Patents

Literature

367results about How to "Low fat content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bacillus subtilis for effectively degrading grease and application thereof

ActiveCN106929449AEfficient degradationMeet the needs of aerobic compostingNon-ionic surface-active compoundsOrganic detergent compounding agentsAdditive ingredientBacteroides dorei

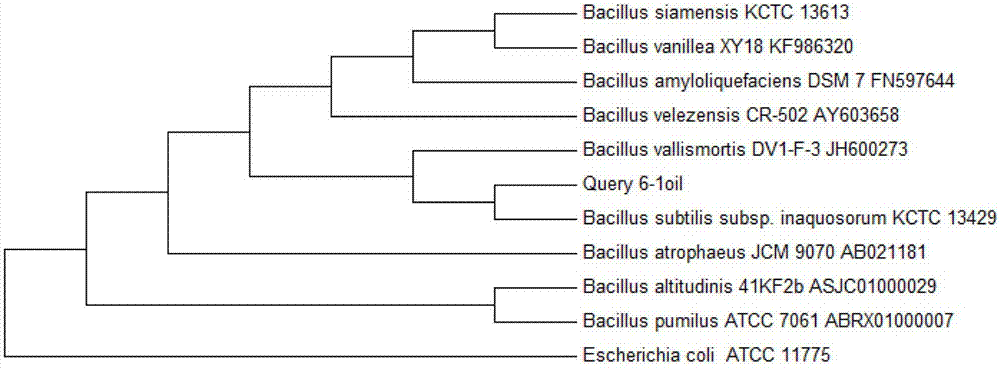

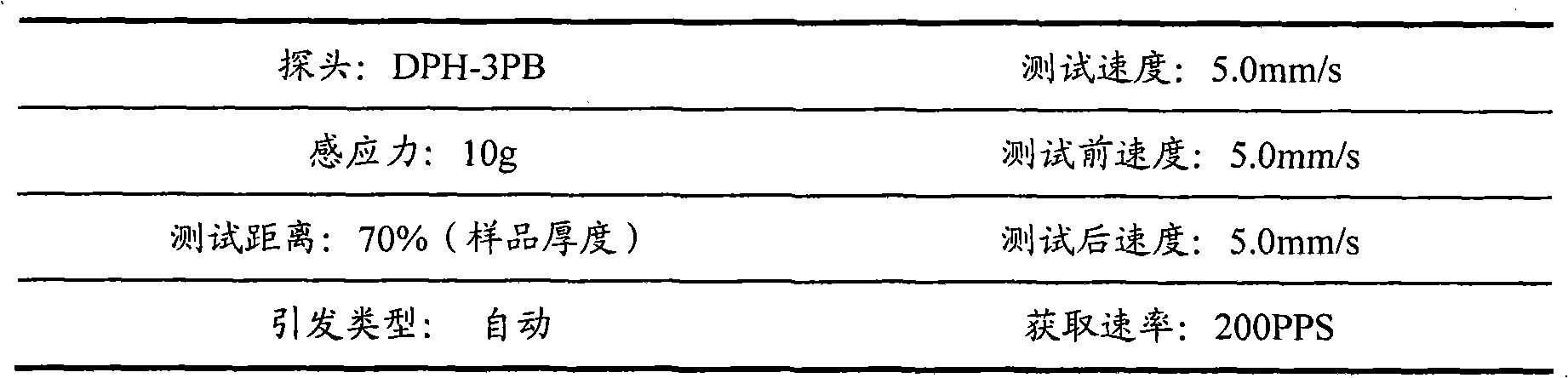

The invention provides a bacillus subtilis for effectively degrading grease. The bacillus subtilis 6-loil is preserved at Guangdong Province Microbiological Culture Collection Center on December 22, 2016. The preservation number is GDMCC No. 60134. The bacillus subtilis 6-loil provided by the invention can utilize the grease as a growth carbon source, can normally grow under an environment of higher grease content and has a capacity of efficiently degrading grease. The bacillus subtilis 6-loil provided by the invention can be compounded with bacillus coagulans, brewer yeast and carrier ingredients so as to be prepared into a kitchen garbage disposal fungicide. The prepared kitchen garbage disposal fungicide can adapt to the condition of high grease content of the domestic kitchen garbage, so that the condition of failure in aerobic composting caused by the reduction of microbial activity resulted from the microorganism wrapped by the grease in aerobic composting can be effectively avoided and the bacillus subtilis can meet the requirement of the domestic kitchen garbage aerobic composting. The bacillus subtilis 6-loil also can be applied to the fields of soil oil stain treatment, biosurfactant production, biological detergent preparation, and the like.

Owner:HANYU GRP CO LTD

Processing method of dried fish leisure food

The invention discloses a processing method of dried fish leisure food. In the method, the fish without intermuscular bones such as tilapia or Spanish mackerel with skin is used as a raw material which is subjected to slicing, rinsing, pickling, baking, frying, seasoning and the like to obtain the dried fish leisure food meeting the requirements for the modern healthy food. Compared with the traditional method, the method disclosed by the invention reduces the use of chemical agents, reduces the grease content of the product, realizes good taste and conforms to the modern food consumption concept concerning environmental protection, health and safety.

Owner:BAIYANG INVESTMENT GRP INC

Process for freezing and frying fruit slices in vacuum

InactiveCN101669605APrevents oxidative browningFlat as everFood preparationRefrigerated temperatureImpurity

The invention discloses a process for freezing and frying fruit slices in vacuum, which is characterized in that the process flow comprises the following steps: selecting raw material, cleaning and removing impurities, slicing precisely, protecting color, dipping, draining, placing into a basket, quick-freezing in a tunnel or a refrigerator, freezing and frying in vacuum, deoiling in vacuum, relishing, packaging, inspecting and putting in storage. The process effectively prevents fruit slices from being easily oxidized and browned; the shape of the fried fruit slice is smooth as original; thecolor is close to the natural color of the raw material; the mouth feel is fragrant and crisp; the thickness is even, the oil content is extra-low ranging from 17% to 20%; and the oil content is lowerby at least 25% than that of the same type of fruit crisp chips. Meanwhile, the vacuum freezing and frying technology effectively prevents generation of harmful substances, such as acrylamide and trans fatty acid and the like, and the traditional constant pressure high temperature frying method and the routine vacuum low temperature frying method can not match with the technology.

Owner:张利彬

Fur fat removal agent

InactiveCN102660396AGood degreasing effectHigh glossOrganic detergent compounding agentsNon-ionic surface-active compoundsPreservativeSurface-active agents

The invention discloses a fur fat removal agent, and belongs to the field of detergent compositions. The fur fat removal agent comprises a non-ionic surface active agent, water-borne high polymer, silicone oil, alkali, solvent, chelant, preservatives and the balance water. The fur fat removal agent has an excellent fat removal effect to the surface and the deep layer of dermatome, removal ability to dirt on fur is high, and washed fur is high in whiteness and gloss. Due to the water-borne high polymer and the silicon oil, the content of fat of the dermatome after the oil of the dermatome is removed by the fur fat removal agent is low, and the fur is bright and smooth.

Owner:HEBEI YONGTAI LEATHER CHEM

Method for preparing quick frozen deep-fried puffy dough strips

ActiveCN101816392AReduce usageImprove securityBakery productsFood preparationSodium bicarbonateAdditive ingredient

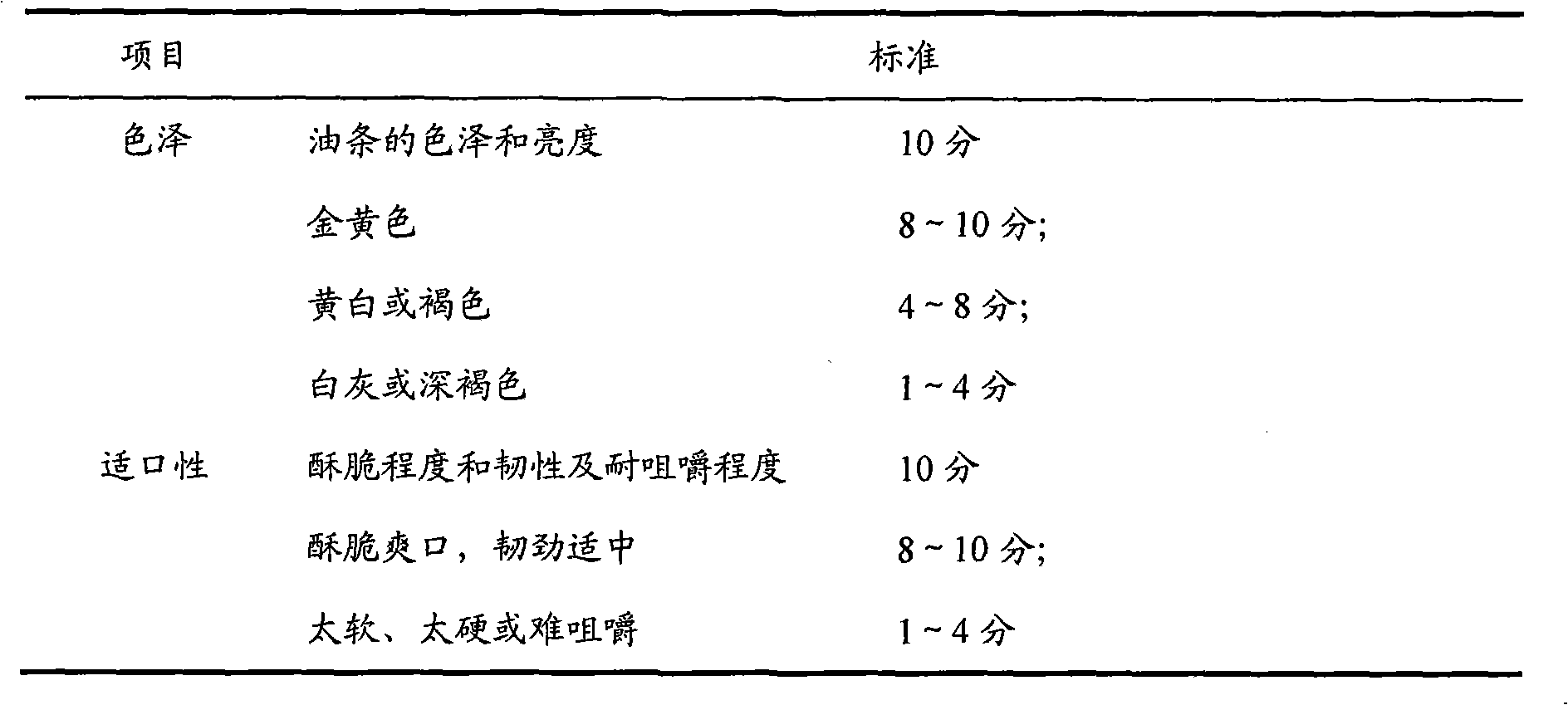

The invention relates to a method for preparing novel aluminum-free quick frozen deep-fried puffy dough strips. The method comprises the steps of: making dough by taking ingredients, such as gluconic acid-delta-lactone, calcium dihydrogen phosphate, sodium bicarbonate, glycerol monolaurate and the like, as a leavening agent and performing the processes of blanks making, frying, quick freezing and the like. Compared with the deep-fried puffy dough strips prepared by the traditional alums formula, the deep-fried puffy dough strips prepared by the method has the advantages that the evaluation result of sense organ is better, and the grease content is reduced by 9.7 percent, so that the process of the deep-fried puffy dough strips is simplified and convenient, the market is convenient to develop and the economic benefit is better.

Owner:JIANGNAN UNIV +2

Flavored low-fat white mushroom crisp chip and preparation method thereof

InactiveCN103689552AImprove processing qualityGood colorFood freezingFood thermal treatmentMushroomFat content

The invention belongs to the technical field of food processing and specifically relates to a flavored low-fat white mushroom crisp chip and a preparation method thereof. The flavored low-fat white mushroom crisp chip comprises the following materials in parts by weight: 1000 parts of white mushrooms, 5-10 parts of konjac glucomannan, 10-80 parts of chitosan, 10-60 parts of salt, 60-200 parts of isolated soybean protein and 40-200 parts of a nutrition balancing agent. The preparation method comprises the following steps: pre-treating the white mushrooms, preparing impregnation liquid, carrying out vacuum soaking and ultrasonic coating, carrying out quick-freezing and slicing, carrying out vacuum frying and dehydrating, removing oil, and packaging. The prepared flavored low-fat white mushroom crisp chip has the advantages of being low in fat content, uniform in color, crisp in mouthfeel, full in nutrition, complete in product shape and almost free of fractures.

