Patents

Literature

43results about How to "Excellent heat resistance temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion secondary battery and a solid electrolyte thereof

InactiveCN101040401AIncrease capacityHigh outputSolid electrolyte cellsActive material electrodesLithiumPolyethylene oxide

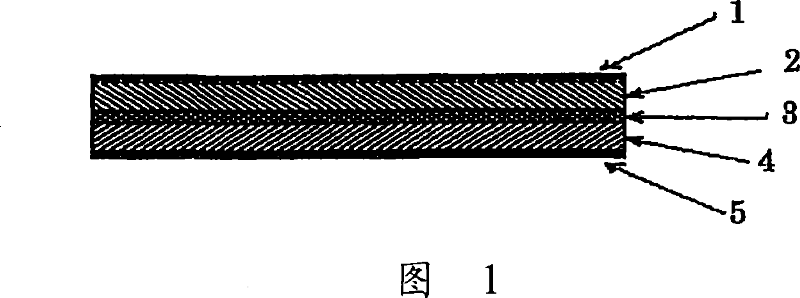

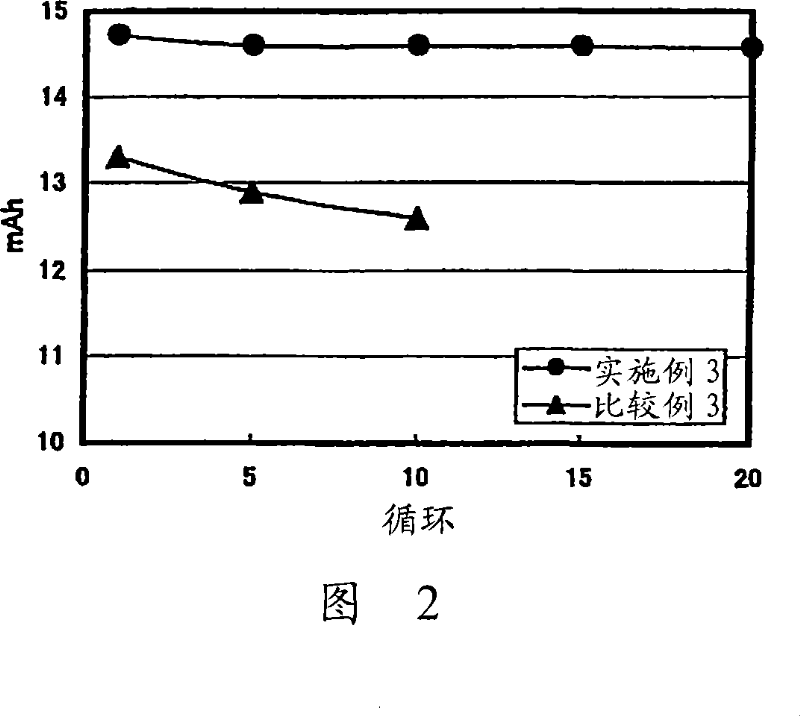

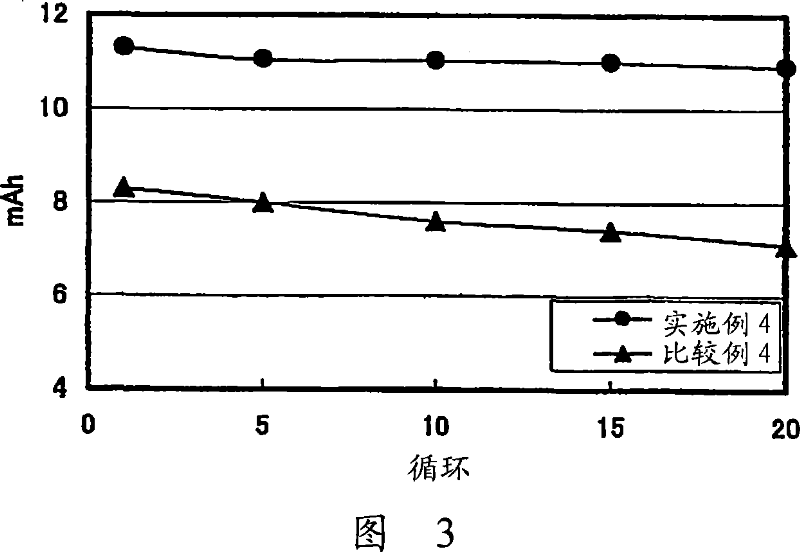

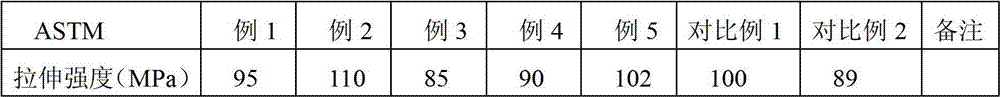

A solid electrolyte comprising powder of an inorganic substance comprising a lithium ion conductive crystal or powder of a lithium ion conductive glass-ceramic and an organic polymer added with an inorganic or organic lithium salt, and being free of an electrolytic solution. The organic polymer is a copolymer, a bridge structure or a mixture thereof of polyethylene oxide and other organic polymer or polymers. A lithium ion secondary battery comprises this solid electrolyte.

Owner:OHARA

Long glass fiber reinforced composite polypropylene material, and preparation method and application thereof

The invention belongs to the technical field of high-molecular materials, and discloses a long glass fiber reinforced composite polypropylene material, and a preparation method and an application thereof The material is prepared by using the following components, by weight, 55-75 parts of polypropylene, 20-40 parts of a continuous glass fiber, 0.1-0.5 parts of a coupling agent, 0.01-0.1 parts of a primary antioxidant, 0.01-0.1 parts of an auxiliary antioxidant, 0.5-1 part of a lubricant and 3.5-4.2 parts of compatilizer. The invention also provides a preparation method of the long glass fiber reinforced composite polypropylene material, and a use of the long glass fiber reinforced composite polypropylene material in automobile components. The long glass fiber reinforced composite polypropylene material can be widely used in automobile components comprising header boards, automobile door panels, inner casings and the like, and has the characteristics of low cost, short injection molding period, low residual stress and small warpage of products, and low fraction defective of the products.

Owner:HEFEI GENIUS NEW MATERIALS

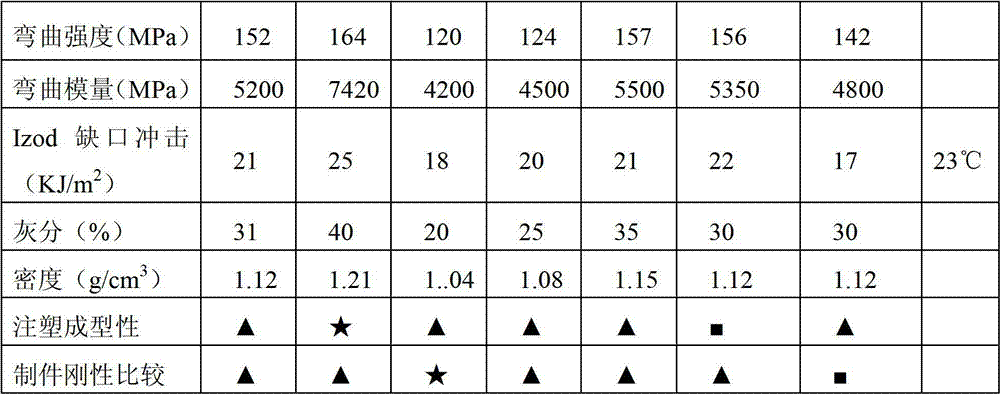

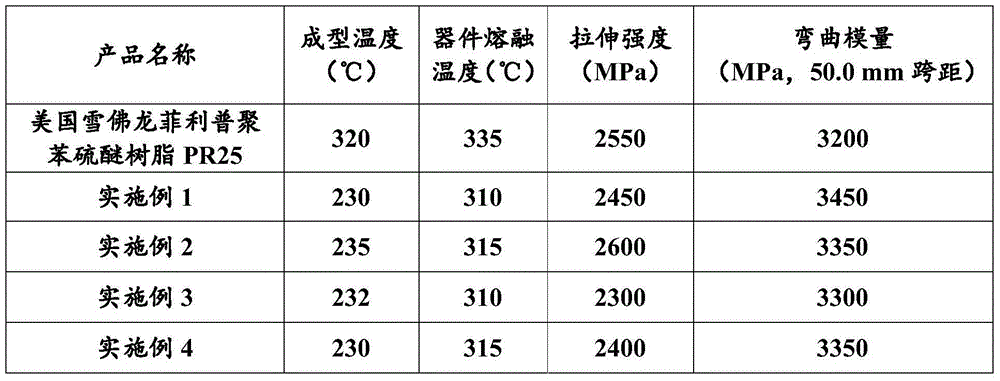

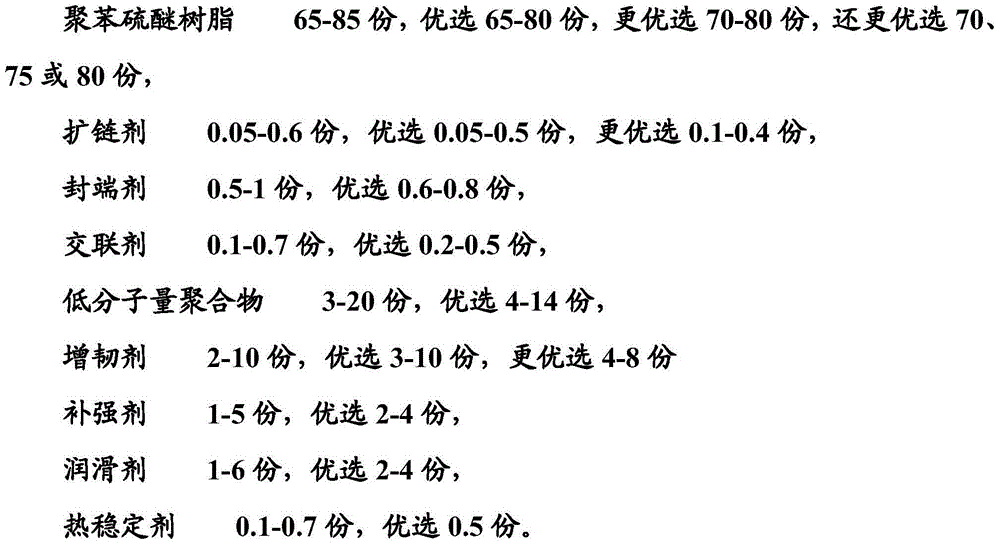

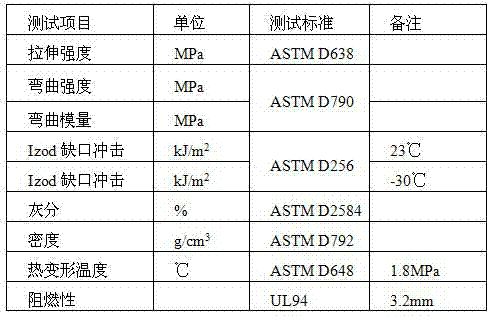

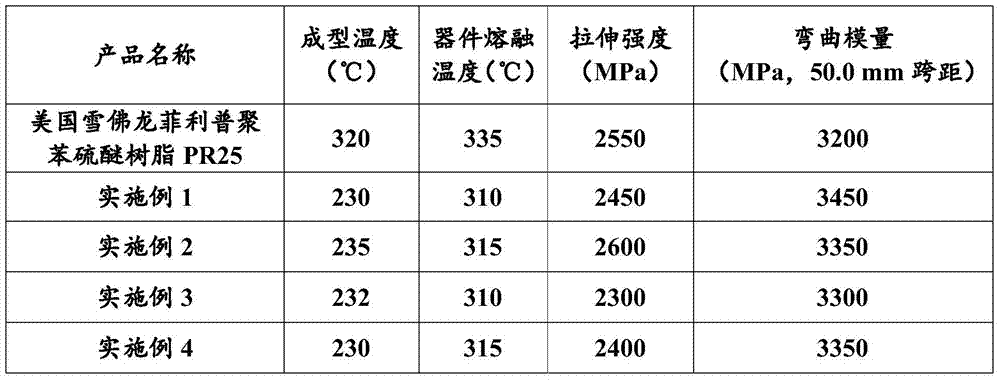

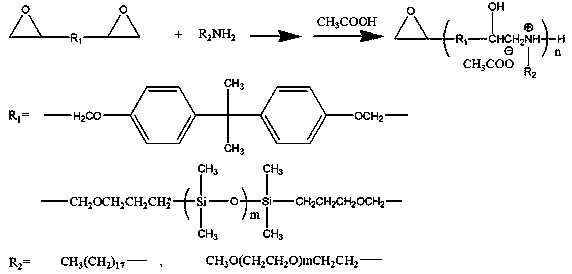

Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

ActiveCN104650587AIncrease profitImprove toughnessAdditive manufacturing apparatusDevice formToughness

