Patents

Literature

1009 results about "Creaming" patented technology

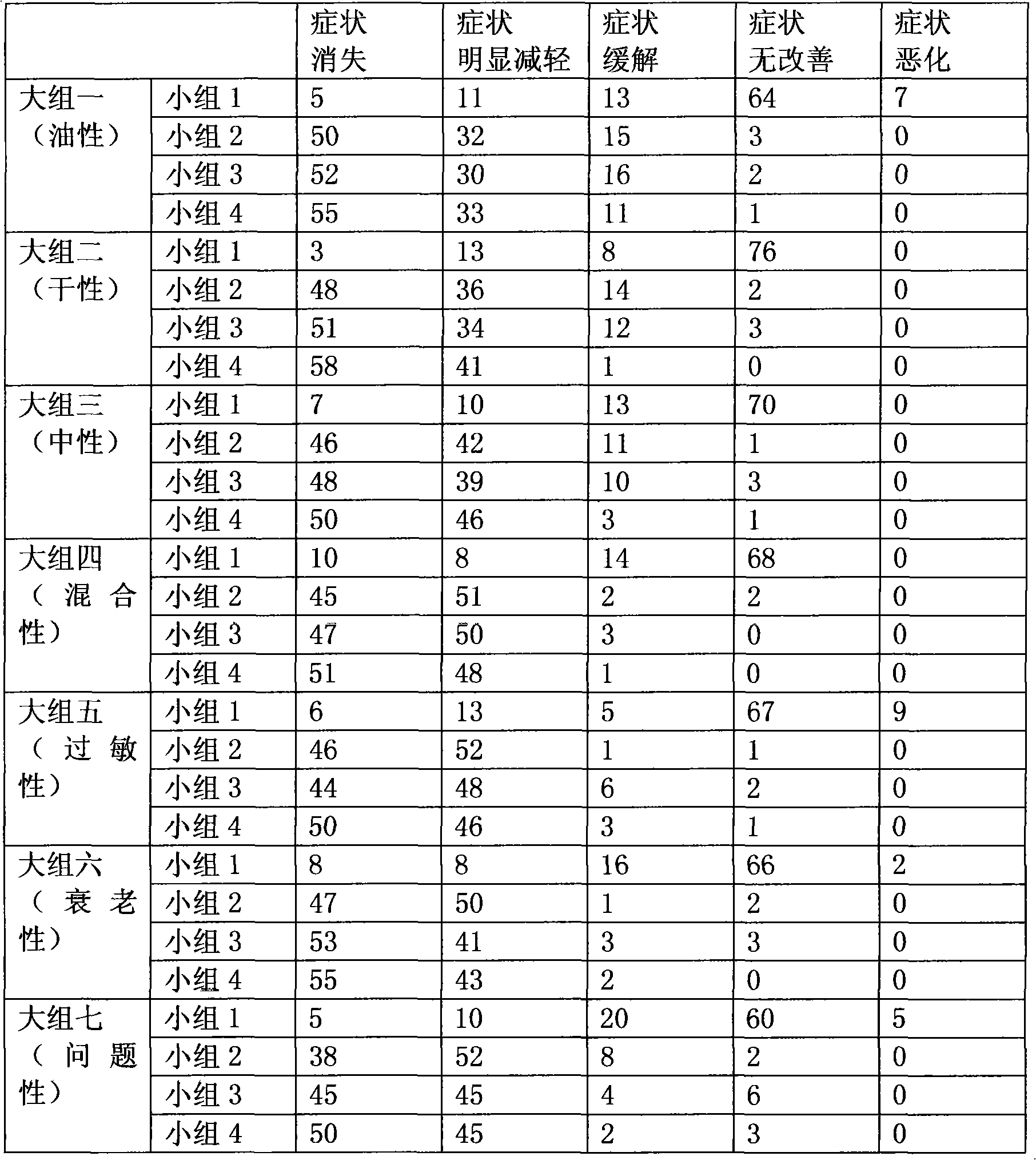

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

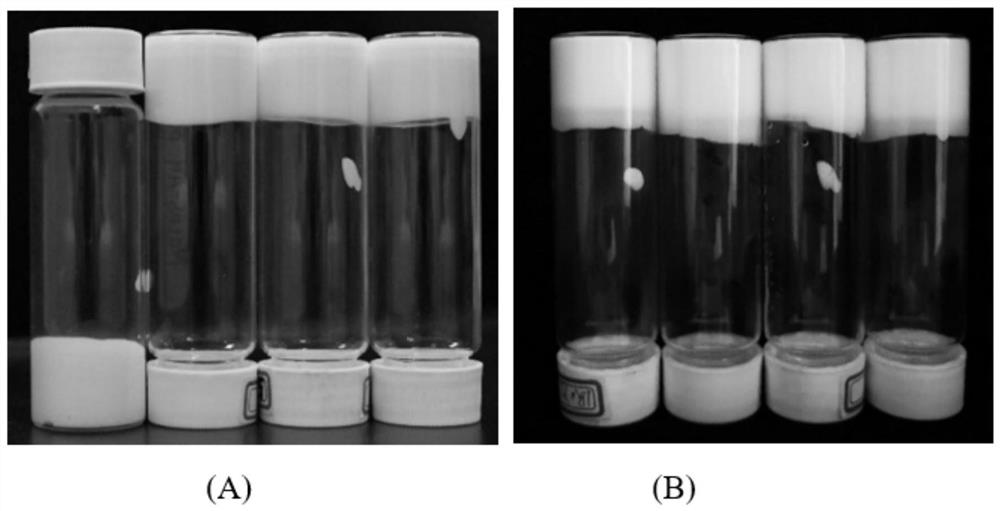

Creaming, in the laboratory sense, is the migration of the dispersed phase of an emulsion, under the influence of buoyancy. The particles float upwards or sink, depending on how large they are and how much less dense or more dense they may be than the continuous phase, and also how viscous or how thixotropic the continuous phase might be. For as long as the particles remain separated, the process is called creaming.

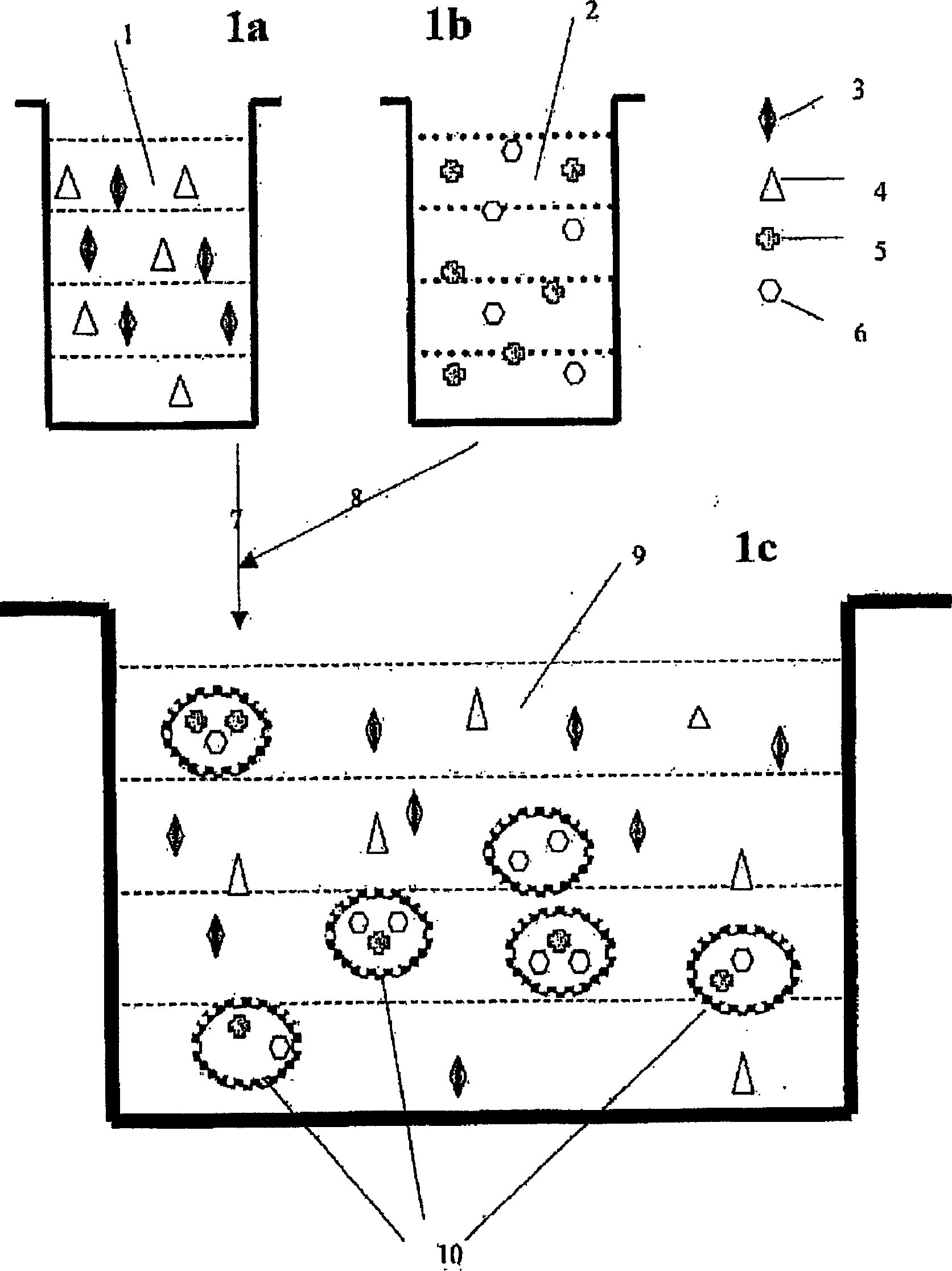

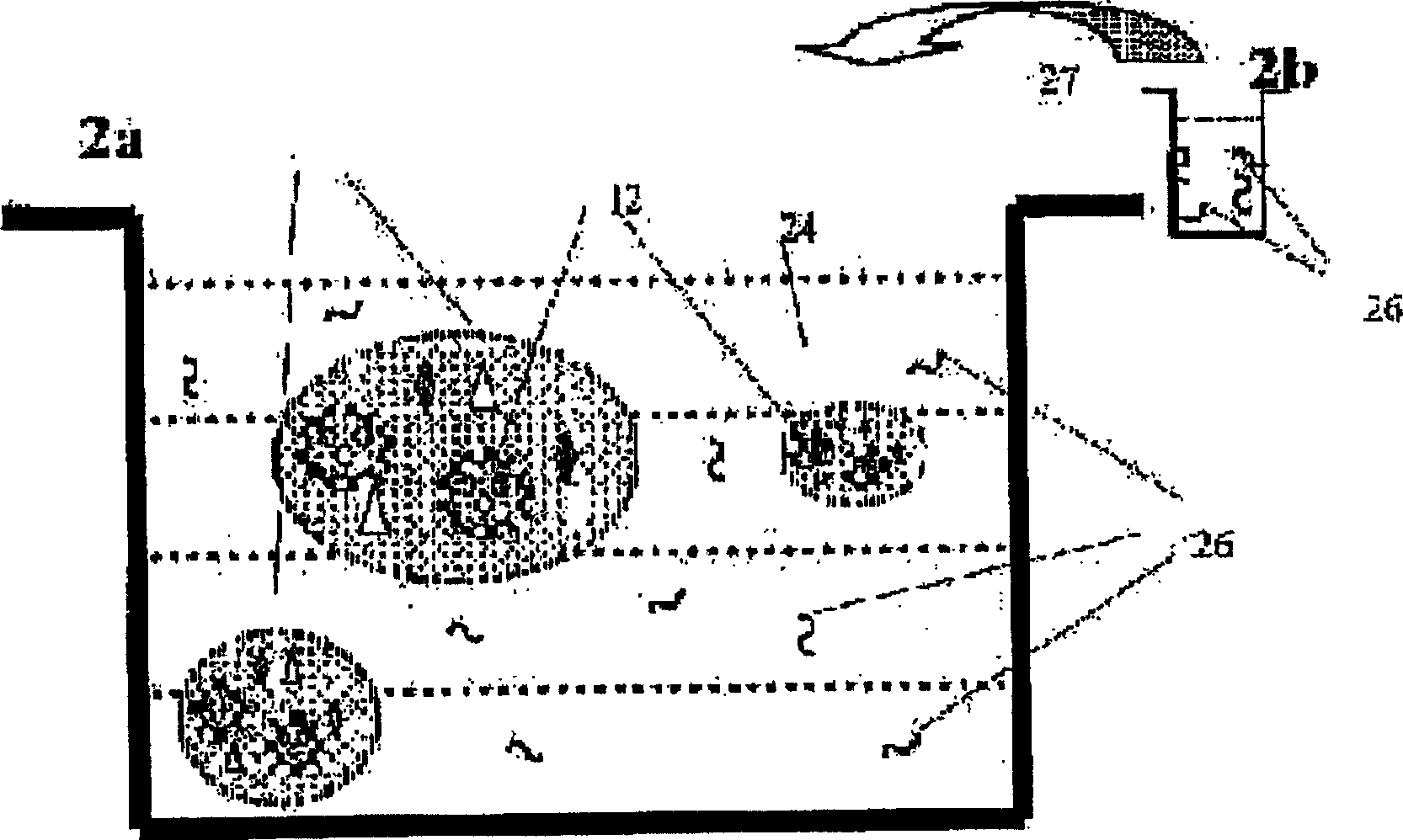

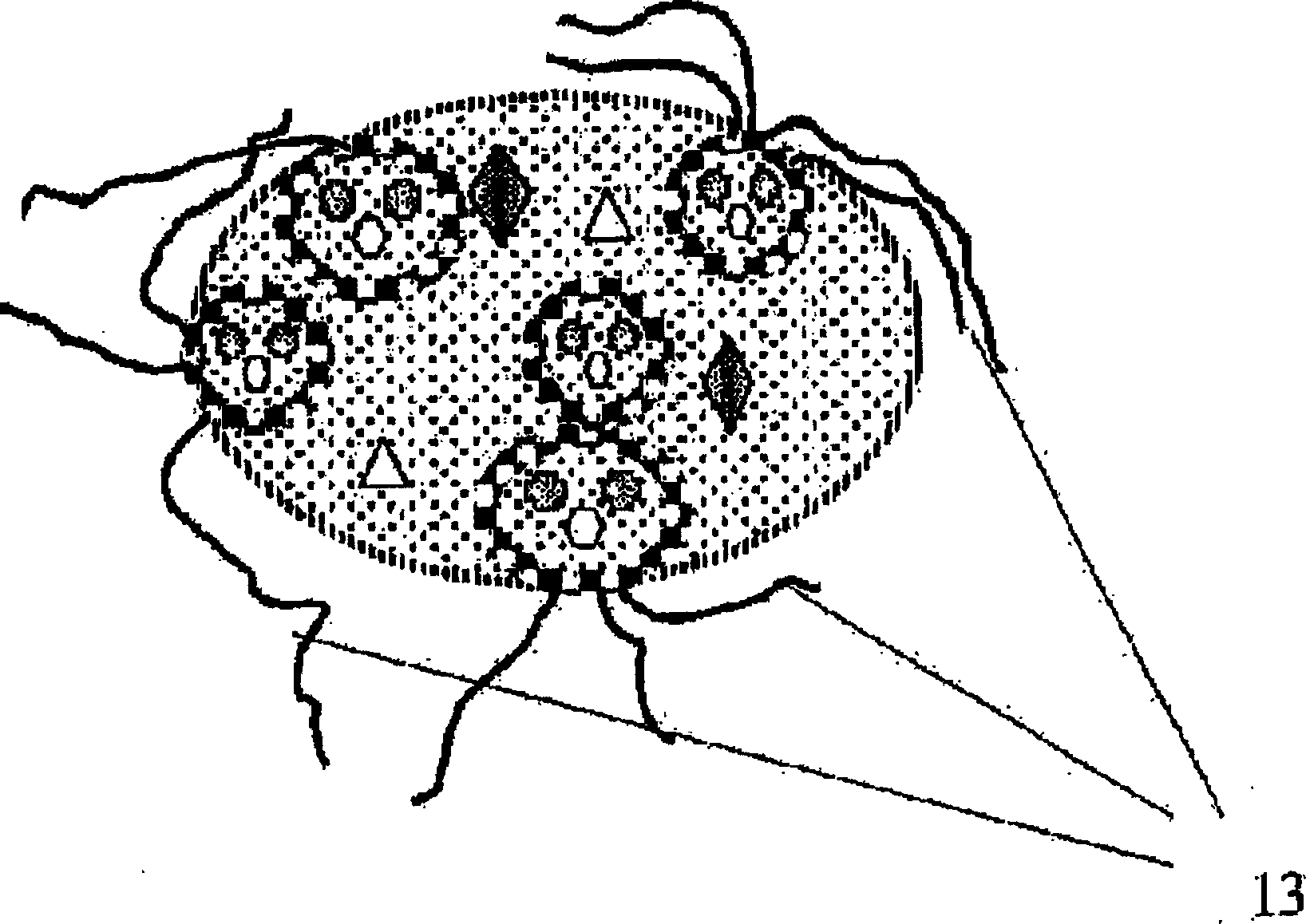

Continuous multi-microencapsulation process for improving the stability and storage life of biologically active ingredients

