Complete set of equipment and process for processing degreased corn grits and corn flour by adopting full-dry method

A technology of corn flour and equipment, which is applied in the fields of grain husking, grain germ removal, and grain processing, which can solve the problems of increasing production energy consumption, increasing production costs, moldy and degeneration, etc., and achieves energy consumption control, production cost reduction, and process improvement. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The object of the invention is achieved through the following technical solutions:

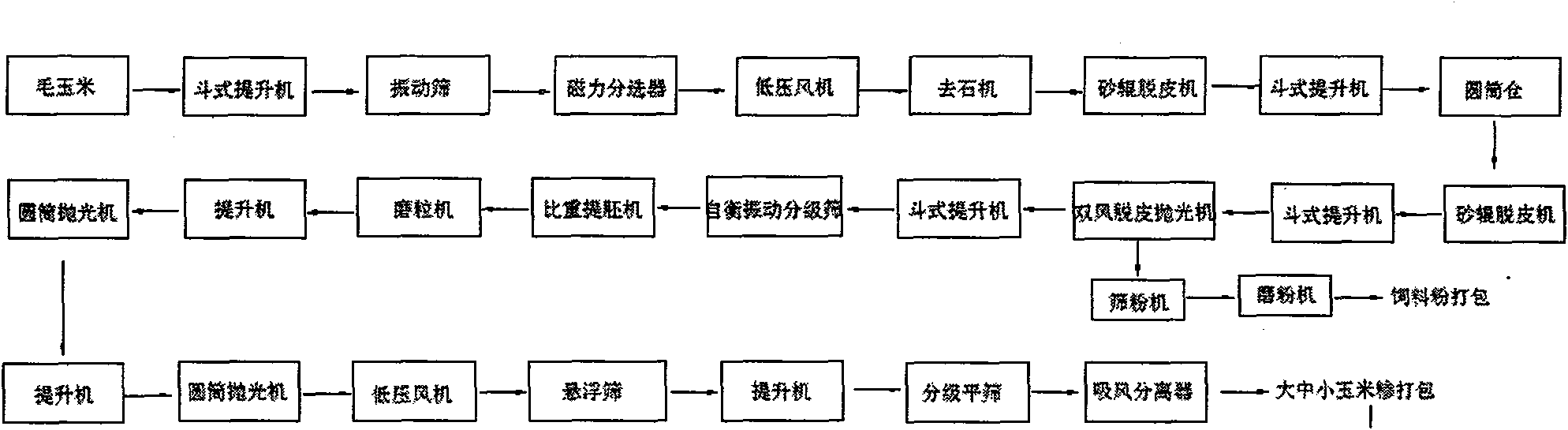

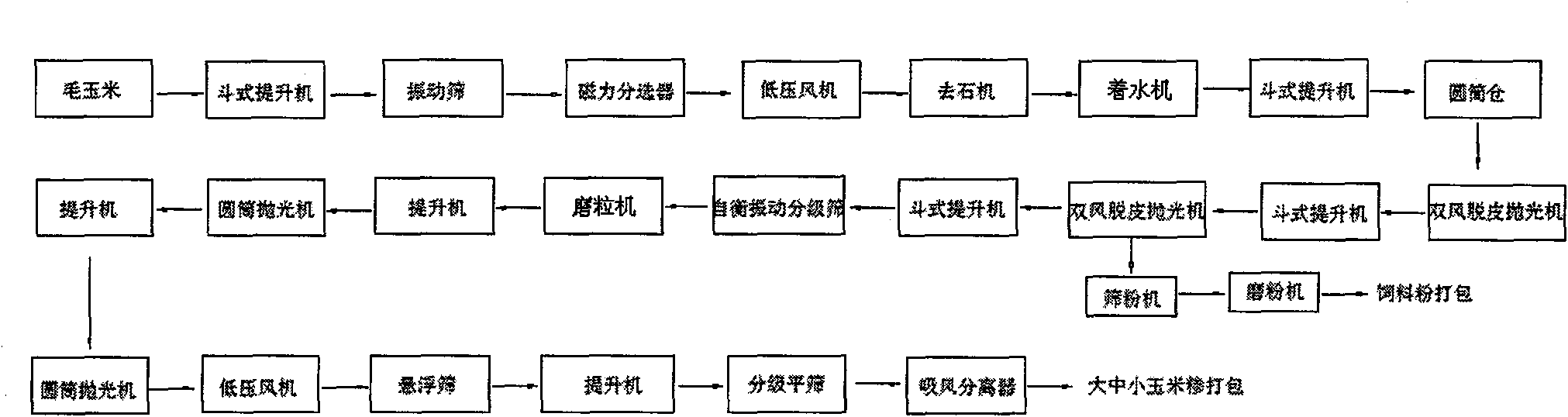

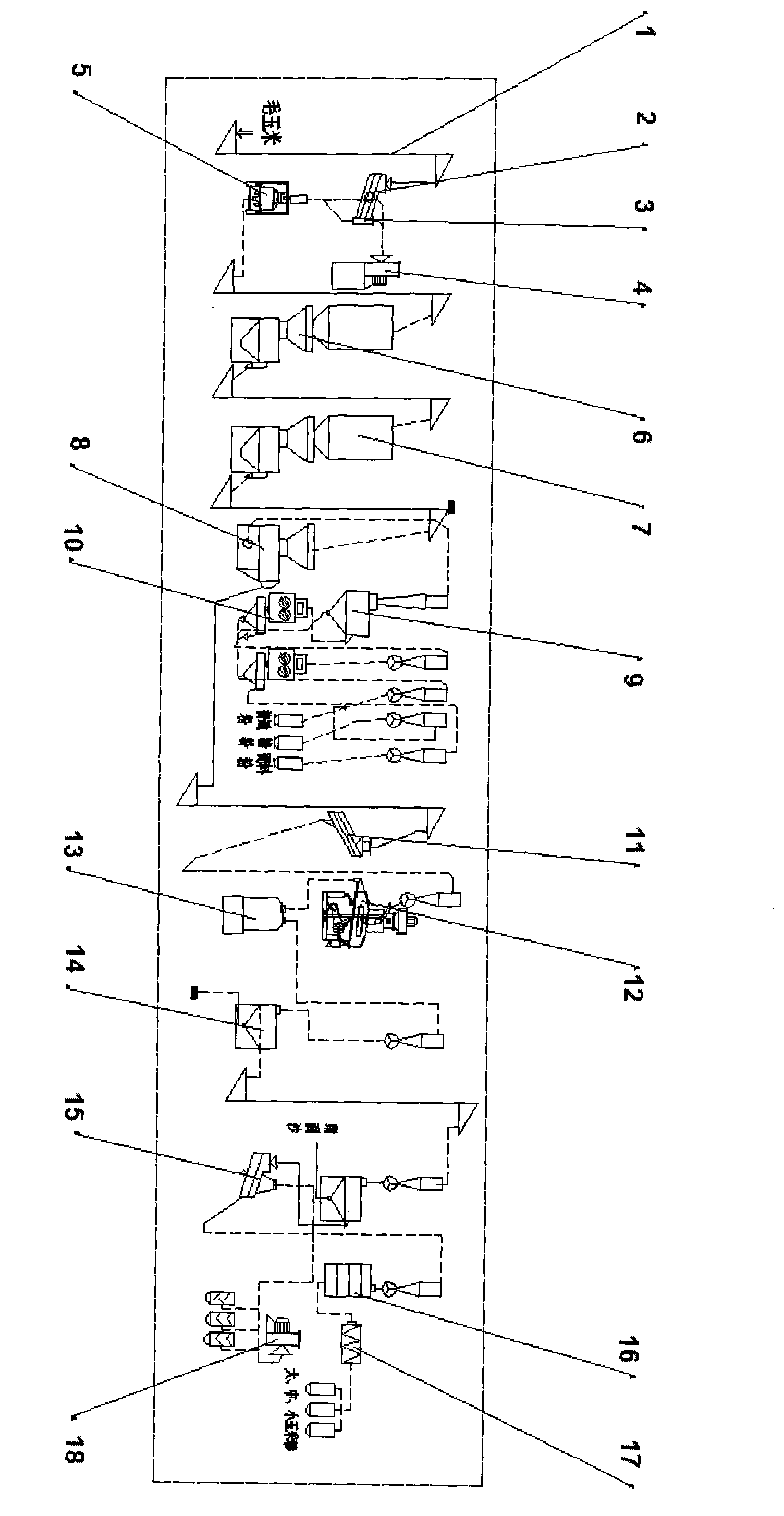

[0017] The rough corn is transported to the vibrating screen 2 by the bucket elevator 1 for rough impurity removal, and then enters the magnetic separator 3 to filter out the ferrous substances in the corn; the light impurities in the corn are removed by the low-pressure fan 4, and then enters the destoner 5 for stones, etc. Miscellaneous treatment; the cleaned corn enters the emery roller peeling machine 6 for peeling and obtains feed powder; after that, it is transported to the silo 7 by the bucket elevator, and then sent to the double wind peeling and polishing by the emery roller peeling machine for the second peeling machine 8 for polishing; a part of the material processed by the double wind peeling and polishing machine 8 is processed by the screening machine 9 and the mill 10 to obtain corn flour; After extracting the residual germ head when the corn is dried, enter the mill 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com