Nut soymilk without beany flavor and preparation method thereof

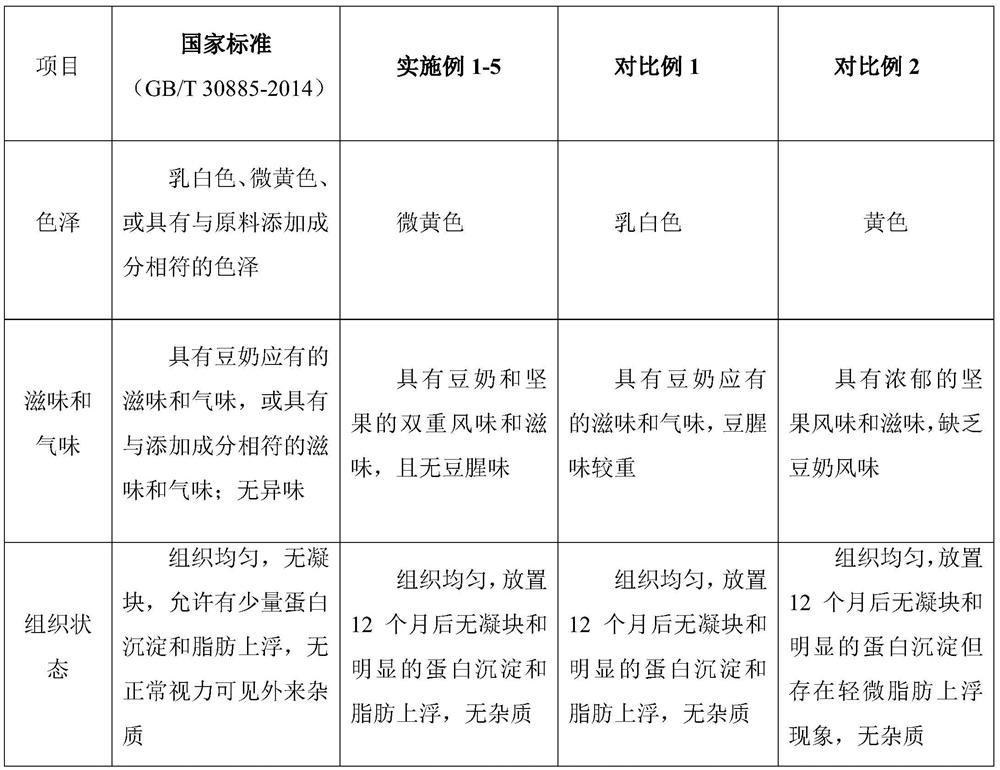

The technology of beany smell and soy milk is applied in the field of vegetable protein beverage processing, which can solve the problem of fishy smell of soy milk, and achieve the effects of improving color and taste, reducing beany smell and promoting nutty flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of peeled soybean watercress: select 1000 parts of soybeans with full grains and bright color, preheat to 55°C in a heater and stay for 20min, and then heat them in a fluidized bed dryer at a hot air temperature of 110°C Soybeans are processed by hot air heating and drying technology, and the heating is stopped when the temperature rises to 80°C and the moisture content is 8%. The peeling machine is used to crush the heat-treated soybeans, combined with the suction fan to realize the separation and conditioning of the skin and kernel, and stop when the temperature of the soybean kernel is 50 ° C, to obtain peeled soybean watercress;

[0028] (2) Grinding: Soak the peeled soybean watercress in 0.1% sodium bicarbonate solution for 10 minutes. After soaking, transport it to the soybean refining extraction system for dry hot water grinding. Use the grinding unit to grind it to 100nm, and then directly mix it with Mix and grind hot water at 70°C to form a slu...

Embodiment 2

[0039] (1) Preparation of peeled soybean watercress: select 500 parts of soybeans with plump grains and bright color, preheat to 70°C in a heater and stay for 30min, and then heat them in a fluidized bed dryer at a hot air temperature of 135°C Soybeans are processed by hot air heating and drying technology, and the heating is stopped when the temperature rises to 95°C and the moisture content is 15%. The peeling machine is used to crush the heat-treated soybeans, combined with the suction fan to realize the separation and conditioning of the skins and kernels, and stop when the temperature of the soybean kernels is 65°C to obtain peeled soybeans;

[0040] (2) Grinding: Soak the peeled soybean watercress in 0.5% sodium bicarbonate solution for 40 minutes. After soaking, transport it to the soybean refining extraction system for dry hot water grinding. Use the grinding unit to grind it to 30 μm, and then directly mix it with Mix and grind hot water at 95°C to form a slurry to ob...

Embodiment 3

[0051] (1) Preparation of peeled soybean watercress: select 600 parts of soybeans with full grains and bright color, preheat to 65°C in a heater and stay for 25min, and then heat them in a fluidized bed dryer at a hot air temperature of 120°C Soybeans were processed by hot air heating and drying technology, and the heating was stopped when the temperature rose to 85°C and the moisture content was 12%. The peeling machine is used to crush the heat-treated soybeans, combined with the suction fan to realize the separation and conditioning of the skins and kernels, and stop when the temperature of the soybean kernels is 60°C to obtain peeled soybean watercress;

[0052] (2) Grinding: After soaking the peeled soybean watercress in 0.25% sodium bicarbonate solution for 25 minutes, transport it to the soybean refining extraction system for dry hot water grinding, use the grinding unit to grind it to 20 μm, and then directly heat it at 75°C Water is mixed and ground into slurry to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com