The invention relates to microcapsules, and a continuous micro-encapsulation water-in-oil-in-water microencapsulation process through in situ and interfacial polymerization of the emulsion. The formulation comprises a continuous water phase having a dispersion of microcapsules which contain oil drops and wherein the inside of each oil phase drop -containing optionally oil-soluble materials- there is a dispersion of water, or aqueous extract or water dispersible material or water soluble material. The oil drops are encapsulated with a polymerisable material of natural origin. Such microcapsules are appropriated for spray-dry processes, to be used as dry powder, lyophilised, self-emulsifiable powder, gel, cream and any liquid form. The active compounds included in te microcapsules are beneficial to the health and other biological purposes. Such formulations are appropriate to be incorporated in any class of food, specially for the production of nutraceuticals, as well as cosmetic products (such as rejuvenescence creams, anti-wrinkle creams, gels, bath and shower consumable products and sprays). The preparations are adequate to stabilise compounds added to the food, media for cultivating microbes and nutraceuticals, specially those which are easily degradable or oxidizable.

Owner:CHEM FAB BUDENHEIM AG

Stability enhanced water-in-oil emulsion and method for using same

InactiveUS7186673B2Improve stabilityImprove emulsion stabilityOther chemical processesMixing methodsWater in oil emulsionPre treatment

A method for enhancing the stability of a water-in-oil emulsion pretreating at least a portion of the oil prior to emulsification. The pretreatment step may consist of adding polymers to the oil, biotreating the oil, photochemically treating the oil, or combinations thereof. The emulsion may be used in various enhanced oil recovery methods including using the emulsion as a flooding agent to displace hydrocarbons in a subterranean formation, and using the emulsion as a barrier fluid for diverting flow of fluids in the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

Biological fermentation day cream and preparation method thereof

ActiveCN103655437ADefensive damagePremature agingCosmetic preparationsToilet preparationsWrinkle skinFiltration

The invention relates to biological fermentation day cream and a preparation method thereof. The preparation method comprises the following steps: firstly, feeding cetearyl alcohol, natural jojoba oil, squalane, superfine titanium dioxide and vitamin E into an oil phase pot, heating to 75-80 DEG C, sufficiently stirring and uniformly dissolving; pouring all water into a water phase pot, subsequently slowly pouring glycerin and oligomerization maltose glucoside, adding hyaluronic acid, holding the temperature for half an hour after the raw materials are all dissolved; performing suction filtration on the oil phase in the oil phase pot into an emulsification pot, stirring, slowly homogenizing, and performing suction filtration on the water phase in the water phase pot into the emulsification pot; after completely sucking the material, rapidly homogenizing for 3 minutes, stopping homogenization, sequentially adding essences, an aloe extract and a composite fermented amino acid total effective nutrient liquid, uniformly stirring, completely adding the materials, continuously stirring for 30 minutes, cooling down and vacuuming through the whole process. Compared with the prior art, the day cream is gentle in property, has the functions of remedying, moisturizing and tightening skin and resisting wrinkles, at the same can prevent environment damage (such as ultraviolet ray and air pollution) to the skin, and can effectively prevent the skin from external pollution which can cause early aging of the skin.

Owner:钱臻

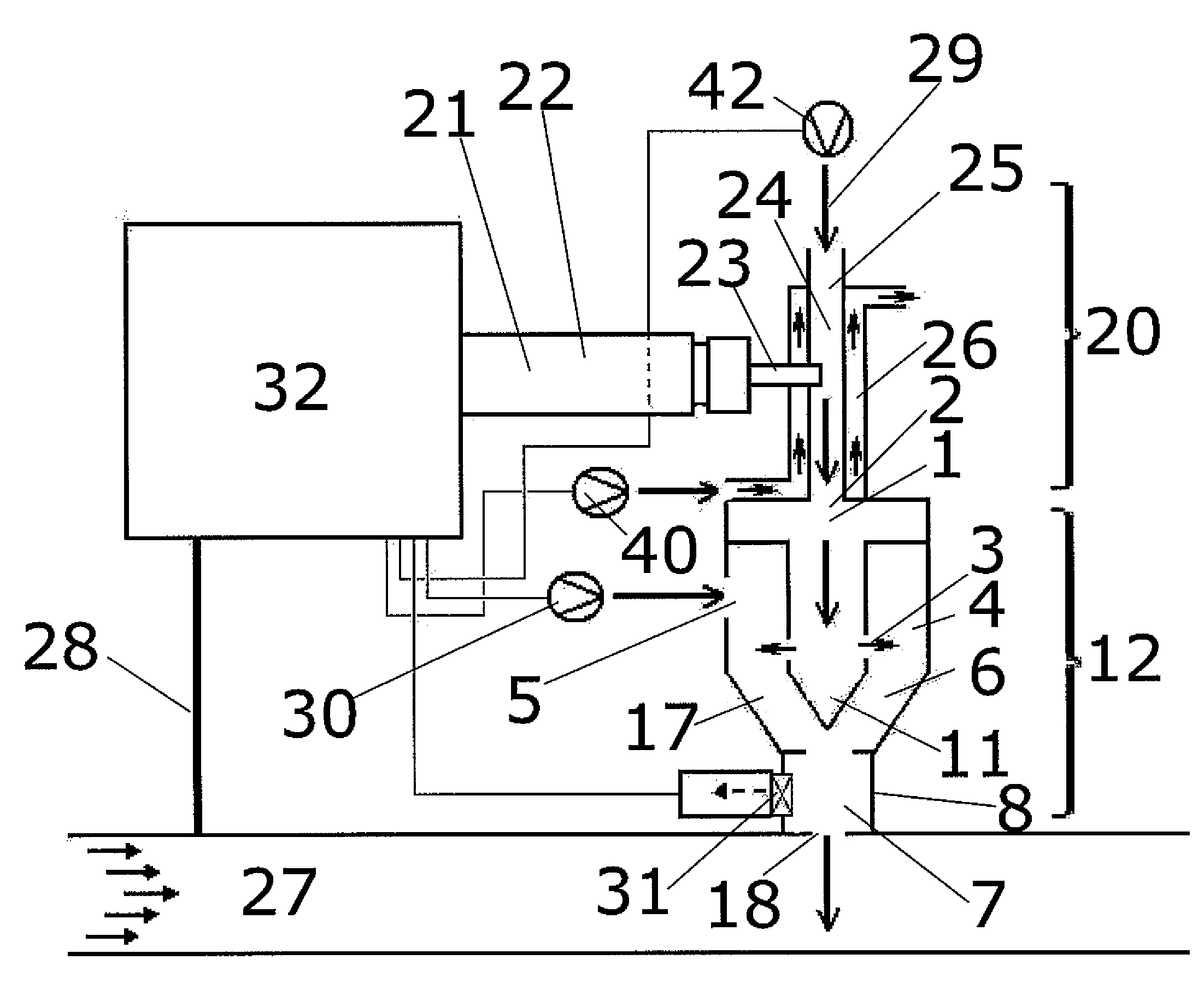

ASA emulsification with ultrasound

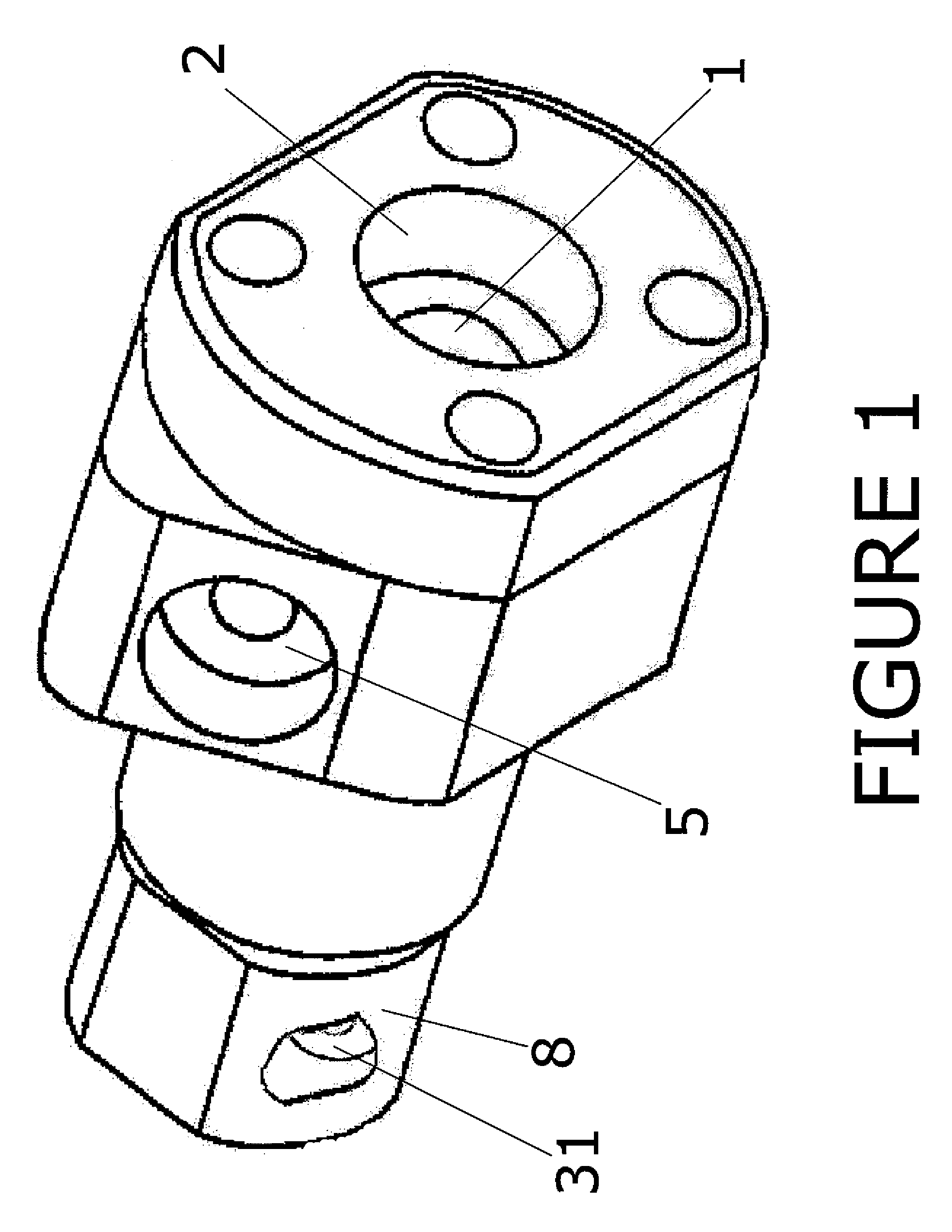

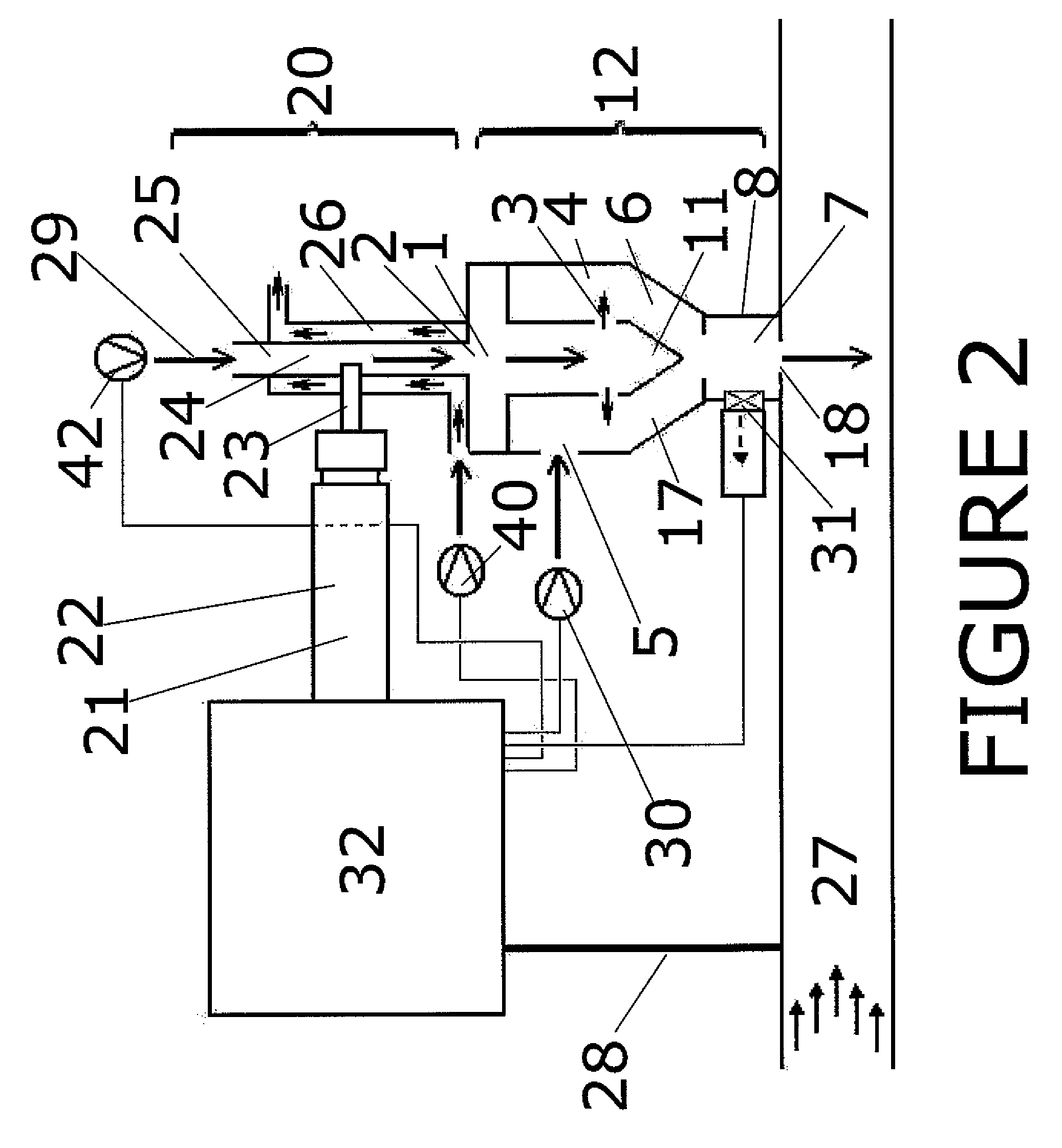

The invention provides a method and apparatus for optimally feeding an ASA emulsion into a papermaking process. An intense transmission of ultrasonic energy rapidly and efficiently forms an ASA emulsion. Nearly simultaneous to forming the emulsion, the emulsion is fed into a high-speed dual conduit feeding apparatus, which quickly mixes the ASA emulsion with other chemicals and feeds the mixture directly into a papermaking process. The invention operates so fast that virtually no hydrolysis of the ASA occurs. This both prevents damage to the papermaking machinery and improves the quality of the produced paper. The invention operates 10-20 times faster than mechanical based emulsion methods and requires 1 / 7 as much energy to operate. The invention also self-monitors the process and can automatically correct any detected problems with the fed ASA emulsion.

