Gradient Silicone Heat Resistant Coating

A technology of heat-resistant coatings and organic silicon, which is applied in coatings and other directions, can solve the problems of poor self-drying performance and narrow heat-resistant temperature range of coatings, and achieve the effects of increased heat-resistant temperature, good anti-corrosion performance, and good drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

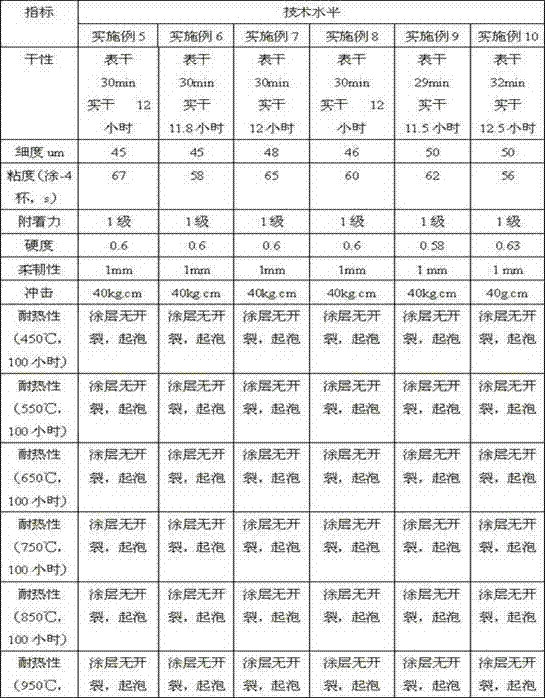

Examples

Embodiment 1

[0020] The synthesis process step of epoxy modified silicone resin solution of the present invention is as follows:

[0021] 1) Synthesis of organosilicon intermediates: Take 15kg of phenyltrichlorosilane, 8kg of dimethyldichlorosilane, 35kg of xylene, 30kg of ethanol, and 12kg of deionized water; Add 1 / 2 xylene to the hydrolysis kettle, drop the mixture of phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / 2 xylene from the high position tank, and control the flow rate at 5.5 hours (at 5-6 within hours) after the dropwise addition, the hydrolysis temperature is controlled at 22°C (all within the range of 20-25°C), keep stirring for half an hour after the dropwise addition, and stand still for 3.5 hours (all within the range of 3-4 hours ), so that the chlorine ions and hydrogen ions in the above raw materials combine to generate hydrochloric acid and precipitate in the lower part of the hydrolysis kettle; let go of the acid water in the lower part of the hydrol...

Embodiment 2

[0024] The synthesis process step of epoxy modified silicone resin solution of the present invention is as follows:

[0025] 1) Synthesis of organosilicon intermediates: Take 20kg of phenyltrichlorosilane, 10kg of dimethyldichlorosilane, 40kg of xylene, 35kg of ethanol, and 15kg of deionized water; Add 1 / 2 xylene to the hydrolysis kettle, drop the mixed solution of 1-phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / 2 xylene from the high position tank, control the flow rate at 6 hours to complete the dropwise addition, and hydrolyze The temperature is controlled at 25°C. After the dropwise addition, keep stirring for half an hour, and stand still for 4 hours, so that the chloride ions and hydrogen ions in the above raw materials combine to form hydrochloric acid and precipitate in the lower part of the hydrolysis kettle; let go of the acid water in the lower part of the hydrolysis kettle, and add Ionized water (dosage is not included in the formula), washed wi...

Embodiment 3

[0028] The synthesis process step of epoxy modified silicone resin solution of the present invention is as follows:

[0029] 1) Synthesis of organosilicon intermediates: Take 20kg of phenyltrichlorosilane, 10kg of dimethyldichlorosilane, 40kg of xylene, 35kg of ethanol, and 15kg of deionized water; Add 1 / 2 xylene to the hydrolysis kettle, drop the mixed solution of 1-phenyltrichlorosilane, dimethyldichlorosilane and the remaining 1 / 2 xylene from the high position tank, control the flow rate at 6 hours to complete the dropwise addition, and hydrolyze The temperature is controlled at 25°C. After the dropwise addition, keep stirring for half an hour, and stand still for 4 hours, so that the chloride ions and hydrogen ions in the above raw materials combine to form hydrochloric acid and precipitate in the lower part of the hydrolysis kettle; let go of the acid water in the lower part of the hydrolysis kettle, and add Ionized water (dosage is not included in the formula), washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com