Method for preparing regenerated cream cheese and obtained cheese

A technology for cream cheese and cheese, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of complex preparation process of natural cream cheese, unstable acidity of the final product, poor water holding capacity of cheese, etc., and achieves good baking function, good The effect of preservation and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

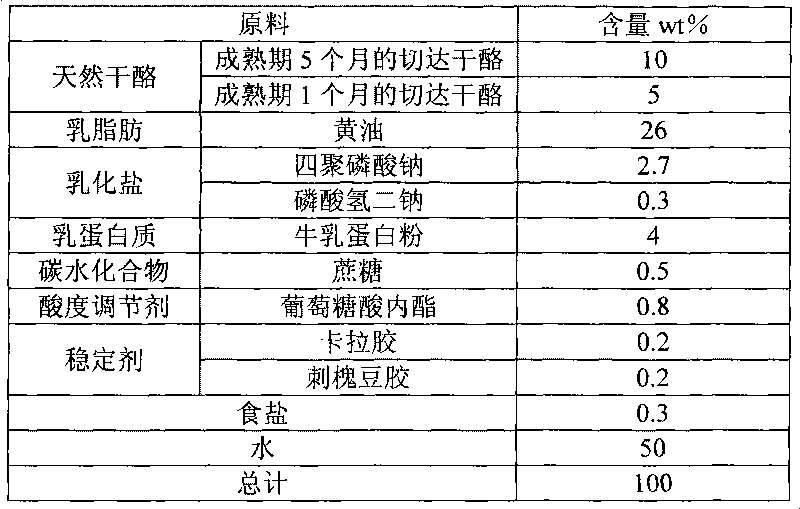

[0038] formula:

[0039]

[0040] Manufacturing method:

[0041] ① Cut the natural cheese and milk fat into pieces, stir with milk protein, emulsifying salt, carbohydrates, salt, stabilizer and water, heat up to 50°C, stir and melt for 5 minutes;

[0042] ②At 50°C, under stirring, add acidity regulator evenly for 5 minutes to adjust the pH to 5.0, stir for 2 minutes, and heat to 75°C to melt;

[0043] ③Pasteurize the melt (75°C, 5min);

[0044] ④ Homogenize while hot, the homogenization temperature is 70°C, and the homogenization pressure is 200Bar;

[0045] ⑤Fill it while it is hot, pack it into shape, and immerse it in running water for rapid cooling. It takes 15 minutes to reach the central temperature of 20°C.

[0046] The product production cycle (including filling) is 40 minutes, and the shelf life is 6 months.

[0047] Product indicators:

[0048] project

Embodiment 2

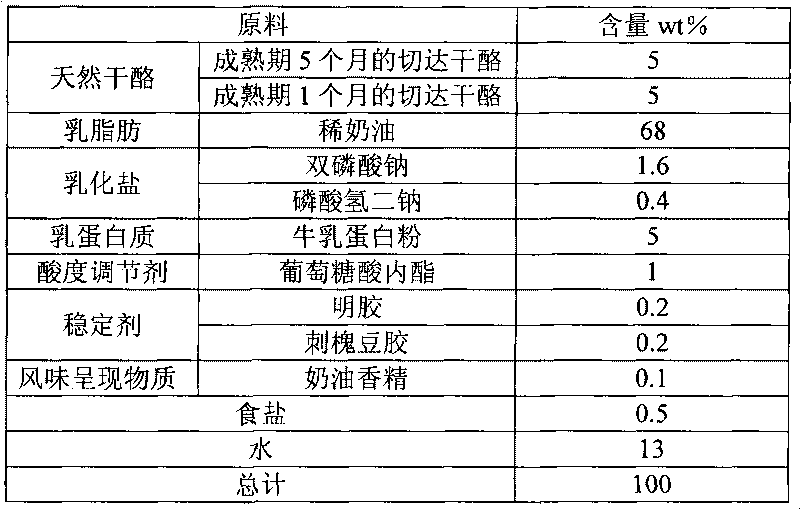

[0050] formula:

[0051]

[0052] Manufacturing method:

[0053] ① Cut the natural cheese into pieces and stir with milk protein, milk fat, emulsifying salt, salt, stabilizer, essence and water, heat up to 45°C and stir for 5 minutes to melt;

[0054] ②At 45°C, under stirring, add an acidity regulator evenly over 3 minutes to adjust the pH to 4.9, stir for 5 minutes, and heat to 85°C to melt;

[0055] ③ pasteurize the melt (95°C, 15 seconds);

[0056] ④ Homogenize while hot, the homogenization temperature is 80°C, and the homogenization pressure is 160Bar;

[0057] ⑤Fill while it is hot, pack into shape, immerse in running water for rapid cooling, and reach the central temperature of 22°C in 20 minutes.

[0058] The product production cycle (including filling) is 45 minutes, and the shelf life is 8 months.

[0059] Product indicators:

[0060] project

Embodiment 3

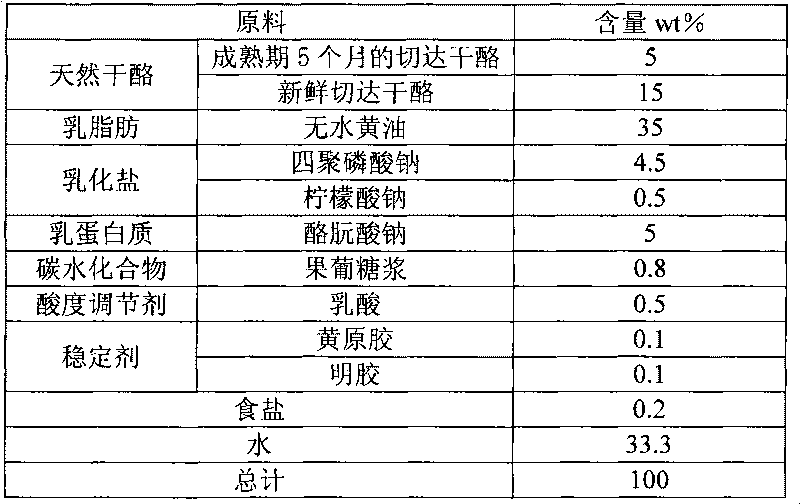

[0062] formula:

[0063]

[0064] Manufacturing method:

[0065] ① Cut the natural cheese and milk fat into pieces and stir with milk protein, emulsifying salt, carbohydrates, salt, stabilizer and water, heat up to 45°C and stir for 10 minutes to melt;

[0066] ②At 45°C, under stirring, add acidity regulator evenly over 4 minutes to adjust the pH to 5.2, stir for 3 minutes, and heat to 80°C to melt;

[0067] ③Pasteurize the melt (80°C, 3min);

[0068] ④ Homogenize while hot, the homogenization temperature is 75°C, and the homogenization pressure is 180Bar;

[0069] ⑤Fill while it is hot, pack into shape, and quickly cool in a cooling tunnel. It takes 30 minutes to reach the central temperature of 30°C.

[0070] The product production cycle (including filling) is 55 minutes, and the shelf life is 9 months.

[0071] Product indicators:

[0072] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com