Patents

Literature

125 results about "Cream cheese" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cream cheese is a soft, usually mild-tasting fresh cheese made from milk and cream. Stabilizers such as carob bean gum and carrageenan are typically added in industrial production. The U.S. Food and Drug Administration defines cream cheese as containing at least 33% milk fat with a moisture content of not more than 55%, and a pH range of 4.4 to 4.9. Similarly, under Canadian Food and Drug Regulations cream cheese must contain at least 30% milk fat and a maximum of 55% moisture. In other countries, it is defined differently and may need a considerably higher fat content.

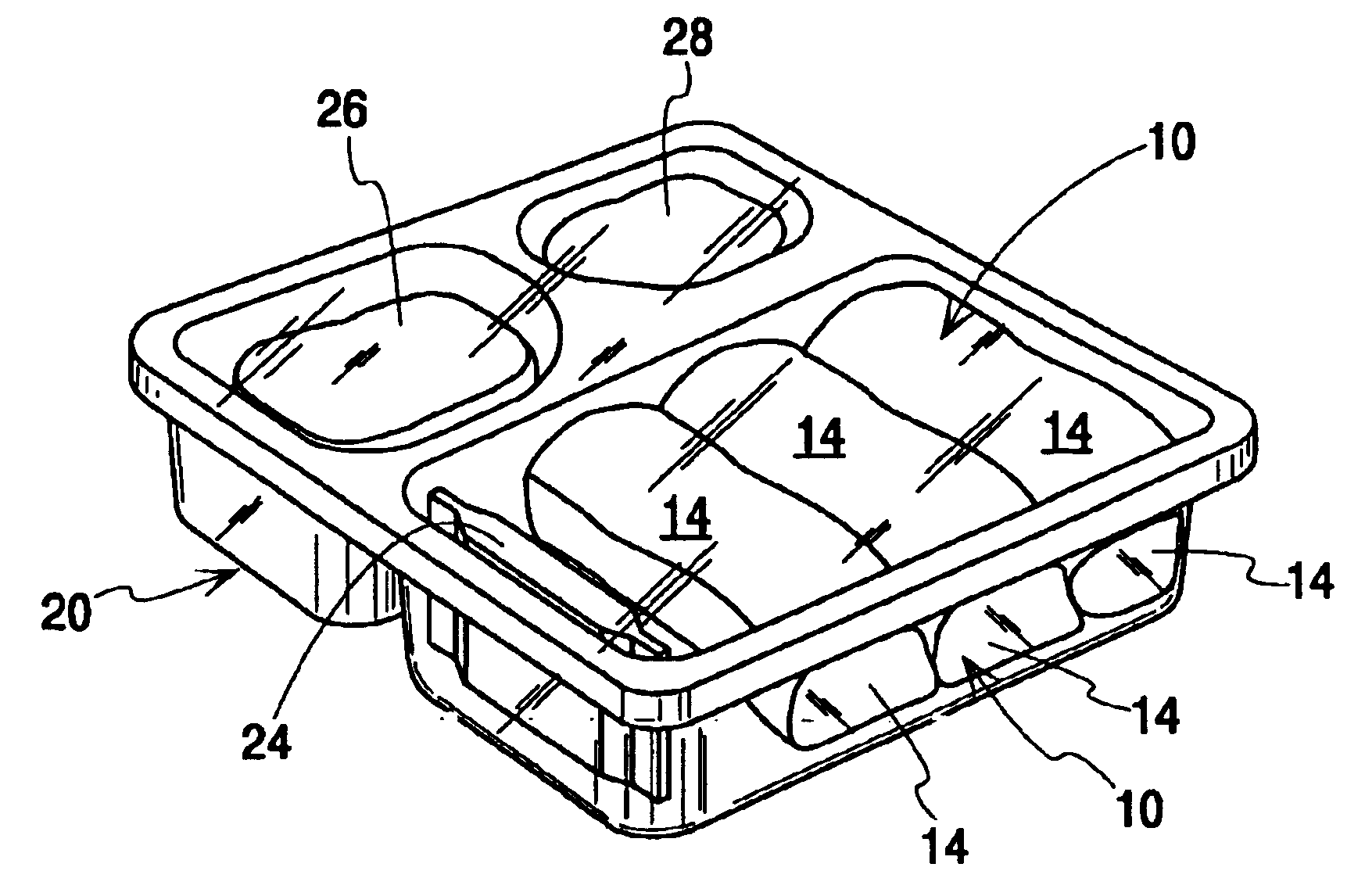

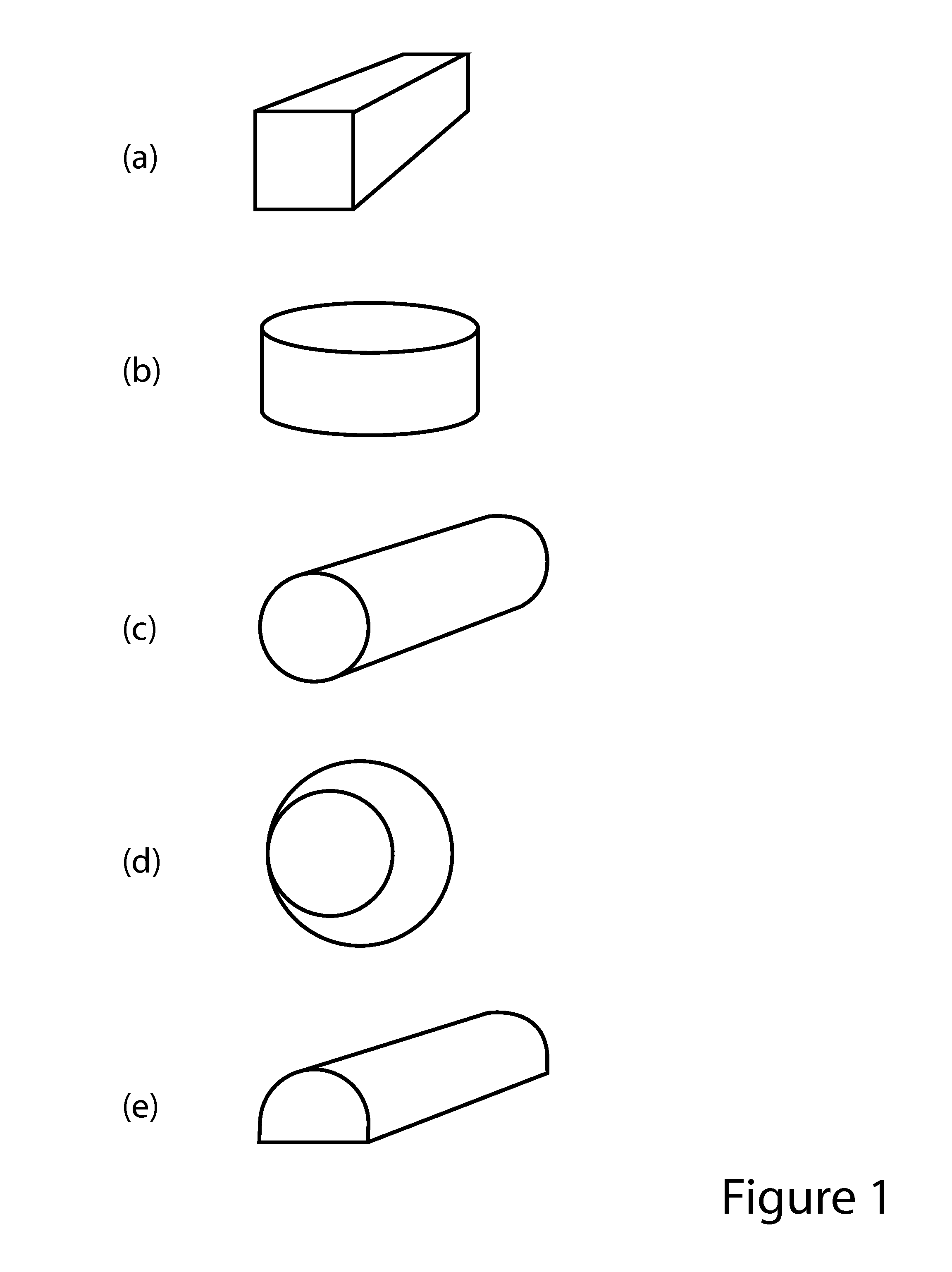

Soft, fully baked breadsticks

InactiveUS6919097B2Satisfactory textureSatisfactory chewability characteristicReady-for-oven doughsDough treatmentReady to eatAdditive ingredient

A fully baked, soft, breadstick product is provided having a water activity in the range of about 0.9 to 0.95. The breadstick product is ideally suited for use in a refrigerated, ready-to-eat kit. The breadstick products are of a convenient size and shape with perforations to allow the breadstick product to be separated into individual breadsticks. The breadstick product is especially adapted as a single serving or snack food product. Also provided is a kit containing the breadstick product with one or more additional food items. Such additional food items include, for example, cheese, cheese products, cheese sauces, tomato sauces, cream cheese, butter, margarine, jam, jelly, honey, peanut butter, olive oil, salad ingredients, salad dressings, and the like. Preferably, each component item is in a separate container sealed from the other food items to substantially retard or prevent flavor, moisture, and microbial migration from one food item to another. The breadstick products retain a soft, desirable texture throughout their anticipated shelf lives.

