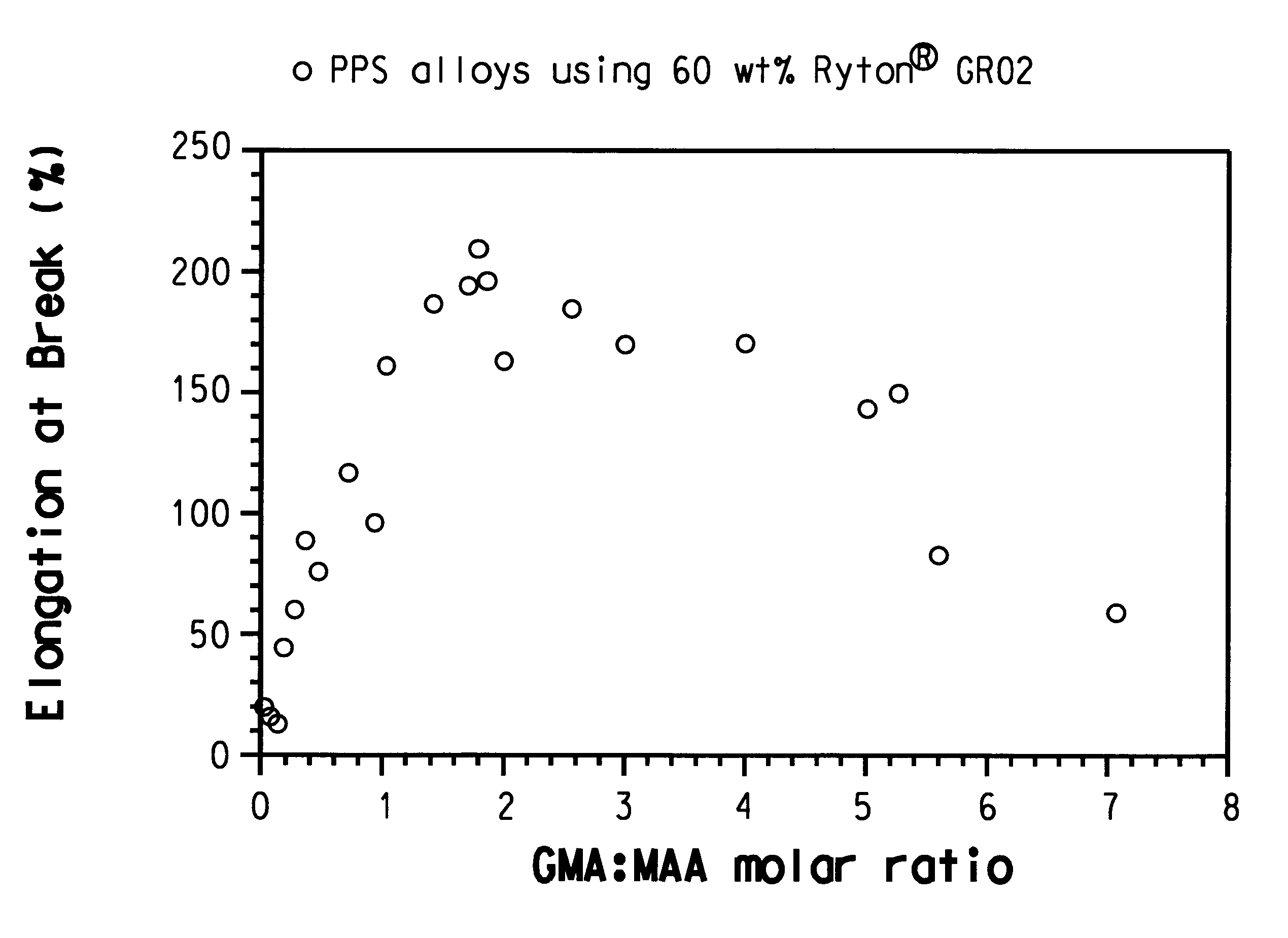

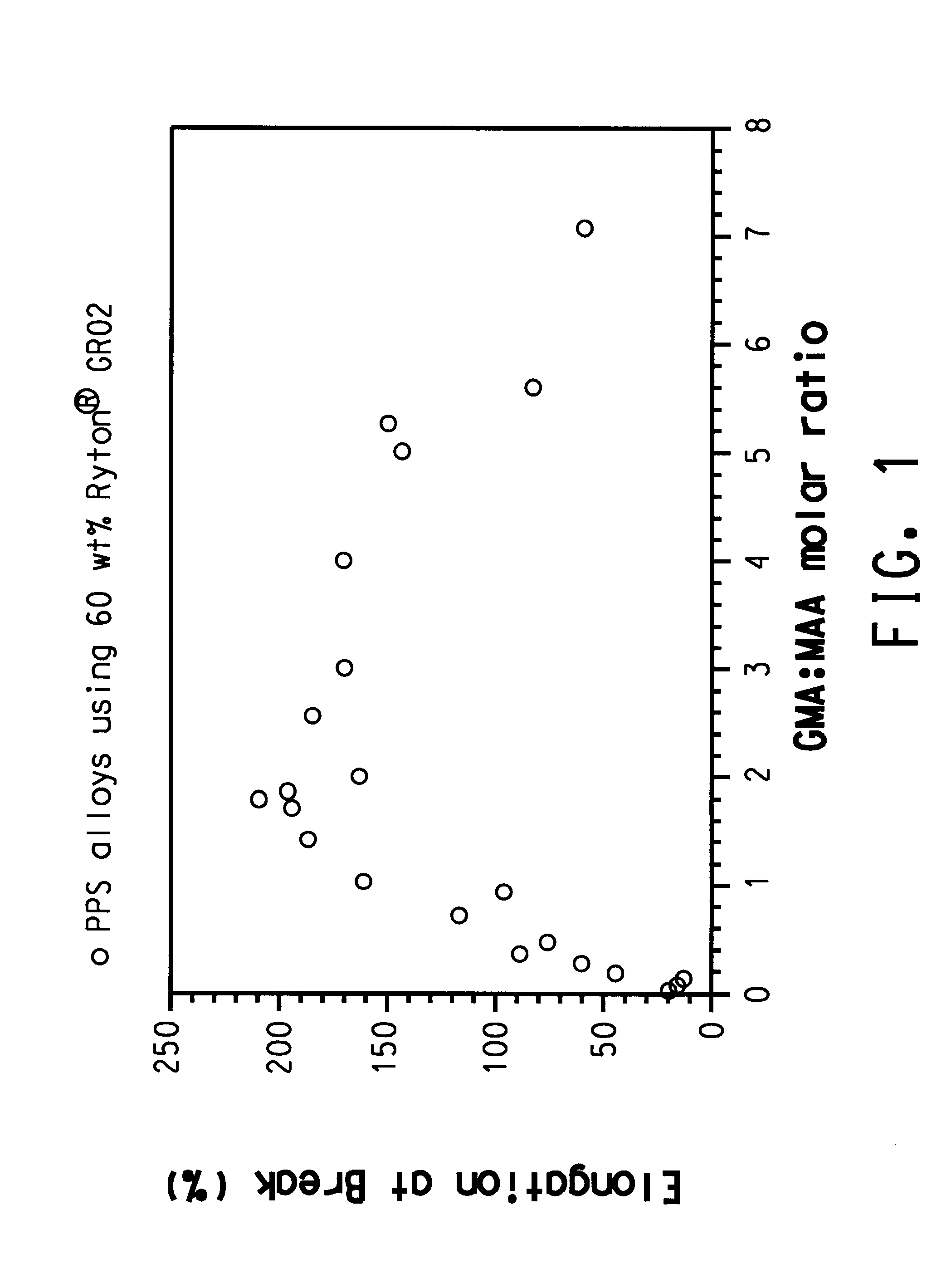

The present invention relates to polymer compositions containing polyphenylene sulfide, a polymeric grafting agent and an ethylene copolymer. The polymeric grafting agent is a copolymer of at least about 50% by weight ethylene, about 0.5% to about 15% by weight of a first reactive moiety selected from the group consisting of: (i) an unsaturated epoxide of 4-11 carbon atoms, (ii) an unsaturated isocyanate of 2-11 carbon atoms, (iii) an alkoxy or alkyl silane wherein the alkyl group is from 1-12 carbon atoms, and (iv) an oxazoline; and about 0 to about 49% by weight of a second moiety selected from at least one of an alkyl acrylate, alkyl methacrylate, vinyl ether, carbon monoxide, and sulfur dioxide, where the alkyl and ether groups are of 1-12 carbon atoms. The ethylene copolymer comprises about 1% to about 20% by weight of an ethylene copolymer which comprises at least about 50% by weight ethylene, about 1% to about 35% by weight of an acid-containing unsaturated mono-carboxylic acid, and about 0 to about 49% by weight of a moiety selected from at least one of alkyl acrylate, alkyl methacrylate, vinyl ether, carbon monoxide, and sulfur dioxide, and further wherein the acid groups are neutralized from 0-100% by a metal ion. The molar ratio of polymeric grafting agent to ethylene copolymer preferably ranges from about 1.0 to about 5.5.

Owner:DUPONT POLYMERS INC

Highly-conductive polyphenylene sulfide composite material and method for making same

InactiveCN101161726AImprove conductivityEvenly dispersedNon-conductive material with dispersed conductive materialFiberSurface resistivity

The invention discloses a high electric conduction polyphenylene sulfide (PPS) composite material and the preparation method thereof. The percentage by weight of the compositions of the high electric conduction polyphenylene sulfide composite material is as follows: 40 to 70 percent of polyphenylene sulfide, 5 to 30 percent of conducting fiber, 5 to 30 percent of conducting powder, and other auxiliary agents from 0 to 5 percent. The conducting fiber and conducting powder in the conducing plastics provided by the invention disperse evenly with a plurality of lapping joints and high electric conductivity, thereby remarkably improving electric conductivity. The surface resistivity and volume resistivity of the material respectively reach 0.3-11.0 ohm and 0.07-8.5 ohm*cm, thereby meeting the requirements of plastic shaping techniques such as repeated injection molding, plastic extruding or die stamping. The processing art of the material is simple and can control the conducting fiber and conducting carbon black to evenly disperse in plastic particles, thereby enabling the PPS composite material to have high electric conductivity and meeting the requirements of industrial big production.

Owner:SHENZHEN KEJU NEW MATERIAL

Low warpage liquid crystal polymer composition and preparation method thereof

The invention relates to a low warpage liquid crystal polymer composition and a preparation method thereof; the composition comprises the following components by weight percentage: 20wt% to 80wt% of thermotropic liquid crystalline polymer with a melting point of at least 290 DEG C, 5wt% to 20 wt% of thermoplastic polyphenylene sulfide with a melting temperature of from 280 DEG C to 290 DEG C, 10 wt% to 70 wt% of reinforcing material and 0 wt% to 10 wt% of other additives. The preparation method comprises the steps: LCP and PPS resin are respectively dried at the temperature of 160 DEG C and 140 DEG C for 4-6 hours; a lubricating agent and a compatilizer to be added are uniformly mixed in a high speed blender and then are dried at the temperature of 80 DEG C for 4 to 6 hours; polyester resin to be added is dried for 4 to 6 hours at the temperature of 120 DEG C; the dried materials are uniformly mixed in the high speed blender and put into a main feeding hopper of a double-screw extruder; the reinforcing material is added from a side feeding opening of the double-screw extruder; and the materials are melted, squeezed out and pelleted. The preparation method has the advantages that the addition of polyphenylene sulfide can obviously reduce the warping degree; the fiber reinforcing material and lubricating material can be matched with polyphenylene sulfide so as to lead the mechanical property of the polyphenylene sulfide in the components to be reinforced.

