A kind of high-strength biodegradable plastic and preparation method thereof

A biodegradable plastic, high-strength technology, applied in the field of high-strength biodegradable plastics and its preparation, can solve the problem of simultaneous completion of toughening modification and heat-resistant modification, restrictions on the application of polylactic acid, heat-resistant modification of polylactic acid and toughening and modification problems, to achieve the effect of improving photocatalytic effect, improving degradation rate and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

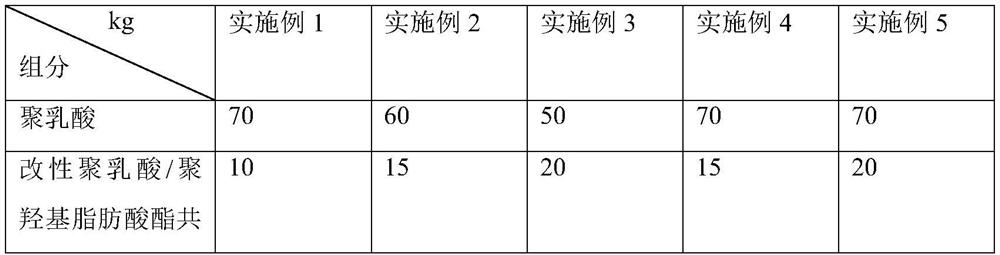

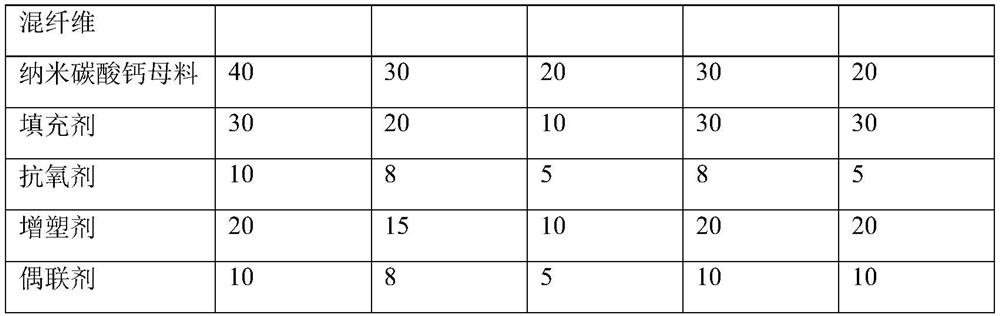

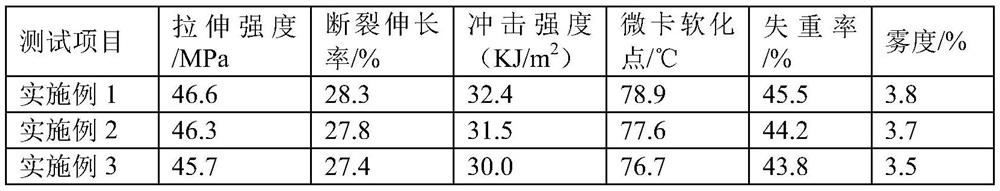

Examples

preparation example 1-4

[0045] In Preparation Examples 1-4, anatase-type titanium dioxide was selected from Nanjing Hongde Nanomaterials Co., Ltd., model HDZY13; silane coupling agent was selected from Dongwanshi Changhe Chemical Co., Ltd., model KH550; polyethyleneimine was selected from Shandong Deng Nuo Chemical Co., Ltd., model PEI.

preparation example 1

[0046] Preparation Example 1: (1) ultrasonically disperse 1kg of anatase titanium dioxide in 2kg of sodium hydroxide solution with a mass fraction of 0.2%, place it at 150 ° C for hydrothermal treatment for 20h, filter, wash and dry to obtain titanium dioxide nanotube;

[0047] (2) The titanium dioxide nanotubes prepared in step (1) were added to 3 kg of methanesulfonic acid aqueous solution, heated to 80° C. in a water bath, acidified for 4 h, and then added to a mixture of 0.2 kg of toluene, 0.5 kg of silane coupling agent and 1 kg of deionized water. In the solution prepared by mixing water, the water bath is heated to 80 ° C, the temperature is kept for 6 h, and then dried to obtain aminopropylated titanium dioxide nanotubes;

[0048] (3) adding 3kg aminopropylated titanium dioxide nanotubes and 0.5kg hexamethylenetetramine to 1kg concentration of ethanolic solution in the zinc acetate of 0.01mol / L, placing at 280 ° C and heat treatment for 30min, cooling after centrifugal...

preparation example 2

[0049] Preparation Example 2: The difference from Preparation Example 1 is that the mass ratio of zinc acetate, aminopropylated titanium dioxide nanotubes and polyethyleneimine aqueous solution is 0.5:0.7:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com