Owner:ECOLAB USA INC

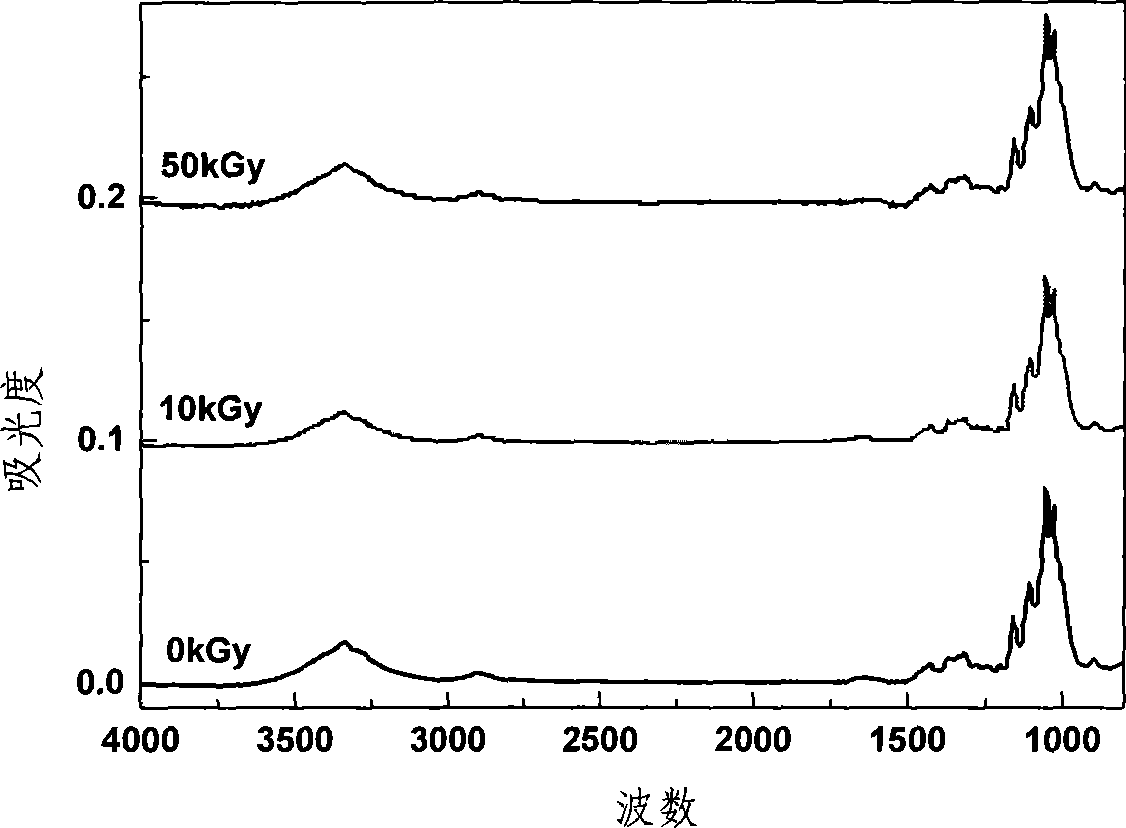

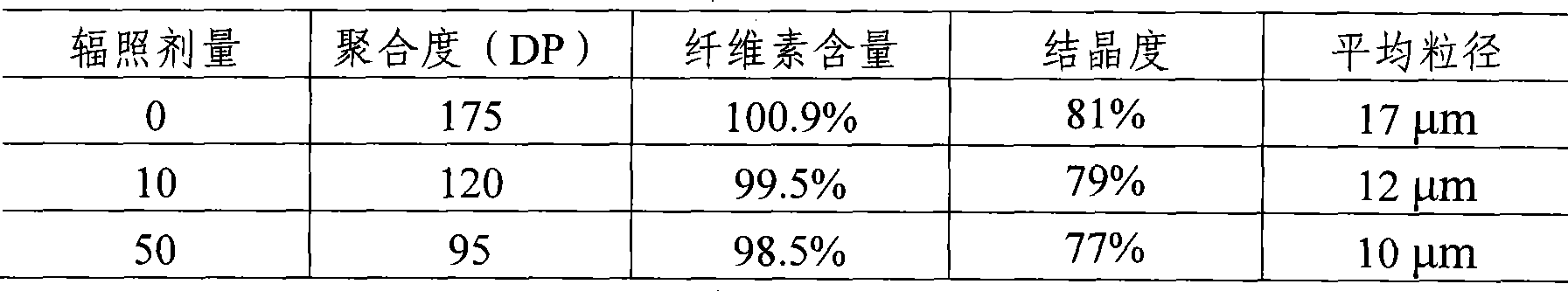

Ultra-fine microcrystalline cellulose and preparation thereof

InactiveCN101481424AGood dispersionImprove stabilityCosmetic preparationsToilet preparationsFood additiveEmulsion

The invention relates to superfine microcrystalline cellulose with particle size less than 10mum. The superfine microcrystalline cellulose with the particle size less than 10mum is obtained by degradation and superfine treatment of microcrystalline cellulose. The superfine microcrystalline cellulose can be widely applied to preparation of food additives, pharmaceutic adjuvants, emulsion stabilizers of cosmetics and thickening stabilizers of coating, and has high dispersibility and storage stability in water, better forming property, adhesiveness, water swellable property, thickening property, thixotropy and the like.

Owner:PEKING UNIV +1

Personal care composition comprising a pre-emulsified formulation

ActiveUS20140309154A1Improve stability and deposition and hair conditioning benefitCosmetic preparationsHair cosmeticsPolyesterPersonal care

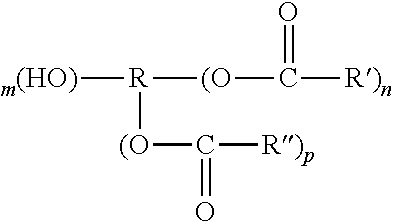

The present invention is directed to a personal care composition comprising a pre-emulsified emulsion comprising from about 0.25% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified emulsion is from about 20 nanometer to 20 microns; from about 5% to about 50% of one or more anionic surfactants, by weight of said hair care composition; at least about 20% of an aqueous carrier, by weight of said hair care composition wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

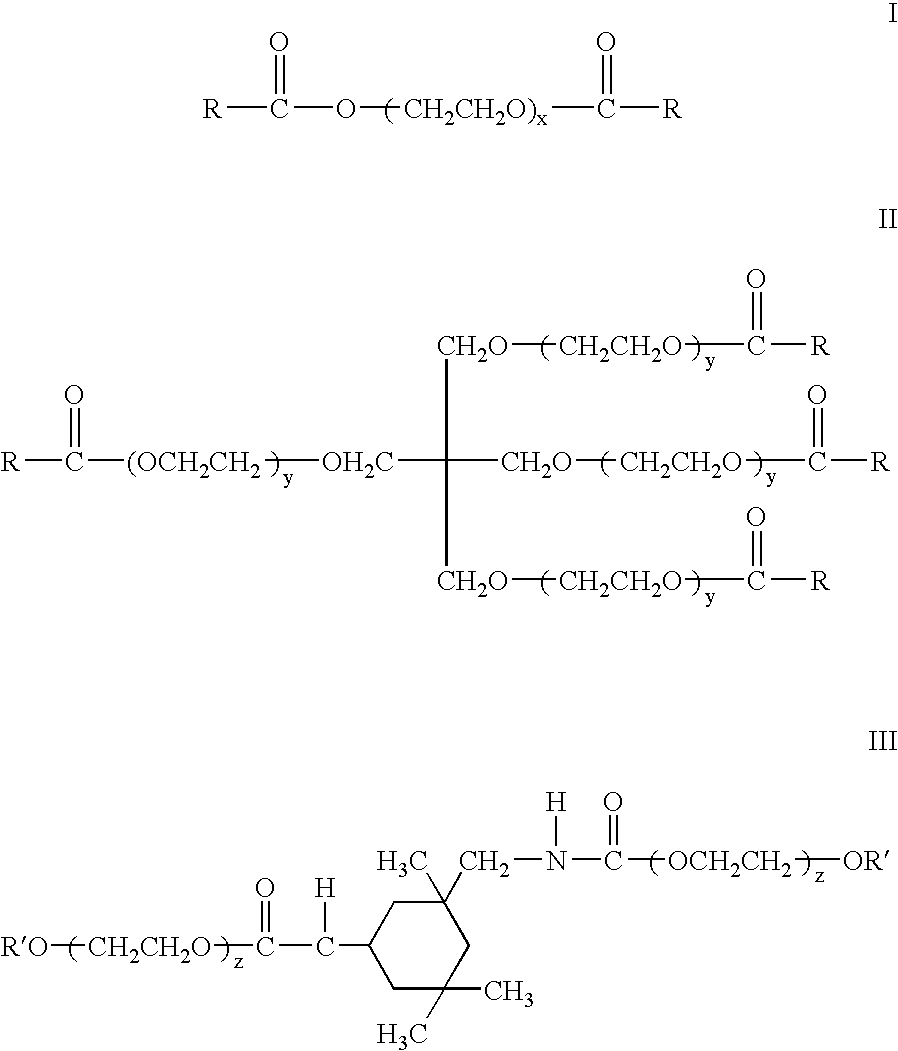

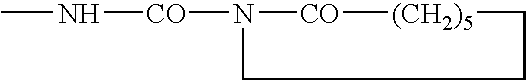

Novel cosmetic emulsions and emulsifiers exhibiting dilatant rheological properties

InactiveUS20060127344A1Simple structureUnexpected dilatancy propertyCosmetic preparationsHair cosmeticsPolyolDilatant