Owner:KINGFA SCI & TECH CO LTD +1

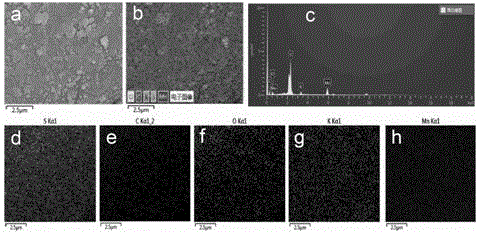

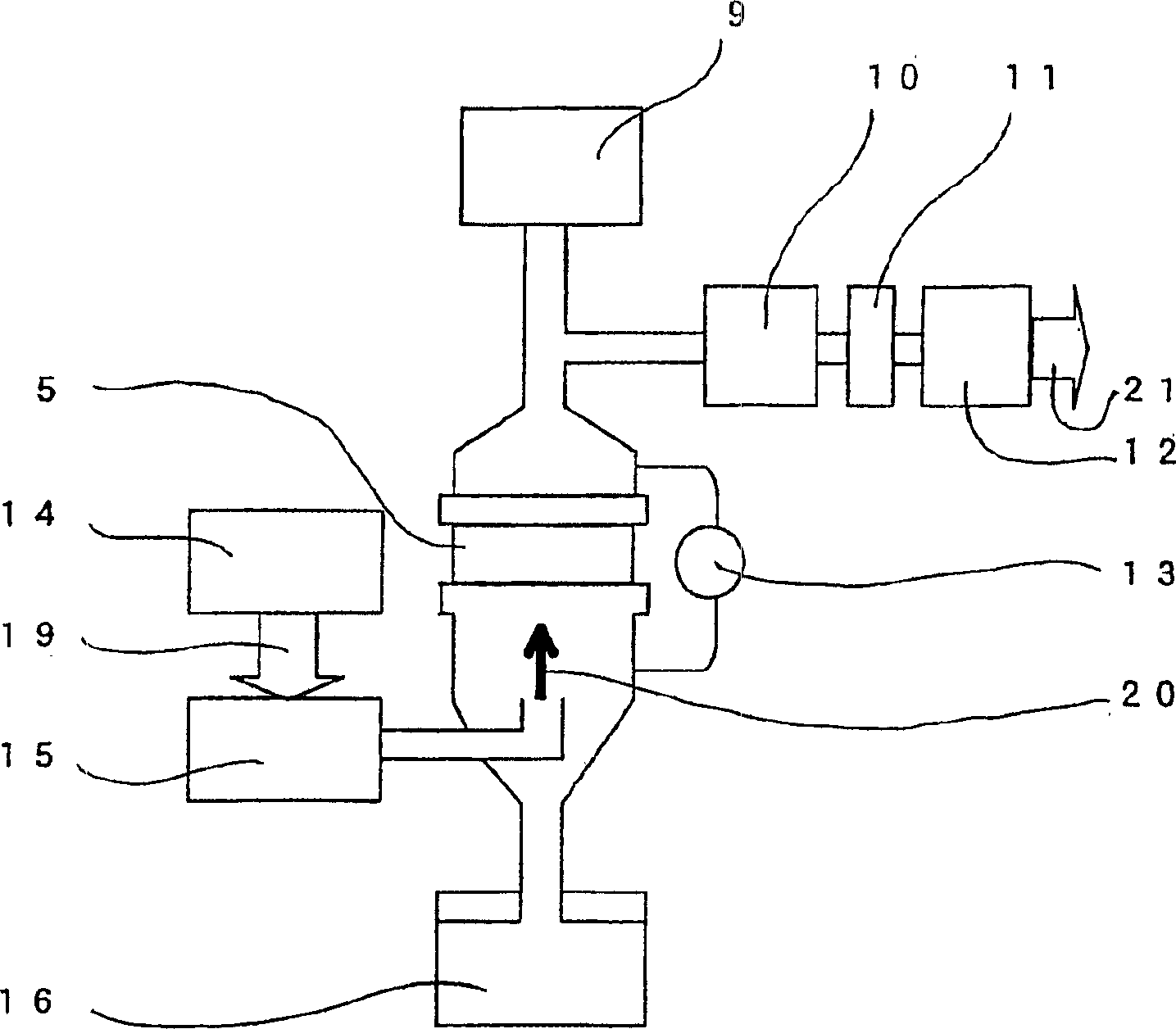

Method for generating denitration catalyst on filter material in situ

ActiveCN103949115AFunctionalEasy to handleDispersed particle separationFiltration separationFiberPtru catalyst

The invention provides a method for generating a denitration catalyst on a filter material in situ. The method comprises the following steps: firstly, modifying the filter material by utilizing the oxidative self-polymerization reaction of dopamine, coating a layer of poly-dopamine film substances rich in such active groups as phenolic hydroxyl groups, nitrogenous functional groups on the surface of the filter material so as to activate the surface of a polyphenylene sulfide filter material fiber which is inert originally; and then generating a MnO2 catalyst on the surface of the poly-dopamine coated filter material by taking potassium permanganate as an oxidizing agent under the chelation of the poly-dopamine layer and a divalent manganese ion, thereby preparing the composite filter material with the denitration function. The method has the advantages of simplicity in operation, low requirement for instrument equipment, mild reaction conditions, no special requirement for types and shapes of base materials, no pollution to the environment and the like, and a novel concept and a method are provided for the modification and denitration functionalization for the filter material.

Owner:FUZHOU UNIV

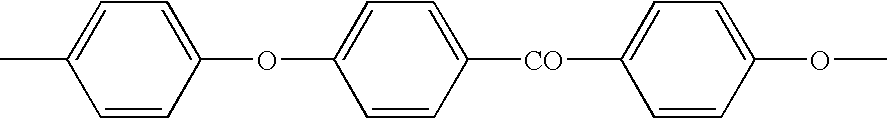

Polyether Ether Ketone/Polyphenylene Sulfide Blend

InactiveUS20080258337A1High retention rateGood chemical resistanceCeramic shaping apparatusPolyether coatingsElectrical conductorPoly ether ether ketone

The present description discloses a polymeric composition which is a melt-processed alloy comprised of (a) a polyarylene sulfide resin, (b) a polyaryl-ether-ketone resin, and a reactive compound which results in (c) a graft copolymer of the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin in addition to the starting resins. Exemplary melt-processed polymeric compositions can be made by reacting an alkoxy silane with the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin to produce a graft copolymer of a portion of one or both of the resins, sufficient to render the composition uniform and homogeneous. It is normally preferred for the exemplary organosilane compound, to be an amino silane. The subject invention further reveals an insulated wire comprising (1) an electrical conductor and (2) a layer of the melt-processed alloy composition; and fiber reinforced composites comprising fibers substantially fully impregnated with the alloy polymeric composition.

Owner:TICONA LLC

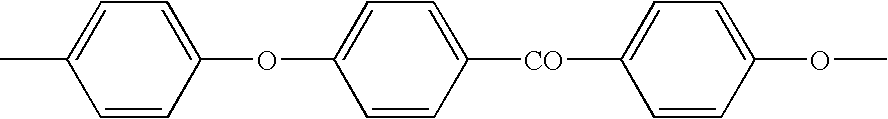

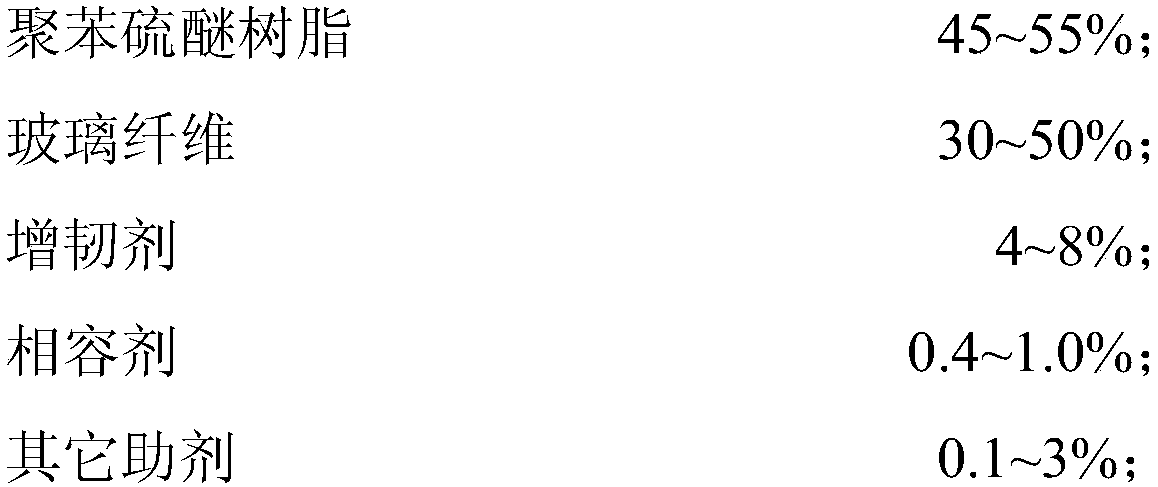

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

Polyphenylene sulfide composite material and preparation method thereof

The invention discloses a polyphenylene sulfide composite material and a preparation method of the composite material, belonging to the technical field of macromolecular material. The polyphenylene sulfide composite material disclosed by the invention comprises following components in parts by weight: 20-35 parts of polyphenylene sulfide resin, 25-50 parts of heat-conducting filler, 10-35 parts of reinforcing fiber, 2-17 parts of elastomer, 0.2-1 parts of antioxidant, 0.3-0.8 parts of coupling agent, 1-2 parts of lubricant, 0.5-1 parts of dispersant and 0.2-0.5 parts of nucleating agent. The invention also discloses a preparation method of the polyphenylene sulfide composite material. The preparation method of the invention is simple; and the polyphenylene sulfide composite material has good heat conductivity and mechanical property.