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

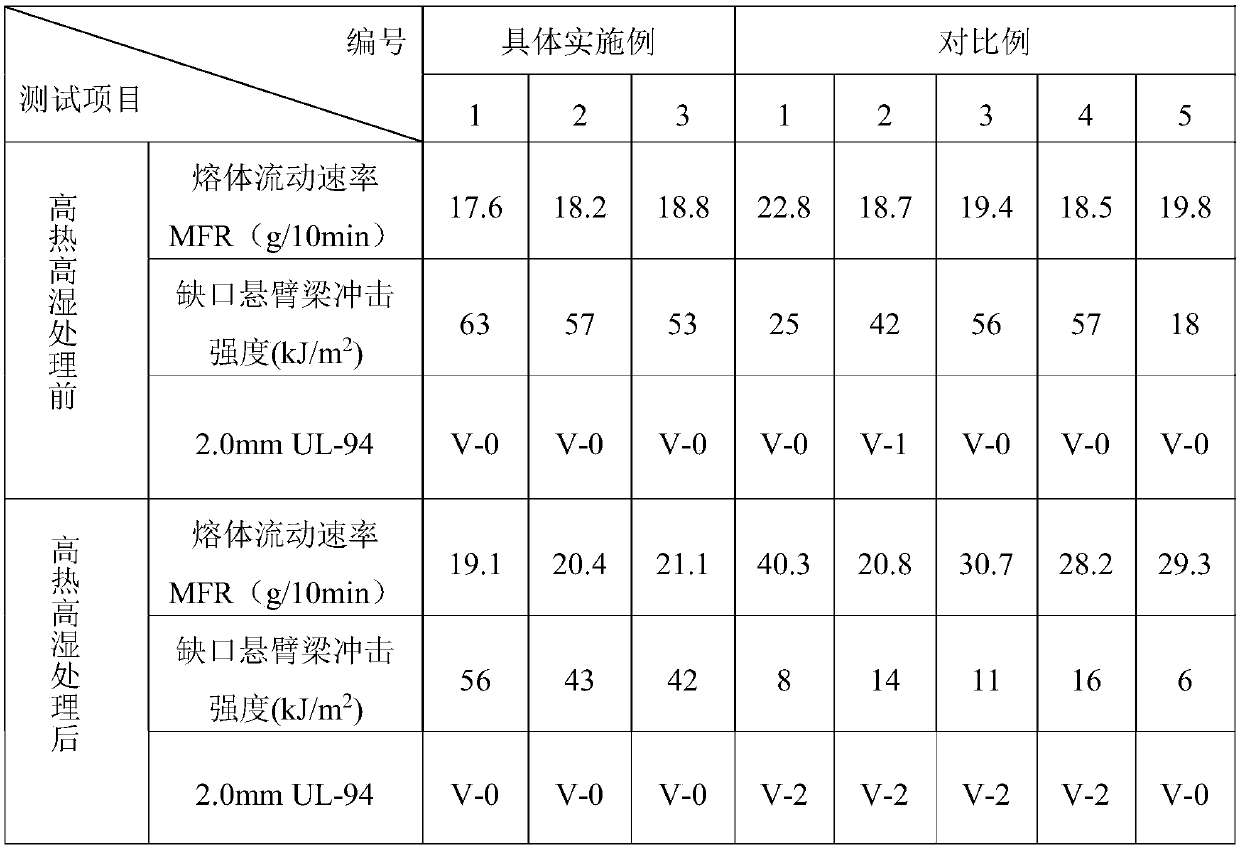

Lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and preparation method thereof

The invention discloses a lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and a preparation method thereof. The lithium battery case flame-retardant material is prepared from the following components in parts by weight: polypropylene, continuous glass fiber, coupling agent, main antioxidant, auxiliary antioxidant, lubricant, compatilizer, composite flame retardant and black master batch. The preparation method comprises the following steps: adding all the components expect the continuous glass fiber into a high-speed mixer, uniformly mixing, sending into an extruding machine, carrying out melt extrusion on the material into an impregnator, and meanwhile, sending the continuous glass fiber into the impregnator to carry out disperse impregnation with the molten material; and finally, carrying out die drawing at a setting port of the impregnator, cooling, carrying out blow-dry, and granulating to obtain the finished product. The lithium battery case flame-retardant material disclosed by the invention has higher strength and toughness, can not be easily combusted in naked fire, can effectively lower the possibility of battery combustion accidents, and ensures the case to have high plasticity and compressive strength.

Owner:HEFEI GENIUS NEW MATERIALS

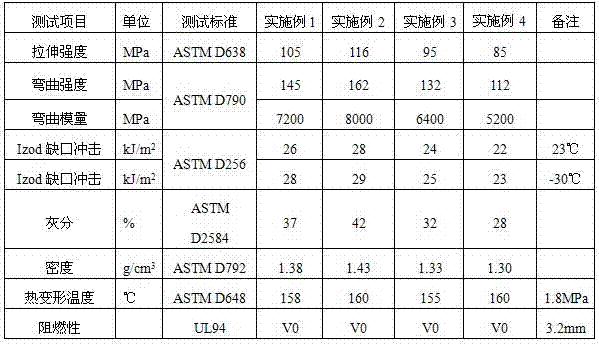

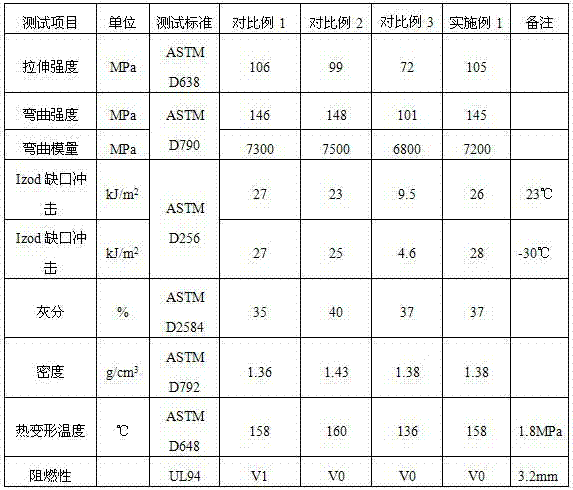

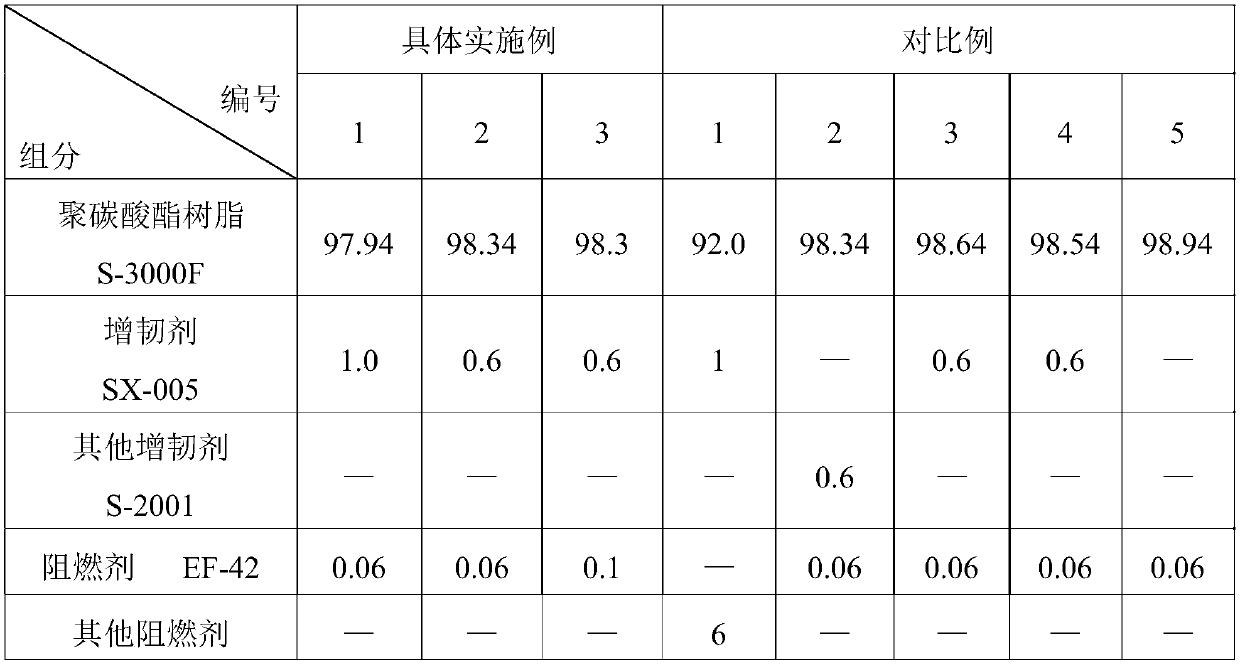

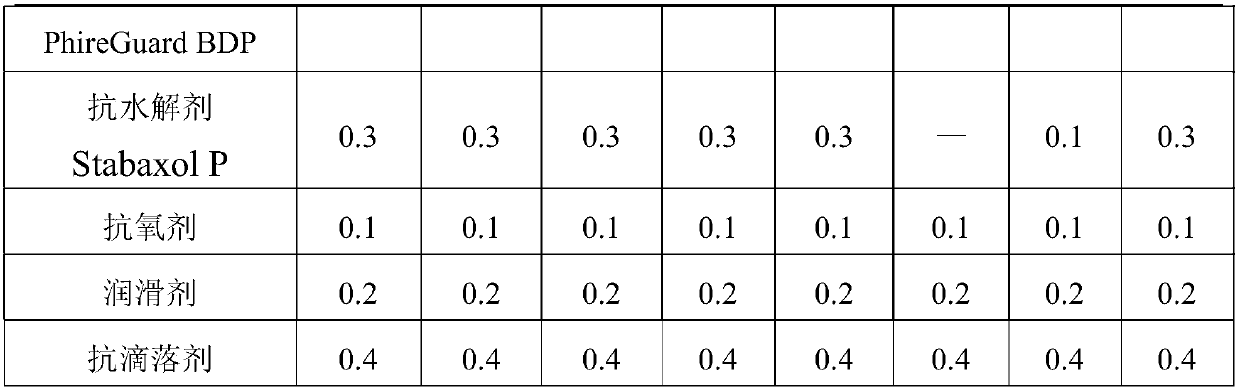

Difficult-flammble polycarbonate composition and preparation method thereof

InactiveCN109535683AHeat resistant temperature retentionExcellent heat resistance temperatureHeat resistanceAntioxidant

The invention provides a difficult-flammble polycarbonate composition and a preparation method thereof. The difficult-flammble polycarbonate composition comprises the following components in parts byweight: 96.0-99.8 parts of polycarbonate resin, 0.1-3.0 parts of a toughening agent, 0. 01-6.0 parts of a flame retardant, 0.1-5.0 parts of an anti-hydrolysis agent, 0.01-2.0 parts of an antioxidant,and 0.01-1.2 parts of other additives; wherein the anti-hydrolysis agent is one of carbodiimide, isocyanate, oxazoline, and an epoxy compound. The difficult-flammble polycarbonate composition has goodflame retardation performance, toughness and anti-hydrolysis performance, the heat resistance temperature is higher than 120 DEG C, and the difficult-flammble polycarbonate composition is especiallysuitable for occasion with high usage environment requirements.

