Soybean aqueous extract with low anti-nutritional components and preparation method of soybean aqueous extract

A technology for water extract and soybean, which is applied in the field of soybean water extract and its preparation, and can solve the problems of restricting the rapid development of soybean products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

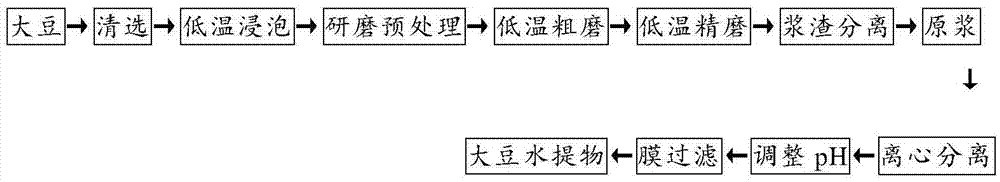

Method used

Image

Examples

Embodiment

[0153] The present invention will be illustrated below in the form of specific examples. It should be understood that these examples are illustrative only and do not limit the scope of the present invention. The methods and reagents involved in the examples, unless otherwise stated, are conventional methods and reagents in the art.

[0154] The measurement of the phytic acid content, the measurement of the protein content, the measurement of the fat content, the measurement of the particle size, the measurement of the solid content, and the polyacrylamide gel electrophoresis concerning an Example were performed as follows.

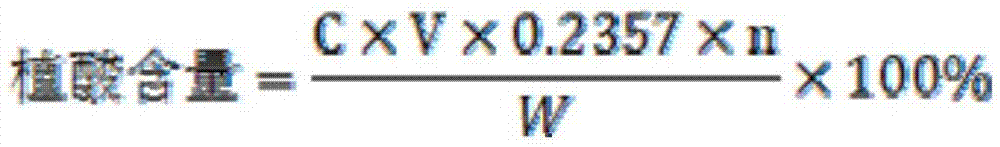

[0155] Determination of phytic acid content:

[0156] Take 10g of soybean milk into the extractor, add 100ml each of 5% trichloroacetic acid and 10% sodium thiosulfate, shake and mix well, place in an ultrasonic oscillator to shake for 30min, take out after shaking well, centrifuge at 3000r / min for 10min, and separate The supernatant is the extract. Tak...

Embodiment 1

[0172] 1. Select soybeans with complete grains, plump, bright, and no mildew, especially soybeans with low petal fragmentation rate.

[0173] 2. Soaking: fully soak soybeans in water, the source of soaking water is tap water, soak according to the mass ratio of dry beans to water of 1:5; the soaking temperature is 4°C, and the soaking time is 18 hours.

[0174] 3. Pretreatment before grinding: peel off the skin and hypocotyl, control the moisture, maintain the integrity of the expanded soybean, and avoid the activation of lipoxygenase by water. Based on the weight of wet beans, add water at a mass ratio of wet beans to water of 1:6. Add potassium chloride, and the addition amount is 0.15% of the total mass.

[0175] 4. Coarse grinding: use stone grinding, the refining temperature is close to 0 ℃, and ice-water mixture.

[0176] 5. Fine grinding: fully blend the mixture of slurry and slag after the first coarse grinding, and then enter the fine grinding again, and the particl...

Embodiment 2

[0185] Repeat the first five steps of Example 1, and use centrifugation to separate pulp and residue to obtain a puree with protein ≥ 4.2% and oil content ≥ 2.33%. At this time, the pH of the soybean water extract is 6.4.

[0186] The obtained puree was centrifuged under the following conditions: 4000×g, 20 min.

[0187] The filtrate is separated and obtained, which is a soybean water extract rich in high protein, high carbohydrate and low fat. The protein of the soybean water extract is ≥ 3.2%, and the oil content is ≤ 0.2%. At this time, the pH of the soybean water extract is 6.4.

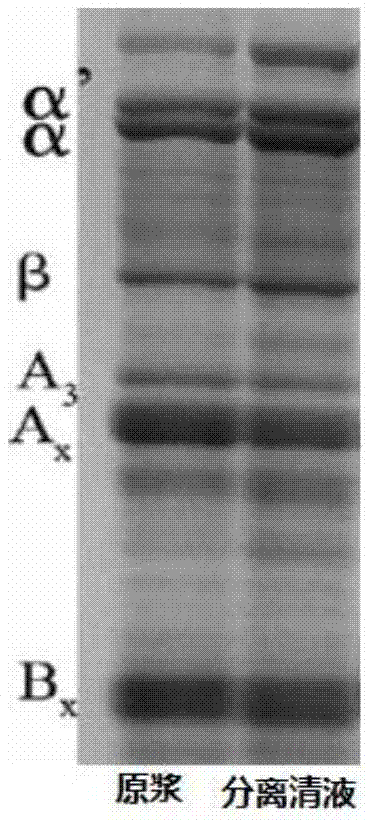

[0188] The samples were subjected to polyacrylamide gel electrophoresis (SDS-PAGE), and the subunit components were characterized, and the results were as follows: figure 2 shown.

[0189] It can be clearly seen from the electrophoretic graph that the brightness of the 7S and 11S subunits of the separated soybean water extract has changed significantly, that is, the original soybean water extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com