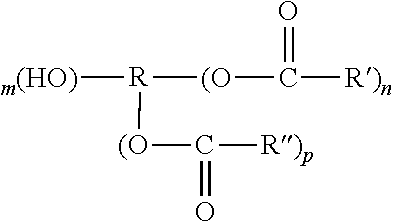

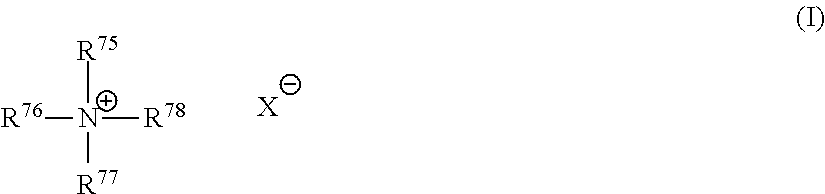

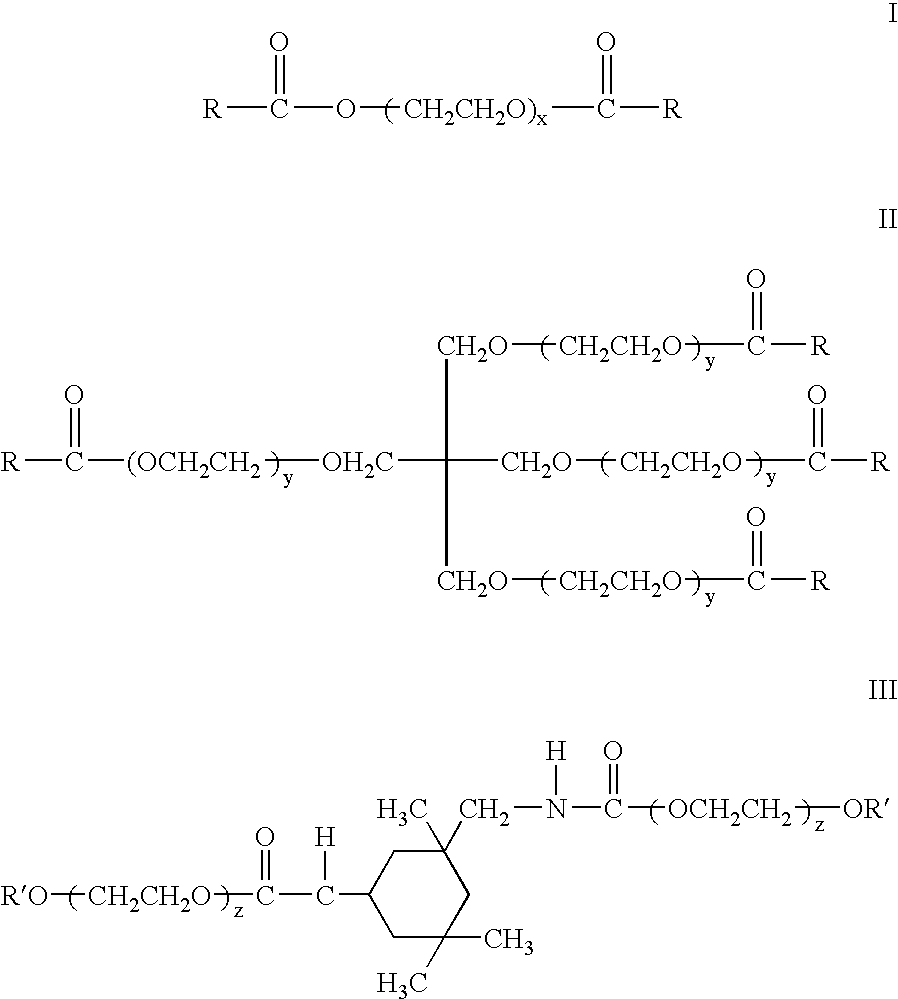

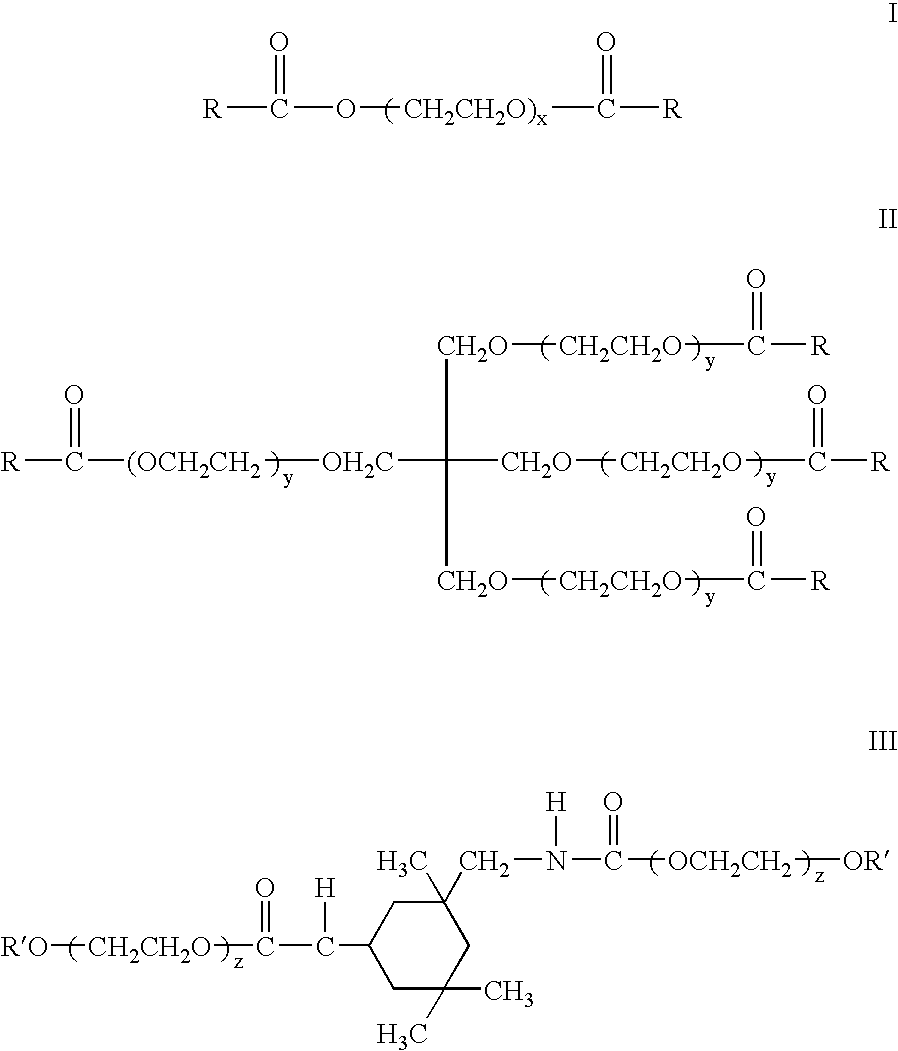

The use of novel nonionic polymeric thickeners that produce cosmetically useful emulsions of an oil phase and a water phase is described. The thickeners of choice are the urethane dimers of ethoxylated fatty alcohols. These materials were not anticipated to have emulsifying properties. Also, it has been found that the esters of ethoxylated polyols show similar emulsifying behavior, although their uses are limited by their inherent susceptibility towards hydrolysis. Further, many of the emulsions produced with these emulsifiers have a dilatant or shear thickening rheology that is unusual and has unique cosmetic applications. In addition, it is possible to produce high internal phase oil-in-water emulsions, with oil phase concentrations greater than 70%, using these emulsifiers. Finally, many of the emulsions, especially the high internal phase ones, have a characteristic “ring” or vibration that is apparent when their container is tapped. This is a characteristic of so called “microemulsions” that has not been observed in conventional appearing, white (albeit dilatant) emulsions.

Owner:ALZO INTTERNAT

Foaming O/W emulsion and use thereof in cosmetics

InactiveUS20060217283A1Good foaming effectGood quality foamCosmetic preparationsOrganic detergent compounding agentsSURFACTANT BLENDPolymer chemistry

Foaming composition in the form of an oil-in-water emulsion, wherein the size of the droplets of the oily phase D[4,3] is less than or equal to 4 μm, the oily phase is present in more than 30% by weight, the composition containing an emulsifying system and a mixture of foaming surfactants, the oily phase (A) / foaming surfactant mixture (c) weight ratio ranging from 1.5 to 12, an amount of less than or equal to 45% by weight of water relative to the total weight of the composition being present.

Owner:LOREAL SA

Brushable cosmetic preparation having a high water content

Brushable cosmetic preparation having a creamy or paste-like consistency, containing 50 to 95 wt. % of water, hydrophobed silicon dioxide powder, at least one cosmetically relevant active ingredient or auxiliary substance that is water-soluble or is dispersible or emulsifiable in an aqueous medium, and a viscosity regulator. It is produced by adding at least one cosmetically relevant active ingredient and / or auxiliary substance and optionally at least one pigment in water to a solution or dispersion adding hydrophobed silicon powder in portions or continuously whilst mixing and continuing mixing until the mixture, which is originally in powder form after addition of hydrophobed silicon dioxide powder, takes on a pasty consistency, and then adding a viscosity regulator and optionally at least one oil body, optionally before, together with or after addition of the viscosity regulator, with mixing. It can be used in pastes, creams, gels, pencils, foams, emulsions, dispersions, roll-ons, lotions.

Owner:DEGUSSA AG

Whitening spot-relieving cream cosmetic and preparation method thereof

ActiveCN101590003AInhibitory activityInhibition interconversionCosmetic preparationsToilet preparationsOil phaseMixed phase

The invention discloses a whitening spot-relieving cream cosmetic, which comprises the following components by weight: A, a main body whitening spot-relieving component; B, an auxiliary whitening spot-relieving component; C, an oil phase component; D, a water phase component; E, thickening stabilization component; and F, an auxiliary agent component. The method for preparing the cosmetic comprises the following steps: a, raising the temperature of the C phase to between 65 and 95 DEG C, keeping the temperature between 75 and 85 DEG C, adding the B phase, and stirring and dissolving the mixture completely; b, raising the temperature of the D phase to between 65 and 95 DEG C, keeping the temperature between 75 and 85 DEG C, and stirring and dissolving the D phase completely; c, sucking the C mixed phase into an emulsification pot first, then sucking the D phase into the emulsification pot slowly, adding the A phase, homogenizing the mixture for 5 to 15 minutes, keeping the temperature and stirring the mixture for 5 to 15 minutes, and vacuumizing the mixture to reduce the temperature; d, adding the E phase when the temperature is between 50 and 70 DEG C, homogenizing the mixture for 2 to 3 minutes, and stirring the mixture evenly; and e, adding the F phase when the temperature is between 30 and 50 DEG C, and stirring the mixture evenly to obtain the product of the whitening spot-relieving cream cosmetic. The invention aims to overcome the defects of the prior art and provide a quick, high-efficiency, green and safe whitening spot-relieving cream cosmetic product.

Owner:ATHENA GUANGZHOU COSMETICS MFR

Hair care composition comprising a pre-emulsified formulation

A hair care composition comprising from about 0.25% to about 80% of a pre-emulsified emulsion comprising from about 0.005% to about 80% of one or more materials selected from the group comprising metathesized unsaturated polyol esters, sucrose polyesters, fatty esters with a molecular weight greater than or equal to 1500 and mixtures thereof and mixtures thereof or, by weight of said hair care composition; wherein an emulsifier is selected from the group consisting of anionic, non-ionic, cationic, amphoteric and mixtures thereof wherein the average particle size of the pre-emulsified oil in water emulsion is from about 20 nanometers to 20 microns; and a cationic surfactant system wherein the composition is stable with respect to one of the following measures selected from emulsion particle size, viscosity or visual phase separation and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Encapsulation of sensitive components using pre-emulsification

ActiveUS7431986B2Increase stabilityIncrease bioavailabilityPowder deliveryLiquid surface applicatorsWater contentOmega 3 fatty acid

A stabilized emulsion is employed to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component to form an emulsion. An antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a film-softening component or plasticizer for the film-forming component may be included in the emulsion. The emulsion is stabilized by subjecting it to homogenization. The pellets are produced by first reducing the water content of the stabilized emulsion so that the film-forming component forms a film around the oil droplets and encapsulates the encapsulant. In embodiments of the invention, the water content of the homogenized emulsion may be reduced by spray-drying to produce a powder. In other embodiments of the invention, after homogenization, the water content of the emulsion may be reduced by admixing the emulsion with at least one matrix material to thereby encapsulate the film-coated oil droplets within the matrix material. After the water content of the emulsion is reduced, a protective coating is applied on the film-coated oil droplets to obtain pellets.

Owner:GENERAL MILLS INC

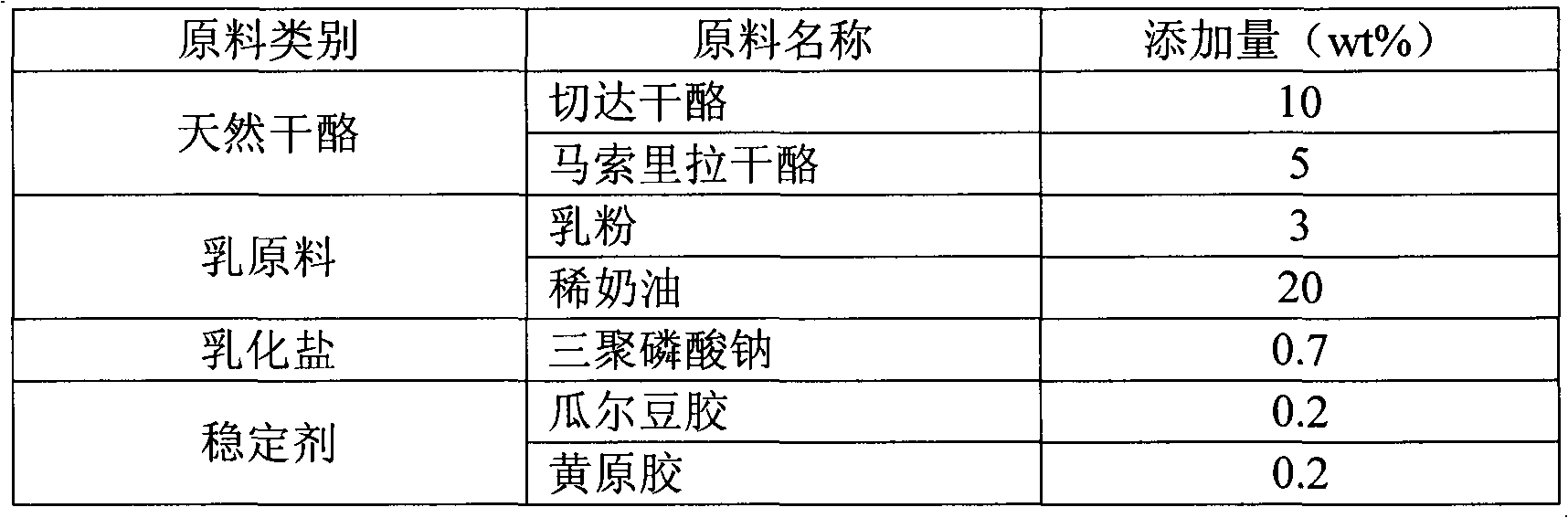

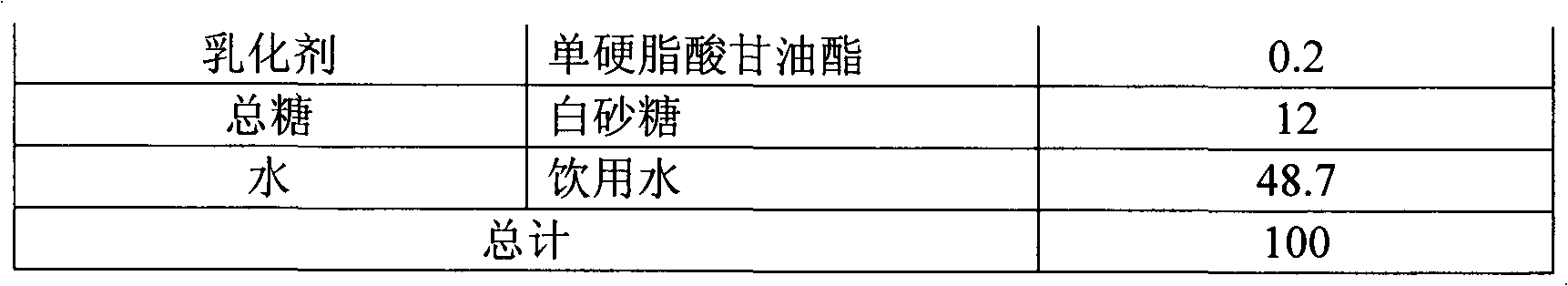

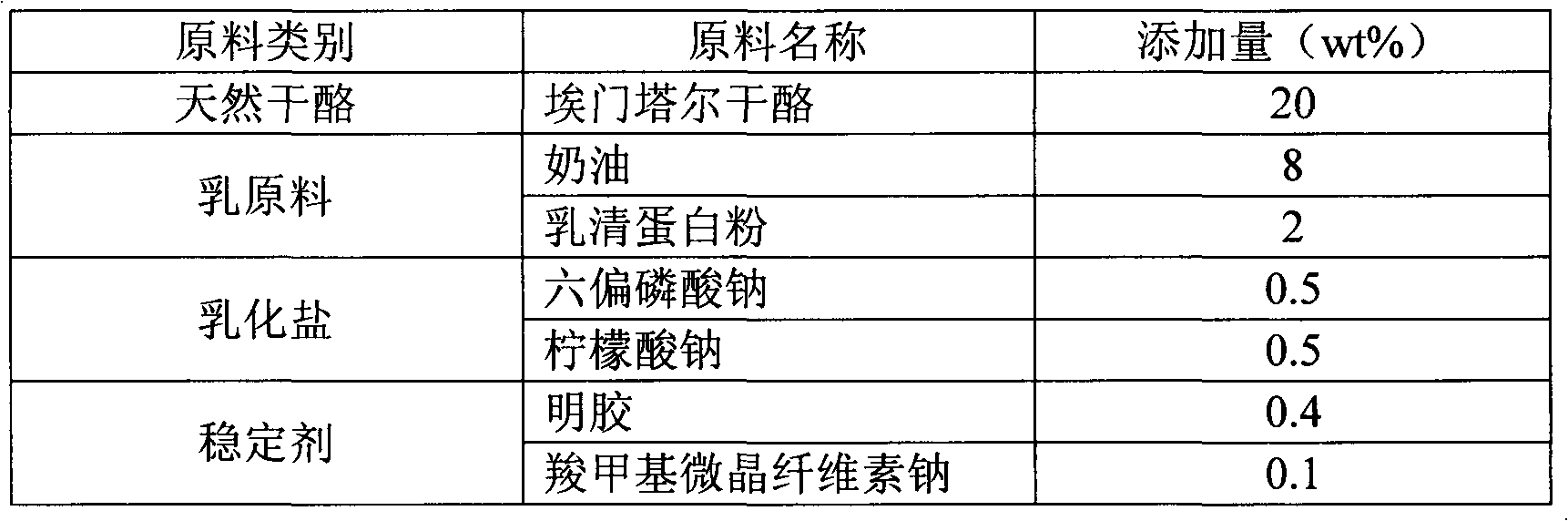

Cheese ice cream and preparation method thereof

InactiveCN102422969AOvercome rough tasteOvercome the problem of strong sandy feelingFrozen sweetsFlavorSugar

The invention discloses a raw material composition of cheese ice cream. The composition comprises the following components, by weight, 3-40% of natural cheese, 3-30% of raw milk, 0.5-1.5% of an emulsification salt, 0.2-2% of a stabilizer, 0.2-0.5% of an emulsifier, 10-25% of total sugar, and the balance water. The invention also discloses a preparation method of the cheese ice cream and the cheese ice cream prepared with the preparation method. By controlling the formula, the sterilization mode, the homogenizing mode, and the additional quick-frozen process of a freezing process of the cheeseice cream in the invention, problems of rough mouthfeel and strong sand-like feeling of the final ice cream, which are caused by the degradation or the denaturation coacervation of cheese proteins, the emulsification capability reduction and the hydratability reduction, are overcome. The cheese ice cream with fine texture, uniform tissue state and unique flavor, which is provided in the invention, allows the perfect combination of cheese and ice cream to be realized.