Owner:TIANJIN KINGFA NEW MATERIAL

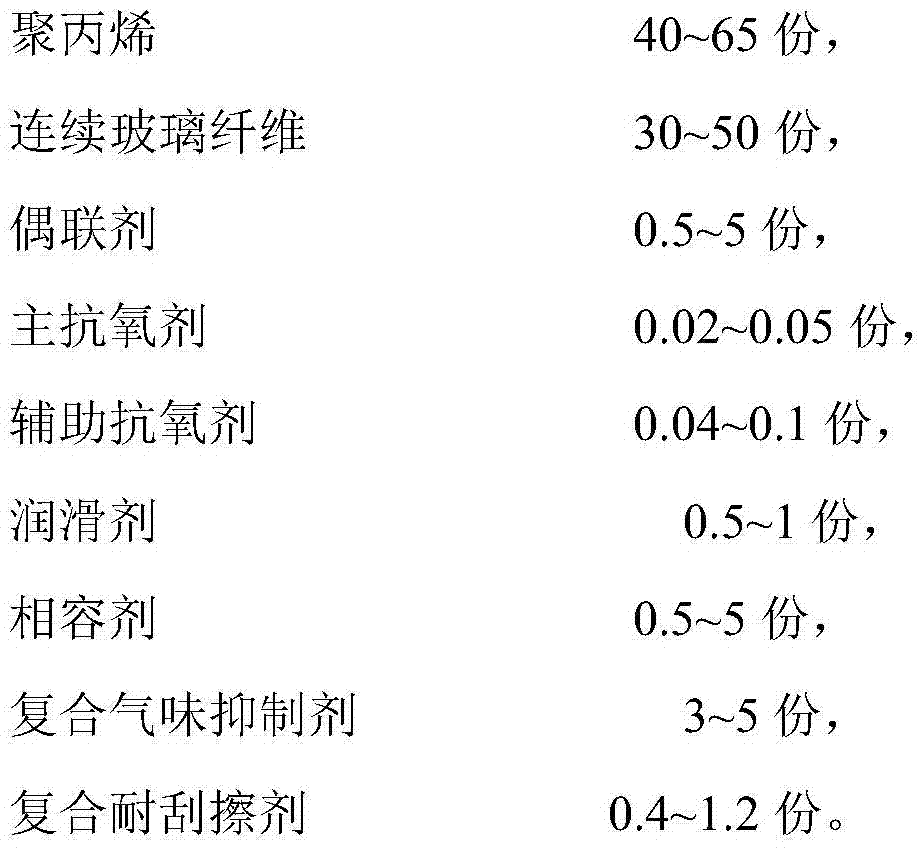

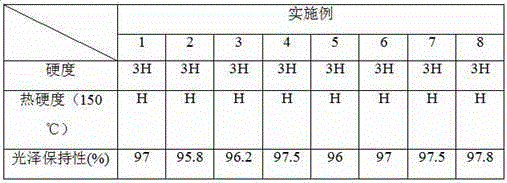

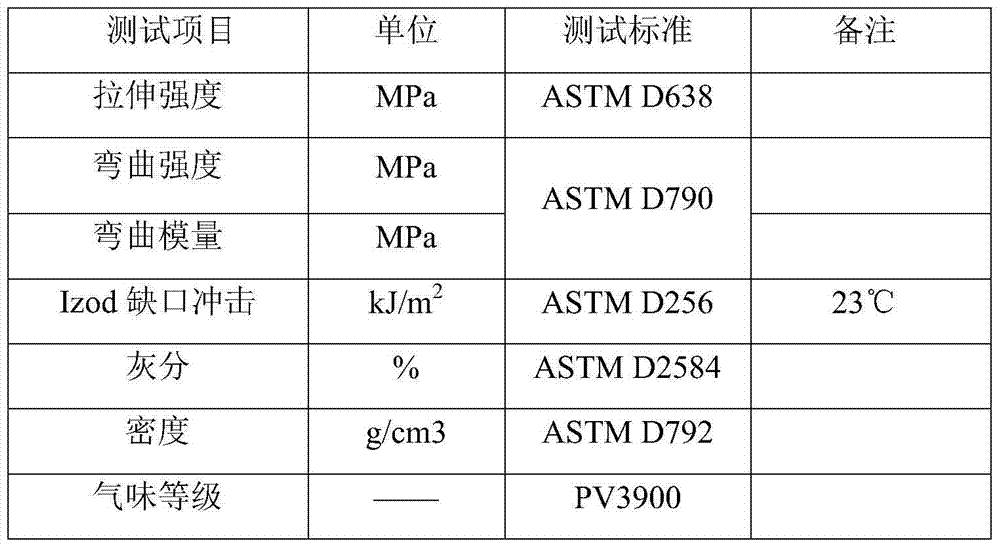

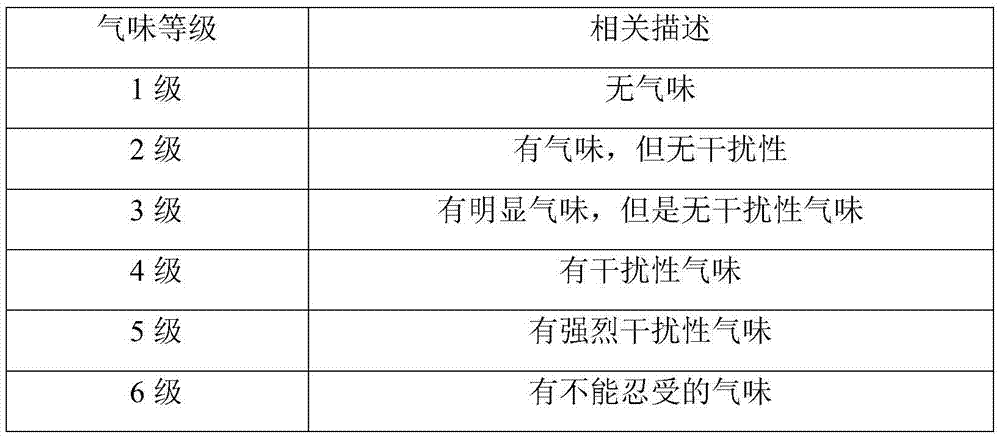

Low-odor and scratch-resistant continuous fiber reinforced polypropylene composite material and preparation method thereof

InactiveCN106995553AMeet the use requirementsOvercome irritating odorGlass fiberPolypropylene composites

The invention belongs to the technical field of high polymer materials, and relates to a low-odor and scratch-resistant continuous fiber reinforced polypropylene composite material and a preparation method thereof. The composite material is prepared from the following ingredients in parts by weight: 40 to 65 parts of polypropylene, 30 to 50 parts of continuous glass fiber, 0.5 to 5 parts of coupling agent, 0.02 to 0.05 part of primary antioxidant, 0.04 to 0.1 part of auxiliary antioxidant, 0.5 to 1 part of lubricant, 0.5 to 5 parts of compatilizer, 3 to 5 parts of compound odor inhibitor and 0.4 to 1.2 parts of compound scratch-resistant agent. By means of adding the compound odor inhibitor and the compound scratch-resistant agent, an odor level of the continuous glass fiber reinforced polypropylene composite material provided by the invention can be 3-level or higher, and a scratch-resistant effect can reach a five-finger scratch color difference value delta L smaller than 1.0; furthermore, original excellent mechanical strength of the continuous glass fiber reinforced polypropylene composite material is not affected after the odor inhibitor and the scratch-resistant agent are added, and application of the continuous glass fiber reinforced polypropylene composite material in automotive upholstery, electric tool casings and parts of home appliance workpieces is widened.

Owner:HEFEI GENIUS NEW MATERIALS

Process for preparing heat-resistant steel plate

InactiveCN104438025AExcellent heat resistance temperatureGood solvent resistancePretreated surfacesPolyester coatingsPolyester resinSilicon

The invention discloses a process for preparing a heat-resistant steel plate. According to the process, bottom paint and surface paint are sprayed and baked on a pre-coating steel plate in sequence, wherein the bottom paint and the surface paint are prepared from organic silicon modified polyester which is used as the binder of a paint composition and other auxiliaries. In the actual application, the organic silicon modified polyester has excellent high-temperature resistant performance, so that the prepared paint composition has better characteristics and can be sprayed on the surfaces of iron, aluminum, or stainless steel and other metals; and moreover, the paint composition is widely applied to heat-resistant materials like a baking tray, an electric frying pan, a barbecue tool.

Owner:CHENGDU JINHUI TECH

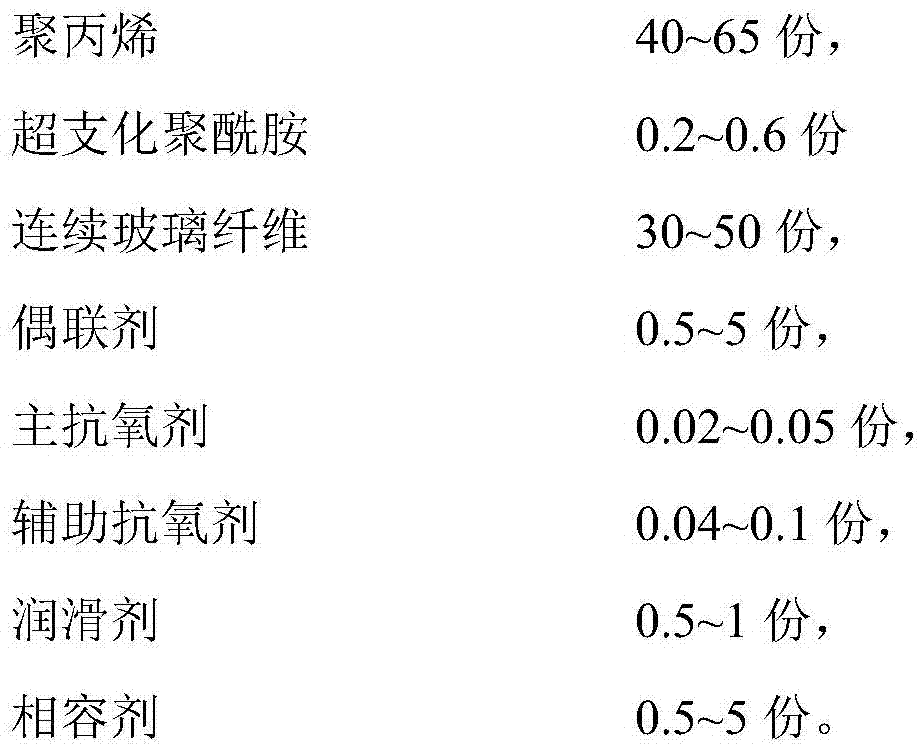

Hyperbranched polyamide modified polypropylene composite material and preparation method thereof

The invention provides a hyperbranched polyamide modified polypropylene composite material and a preparation method thereof. The hyperbranched polyamide modified polypropylene composite material is prepared from 40 to 65 parts of polypropylene, 0.2 to 0.6 part of hyperbranched polyamide, 30 to 50 parts of continuous glass fiber, 0.5 to 5 parts of coupling agent, 0.02 to 0.05 part of primary antioxidant, 0.04 to 0.1 part of auxiliary antioxidant, 0.5 to 1 part of lubricant and 0.5 to 5 parts of compatilizer. The raw materials are mixed, molten, dipped, pulled and extruded to be prepared into the hyperbranched polyamide modified polypropylene composite material. According to the hyperbranched polyamide modified polypropylene composite material disclosed by the invention, alkyl terminated hyperbranched polyamide is utilized as a flow accelerant to be mixed and modified with the low melt index polypropylene to reduce system viscosity, and a melting, pulling and extruding technology is utilized to prepare the continuous glass fiber reinforced polypropylene composite material; thus, material cost is obviously reduced, mechanical property of the material is remarkably improved, and the problems of high raw material cost, difficult processing and shaping and poor product odor in existing continuous glass fiber reinforced polypropylene production are solved.

Owner:HEFEI GENIUS NEW MATERIALS

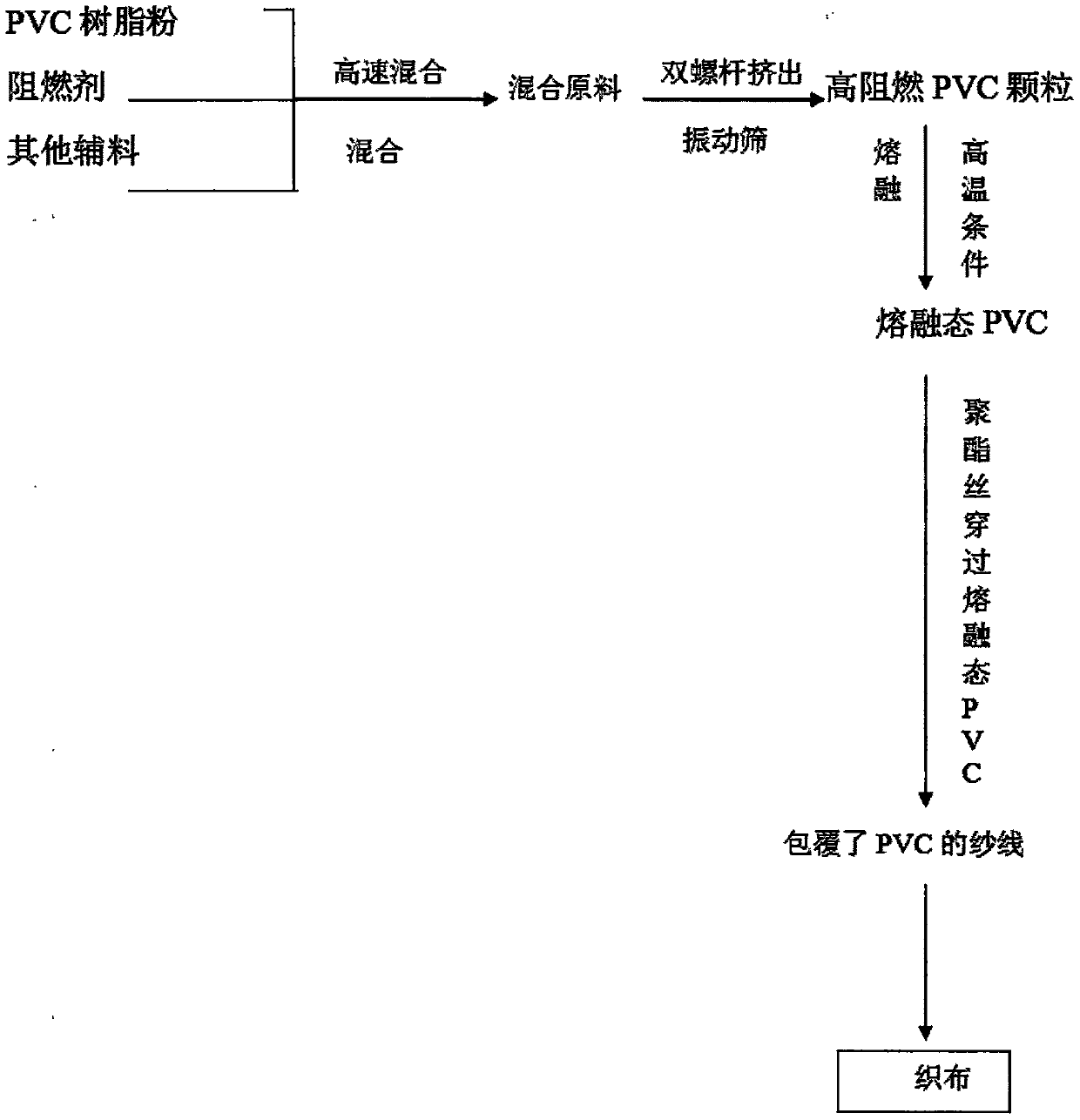

High-flame-retardant soft PVC coated polyester yarn high-molecular composite sun-shading material

PendingCN109930385AInhibition of autocatalysisHigh heat resistanceFibre typesFilament manufactureSolid phasesParaffin oils

The invention provides a high-flame-retardant soft PVC coated polyester yarn high-molecular composite sun-shading material, which is synthesized by PVC resin powder, a flame retardant and other auxiliary materials, wherein the main raw materials of the flame retardant comprise phosphate ester, zinc stannite, metal hydroxide, decabromodiphenyl ethane and antimony trioxide, and simultaneously contain chlorinated polyvinyl chloride and chlorinated paraffin; the coated polyester fiber is woven into a sunlight fabric with high-flame-retardant performance, and the limiting oxygen index can exceed 32.0 %. The high-molecular composite sun-shading material can interact with a gas phase and a solid phase through the compound system, the flame retardancy of the soft PVC coated polyester yarn high-molecular composite sun-shading material is significantly improved, the limiting oxygen index of the material is 32. 4 %, the problem of low limiting oxygen index of the high-molecular composite sun-shading material is solved, the flame retardant efficiency of products is significantly improved, the fire risk of products is reduced, the products are more competitive, this innovation has made a breakthrough in the flame retardancy of soft polymers in the textile field.

