Patents

Literature

38results about How to "Little color impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

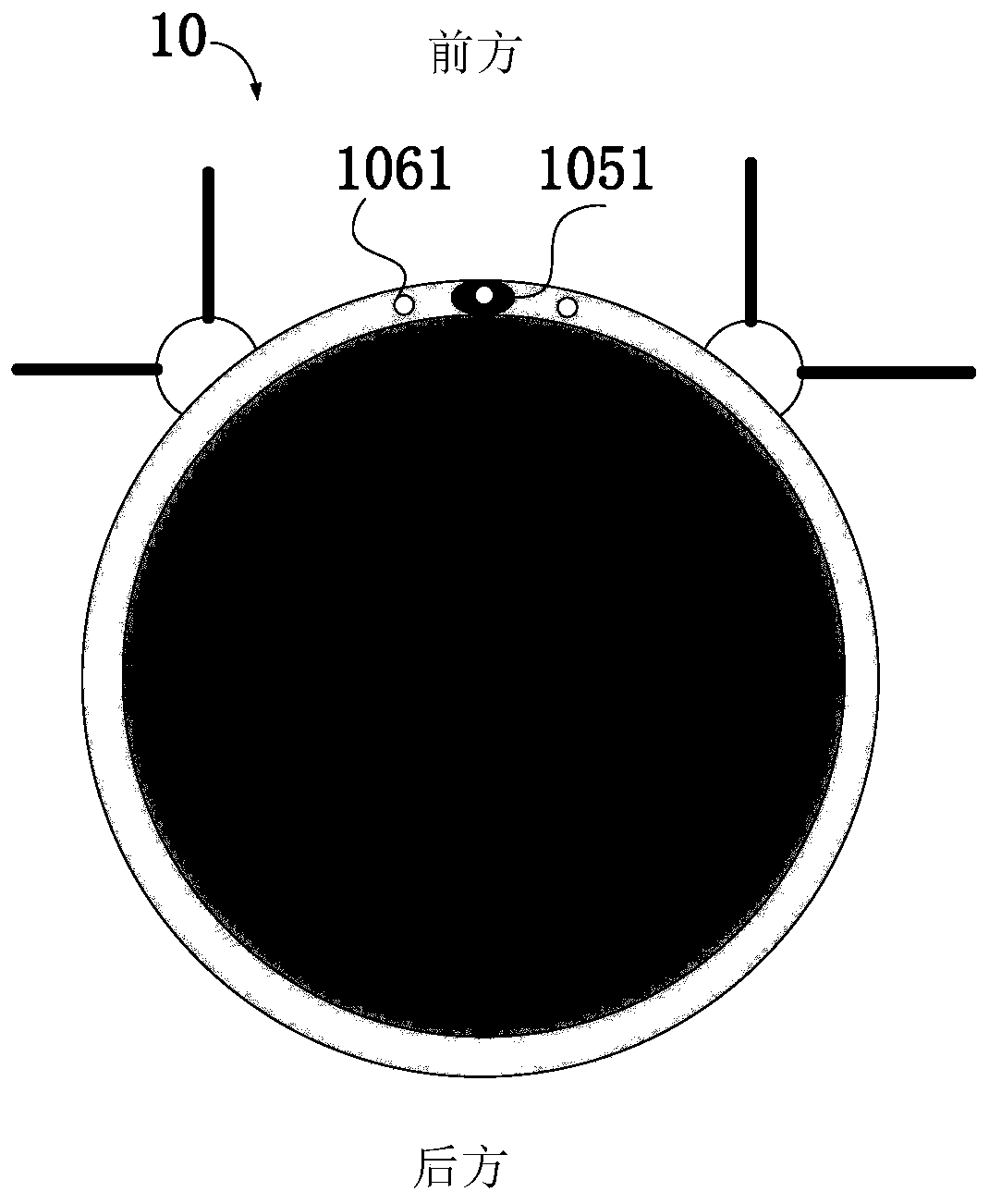

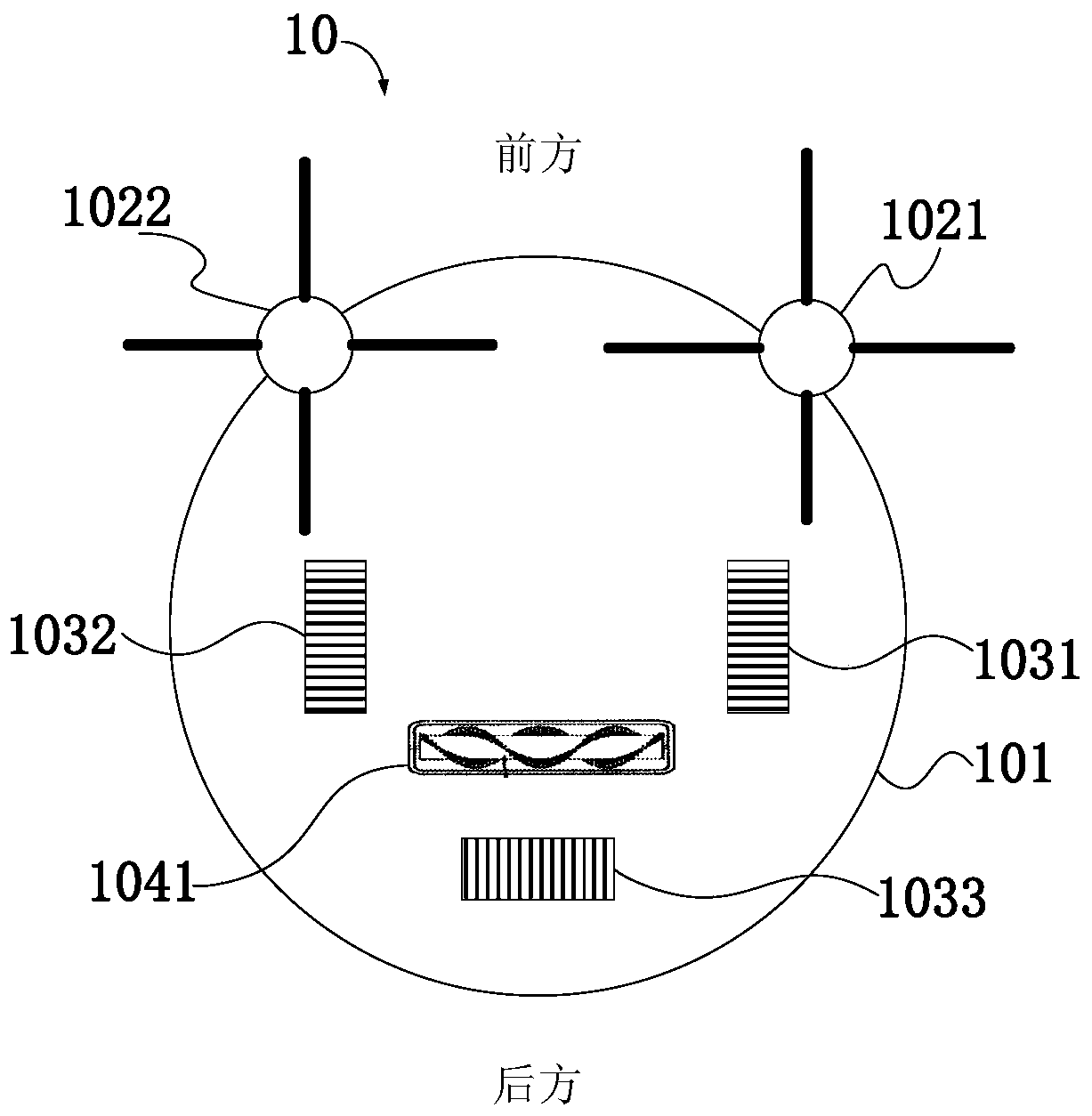

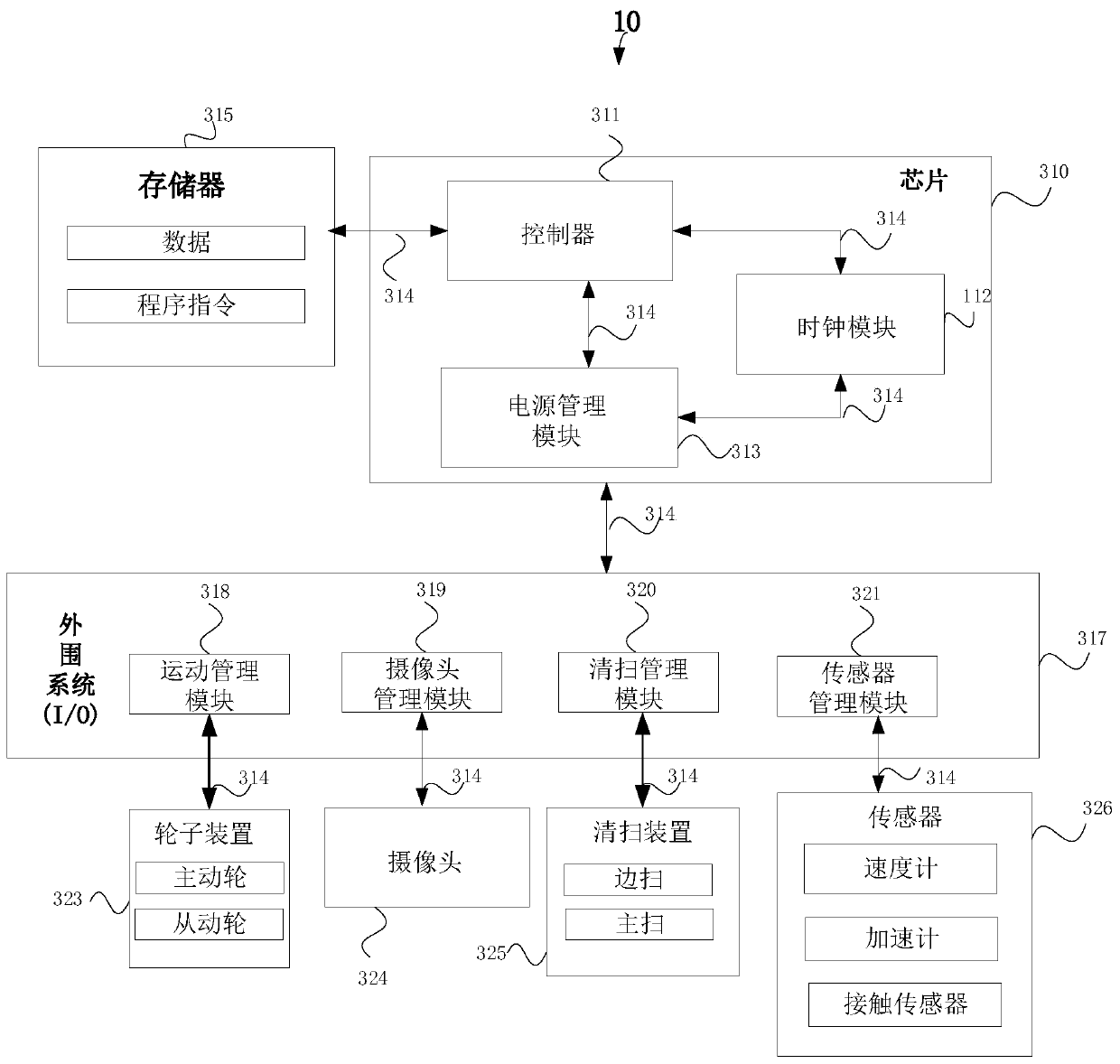

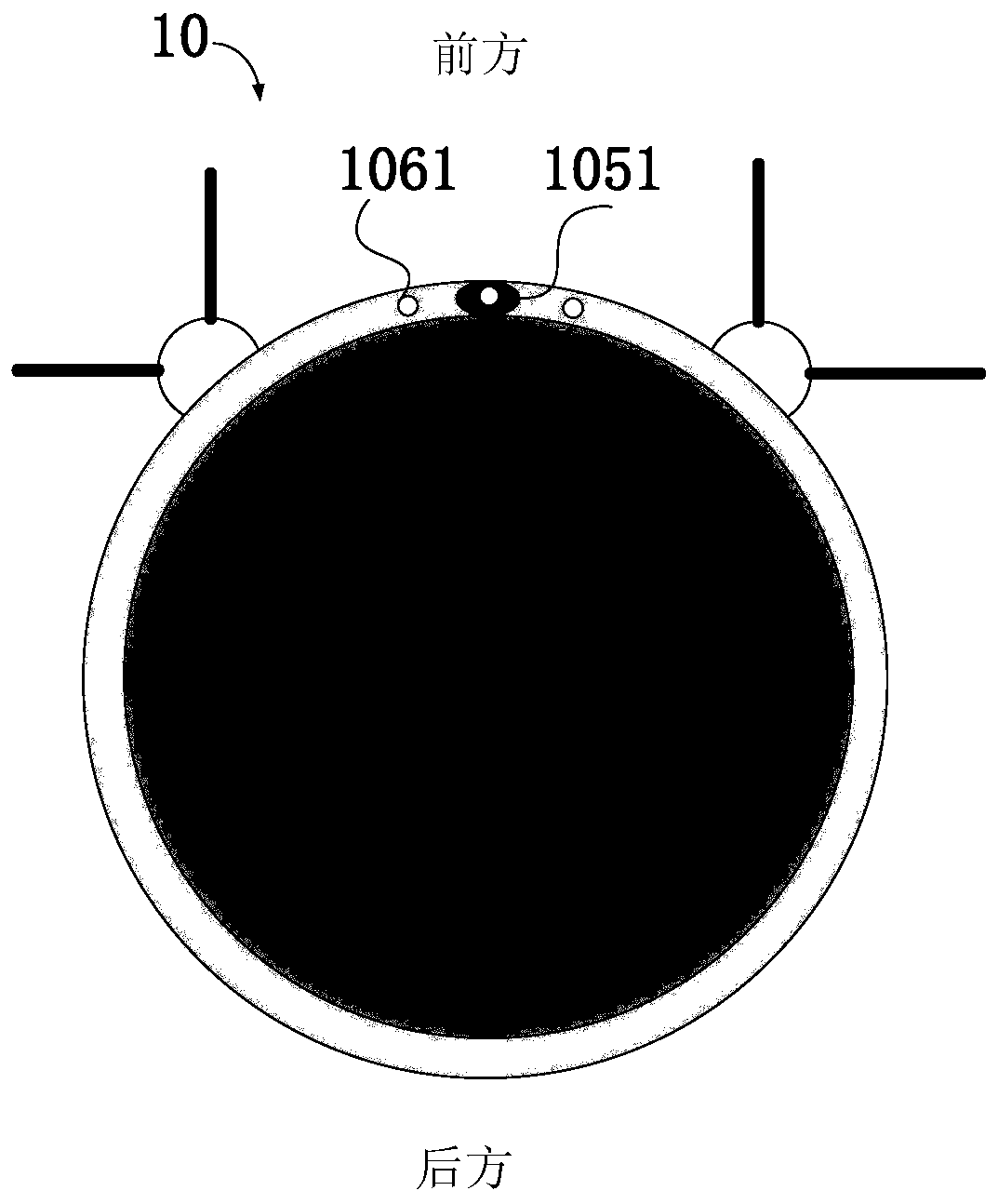

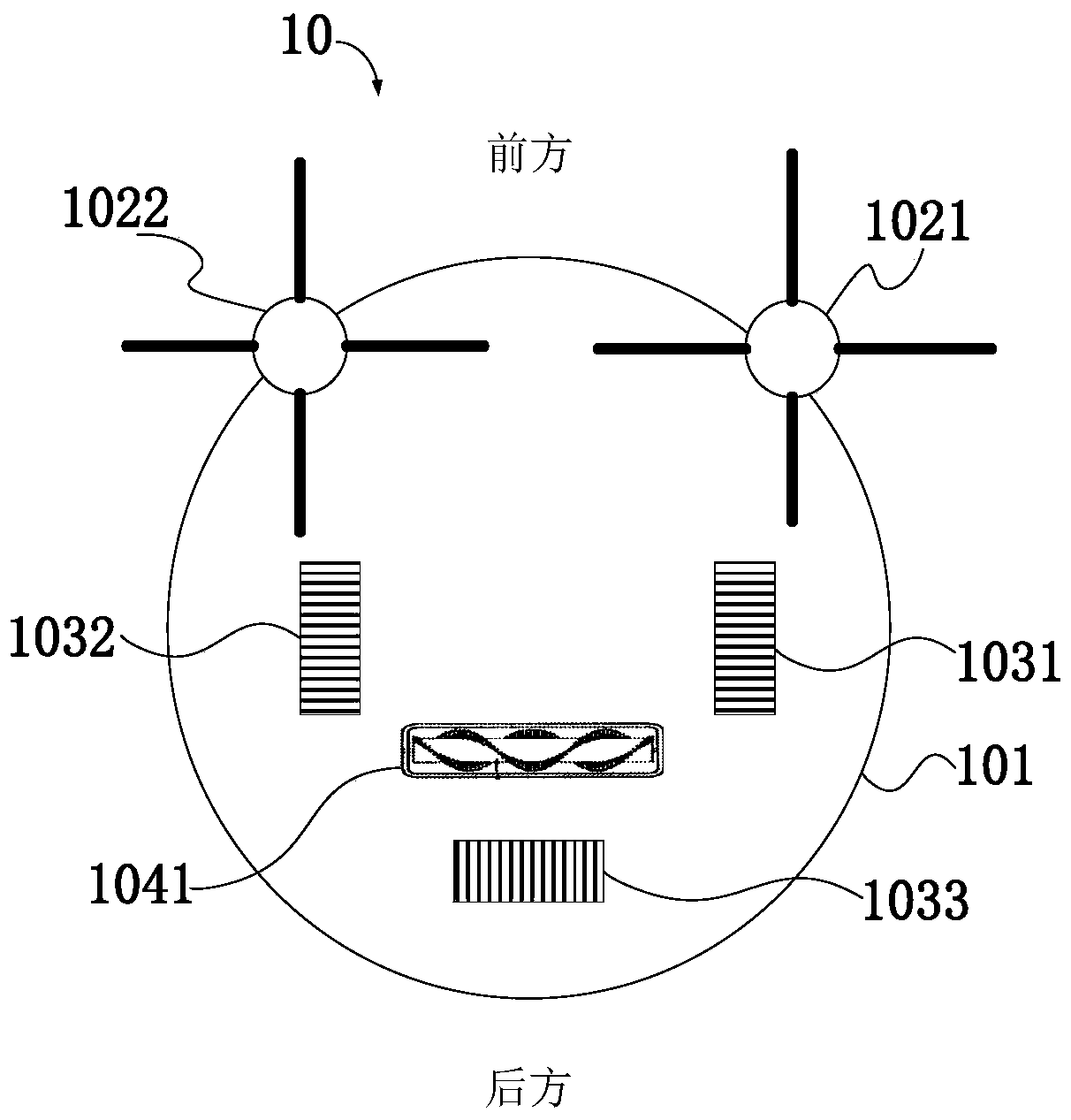

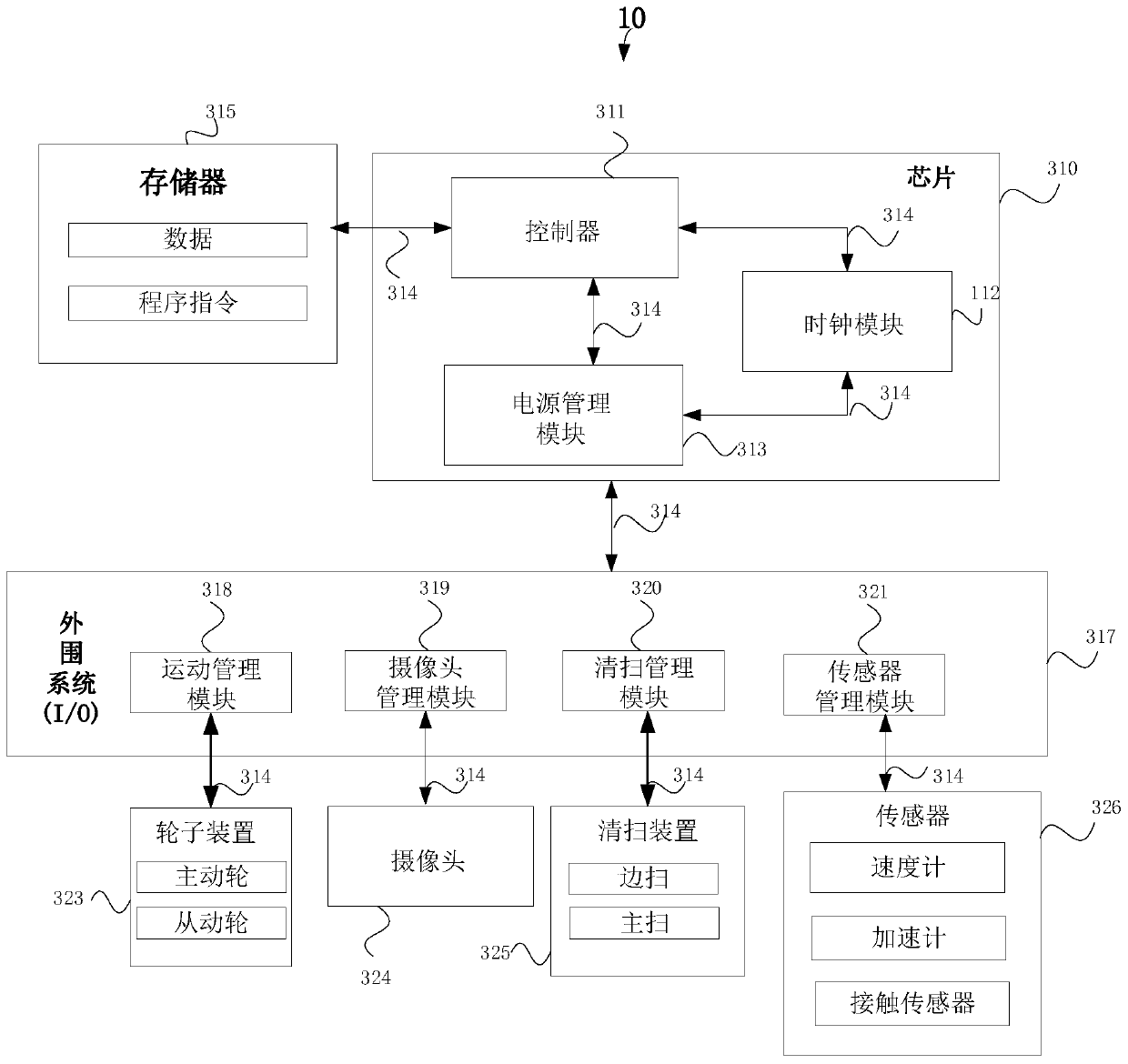

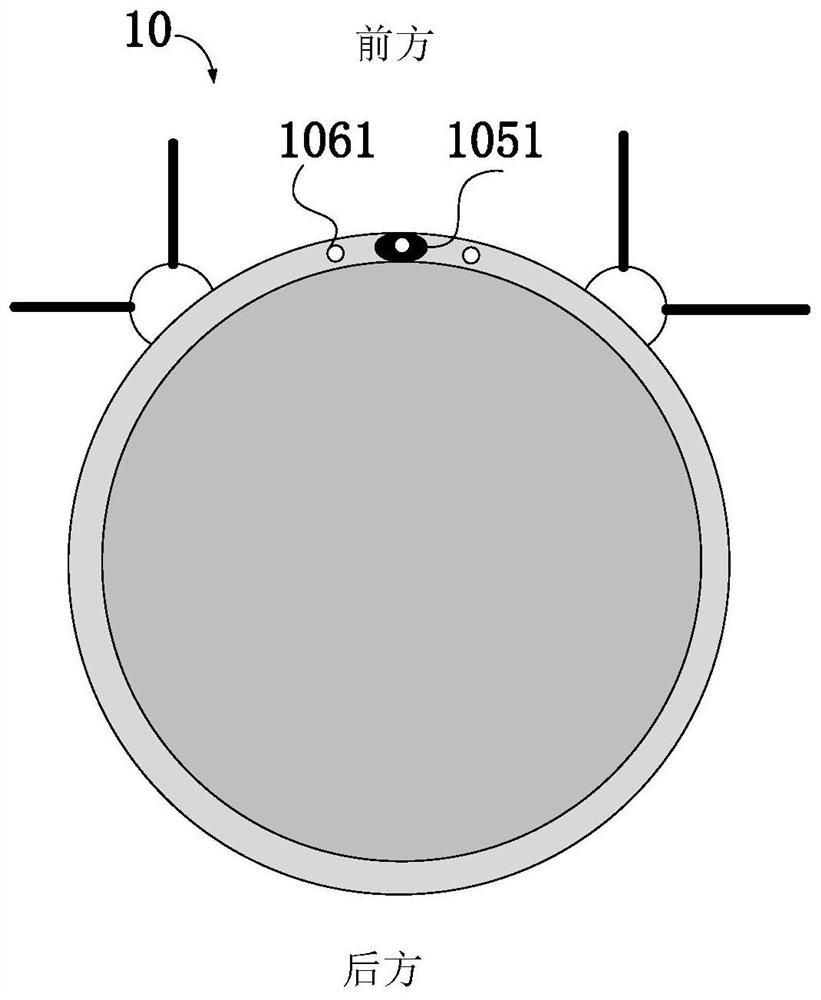

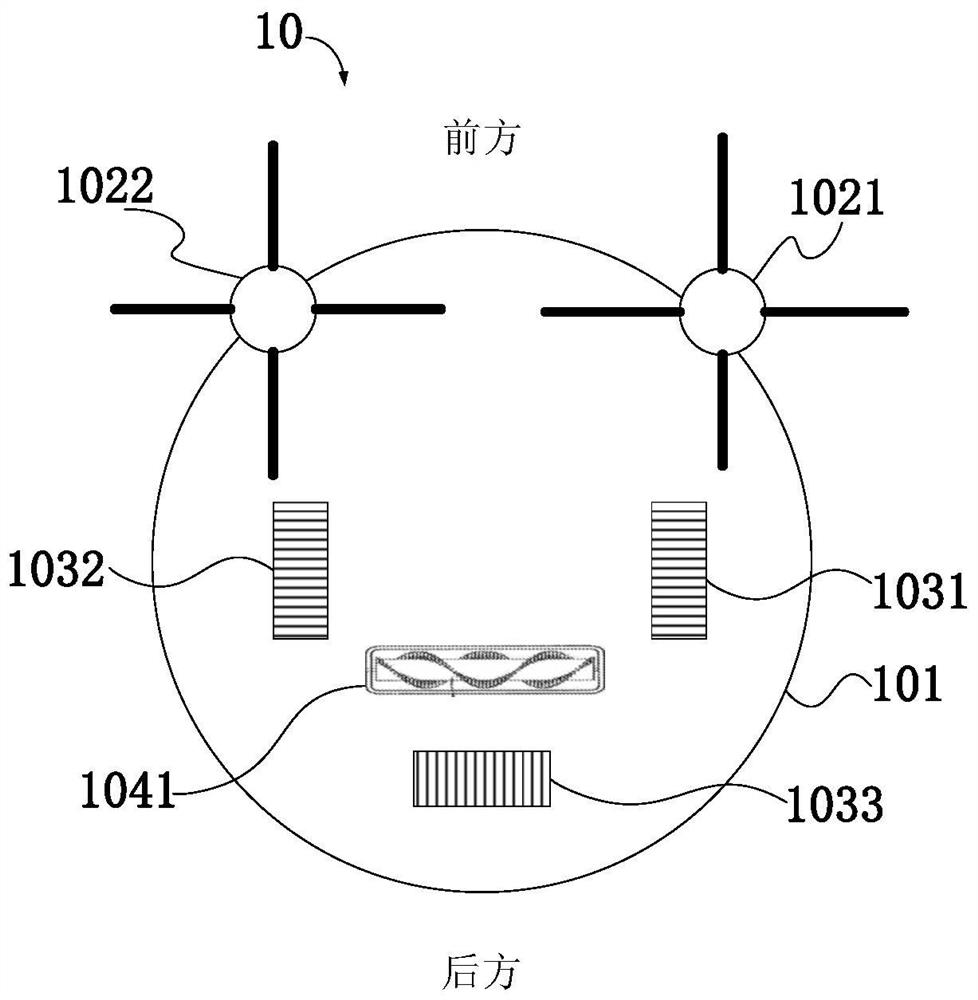

Obstacle processing method and cleaning robot

ActiveCN111067439AImprove cleaning coverageReduce riskAutomatic obstacle detectionTravelling automatic controlEdge mapsEngineering

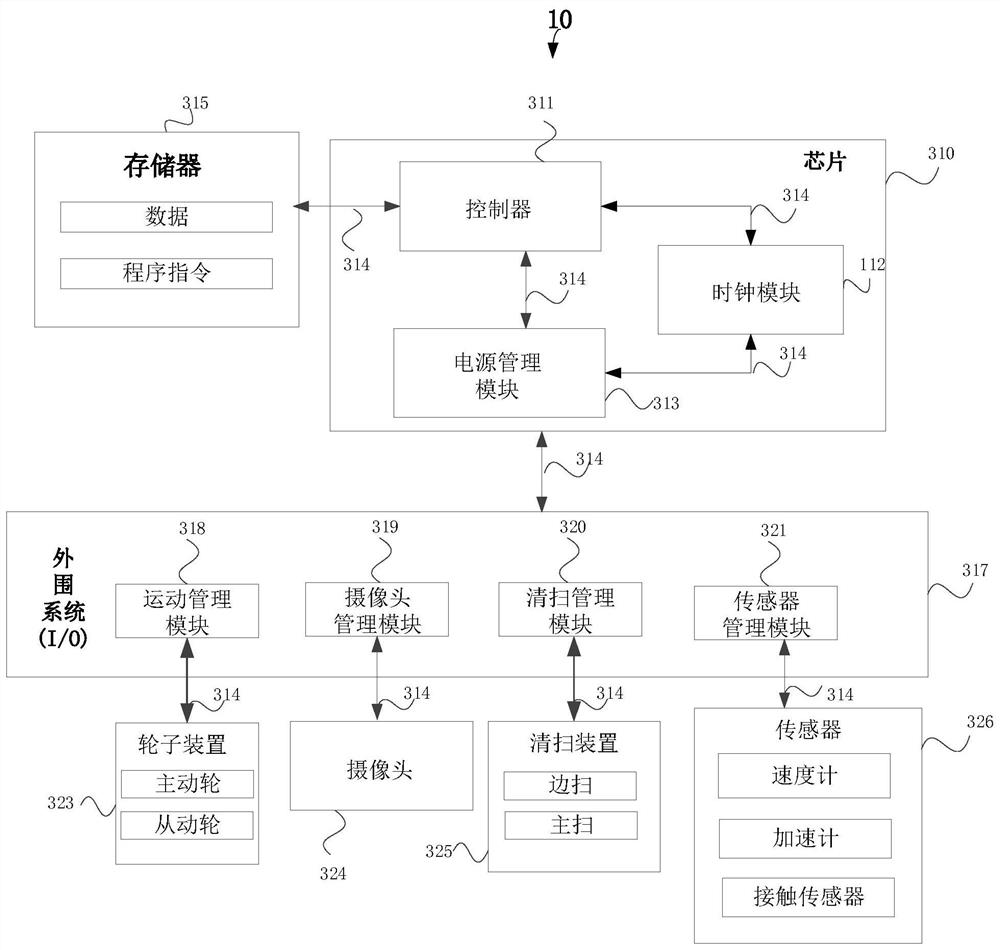

The invention provides an obstacle processing method and a cleaning robot. The cleaning robot comprises a controller, an image acquisition device, a robot body and a side sweeper, and the side sweeperextends to exceed the edge of the robot body. The image acquisition device is used for acquiring a first image of an obstacle in the advancing direction of the cleaning robot. The controller is usedfor identifying the type of the obstacle according to the first image of the obstacle; determining an obstacle processing mode corresponding to the type of the obstacle, the obstacle processing mode including whether the cleaning robot continues to advance according to the advancing direction before the obstacle, and distance information between the robot body and the obstacle and distance information between the side sweeper and the obstacle when the cleaning robot changes the advancing direction before the obstacle. The controller is used for controlling the cleaning robot to move accordingto an obstacle processing mode corresponding to the type of the obstacle. By implementing the method, the sweeping coverage rate can be increased for different obstacles, and meanwhile, the sweeping risk is reduced.