Owner:SHANDONG INST OF COMMERCE & TECH

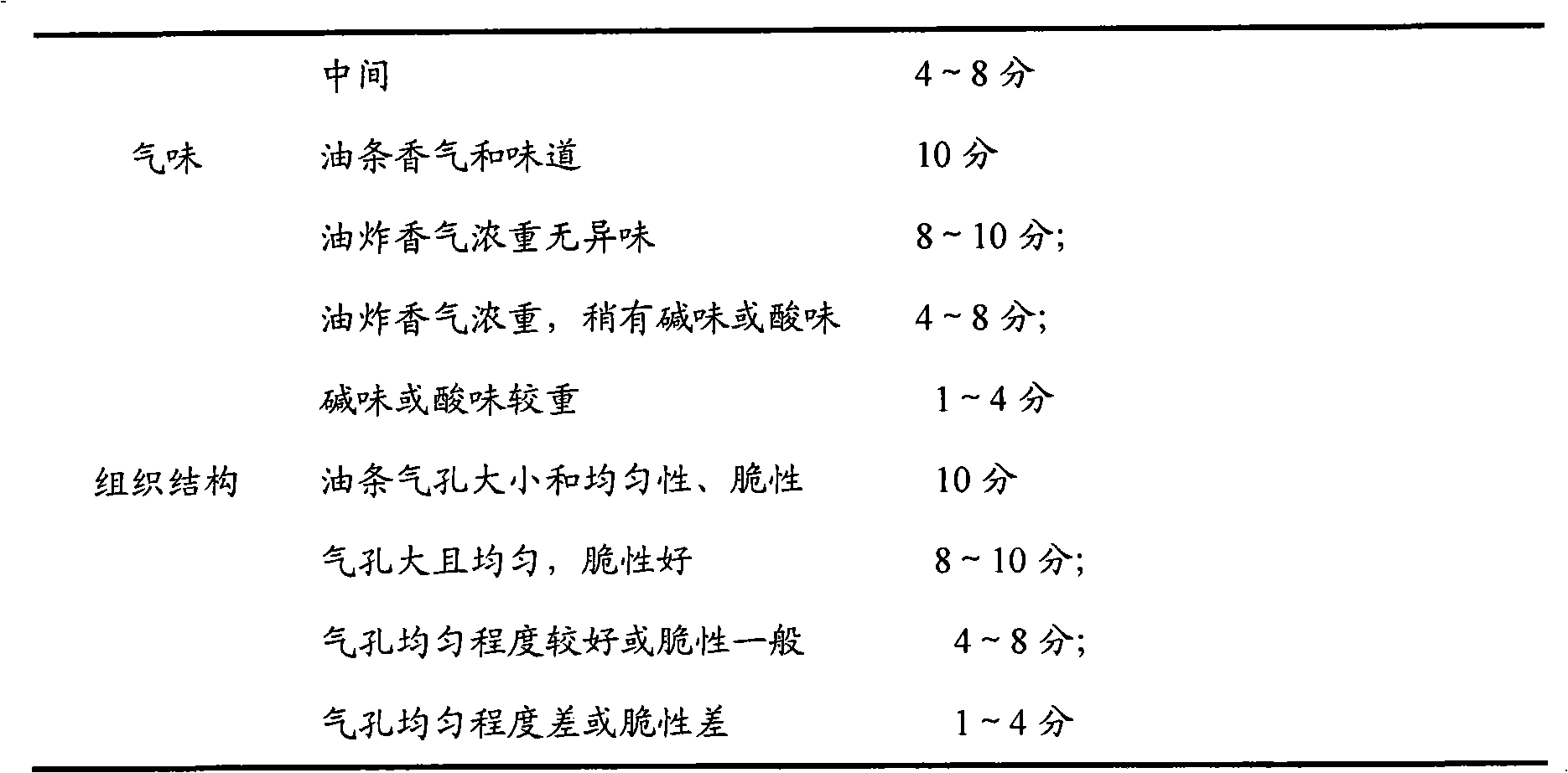

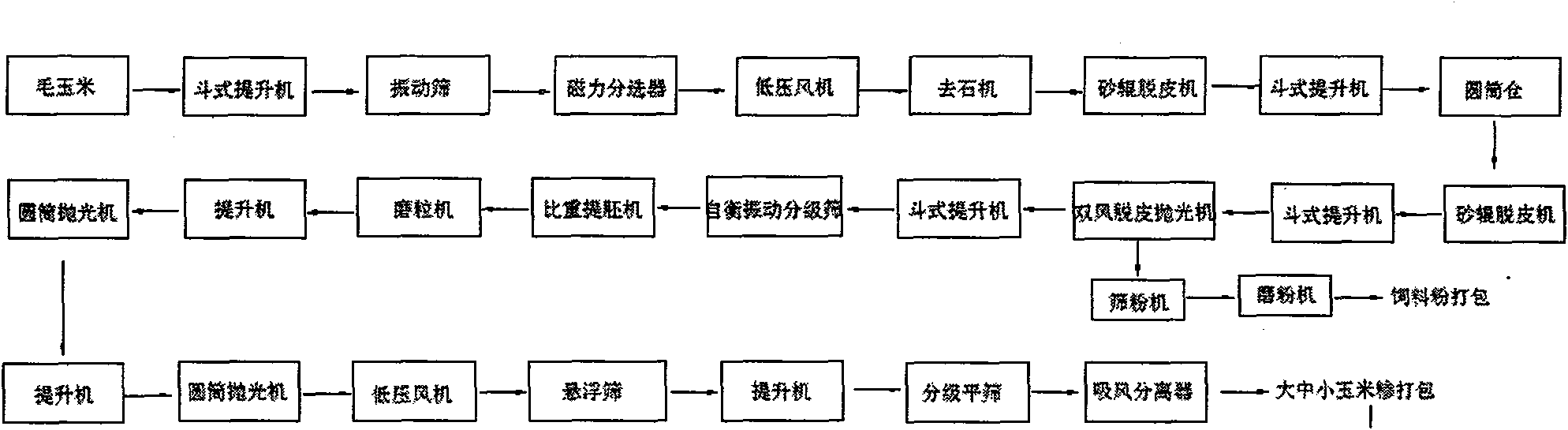

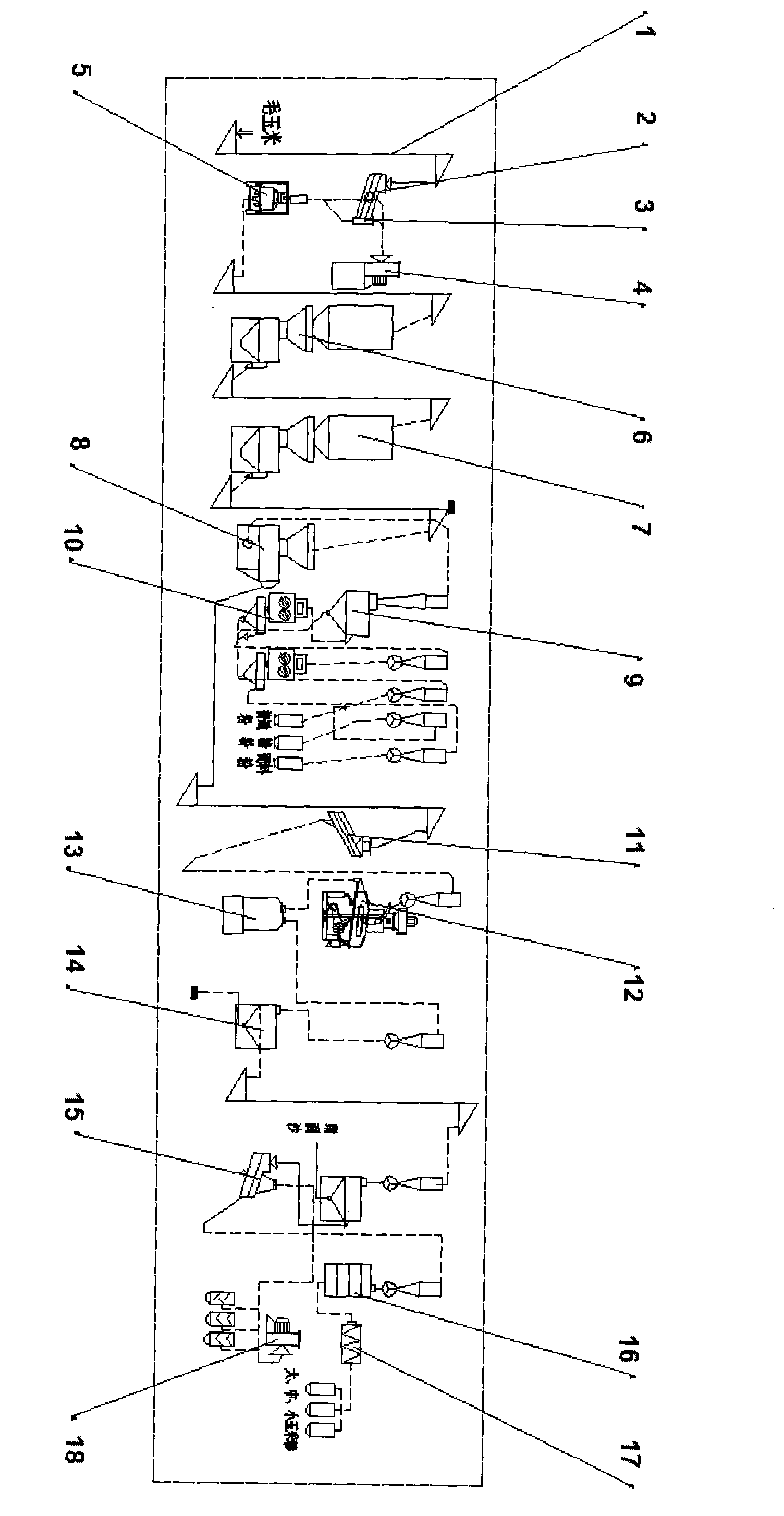

Complete set of equipment and process for processing degreased corn grits and corn flour by adopting full-dry method

InactiveCN102133548ASimple processControl energy consumptionGrain huskingGrain polishingMagnetic separatorSpecific gravity

The invention discloses a complete set of equipment and process for processing degreased corn grits and corn flour by adopting a full-dry method relating to a novel full-dry method corn processing method. The complete equipment comprises a plurality of bucket elevators, a vibration sieve, a magnetic separator, a low-pressure blower (4), a destoner, two emery roll husking machines, a silo, a double-wind husking polisher, a self-balanced vibrating grading sieve machine, a specific-gravity corn degerminating machine, a milling machine, a plurality of elevators, two cylindrical polishers, a low-pressure blower (18), a suspended sieve, a grading flat sieve, an induced-draft separator and other equipment. Compared with the traditional full-wet method corn processing technology and method, the full-dry method corn processing method disclosed by the invention is characterized in that raw corns are processed into flour under a completely drying condition. The defect that the corn flour processed by adopting the full-wet method corn flour processing technology contains water is overcome, the drying process or drying equipment required in the full-wet method corn flour processing technology for avoiding the high possibilities of deterioration and mildewing of the corns containing water is omitted, the production cost is reduced, the production efficiency is improved, the general yield rate of finished products is increased by 10 percent, and the grease content is reduced by 3 percent.