Owner:上海光明奶酪黄油有限公司

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

Fat emulsion injection of 'Xingnaojing' and its preparing process

InactiveCN1628779AHigh purityFully extractedMammal material medical ingredientsEmulsion deliveryHas active ingredientEmulsion

Disclosed is a fat emulsion injection of 'Xingnaojing' and its preparing process, which comprises using supercritical extraction technology and macroscopic adsorption resin technology for isolating and purifying the water soluble and fat soluble parts in the medicinal materials including musk, cape jasmine, and curcuma root, finally utilizing emulsion technology to obtain the end product.

Owner:JIANGSU QINGJIANG PHARMA

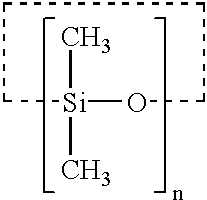

Micro emulsion cutting fluid composition and preparation method thereof

InactiveCN102002424AGood rust protectionImprove the lubrication effectLubricant compositionEmulsionOil additive

The invention relates to a micro emulsion cutting fluid composition and a preparation method thereof. The composition comprises the following raw materials in percentage by weight: 22-32 mineral oil, 2-10 anionic surfactant, 1-5 nonionic surfactant, 1-3 emulsion stabilizer, 5-10 oiliness additive, 5-10 extreme pressure additive, 5-15 rust-inhibiting additive, 0.5-3 anticorrosion fungicide, 0.1-0.3 antifoam additive and the balance of water. The preparation method of the micro emulsion cutting fluid composition is simple and convenient, the provided cutting fluid S50 composition is an ecological stable product and has good lubricity and cooling performance, and the machining accuracy of workpieces can be improved. The cutting fluid S50 composition has strong antimicrobial capability, long service life and good PH value stability and provides good rust-inhibiting performance for the workpieces.

Owner:上海德润宝特种润滑剂有限公司

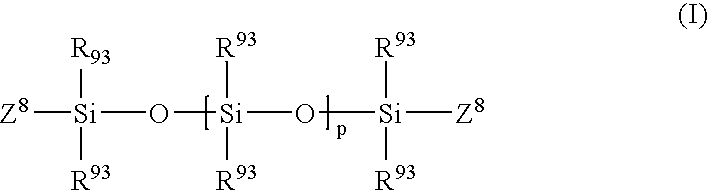

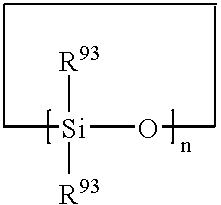

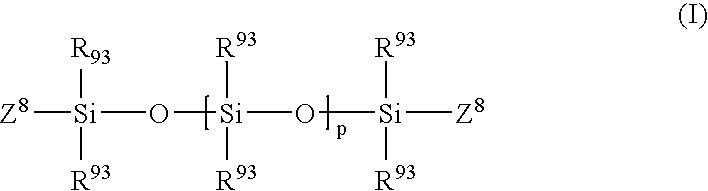

Silicone elastomer emulsion cosmetic composition comprising colorant inclusive internal phase

The present invention relates to silicone elastomer emulsion cosmetic compositions that comprise an internal phase the further includes a colorant. These compositions are intended to deliver such colorant ingredients to the skin of the user in such a manner as to provide a smooth and even colored appearance. In particular, the present invention relates to a cosmetic composition comprising an emulsion that further comprises:a) a continuous aqueous phase comprising:1) from about 0.1% to about 10%, by weight of the composition, of a non-emulsifying crosslinked siloxane elastomer;b) a dispersed oil phase comprising:1) from about 1% to about 25%, by weight of the composition, of an oil compatible colorant; and2) from about 0.01% to about 20%, by weight of the composition, of a binder; andc) from about 0.01% to about 15%, by weight of the composition, of an emulsifier.

Owner:NOXELL CORP

Coenzyme Q10 oral emulsion and preparing process thereof

InactiveCN101015524AImprove stabilityEasy to takeOrganic active ingredientsAntinoxious agentsPurified waterAnti oxidant

The invention relates to a coenzyme Q10 oral emulsion and its preparation method, wherein the constituents include coenzyme Q10 0.1-80%, medicinal oil 1-95%, emulsifying agent 0.5-30%, auxiliary emulsifying agent 0-10%, anti-oxidant 0.001-15%, and balancing purified water. The emulsion can be prepared through inversion phase emulsification method, PIT emulsification method, alternative liquid feeding emulsification method, or continuous emulsification method.

Owner:SHENYANG PHARMA UNIVERSITY

Biological fermentation night cream and preparation method thereof

The invention relates to a biological fermentation night cream and a preparation method thereof. The method comprises the following steps: adding cetostearyl alcohol, natural jojoba oil, squalane and vitamin E into an oil-phase pan, heating to 75-80 DEG C, and sufficiently stirring until dissolving uniformly; pouring all water into a water-phase pan, slowly pouring glycerol and maltooligosaccharide-base glucoside, scattering hyaluronic acid while heating to 75-80 DEG C, and keeping the temperature for half an hour after all the raw materials are dissolved; carrying out vacuum filtration on the oil phase in the oil-phase pan into an emulsifying pan, starting stirring, carrying out vacuum filtration on the water phase in the water-phase pan into the emulsifying pan while slowly homogenizing, and quickly homogenizing for 3 minutes when all the materials are sucked into the emulsifying pan; and stopping homogenizing, sequentially adding essence, aloe extract and composite fermented amino acid complete-effect nutrient solution, uniformly stirring, and cooling while vacuumizing in the whole process. Compared with the prior art, the product provided by the invention has the advantages of mild properties, high active components and moist texture, and has the functions of moisturization, repair, whitening, aging resistance, tightening and nourishing.

Owner:钱臻

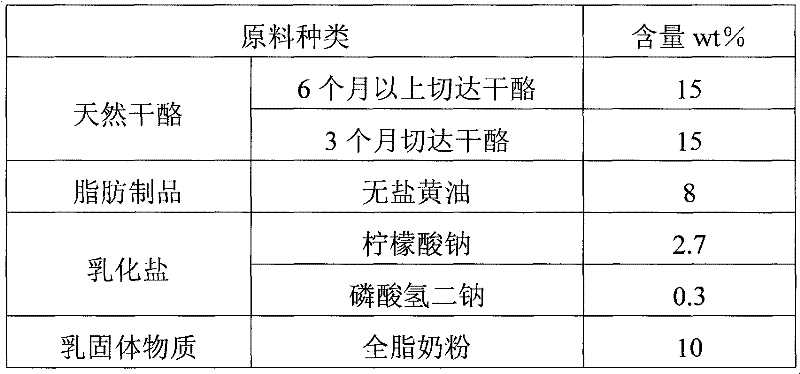

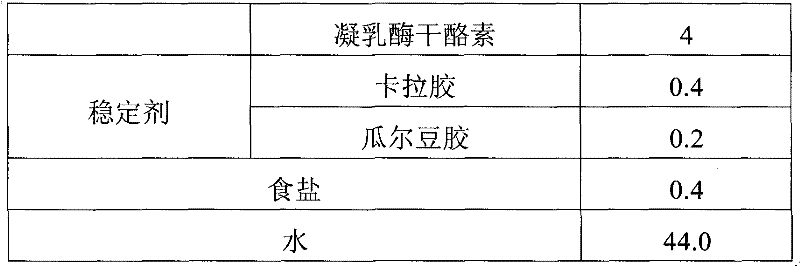

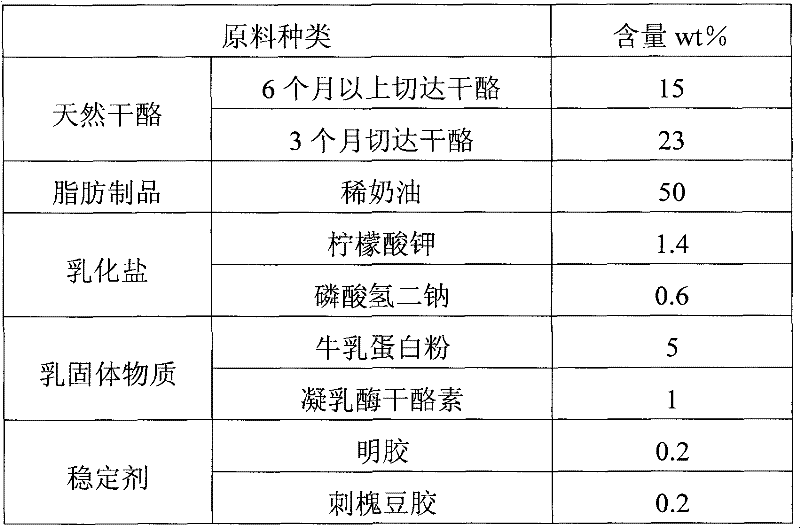

Preparation method of flaky processed cheese and prepared flaky processed cheese

ActiveCN102239926AMeet the requirements of fast food ingredientsStable stateCheese manufactureStable stateCITRATE ESTER

The invention discloses a preparation method of flaky processed cheese and prepared flaky processed cheese. The preparation method comprises the following steps: melting and mixing raw materials; then, sterilizing according to the common operation in the field; stirring, emulsifying and quickly cooling, wherein the raw materials contain 30-60% of natural cheese, 2-5% of emulsifying salt, 5-50% of fat product and 3-44% of water, and the percentage by weight is the mass ratio of each raw material in the total amount of the raw materials. The natural cheese is Cheddar cheese with the mature period more than 3 months, and the emulsifying salt contains citrate and monophosphate. The condition for stirring and emulsifying is as follows: the emulsification temperature is 80-90DEG C, the stirring revolving speed is 300-1000rpm (revolutions per minute), and the stirring emulsification temperature is 2-10 minutes. The preparation method provided by the invention has a simple technology, and 50% of the prepared flaky processed cheese can be melted within 20 seconds under the microwave of below 500W, thereby satisfying the requirement of the flaky processed cheese on serving as quick food ingredients. In addition, the prepared flaky processed cheese has the advantages of stable state and good texture and taste.