Owner:SHANGHAI FLYCO ELECTRICAL APPLIANCE

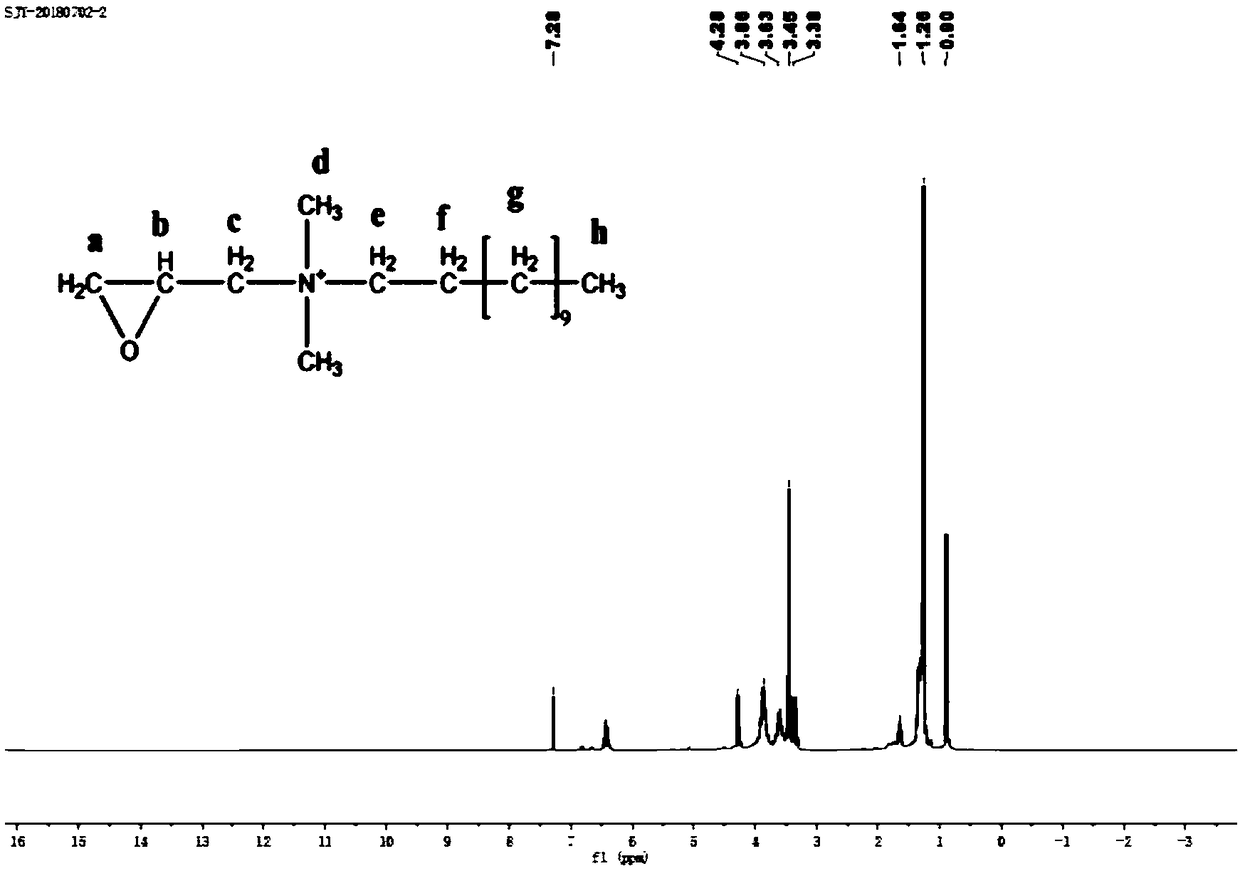

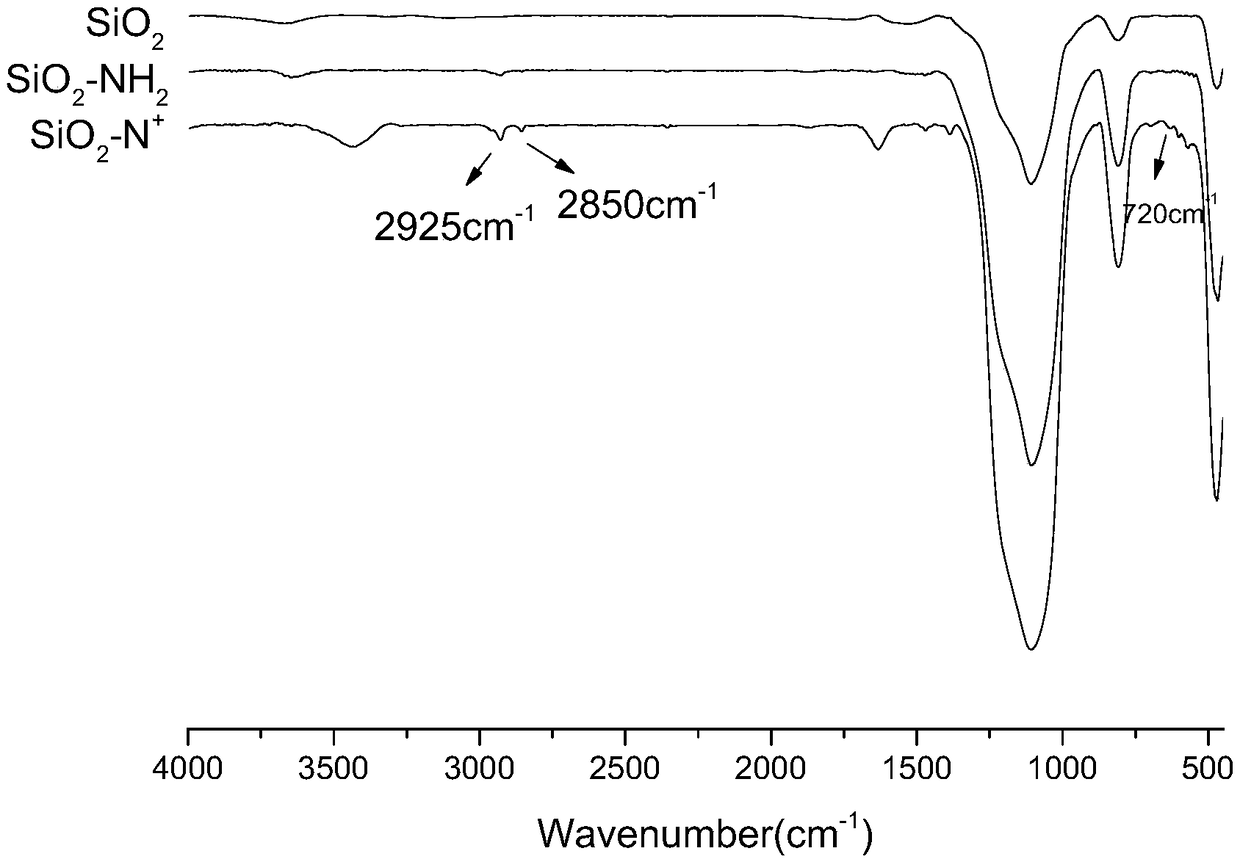

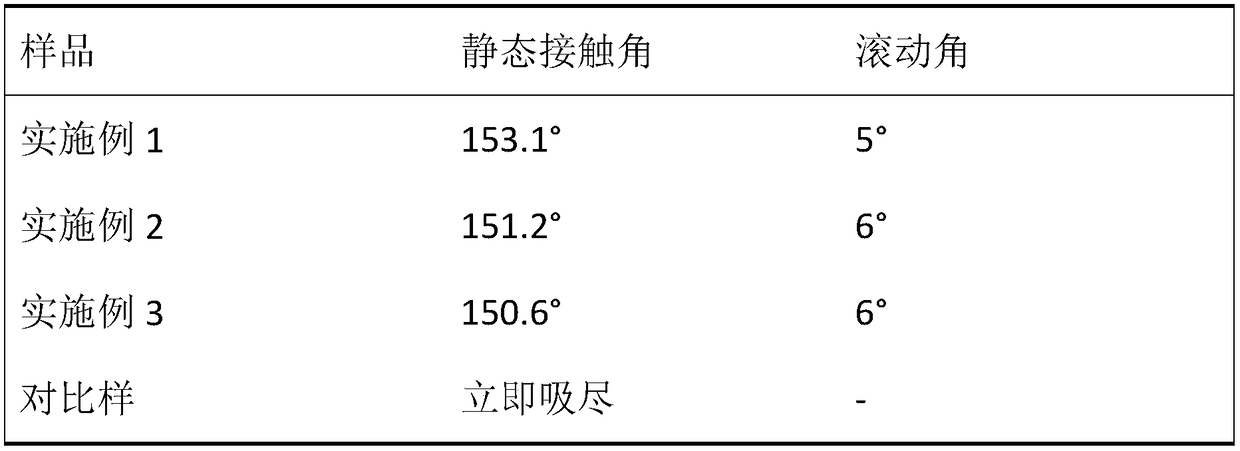

Method for preparing superhydrophobic antibacterial fabric based on quaternary silica

InactiveCN109162091AHas antibacterial functionWon't hurtBiochemical fibre treatmentLiquid repellent fibresSilica particleRough surface

The invention discloses a method for preparing superhydrophobic antibacterial fabric based on quaternary silica. The method comprises the following steps: firstly, an epoxypropyl dimethyl dodecyl ammonium chloride antibacterial compound is synthesized, then silica is modified, the antibacterial compound is grafted onto the surface of silica particles, and silica is endowed with antibacterial property; padding, is performed on the fabric with a mixed dispersion solution of an adhesive and antibacterial silica as a padding solution, then drying and baking are performed, so that the antibacterialsilica particles are fixed on the surface of the fabric, the fabric is endowed with antibacterial performance, and a rough surface required for obtaining superhydrophobicity is constructed; finally,the fabric is further treated with a fluorine-free water repellent, and the superhydrophobic property is obtained. The prepared fabric has excellent antibacterial performance and super hydrophobicity,multifunction of the fabric is achieved, and the preparation method is simple and convenient.

Owner:SOUTH CHINA UNIV OF TECH

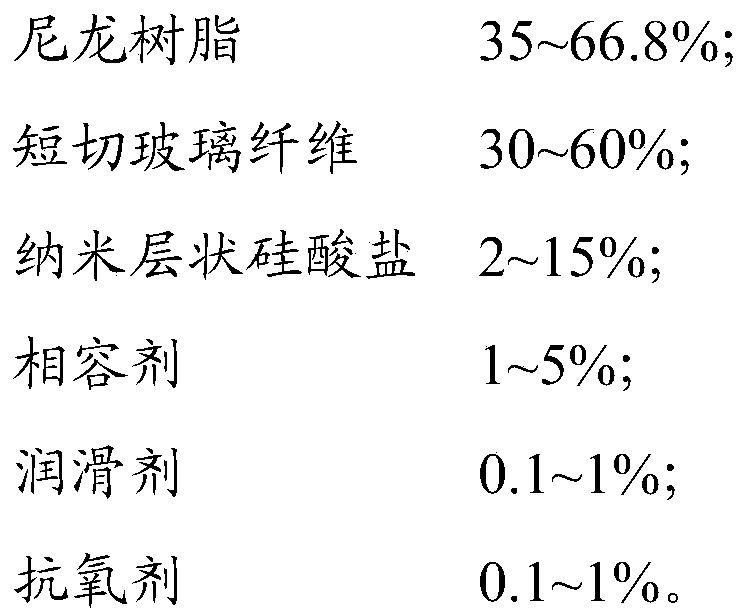

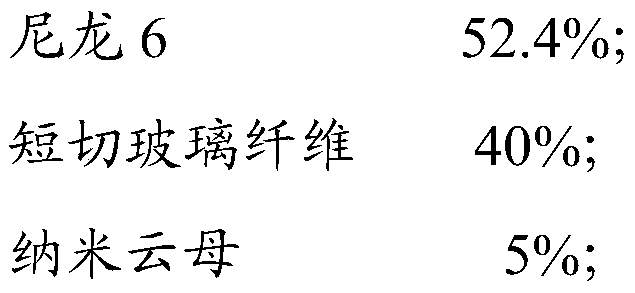

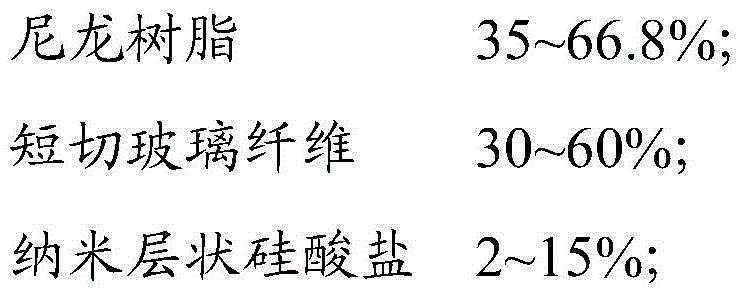

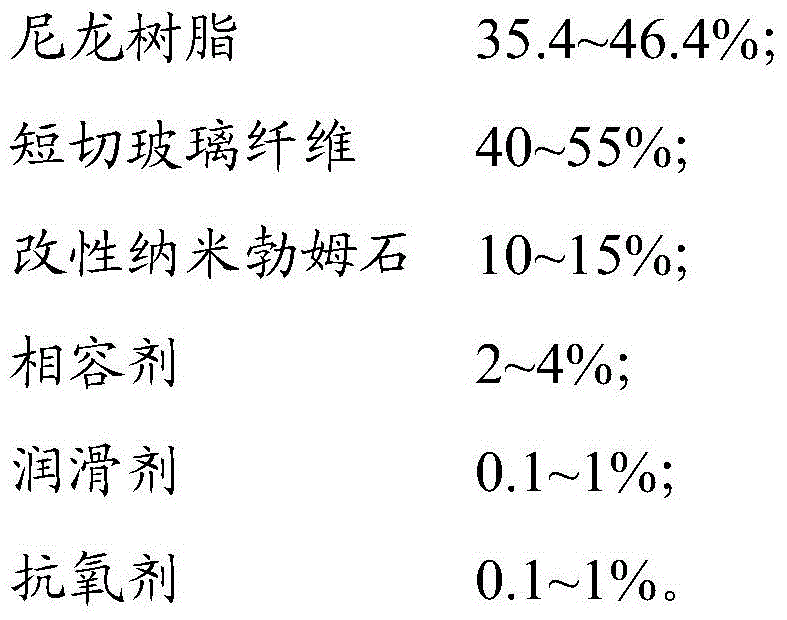

Glass fiber reinforced nylon composite material

The invention provides a glass fiber reinforced nylon composite material. The composite material is prepared from the following components in percentage by weight: 35-66.8 percent of nylon resin, 30-60 percent of chopped glass fibers, 2-15 percent of nano-phyllosilicate, 1-5 percent of compatilizer, 0.1-1 percent of a lubricating agent and 0.1-1 percent of antioxidant. According to the glass fiber reinforced nylon composite material, the nano-phyllosilicate filler and glass fibers are used for synergically reinforcing, advantages of a glass fiber reinforced nylon composite material are maintained, the strength and toughness of the composite material are further improved, the defects of poor size stability, poor surface and the like of the material caused by reinforcing adopting high glass fiber content can be overcome, and the color of the material is little influenced. Furthermore, the glass fiber reinforced nylon composite material has excellent mechanical performance and good fluidity, and can be applied to manufacture of machinery and automobile parts requiring high strength.

Owner:惠州市华聚塑化科技有限公司

Cleaning robot control method and cleaning robot

InactiveCN111067440AImprove cleaning coverageReduce risk or negative impactAutomatic obstacle detectionTravelling automatic controlRobot controlImage identification

The invention provides a cleaning robot control method and a cleaning robot. The cleaning robot comprises a robot body, a controller and an image acquisition device. The image acquisition device is used for acquiring an image of an obstacle in an operation environment of the cleaning robot. The controller is used for identifying the type of the obstacle according to the image of the obstacle, andis also used for determining wall-following distances corresponding to the types of the obstacles, wherein different obstacle types correspond to different wall-following distances. The controller controls the cleaning robot to move along the wall along the boundary of the obstacle according to the wall-following distance corresponding to the type of the obstacle. By implementing the method, the sweeping coverage rate in the walking process along the wall can be increased for different obstacles, and meanwhile, the sweeping risk is reduced.

Owner:深圳飞科机器人有限公司

Hydrophilic softener for towel fabric

ActiveCN105755829AIncreased versatilityGood antibacterial and deodorizing propertiesFibre treatmentOrganic acidPolyester

The invention relates to a fabric softener, in particular to a hydrophilic softener for towel fabric and belongs to the field of textile softeners.The softener comprises the components according to percent by weight: 10-20% of modified amino siloxane, 5-10% of polyether polyester, 1-8% of quaternary ammonium salt, 5-10% of nonionic emulsifying agent, 0.1-0.5% of an organic acid, and 51.5-78.9% of deionized water.The softener is prepared: according to the above-mentioned ratio, adding the modified amino siloxane and the nonionic emulsifying agent into a variable speed mixer first, mixing well, adding the polyether polyester and the quaternary ammonium salt and stirring, and finally adding citric acid and deionized water according to a ratio for emulsification; stirring well, and packaging.The hydrophilic softener is good in quality stability, can impart fluffy and thick handle to the towel fabric without affecting hydrophilicity and color of the towel fabric and is also functional in inhibiting bacteria and removing odor.