Owner:HENAN CHENGLI GRAIN & OIL MACHINERY

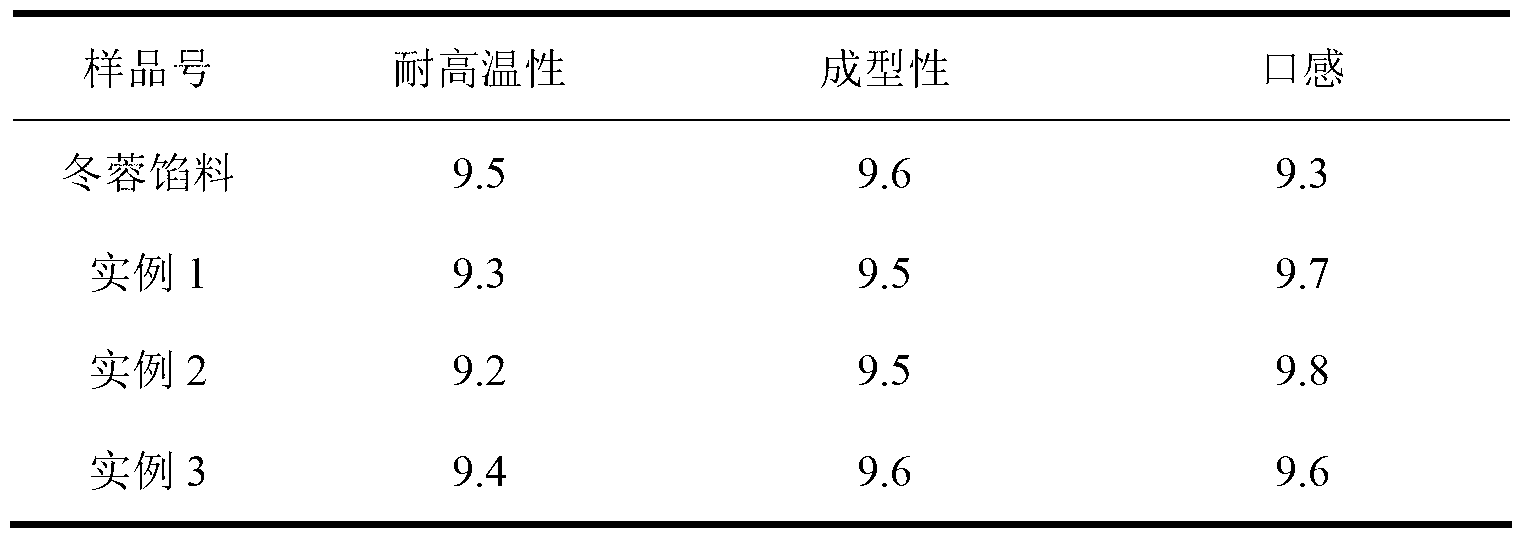

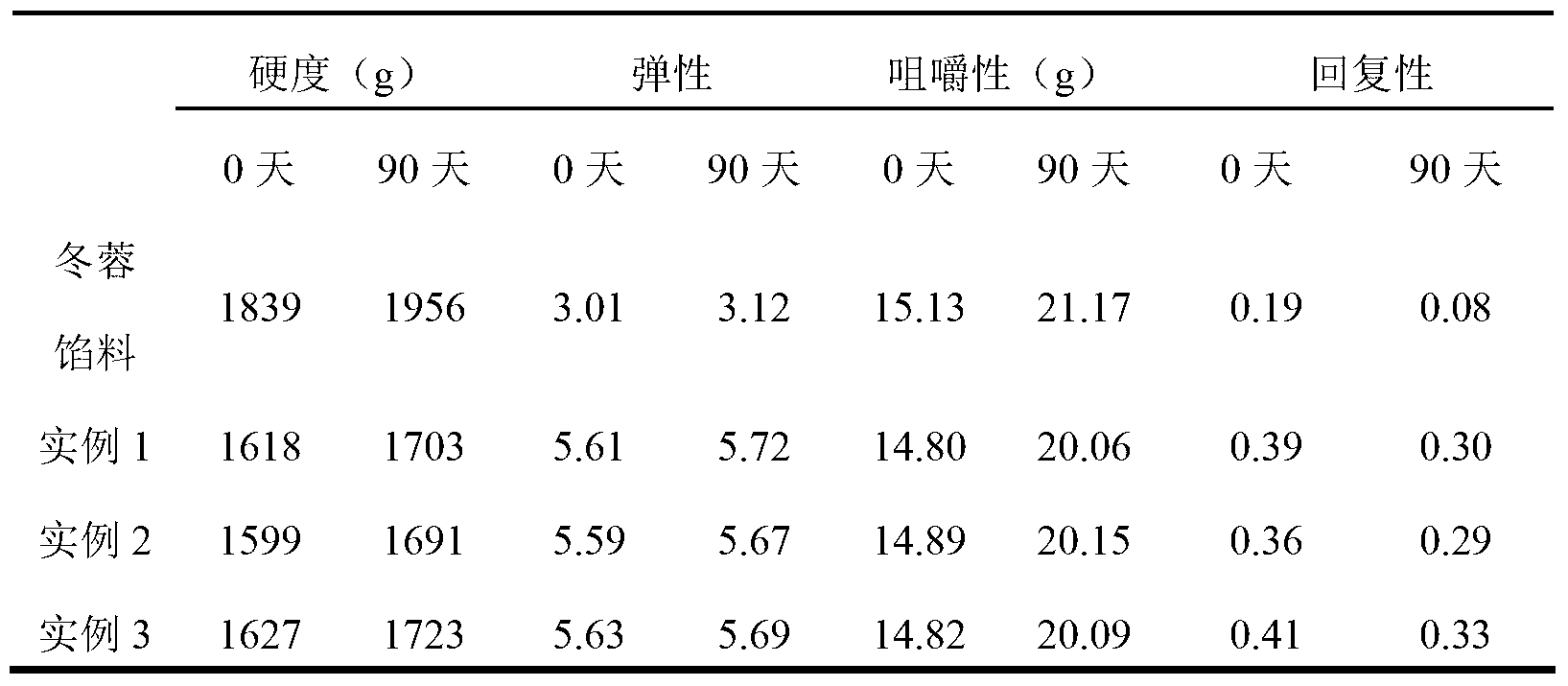

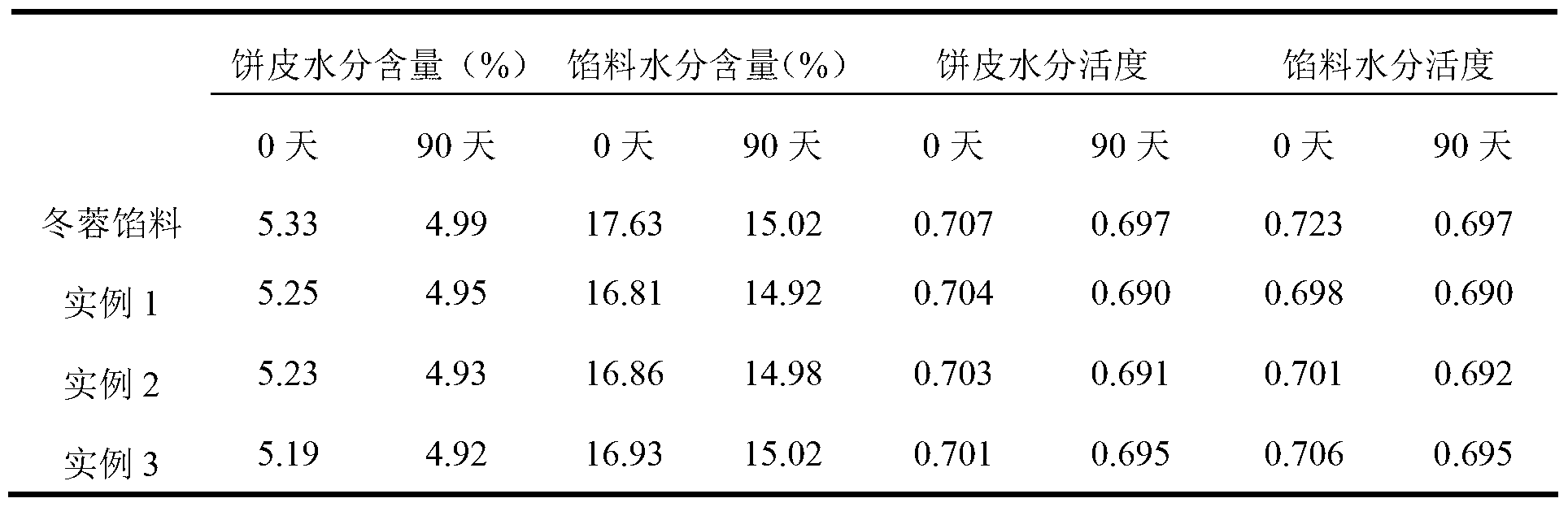

Baked-resistant mooncake stuffing pre-mixed powder and mooncake fruit jam stuffing and preparation methods thereof

ActiveCN103283789ASimple processLow costDough treatmentBakery productsSodium polyacrylateSodium carboxymethylcellulose

The invention discloses a baked-resistant mooncake stuffing pre-mixed powder and mooncake fruit jam stuffing and preparation methods thereof. The baked-resistant mooncake stuffing pre-mixed powder comprises, by mass percentage, 34.7-36.5% of oxidized hydroxypropyl starches, 26.9-28% of hydroxy propyl distarch phosphate, 32.6-33% of distarch phosphate, 0.7-1% of sodium polyacrylate, 1.1-1.2% of sodium carboxymethyl cellulose, 1.1% of sucrose fatty acid ester and 0.8-1% of molecular distillation monoglyceride. Stuffing prepared by the baked-resistant mooncake stuffing pre-mixed powder is good in taste, low in oil content, good in shape preserving and resistant to high-temperature baking, and overcomes the defect of high oil content of conventional mooncake stuffing. Besides, the baked-resistant mooncake stuffing pre-mixed powder is good in ageing resistance, can be stored in six months at room temperature, is simple in manufacturing process and low in cost and has wide market prospect.

Owner:广州合诚实业有限公司

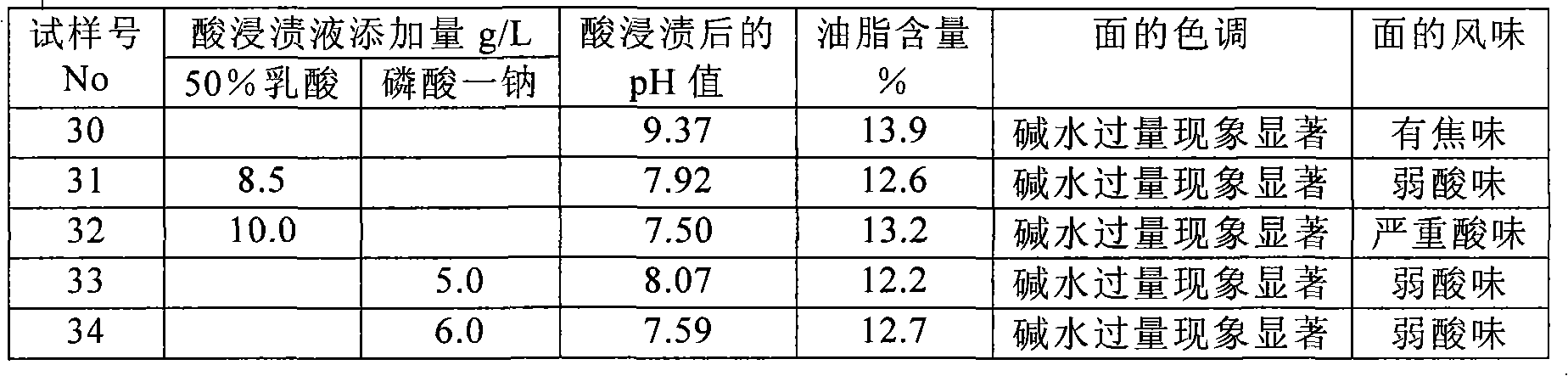

Instant fried noodles and process for producing the same

InactiveCN101686717ALow fat contentNo excessive alkaline water will occurFood ingredient functionsFood preparationSodium carbonateFried noodles

In producing instant fried noodles, it is intended to provide instant fried noodles having a reduced fat content and yet showing favorable taste and texture which can be produced by a very simple process without resorting to any special apparatus, etc. Instant fried noodles are produced by adding sodium carbonate and / or potassium carbonate in a total amount of from 0.3 to 0.6% by weight, based onthe starting powdery materials such as wheat flour, to starting materials for noodles, also adding an acidic substance usable in foods in such an amount as adjusting to pH 7.5 to 8.5, kneading the resultant mixture with water to prepare a dough, rolling, cutting, cooking, seasoning and / or allowing the noodles to adsorb water, followed by frying in oil at 130 to 160 DEG C and drying. Thus, the fatcontent in an instant noodle mass can be reduced while preventing the noodles from weakening caused by brine (i.e., so-called ''kansui yake'').

Owner:NISSIN YORK

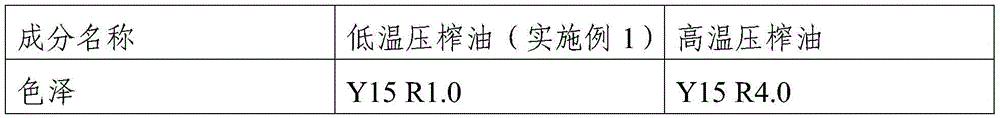

Method for synchronously preparing low-temperature squeezed peanut oil and semi-deoiled peanut snack food

InactiveCN105533602ACrispy tasteLow fat contentFatty-oils/fats productionEdible oils/fatsFiltrationSnack food

The present invention discloses a method for synchronously preparing low-temperature squeezed peanut oil and semi-deoiled peanut snack food. A hydraulic squeezing technology is used to squeeze out peanut oil at an oil amount of 50-70% in the peanut kernels, the obtained peanut oil is subjected to sedimentation and filtration to obtain the low-temperature squeezed peanut oil product, and the peanut cake is subjected to seasoning, re-shaping and drying to prepare the semi-deoiled peanut snack food. A gradient and batch-type pressurization method is used, the squeezing pressure is low, and the obtained semi-deoiled peanut kernels are low in particle broken rate and beautiful in appearance after the re-shaping. Besides, during the squeezing process, the squeezing temperature is tightly controlled to enable the heat-sensitive functional active materials in the peanut oil to be preserved. At the same time, the natural drying, microwave puffing and drying, and water control and moisture keeping methods reduce the water content in the re-shaped peanuts, the mouthfeel of the peanut snack food is improved, and the shelf life of the product is prolonged. The method improves the utilization of the peanuts and fills the gaps of the industry synchronous industrialization preparation.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Low-fat flavour chilli sauce and method for making same

A low-oil fragrant hot paste with different tastes is prepared from primary raw material, stabilizing material and fragrant hot material in weight ratio of (60-75):(24-37):(1-3) through mixing, stirring, steam heating to 50-100 deg.C, grinding by colloid mill 2-3 times, loading in sterilized containers, and sealing. Its advantages are low content of oil, rich nutrients, and optimal color, smell and taste.

