Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

A polyphenylene sulfide resin and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems that polyphenylene sulfide resin is not suitable for 3D printing technology, achieve high modifier utilization rate, controllable crosslinking degree, Effect of low molding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

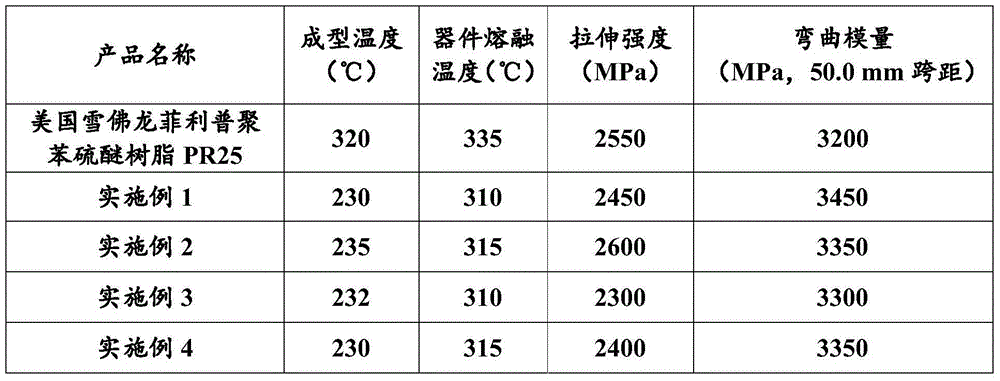

Examples

Embodiment 1

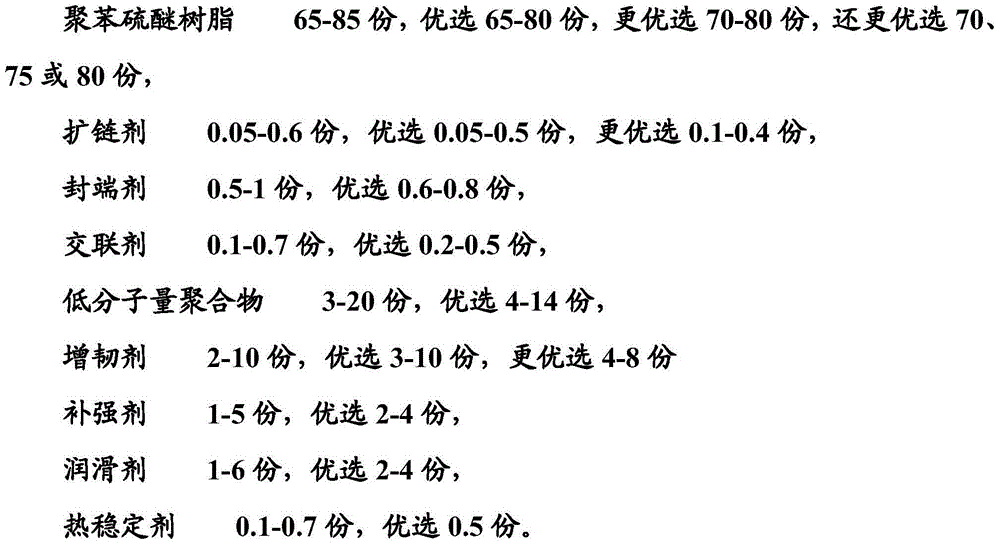

[0058] 1) 70 parts of thermoplastic polyphenylene sulfide resin with a molecular weight of 25000 and 14 parts of polyimide oligomers with a molecular weight of 600 are added to the mixer, followed by adding 0.4 parts of chain extender triphenylmethane triisocyanate, 0.6 parts End-capping agent propylene alcohol, react for half an hour, then add 0.5 parts of crosslinking agent isobutyl methacrylate, 4 parts of reinforcing agent nano-silica, fully mix at 600r / min for 2 hours and then discharge ;

[0059] 2) the mixture obtained in step 1) is mixed with 5 parts of toughening agent poly(adipic acid-succinic acid) butanediol copolyester, 5 parts of lubricant graphite / molybdenum sulfide / antimony sulfide (3 / 1 / 1) and 0.5 parts of stabilizer 1096 are mixed and extruded into pellets with a twin-screw extruder, and the time for the materials in the extruder is not more than 3 minutes. The screw diameter of the twin-screw extruder is 71mm, the extruder temperature is set at 230-240°C, a...

Embodiment 2

[0062] 1) 75 parts of thermoplastic polyphenylene sulfide resin with a molecular weight of 25000 and 9 parts of polyimide oligomers with a molecular weight of 600 are added to the mixer, followed by adding 0.4 parts of chain extender triphenylmethane triisocyanate, 0.6 parts of End-blocking agent propylene alcohol, react for half an hour, then add 0.5 parts of crosslinking agent isobutyl methacrylate, 4 parts of reinforcing agent nano-silica, fully mix at 600r / min for 2 hours, and then discharge;

[0063] 2) the mixture obtained in step 1) is mixed with 5 parts of toughening agent poly(adipic acid-succinic acid) butanediol copolyester, 5 parts of lubricant graphite / molybdenum sulfide / antimony sulfide (3 / 1 / 1) and 0.5 parts of stabilizer 1096 are mixed and extruded into pellets with a twin-screw extruder, and the time for the materials in the extruder is not more than 3 minutes. The screw diameter of the twin-screw extruder is 71mm, the extruder temperature is set at 230-240°C,...

Embodiment 3

[0066] 1) 80 parts of thermoplastic polyphenylene sulfide resin with a molecular weight of 25000 and 4 parts of polyimide oligomers with a molecular weight of 600 are added to the mixer, followed by adding 0.4 parts of chain extender triphenylmethane triisocyanate and 0.6 parts of End-blocking agent propylene alcohol, react for half an hour, then add 0.5 parts of crosslinking agent isobutyl methacrylate, 4 parts of reinforcing agent nano-silica, fully mix at 600r / min for 2 hours, and then discharge;

[0067] 2) the mixture obtained in step 1) is mixed with 5 parts of toughening agent poly(adipic acid-succinic acid) butanediol copolyester, 5 parts of lubricant graphite / molybdenum sulfide / antimony sulfide (3 / 1 / 1) and 0.5 parts of stabilizer 1096 are mixed and extruded into pellets with a twin-screw extruder, and the time for the materials in the extruder is not more than 3 minutes. The screw diameter of the twin-screw extruder is 71mm, the temperature of the extruder is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com