Owner:江西氟聚新材料科技有限公司

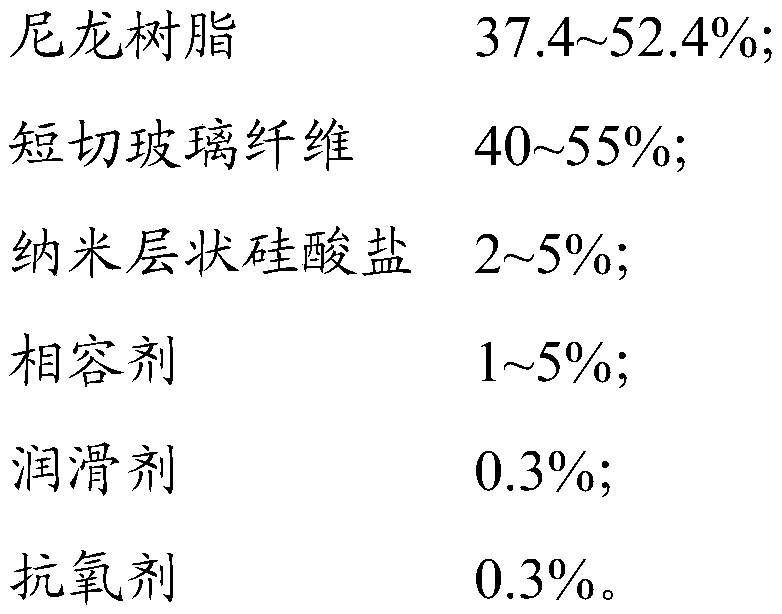

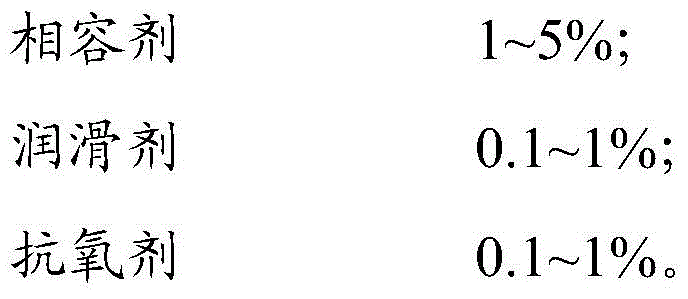

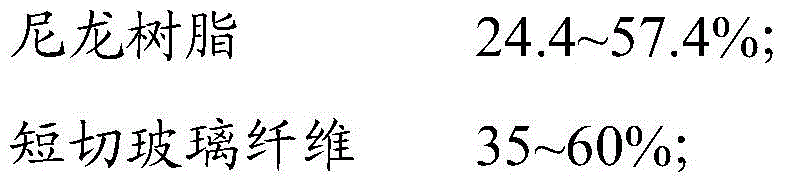

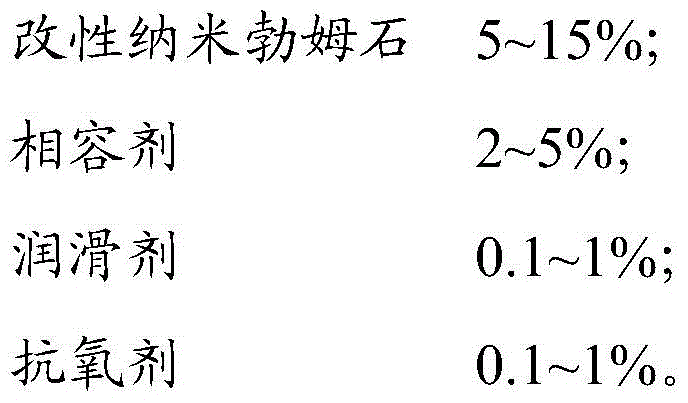

Nylon composite material

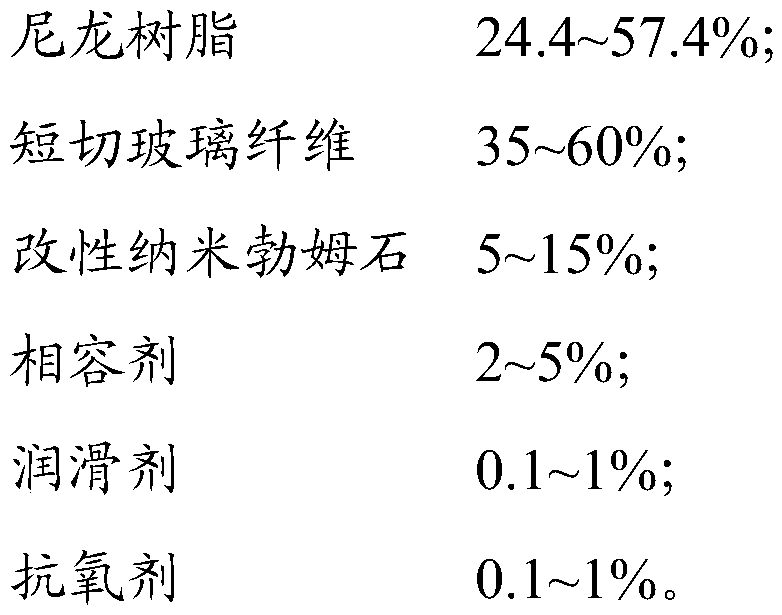

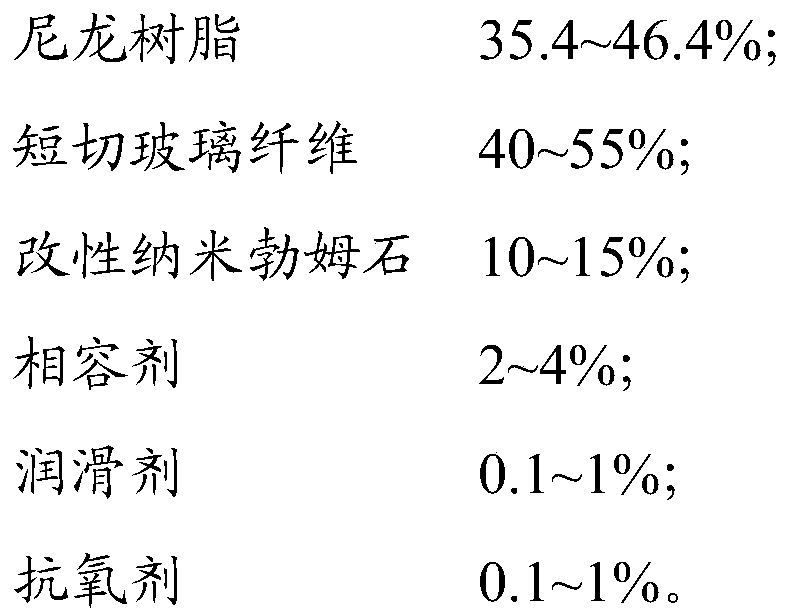

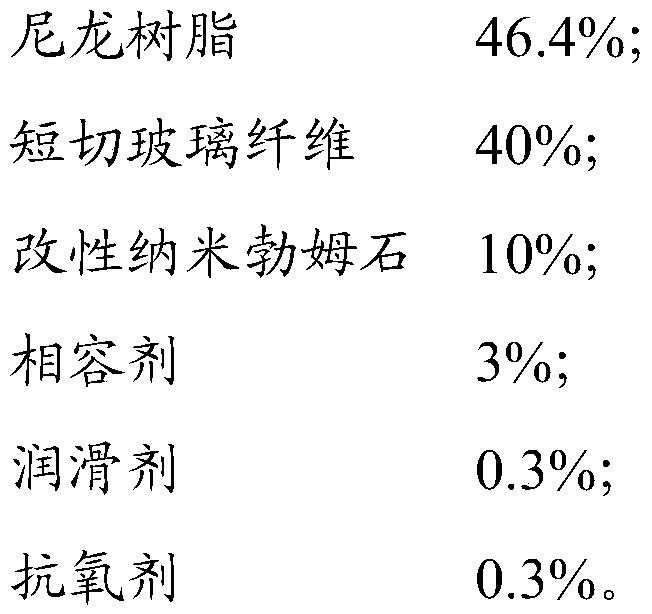

The invention relates to a nylon composite material which comprises the following components in percentage by weight: 24.4-57.4% of nylon resin, 35-60% of chopped glass fiber, 5-15% of modified nano boehmite, 2-5% of compatilizer, 0.1-1% of lubricant and 0.1-1% of antioxidant. The glass-fiber-reinforced nylon composite material has the characteristic of high strength. The modified nano boehmite and glass fibers are used for synergic reinforcement, thereby maintaining the advantages of the glass-fiber-reinforced nylon composite material, enhancing the strength and toughness of the material, overcoming the defects of poor dimensional stability and surface defects of the material due to high glass fiber content and having small influence on the material color. The nylon composite material has the advantages of excellent mechanical properties and favorable flowability, and is applicable to manufacturing of machines and automobile parts in need of high strength.

Owner:惠州市华聚塑化科技有限公司

Acrylic color fixing agent and preparation method thereof

InactiveCN105926329AThe effect of removing floating color is obviousFloating effect is obviousDyeing processYarnFiber

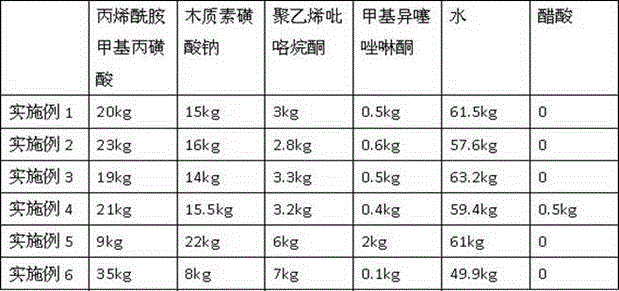

The invention provides an acrylic color fixing agent, comprising the following components according to parts by weight: 10-30 parts of acrylamido methylpropanesulfonic acid, 10-20 parts of sodium lignosulfonate, 1-5 parts of polyvinylpyrrolidone, 0.2-1 part of methylisothiazolinone, and 40-70 parts of water. The invention also provides a preparation method of the acrylic color fixing agent, comprising: mixing well the components according to a matching ratio and reacting at high temperature. Fiber treated with the acrylic color fixing agent of the invention has high color fastness; the acrylic color fixing agent has high affinity to a dye not reacted with the fiber; the impact on color of yarn or fabric color-fixed with the acrylic color fixing agent is low; water can be effectively saved for a dyeing plant, and production efficiency can be effectively improved; the acrylic color fixing agent is a special surfactant and is free of bubbles.

Owner:广东博科纺织科技有限公司

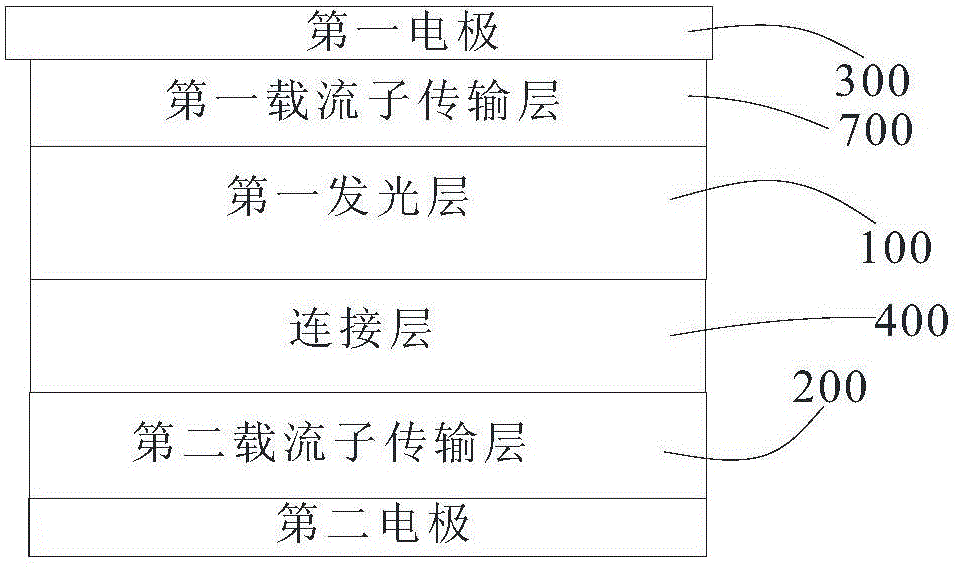

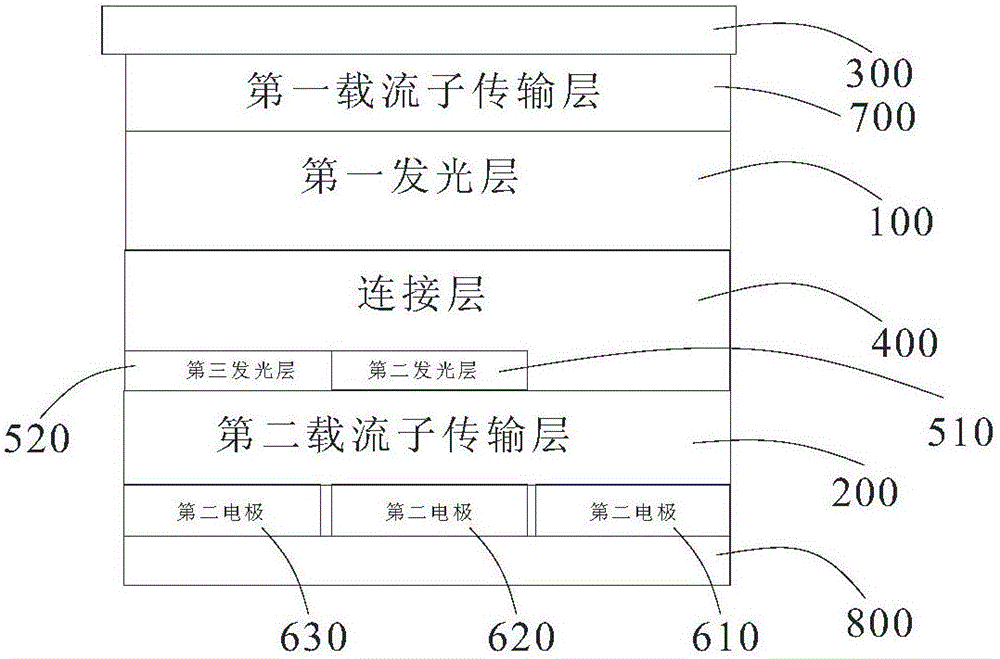

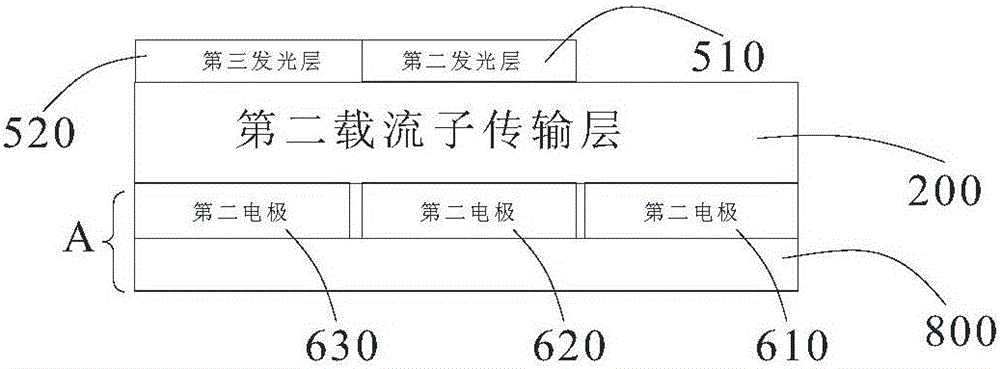

Organic light emitting diode and manufacturing method thereof and display device

ActiveCN105895821ANot easy to quenchSmall defects on the interfaceSolid-state devicesSemiconductor/solid-state device manufacturingDopantTransport layer

The invention provides an organic light emitting diode. The organic light emitting diode comprises a first function part and a second function part which are arranged in a laminating manner; the first function part comprises a first carrier transporting layer and a first light emitting layer which are sequentially arranged in a laminating manner; the second function part comprises a second carrier transporting layer; the first function part and the second function part are produced by adopting different methods; the first function part also comprises a connecting layer; the connecting layer is positioned between the first light emitting layer and the second function part; the first light emitting layer comprises matrix materials and dopants doped in the matrix materials; the matrix materials comprise an N type matrix material and a P type matrix material. The organic light emitting diode provided by the invention has the effects of stably emitting light and obtaining light with ideal color.