Owner:杨辉

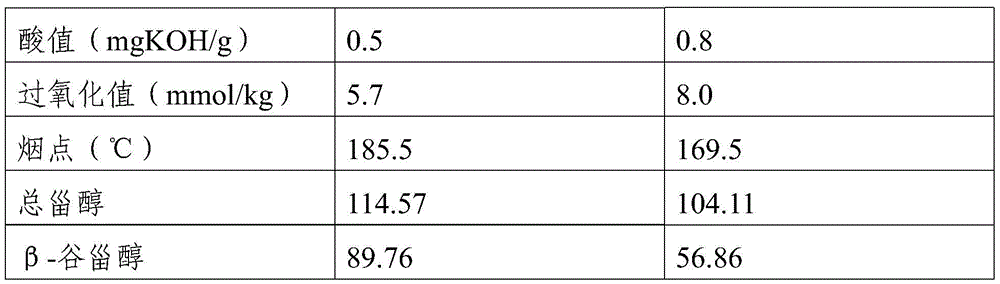

Peanut protein solid drink and preparation method thereof

The invention provides a peanut protein solid drink and a preparation method thereof. The preparation method comprises the following steps of: a, crushing peanut meal obtained after low-temperature pressing into 80-120-mesh peanut meal coarse granules at 20-25 DEG C; b, adding water to the peanut meal coarse granules prepared in the step a, stirring uniformly and steaming in a steamer for 30-60 minutes; c, cooling the peanut meal cooked in the step b at room temperature, drying at 40-50 DEG C till the water content is 5-10% of the weight of the peanut meal coarse granules; d, super-finely crushing the peanut meal coarse granules processed in the step c into superfine peanut meal powder with size not less than 1200 meshes; and e, adding sugar and / or defatted milk powder, as well as whole milk powder, dried fruit juice, coffee powder, walnut powder, soybean powder or cocoa powder to the superfine peanut meal obtained in the step d, sterilizing and finally packaging to obtain the finished product.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Technique of processing Huoma albumen powder

InactiveCN101176504AQuality impactHigh purityProtein composition from vegetable seedsFood industryEmbryo

The invention relate to a processing technology of hemp albumen powder. The invention adopts hemp seeds as the material and obtains the cold rolled prepared hemp seed albumen powder through water removal, filter and cleaning, desquamating, drying, quality adjusting, squeezing, treatment of cold rolling embryo and super micron crushing. The invention can be widely used as the material of food industry and albumen addition agent.

Owner:广西巴马常春藤生命科技发展有限公司

\Walnut protein powder and preparation method thereof

The invention discloses a walnut protein powder and a preparation method thereof. The method comprises the following steps: 1) squeezing walnut kernels until the grease content of the walnut kernels in percentage by mass is less than 10%, thereby obtaining a walnut cake; 2) crushing the walnut cake prepared in the step 1), and carrying out supercritical CO2 extraction on the crushed walnut cake; and 3) carrying out superfine crushing on the walnut cake subjected to extraction in the step 2), thereby obtaining the walnut protein powder. The method is simple in production process operation, and easy to control. In the walnut protein powder prepared by using the method, proteins are basically not denatured, the grease content is less than 1%. A walnut protein powder product does not cause too much grease intake while providing high-quality proteins for the human body, and keeps the unique flavor of walnuts; the walnut protein powder contains no any toxic chemical additives and residuals, is uneasily subjected to oxidative deterioration, and has an extremely high nutritional value.

Owner:SHAANXI TIANYU IND +1

Pastry moon cake and preparation method thereof

The present invention aims to provide a pastry moon cake and a preparation method thereof. The preparation method includes water-oiled dough production, pastry production, a pastry filling process, filling production, raw cake production and a baking process, wherein warm water is used in the production of water-oiled dough, and the temperature of the warm water is controlled at 40-80 DEG C, and green tea powder is added in the production process of fillings. Beneficial effects of the pastry moon cake: grease contents and sugar contents in moon cakes are reduced by using vegetable oil instead of traditional animal oil and using xylitol instead of sucrose in the moon cake production process, so that the pastry moon cake can inhibit the increase of blood sugar and fat accumulation in the human body, and is suitable for diabetics and the elderly to eat; and the introduction of green tea powder into the traditional five-kernel fillings makes the pastry moon cake light in taste and delicate in fragrance, healthy and nutritional.

Owner:TIANJIN YOUHAO INTERCONNECTION TECH CO LTD

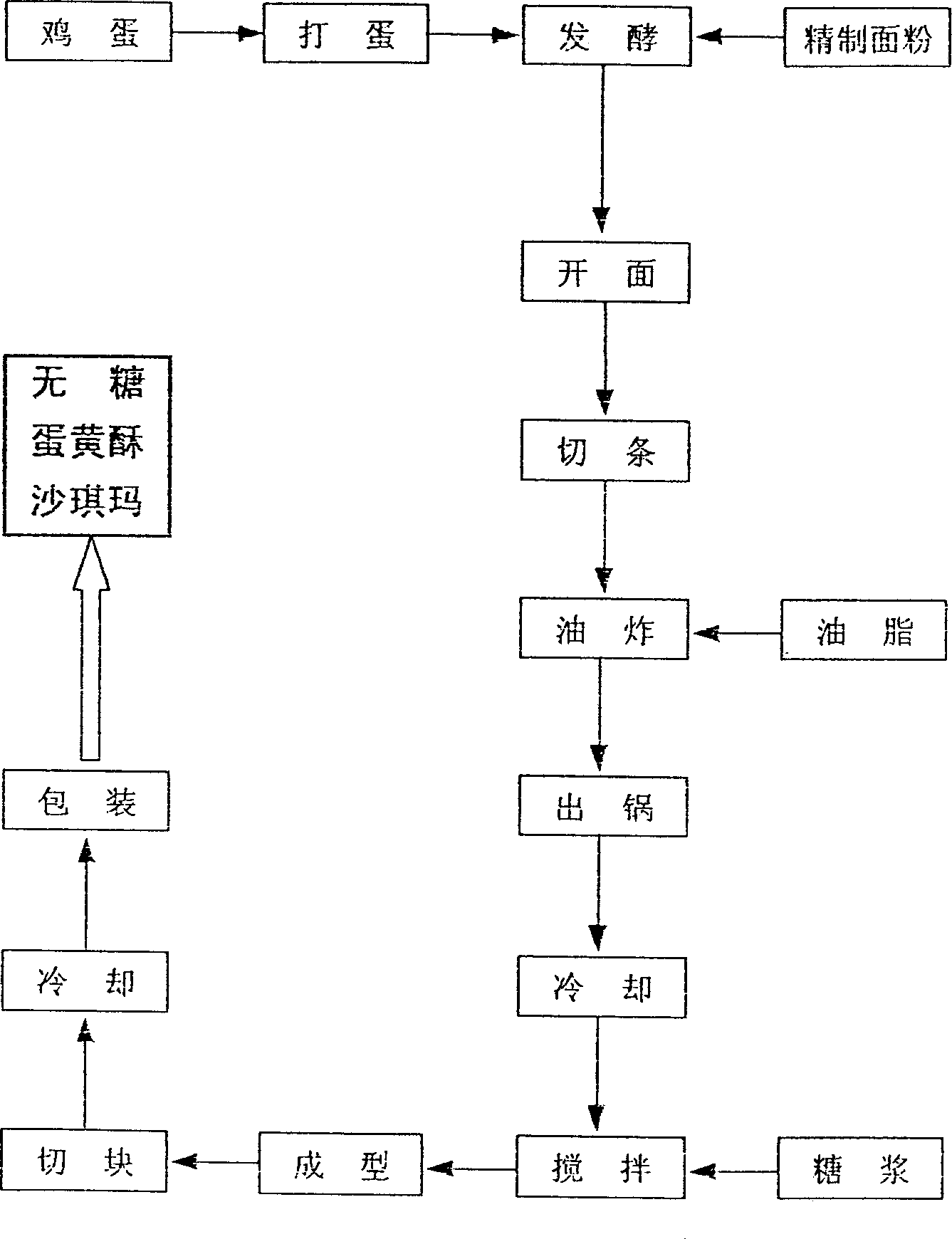

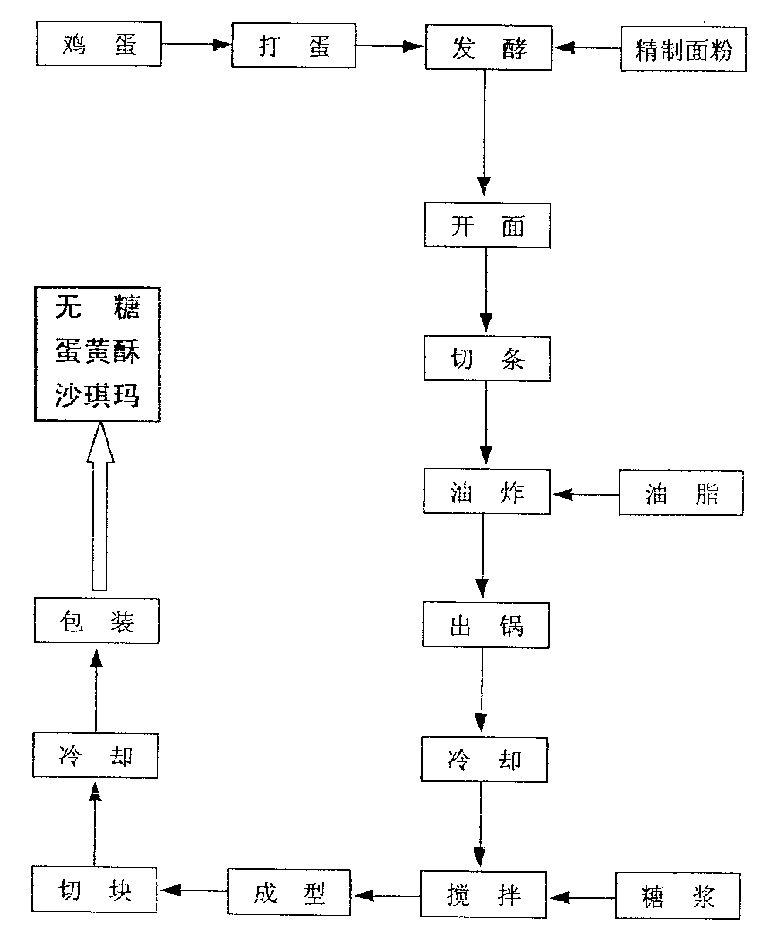

Sugar-free yolk saqima and its preparing process

A sugar-free yolk Saqima, a food, is made from fresh egg, sweetening agent, edible fibres, refined wheat flour, oil, maltitol, algal polysaccharides and essence through proportioning, boiling down the mixture of sweetening agent, edible fibres, maltitol, algal polysaccharides and essence to obtain syrup, mixing fresh egg with wheat flour to obtain dough, fermenting in oven, cutting, frying in oil, cooling, mixing, shaping, mixing with said syrup, shaping, cooling, cutting into blocks and packing. Its advantages are no sugar content, low energy, pure taste, crisp and soft mass, and long storage period. It is suitable of the patients of diabetes and obesity.