Owner:HEFEI GENIUS NEW MATERIALS

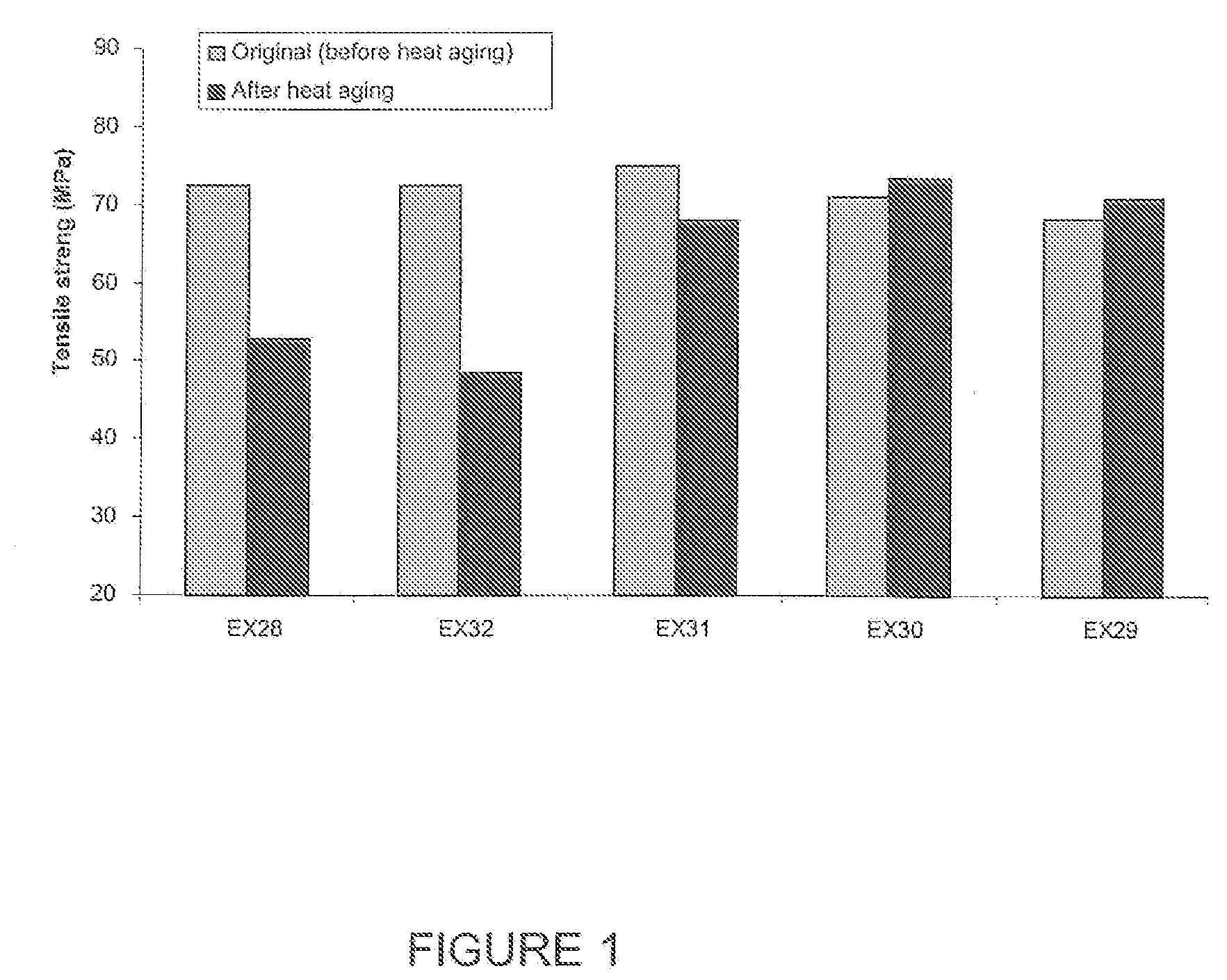

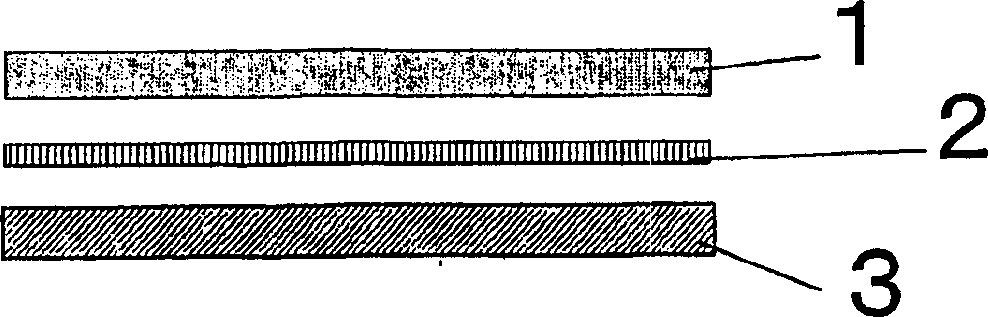

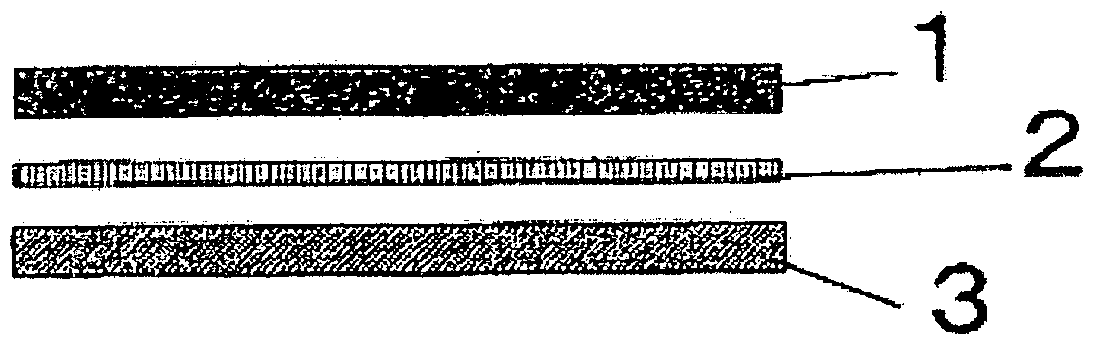

Insulated wire

ActiveUS20110226508A1Excellent solvent resistance and abrasion resistanceHigh voltagePlastic/resin/waxes insulatorsInsulated cablesResilient modulusMelt viscosity

An inverter surge-resistant insulated wire, having an enamel baked layer, an adhesive layer, and an extrusion-coated resin layer, around the outer periphery of a conductor, wherein the sum of the thickness of the enamel baked layer, the extrusion-coated resin layer, and the adhesive layer is 60 μm or more, wherein the thickness of the enamel baked layer is 50μm or less, and wherein the extrusion-coated resin layer is formed from a polyphenylene sulfide resin composition, which contains a polyphenylene sulfide polymer having a melt viscosity at 300° C. of 100 Pa·s or more, 2 to 8 mass % of a thermoplastic elastomer, and an antioxidant, and which has a tensile modulus of elasticity at 25° C. of 2,500 MPa or more, and a tensile modulus of elasticity at 250° C. of 10 MPa or more.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD +2

Filter medium

InactiveCN1767882AGood dust collection efficiencyLess rise in pressure lossHuman health protectionFiltration separationFinenessFilter material

A filter material containing polyphenylene sulfide fiber satisfies the following characteristics (1) and (2), thereby providing a filter material with excellent dust collection efficiency and high mechanical strength and a composition thereof The bag filter, (1) contains at least 2 layers of fiber mesh, the fiber mesh on the air inflow side contains 50wt% or more heat-resistant fibers with a fiber diameter of less than or equal to 15 μm, and the fiber on the air discharge side The net contains 50wt% or more of heat-resistant fibers with a fiber diameter greater than or equal to 20 μm; (2) contains a fiber net, which contains polyphenylene sulfide short fibers with a fineness in the range of 1 to 3 decitex and a fineness in the range of Short fibers of fluorine-based fibers in the range of 2 to 4 dtex.