Owner:BOE TECH GRP CO LTD

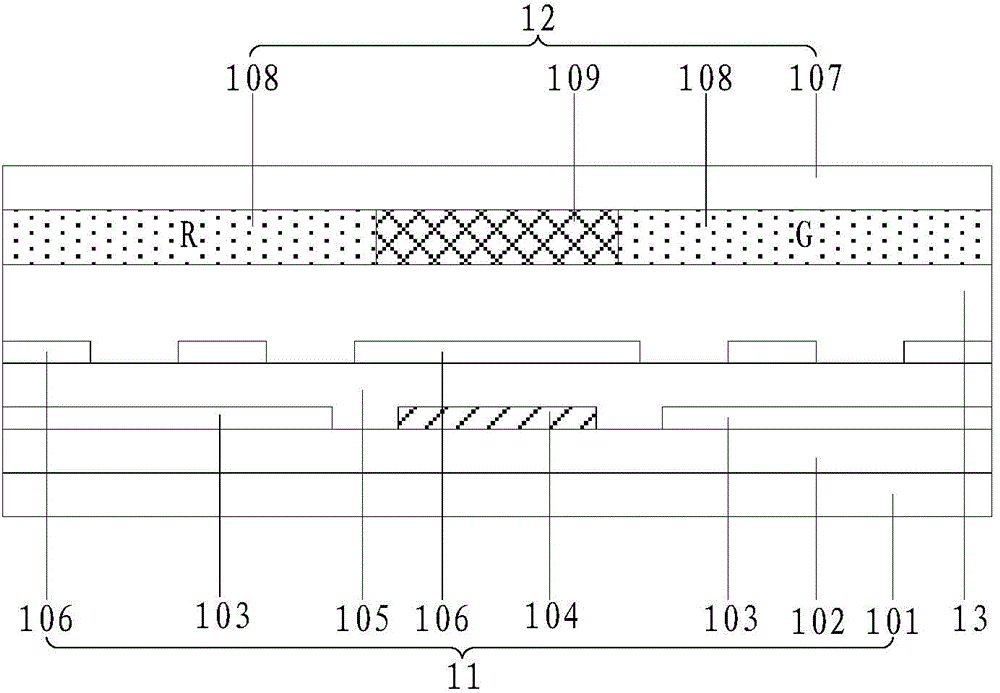

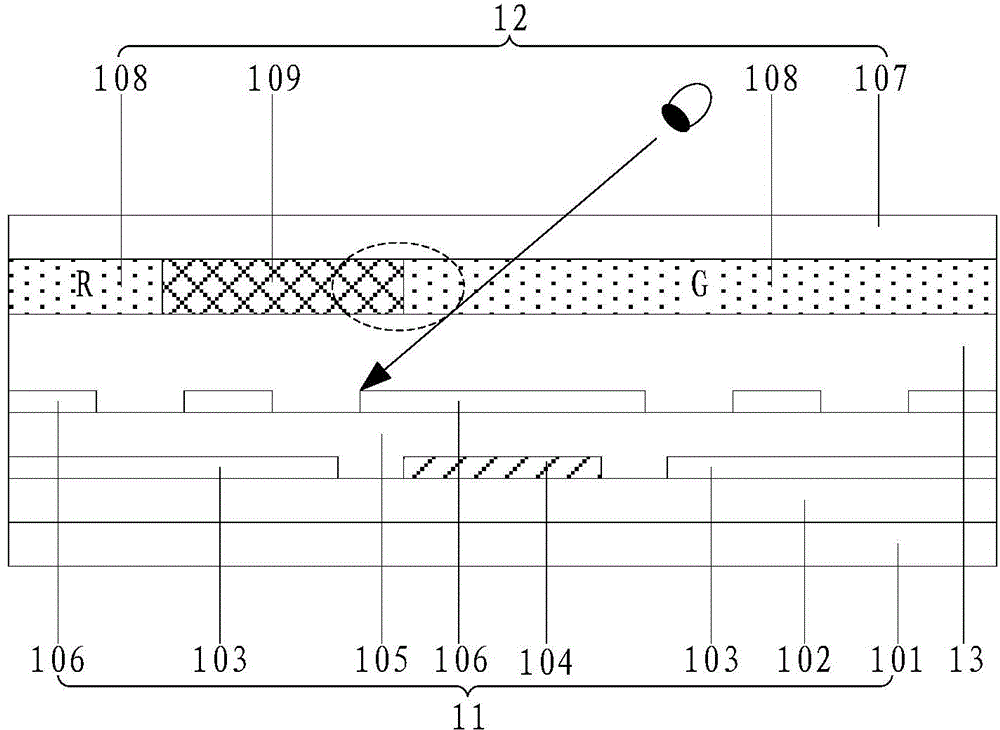

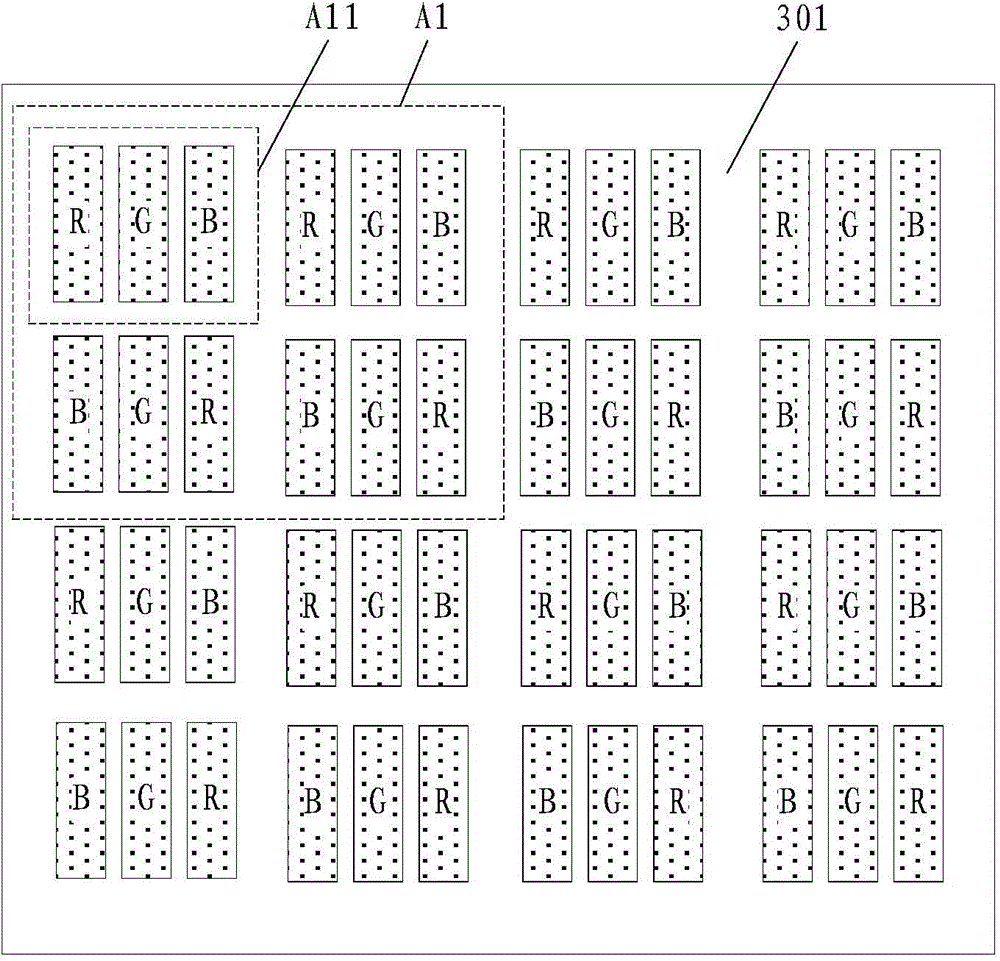

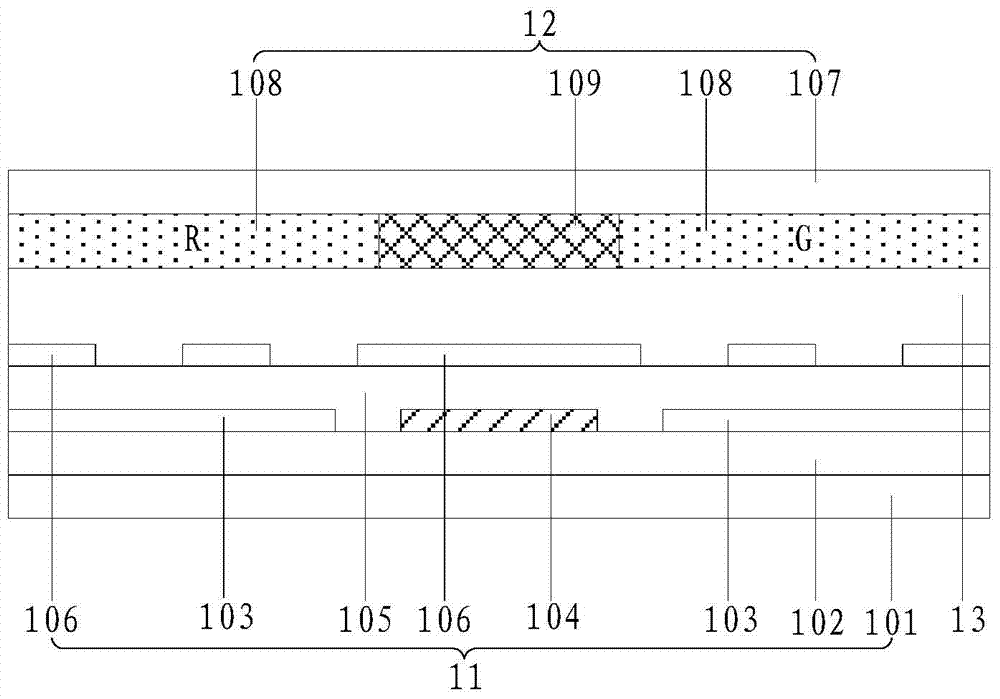

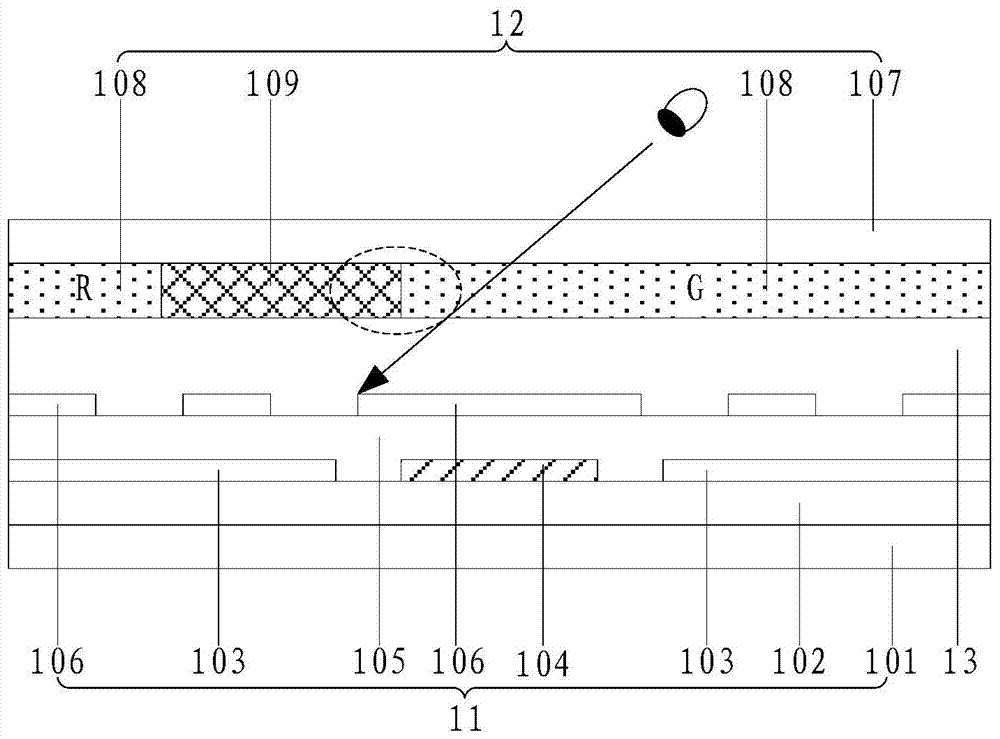

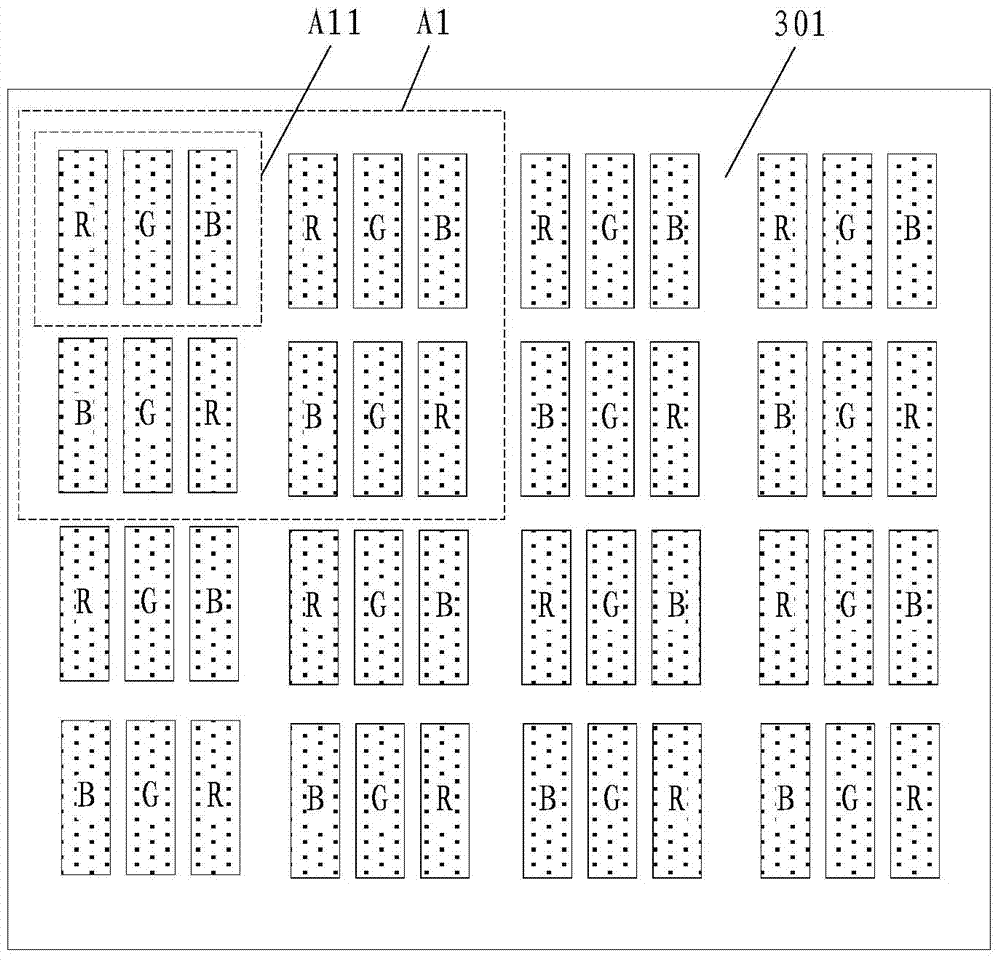

Color-film substrate and display device

The invention provides a color-film substrate and a display device. The color-film substrate comprises a plurality of pixels distributed in an array mode, each pixel comprises three color photoresists with different colors, one pixel comprises three side-by-side color photoresist rows, the color photoresist rows on the two sides comprise color photoresists of two colors, and the color photoresists of two colors are distributed at intervals. According to the color-film substrate, in a pixel unit formed by four pixels, color photoresists of one color on the left side or the right side are always adjacent to the color photoresists of two colors, when the color-film substrate deviates leftwards and rightwards relative to an array substrate or a user observes a picture along an inclined visual angle, two colors will be added into sub pixels of one color, and the influence of overlaying of the two added colors and the original color of the sub pixels on the color, needing to be displayed, of the sub pixels is far smaller than the influence caused by adding one color, so that the cross-color problem caused by poor alignment of the color-film substrate and the array substrate is solved, and picture quality is improved.

Owner:BOE TECH GRP CO LTD +1

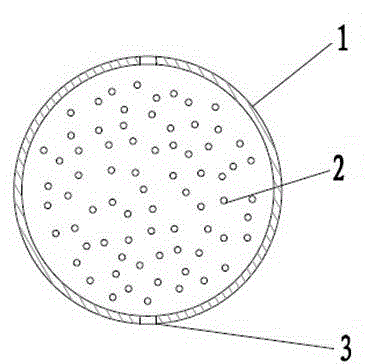

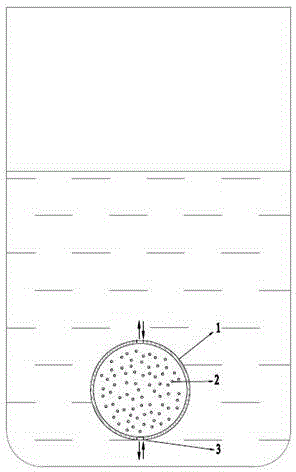

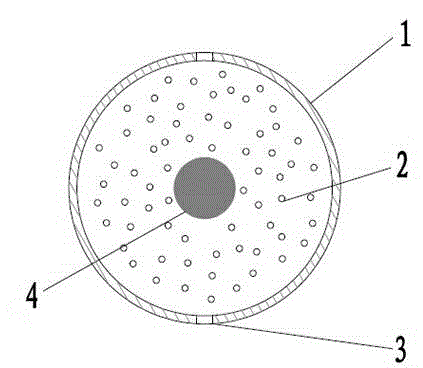

Controlled-release brewing-drinking device and method for Chinese medicine particles

InactiveCN104787501AGuaranteed sealed storageSmall original flavorTransportation and packagingControlled releaseBrewing

The invention discloses a controlled-release brewing-drinking device and method for Chinese medicine particles. The device comprises a container, at least one micro hole is formed in the surface of the container, and the Chinese medicine particles are contained inside the container. In addition, a water-absorbing swelling inner core can be further contained inside the container of the device. Through setting the size and the number of the micro holes in the surface of the container, control over a water and Chinese medicine particle exchanging channel is achieved, and then the speed of dissolving and releasing the Chinese medicine particles in water is controlled. The water-absorbing swelling inner core contained inside the container absorbs the water and swells, so that power capable of pushing and extruding the dissolved Chinese medicine particles outwards is generated; when the water-absorbing swelling inner core swells to occupy the space inside the whole container, the dissolved Chinese medicine particles in the container are completely extruded out, and the water-absorbing swelling inner core and the micro holes are matched so that the speed of releasing the Chinese medicine particles can be further controlled, and the Chinese medicine particles inside the container can be completely released.

Owner:LANZHOU WENHEYUAN MEDICAL TECH

Environmental protection interior wall paint

InactiveCN106810950AStrong antibacterial abilityWide rangeAntifouling/underwater paintsPaints with biocidesBenzeneLight source

The invention relates to the technical field of paint industry, in particular to an environment-friendly interior wall paint. It is prepared from the following raw materials by mass: 40-50 parts of calcined shell powder, 15-20 parts of light calcium carbonate, 20-25 parts of titanium dioxide, 15-20 parts of hydroxypropyl cellulose, 0.5-20 parts of alkaloid 1 part, 0.5-1 part of wetting agent, 10-15 parts of vegetable glue, 3-5 parts of chitosan, 0.5-1 part of nano titanium dioxide silver chelating agent. The environment-friendly interior wall coating of the present invention adopts natural shell powder as raw material, is made through grinding, high-temperature firing and special process, and has the function of absorbing and decomposing these harmful gases; the nano-titanium dioxide silver chelating agent has both the visible light of nano-titanium dioxide itself It has the functions of sterilization, anti-virus, and degradation of bacteria and organic matter under ultraviolet light, and has strong anti-bacterial and virus-killing effects of nano-silver without light source, and has the advantages of strong anti-bacterial ability, wide range, and long anti-bacterial time; plant glue Does not emit formaldehyde, benzene, ammonia and other harmful gases.