Owner:温多利遮阳材料(德州)股份有限公司

High-heat-conductivity organic silicon potting adhesive, and preparation method and application thereof

ActiveCN106833511AImprove thermal conductivityImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesPolymer scienceHeat conducting

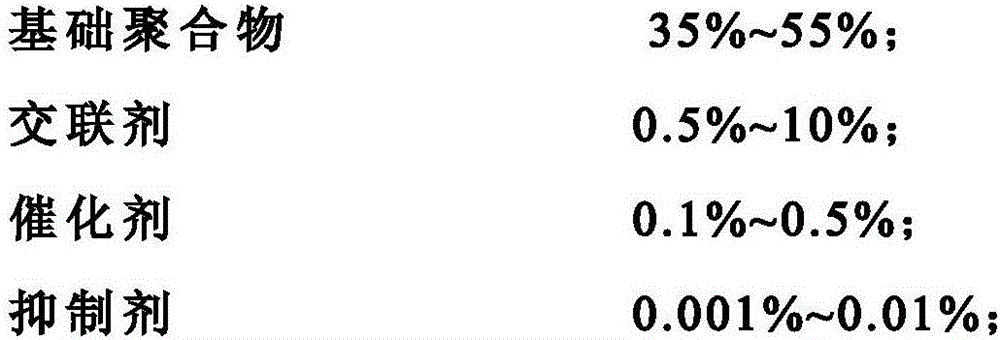

The invention relates to a high-heat-conductivity organic silicon potting adhesive, and a preparation method and application thereof. The potting adhesive comprises the following raw materials in percentage by weight: 35-55% of base polymer, 0.5-10% of crosslinking agent, 0.05-0.5% of catalyst, 0.001-0.01% of inhibitor and 40-60% of filler. The base polymer is polysiloxane containing two or more vinyls, and the rotary viscosity at 25 DEG C is 200-4000 mPa.s. The crosslinking agent is prepared by carrying out reaction on 3-methylacryloyloxypropylmethyldimethoxysilane, hexamethyldisiloxane, octamethylcyclotetrasiloxane and tetramethylcyclotetrasiloxane in the presence of water and an acidic catalyst. The potting adhesive has the advantages of excellent heat-conducting property, high salt spray resistance, high / low temperature resistance, ozone corrosion resistance, ultraviolet aging resistance, excellent tensile strength, excellent extension at break, excellent hardness and simple forming technique, and is suitable for complicated and changeable environments of navigation motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Coating composition used for steel plates with weatherability and preparation method thereof

InactiveCN104449367AExcellent heat resistance temperatureGood solvent resistanceAnti-corrosive paintsSolventTemperature resistance

The invention discloses a coating composition used for steel plates with weatherability and a preparation method thereof. The coating composition comprises the following components by weight percent: 30-50% of organosilicone modified polyester resin, 20-46% of fillers, 1-2% of a siloxane coupling agent, 0.5-1% of phthalic ester and 1-48.5% of a xylene solvent. The coating composition is prepared by mainly using the organosilicone modified polyester resin as a coating base material, then mixing the organosilicone modified polyester resin with auxiliary materials including the fillers, the siloxane coupling agent, phthalic ester and the xylene solvent and grinding the mixture into a paste with a ball mill, wherein the fineness of the paste is 10-20mu m. During actual use, as the organosilicone modified polyester resin has excellent high temperature resistance, a coating formed by the organosilicone modified polyester resin has good properties, can be sprayed onto the surfaces of metals, such as iron, aluminium or stainless steel, and is widely applied to heat resistant materials in a high temperature working condition for a long term, such as petroleum refining furnaces, aluminium refining furnaces, engine exhaust systems and motor vehicle mufflers.

Owner:CHENGDU JINHUI TECH

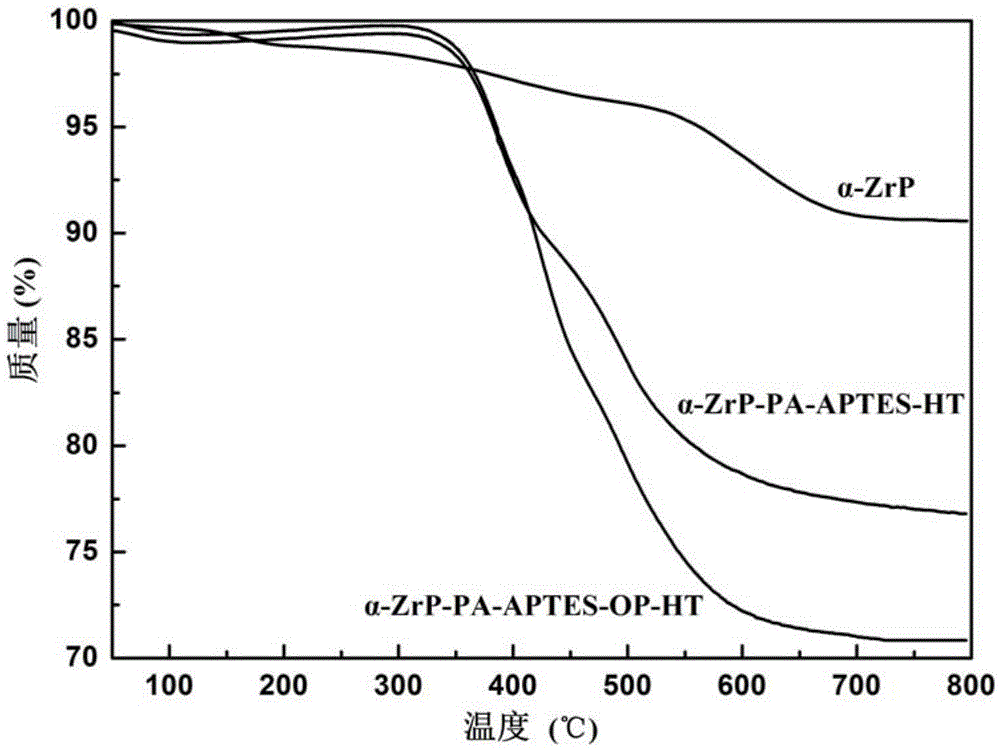

Organophosphorus hybrid alpha-ZrP flame-retardant material and preparation method thereof

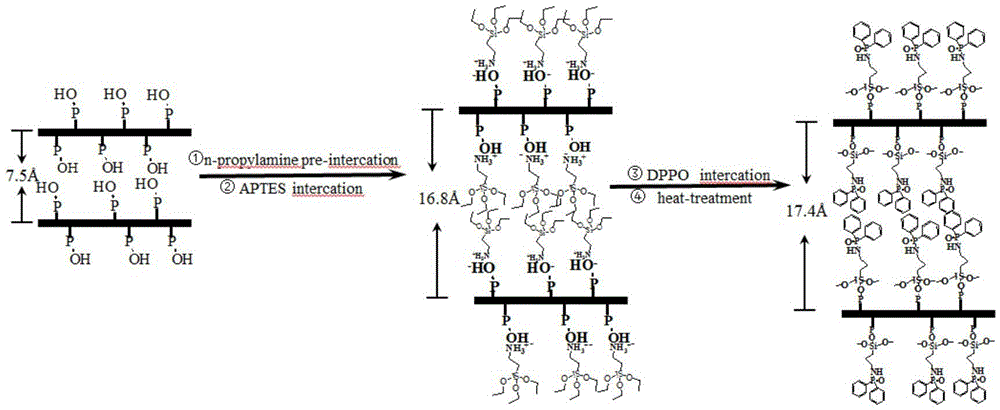

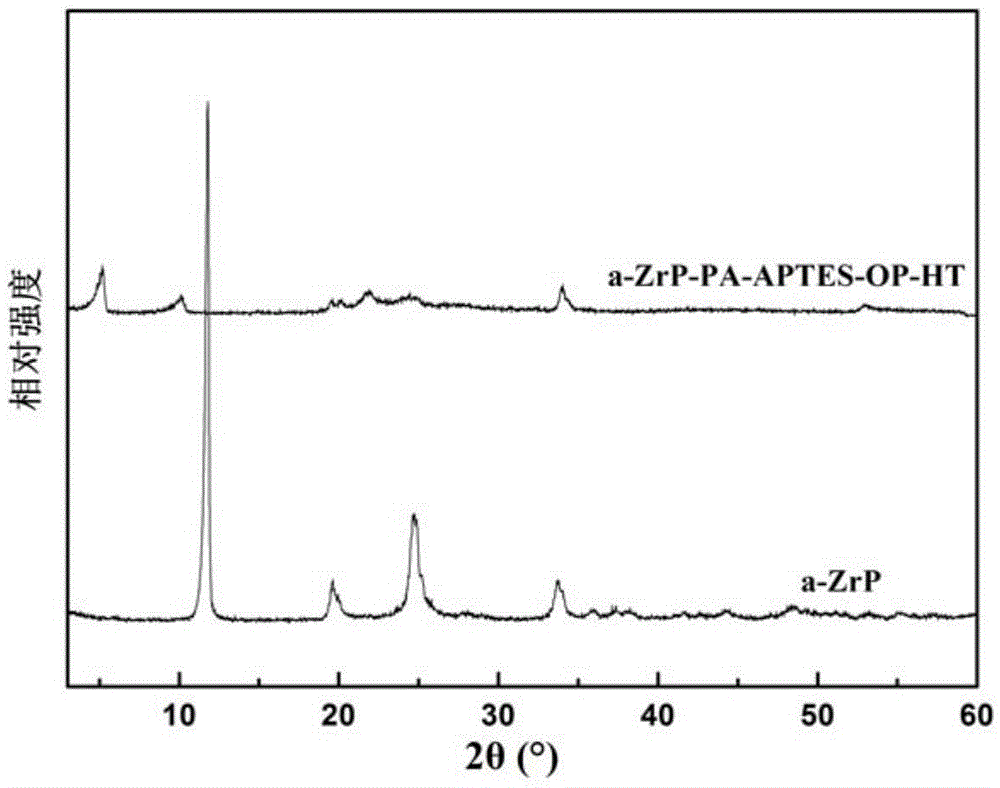

InactiveCN105482498AImprove thermal stabilityOvercome the disadvantage of heat resistance temperature lower than 300℃Pigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsTO-18Polymer science

The present invention relates to an organophosphorus hybrid alpha-ZrP flame-retardant material and a preparation method thereof, alpha-ZrP is used as a substrate, a small molecule amine is used for supporting in advance to reduce alpha-ZrP inter-laminate force and increase interlayer spacing, then a silane coupling agent is inserted between layers, the small molecule amine for supporting in advance is removed by heat treatment, and the organophosphorus hybrid alpha-ZrP flame-retardant material can be prepared by the effect of formation of chemical bonding of a terminal group of the silane coupling agent and organophosphorus, wherein the initial decomposition temperature of the organophosphorus hybrid alpha-ZrP is 340-450 DEG C, the interlayer spacing is 1.60-2.50nm, the grafting ratio of the silane coupling agent is 6 to 18%, and the organophosphorus content is 1 to 15%. The organophosphorus hybrid alpha-ZrP flame-retardant material has high thermal stability, grafting ratio, interlayer spacing and organophosphorus content, has stronger nonpolar organic substance affinity, can be uniformly dispersed in a hydrophobic organic polymer material, may be added into most polymer materials (PET, PBT, PP, and the like) processed by melting for e preparation of flame-retardant materials, and has excellent flame retardant properties.