Owner:TORAY IND INC

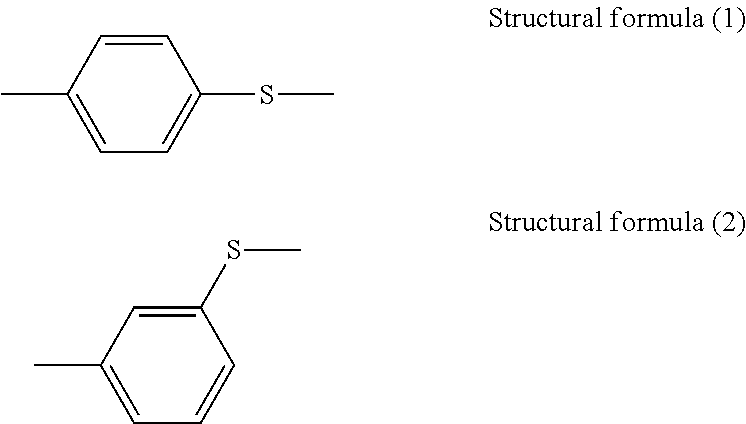

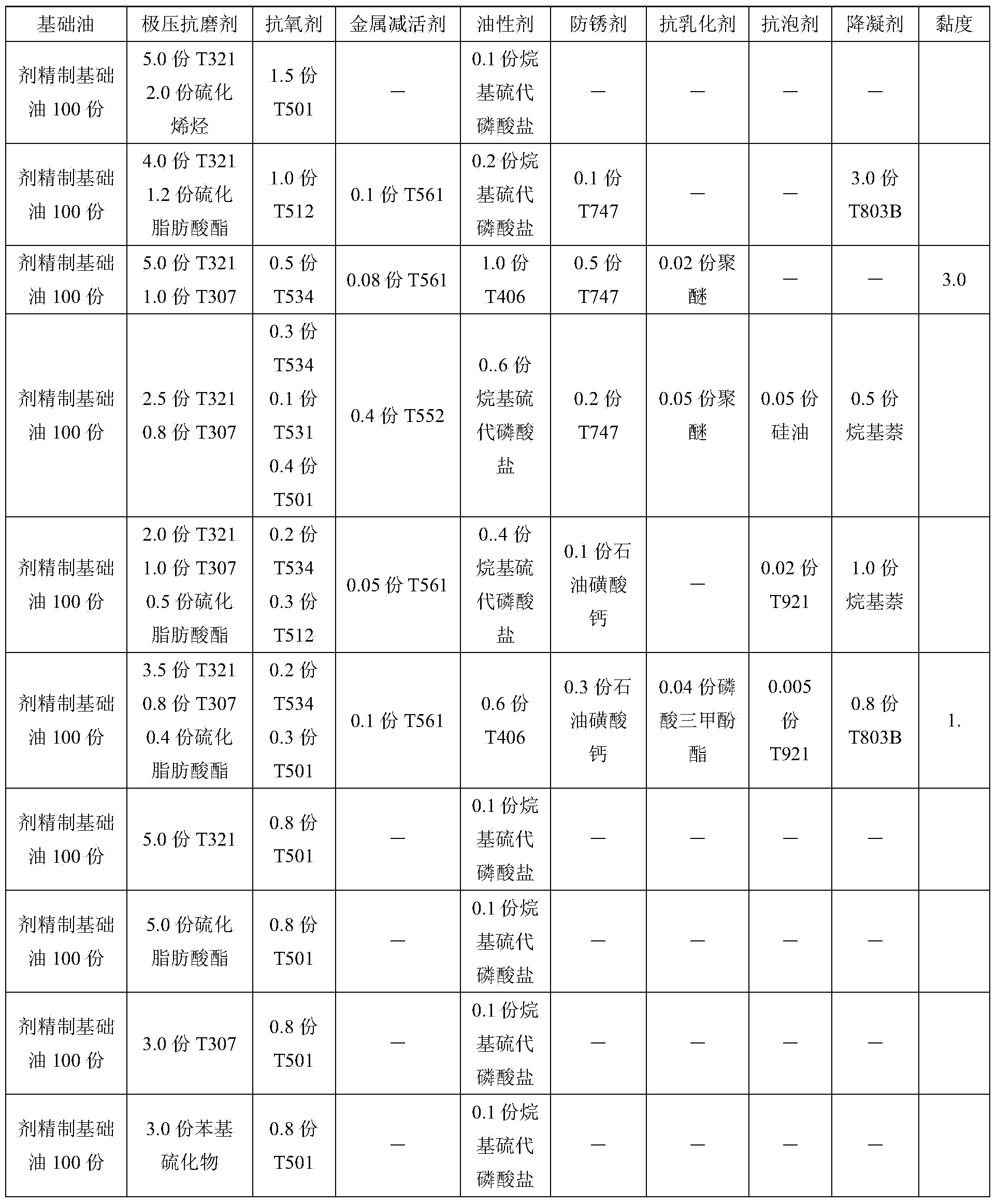

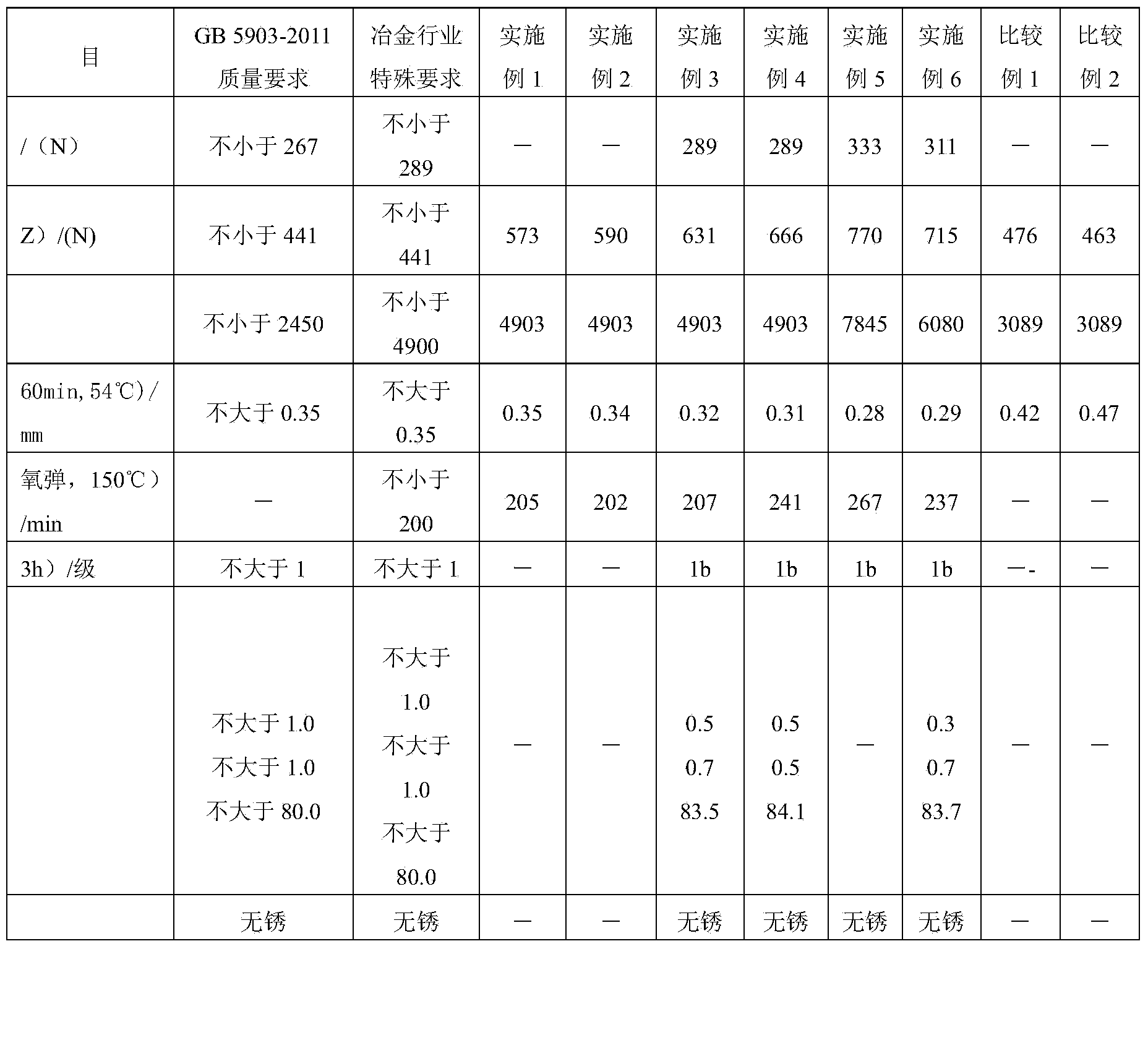

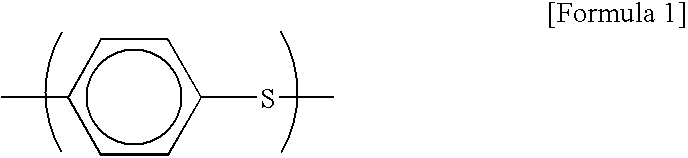

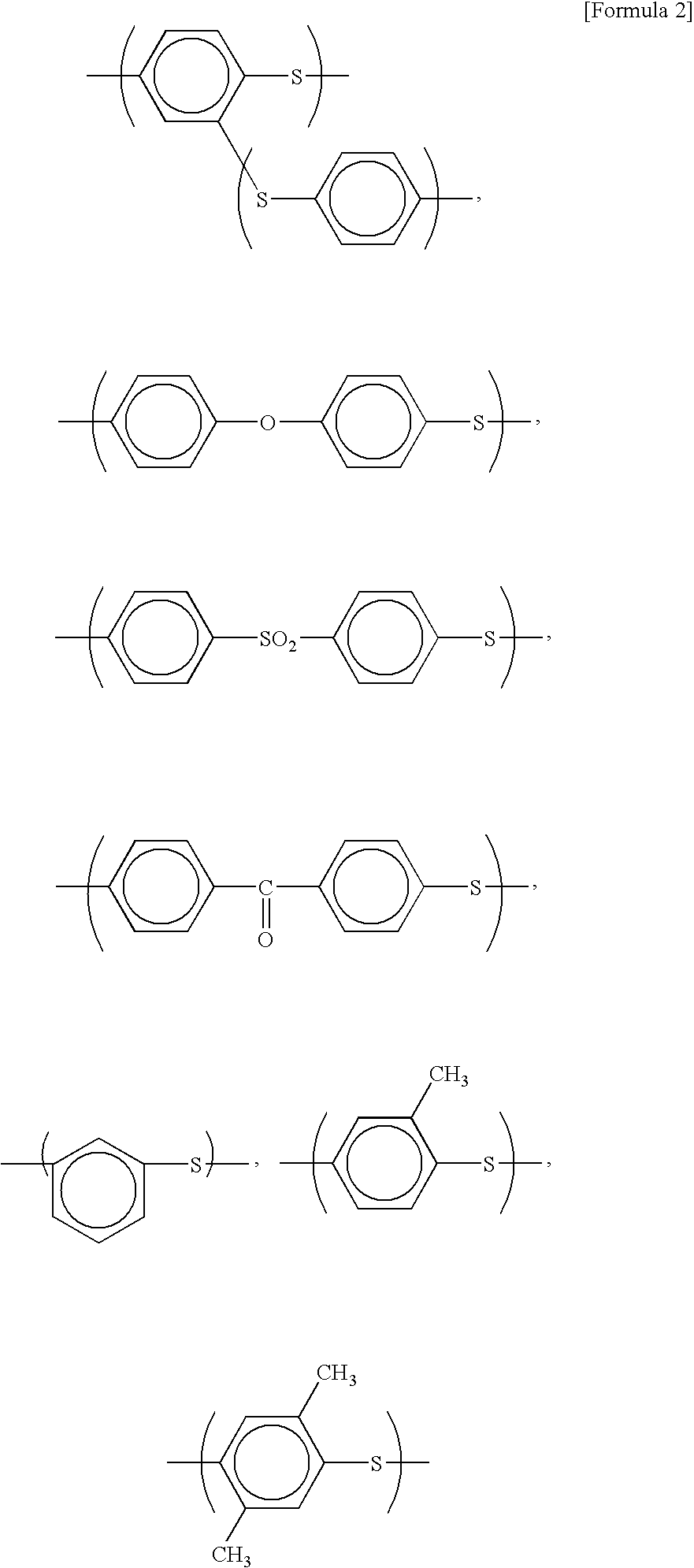

Gear oil composition and applications thereof

The invention relates to a gear oil composition and applications thereof, mainly solving problems of abnormal gear wear and poor oxidation stability of an oil product which are caused by that the extreme pressure property of industrial gear oil in the prior art fails to satisfy a part of using requirements of the metallurgy industry. According to the technical scheme adopted by the gear oil composition, the gear oil composition comprises following components by weight: a) 100 parts of mineral base oil; b) 0.1-10.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-2.0 parts of an antioxidant; d) 0.01-0.5 part of a metal deactivator and e) 0.01-1.5 parts of an oiliness agent, wherein the anti-wear reagent at extreme pressure is a mixture of sulfurized isobutylene and at least one selected from sulfurized olefin, phenyl sulfide, sulfurized aliphatic ester or amine thiophosphate diester; and the antioxidant is at least one selected from 2,6-di(tertbutyl)-p-cresol, 3.5-di(tertbutyl)-4-hydroxy phenyl acrylate, pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], N-phenyl-1-naphthylamine or alkylated diphenylamine. By the technical scheme, the problems are solved well and the gear oil composition can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

Composite material, method for the production and use thereof

ActiveUS7867612B2Increase apparent interlaminar shear strength and bending strengthLayered productsSpecial tyresInterlaminar shearUltimate tensile strength

A composite material is described that contains a reinforcing resin and reinforcing fibers, wherein the reinforcing fibers have a coating containing polyphenylene sulfide and the proportion of polyphenylene sulfide relative to the uncoated fibers is 0.001 to <0.01 wt. %. The composite material shows higher apparent interlaminar shear strength and bending strength as compared with similar composite materials having no PPS coating in the above concentration range.

Owner:TOHO TENAX EURO

Polyphenylene sulfide resin compositions

InactiveUS20070021549A1Avoid breakingReduce heat resistance requirementsSpecial tyresGlass fiberHeat deflection temperature

A polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 12 μm or lager and has a crystallization temperature during cooling of 205° C. or lower. Also provided is a polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 10 to 12 μm, excluding 12 μm, has a crystallization temperature during cooling of 205° C. or lower and a chloroform-extractable content of 0.5 wt. % or lower, and gives a 2 mm-thick molded product which has a transmittance of 15% or higher for laser beam having a wavelength of 940 nm and a heat distortion temperature of 230° C. or higher under a load of 1.82 MPa.

Owner:TORAY IND INC

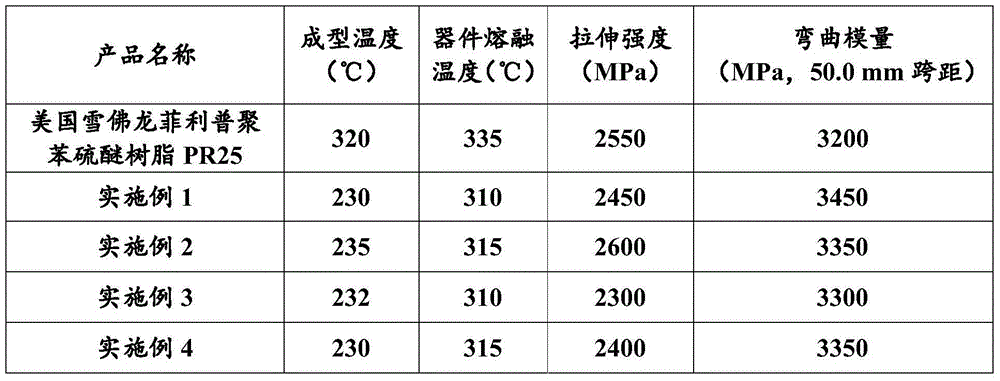

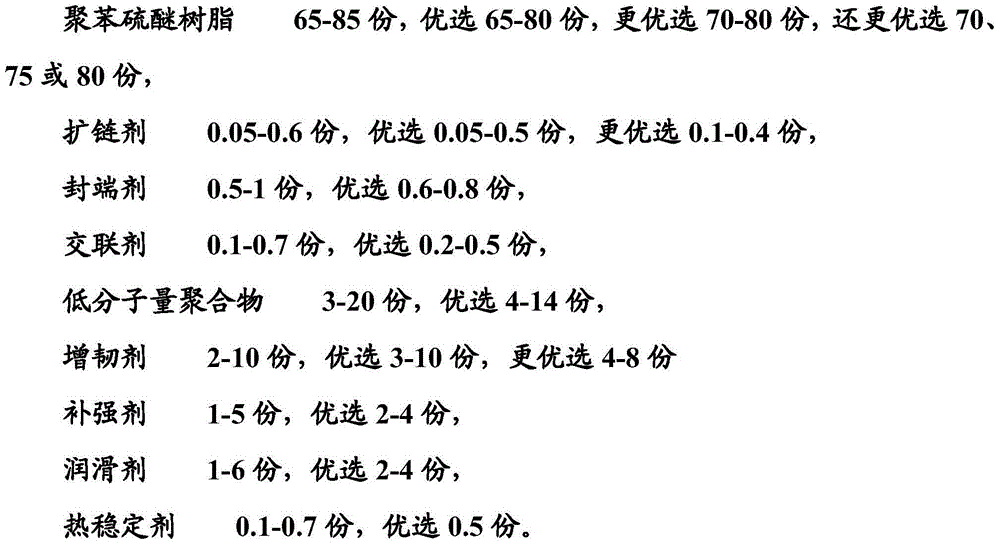

Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

ActiveCN104650587AIncrease profitImprove toughnessAdditive manufacturing apparatusDevice formToughness

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Filter medium

ActiveUS20060172639A1Excellent in dust-collecting efficiencySmall in rise of pressure lossHuman health protectionDispersed particle filtrationPolymer scienceFilter media

The filter fabric containing polyphenylene sulfide fibers, characterized in that the following (1) and / or (2) is satisfied is used to provide a filter fabric and a bag filter composed of the filter fabric excellent in dust-collecting efficiency and high in mechanical strength: (1) Containing at least two webs, one of which on the dust side contains 50 wt % or more of heat resistant fibers with a fiber, diameter of 15 μm or less, while the other web on the clean side contains 50 wt % or more of heat resistant fibers with a fiber diameter of 20 μm or more (2) Containing a web containing polyphenylene sulfide staple fibers with their fineness kept in a range from 1 to 3 dtex and fluorine-based staple fibers with their fineness kept in a range from 2 to 4 dtex.