Owner:青岛力天宏泰新能源科技有限公司

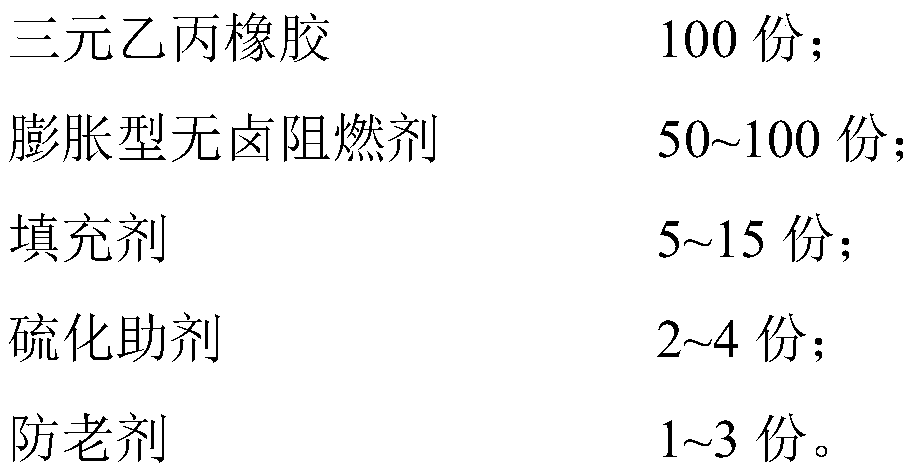

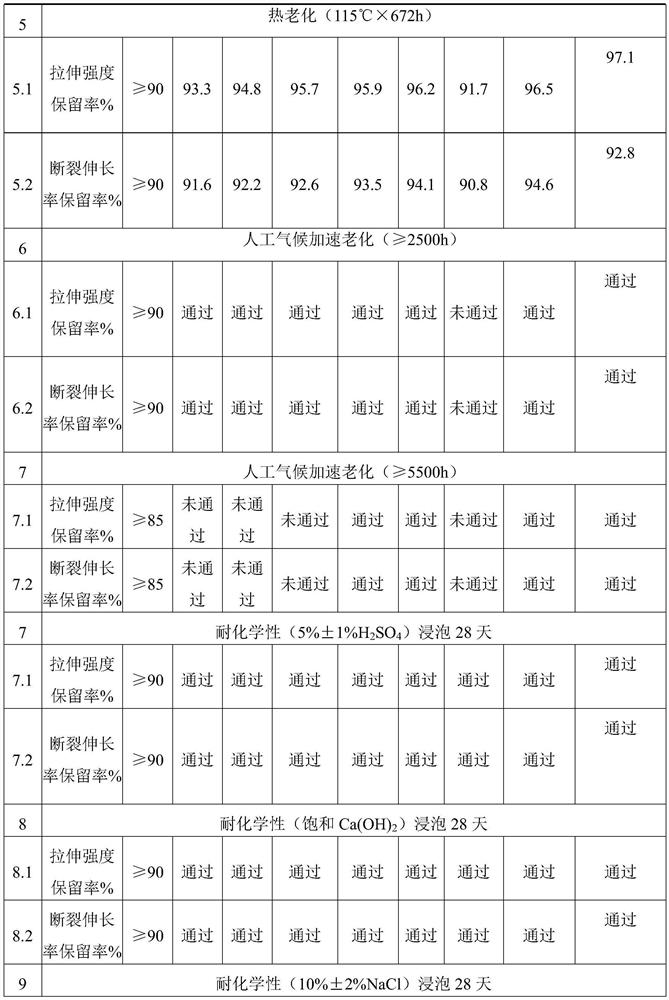

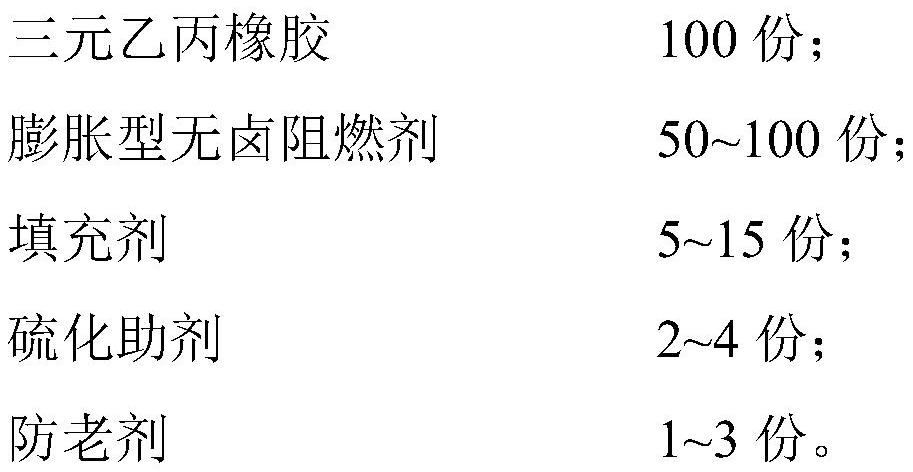

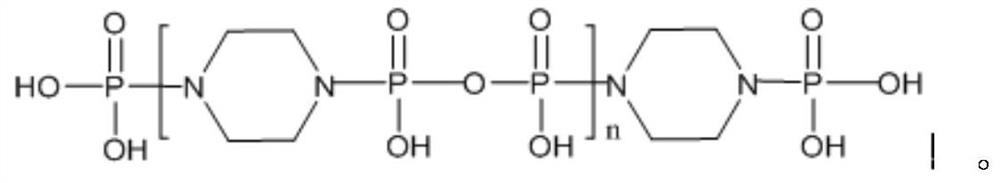

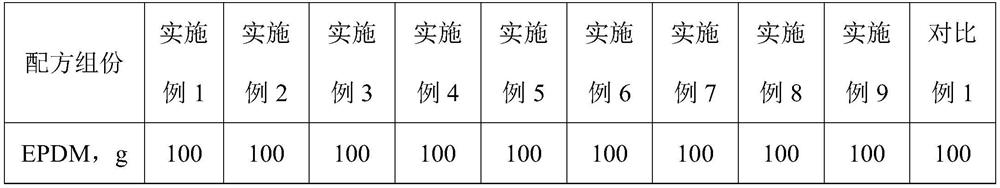

Low-smoke zero-halogen ethylene-propylene-diene monomer rubber composition and preparation method

The invention relates to a low-smoke zero-halogen ethylene-propylene-diene monomer (EPDM) rubber composition and a preparation method. The composition comprises, by weight, 100 parts of EPDM rubber, 50-100 parts of an intumescent zero-halogen flame retardant, 5-15 parts of a filling agent, 2-4 parts of a vulcanizing agent and 1-3 parts of an anti-aging agent. Compared with the prior art, the prepared flame-retardant EPDM rubber is low in smoke and free of halogen, reaches a UL94 (1.6mm) V-0 grade and has good mechanical properties; and meanwhile, the product is white and can be subjected to color matching, so that the application of the flame-retardant rubber in the fields of automobiles, electronic appliances, buildings and the like is expanded.

Owner:SHANGHAI RES INST OF CHEM IND

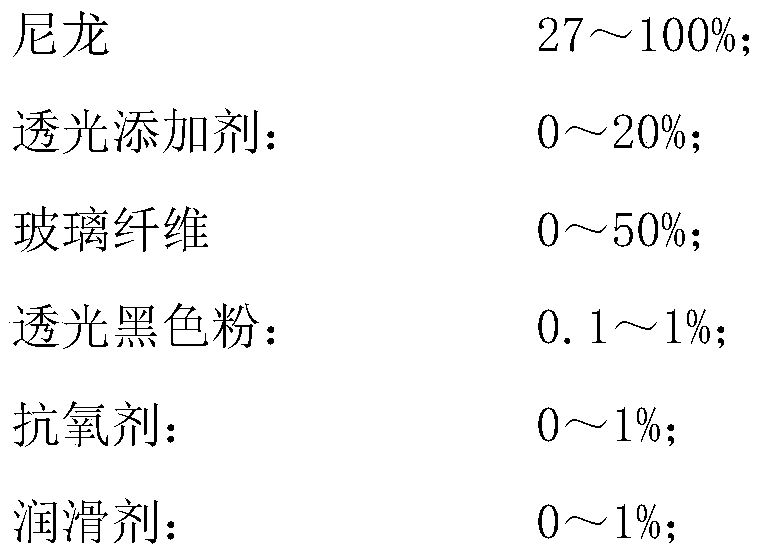

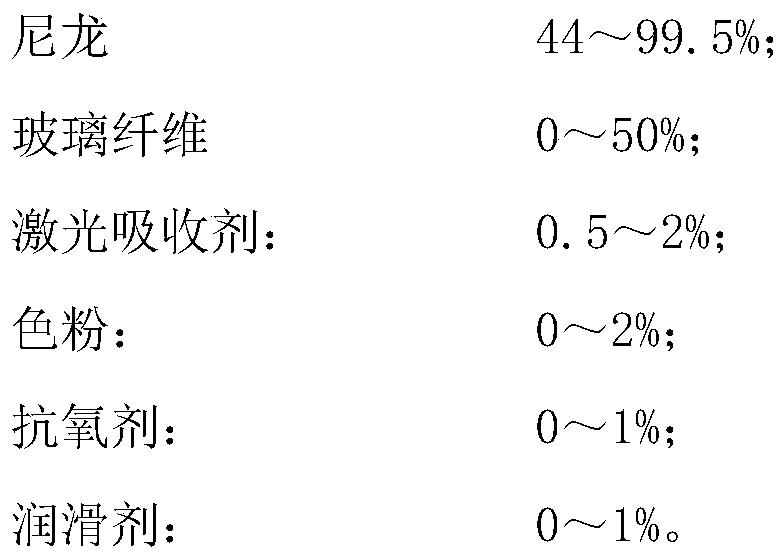

Color-selectable nylon composite material for laser welding and preparation method thereof

The invention discloses a color-selectable nylon composite material for laser welding and a preparation method thereof. The color-selectable nylon composite material comprises the following raw materials in percentage by weight: a light-transmitting component comprising: 27-100% ofnylon, 0-20% of a light-transmitting additive, 0-50% of glass fiber, 0.1-1% of light-transmitting black powder, 0-1% of an antioxidant and 0-1% of a lubricant; a light absorption component comprising: 44-99.5% of nylon, 0-50% of glass fiber, 0.5%-2% of a laser absorbent, 0-2% of a toner, 0-1% of an antioxidant, 0-1%of lubricant. According to the requirements of laser welding on the performance of the nylon material, the laser penetration efficiency of the nylon material is improved by adding a light-transmittingadditive into the light-transmitting layer; by using the light-transmitting black powder, the natural color material can be used as a light-transmitting layer, and the black material can also be usedas a light-transmitting layer; the laser absorbent is introduced into the material of the light-absorbing layer, so that the color of the laser absorbent is transparent, the influence on the color ofthe material is small, and the absorption efficiency of the laser absorbent is relatively high.

Owner:ZHEJIANG PRET NEW MATERIALS +3

Finishing method and auxiliaries for shape memory wash and wear woolen worsted face fabric

The invention discloses a finishing method and auxiliaries for shape memory wash and wear woolen worsted face fabric. The main technical project is that: putting the finished face fabric into the auxiliaries with the concentration of 3% for slop padding to make the face fabric retention rate of 60-70% after the normal treatment for the woolen worsted textile, drying below 110 DEG C and treating to finised face fabric. The durability of the evenness and the gathering is arranged from 3.5 to 4.5 level.

Owner:XUZHOU JINDING WOOL TEXTILE

Low-temperature degumming agent for natural colored silk and degumming method of low-temperature degumming agent

The invention belongs to the technical field of silk degumming, and discloses a low-temperature degumming agent for natural colored silk and a degumming method of the low-temperature degumming agent.The low-temperature degumming agent is prepared from, by weight, 3-6 parts of saponin, 1-2 parts of a semen hoveniae extract, 1-4 parts of polyoxyethylene ether, 1-3 parts of paeoniflorin, 3-5 parts of betaine, 1-10 parts of ethanol and 75-90 parts of water. By adopting the low-temperature degumming method for silk degumming, the energy is saved. Pigments in the natural colored silk can also be prevented from being destroyed by high temperature, and the natural colored silk is prevented from color fading. According to the silk degumming agent, since degumming components with the lower molecular weight are selected and various components which improve the permeability and degumming effect of the degumming agent are selected, the degumming process is more convenient, and the degumming effectis better. The degummed silk has antibacterial functionality and can be endowed with good antibacterial properties after the low-temperature degumming agent is applied.