Owner:KRAFT FOODS INC

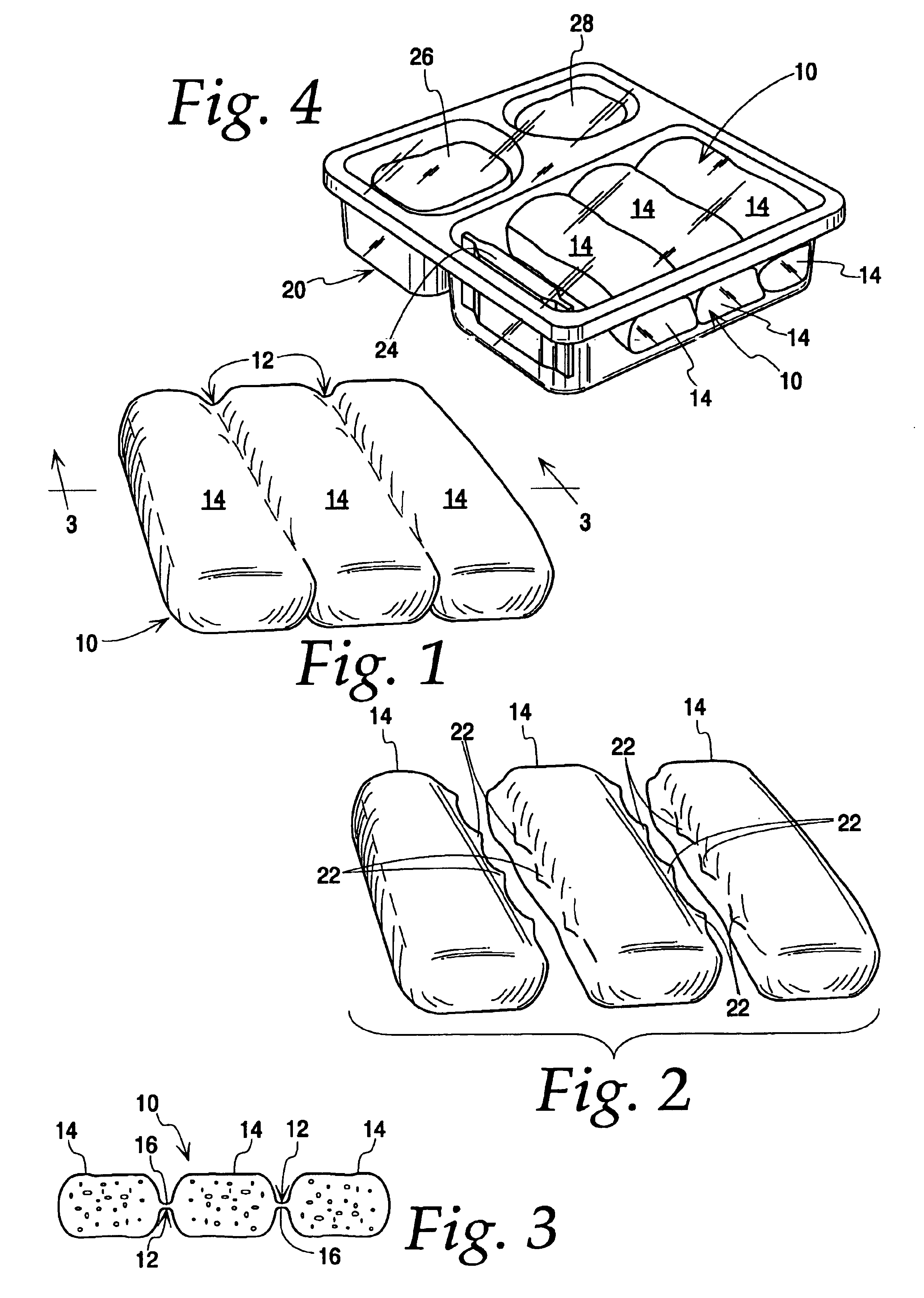

Dairy products with reduced average particle size

InactiveUS6861080B2Improve the immunityIncrease pressureMilk preparationCheese manufactureCream cheeseMilk products

The present invention relates to superior dairy products which have firmness qualities and textural qualities not observed in conventional dairy products. The dairy products of this invention have average fat particle sizes of less than about 0.8 microns, preferably of about 0.1 to about 0.8 microns, and more preferably about 0.2 to about 0.6 microns. The dairy products which may be manufactured using this process are cream cheese, sour cream, and dairy products containing at least 4 percent fat. The present invention also provides a process for making a cream cheese product without the removal of whey and having average fat particle sizes of less than about 0.8 microns, preferably of about 0.1 to about 0.8 microns, and more preferably about 0.2 to about 0.6 microns.

Owner:KRAFT FOODS GRP BRANDS LLC

Pre-mix formulations comprising ingredients for dairy products

InactiveUS20060134297A1Avoid disadvantagesMilk preparationCheese manufacturePreservativeAdditive ingredient

Ingredients and methods of using ingredients to produce dairy based food products. The ingredients may include milk protein concentrate, fat containing powders and other compounds including sweetening agents, flavours, preservatives, salts and emulsifiers. Food products that can be made according to the invention include yoghurt, cheese, cheese spreads, sweet spreads, nutrition bars, cream cheese, dairy desserts and sour cream.