Owner:DONGHUA UNIV

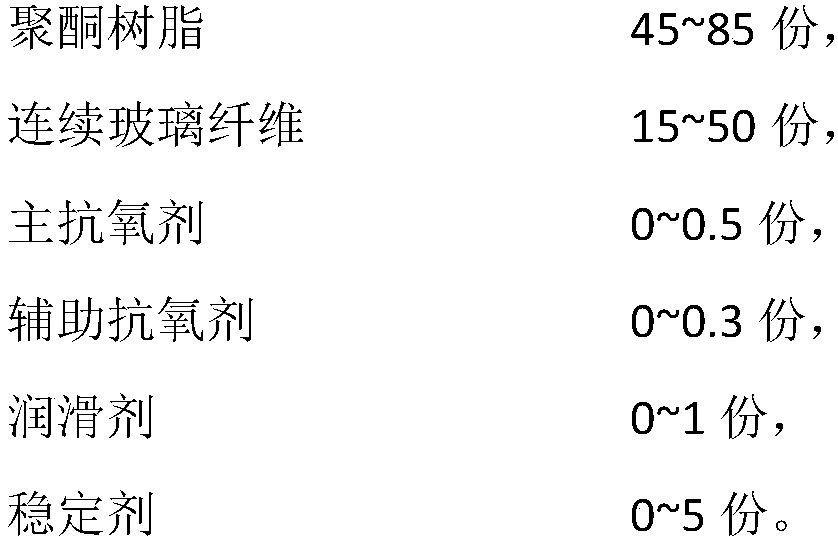

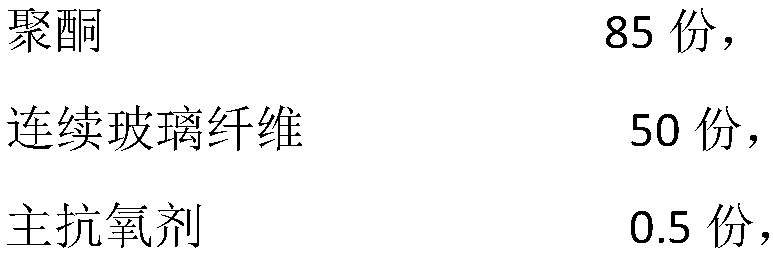

Long glass fiber reinforced polyketone material and preparation method thereof

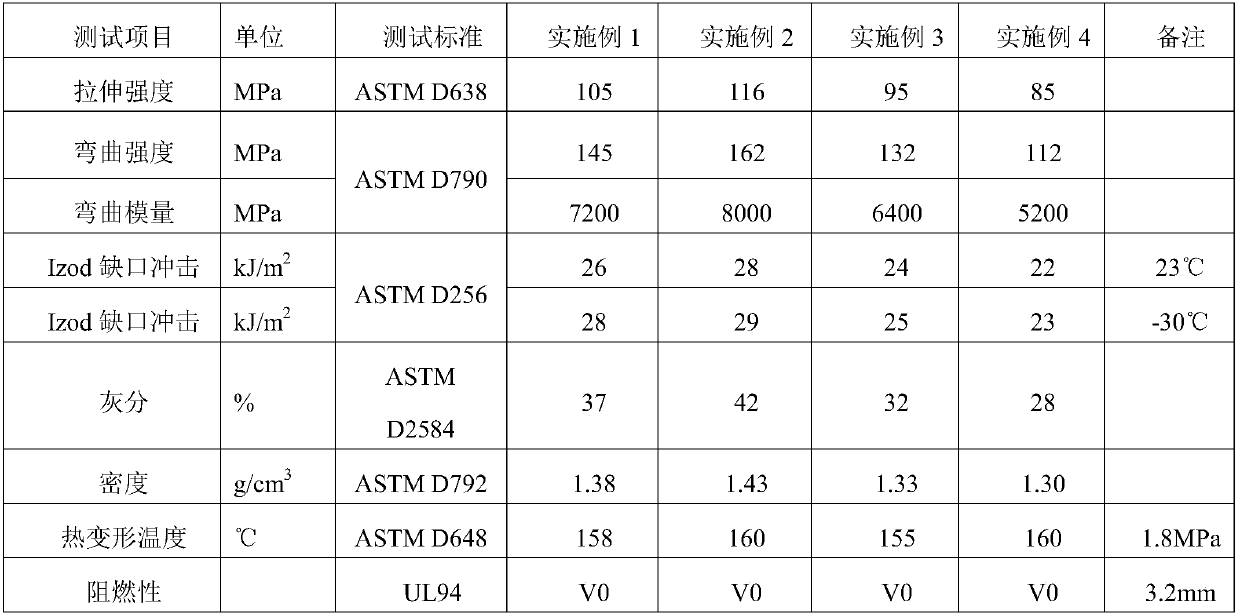

The invention belongs to the technical field of polymer materials, and in particular, relates to a long glass fiber reinforced polyketone material prepared from the following components in parts by weight: 45-85 parts of polyketone resin, 15-50 parts of continuous glass fibers, 0-0.5 part of a main antioxidant, 0-0.3 part of an auxiliary antioxidant, 0-1 part of a lubricant, and 0-5 parts of a stabilizer. With adopting of the long glass fiber reinforced polyketone material, the grain-sized dicing length of grains is 10-15 mm, fibers in the grains are in ordered arrangement in the resin along the grain-sized dicing direction, and the fiber length is equal to the grain length; the material also has excellent rigidity, impact toughness and good heat-resistant temperature, especially has excellent low-temperature impact properties, and has the advantages of simple design, low cost and high productivity.

Owner:HEFEI GENIUS NEW MATERIALS

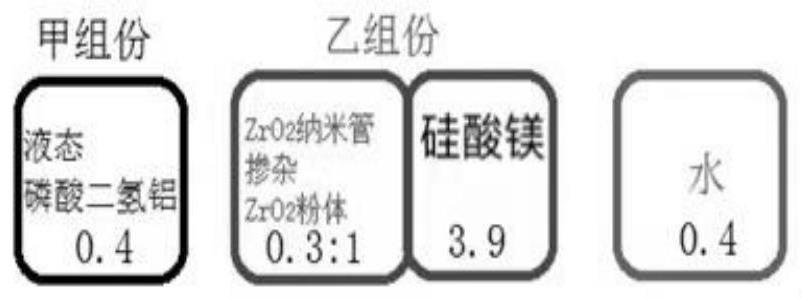

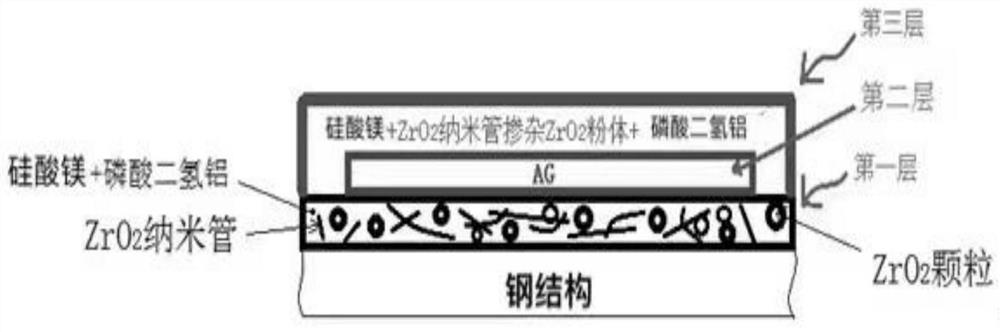

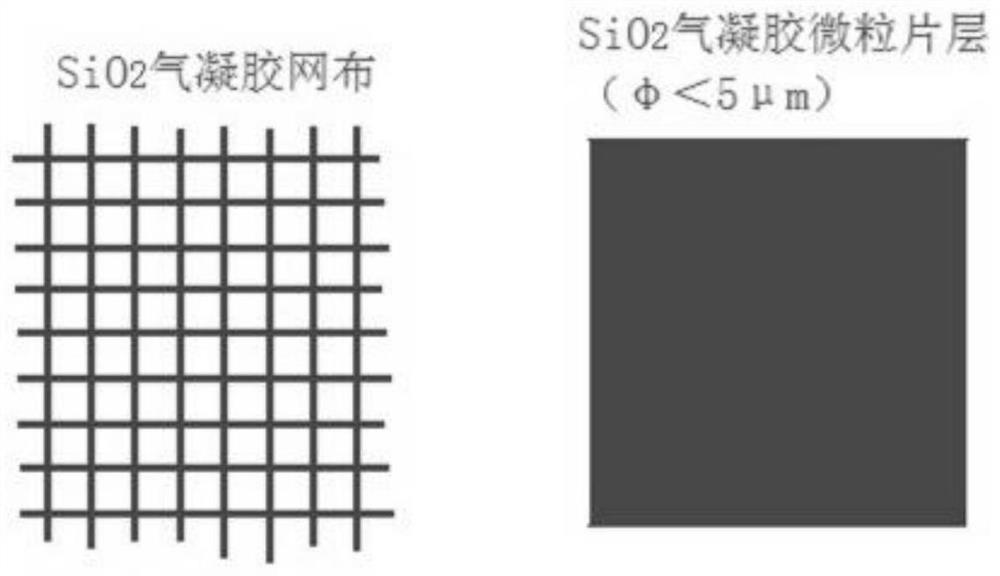

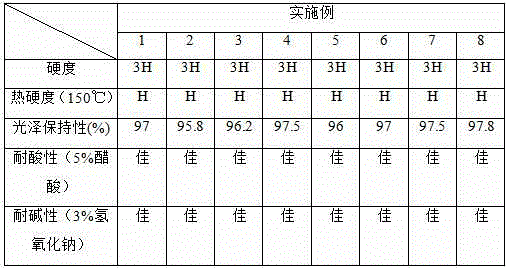

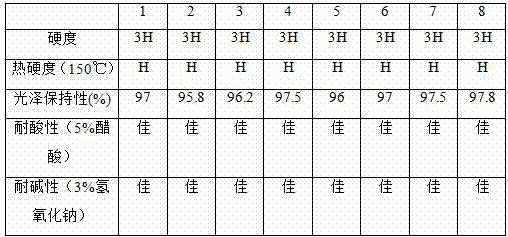

High-strength high-temperature-resistant fireproof thermal insulation material

ActiveCN114249590AImprove heat resistance temperaturePrevent crackingConstruction materialInsulation improvementThermal insulationPowder

The invention provides a high-strength high-temperature-resistant fireproof thermal insulation material which comprises a component A and a component B which are not mixed with each other or a component A and a component B which are not mixed with each other and water, the component A is an inorganic liquid high-temperature-resistant fireproof material, and the component B is an inorganic powdery high-temperature-resistant fireproof material, the inorganic powdery high-temperature-resistant fireproof material of the component B comprises high-temperature-resistant modified silicate powder, and at least one of super-high-temperature-resistant fireproof powder and heat-insulating cooling powder. And a reinforced protection effect at the highest temperature of 2300 DEG C for more than 5 hours is formed, so that a structural material is protected from unacceptable deformation influence caused by high temperature.

Owner:深圳市元亨高新科技高分子材料开发有限公司

Weather-resistant steel plate

ActiveCN104403521AExcellent heat resistance temperatureGood solvent resistanceLayered productsPolyester coatingsWeather resistancePolyester resin

The invention discloses a weather-resistant steel plate which is prepared from a pre-coated steel plate coated and roasted by a basic coating and a surface coating sequentially. The basic coating and the surface coating used by the invention are prepared from organosilicone modified polyester resin as a base material and other auxiliaries. According to the weather-resistant steel plate disclosed by the invention, due to excellent heat resisting temperature, excellent adhesiveness and processibility on metal materials, excellent solvent resistance, good high-heat hardness and the like, the organosilicone modified polyester resin can be used for being sprayed on metal surfaces of iron materials, aluminum products or stainless steel and the like and can be widely applied to heat-resisting materials, such as a petroleum refining furnace, an aluminum refining furnace, an engine exhaust system and an engine silencer, which are in a high-temperature working condition for a long time.

Owner:GUANGDONG ARMSTRONG METAL CEILING PRODS

Weather-resistant steel plate and preparation process thereof

InactiveCN104497806AExcellent heat resistance temperatureGood solvent resistancePretreated surfacesAnti-corrosive paintsPolyester resinTemperature resistance

The invention discloses a weather-resistant steel plate and a preparation process thereof. A base coating and a surface coating applied to the weather-resistant steel plate are prepared from organosilicone-modified polyester resin serving as a base material of a coating composition and assisted by other assistants. In a practical preparation process, the base coating and the surface coating employing the organosilicone-modified polyester resin as the base material are mainly adopted; and coating and baking are sequentially carried out on a pre-coated steel plate, so that the operation flow is simple and rapid. In practical use, the organosilicone-modified polyester resin has relatively excellent high-temperature resistance, and therefore the prepared coating composition has relatively good property, can be sprayed on metal surfaces such as iron material, aluminum products or stainless steel, and can be widely applied to heat-resistant materials of an oil refining furnace, an aluminum refining furnace, an engine exhaust system, a motor vehicle exhaust silencer and the like in a high-temperature working state for a long time.