Owner:SUZHOU SISEON TEXTILE TECH CO LTD

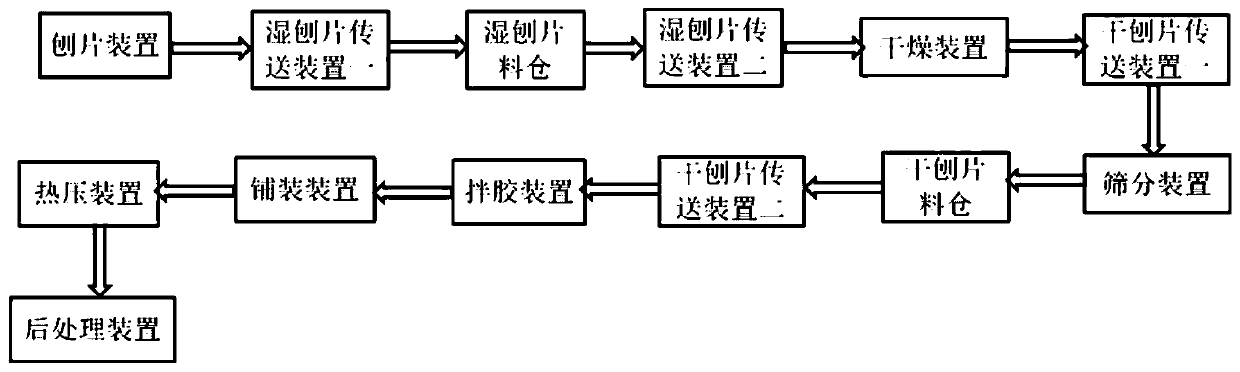

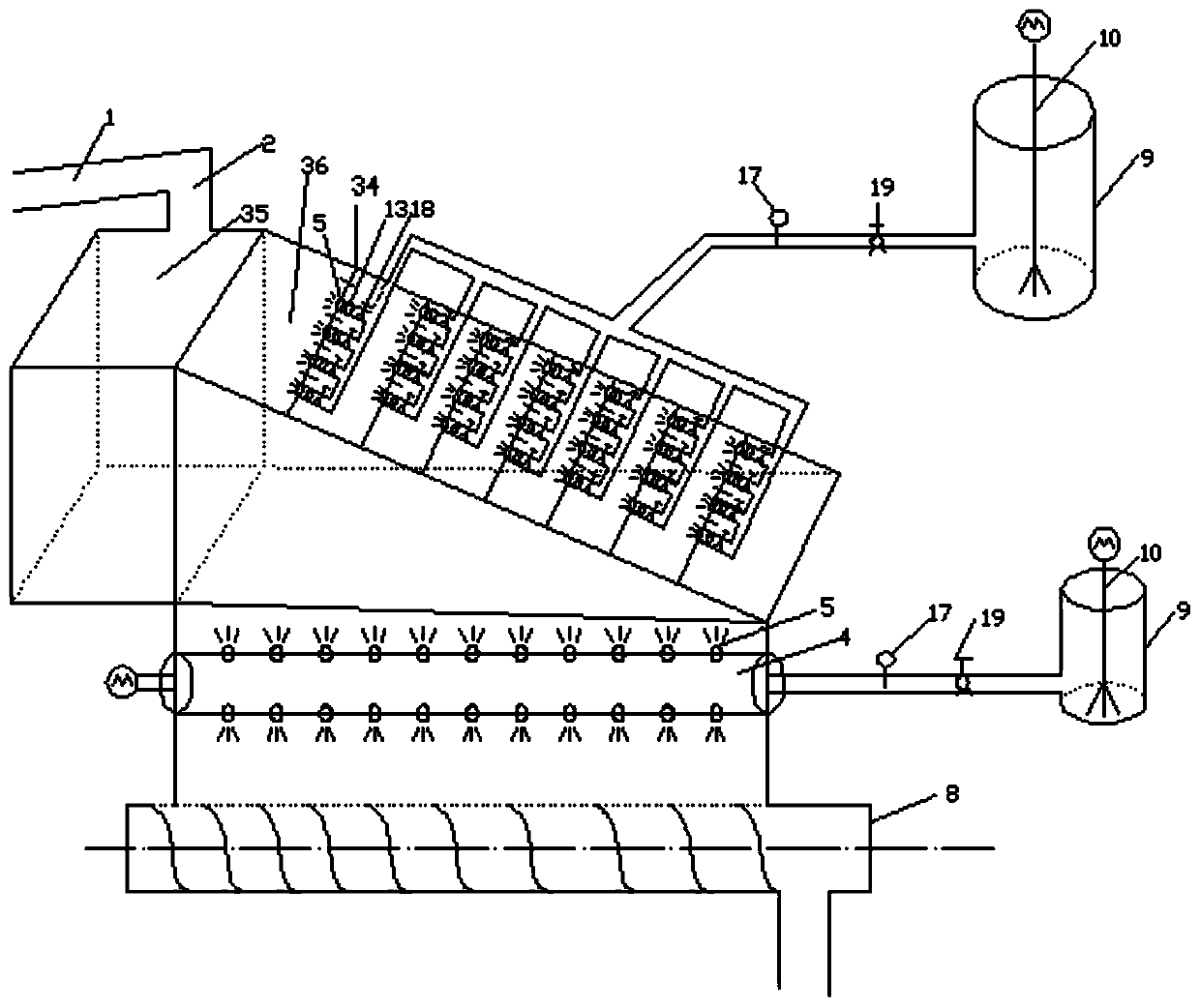

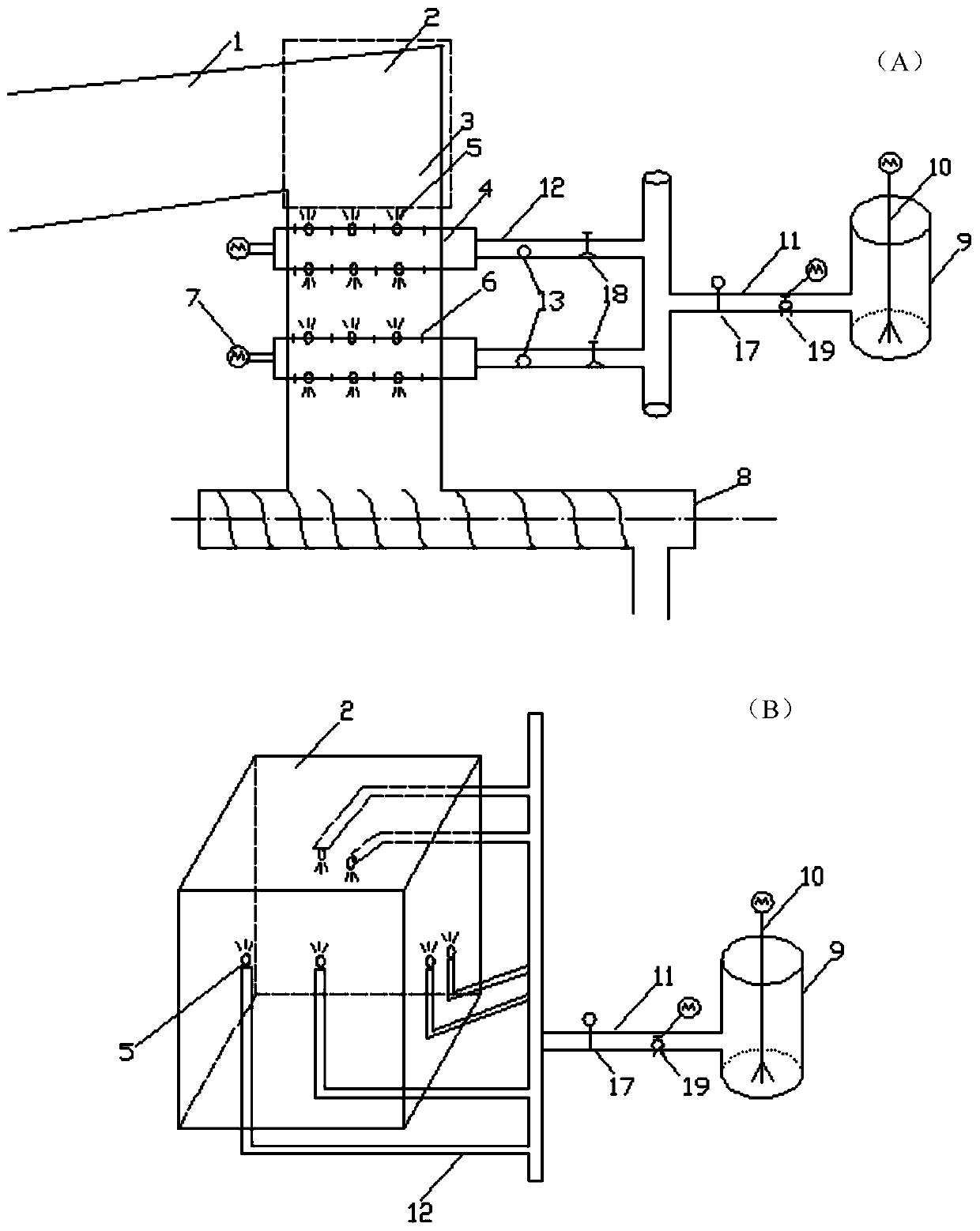

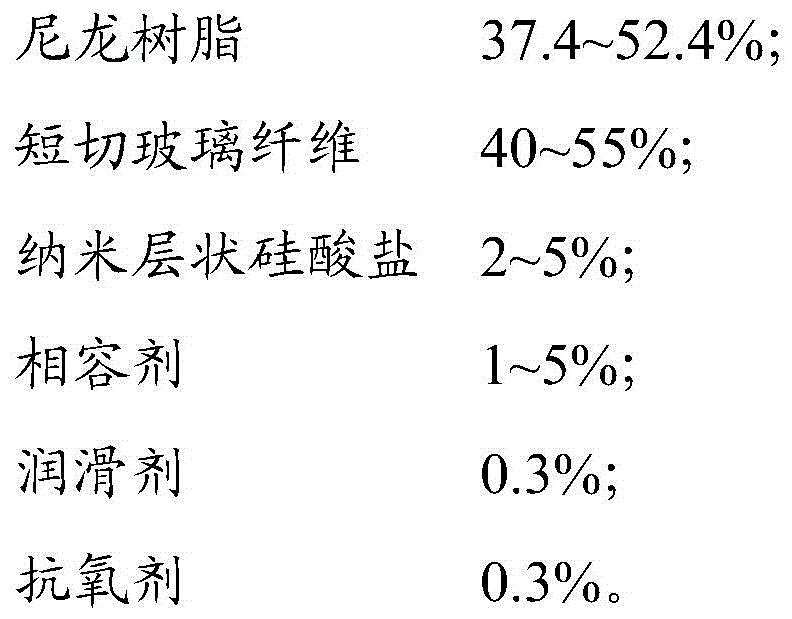

System and process for producing flame-retardant oriented strand board

ActiveCN109747019AGood adhesionIncrease coverageDomestic articlesFlat articlesAfter treatmentEngineering

The invention discloses a system and process for producing a flame-retardant oriented strand board. The system comprises a flaking device, a first wet flake conveying device, a wet flake bin, a secondwet flake conveying device, a drying device, a first dry flake conveying device, a screening device, dry flake bins (including the surface dry flake bin and the core dry flake bin), a second dry flake conveying device, glue mixing devices (including the surface dry flake glue mixing device and the core dry flake glue mixing device), a mat formation device, a hot-pressing device, and an after-treatment device and a flame retardant spraying structure used after hot-pressing. According to the system and process, a flame retardant is sprayed in multiple procedures to be sufficiently absorbed by flakes and is evenly distributed, and the flame-retardant oriented strand board obtained through the system and process has an excellent flame retardant property.

Owner:湖北宝源木业有限公司

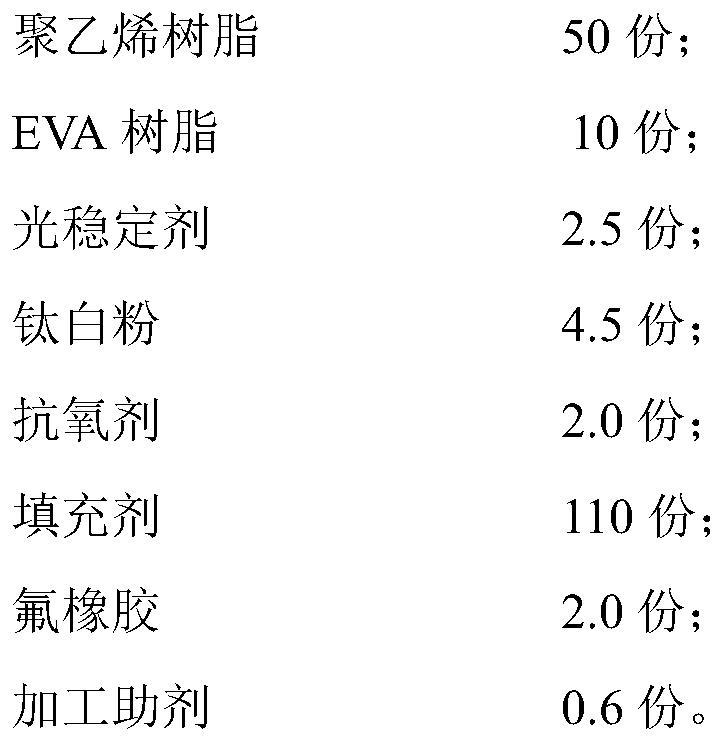

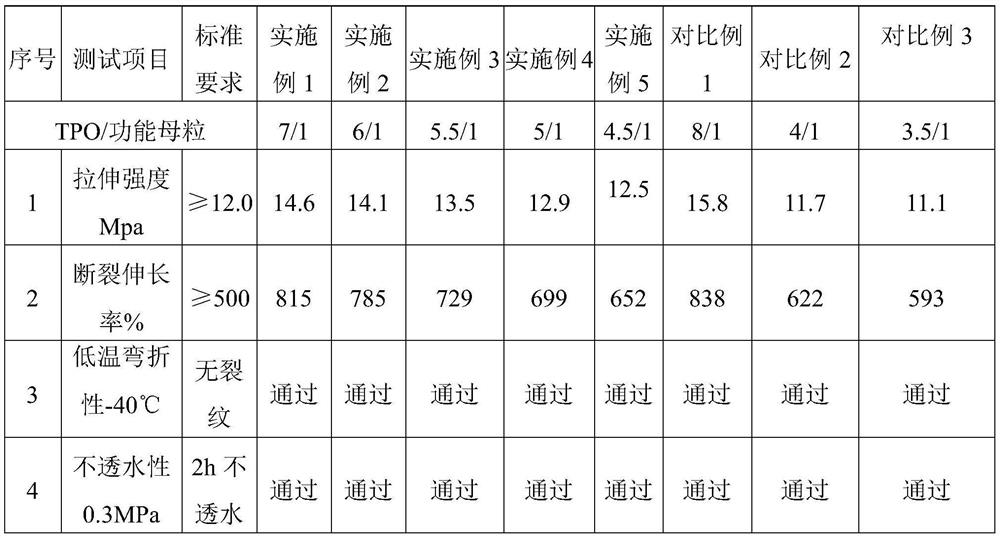

Waterproof roll particles as well as preparation method and application thereof

The invention provides waterproof roll particles as well as a preparation method and application thereof. The waterproof roll particles are prepared from a component A and a component B in a weight ratio of 7: 1 to 4.5: 1 through mixed granulating or mixed blending and extruding, wherein the component A is TPO resin, and the component B is a functional master batch. The invention further providesa preparation method and application of the waterproof roll particles. The waterproof roll particles have the advantages of good ultraviolet resistance, excellent weather resistance, stable color andeasiness in extrusion processing.

Owner:ANHUI CHUZHO DEWEI NEW MATERIAL

A kind of low-smoke halogen-free EPDM rubber composition and preparation method

Owner:SHANGHAI RES INST OF CHEM IND

Glass Fiber Reinforced Nylon Composite

The invention provides a glass fiber reinforced nylon composite material. The composite material is prepared from the following components in percentage by weight: 35-66.8 percent of nylon resin, 30-60 percent of chopped glass fibers, 2-15 percent of nano-phyllosilicate, 1-5 percent of compatilizer, 0.1-1 percent of a lubricating agent and 0.1-1 percent of antioxidant. According to the glass fiber reinforced nylon composite material, the nano-phyllosilicate filler and glass fibers are used for synergically reinforcing, advantages of a glass fiber reinforced nylon composite material are maintained, the strength and toughness of the composite material are further improved, the defects of poor size stability, poor surface and the like of the material caused by reinforcing adopting high glass fiber content can be overcome, and the color of the material is little influenced. Furthermore, the glass fiber reinforced nylon composite material has excellent mechanical performance and good fluidity, and can be applied to manufacture of machinery and automobile parts requiring high strength.

Owner:广东华聚科技有限公司

3D printing method, 3D printing light-curing color-changing indicating resin and preparation method thereof

ActiveCN109517111BDoes not affect appearanceImprove mechanical propertiesAdditive manufacturing apparatus3D object support structures3d printPolymer science

The invention relates to a 3D printing light-curing color-changing indicating resin and a 3D printing method. The light-curing color-changing indicating resin for 3D printing comprises the following components in parts by weight: 20-40 parts of oligomers; 10-20 parts of monomers; diluted 20-50 parts of the photoinitiator; 1-5 parts of the photoinitiator; 0.1-3 parts of the light indicator; wherein, the light indicator is a nitrogen-containing acrylate monomer, a nitrogen-containing compound, etc., which have a similar potential light indicating effect. A 3D printing method, using the above 3D printing photocurable color-changing indicator resin as a 3D printing photosensitive resin; the 3D printer light source is ultraviolet light with a wavelength of 280-420nm; the secondary curing light source is ultraviolet light with a wavelength of 280-420nm. In the present invention, by adding a "light indicator" into the photosensitive resin, the appearance of the material presents obvious differences before and after secondary curing, thereby effectively avoiding the problems of multiple curing and no secondary curing of the material.

Owner:杭州先临齿科技术有限公司

Non-woven interior decoration material used for vehicle and containing silver-loaded titanium dioxide and preparing system thereof

ActiveCN105420973ARelease rate is stable and long-lastingLittle color impactSucessive textile treatmentsFibre treatmentControl systemEngineering

The invention relates to the technical field of non-woven fabric processing, in particular to a non-woven interior decoration material used for a vehicle and containing silver-loaded titanium dioxide and a preparing system thereof. The non-woven interior decoration material is characterized by comprising a mixed liquor preparing system, a padding system, a heat braking system, an air cooling system, a setting system, a clipping system, an emergency shutdown system and a comprehensive control system. The mixed liquor preparing system, the padding system, the heat braking system, the air cooling system, the setting system and the clipping system are in signal connection.