Owner:BRIGHT DAIRY & FOOD CO LTD

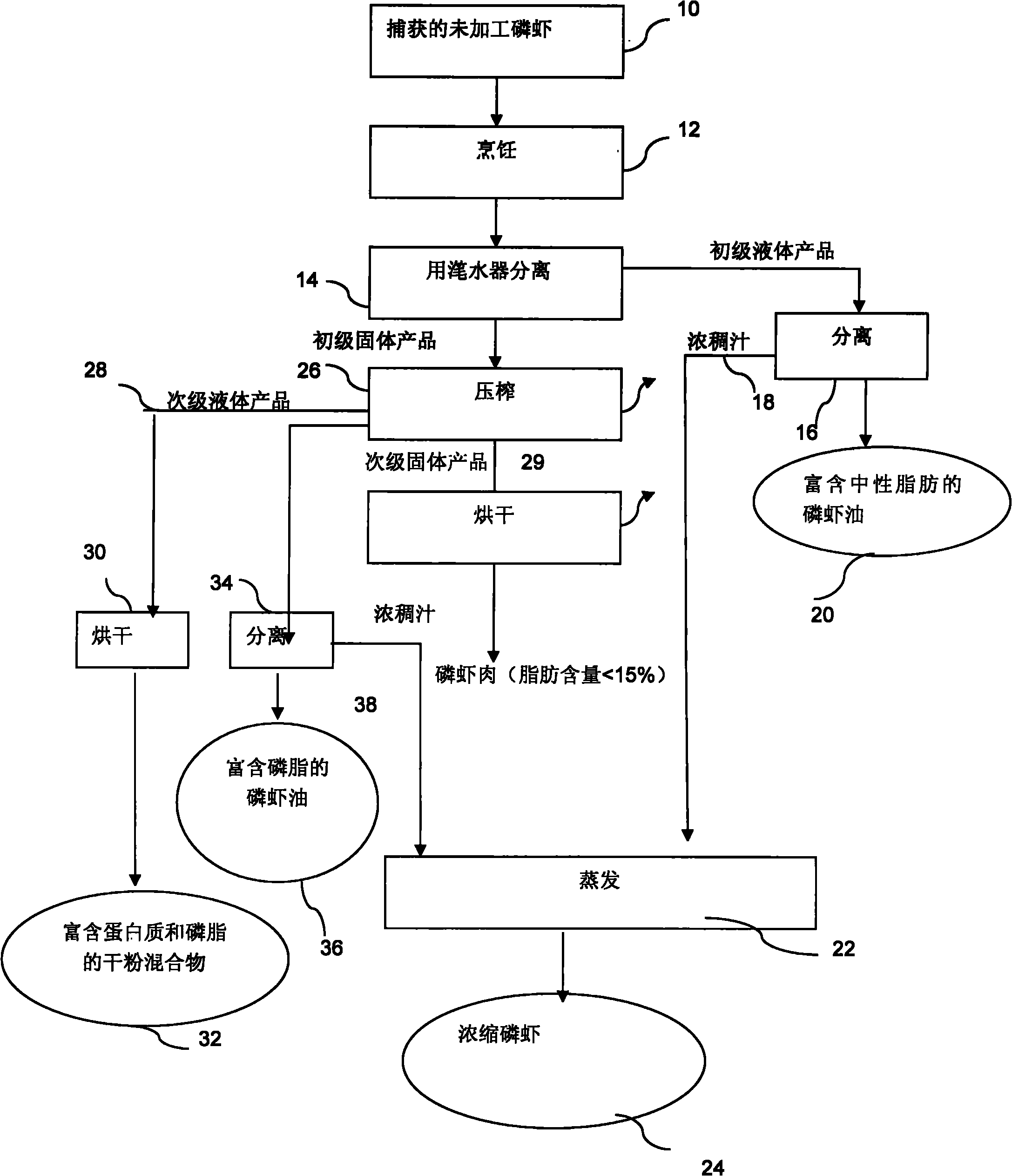

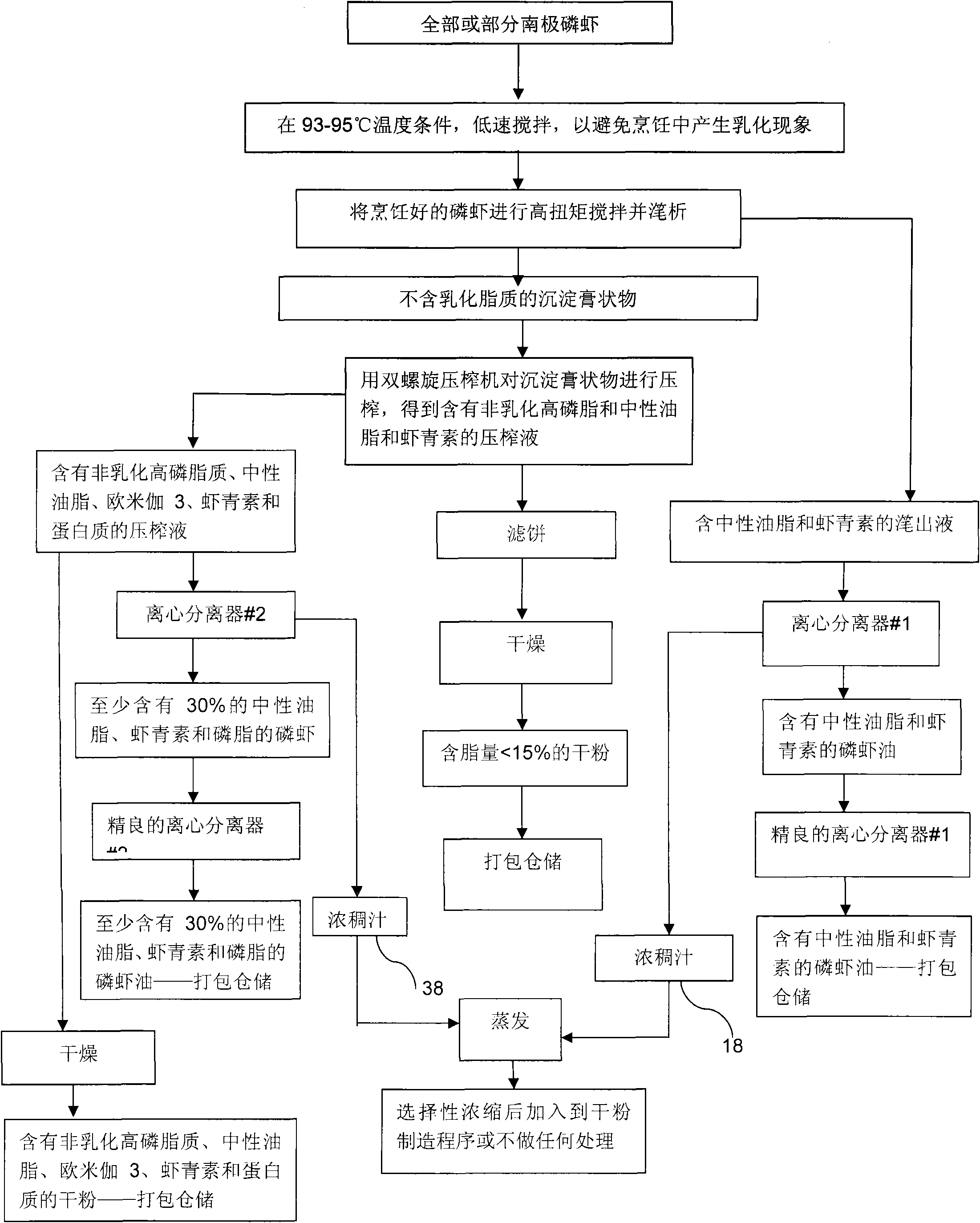

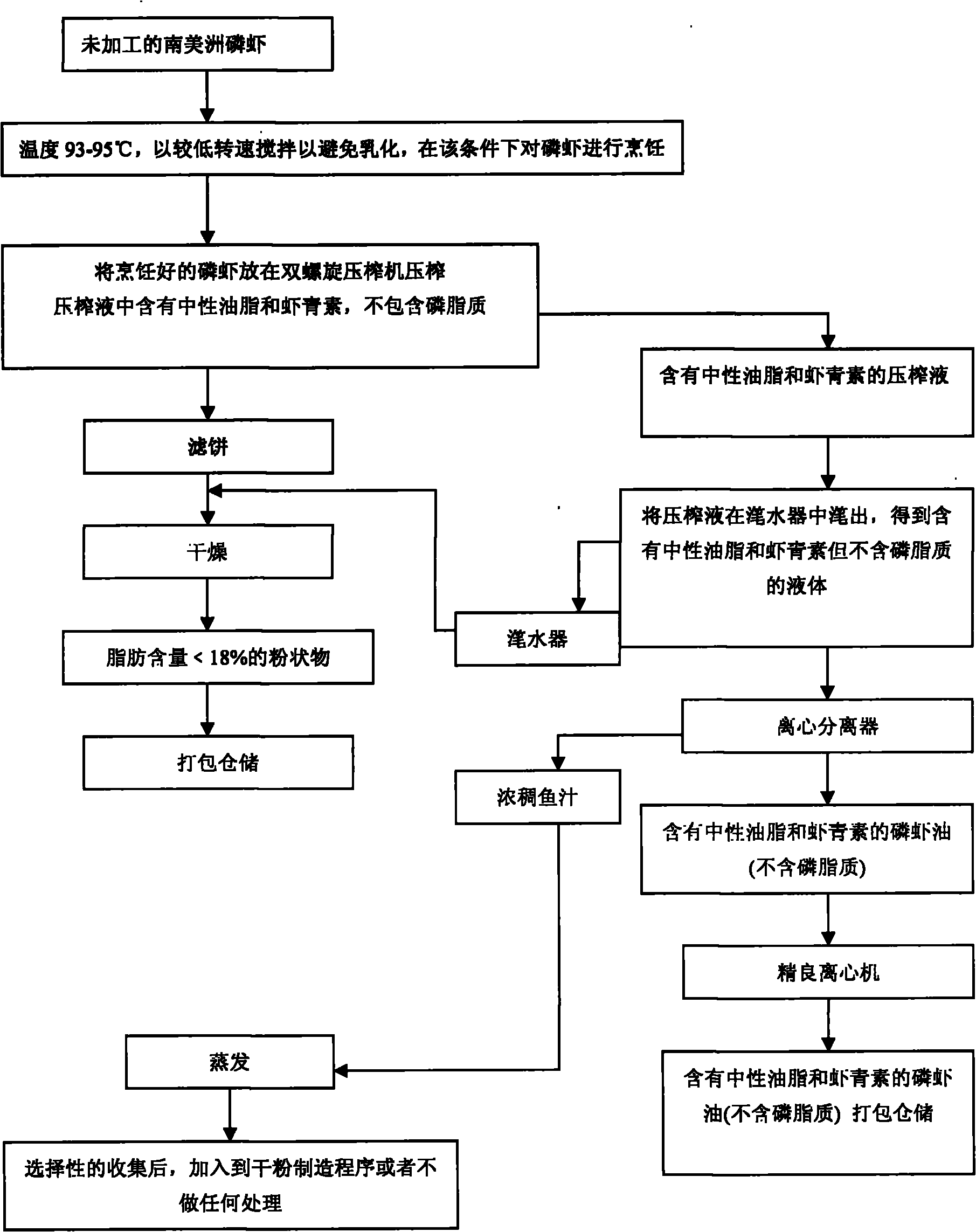

Method for extracting krill oil rich in phospholipids and neutral lipid without using solvent

The invention discloses a method for acquiring krill oil composition without using an organic solvent. The process comprises the following steps of: a) placing krills into a steamer, steaming for a period of time at certain temperature to denature protein contained in the krills, so as to obtain a primary solid product and a primary liquid product of the krills, wherein the condition that the primary solid product and the primary liquid product are formed into emulsion is avoided; b) under the condition that temperature is not less than 90 DEG C, taking out the primary solid product and the primary liquid product of the krills from the steamer container; c) separating the primary solid product from the primary liquid product; d) extracting the krill oil rich in neutral lipid from the primary liquid product; and e) squeezing the primary solid product to obtain squeezed liquid namely a secondary liquid product, and producing the krill oil rich in phospholipids from the liquid product. The method has the characteristic that no organic solvent is used in the whole separation and extraction steps. The invention also discloses composition of the krill oil produced by the method disclosed by the invention.

Owner:THAROS +1

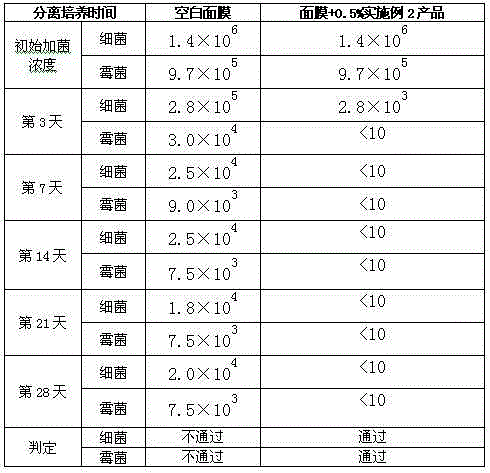

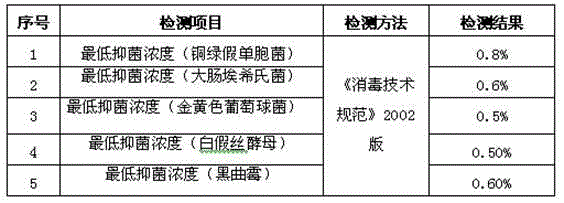

Composition with high-efficiency broad-spectrum antibacterial capacity and application of composition in cosmetics

InactiveCN104546522AWith inhibitionMoisturizingBiocideCosmetic preparationsBiotechnologyActive agent

The invention provides a composition with high-efficiency broad-spectrum antibacterial capacity. The composition is prepared by the following steps: mixing the following components in percentage by weight: 10-40 percent of hydroxyacetophenone, 5-30 percent of glycerol caprylate and 30-60 percent of C2-10 dihydric alcohol, heating to the temperature of 80-90 DEG C, completely dissolving the materials, thereby obtaining the product. According to the composition disclosed by the invention, Gram negative bacteria, gram-positive bacteria, moulds and saccharomycetes thereof in the cosmetics can be effectively inhibited and killed under the conditions of low addition amount, high safety, mildness and low irritation, and the composition has certain effects of moisturizing, assisting emulsification and resisting oxidation and is particularly suitable to serve as a preservative in the transparent system, W / O or O / W cream emulsification system and surfactant washing system. The invention also provides an application of the composition serving as a preservative in the cosmetics.

Owner:GUANGDONG YAWEI BIOTECH

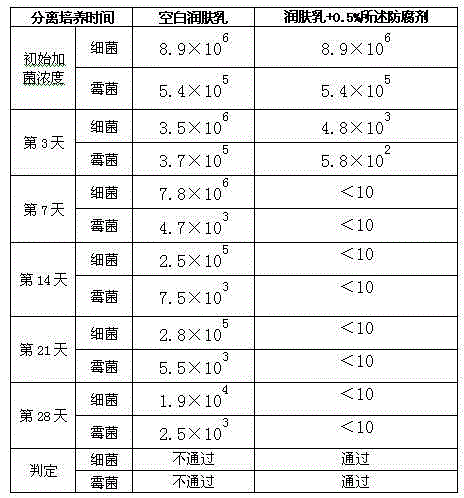

AKD emulsion and preparation method thereof

ActiveCN104499363AImprove emulsifying performanceRapid emulsificationWater-repelling agents additionWaxEmulsion