Owner:TORAY IND INC

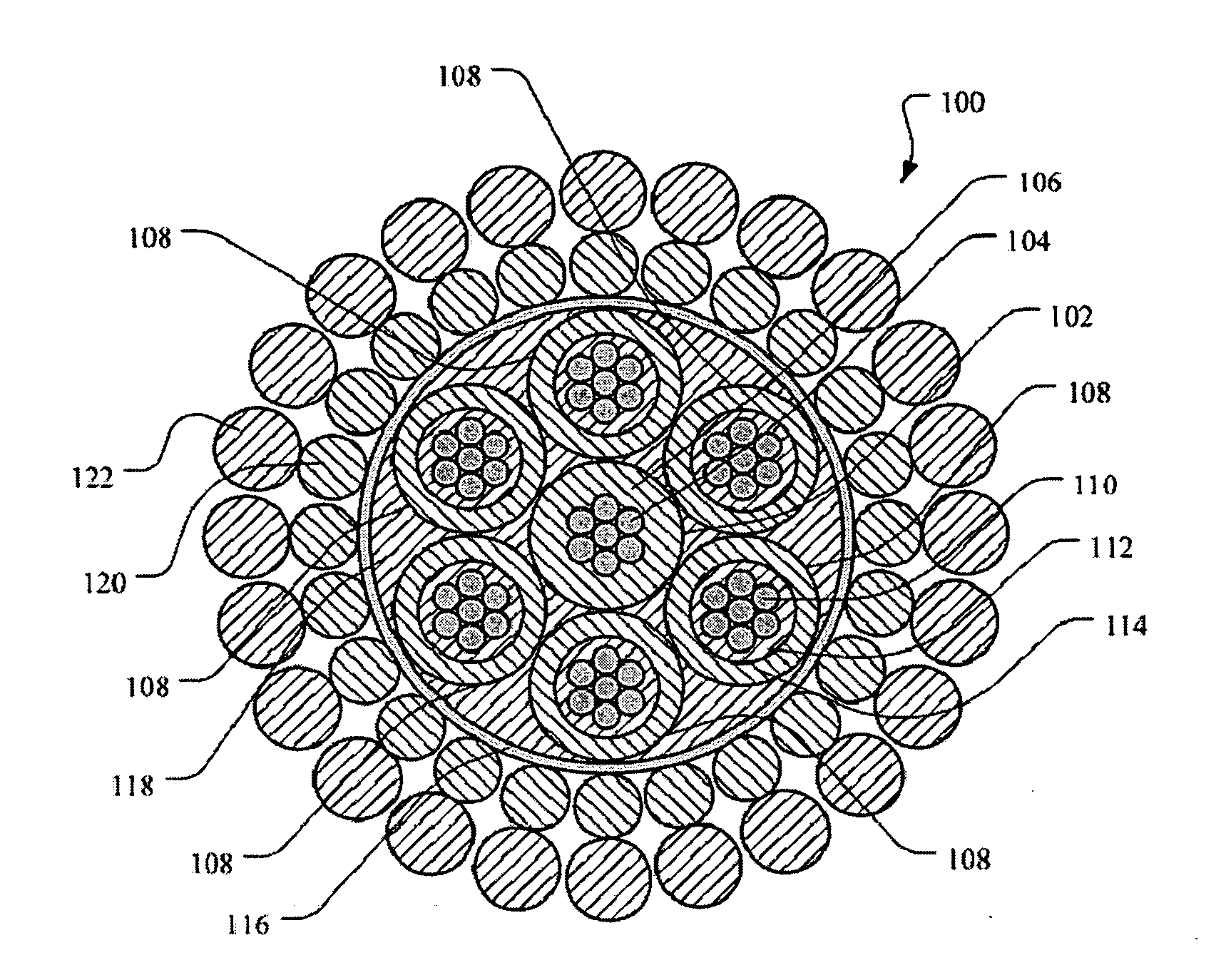

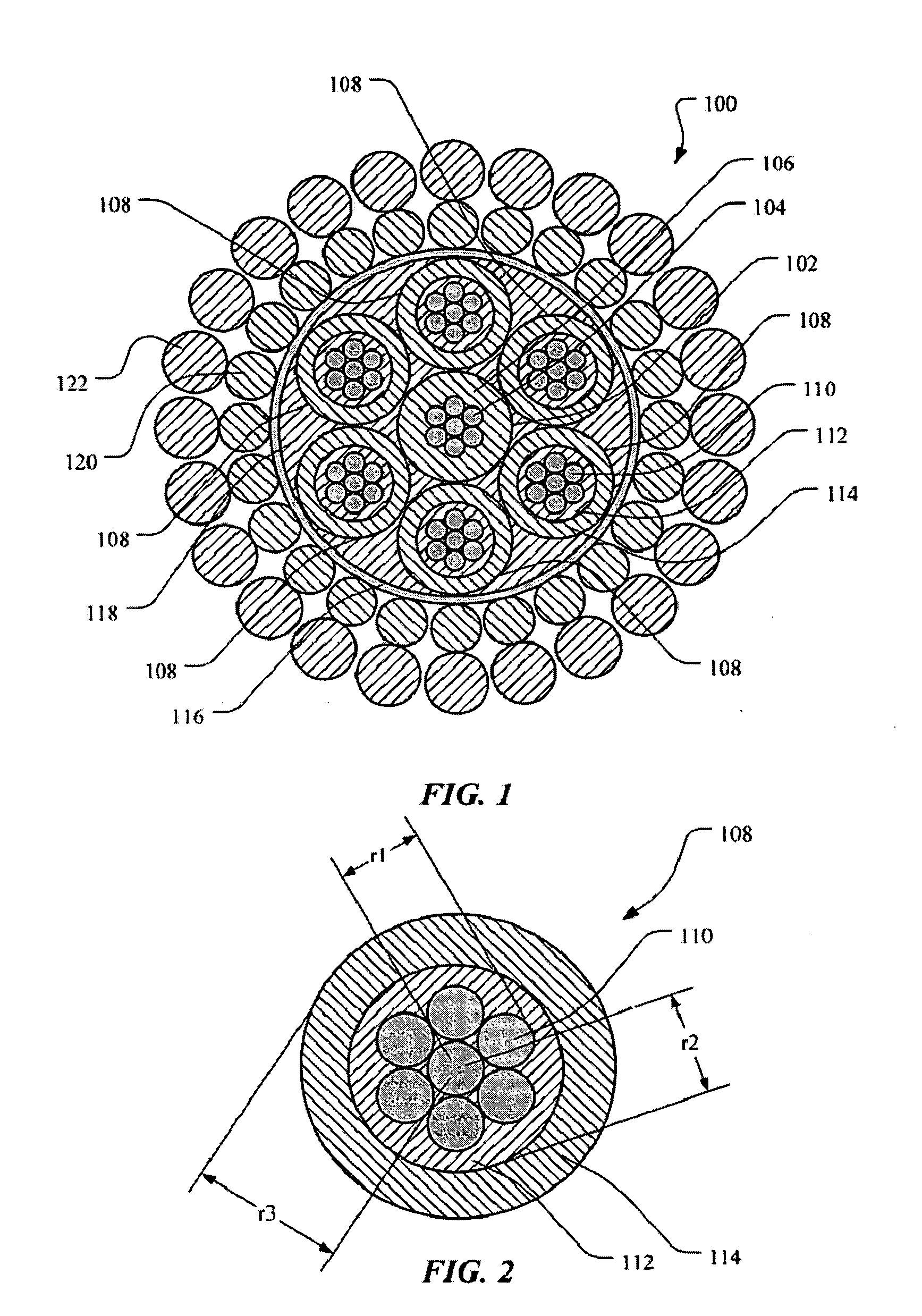

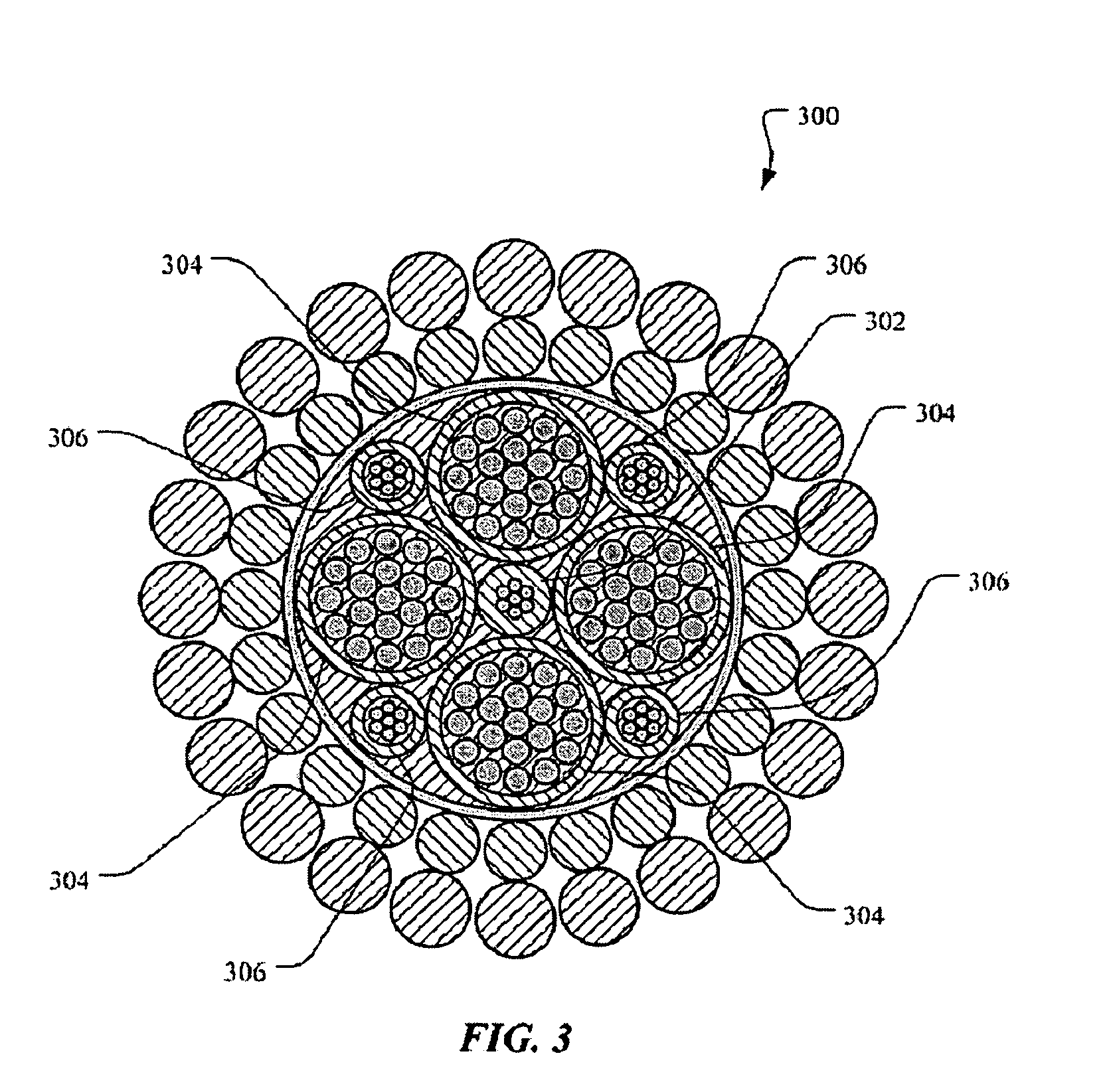

Electrical cables

InactiveUS20060065429A1Insulated cablesPower cables including optical transmission elementsElectrical conductorEngineering

An electrical cable is provided which includes an electrical conductor, a first insulating jacket disposed adjacent the electrical conductor and having a first relative permittivity, wherein the first insulating jacket is prepared from an admixture of: a polymer selected from the group consisting of polyaryletherether ketone polymer, polyphenylene sulfide polymer, polyether ketone, maleic anhydride modified polymers, Parmax® SRP polymers, and any mixtures thereof; and, a fluoropolymer additive. A second insulating jacket disposed adjacent the first insulating jacket and having a second relative permittivity that is less than the first relative permittivity, and wherein the insulating jacket is mechanically bonded to the second insulating jacket. In another aspect of the present invention, a method is provided for manufacturing a cable that includes providing an electrical conductor, extruding a first insulating jacket over the electrical conductor, and extruding a second insulating jacket thereon.