Owner:CHENGDU JINHUI TECH

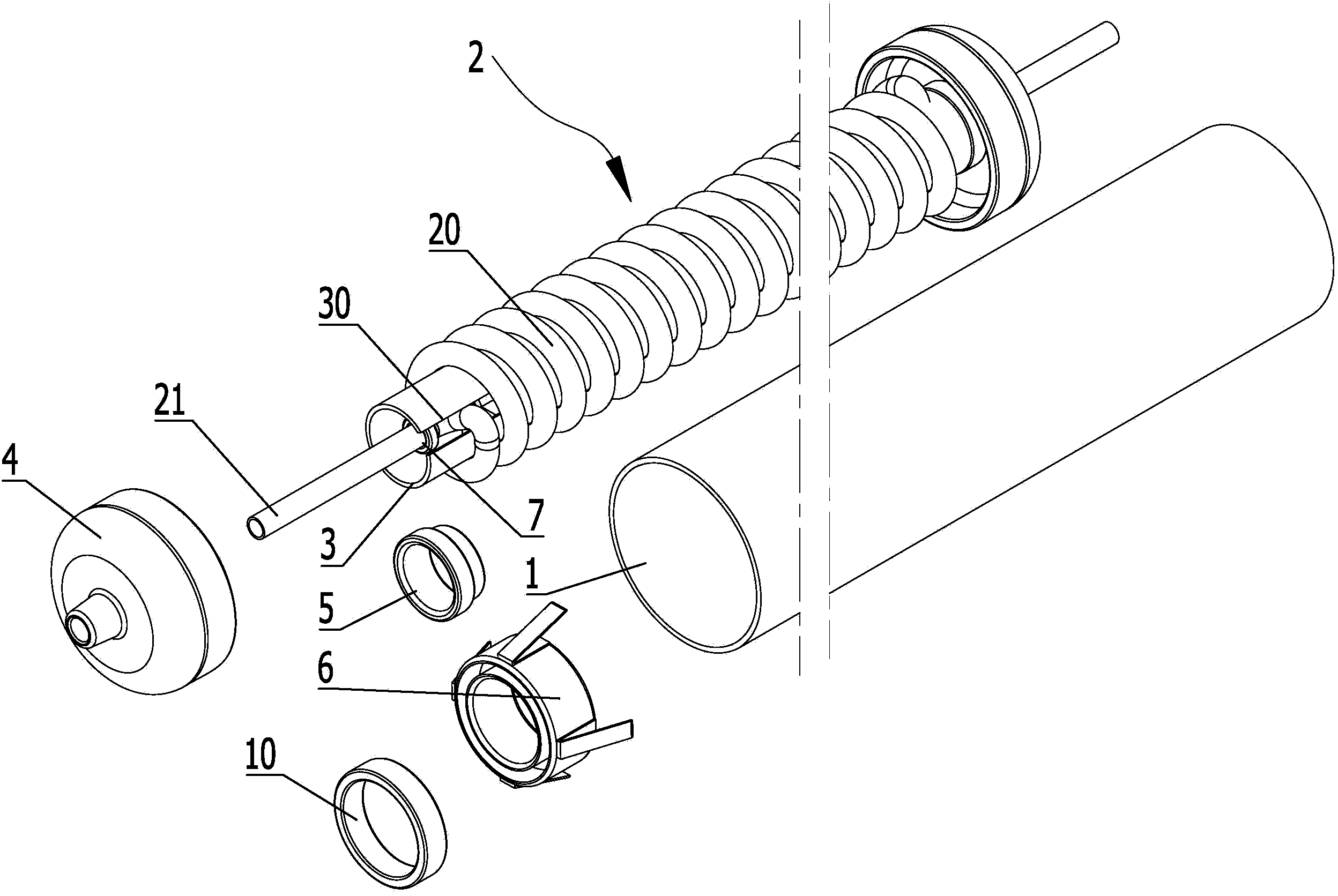

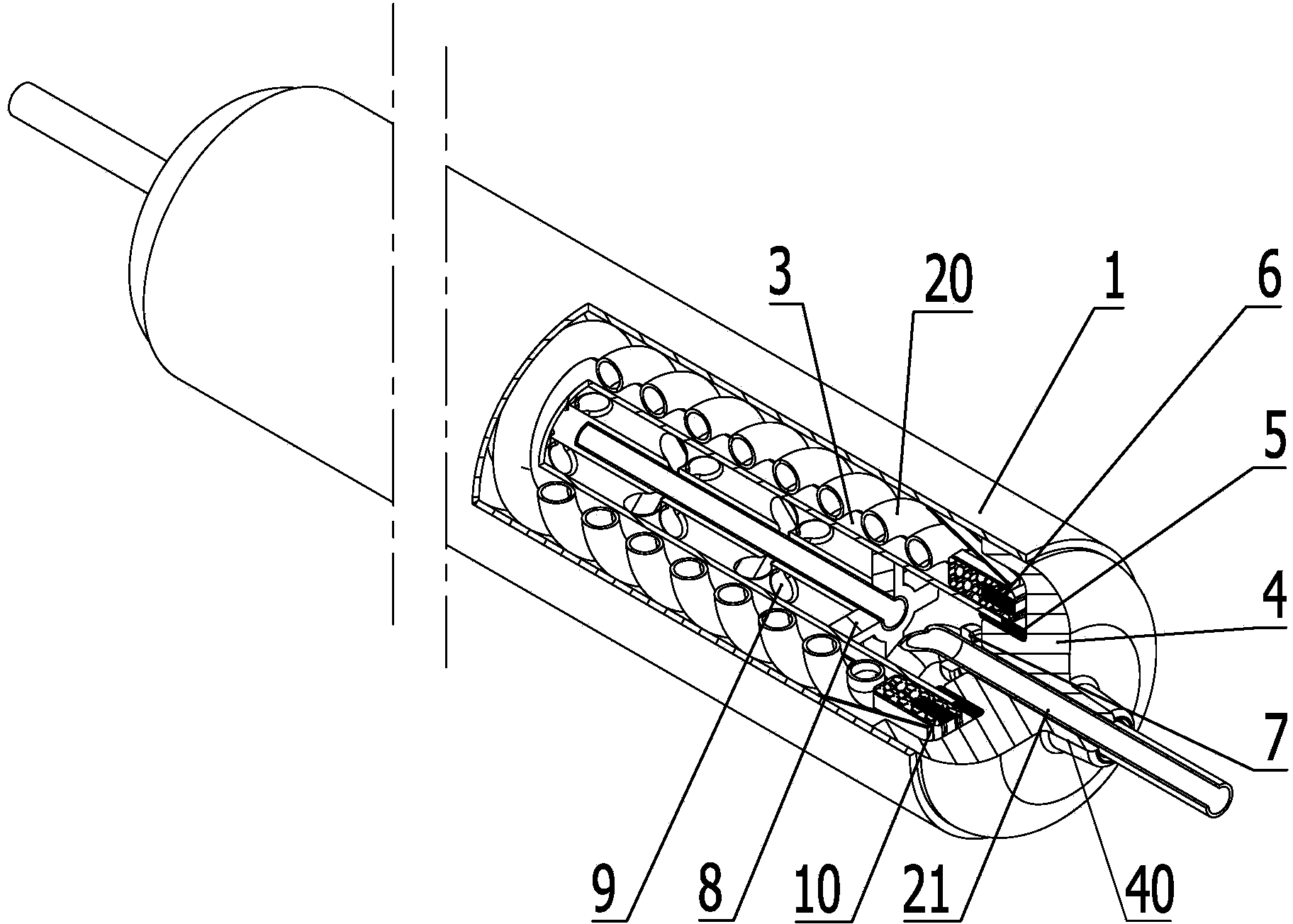

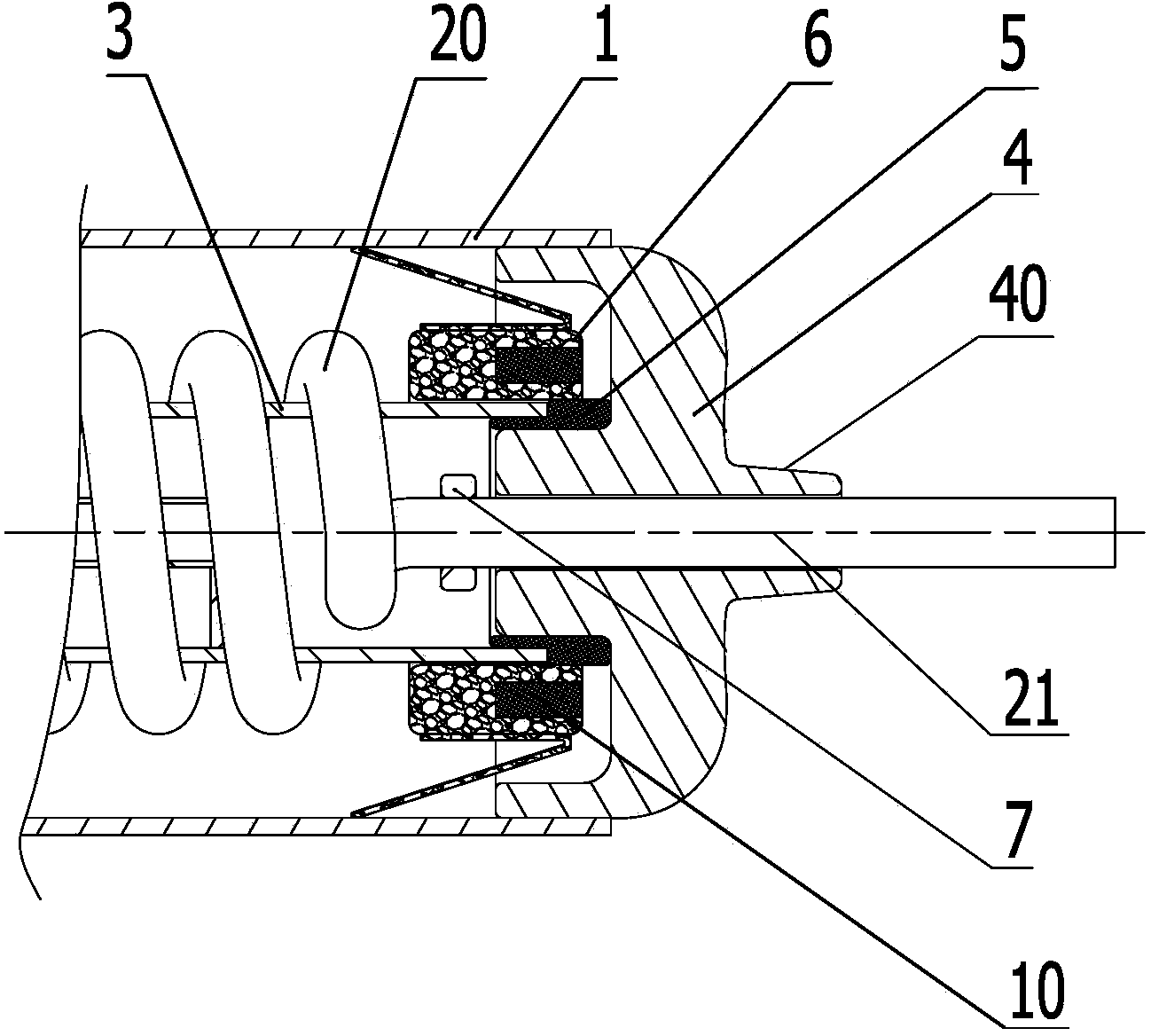

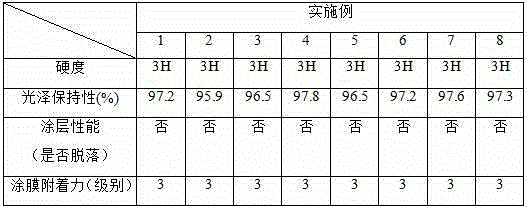

Spiral inner-tube vacuum heat collecting tube suitable for large temperature difference

ActiveCN104279777AExcellent heat resistance temperatureExtended service lifeGeneral water supply conservationSolar heat devicesThermodynamicsSolar heat

The invention relates to a spiral inner-tube vacuum heat collecting tube suitable for large temperature difference. The spiral inner-tube vacuum heat collecting tube comprises an outer tube, a sealing element, an inner tube and a supporting tube, wherein the sealing element is used for sealing the two end parts of the outer tube and enclosing a vacuum space; the inner tube is arranged inside the outer tube, and two ends of the inner tube penetrate out of the sealing element; two ends of the supporting tube are connected with the sealing element, and the supporting tube is used for supporting the inner tube; and the inner tube comprises a spiral section located in the middle and linear sections located at two ends, wherein the spiral section is wound on the supporting tube, the linear sections penetrate out of the sealing element, and annular bulges for preventing the linear sections from sliding relative to the sealing element are also arranged at positions, penetrating out of the sealing element, on the linear sections. By using the spiral inner-tube vacuum heat collecting tube, a favorable vacuum degree can be kept between the outer tube and the spiral inner tube under the conditions of high temperature and large temperature difference; and the spiral inner-tube vacuum heat collecting tube is low in manufacturing cost, long in working life, high in heat efficiency and capable of greatly promoting the industrialization and large-scale production of solar heat collecting tubes and promoting environment protection.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

Coating composition for weather-resistant steel plate

InactiveCN104403522AExcellent heat resistance temperatureGood solvent resistancePolyester coatingsSheet steelPolyester resin

The invention discloses a coating composition for a weather-resistant steel plate. The coating composition is prepared from the following components in percentage by weight: 30-50% of organosilicone modified polyester resin, 20-46% of filler, 1-2% of a siloxane coupling agent, 0.5-1% of phthalic ester and 1-48.5% of a xylene solvent; the coating composition is prepared from organosilicone modified polyester resin which is use as a base material of the coating composition and other auxiliaries. In actual use, as the organosilicone modified polyester resin has a relatively excellent high-temperature resisting performance, the formed coating composition further has good properties, can be sprayed on metal surfaces such as iron materials, aluminum products and stainless steel, and can be widely applied to heat-resisting materials, such as a petroleum refining furnace, an aluminum refining furnace, an engine exhaust system and an engine silencer, which are in a high-temperature working condition for a long time.