Owner:DEYANG YONGSHENG NONWOVEN PROD

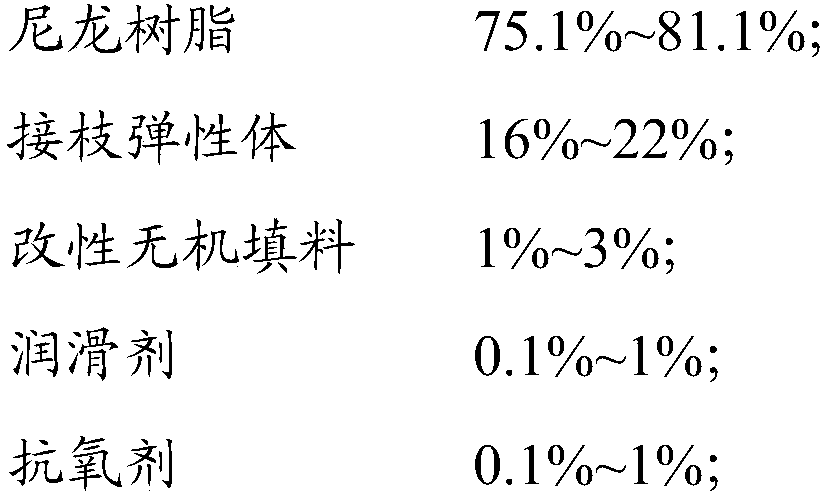

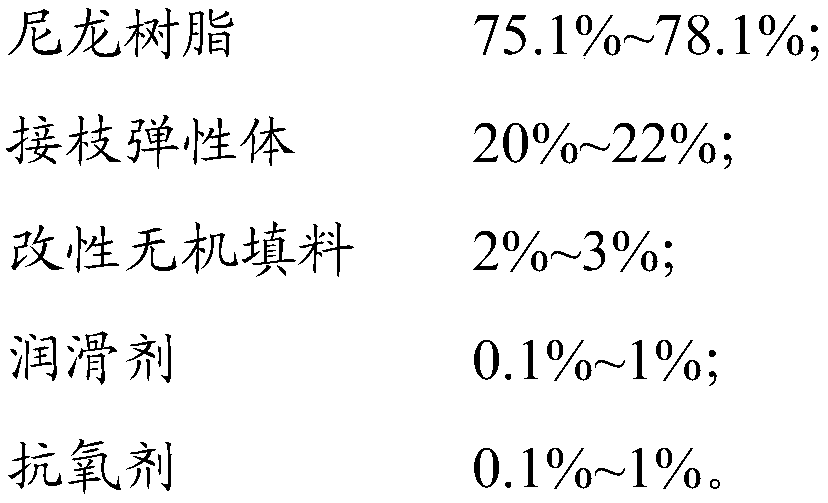

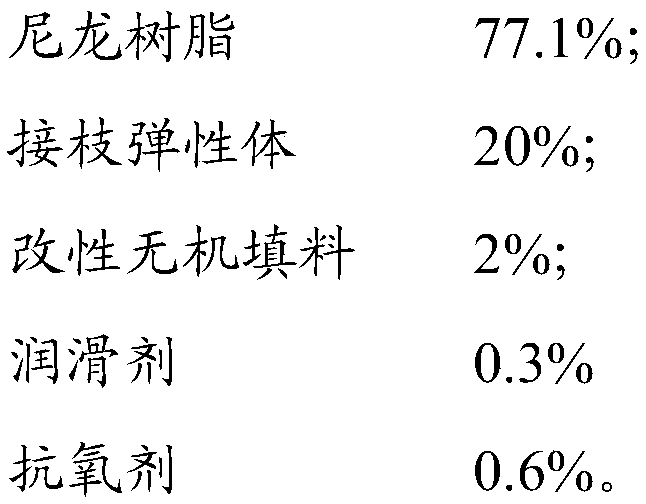

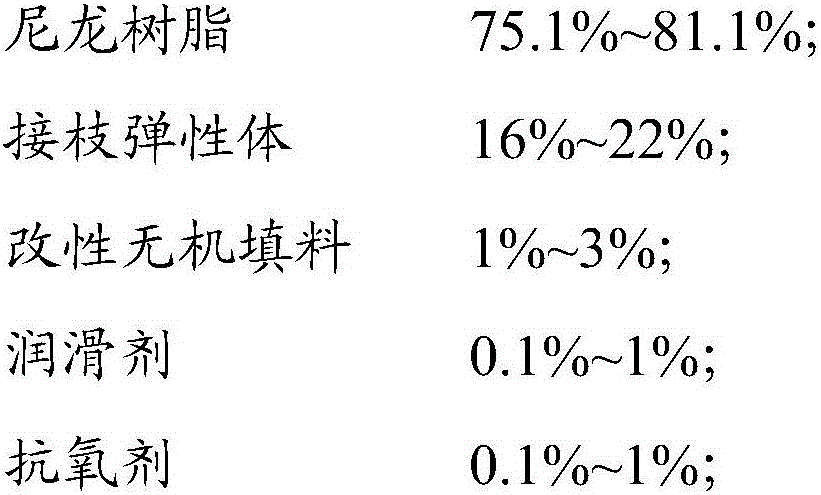

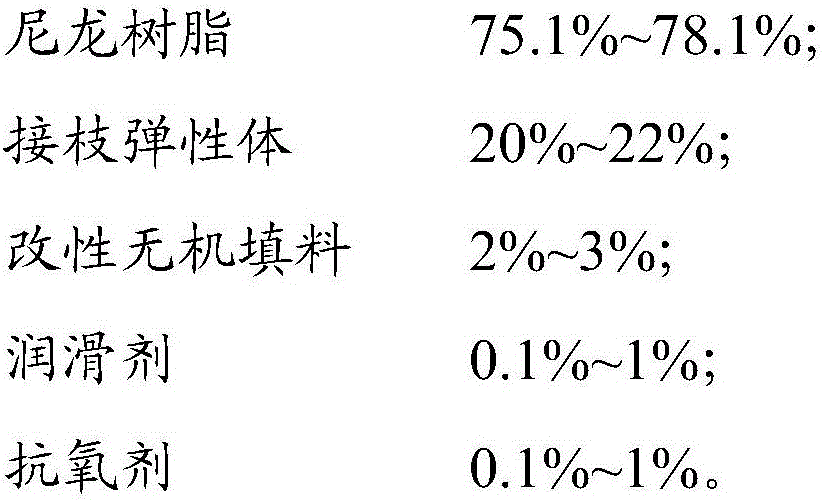

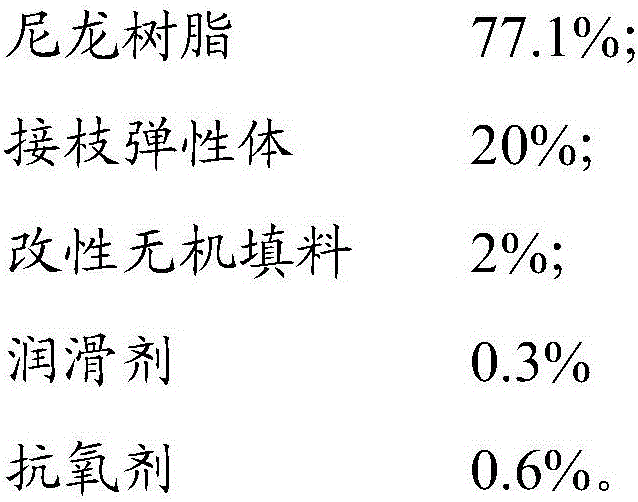

nylon composite

ActiveCN106280416BImprove the disadvantage of poor toughnessLittle color impactElastomerFunctional monomer

The invention provides a nylon composite material. The nylon composite material is prepared from, by weight, 75.1-81.1% of nylon resin, 16-22% of a grafting elastomer, 1-3% of a modified inorganic filler, 0.1-1% of a lubricant and 0.1-1% of an antioxidant. According to the modified inorganic filler, an organic filler is adopted as a core layer, methyl acrylate is adopted as a shell layer, a functional monomer methacrylic acid is copoplymerized on the outmost layer, and an emulsion polymerization method is used for preparing the nylon composite material. According to the nylon composite material, the grafting elastomer and the modified inorganic filler are composited to form the reinforcing and toughening nylon material, inherent advantages of the nylon material are kept, the toughness of the nylon material is greatly improved, the defect that the toughness of the nylon material is poor is overcome, the influence on the color of the material is small, and the mechanical property of the product is better.

Owner:惠州市华聚塑化科技有限公司

Nylon composite material

ActiveCN106280416AImprove the disadvantage of poor toughnessLittle color impactFunctional monomerAntioxidant

The invention provides a nylon composite material. The nylon composite material is prepared from, by weight, 75.1-81.1% of nylon resin, 16-22% of a grafting elastomer, 1-3% of a modified inorganic filler, 0.1-1% of a lubricant and 0.1-1% of an antioxidant. According to the modified inorganic filler, an organic filler is adopted as a core layer, methyl acrylate is adopted as a shell layer, a functional monomer methacrylic acid is copoplymerized on the outmost layer, and an emulsion polymerization method is used for preparing the nylon composite material. According to the nylon composite material, the grafting elastomer and the modified inorganic filler are composited to form the reinforcing and toughening nylon material, inherent advantages of the nylon material are kept, the toughness of the nylon material is greatly improved, the defect that the toughness of the nylon material is poor is overcome, the influence on the color of the material is small, and the mechanical property of the product is better.

Owner:惠州市华聚塑化科技有限公司

Obstacle handling method and cleaning robot

ActiveCN111067439BPracticalAccuracyAutomatic obstacle detectionTravelling automatic controlEdge mapsEngineering

The application provides an obstacle handling method and a cleaning robot. Wherein, the cleaning robot includes a controller, an image acquisition device, a fuselage main body and a side sweep, and the side sweep extends beyond the edge of the fuselage main body; image; the controller is used to, according to the first image of the obstacle, identify the type of the obstacle; determine the obstacle handling method corresponding to the obstacle type, and the obstacle handling method includes whether the cleaning robot moves ahead according to the The direction continues to move forward, and when the cleaning robot changes its forward direction in front of the obstacle, the distance information between the main body of the fuselage and the side scan and the obstacle respectively; the controller is used to control the obstacle handling method corresponding to the type of obstacle Clean robot movement. The implementation of this application can improve the cleaning coverage for different obstacles and reduce the risk of cleaning.

Owner:SHANGHAI FLYCO ELECTRICAL APPLIANCE

Composition for nail sticker and preparation method thereof

ActiveCN113576144AFast curingImprove curing efficiencyNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceChemical reaction

The invention discloses a composition for a nail sticker and a preparation method thereof, the raw material of the composition comprises a sizing material, and the sizing material is prepared from the following raw materials in parts by weight: 45-85 parts of UV thermosetting resin; 2-9 parts of a photoinitiator; 1.5-2 parts of a curing agent; 0.1-1 part of a thermal accelerator; and 0.1-1 part of a leveling agent. The composition disclosed by the invention can generate wonderful physical and chemical reactions under the action of light and heat like baked food, a film formed after accelerated curing is full and glossy, the toughness, the hardness, the weather resistance and the insulativity of the nail sticker are improved, the edge of the nail sticker is not easy to wrinkle or tilt, and the adhesive force is high. Meanwhile, according to the composition, temperature-sensitive slow-release essential oil microcapsules are added, essential oil in capsule cores is released for a long time through micropores in capsule walls, and the fragrance is pleasant. Essential oil molecules in the capsule core are released synchronously with photo-thermal curing, so that the essential oil molecules can be diffused into the sizing material more uniformly in a larger range, and attractive fragrance can be emitted like baked food in the curing and film forming process.

Owner:SHANGHAI HUIZI COSMETICS CO LTD

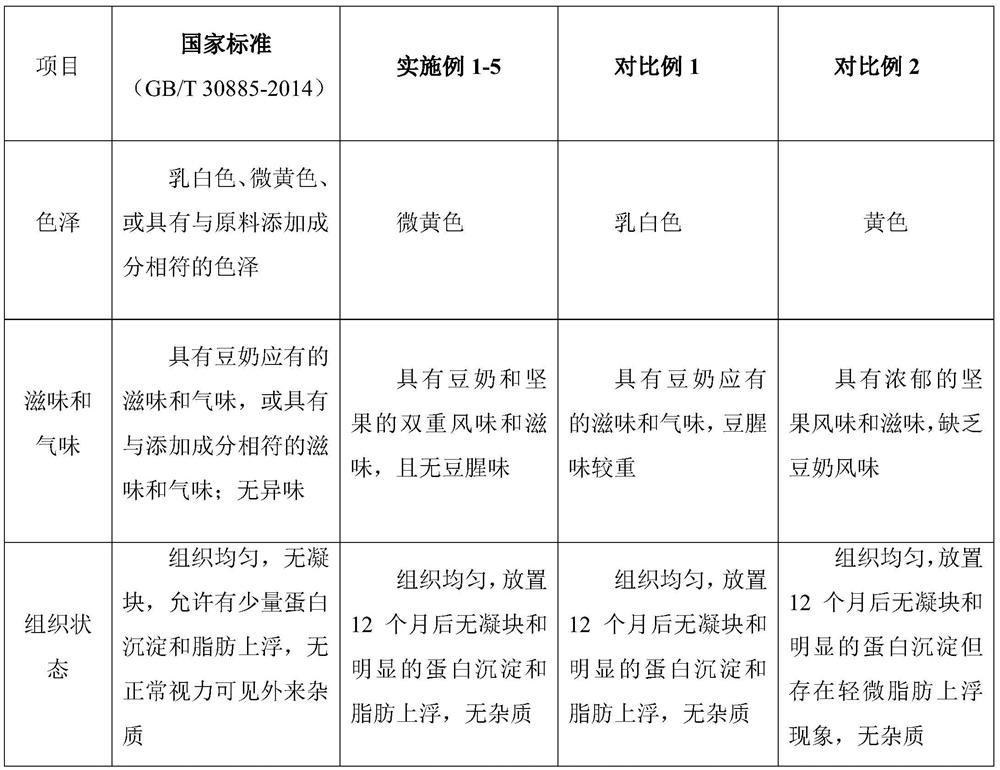

Nut soymilk without beany flavor and preparation method thereof

PendingCN114009692AImprove color and tasteReduce beany smellFood preservationFood ingredientsChemistrySoy milk

The invention discloses nut soymilk without beany flavor and a preparation method of the nut soymilk, belonging to the technical field of vegetable protein beverage processing. The invention aims to solve the technical problem of how to remove beany smell of soymilk. The method provided by the invention comprises the following steps: preparing the halves of peeled soybeans, conducting grinding, centrifugally removing residues, deactivating enzyme, preparing auxiliary materials, and then successively carrying out blending, sterilizing, homogenizing and aseptic filling. Through organic combination of nuts and soymilk, perfect compounding of nutritional ingredients in the soybeans and nutritional ingredients in the nuts is achieved; meanwhile, the beany flavor of the nut soymilk is removed through dry-method hot water grinding, steam jet type enzyme deactivation and VTIS sterilization technologies, the color, luster and taste of the nut soymilk are improved, the beany flavor is reduced, the smoothness and lubrication degree of the product are improved, and the palatability and the nutritional value of the nut soymilk are enhanced; and consumers can obtain maximum nutritional ingredients and relatively perfect taste experience while drinking the nut soymilk.

Owner:莱蒂斯(黑龙江)生物科技集团股份有限公司

Novel efficient antibacterial PP composite material

InactiveCN110194866AImprove photocatalytic activityStrong photocatalytic antibacterial performancePolypropyleneAntibacterial agent

The invention relates to a novel efficient antibacterial PP composite material, which comprises: 70-85 parts of a polypropylene resin, 4-8 parts of an antibacterial agent, and 3-6 parts of an auxiliary agent. According to the present invention, the novel efficient antibacterial PP composite material has advantages of good antibacterial effect and stability, and the composite material produced fromthe novel efficient antibacterial PP composite material has long service life, can reduce economic input, has good market competitiveness, and is suitable for promotion.

Owner:SUQIAN CHUNMING MEDICAL EQUIP CO LTD

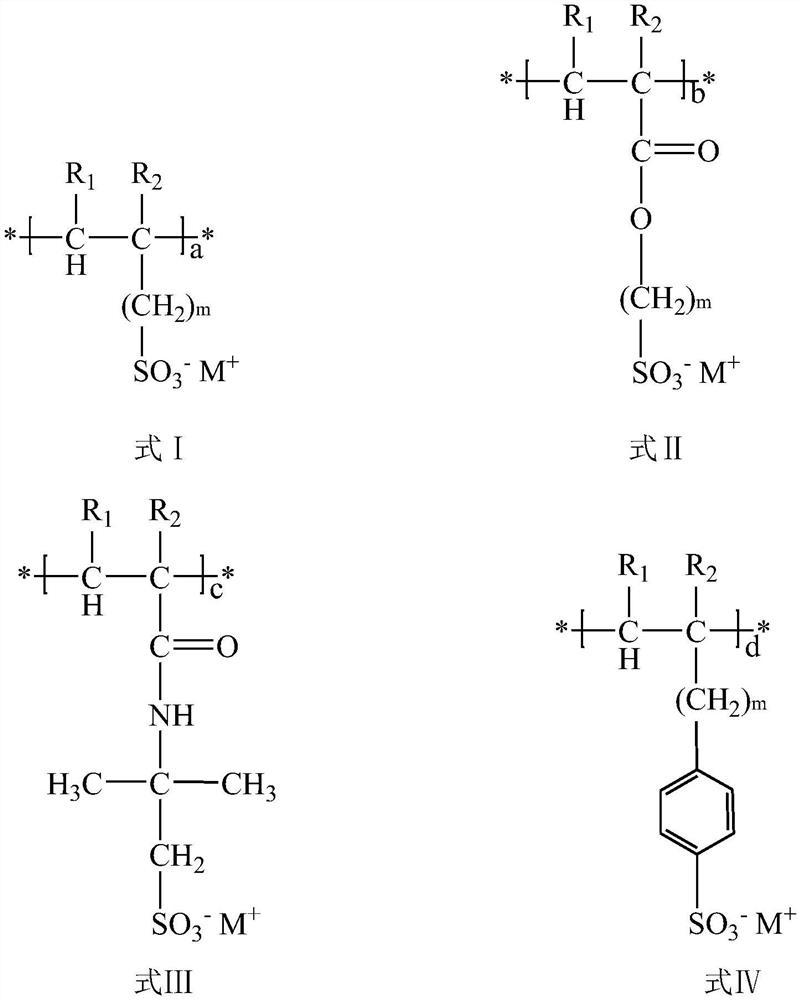

Foamless anti-phenolic yellowing agent as well as preparation method and application thereof

ActiveCN114437295AEfficient use ofImprove working environmentLight resistant fibresTextile/flexible product manufacturePolyesterYarn

The invention discloses a foamless phenolic yellowing resistant agent as well as a preparation method and application thereof. The foam-free phenolic yellowing resistant agent is an organic polymer with a sulfonic side chain, and the molecular structure of the foam-free phenolic yellowing resistant agent contains any one or more structural units with sulfonate shown in a formula I, a formula II, a formula III or a formula IV. The phenolic yellowing resistant agent is excellent in phenolic yellowing resistance, free of bubbles and free of blistering in the whole application process. The anti-phenolic yellowing agent can be applied to anti-phenolic yellowing treatment of textiles such as yarns, laces, braids, knitted fabrics, woven fabrics and the like made of fiber materials such as chinlon, polyester, acrylic fibers, spandex, cotton, rayon, tencel, modal, lyocell, silk, wool, cashmere, bamboo fibers, jute fibers and the like.

Owner:东莞市中纺化工有限公司 +1

nylon composite

The invention relates to a nylon composite material which comprises the following components in percentage by weight: 24.4-57.4% of nylon resin, 35-60% of chopped glass fiber, 5-15% of modified nano boehmite, 2-5% of compatilizer, 0.1-1% of lubricant and 0.1-1% of antioxidant. The glass-fiber-reinforced nylon composite material has the characteristic of high strength. The modified nano boehmite and glass fibers are used for synergic reinforcement, thereby maintaining the advantages of the glass-fiber-reinforced nylon composite material, enhancing the strength and toughness of the material, overcoming the defects of poor dimensional stability and surface defects of the material due to high glass fiber content and having small influence on the material color. The nylon composite material has the advantages of excellent mechanical properties and favorable flowability, and is applicable to manufacturing of machines and automobile parts in need of high strength.

Owner:广东华聚科技有限公司

Color filter substrate and display device

The invention provides a color filter substrate and a display device, which include a plurality of pixels arranged in an array, each pixel includes three color photoresists with different colors, and a row of pixels includes three parallel rows of colored photoresists. Resist row, the color photoresist rows on both sides include two colors of color photoresist, and the two colors of color photoresist are arranged at intervals. In the above-mentioned color filter substrate, in a pixel unit composed of four pixels, the color photoresist of one color is adjacent to the color photoresist of two colors on the left side or the right side, when the color filter substrate is opposite to When the array substrate is shifted left and right and the picture is observed along an oblique viewing angle, a sub-pixel of one color will be inserted into the other two colors, and the two colors inserted in the series will be superimposed on the color of the sub-pixel itself to display the sub-pixel The influence of color is much smaller than that of a single color, which solves the problem of cross-color caused by poor alignment between the color filter substrate and the array substrate, and improves the picture quality.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com