Owner:SCHLUMBERGER TECH CORP

High impact polyphenylene sulfide alloy material and method of producing the same

InactiveCN101130633AImprove impact resistanceGood physical and mechanical propertiesHigh intensityMass ratio

The invention discloses a high impact polyphenylene sulfide alloy material and preparing method, which comprises the following steps: allocating with mass ratio as 30-55% polyphenylene sulfide, 5-20% polycaproamide, 30-50% glass fiber, 2-8% inclusive agent, 0. 2-0. 5% anti-oxidant and 0. 1-2% other auxiliary agent; mixing; adding into twin-screw extruder; controlling the temperature at 250-280 deg. c; controlling the rotary speed of the bolt at 400-500rpm; pelleting; getting the product. This invention possesses high impact strength, high modulus and high-intensity, which can modify the defects of the material.

Owner:SHENZHEN KEJU NEW MATERIAL

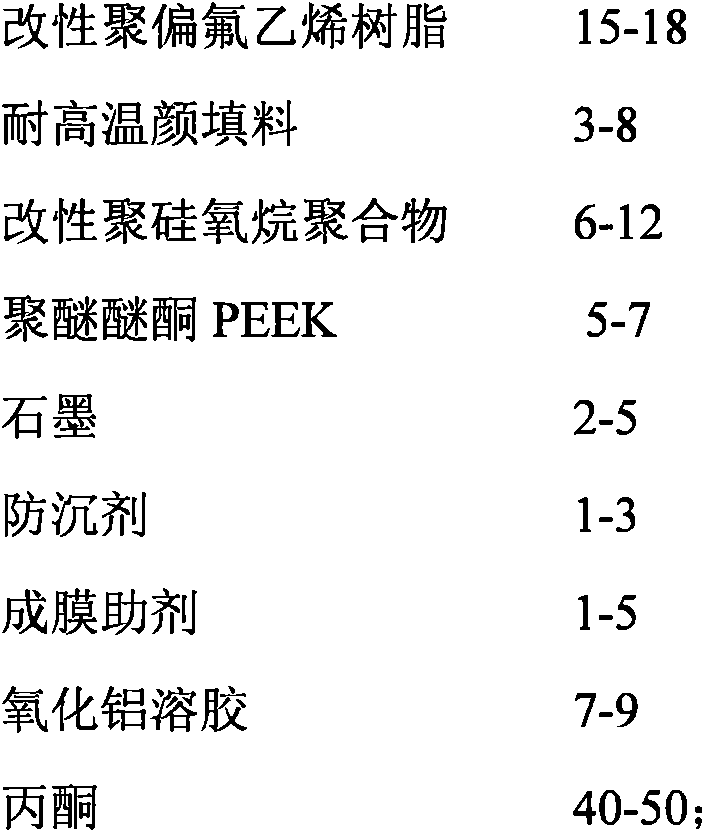

Wear-resistant and mildewproof non-stick pan coating

ActiveCN105111926AChemically stableDoes not generate PFOACooking-vessel materialsAntifouling/underwater paintsEpoxyWear resistant

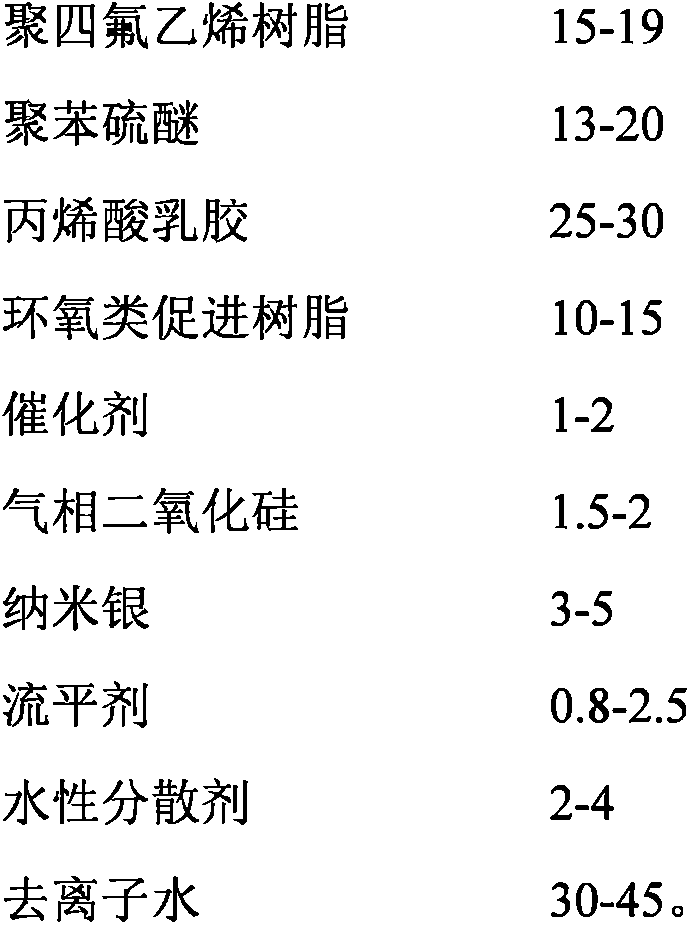

The present invention relates to a wear-resistant and mildewproof non-stick pan coating. The coating comprises a bottom layer and a surface layer; The bottom layer consists of the following materials in parts by weight: polyimide resin, modified polyvinylidene fluoride resin, a high-temperature-resistant pigment filler, modified polyorganosiloxane polymer, polyetheretherketone PEEK and graphite. The surface layer consists of the following materials in parts by weight: polytetrafluoroethylene resin, phenylene sulfide, acrylate rubber latex, epoxy accelerated resin, a catalyst, fumed silica, nano silver and the like. The wear-resistant and mildewproof non-stick pan coating prepared in the invention is chemically stable at the cooking temperature and does not generate hazardous substance PFOA. The coating has relatively great hardness and the damages of spatulas or spoons to the surface coating of the non-stick pan can be avoided. The non-stick pan prepared from the coating has low cost and a long service life.

Owner:NINGBO GRAMMY KITCHENWARE

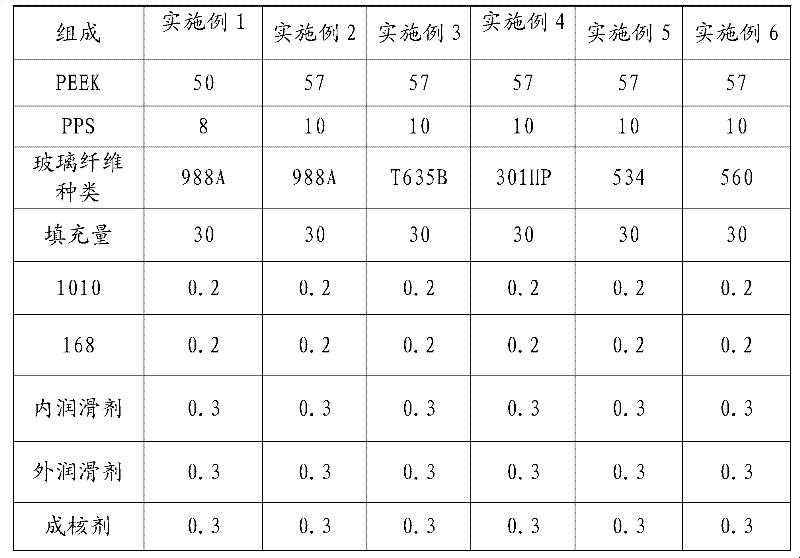

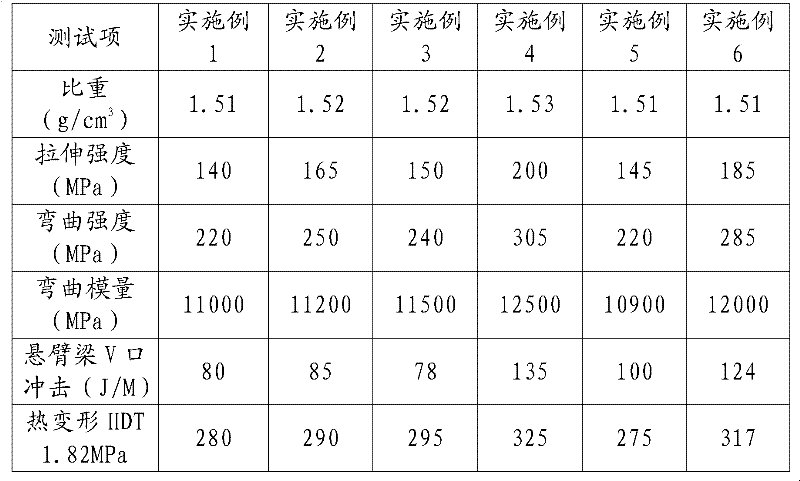

Modification-enhanced polyether ether ketone material and preparation method thereof

InactiveCN102329477AOvercome the disadvantage of poor liquidityReduce processing temperatureAntioxidantEconomic benefits

The invention discloses a modification-enhanced polyether ether ketone material and a preparation method thereof. The modification-enhanced polyether ether ketone material is prepared from the following components in parts by weight: 50-60 parts of polyether ether ketone, 8-15 parts of polyphenylene sulfide, 30-35 parts of filling enhancer, 0.2-0.6 part of antioxidant, 0.2-0.8 part of lubricant and 0.3-0.6 part of nucleating agent. The invention has the characteristics that: the defect of poor fluidity of polyether ether ketone is overcome by adding polyphenylene sulfide, and the processing temperature and difficulty of the polyether ether ketone are greatly reduced; because the polyether ether ketone is expensive, the production cost is greatly lowered by introducing polyphenylene sulfide; and the preparation process disclosed by the invention is simple, low in cost and high in benefit and can obtain good economic benefit.

Owner:SHENZHEN KEJU NEW MATERIAL

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

Method for recycling lithium salt and solvent in preparation of polyphenylene sulfide

The invention discloses a method for recycling lithium salt and a solvent in preparation of polyphenylene sulfide. The method comprises the following operation processes: 1', washing a polyphenylene sulfide product by use of an N-methyl pyrrolidone solution of which the percentage by weight of water is not larger than 50% at the temperature of 150 to 250 DEG C in an inert gas environment, and combining the washing solution with a reaction medium solution; 2', transforming sodium sulfide into sodium chloride under the condition that the pH value of the combined solution is regulated to 6.5-7.0 in the inert gas environment; 3', adding water into the solution transformed in the step 2 so that the low-molecular polyphenylene sulfide is precipitated and then separated; and 4', respectively separating and recycling the sodium chloride, the N-methyl pyrrolidone and the lithium chloride from the separated solution under the inert gas environment. According to the method, the solvents need not to be evaporated out completely, so the energy consumption is reduced greatly; the method can be performed in various intermittent or continuous ways and convenient and easy to implement, degradation caused because the solvent is at high temperature for a long time is avoided, so the recycle rate of the solvent is high, and the recycling quality is good; a separated and recycled polyphenylene sulfide oligomer is utilizable, the purity of the recycled lithium chloride is not lower than 98%, and the quality of the recycled sodium chloride is excellent.

Owner:SHANDONG MINGHUA NEW MATERIAL CO LTD

Flame Retardant Thermoplastic Resin Composition

Disclosed is a flame retardant thermoplastic resin composition that includes about 100 parts by weight of a mixed resin (A) including about 10 to about 90 wt % of an aromatic polyamide resin (A-1) and about 10 to about 90 wt % of a polyphenylene sulfide resin (A-2), about 0.5 to about 30 parts by weight of a phosphinic acid metal salt flame retardant (B), and about 10 to about 100 parts by weight of a filler (C).