Owner:FONTERRA COOP GRP LTD

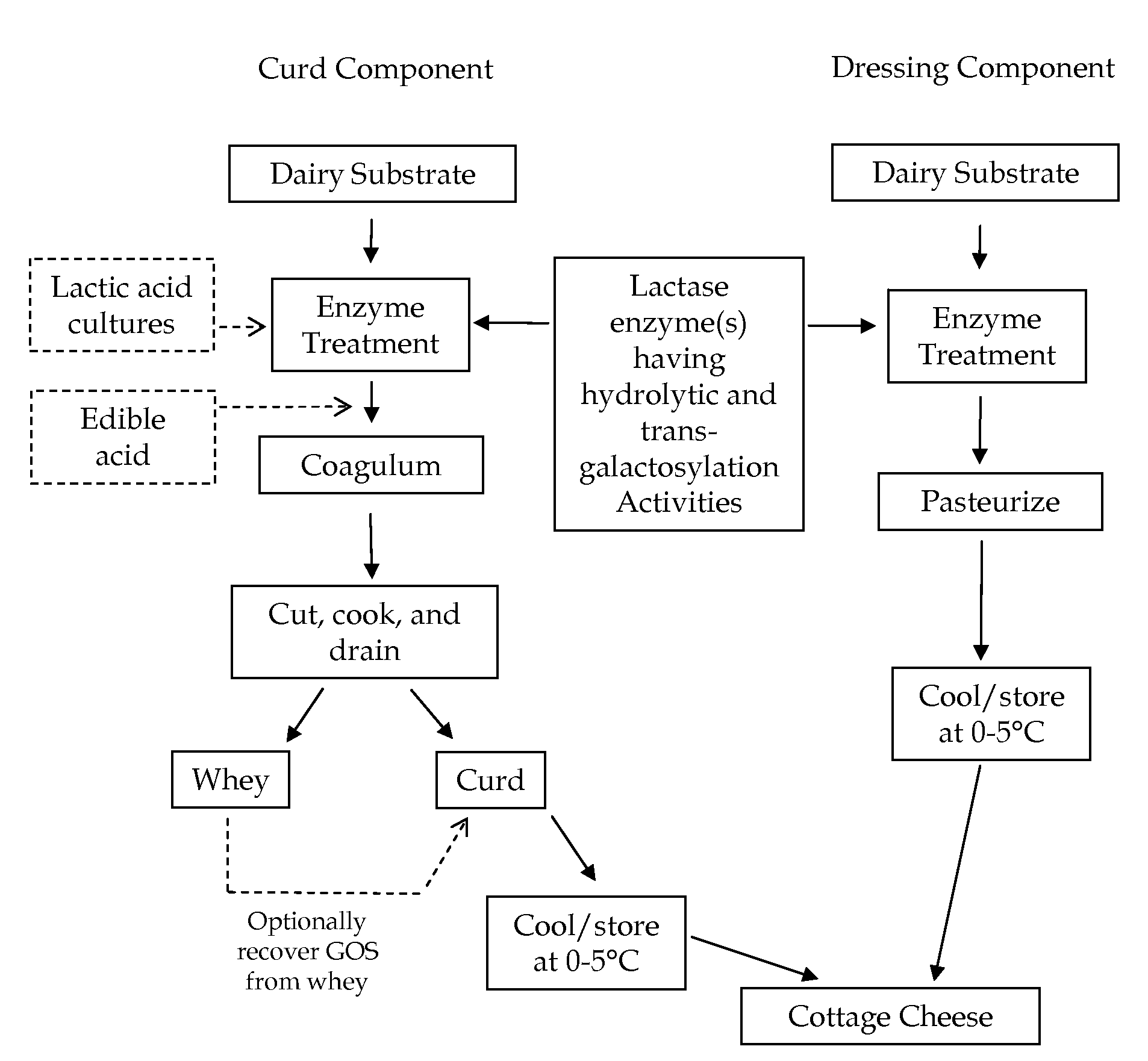

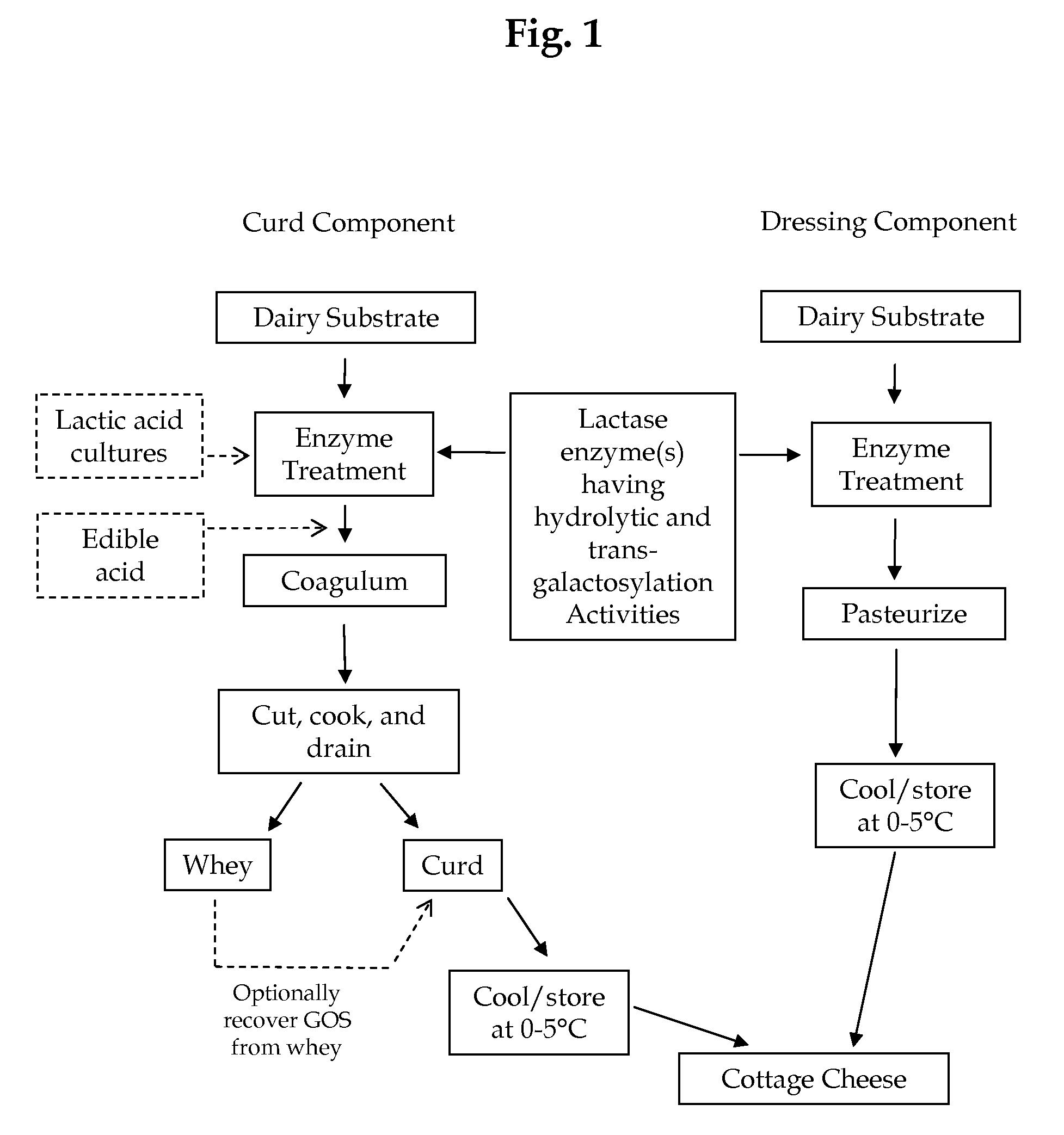

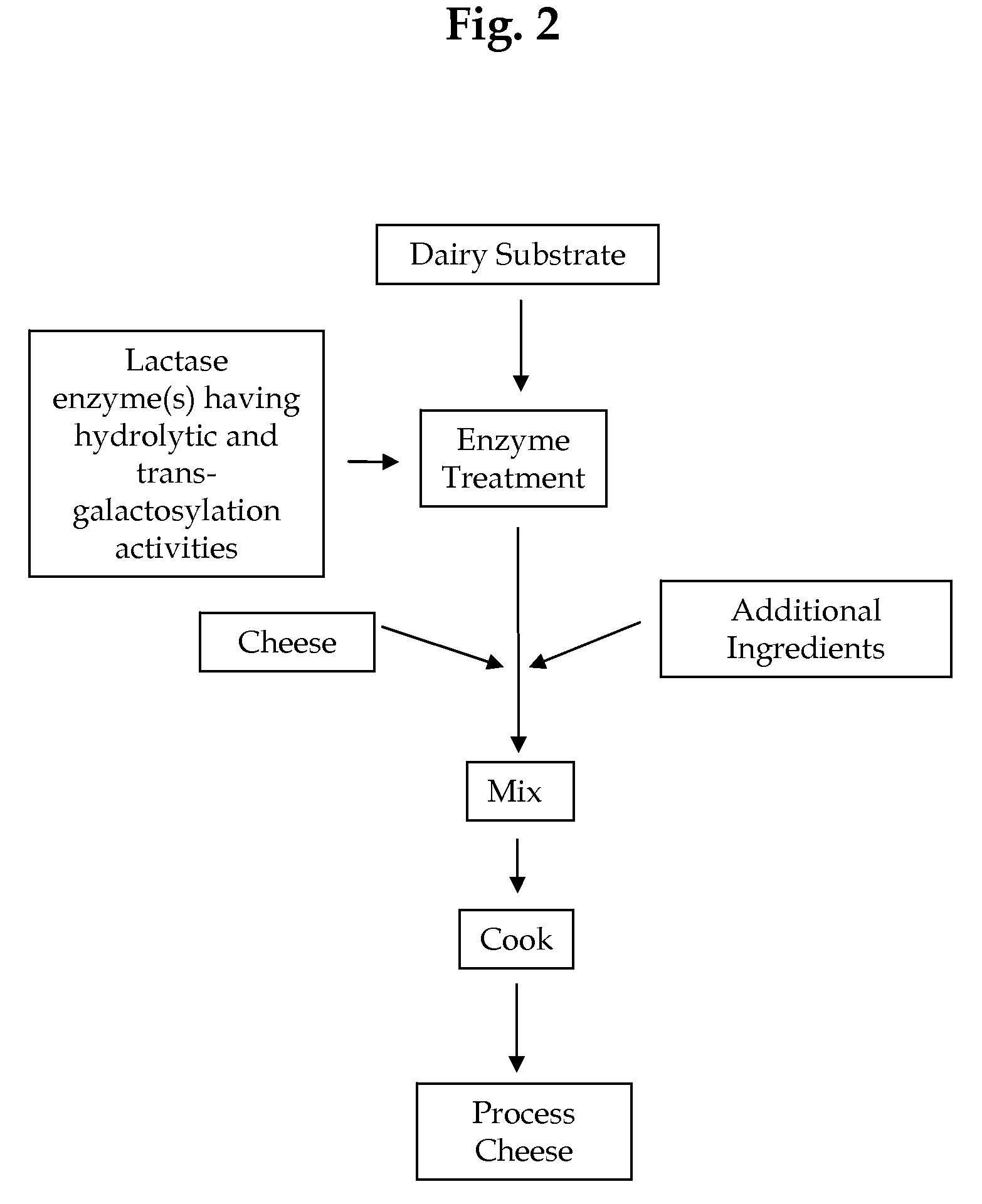

Cheese Products Containing Galacto-Oligosaccharides And Having Reduced Lactose Levels

InactiveUS20090297660A1Lower Level RequirementsReduce lactose levelMilk preparationWhey manufactureLactaseGalactooligosaccharide

The processes described herein are directed to cream cheese products containing galacto-oligosaccharides and having significantly reduced lactose levels. More specifically, lactose-containing dairy substrates are contacted with lactase enzyme(s) having hydrolytic and trans-galactosylation activities effective for converting at least 20 percent of the lactose in the dairy substrate to galacto-oligosaccharides. The enzyme-treated dairy substrate is then processed into galacto-oligosaccharide containing cream cheese products having reduced lactose levels. The cream cheese products provided herein have excellent nutritional and organoleptic properties.

Owner:KRAFT FOODS INC

Cream cheese and preparation method thereof

InactiveCN101167500ABroaden sources of raw materialsStable textureCheese manufactureStaphylococcus lactisAdditive ingredient

The invention relates to a cream cheese and a preparation method thereof. The technical scheme is to use milk fat raw material: 15-85%; whole milk: 10-80%; milk protein raw material: 1-10%; carbohydrate raw material: 1-10%. The present invention expands the raw material source of the cream cheese, uses milk protein raw material, carbohydrate raw material and stabilizer as ingredients, forms a stable texture without whey precipitation, and omits the process step of removing whey. The invention uses lactic acid bacteria including diacetyl lactis streptococcus to mix and ferment the ingredients of cream cheese, so that the product can form a new flavor.