Owner:CHENGDU JINHUI TECH

A modified polyphenylene sulfide resin material suitable for 3D printing and its preparation method and application

ActiveCN104650587BIncrease profitImprove toughnessAdditive manufacturing apparatusSulfideMelting temperature

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

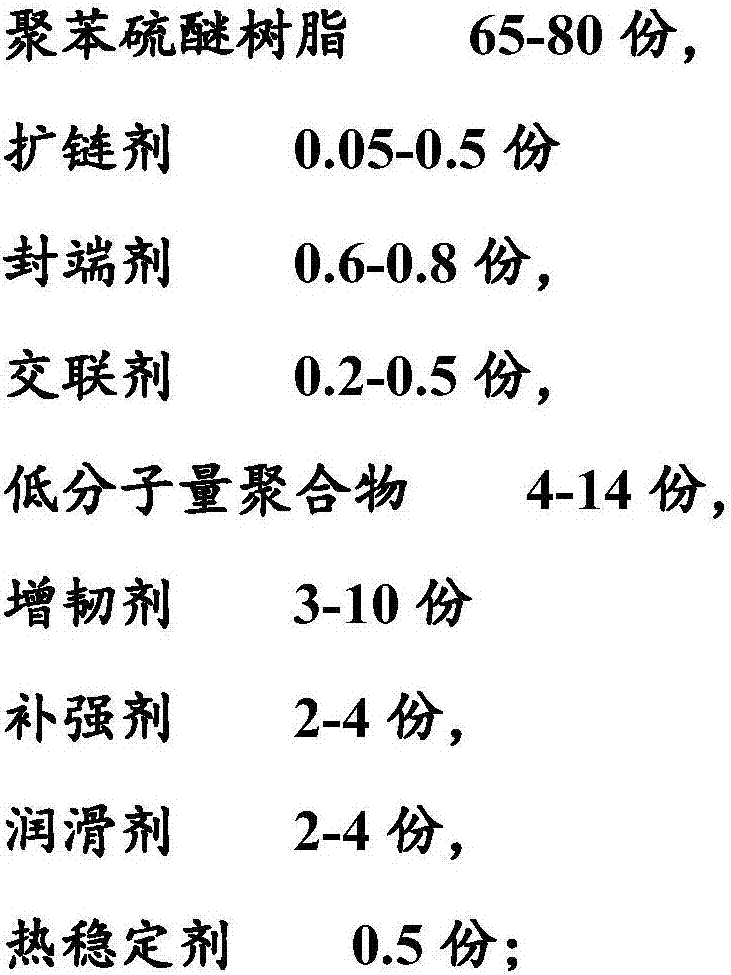

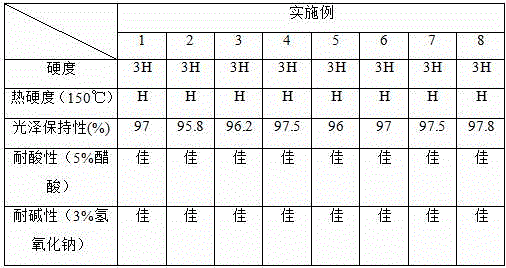

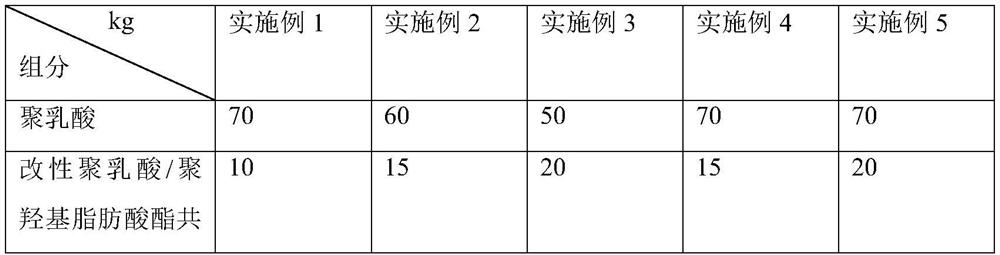

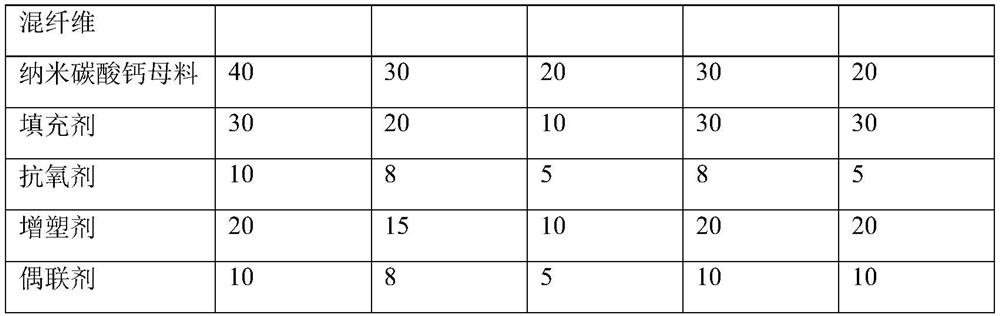

Quantum dot luminous compound for 3D (Three Dimensional) printing and preparation method thereof

InactiveCN109265946AImprove heat resistanceImprove mechanical propertiesAdditive manufacturing apparatusLuminous intensity3d printed

The invention provides a quantum dot luminous compound for 3D (Three Dimensional) printing. The quantum dot luminous compound is prepared from the following raw materials in parts by weight: 100 partsof polylactic acid, 0.2 to 0.5 part of a chain extender, 5 to 17 parts of a plasticizer, 20 to 60 parts of an organic matter, 20 to 60 parts of graphene quantum dots, 1 to 5 parts of a reinforcing agent and 1 to 5 parts of a lubricant, wherein the organic matter is nano silicon dioxide or nano titanium dioxide. According to the quantum dot luminous compound, the polylactic acid is modified through the chain extender and the performance of the polylactic acid is enhanced; then the graphene quantum dots are mixed with the organic matter, so that the luminous intensity of the quantum dot luminous compound is enhanced; finally, mixed powder of the graphene quantum dots and the organic matter is mixed with the modified polylactic acid, the plasticizer, the reinforcing agent and the lubricant;the three-dimensional size of the graphene quantum dots is commonly less than 10 nm, scattering is relatively small and agglomeration and sedimentation are not prone to occur; the quantum dot luminouscompound has excellent performance and can be used for printing luminous bodies with different shapes; the quantum dot luminous compound is matched with a laser source and the luminous bodies with different shapes and functions can be manufactured, so that the quantum dot luminous compound has good application prospects.

Owner:LULIANG UNIV

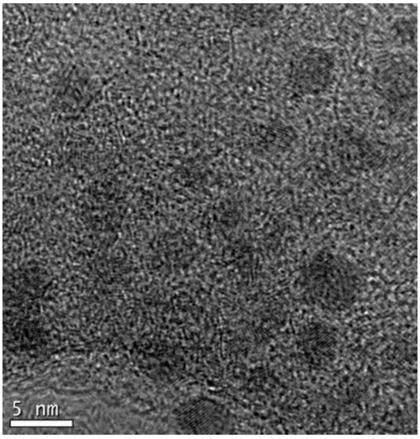

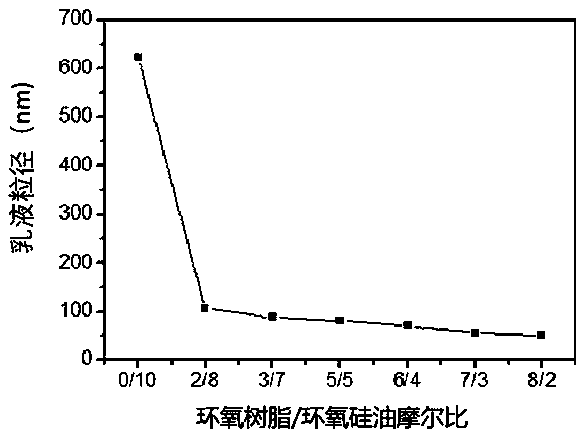

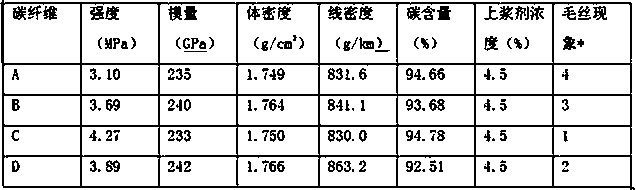

Preparation method of cationic amino modified epoxy silicone oil and compounding and application of polyacrylonitrile carbon fiber precursor oil agent

The invention relates to a preparation method of self-assembled self-emulsified water-based cationic amino modified epoxy silicone oil and compounding and application of polyacrylonitrile carbon fiberprecursor oil. A certain amount of hydrophilic M1 and hydrophobic primary amine (R-NH2) or a secondary diamine (R1NH-R-NHR1) are put into a reaction kettle, heating is executed to 50-80 DEG C for melting or dissolving, then a certain amount of epoxy resin and a certain amount of epoxy silicone oil are added, reaction occurs for 2-6 hours under a nitrogen atmosphere at 90-115 DEG C, cooling is executed to room temperature to obtain amino modified epoxy silicone oil (AMOA), and a salt forming agent is added into a reaction kettle for neutralization; and after even stirring, a certain amount ofwater is added for emulsification to obtain a self-assembled self-emulsified aqueous cationic amino modified epoxy silicone oil emulsion. AMOA is compounded with one or more of auxiliary silicone oilsAMS1, AMS2 and AMS3, other additives and deionized water are added, and polyacrylonitrile carbon fiber protofilament oil agent is prepared under stirring. The oil agent is applied to a polyacrylonitrile carbon fiber production line.

Owner:吉林乾仁新材料有限公司

Preparation process of color paint steel plate

ActiveCN105295677AExcellent heat resistance temperatureExcellent adhesion and processabilityPolyester coatingsSolventMicrometer

The invention discloses a preparation process of a color paint steel plate. A weather-resistant steel plate is prepared by coating and baking a pre-coated steel plate by virtue of a bottom prime paint, wherein the coating and baking step includes: smearing color paint on the surface layer of the pre-coated steel plate, wherein the thickness of the coating is 3 to 15 micrometers, after the smearing, sending the steel plate into an electric furnace, baking the steel plate for 1 to 6 hours, and then obtaining the color paint steel plate. Saturated carboxylated polyester is used as a base material of the prime paint, in the real application, since the saturated carboxylated polyester has excellent heat resistance, excellent adhesion and machinability for a metal material, excellent solvent resistance and good high heat hardness, can be used for being smeared on the metal surface such as an iron material, an aluminum material, stainless steel and the like and is widely applied to the heat resisting materials such as a baking tray, an electric frying pan and a roaster.

Owner:佛山市高悦五金电器有限公司

Gradient Silicone Heat Resistant Coating

ActiveCN103113826BExcellent heat resistance temperatureSolve the problem of narrow heat-resistant temperature rangeCoatingsEpoxySolvent

The invention relates to a gradient organic silicon heat-resisting coating which is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of no less than 65wt% epoxy modified organic silicon resin solution, 0.5 parts of dispersing agent BYK-110, 0.6 parts of organobentonite, 10-15 parts of dye, 3-5 parts of mica powder with the granularity of 350-450 meshes, 5-10 parts of precipitated barium sulphate with the granularity of 350-450 meshes, 5-10 parts of M-1 glass material, 5-8 parts of B-11 glass material, 5-10 parts of B-12 glass material and 5-10 parts of mixing solvent (the ratio of dimethylbenzene to butanol is 7:3), wherein the epoxy modified organic silicon resin solution is prepared from the following raw materials in parts by weight: 30-40 parts of E-20 epoxy resin, 50-60 parts of 65-70wt% organic silicon middle body, and 5-10 parts of dimethylbenzene. The coating can be used for solving the defects that the conventional organic silicon product is low in thermal resistance when being compared with an inorganic coating, and the coating has good thermal-resistance. The coating provided by the invention is applicable to decoration and protection of a large-sized thermal-resisting component, and the coated component can endure high temperature of 400-1,000 DEG C for long term.