Owner:CHEIL IND INC

Flame retardant thermoplastic resin composition and mould product produced therefrom

Disclosed is a flame retardant thermoplastic resin composition and a mould product produced therefrom, the flame retardant thermoplastic resin composition includes about 100 parts by weight of a mixed resin (A) including about 10 to about 90 wt.% of an aromatic polyamide resin (A-1) and about 10 to about 90 wt.% of a polyphenylene sulfide resin (A-2), about 0.5 to about 30 parts by weight of a phosphinic acid metal salt flame retardant (B), and about 10 to about 100 parts by weight of a filler (C).

Owner:CHEIL IND INC

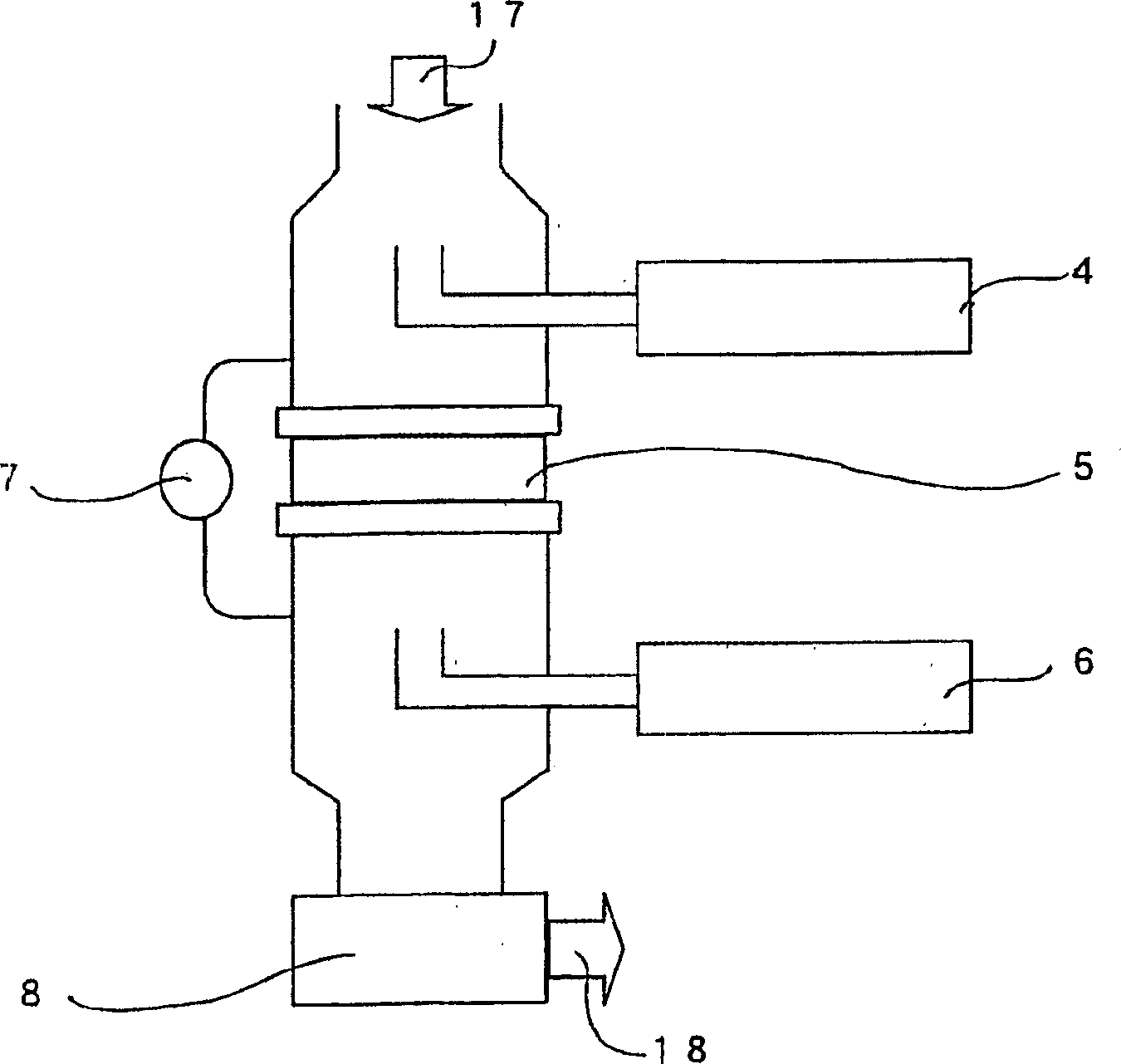

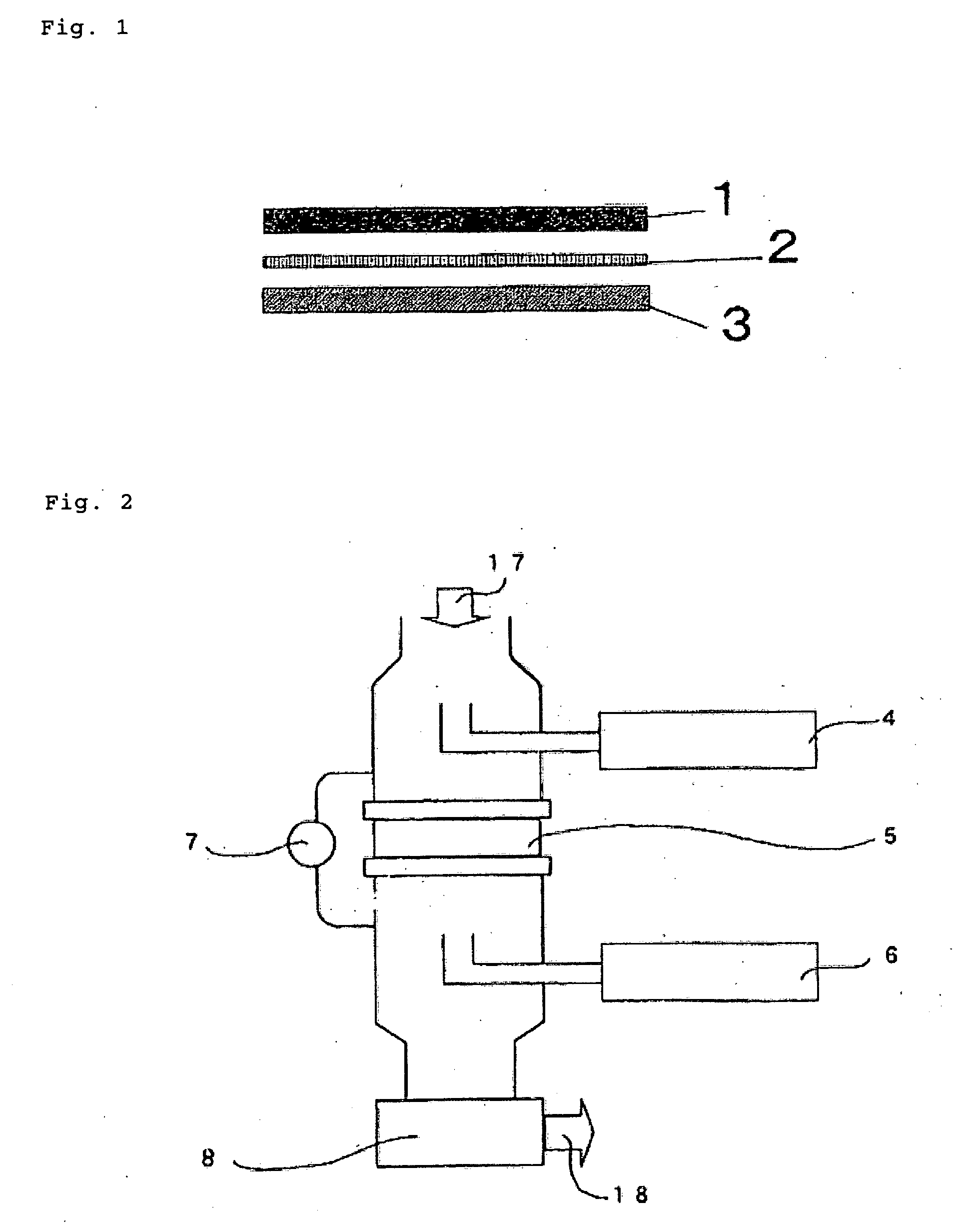

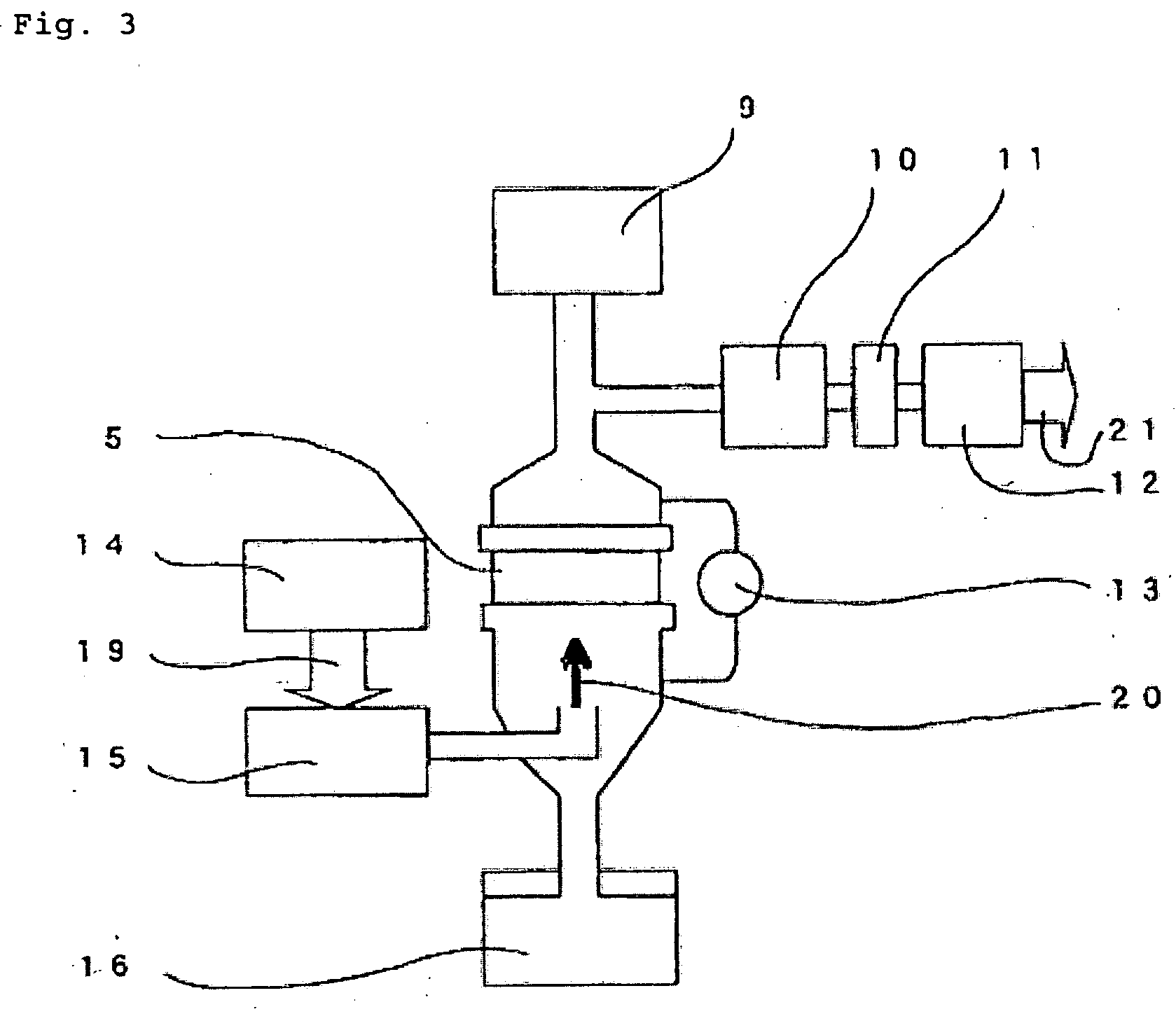

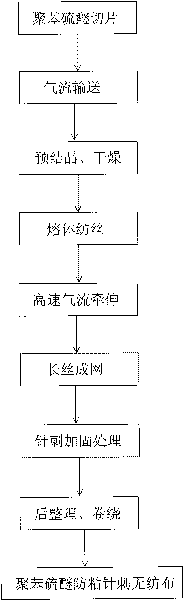

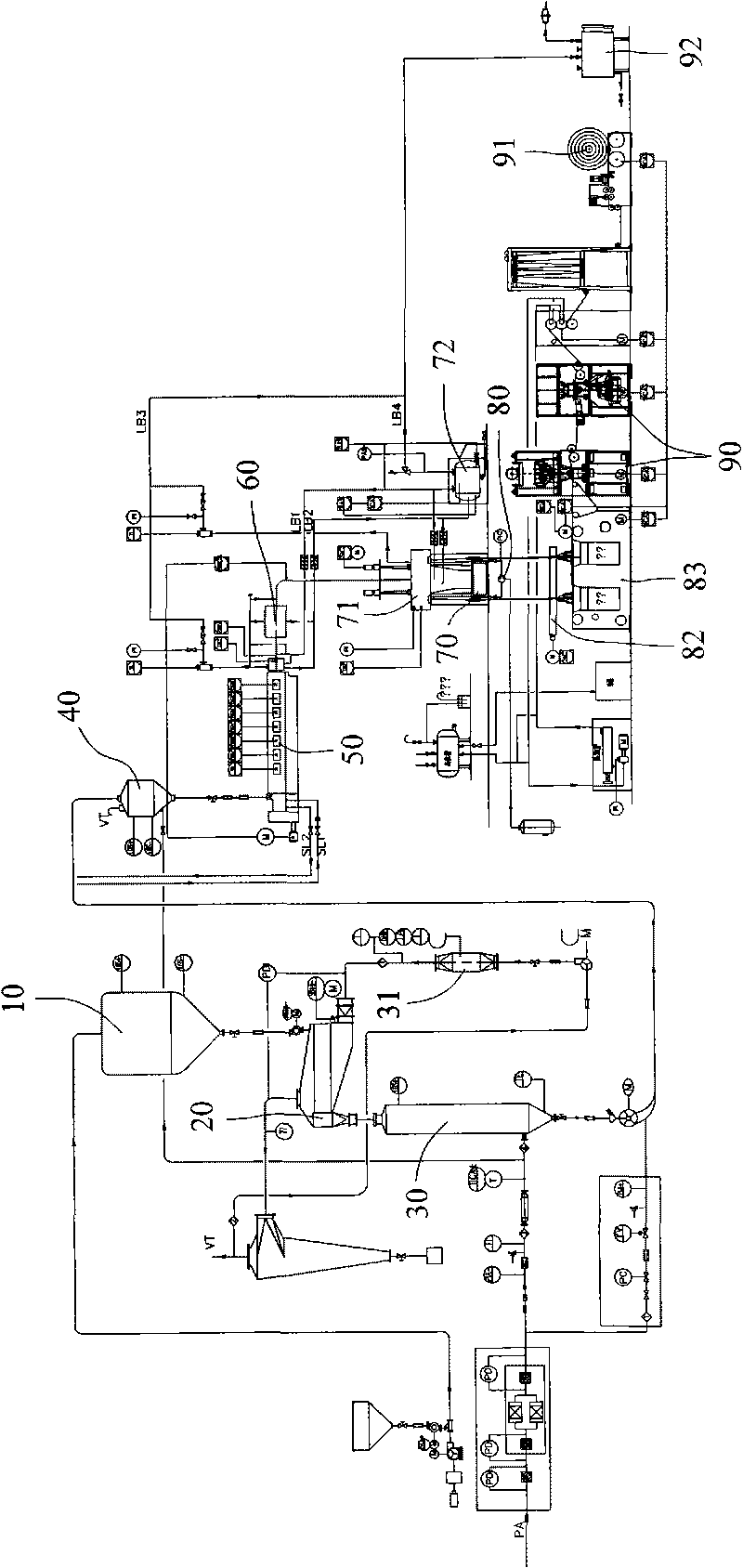

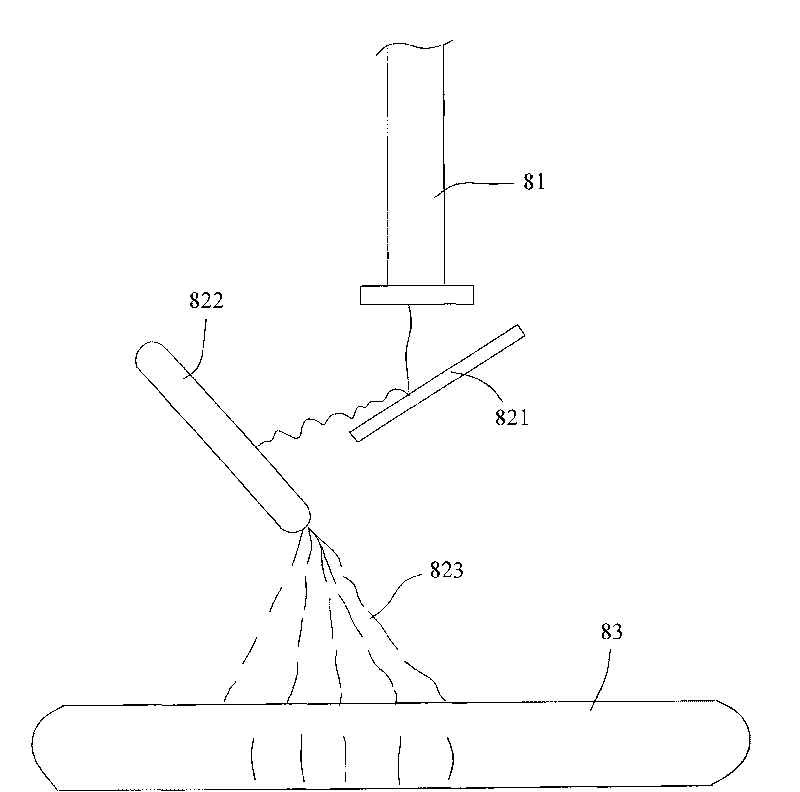

Method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics and device thereof

ActiveCN101760903ASpeed up the processLabor savingArtificial thread manufacturing machinesMelt spinning methodsPunchingSulfide

The invention relates to a method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics, comprising the steps: slicing of polyphenylene sulfide-pneumatic conveying-precrystallization-drying- melt spinning-air drawing-filament web-forming-needle-punching reinforcement-after finishing-winding, resulting in the polyphenylene sulfide spun-bonded needle punched non-woven fabrics. The invention further discloses a device for the implementation of the method for preparing polyphenylene sulfide spun-bonded needle punched non-woven fabrics. Compared with short fiber needle-punched method for the production of polyphenylene sulfide needle punched non-woven fabrics, the method for preparing polyphenylene sulfide needle punched non-woven fabrics by using spun-bonded filament needle punched method has the advantages of short technological procedures, small number of apparatuses, less required labor force, high production efficiency and large yield.

Owner:FOSHAN S L P SPECIAL MATERIALS

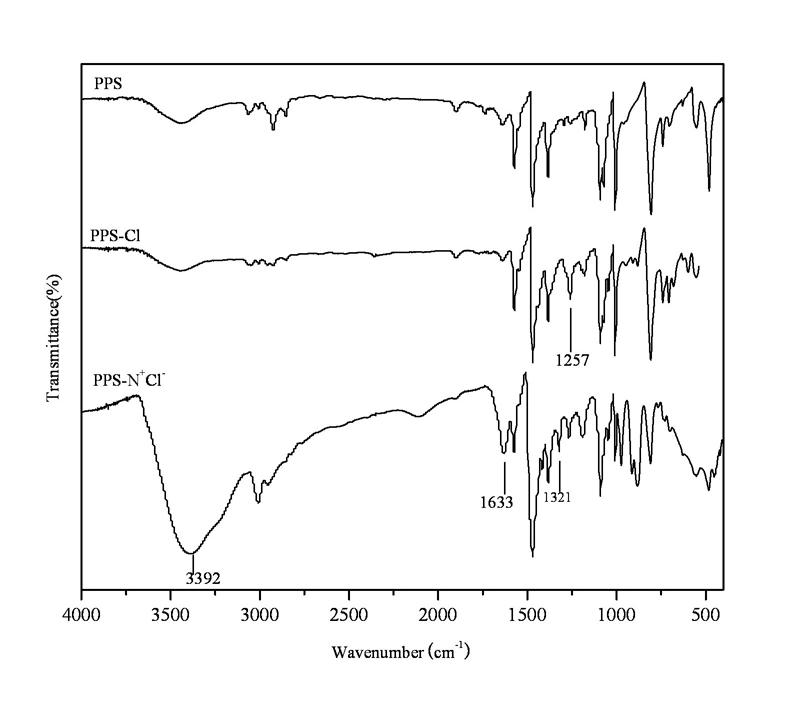

Method for preparing polyphenylene sulfide-based strong basic ion exchange fibers

InactiveCN102051811AEasy to operateEasy to prepareIon-exchange process apparatusOrganic anion exchangersFiberIndustrial effluent