Owner:TIANJIN UNIV OF SCI & TECH

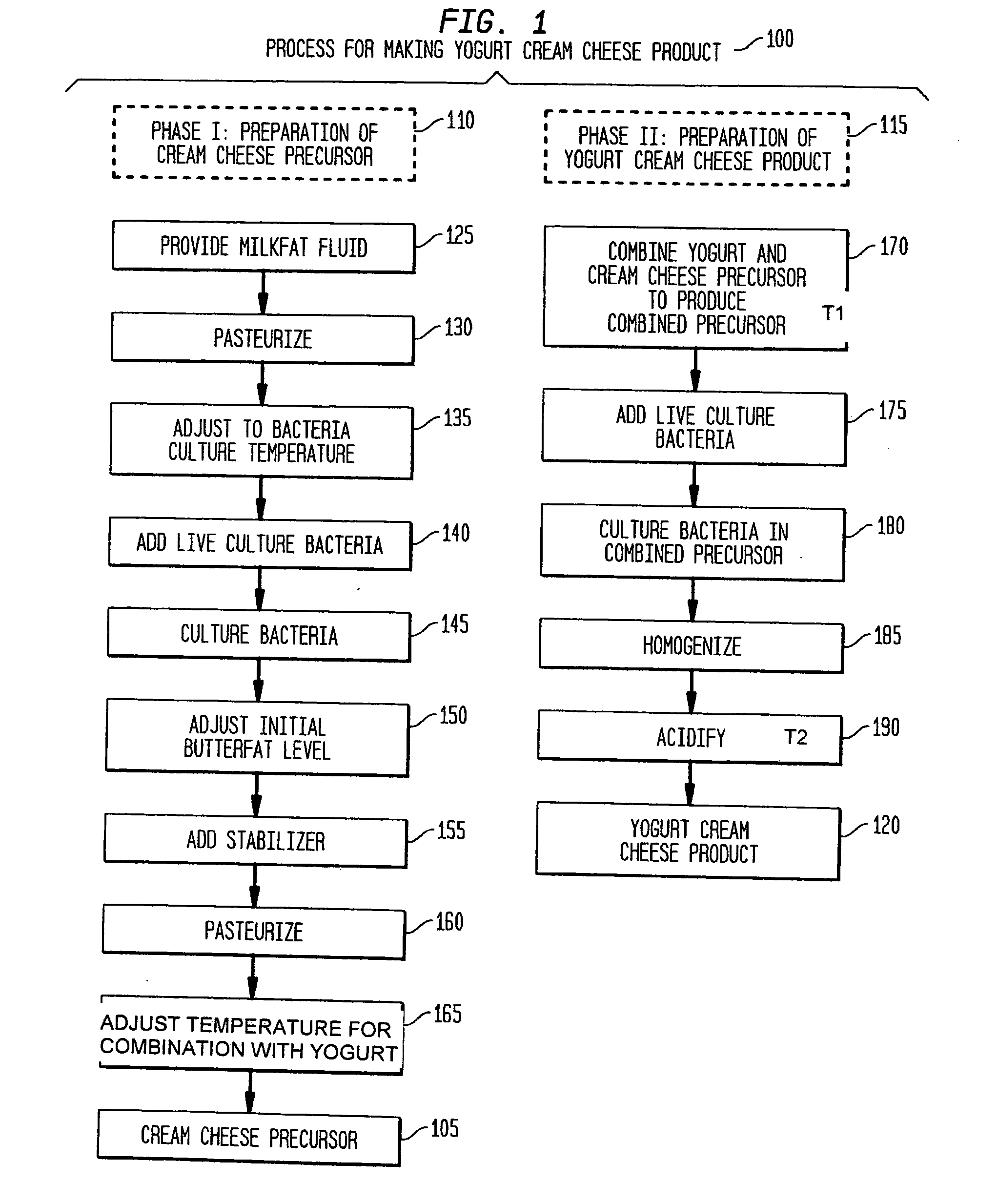

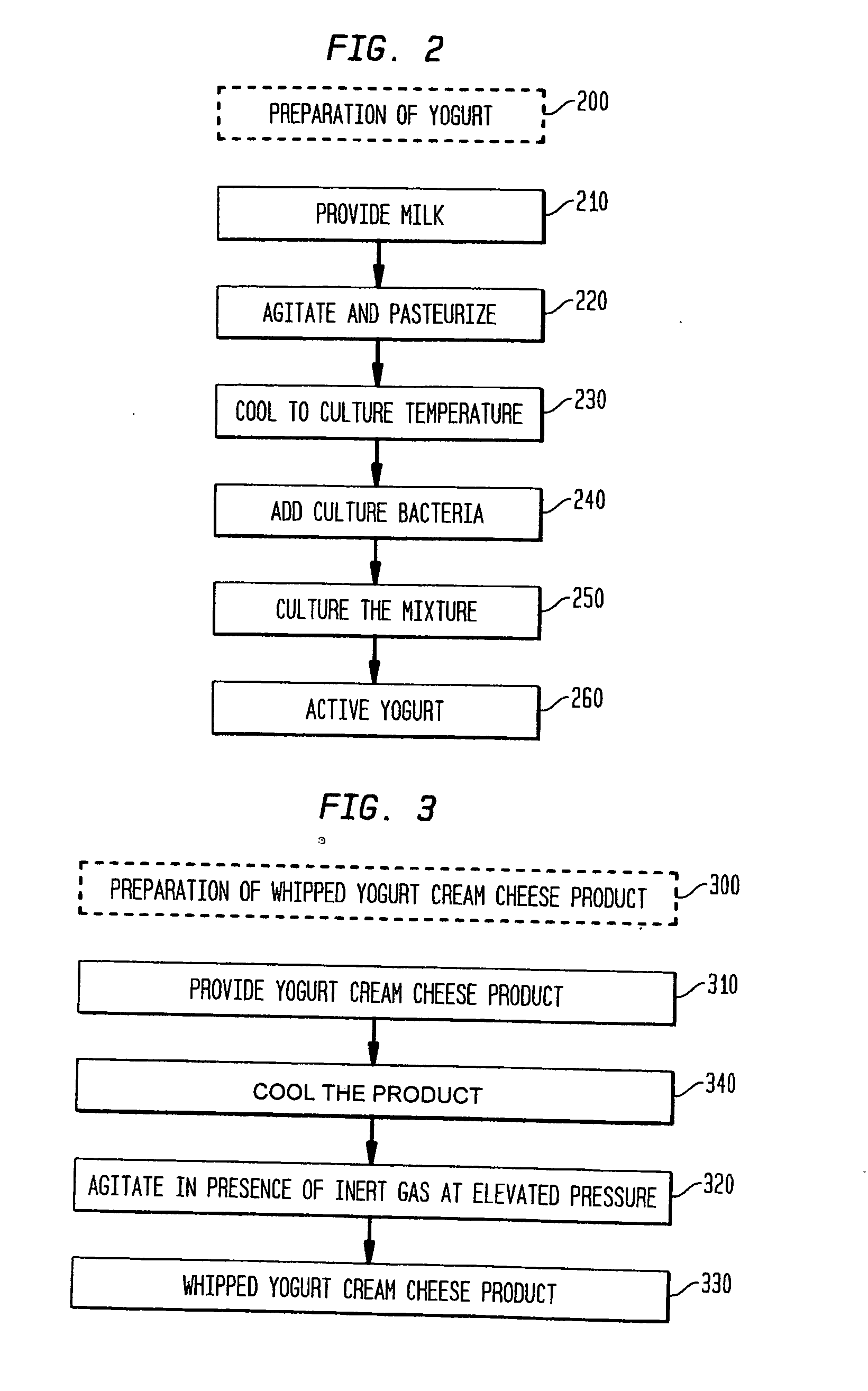

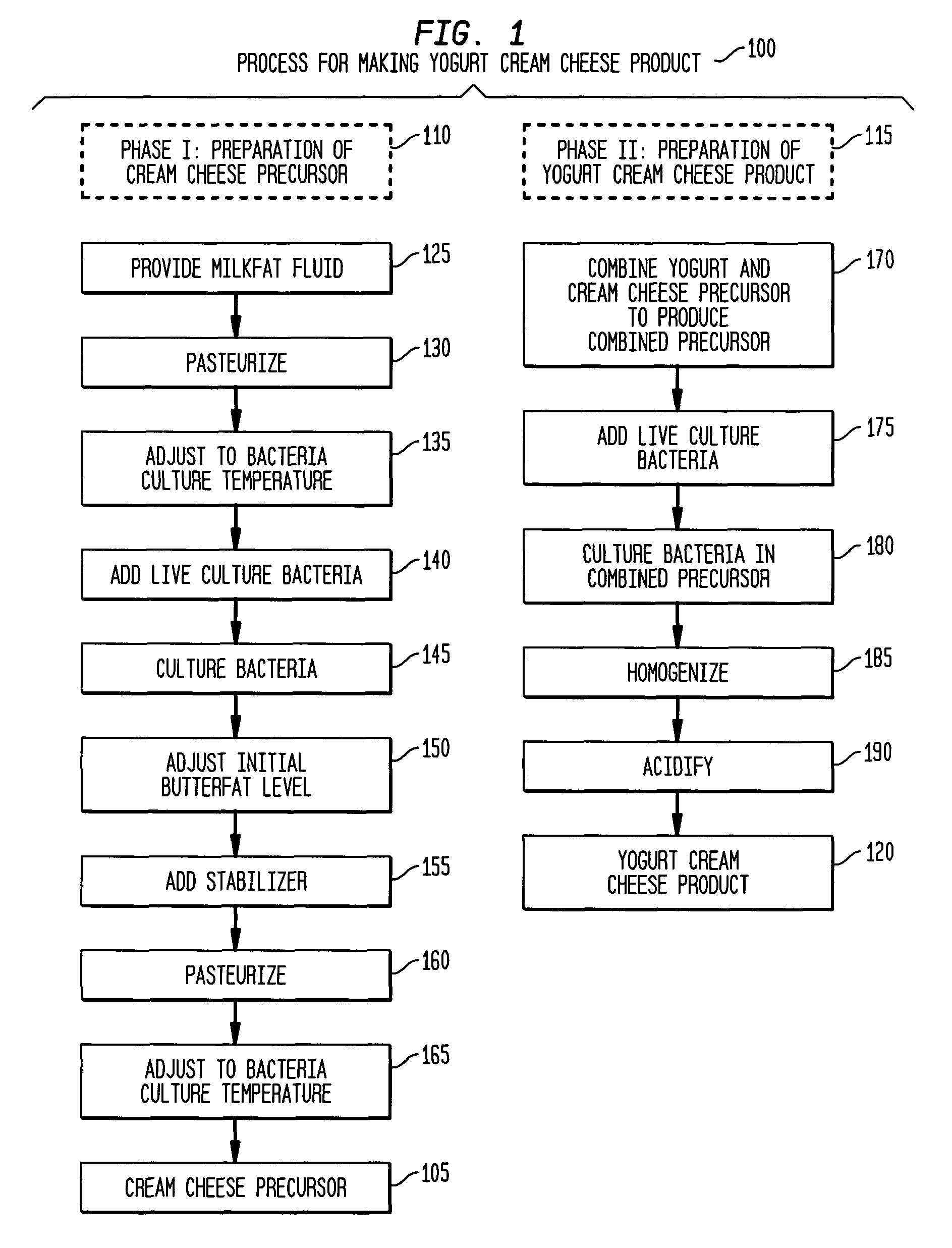

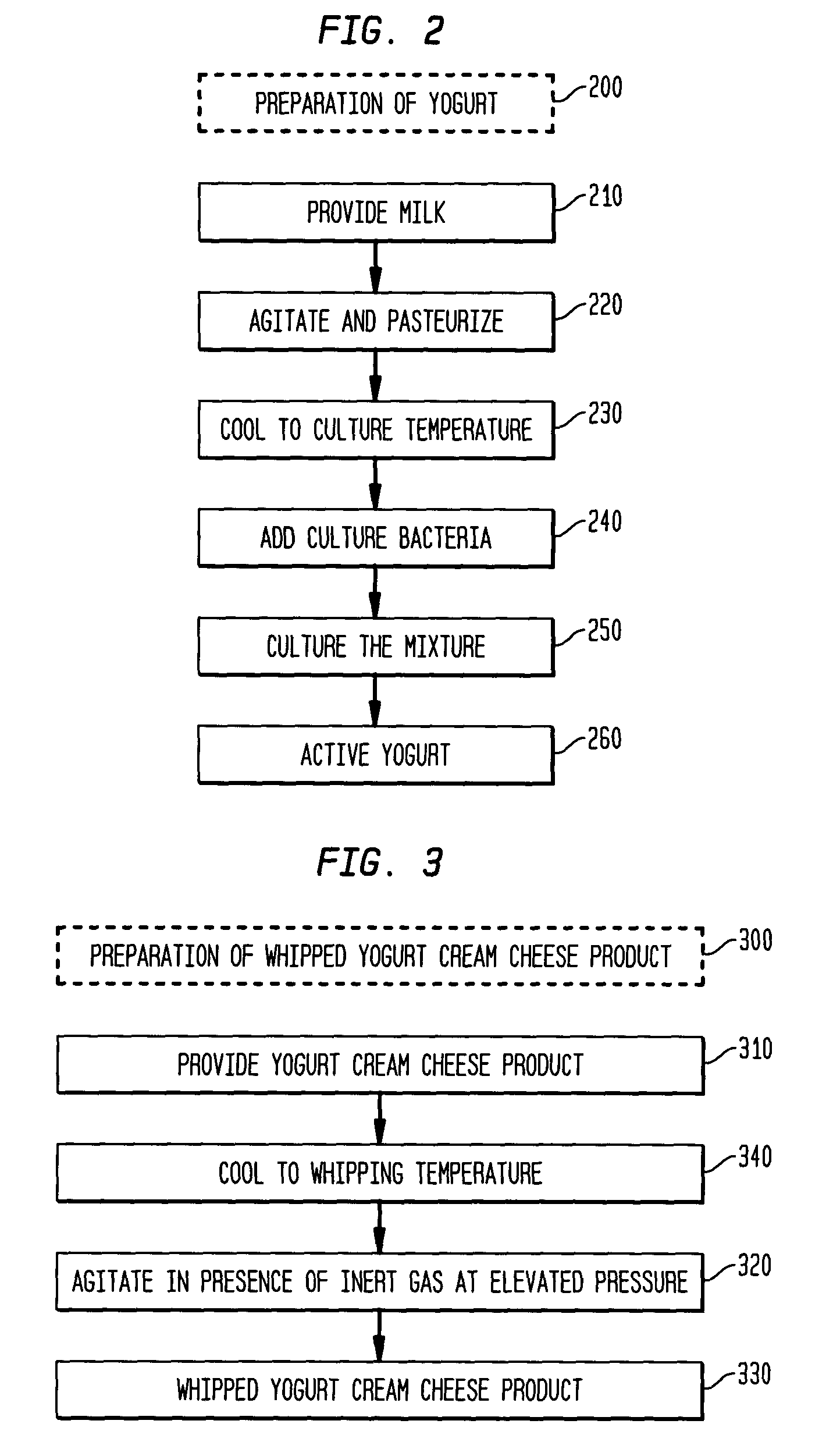

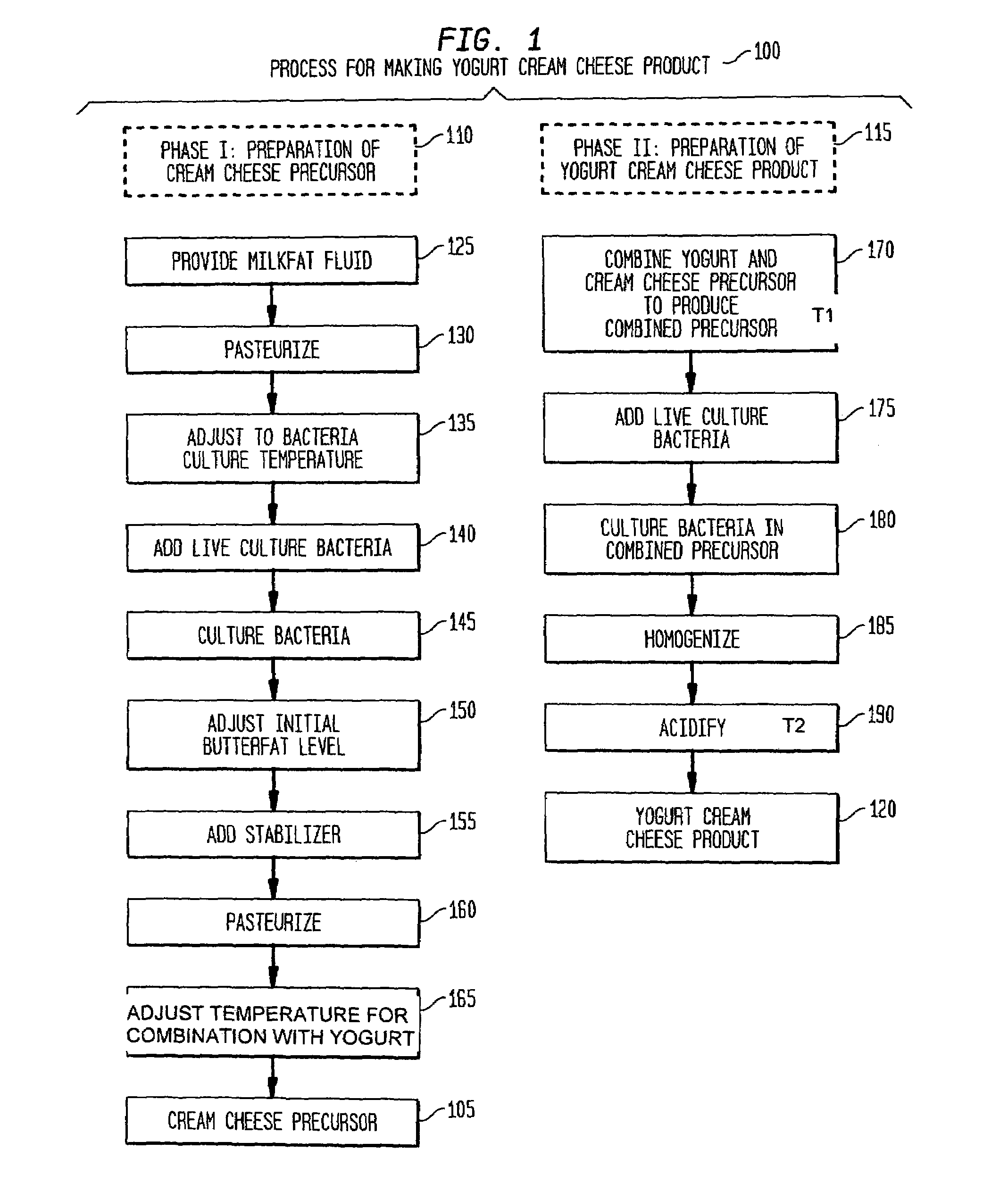

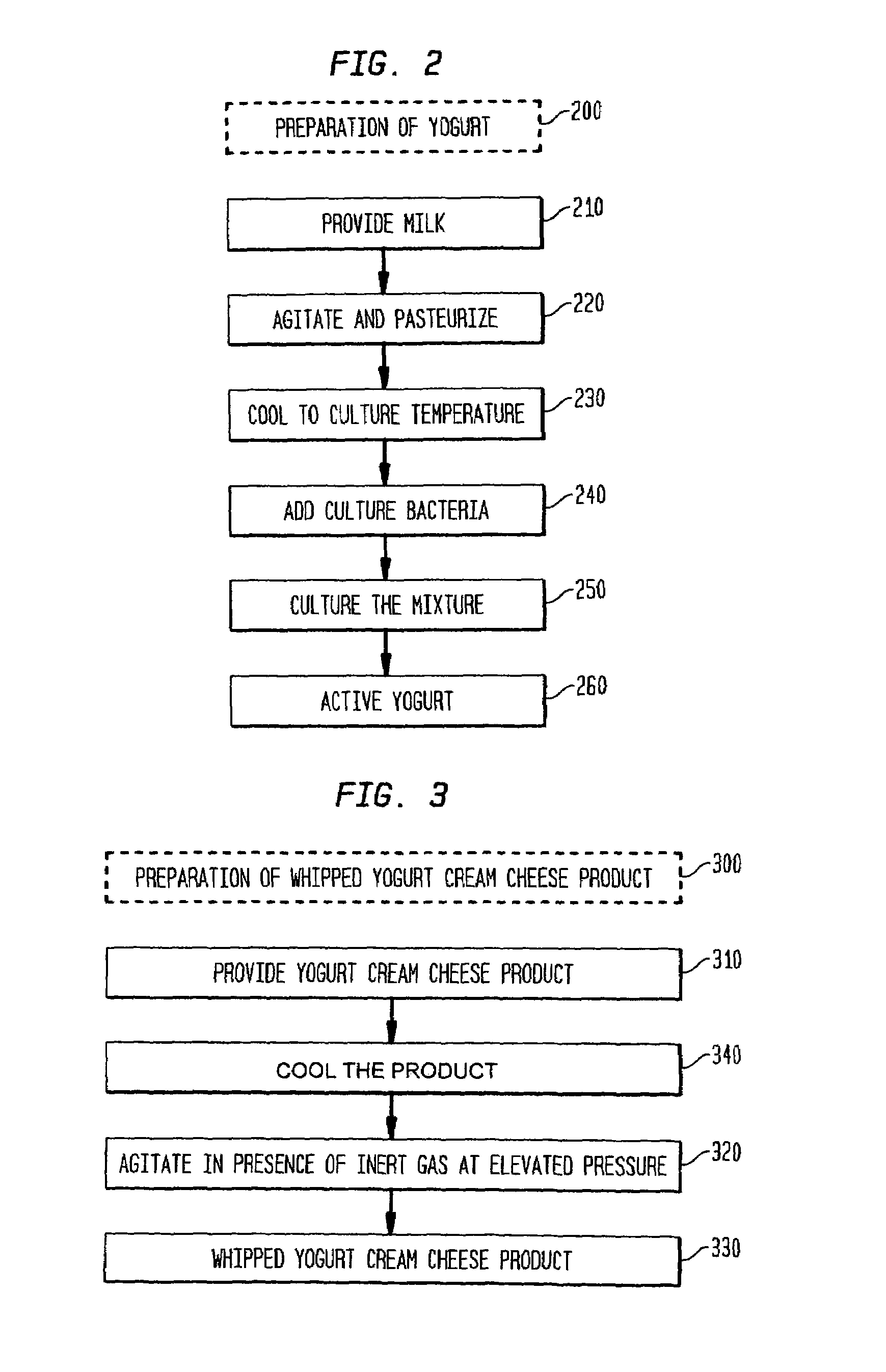

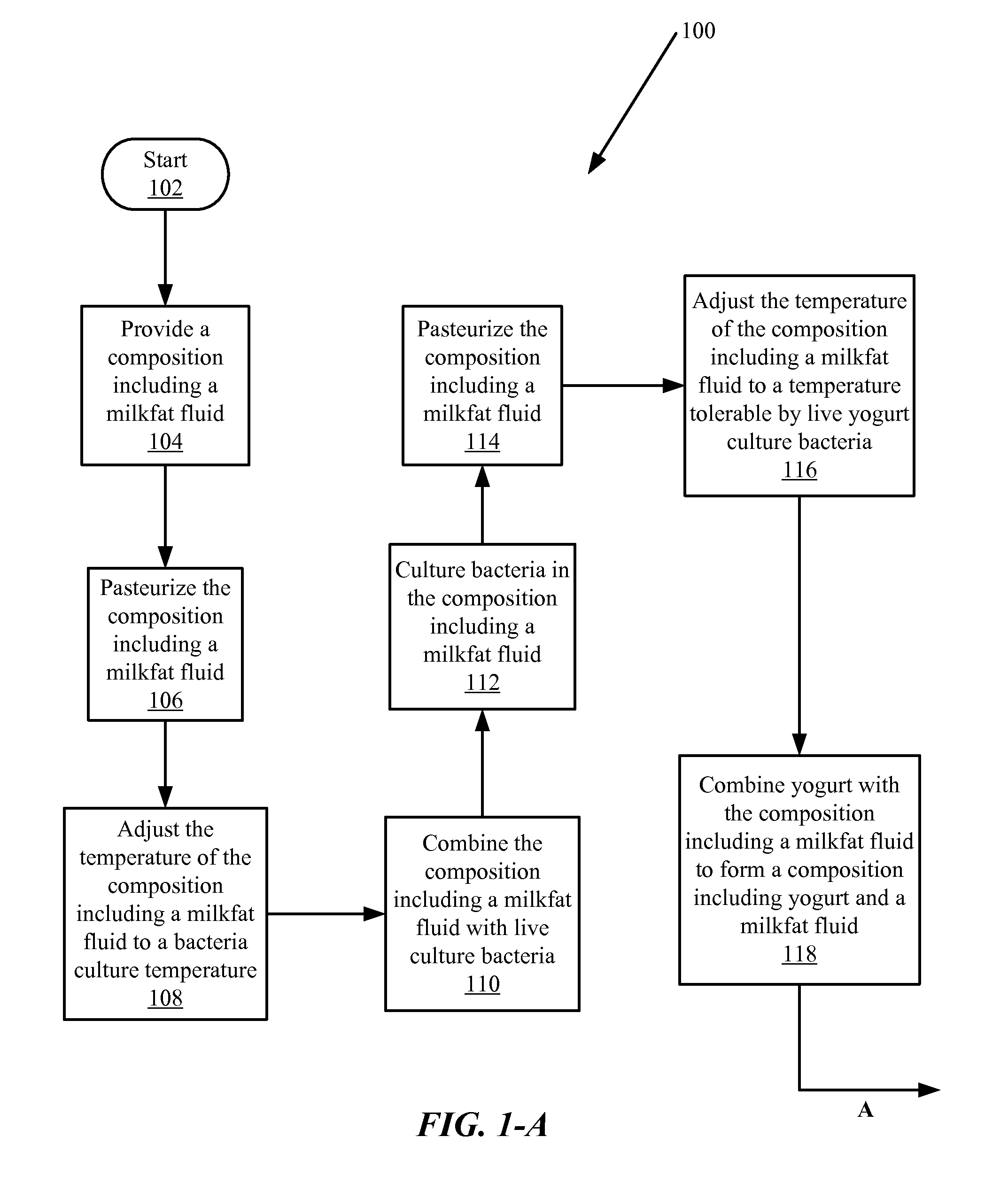