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

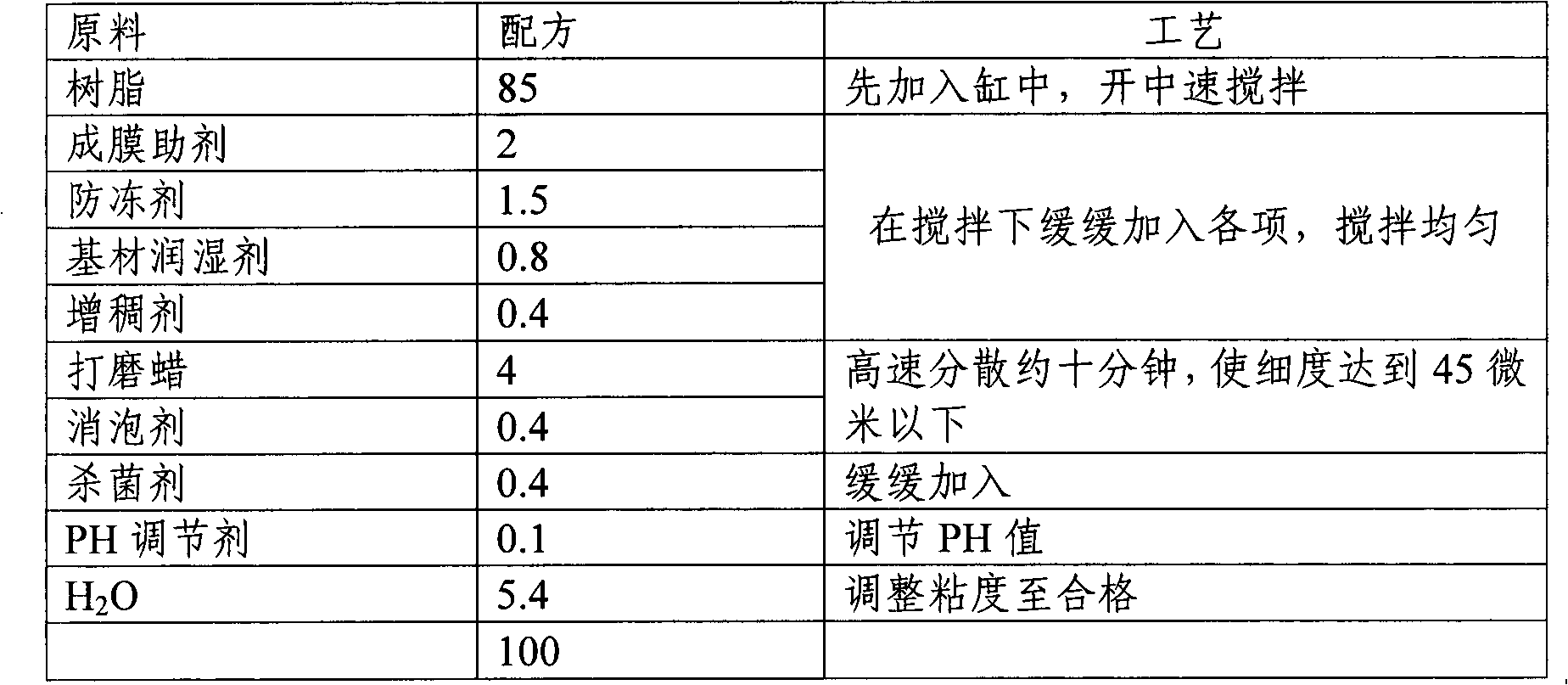

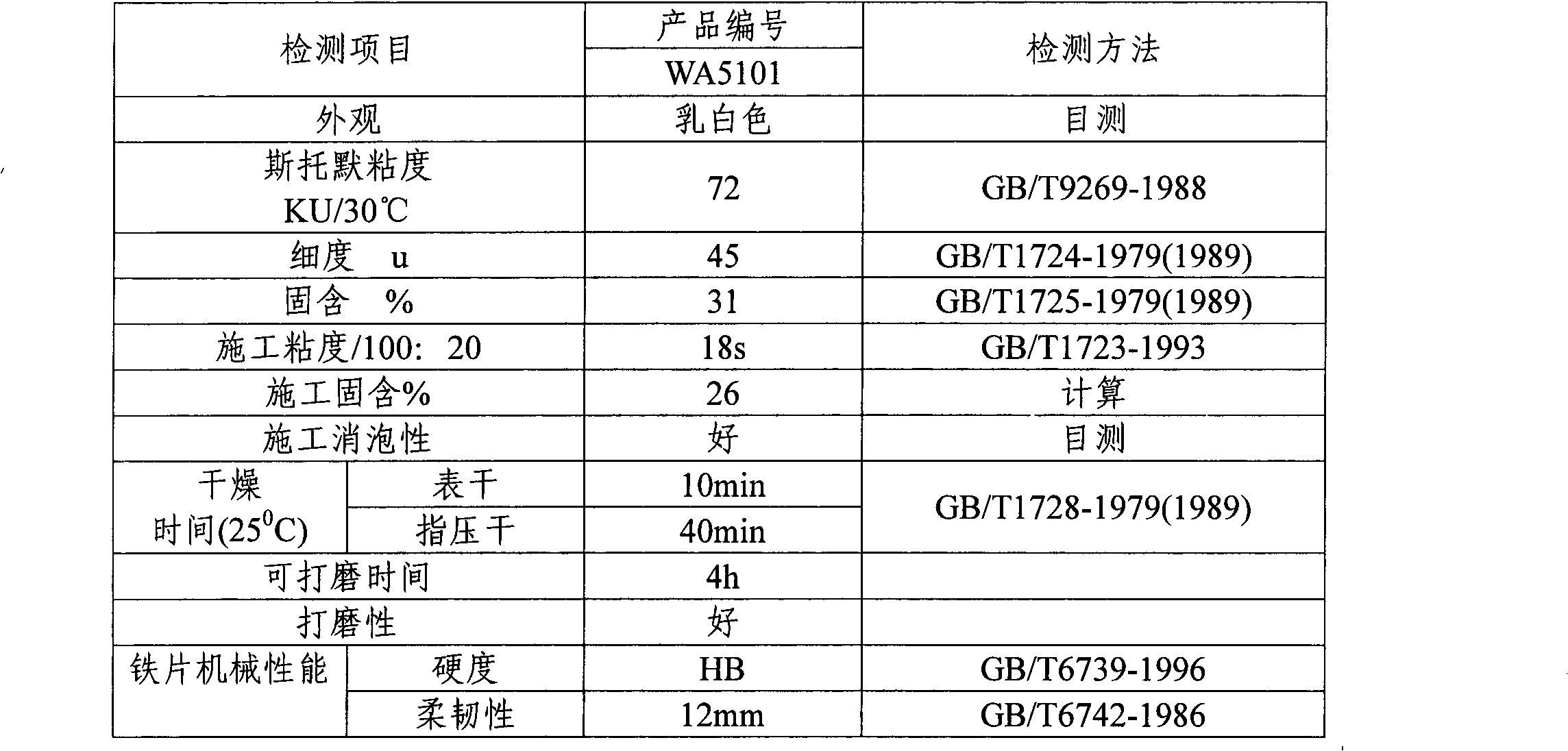

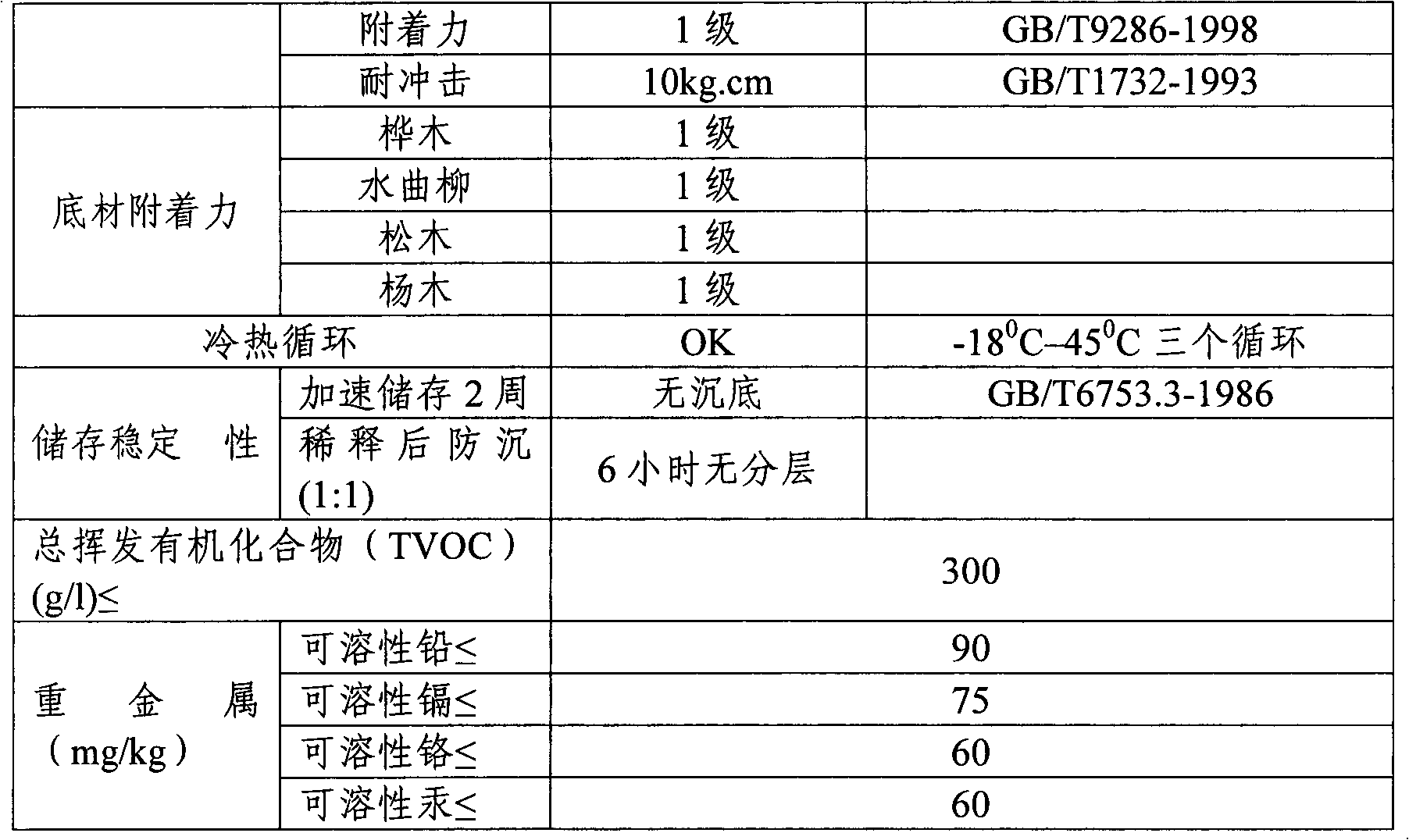

Water -emulsifiable nitrolacquer and preparation method thereof

The invention provides a water-emulsifiable nitrolacquer and a preparation method thereof. The water emulsion nitrolacquer comprises the following components in percentage by weight: 70%-90% of water-base nitro resin, 0.2%-0.5% of defoaming agent, 0.1%-0.5% of preservative, 2.5%-1% of substrate wetting agent, 3%-5% of sanding wax, 0.2%-0.6% of thickening agent, 1%-2% of antifreeze, 0%-0.2% of pH adjusting agent, 1%-3.5% of film forming auxiliary agent and 4%-20% of water. The water emulsion nitrolacquer has the advantages of good penetration property, quick drying, good sanding property, no adhesion to sand paper, little odor and no toxicity, and can be used as American water-base full-open spray after being produced. The product conforms to national standards and law regulations when exported to American and European Union, and has little odor; and the nitrolacquer film has the advantages of good sanding and adhesion property, quick drying and the like, thereby being suitable for flowline production.

Owner:珠海展辰新材料股份有限公司

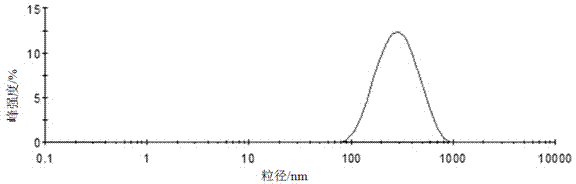

Ceramide nano-emulsion and preparation method thereof

ActiveCN104739658AIncrease contentReduce usageCosmetic preparationsToilet preparationsInorganic saltsPolyol

The invention discloses a ceramide nano-emulsion and a preparation method thereof. The ceramide nano-emulsion is composed of the following components by weight percentage: 0.1-8% of ceramide, 0.01-5% of emulgator, 5-30% of grease, 6-20% of polyhydric alcohols, 0.01-1% of inorganic salt and the balance of water. The preparation method comprises the following steps: mixing the ceramide and the grease and heating till the ceramide is completely dissolved; adding the emulgator and the polyhydric alcohols to obtain an oil phase component, mixing the inorganic salt with the water to obtain a water phase component, respectively heating the oil phase component and the water phase component to 80-90 DEG C, adding the water phase component into the oil phase component, homogenizing and emulsifying; performing high-pressure homogenizing on the obtained crude emulsion under the pressure of 150-600 bar under the condition that the number of cycle is 2-5 to obtain the ceramide nano-emulsion, wherein after the ceramide nano-emulsion is stored for 30d at a high temperature of 50 DEG C, the particle size is basically the same. The ceramide nano-emulsion is excellent in water dispersibility and biocompatibility and can be randomly matched with the cosmetic formula at normal temperature.

Owner:王亚平

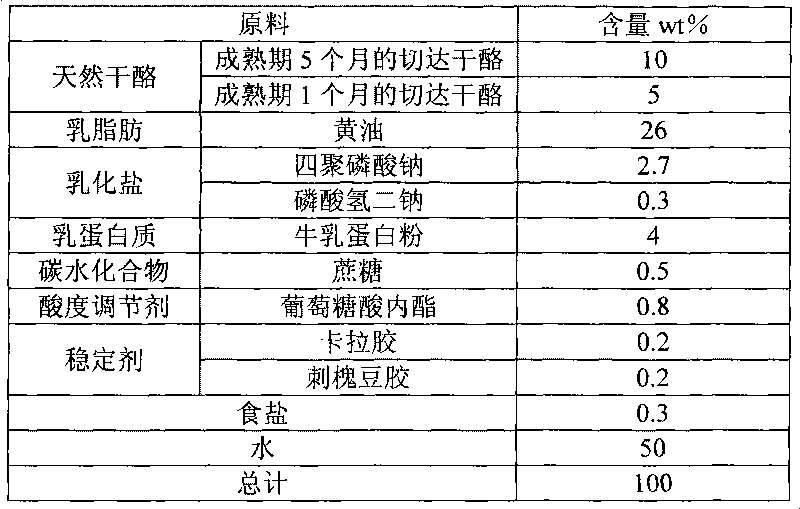

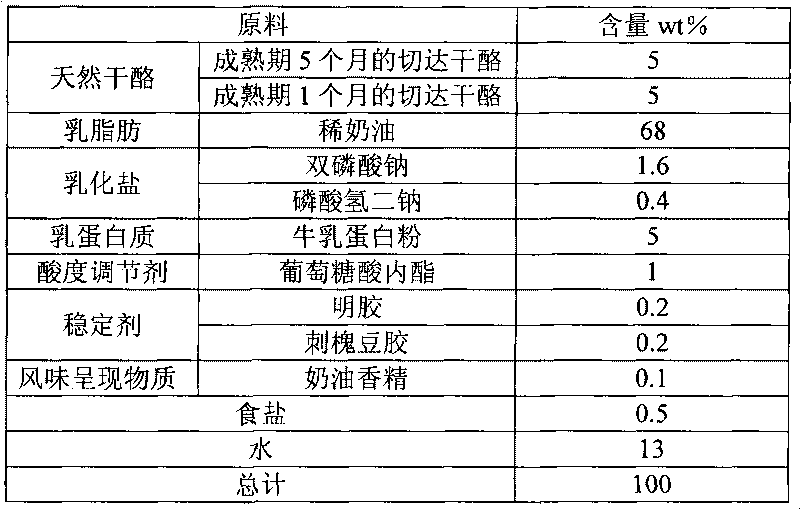

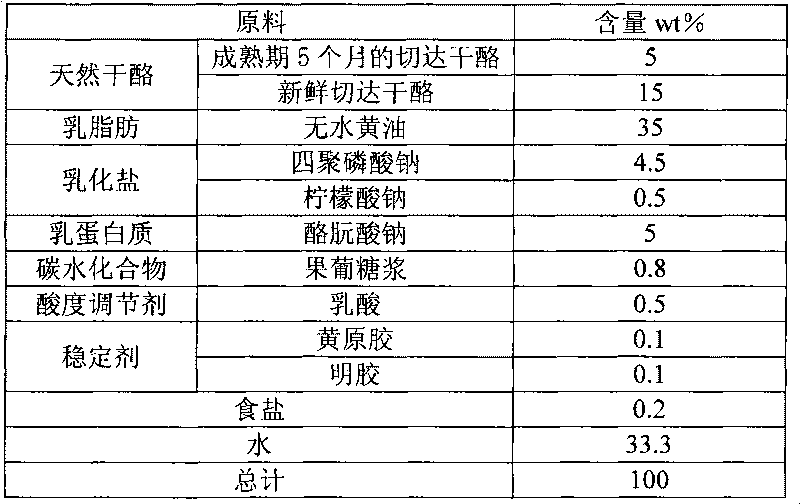

Method for preparing regenerated cream cheese and obtained cheese

The invention discloses a method for preparing regenerated cream cheese, which comprises the following steps: (1) melting and mixing raw materials comprising natural cheese, milk fat, milk protein, emulsifying salt, carbohydrates, edible salt, stabilizer and water in addition to fermentation acid-producing yak milk type cheese; (2) low-temperature acid-adding process; (3) pasteurization; (4) homogenization process; and (5) fast cooling. The invention can overcome the defects of all aspects of the natural cream cheese process, the existing regenerated cream cheese process, the conventional regenerated cheese process and the like and provides the method for preparing the regenerated cream cheese; compared with the traditional natural cheese production process, the method is greatly simplified and has the advantages of simple production process, small equipment input and short production cycle, thereby having great advantages on the cost, leading a product to have high additional value, leading the better raw materials of the product to have relative advantages on the cost and being more realistic and convenient when in real production. Compared with the natural cheese, the senses of the prepared regenerated cream cheese are better.