The invention discloses a method for preparing polyphenylene sulfide-based strong basic ion exchange fibers, which comprises the following steps of: first swelling raw polyphenylene sulfide fibers in a solvent, adding a raw material polyphenylene sulfide and a catalyst after the raw polyphenylene sulfide fibers are swelled, heating the mixture for chloromethylation and crosslinking reaction, and obtaining chloromethylated crosslinked polyphenylene sulfide fibers after the reaction is finished; then swelling the obtained chloromethylated crosslinked polyphenylene sulfide fibers in the solvent, adding trimethylamine solution after the chloromethylated crosslinked polyphenylene sulfide fibers are swelled, heating the reaction solution for quaternization reaction, and obtaining the polyphenylene sulfide-based strong basic ion exchange fiber products after the quaternization reaction is finished; and finally washing the products, and performing extraction, brine-washing and drying. The method for preparing the polyphenylene sulfide-based strong basic ion exchange fibers is simple and easy to industrially popularize and apply, and ensures relatively lower production cost. The products prepared by the method can be applied in the fields of treatment of industrial wastewater, air purification, preparation of ultrapure water, separation and extraction of medicinal chemicals, and the like.

Owner:ZHENGZHOU UNIV +1

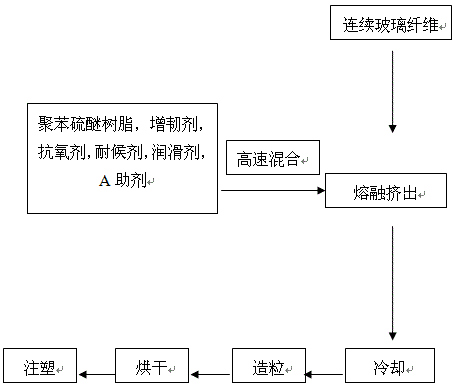

Glass fiber reinforced polyphenylene sulfide composite with high metal bonding strength and preparation method thereof

The invention relates to the polyphenylene sulfide resin processing preparation field, and in particular relates to a glass fiber reinforced polyphenylene sulfide composite with high metal bonding strength and a preparation method thereof; the glass fiber reinforced polyphenylene sulfide composite comprises the following raw materials by weight: 51.7-81.2 parts of polyphenylene sulfide resin, 0-40 parts of continuous glass fiber; 5-13 parts of a toughening agent; 0.2-1 part of a weathering agent; 0.3-0.5 part of an antioxidant; 0.3-0.5 part of a lubricant and 2-4 parts of an additive A, the glass fiber reinforced polyphenylene sulfide composite not only has excellent weathering properties and excellent metal bonding strength, after metal bonding and anode oxidation treatment, the glass fiber reinforced polyphenylene sulfide composite may not discolor, the bonding strength decay is small, the glass fiber reinforced polyphenylene sulfide composite also has excellent weather resistance and low dielectric properties and loss factor, can satisfy the customer demand of different colors, and greatly improves the product appearance design freedom degree.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com