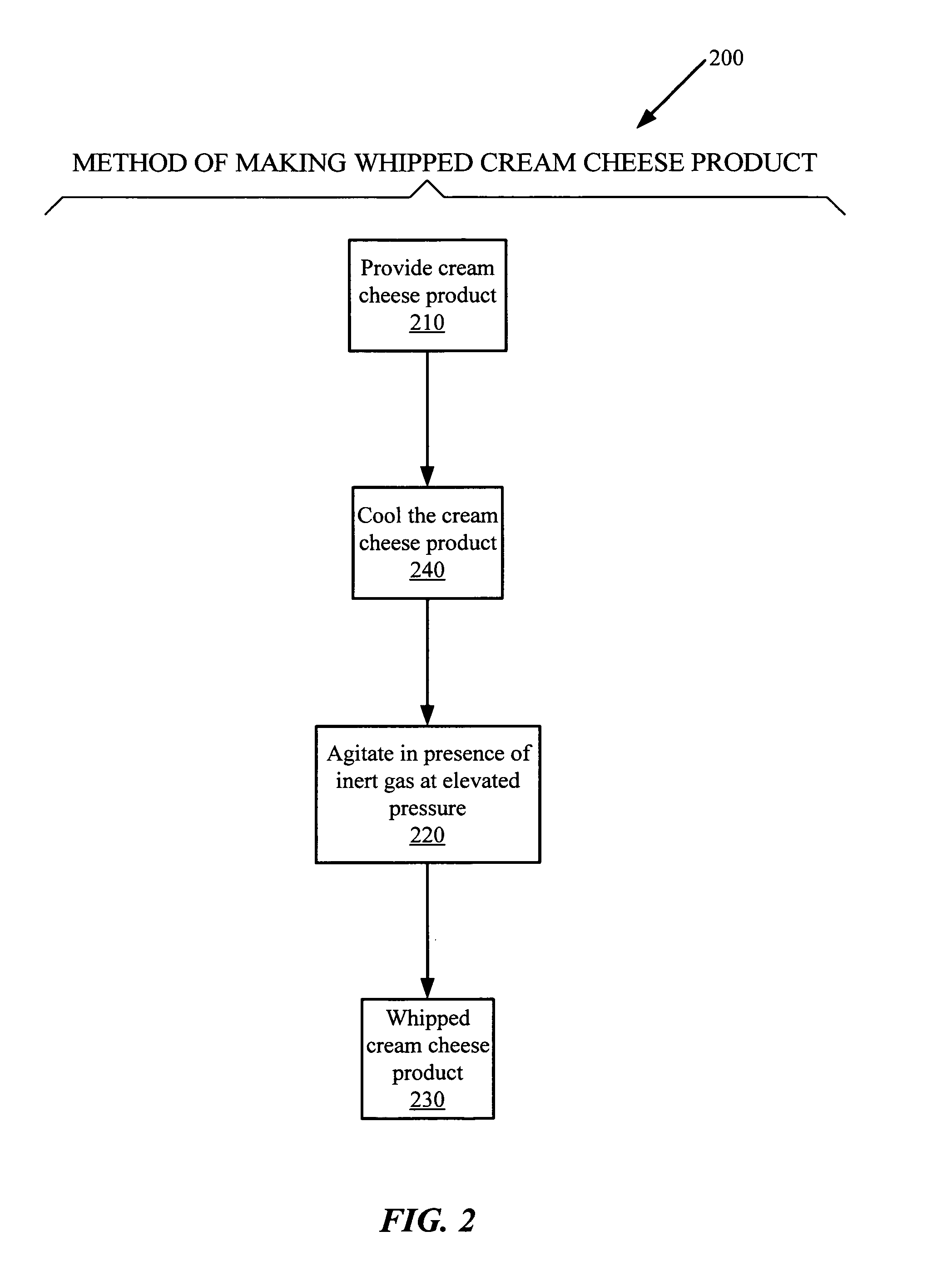

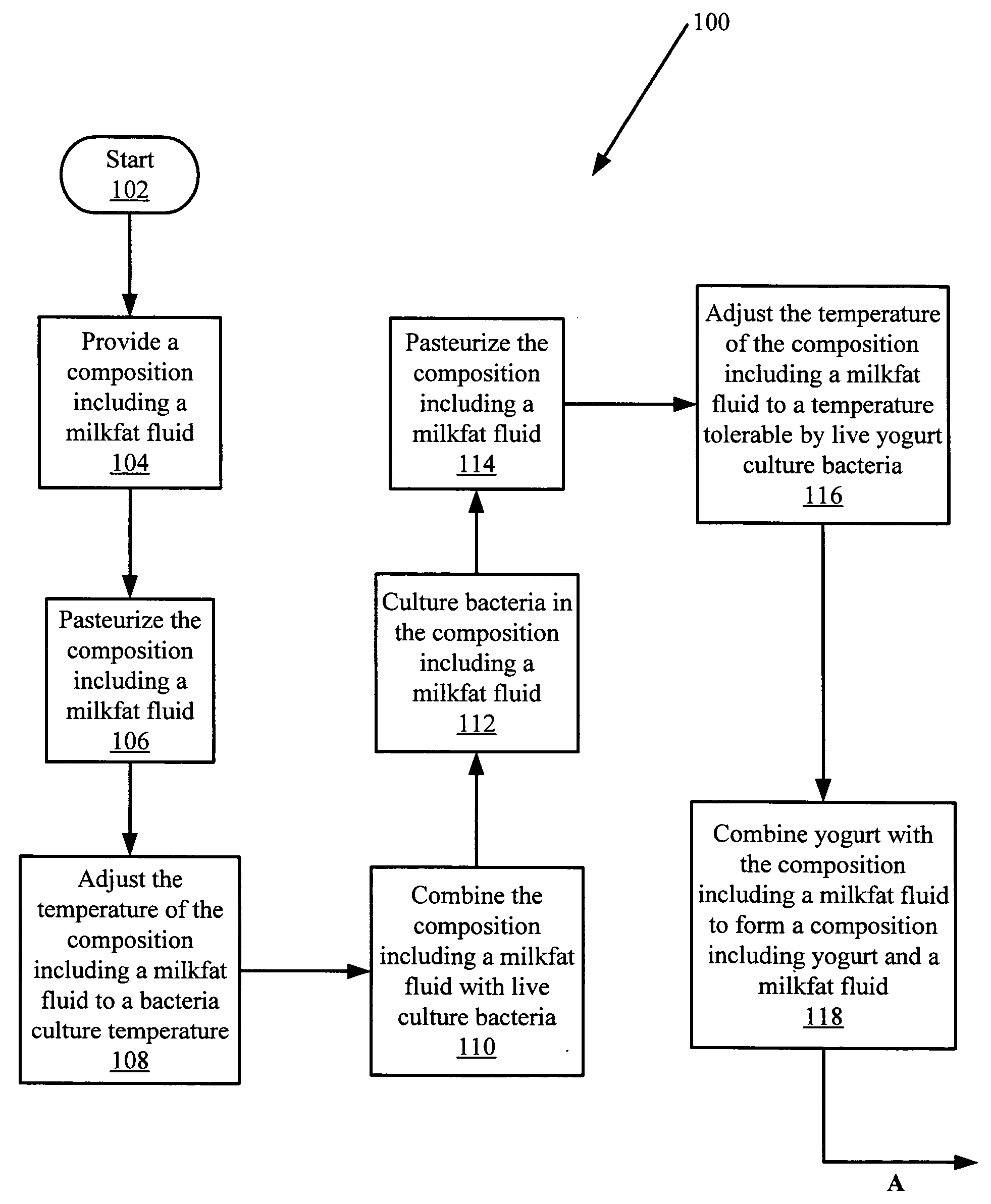

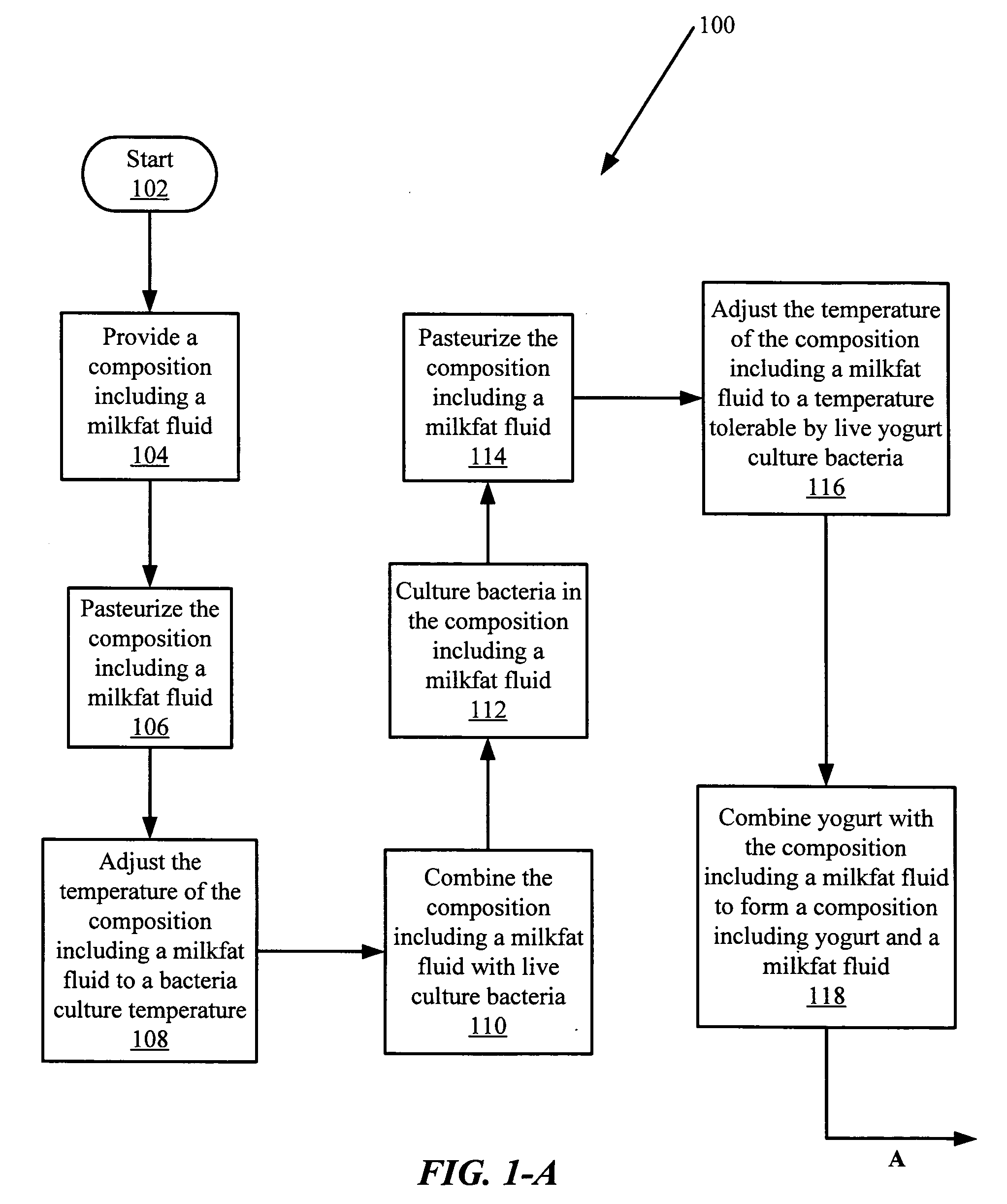

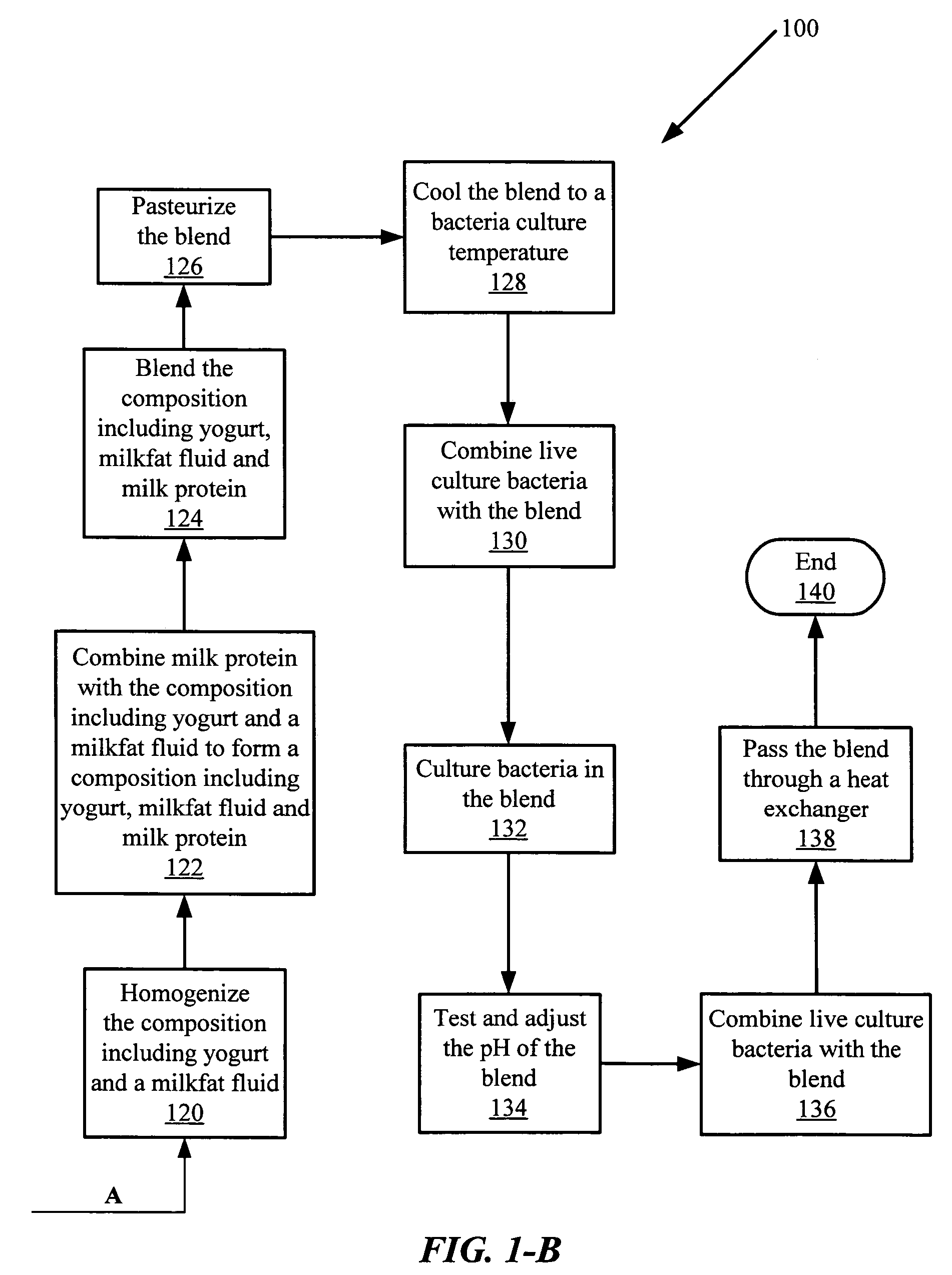

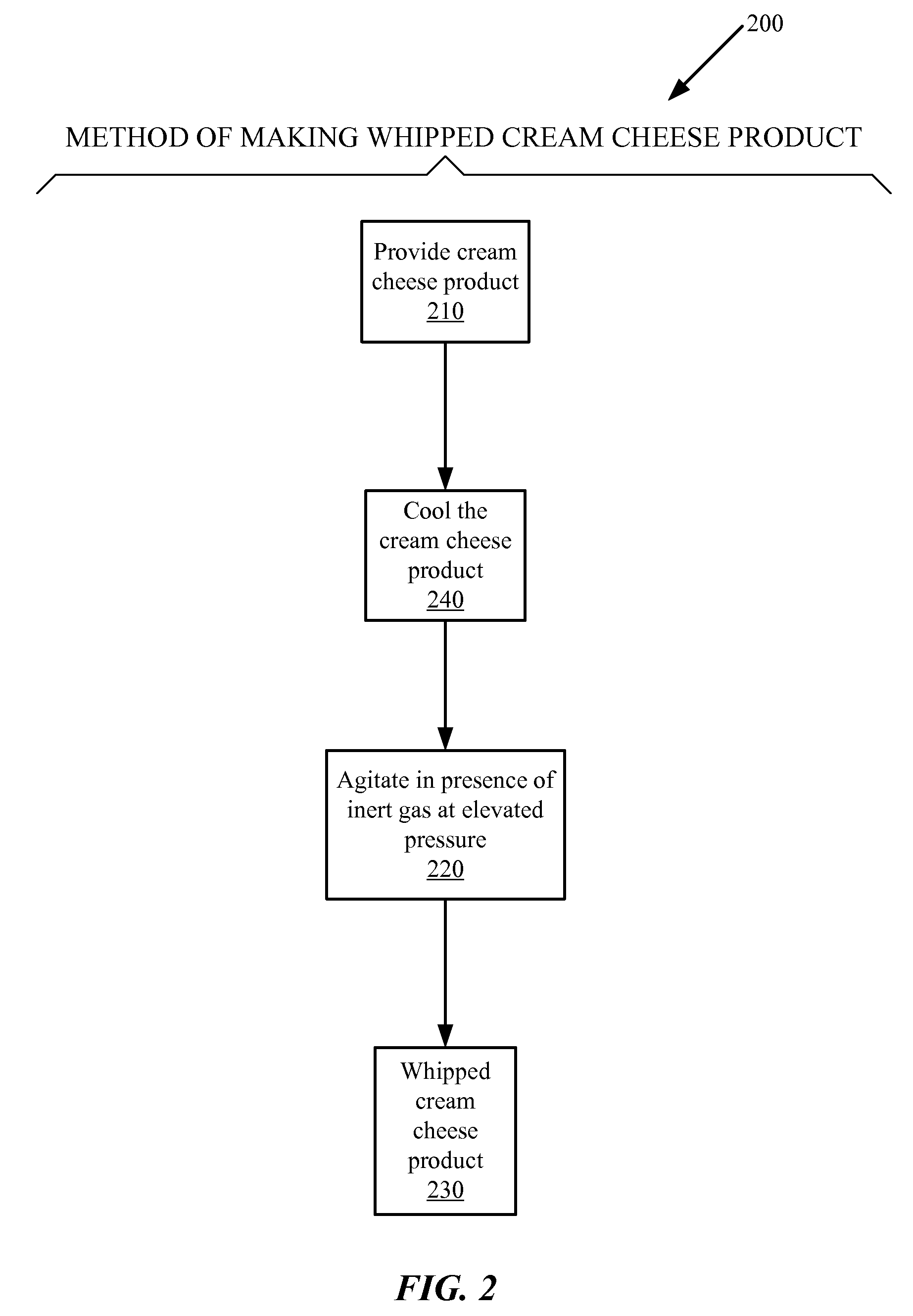

Process for making yogurt cream cheese, and the resulting products

Techniques for making a yogurt cream cheese product comprising steps of providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid to produce a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to produce a combined precursor; and homogenizing and acidifying the combined precursor; wherein the acidification is completed within about three hours following production of the combined precursor; producing a yogurt cream cheese product. Techniques wherein the combined precursor is cooled to retard bacteria activity prior to the acidifying. Techniques for making a whipped yogurt cream cheese product. Yogurt cream cheese products produced by the processes.