Owner:常州花而美食品有限公司

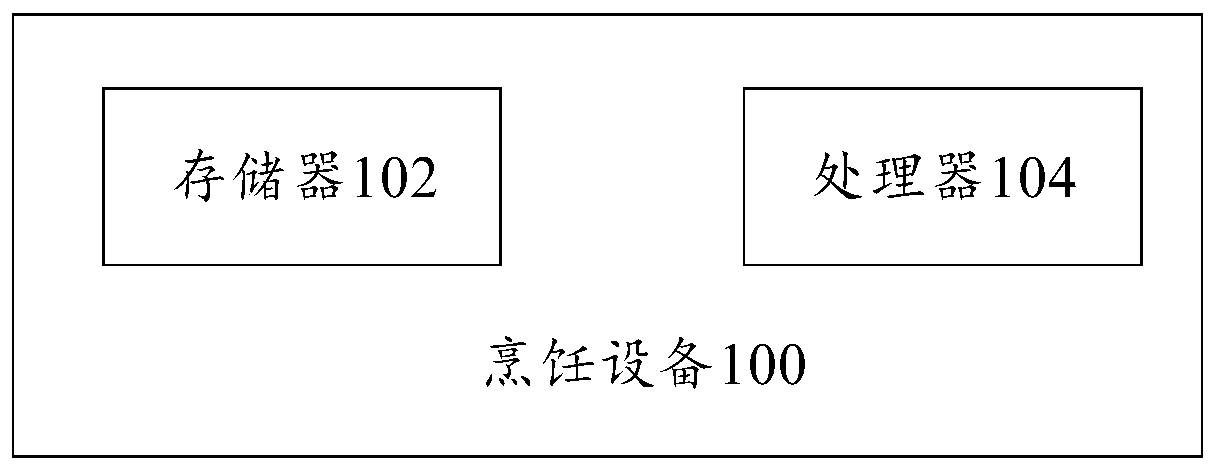

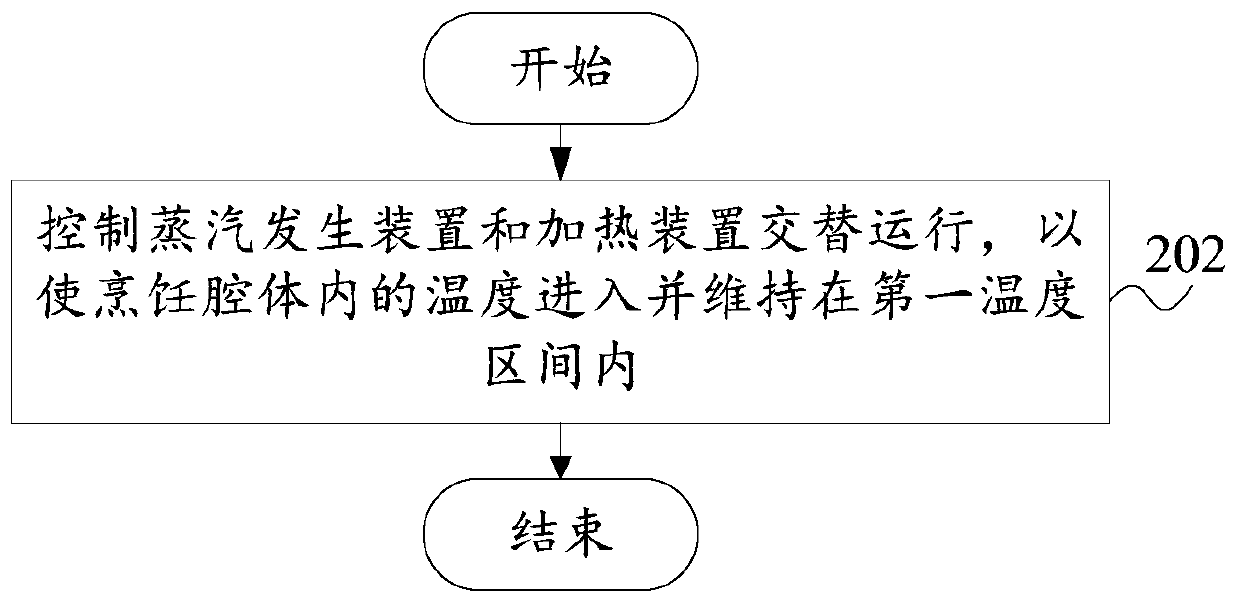

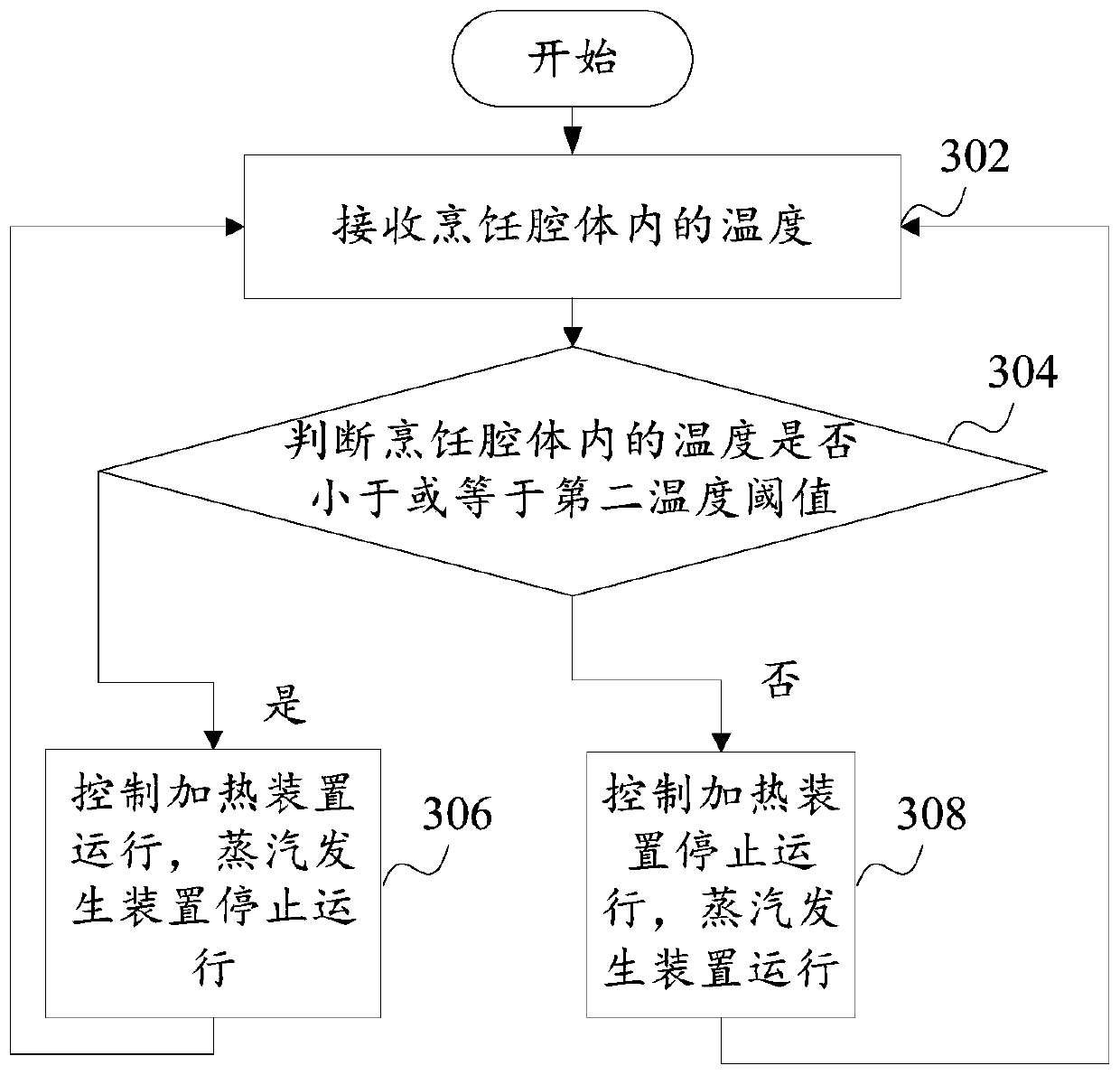

Cooking equipment, control method of cooking equipment and storage medium

InactiveCN111000454AIncrease temperatureAffect heating rateSteam cooking vesselsRoasters/grillsProcess engineeringFat content

The invention provides cooking equipment, a control method of the cooking equipment and a storage medium. The cooking equipment comprises a cooking cavity; a heating device, which is configured to generate heat energy; a steam generation device, which is configured to generate steam; a memory configured to store a computer program; a processor, which is configured to be used for executing a computer program so as to control the steam generation device and the heating device to alternately operate, so that the temperature in the cooking cavity enters and is maintained in a first temperature interval, wherein the power of the steam generation device during operation is the first power. The steam generating device operates according to the first power, steam can enter food materials to heat fat in the food materials, the food fat is rapidly heated and flows out, and the fat content of the food materials is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Oil-in-water type emulsion composition, and method for producing said oil-in-water type emulsion composition

PendingCN110113949AGuaranteed emulsification stabilityLow emulsification stabilityCosmetic preparationsEdible oils/fats ingredientsActive agentOil phase

The present invention addresses the problem of providing an emulsion composition which can retain emulsion stability even when undergoing a high-temperature process such as sterilization (heat resistance) and has a small change in particle diameter distribution before and after heating, and of which the emulsion stability can be retained even when an oily phase component causes the change in state(e.g., the oily phase component is coagulated and crystallized by decreasing the temperature of the composition, or the oily phase is melted by increasing the temperature of the composition) (i.e., resistance to decrease in temperature), and which is easy to handle during the production thereof. The problem can be solved by an oil-in-water type emulsion composition comprising solid particles, a surfactant having one alkyl group, an oily phase component and an aqueous phase component, wherein the oily phase component comprises an oily phase component having an unsaturated bond and / or an oxygenatom, and the solid particles exist on the interface between the oily phase component and the aqueous phase component.

Owner:MITSUBISHI CHEM CORP

Complex sprouting protein nutrition powder and preparation method thereof

InactiveCN104286729AHigh nutritional valueImprove bioavailabilityFood ingredient functionsFood preparationBiotechnologyBrowning

The invention relates to complex sprouting protein nutrition powder and a preparation method thereof, and belongs to the field of food processing. The complex sprouting protein nutrition powder is prepared through the following steps: firstly, soybean sprouts and peanut sprouts are steamed for 30-50 minutes at 95-100 DEG C, and then subjected to forced air drying at 60 DEG C; secondly, the dried sprouts are smashed into soybean sprout coarse powder and peanut sprout coarse powder with particle sizes of 80-120 meshes at 20-25 DEG C; thirdly, the soybean sprout coarse powder and peanut sprout coarse powder are mixed and smashed into fine powder with the particle sizes of 400 meshes above. According to the complex sprouting protein nutrition powder and the preparation method thereof, the soybean sprouts and peanut sprouts are prepared into powder products for the first time; the bioavailability and the working depth of the soybeans and the peanuts are improved; the utilization rate of the edible parts is improved to 95% above; through the adoption of a steaming method for curing, the brown stain of the soybean sprouts and the peanut sprouts as well as the loss of the effective components in the sprouts are prevented effectively; the protein nutrition powder provided by the invention has the unique fragrance and flavor of the soybeans and the peanuts, and is fresh and pleasing in color and luster, fine and smooth in mouthfeel, low in grease content, and long in storage period.

Owner:UNIV OF JINAN

Nutrient chicken skin jelly and preparation method thereof

ActiveCN101849681AClear and transparent textureUniform color on cut surfaceFood preparationBiotechnologyAnimal science

The invention relates to a nutrient chicken skin jelly and a preparation method thereof, and belongs to the field of food processing. The nutrient chicken skin jelly comprises the following raw materials in percentage by weight: 40 to 60 percent of chicken skin, 2 to 6 percent of hydrophilic gel, 0.01 to 0.08 percent of vitamin C, 0.5 to 2.5 percent of garlic, 0.1 to 0.5 percent of ginger powder,0.5 to 2 percent of KC, 0.1 to 2 percent of salt and the balance of water. The preparation method comprises the following steps of: removing redundant grease from the chicken skin and then soaking the chicken skin into hydrochloric acid, flushing the chicken skin, boiling the chicken skin by adding water and extracting gel, then adding the hydrophilic gel to dissolve the gel, adding flavoring agent into the gel, cooling and shaping the gel, and freezing and storing the gel to obtain the nutrient chicken skin jelly. The preparation method has the advantages of simple production process, wide raw materials and low cost; and the chicken skin jelly product is health-care food for home, traveling, clearing heat and relieving summer heat, and has smooth mouthfeel, rich collagen protein, low fat content, rich nutrient and convenience for eating.

Owner:FUZHOU UNIV

A kind of low-fat moon cake skin and preparation method thereof

The invention discloses a low-fat moon cake crust. The low-fat moon cake crust is made from the following raw materials in parts by weight: 5-10 parts of lye water, 110-130 parts of sirup, 35-50 parts of peanut oil, 12-25 parts of oil succedaneums and 180-220 parts of flour. According to the low-fat moon cake crust disclosed by the invention, the peanut oil contained in a moon cake crust is partially replaced with the oil succedaneums with similar taste and property to that of oil and lower heat quantity, and therefore, the oil content and the heat quantity of the moon cake crust are lowered,the health of people is facilitated and the development trend of present healthy foods is fitted; in addition, the low-fat moon cake crust has a wide market prospect. The invention also discloses a making method of the low-fat moon cake crust. The making method disclosed by the invention has the advantages of simple process and low cost.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD

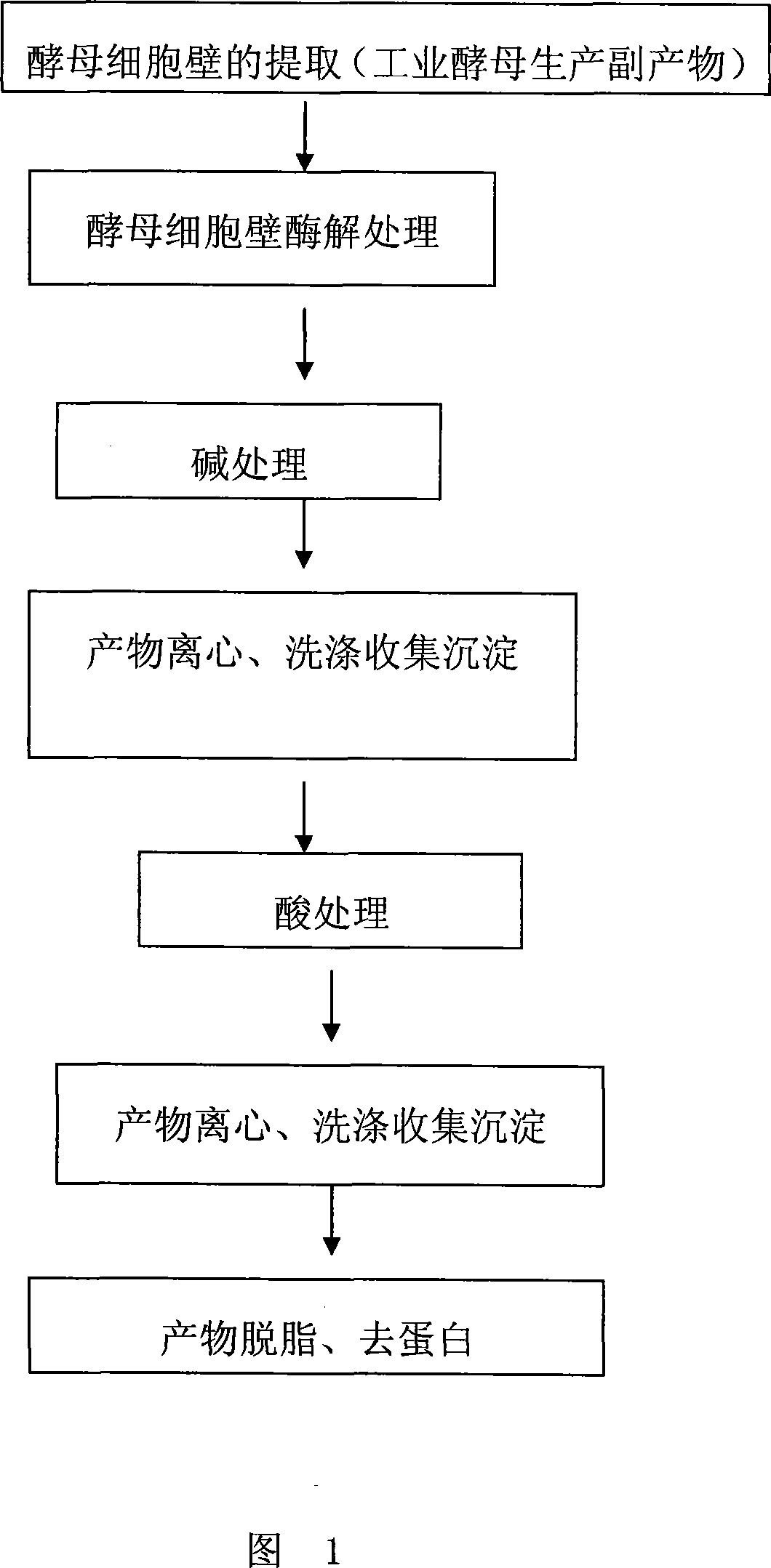

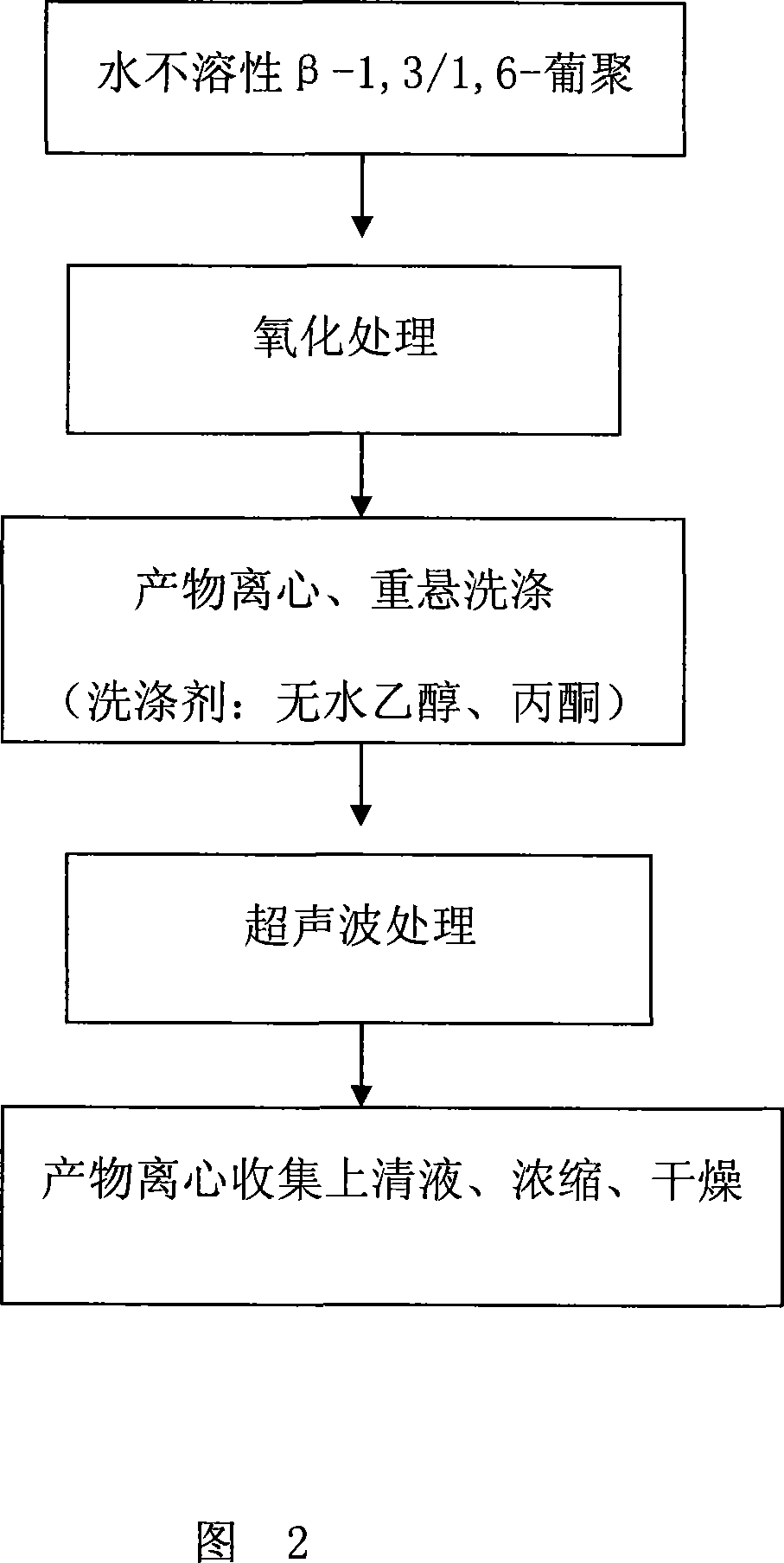

Method for preparing water-soluble beta-1,3/1,6-dextran

The invention discloses a method for preparing water-soluble beta-1, 3 / 1, 6-qlucan. The method has the steps as follow: 1) oxidization process: suspending water-insoluble beta-1, 3 / 1, 6-qlucan in oxidant solution at 2 to 8 DEG C, laying aside for oxidizing reaction for 16 to 24 hours for centrifugation and collection; 2) washing: stirring and washing the deposition treated from step 1) by ethyl alcohol and acetone respectively for 30mins to 1 hour for then centrifugation and collection; 3) ultrasonic process: heavy-density suspending the deposition treated from step 2) in the DMSO solution of concentration expressed in percentage by volume of 0.05 to 0.2 percent, and ultrasonic processing the heavy-density suspension liquid for 20 mins; and centrifugally collecting the supernatant fluid to achieve water-soluble beta-1, 3 / 1, 6-qlucan. Being detected, the water-soluble beta-1, 3 / 1, 6-qlucan prepared by the method has the yield over 95 percent and has little protein content and fat content.

Owner:CHINA AGRI UNIV

Health characteristic non-standardized or standardized high cocoa dark chocolate with improved taste texture, melt, creaminess and reduced bitterness

InactiveUS20100278984A1Great tasteReduce bitternessMilk preservationDough treatmentMilk ChocolateAntioxidant

The present invention provides for a non-standardized dark chocolate composition to have up to 75% less saturated fat content than regular dark chocolate and have an improved healthier fat structure. A non-standardized and standardized dark chocolate include an antioxidant blend of; Virgin Coconut Oil, Vanilla Powder, Blackberry Powder, and Acai Berry Extract that creates a synergistic affect making the compositions have the rich and creamy taste, texture, melt and creaminess similar to milk chocolate. The final compositions have improved health characteristics, antioxidant content, and significantly less bitterness. Additionally, the method for preparing such non-standardized and standardized dark chocolate compositions is covered.

Owner:ANTIOXIDANT SUPERFOODS

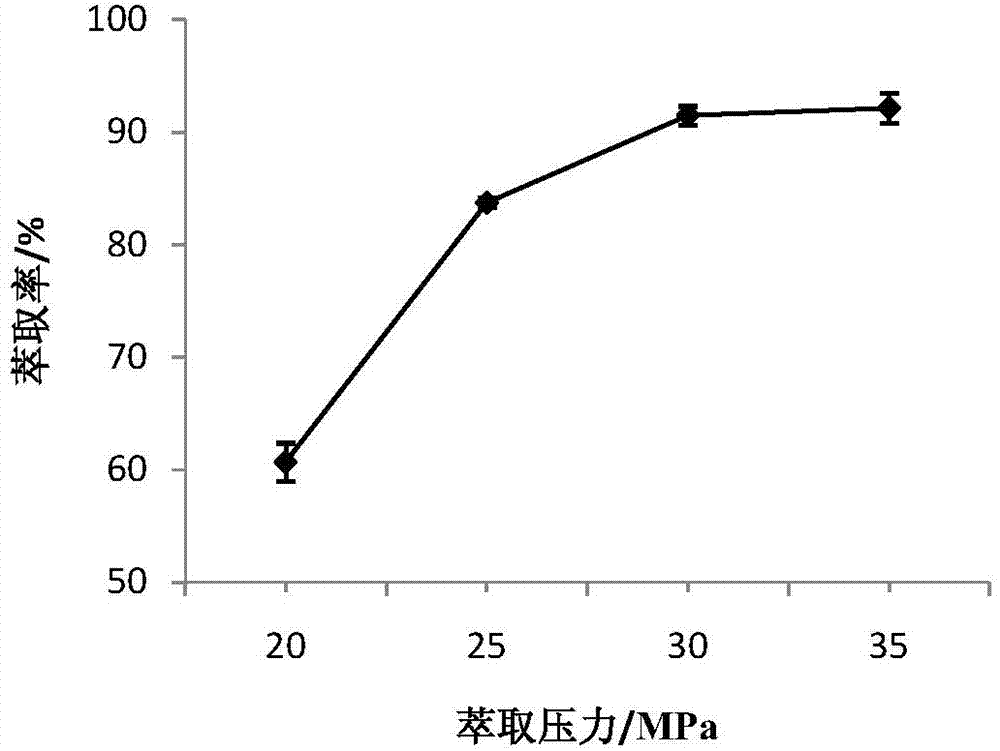

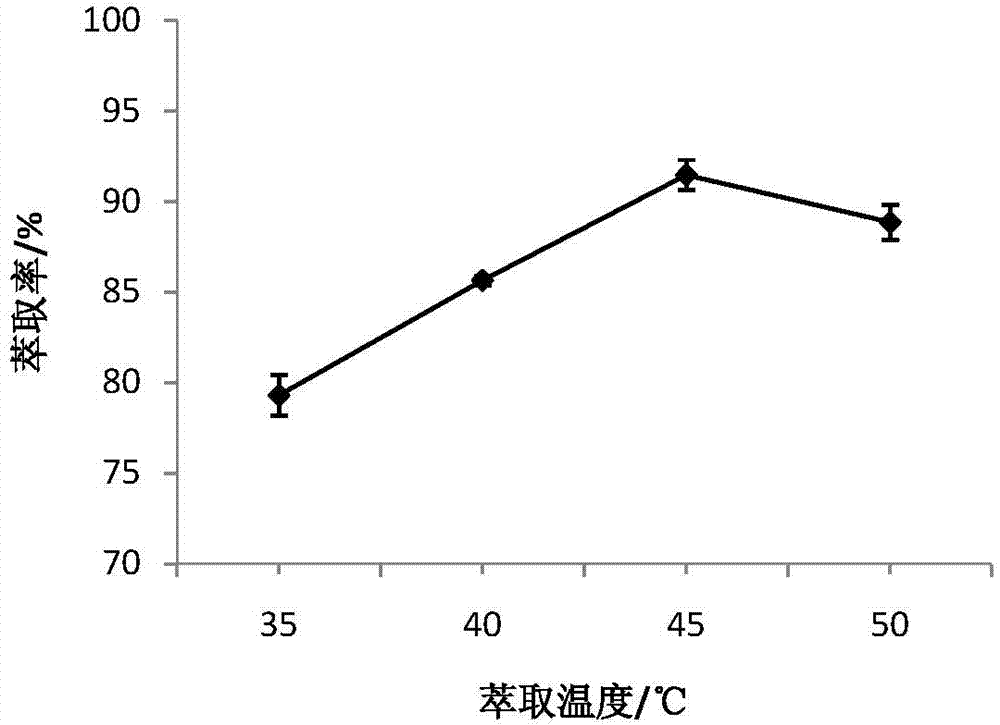

Raw wool treating supercritical CO2 process

The raw wool treating supercritical CO2 process includes the following steps: 1. depurating raw wool; 2. extracting depurated raw wool with supercritical CO2 to obtain lanolin and degreased wool. The supercritical CO2 process has the conditions, including extraction pressure 30-40 MPa, extraction temperature 60-75 deg.c, the first stage separation pressure 9-10 MPa, the first stage separation temperature 45-50 deg.c, the second stage separation pressure 5-6MPa, and the second stage separation temperature 36-42 deg.c. The present invention has simple technological process, high product yield, environment friendship, low cost and high product quality.

Owner:廖秀义

Baking-resistant oil-in-water type Caska sauce and preparation method thereof

InactiveCN109645440AGood baking resistanceImprove applicabilityFood scienceOil and greaseCooking & baking

The invention discloses a baking-resistant oil-in-water type Caska sauce and a preparation method thereof. The sauce comprises the following raw materials by mass percentage: 30-50% of water, 10-35% of syrup, 2-10% of modified starch, 5-10% of edible vegetable oil, 2-10% of white granulated sugar, 2-8% of milk powder, 0.2-2% of protein, 1-5% of whey powder, 0.05-3% of an emulsifier, 0.02-2% of edible gum, 0.01-0.2% of beta-carotene, and 0.008-0.0015% of food flavor. The method adopts the synergistic use of protein, edible glue and starch, so that the obtained product has good baking resistanceand good application effect in bread, as a surface decoration, the product is not foamed and fractured after high-temperature baking, and as a stuffing material, the product does not collapse. The baking-resistant oil-in-water type Caska sauce of the invention has smooth and delicate taste, good mouth-forming property and good flavor. The baking-resistant oil-in-water type Caskada sauce of the invention has low oil content and conforms to the healthy eating concept of the consumer. Under the condition of low oil content, the prepared Caska sauce tastes refreshing and smooth.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Method for extracting fish collagen

ActiveCN106967169AHigh purityLow in fatConnective tissue peptidesPeptide preparation methodsChemistrySolubility

The invention relates to a method for extracting fish collagen, and belongs to the technical field of natural protein extraction. Through adoption of a fish collagen extracting process in which an organic solvent is not used, removal and separation of fat are achieved. The invention adopts the technical concept as follows: firstly, through grinding and homogenizing under an ultrasonic action, tissue cells of fish skin are completely broken, and during subsequent alkali treatment and enzymatic treatment, fat and protein can be more removed, so that a crude extract with low fat content can be obtained; then, a crude extract solution is enabled to pass through a resin bed obtained after lipophilic modification, so that the purpose of adsorbing low-content lipids is achieved. The prepared fish collagen has the advantages of high purity, low fat content and good water solubility.

