Oil-in-water type emulsion composition, and method for producing said oil-in-water type emulsion composition

An emulsified composition, oil-in-water type technology, applied in chemical instruments and methods, chemical/physical processes, food ingredients as emulsifiers, etc., can solve problems such as high risk, skin itching or inflammation, anaphylactic shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0294]

[0295] (Oil-in-water emulsion composition A)

[0296] 3.007 g of silica fine particles (SANSIL SS-07, manufactured by Tokuyama Co., Ltd.) as solid particles, and 3.007 g of cetyltrimethylammonium bromide (CTAB, manufactured by Wako Pure Chemical Industries, Ltd.) 12.008 g of the aqueous solution was fractionated into a container, and treated at 9000 rpm for 2 minutes using a homogenizer (IKA T25 digital ULTRA TURRAX), thereby obtaining an aqueous phase. The CTAB aqueous solution used at this time was prepared in advance by stirring 0.0049 g of CTAB and 70.082 g of deionized water (1.9×10 -4 mol / L).

[0297] 10.509 g of the said water phases and 4.497 g of hydrogenated coconut oil heated to 60 degreeC were divided into a container, and this was heated to 60 degreeC further. The oil-in-water emulsion composition A was obtained by stirring at 17000 rpm for 2 minutes using a homogenizer.

[0298] (Oil-in-water emulsion composition B)

[0299] 0.920 g of hydrophilic ...

Embodiment A1

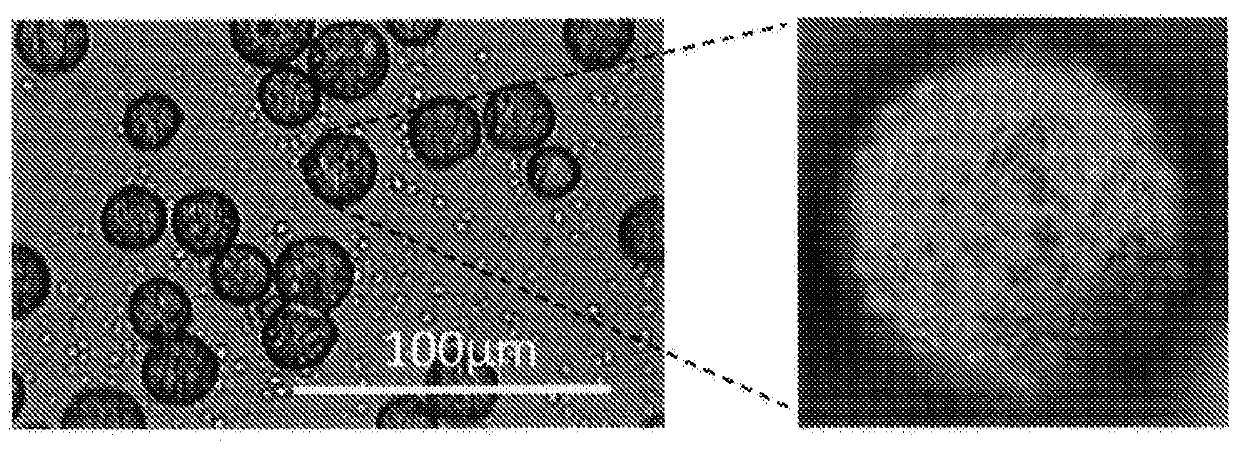

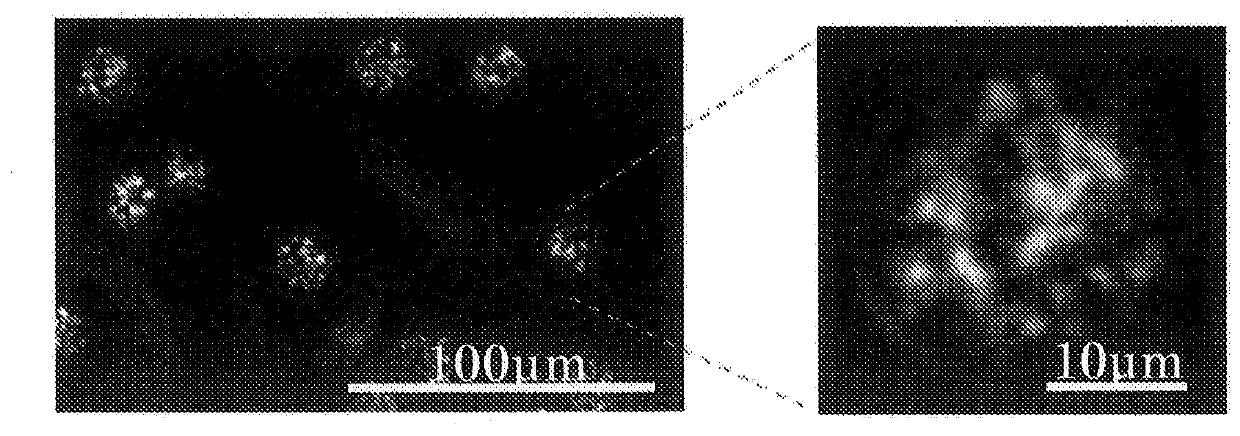

[0326] Observation of the oil-in-water emulsion composition A at 60°C using a polarizing microscope ECLIPSELV100NPOL manufactured by Nikon Corporation, image integration software NIS-ElementsVer3.2 manufactured by Nikon Corporation, and cooling / heating device TH-600PM for a microscope manufactured by Linkham Corporation . The presence of silica particles was confirmed on the surface layer of the emulsion. Therefore, it can be seen that when the water phase is prepared by adding a surfactant and silica particles in combination, fine particles exist at the water phase-oil phase interface.

Embodiment A2

[0330] After maintaining the oil-in-water emulsion composition B in a 60 degreeC hot water bath for 1 hour, no separation of the oil phase was confirmed. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com