Owner:西安经建油漆有限责任公司

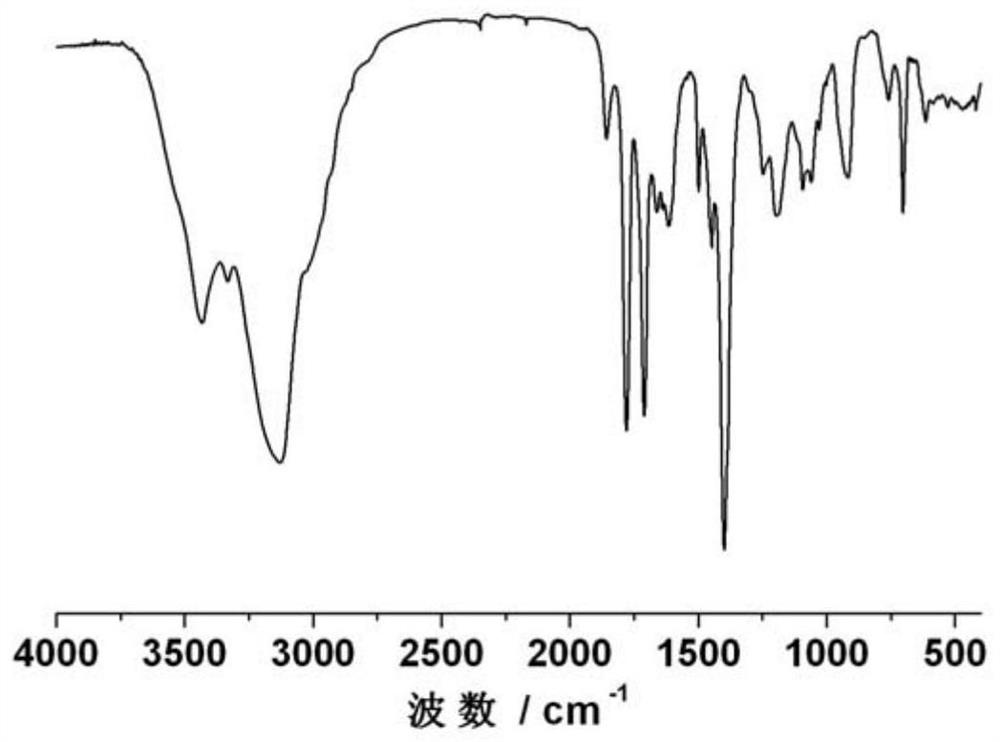

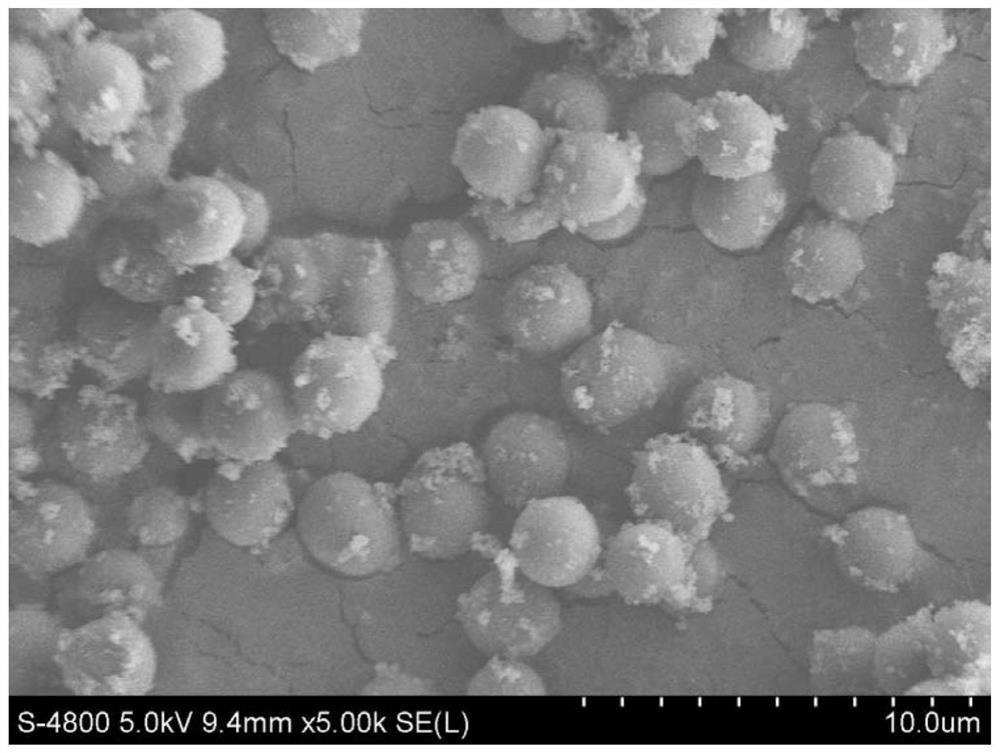

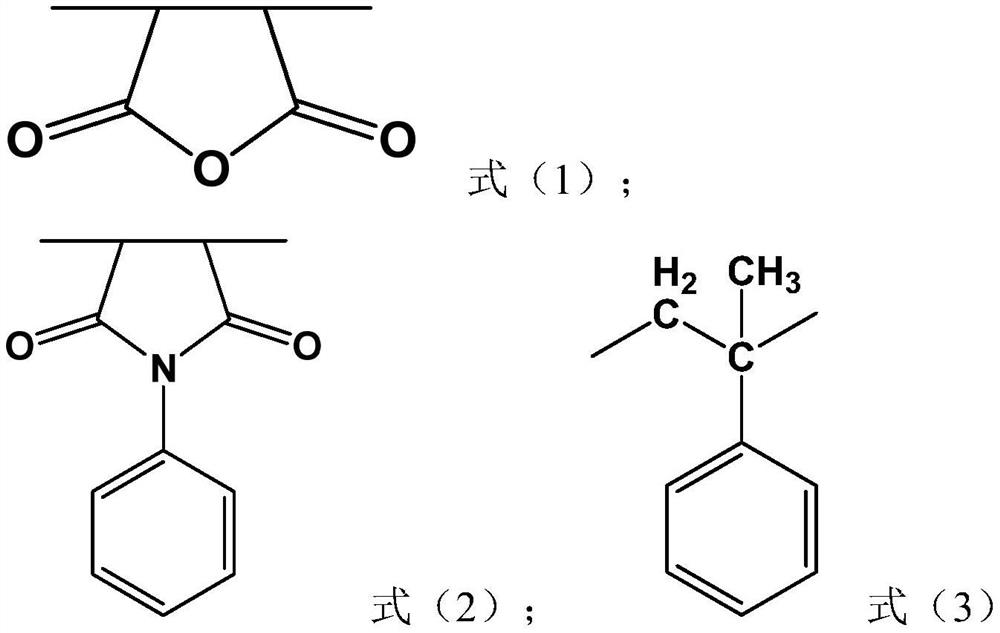

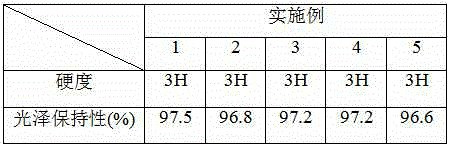

Maleic anhydride/N-phenylmaleimide/alpha-methylstyrene copolymer microsphere as well as preparation method and application thereof

The invention relates to the field of high-molecular polymerization, and discloses a maleic anhydride / N-phenylmaleimide / a-methyl styrene copolymer microsphere as well as a preparation method and an application thereof. A copolymer in the copolymer microsphere comprises a structural unit shown in a formula (1), a structure shown in a formula (2) and a structural unit shown in a formula (3), based on the total molar weight of each structural unit of the copolymer, the molar content of the structural unit shown in the formula (1) is 30-52%, the molar content of the structural unit shown in the formula (2) is 5-30%, and the molar content of the structural unit shown in the formula (3) is 20-45%. The copolymer microsphere has the advantages of clean surface, uniform particle size and simple preparation process, and can be used as a heat-resistant modifier for polymers, especially polypropylene, thereby enhancing the heat-resistant temperature of the polymers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of coating for heat-resistant steel plate

InactiveCN104449366AExcellent heat resistance temperatureExcellent adhesion and processabilityAnti-corrosive paintsSolventPolyamide

The invention discloses a preparation method of a coating for a heat-resistant steel plate. The preparation method comprises the steps of with organic silicon modified polyester resin as a coating matrix, adding auxiliary materials including pigment, a polyamide curing agent, filler, a siloxane coupling agent and a solvent, and mixing; and grinding by using a ball mill to form paste with the fineness of 10-20mu m. In actual use, the organic silicon modified polyester resin has relatively good high temperature resistance, so that the coating prepared from the organic silicon modified polyester resin has favorable property, can be sprayed on the surface of metal such as an iron material, an aluminum material or stainless steel and is widely applied to a heat-resistant material such as a baking tray, an electric frying pan and a grilling apparatus.

Owner:CHENGDU JINHUI TECH

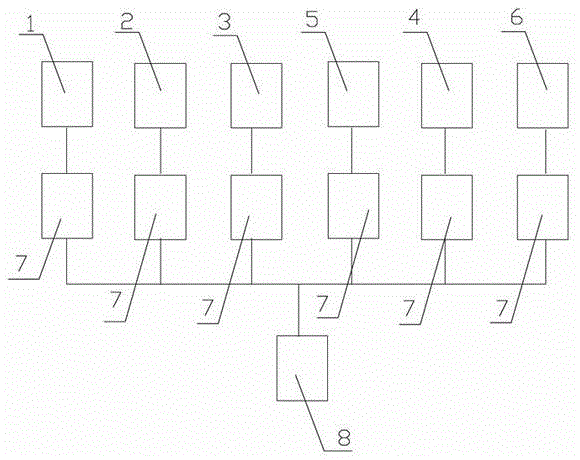

Non-woven interior decoration material used for vehicle and containing silver-loaded titanium dioxide and preparing system thereof

ActiveCN105420973ARelease rate is stable and long-lastingLittle color impactSucessive textile treatmentsFibre treatmentControl systemEngineering

The invention relates to the technical field of non-woven fabric processing, in particular to a non-woven interior decoration material used for a vehicle and containing silver-loaded titanium dioxide and a preparing system thereof. The non-woven interior decoration material is characterized by comprising a mixed liquor preparing system, a padding system, a heat braking system, an air cooling system, a setting system, a clipping system, an emergency shutdown system and a comprehensive control system. The mixed liquor preparing system, the padding system, the heat braking system, the air cooling system, the setting system and the clipping system are in signal connection.

Owner:DEYANG YONGSHENG NONWOVEN PROD

A weather-resistant steel plate

ActiveCN104403521BExcellent heat resistance temperatureGood solvent resistanceLayered productsPolyester coatingsWeather resistancePolyester resin

The invention discloses a weather-resistant steel plate which is prepared from a pre-coated steel plate coated and roasted by a basic coating and a surface coating sequentially. The basic coating and the surface coating used by the invention are prepared from organosilicone modified polyester resin as a base material and other auxiliaries. According to the weather-resistant steel plate disclosed by the invention, due to excellent heat resisting temperature, excellent adhesiveness and processibility on metal materials, excellent solvent resistance, good high-heat hardness and the like, the organosilicone modified polyester resin can be used for being sprayed on metal surfaces of iron materials, aluminum products or stainless steel and the like and can be widely applied to heat-resisting materials, such as a petroleum refining furnace, an aluminum refining furnace, an engine exhaust system and an engine silencer, which are in a high-temperature working condition for a long time.

Owner:GUANGDONG ARMSTRONG METAL CEILING PRODS

Manufacturing process of weather-resistant steel plate

InactiveCN104399658AExcellent heat resistance temperatureGood solvent resistanceLiquid surface applicatorsPolyester coatingsPolyester resinTemperature resistance

The invention discloses a manufacturing process of a weather-resistant steel plate. The manufacturing process is characterized in that a base coating and a surface coating are sequentially coated and roasted on a pre-coating steel plate, wherein the base coating and the surface coating used are prepared through silicone modified polyester resin serving as the base materials of the coating composite and other auxiliaries; when in actual use, the silicone modified polyester resin is outstanding in high temperature resistance, so that the resulting coating composite is of high property and can be coated to the surfaces of iron, aluminum or stainless steel and other metals; the coating composite can also be widely applied to heat-resisting materials used in a high-temperature working state for a long term, such as an oil refining furnace, an aluminum refining furnace, an engine exhaust system and a silencer of a motor vehicle.

Owner:CHENGDU JINHUI TECH

A flame retardant material for lithium battery shell based on long glass fiber reinforced polypropylene and its preparation method

The invention discloses a lithium battery shell flame-retardant material based on long glass fiber reinforced polypropylene and a preparation method thereof. The lithium battery shell flame-retardant material is prepared from the following components in parts by weight: polypropylene, continuous glass fiber , coupling agent, main antioxidant, auxiliary antioxidant, lubricant, compatibilizer, composite flame retardant and black masterbatch. The preparation method is to put the above components except the continuous glass fiber into the high mixer and mix them evenly before entering the extruder, and then the extruder melts and extrudes the above materials into the impregnation equipment, and at the same time the continuous glass fiber enters the impregnation equipment It is dispersed and impregnated with the molten material, and finally pulled out from the shaping die of the impregnation equipment, cooled, dried, and pelletized to obtain the finished product. The invention has more excellent strength and toughness, is not easy to burn under an open flame, can effectively reduce the occurrence of battery burning accidents, and ensures that the shell has good plasticity and compressive strength.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com