Owner:GUANGDONG TIMES FOOD & LIFE HEALTH RES CO LTD

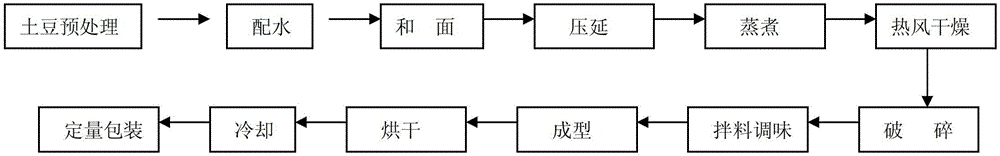

Method for preparing non-fried potato-flavor dry eaten instant noodles and convenient foods

ActiveCN102871053ASolve the problem of hard foodCrispy tasteFood preparationSnack foodInstant noodle

The invention relates to a method for preparing non-fried potato-flavor dry eaten instant noodles. The method comprises the following steps of: (1) uniformly stirring table salt, white sugar, aginomoto, mashed potato and water, mixing with wheat flour, modified starch and a swelling agent, and uniformly stirring to obtain dough; (2) pressing the dough in the step (1) into a sheet in the thickness of 0.85-0.90mm through a pressing procedure; and (3) shredding the sheet, cooking, and drying by using hot air to obtain noodle cakes, namely the non-fried potato-flavor dry eaten instant noodles. The instant noodles are rapidly dehydrated in the hot air drying process during preparation, so that a porous structure is formed in the noodles, the non-fried potato-flavor dry eaten instant noodles are crispy in mouthfeel, suitable for dry eating, solve the problem that noodles produced by a non-frying process are hard for dry eating, and can be made into round, square or triangular convenient foods through noodle cake crushing, flavoring, extrusion forming, drying and other procedures, and the convenient foods are novel healthy and delicious leisure snack foods.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

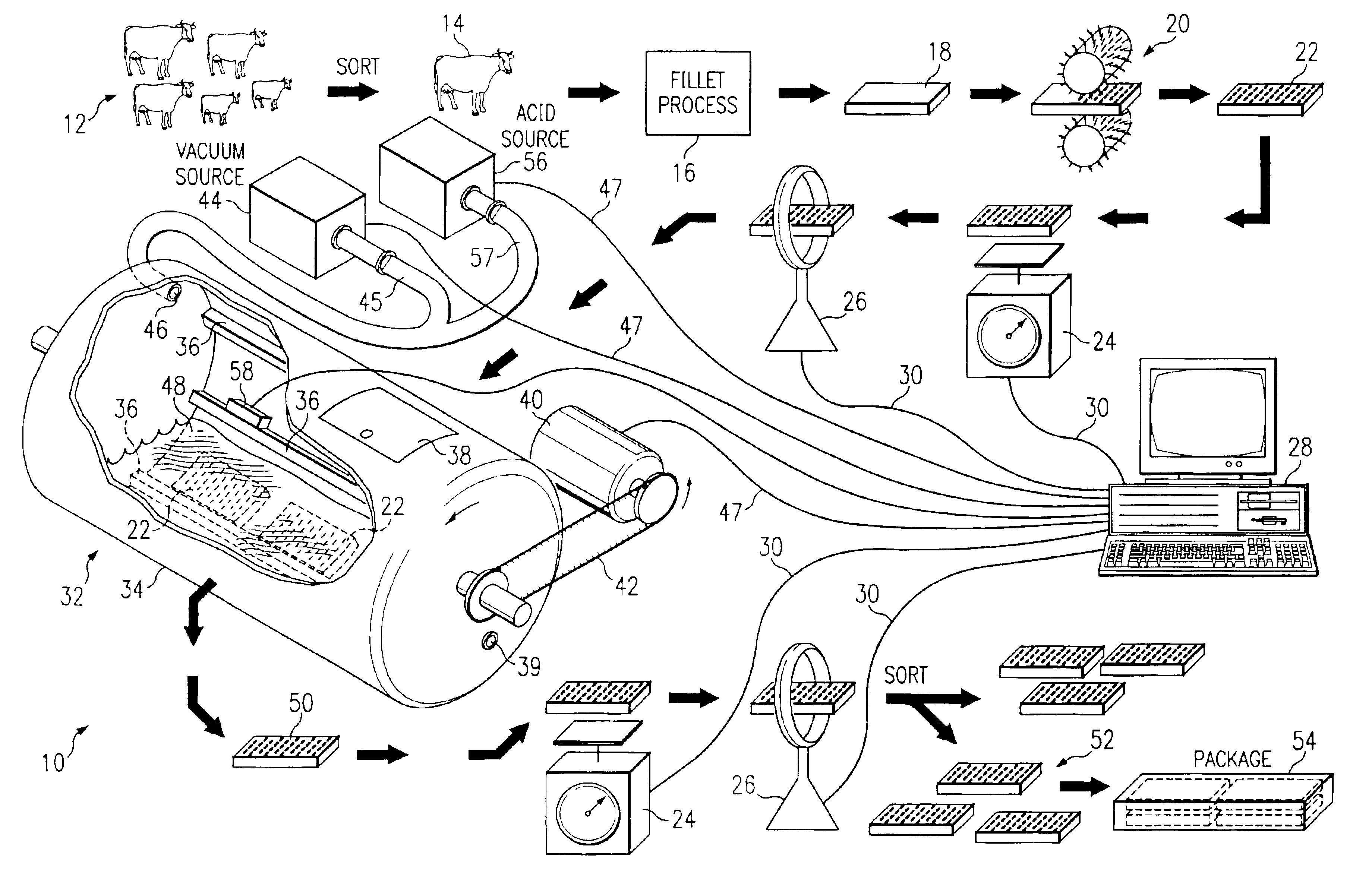

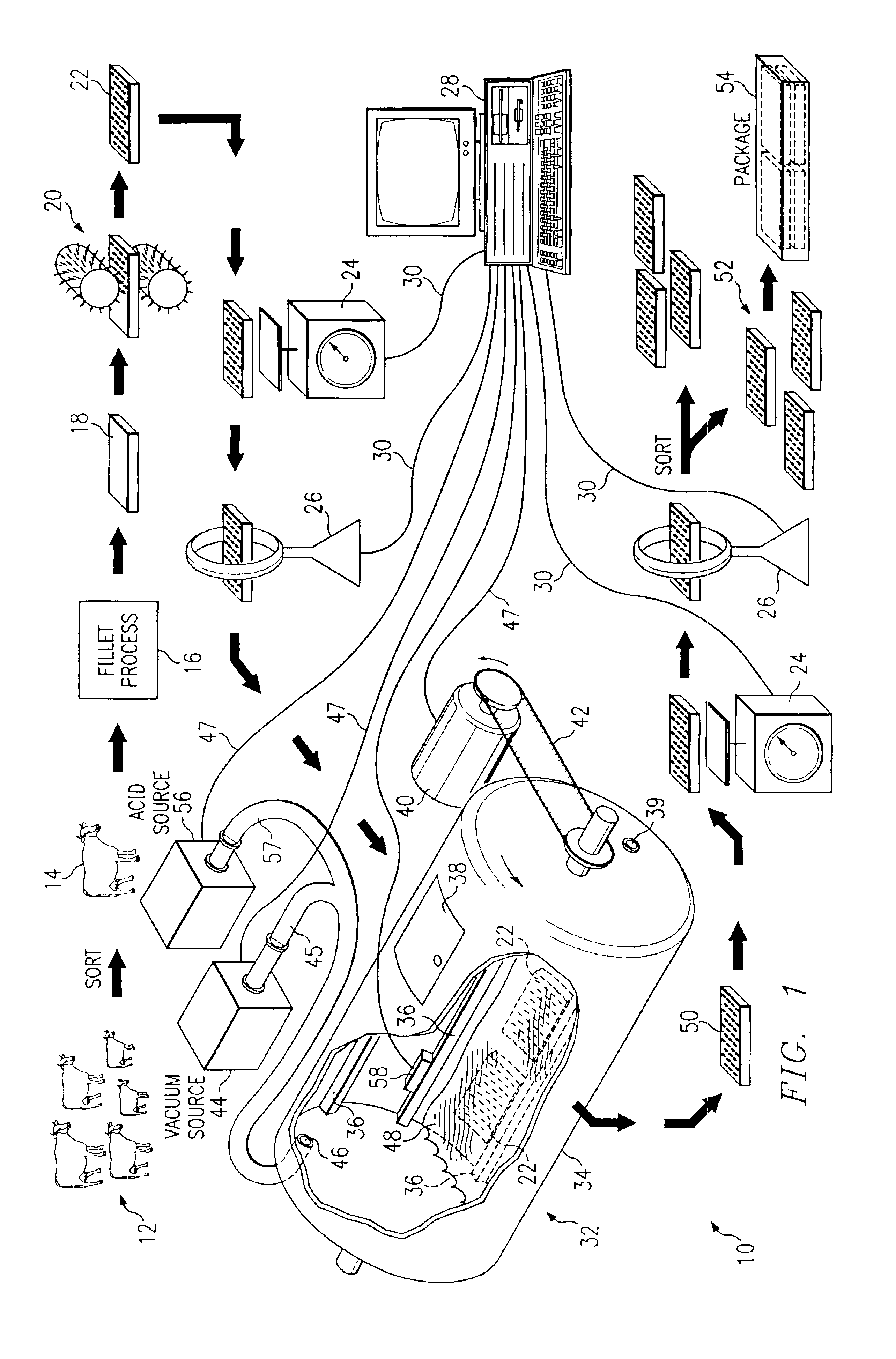

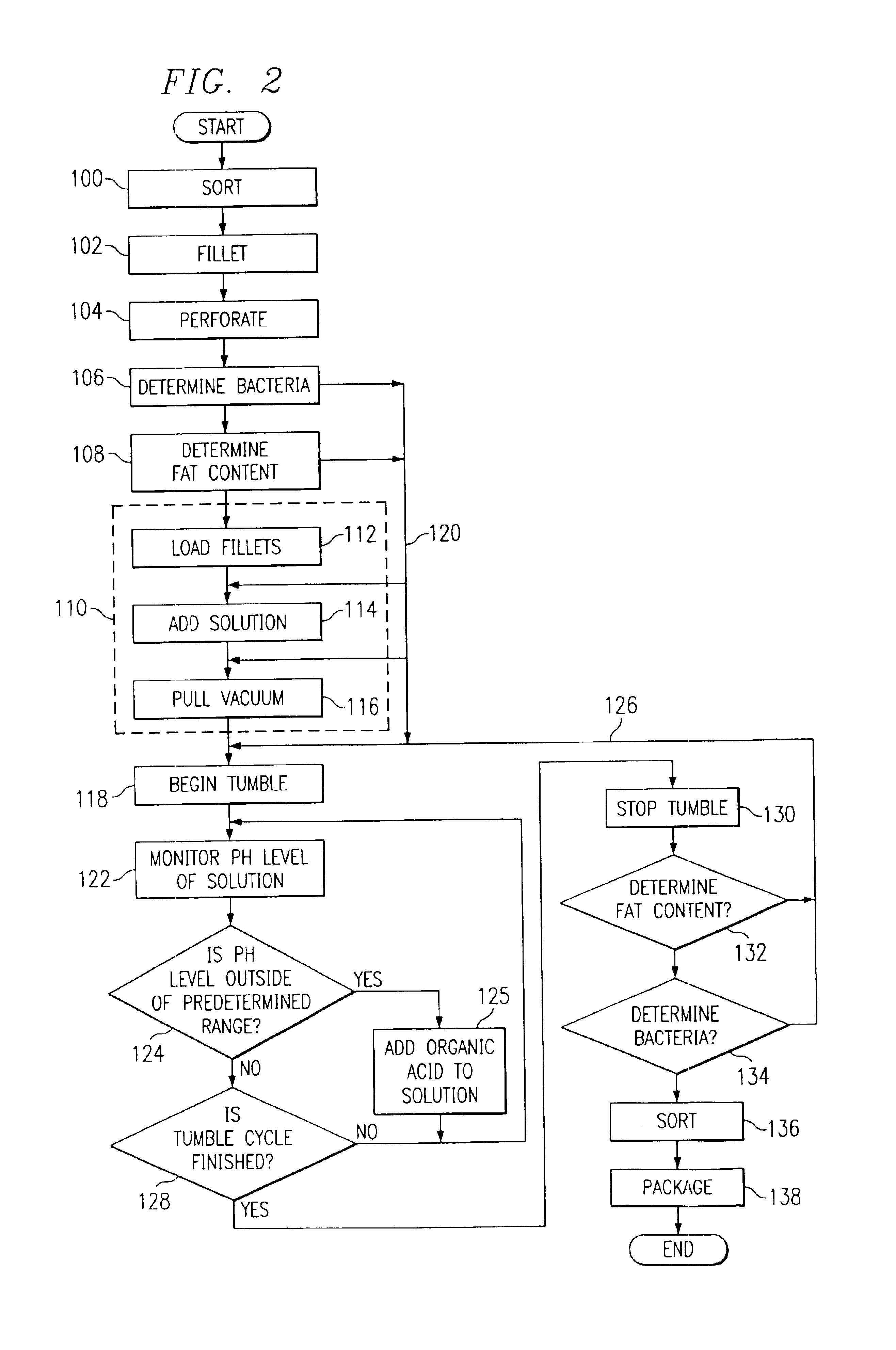

Method of reducing bacteria and fat content of food products

InactiveUS6896921B2Eliminates and reduces disadvantageEliminates and reduces and problemGrain huskingGrain polishingOrganic acidSalt content

In one embodiment of the present invention a method for processing a plurality of food products includes loading the food products into a vacuum tumbler, filling the vacuum tumbler to a predetermined level with a processing solution having a pH level within a predetermined range, withdrawing air from the vacuum tumbler to create a partial vacuum, rotating the vacuum tumbler for a predetermined time period to expose the food products to the processing solution and the partial vacuum, periodically adding, during the predetermined time period, a predetermined amount of an organic acid to the processing solution to maintain the pH level within the predetermined range, and removing the food products from the vacuum tumbler after the predetermined time period.