Owner:BRIGHT DAIRY & FOOD

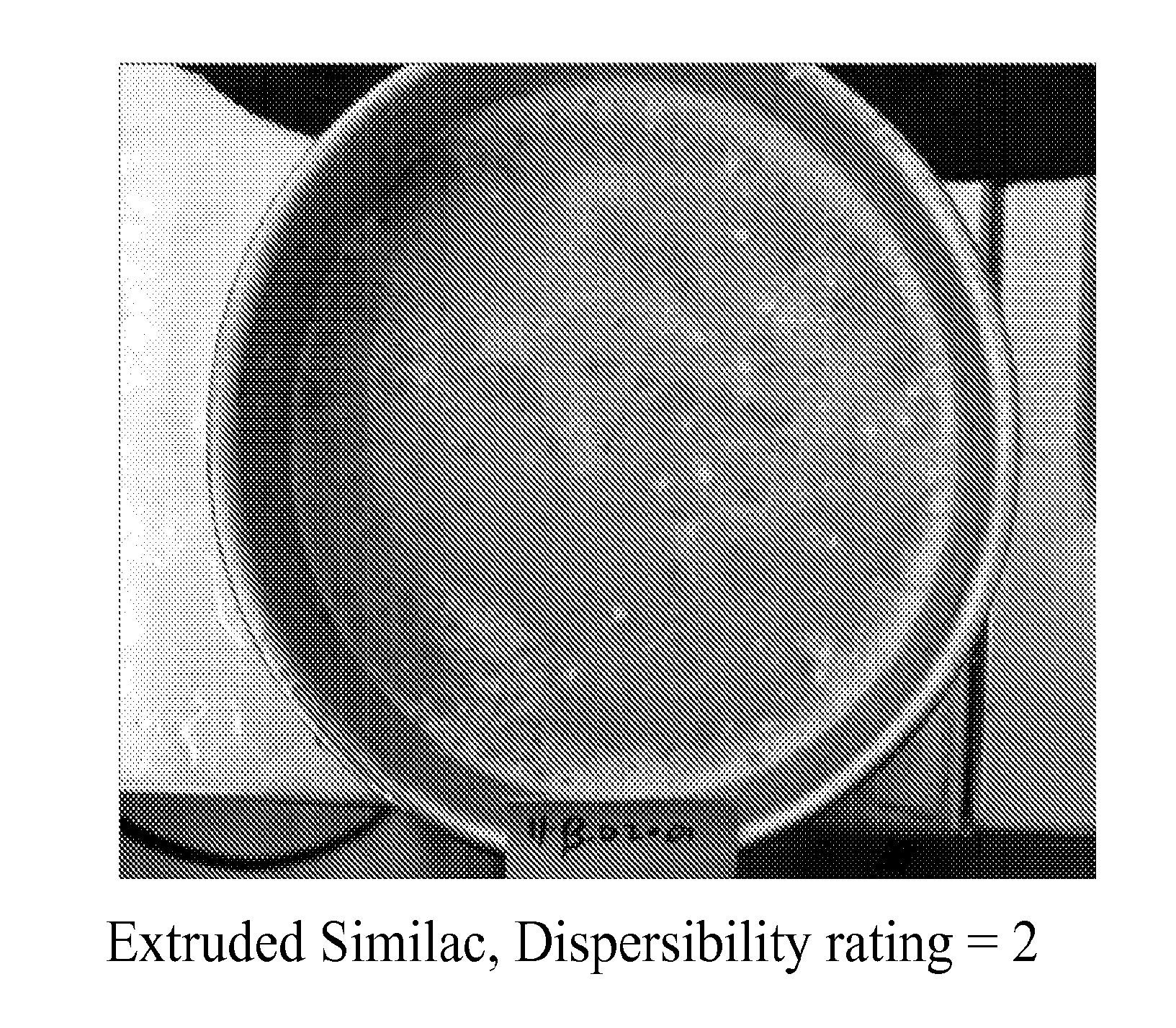

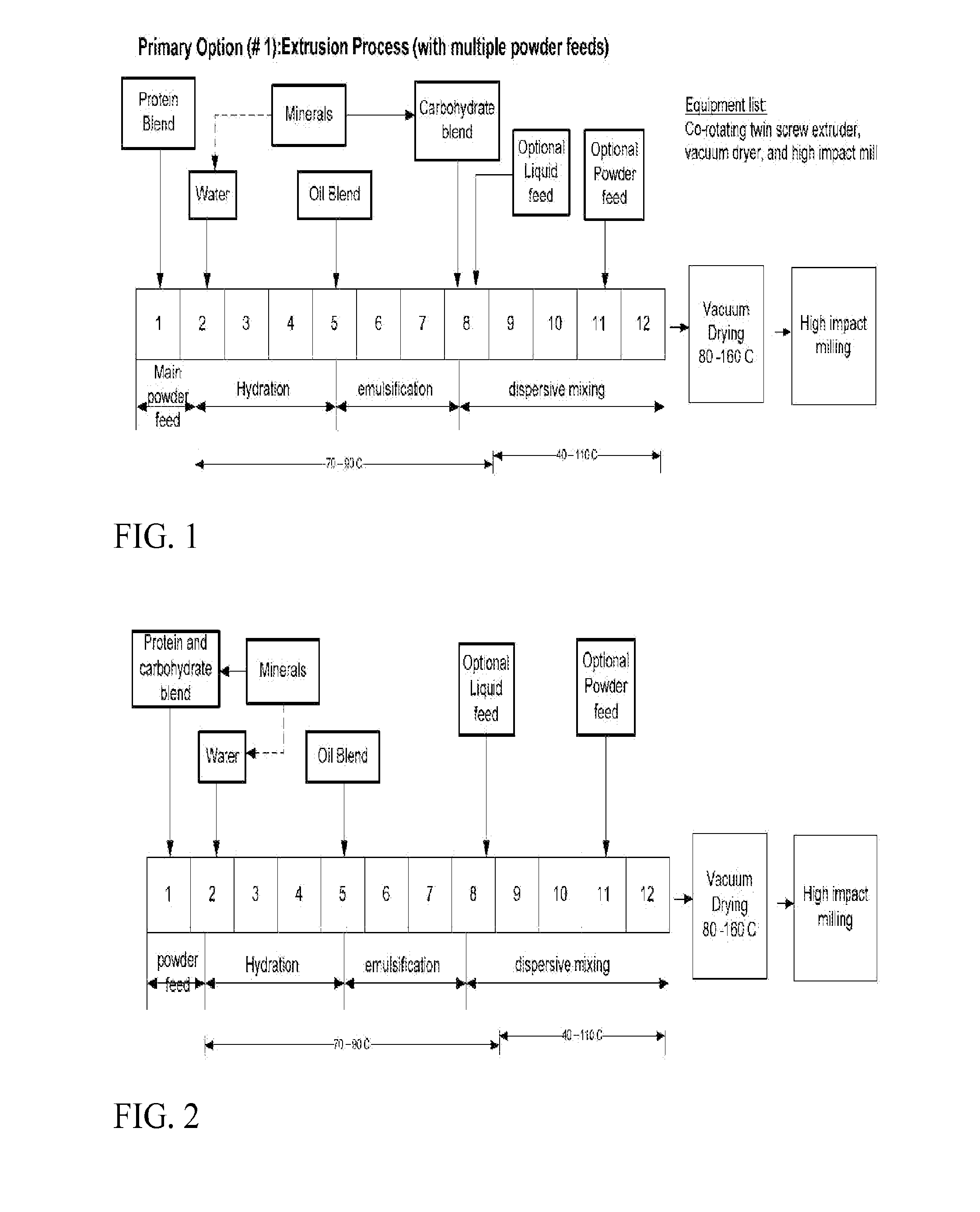

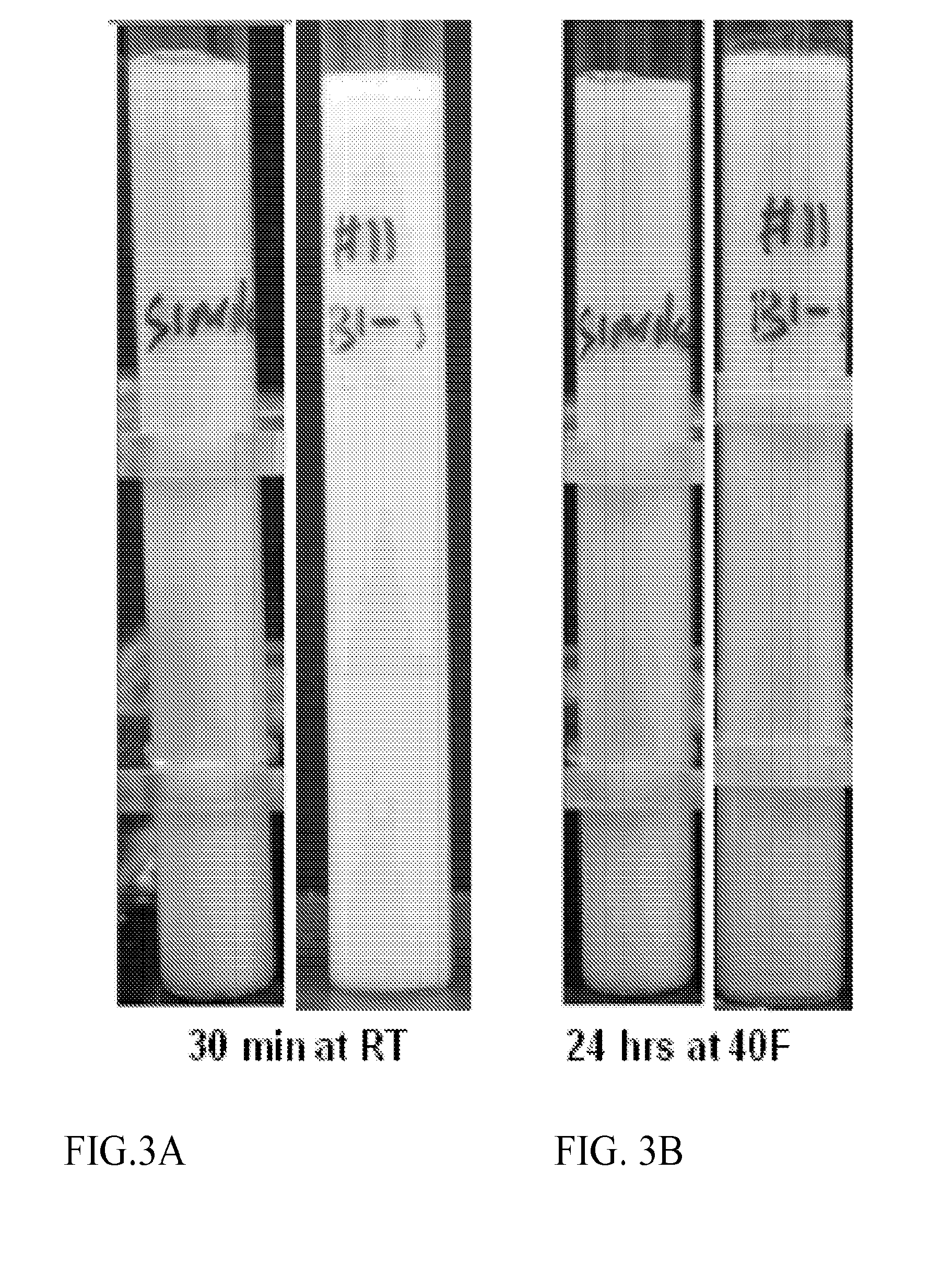

Extruded nutritional powders having improved emulsion stability and dispersibility and methods of manufacturing same

InactiveUS20150305394A1Reduce lossesAvoid the needMilk preparationFood preservationEmulsionMaterials science

Extruded nutritional powders and methods of manufacturing the extruded nutritional powders, including extruded infant nutritional powders and extruded adult nutritional powders are provided. The processes utilize an extruder that is capable of internally mixing and emulsifying protein, and optionally, a carbohydrate with fat and water into an emulsion that can be dried into a powder having equivalent fat separation and dispersibility as compared to spray dried powders.

Owner:ABBOTT LAB INC +1

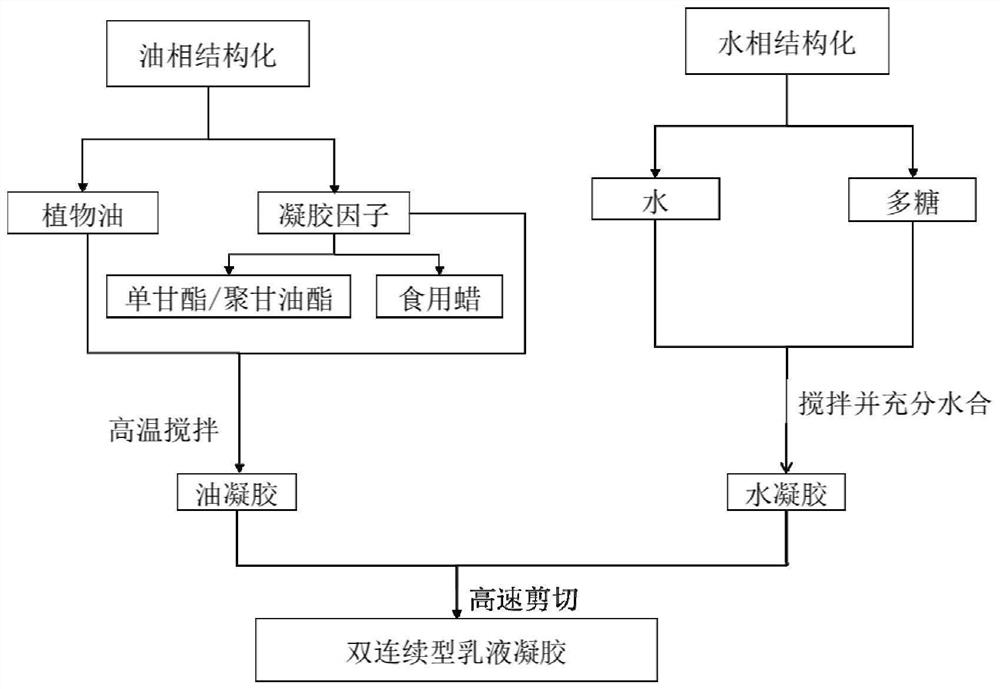

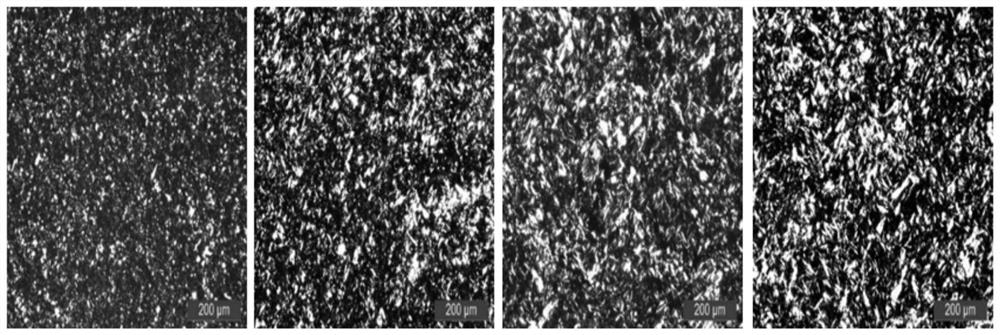

Preparation method and application of bicontinuous emulsion gel

The invention discloses a preparation method and application of bicontinuous emulsion gel, and belongs to the technical field of food gel emulsification. The method comprises the following steps: respectively adding food-grade gel factors into an oil phase, and generating a fat crystal network in the oil phase to solidify the oil phase; adding polysaccharide into a water phase to form a hydrogel three-dimensional network space structure to solidify the water phase; and performing high-speed shearing on the two phases to form the ultra-stable bicontinuous emulsion gel. The emulsion gel obtainedby the invention has extremely low contents of trans-fatty acid and saturated fatty acid, can be applied to the filling of smearing fat and baking products, serves as an effective way for reducing the content of fat in food, can also transport hydrophobic and hydrophilic nutrient substances with high loading capacity simultaneously, and has potential application value in the fields of food, medicine and the like.

Owner:JIANGNAN UNIV

Solid water-in-oil emulsion make-up composition

InactiveUS20050191329A1Good lookingGood spreadabilityCosmetic preparationsHair cosmeticsWaxTransmittance

Disclosed is a solid water-in-oil emulsified make-up composition comprising by weight: (a) from about 10% to about 25% of a powder component; the powder component comprising by weight of the powder component from about 50% to about 80% of a spherical powder having an average particle size of from about 0.1 μm to about 50 μm; the spherical powder comprising by weight of the entire composition: (i) from about 2% to about 20% of a spherical soft focus powder having a Total Luminous Transmittance (Tt) of from about 55 to about 90, a Diffuse Luminous Transmittance (Td) of from about 34 to about 81 and a Haze value {(Td / Tt)×100} of from about 62 to about 90; and (ii) from about 1% to about 10% of a spherical oil absorbing powder having an oil absorbency of at least about 100 ml / 100 g; (b) a volatile silicone oil; (c) a non-volatile oil; (d) a solid wax; (e) a lipophilic surfactant having an HLB of less than about 8; and (f) water.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of agar gel microspheres

ActiveCN102389755AImprove uniformityHigh mechanical strengthMicroballoon preparationMicrocapsule preparationMicrosphereHeat stability

The invention relates to a preparation method of agar gel microspheres. Through the method, the uniformly spherical agar gel microspheres with even grain diameter which contain 4-20wt% of agar, and are controllable in the range of 1-900 mum are prepared through the processes of taking the agar as the raw material, preparation of oil phase and aqueous phase, dispersed emulsion, cooling and solidifying, crosslinkage and ligand modification. The agar gel microspheres are excellent in mechanical strength, high in heat stability, strong in renewability, low in cost and can be used as separation medium. The method is simple in operation process, low in equipment requirement, low in energy consumption, and can be used for realizing industrial preparation.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com