Owner:GROVAC SYST INT L C

Processing method of air puffing and swelling fish maw

The invention relates to a processing method of air puffing and swelling fish maw. According to the processing method, water in a pot is boiled, baking soda is added into the water, and clean-washed fish maw is put into the water to be degreased. The degreased fish maw is fished out and placed in a drying oven with a temperature between 30 DEG C to 40 DEG C to be dried for 16 hours to 24 hours, and then the degreased fish maw is placed in an electric oven to be baked. The fish maw is placed in a first layer of the electric oven to be baked for 30 minutes to 40 minutes with an upper heating temperature of the first layer 85 DEG C to 95 DEG C and a lower heating temperature 95 DEG C to 105 DEG C, then the fish maw is placed in a second layer of the electric oven to be baked for 1 minute to 4 minutes with the upper heating temperature and the lower heating temperature both are 210 DEG C to 230 DEG C until the fish maw is completely puffed. The processing method of air puffing and swelling the fish maw overcomes defects that a medium temperature and swelling time are hard to control, loss of nutritional ingredients is large, edible fat and oil produces harmful substances after being heated, greasy dirt influences flavor of the fish maw, a quality guarantee period is short, pollution is caused and the like. The processing method of air puffing and swelling the fish maw utilizes hot air as a heat-transfer medium, temperature and time are automatically adjusted, and electric oven equipment is controlled, so the processing method is suitable for industrial production. The swelled fish maw has even bubbles, yellow fraction color, aromatic flavor, low coil content, small loss of nutrient content and is convenient to eat.

Owner:YANGZHOU UNIV

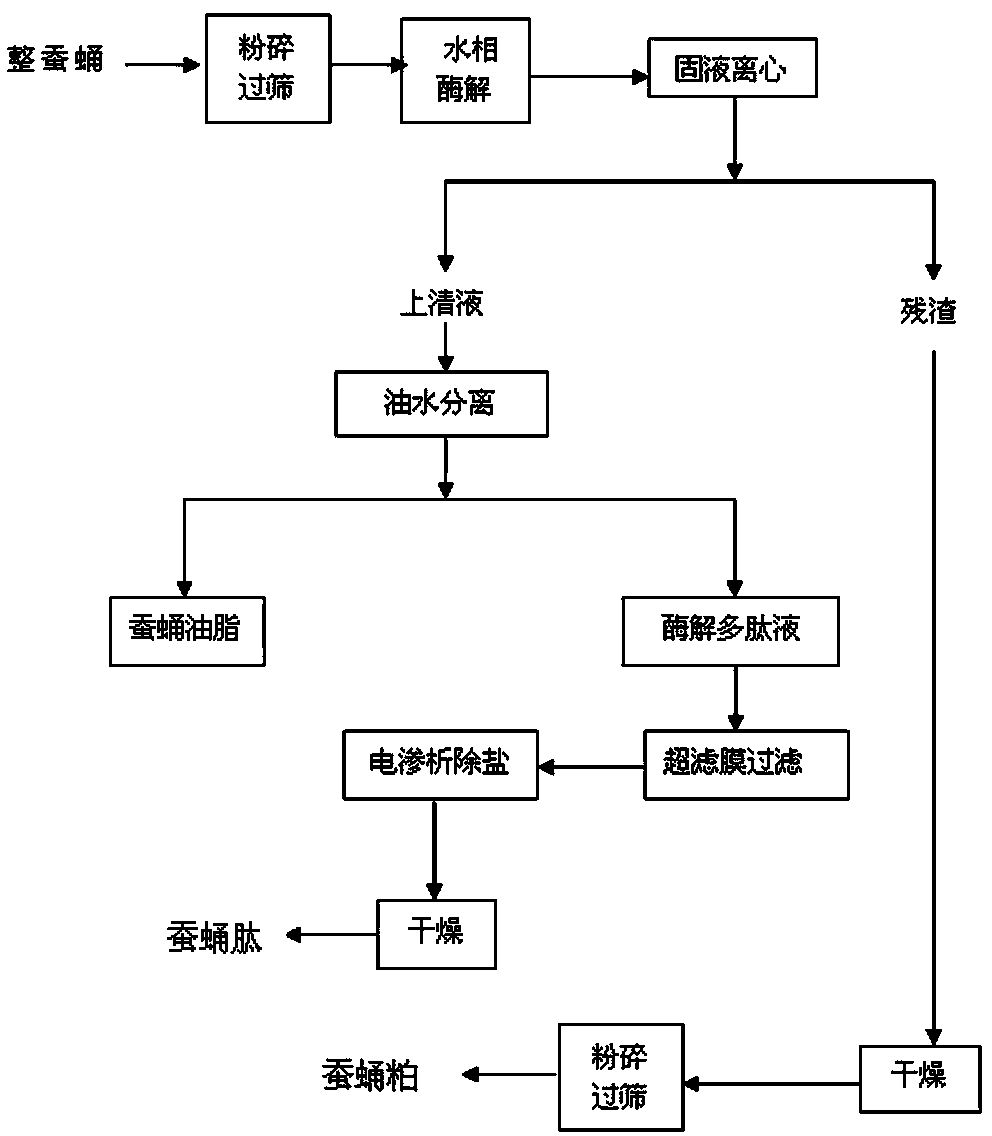

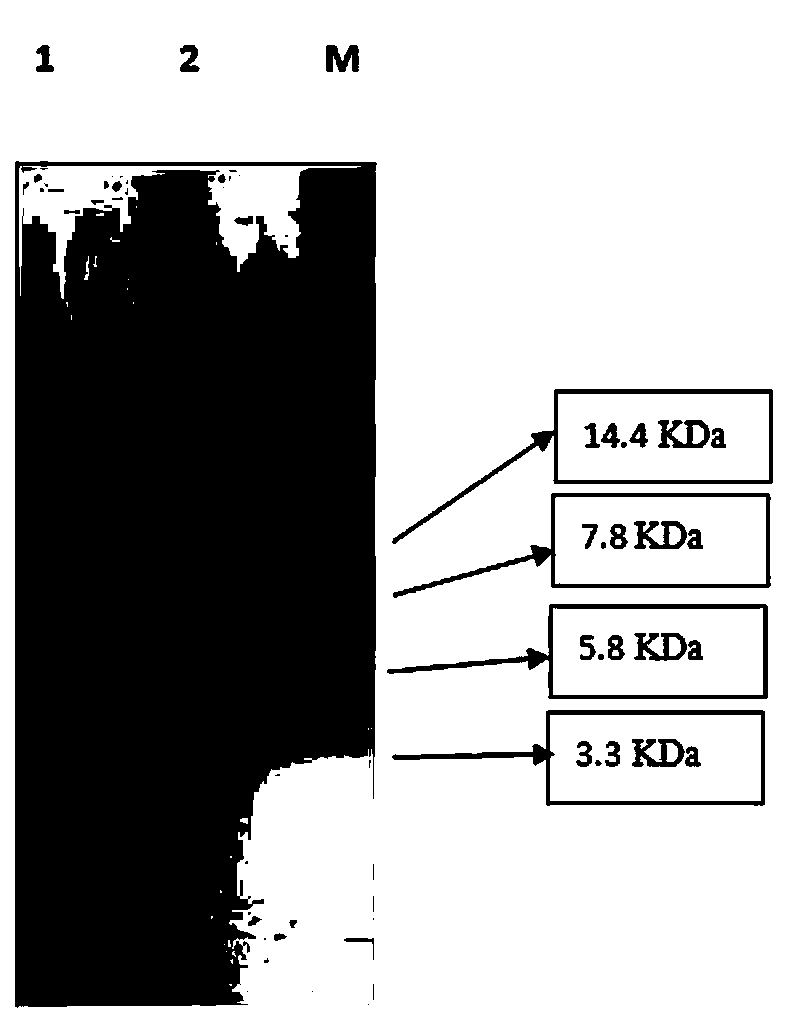

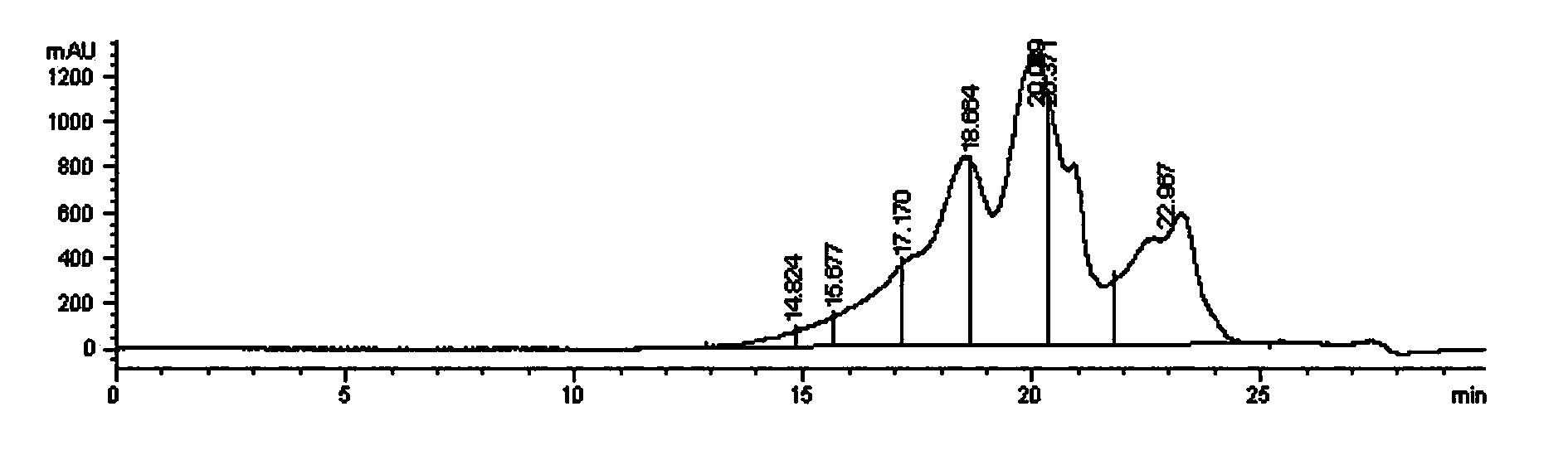

Method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method

ActiveCN103540639AImprove qualityGood effectAnimal feeding stuffPeptide preparation methodsBiotechnologyUltrafiltration

The invention relates to a method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by an aqueous biological enzyme method. According to the method, silkworm chrysalises serve as raw materials, an enzymolysis solution is obtained through drying, crushing and carrying out aqueous-phase enzymolysis, a supernatant and residues are obtained through carrying out centrifugation on the enzymolysis solution, the silkworm chrysalis meal is obtained through drying and crushing the residues, and the silkworm chrysalis peptide powder is obtained through carrying out oil-water separation, ultrafiltration-membrane ultrafiltration and desalination on the supernatant and then drying and crushing. The method specifically comprises the following steps of (1) drying and crushing; (2) carrying out aqueous-phase enzymolysis; (3) carrying out centrifugation and oil-water separation; (4) carrying out ultrafiltration-membrane filtration; (5) carrying out desalination; (6) drying and crushing, thereby obtaining the silkworm chrysalis peptide powder. According to the method, the aqueous biological enzyme method is applied to insect cells-silkworm chrysalis cells for the first time; the method has the advantages that the process is simple, safe and environmental-friendly, the cost is low, the quality of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like; the method disclosed by the invention has the characteristics that the oil and fat removal efficiency is high, the residual fat content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is low, the oligopeptide content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com