Owner:FRLIN FOODS HLDG

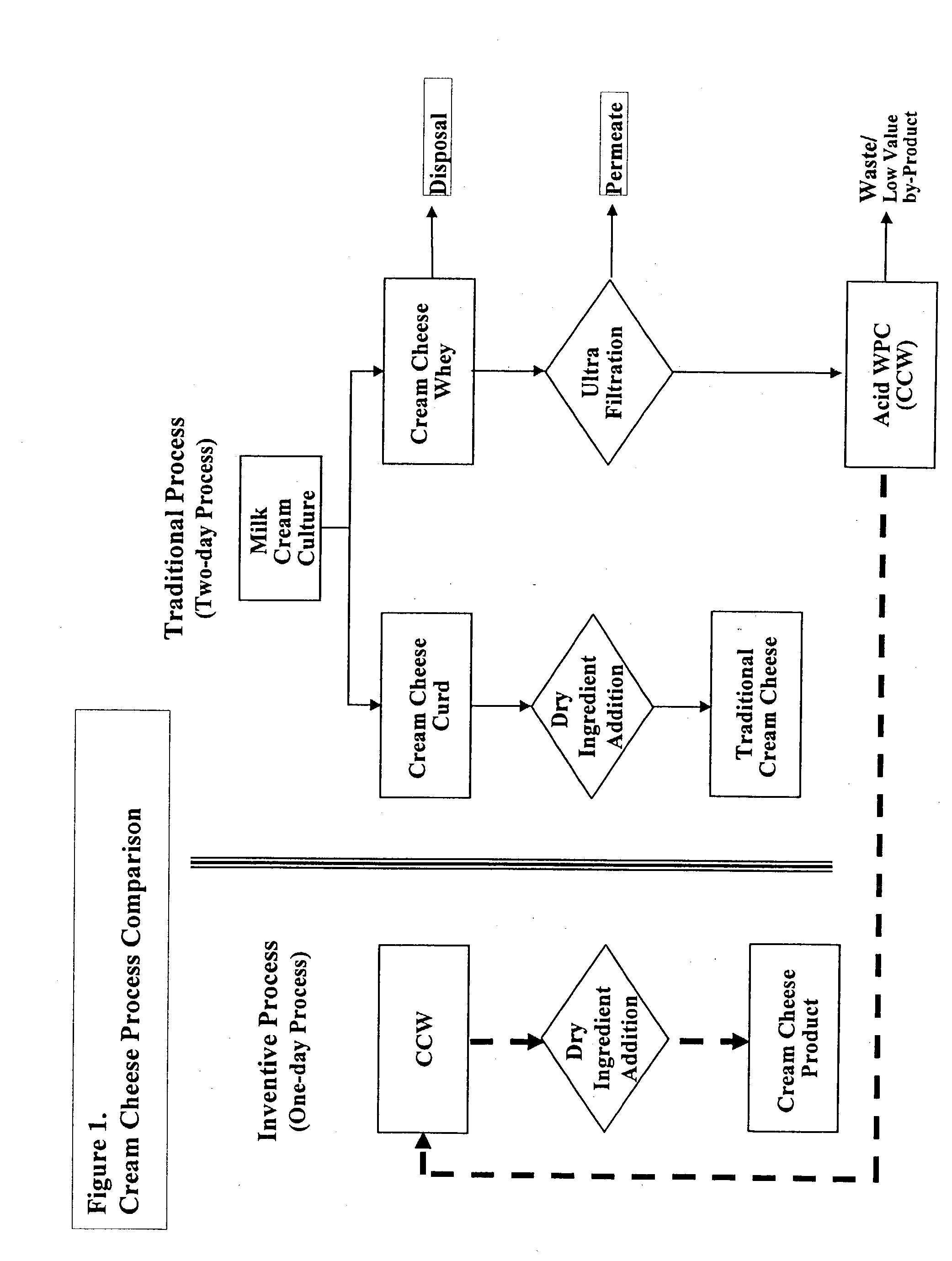

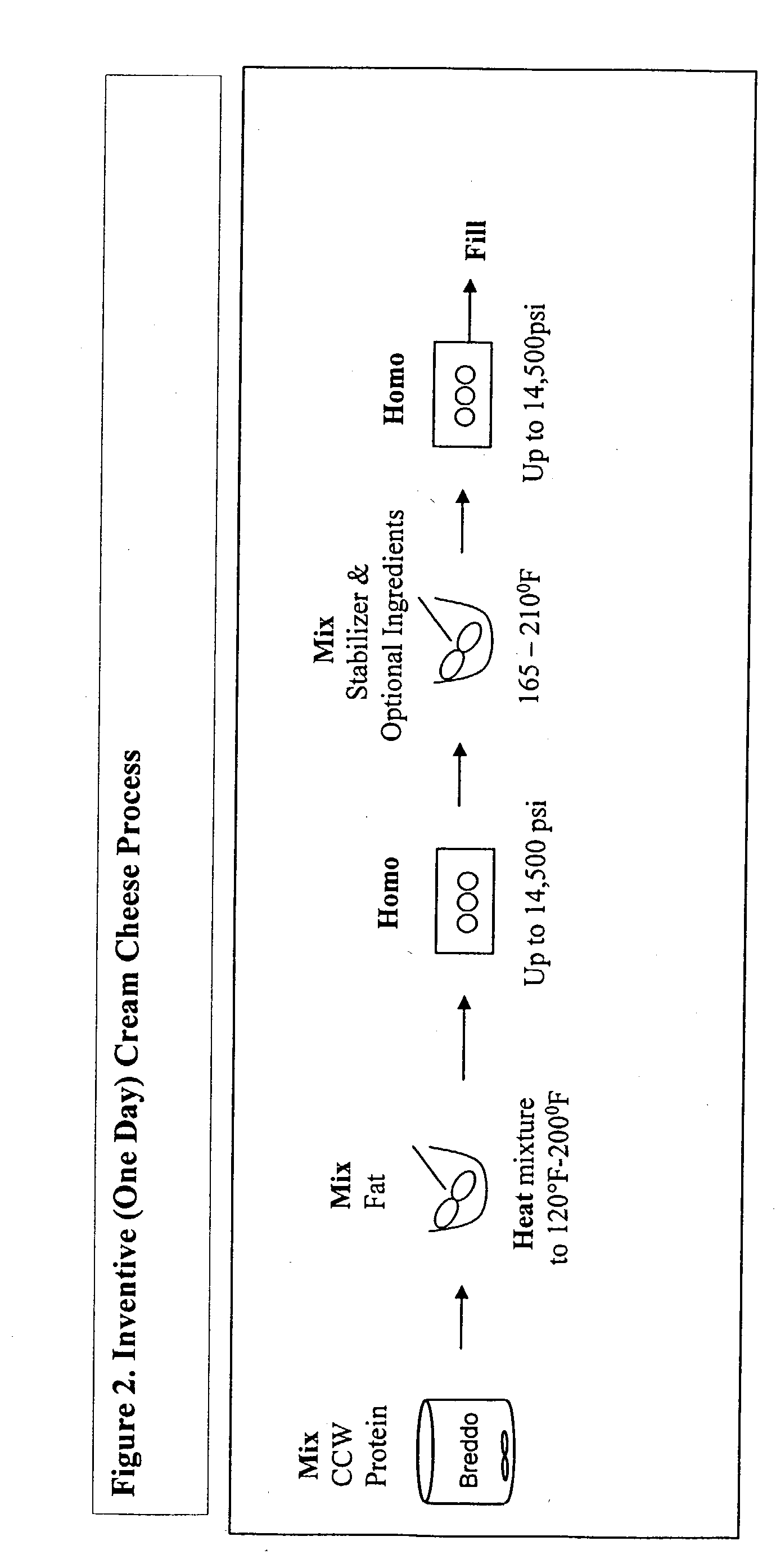

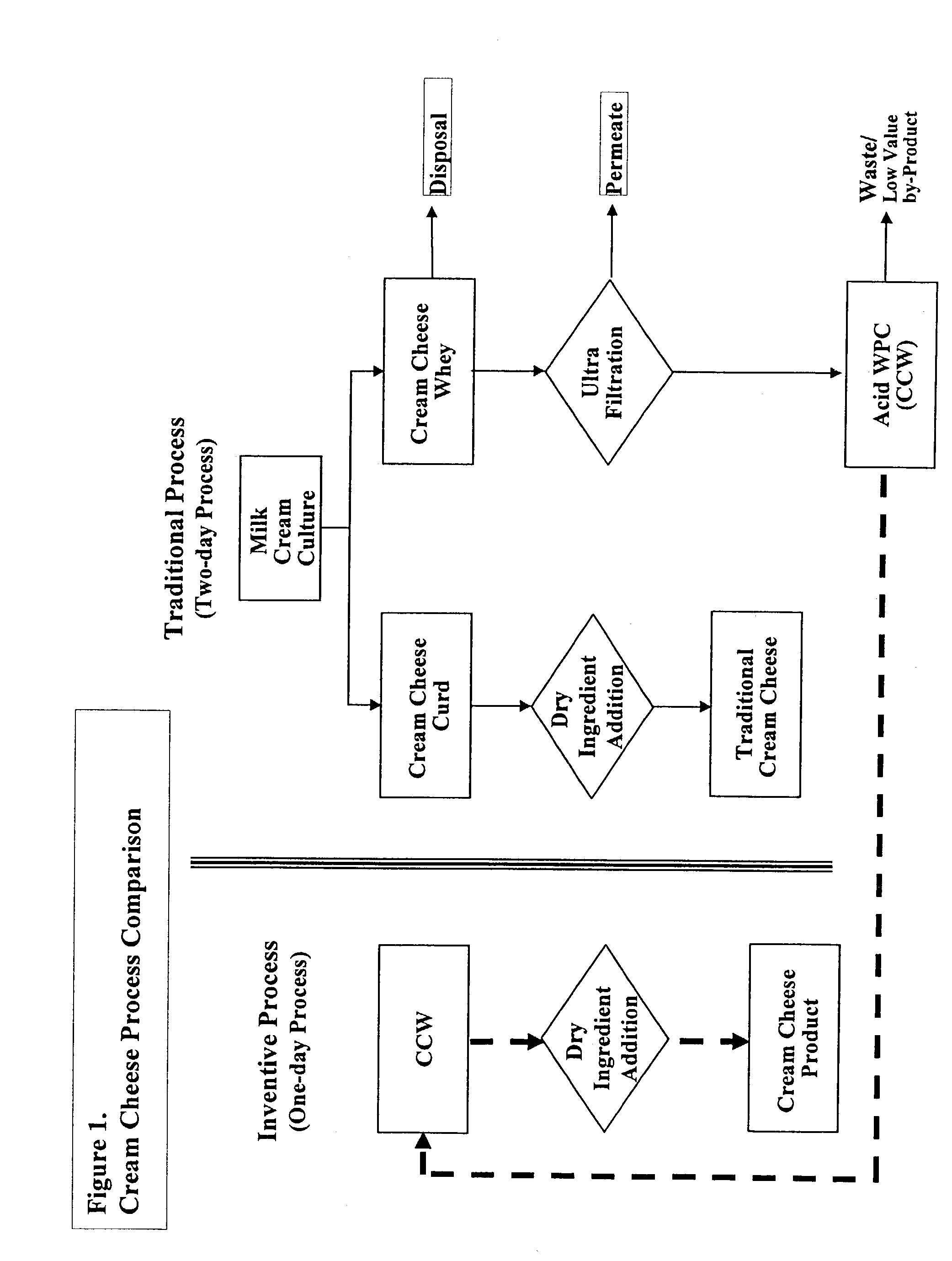

Acid whey texture system

The present invention relates to a method for directly using acid cheese whey and / or its by-products from conventional cheese production to make additional food products. More particularly, the present method provides an economical way to profitably utilize a traditional waste or by-product in the manufacture of cream cheese or other high-value added products without re-culturing, without combining with cheese curd, without neutralizing, and without the disposal or recycling costs common in the industry.

Owner:KRAFT FOODS GRP BRANDS LLC

Process for making yogurt cream cheese, and the resulting products

A process for making a yogurt cream cheese product comprising steps of: providing a milkfat fluid having an initial butterfat content level; pasteurizing the milkfat fluid to yield a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to yield a combined precursor; and homogenizing and acidifying the combined precursor; yielding a yogurt cream cheese product. A yogurt cream cheese product comprising between about 8% by weight and about 35% by weight of total butterfat; the yogurt cream cheese product comprising between about 10% by weight and about 40% by weight of yogurt, having a viscosity between about 1,000,000 centipoises and about 3,000,000 centipoises at a temperature of about 74° F.; and yielding less than about 1% syneresis by weight after 15 hours at about 74° F. to about 75° F.

Owner:FRLIN FOODS HLDG

Fine Textured Dairy Product and Process for its Preparation

InactiveUS20090041920A1Improve microstructureIncrease creaminessMilk preparationCheese manufactureCream cheeseMilk products

The present invention relates to finely textured dairy products such as cream cheese. Morever, the present invention relates to a process for the preparation of said diary products.

Owner:KRAFT FOODS R & D INC

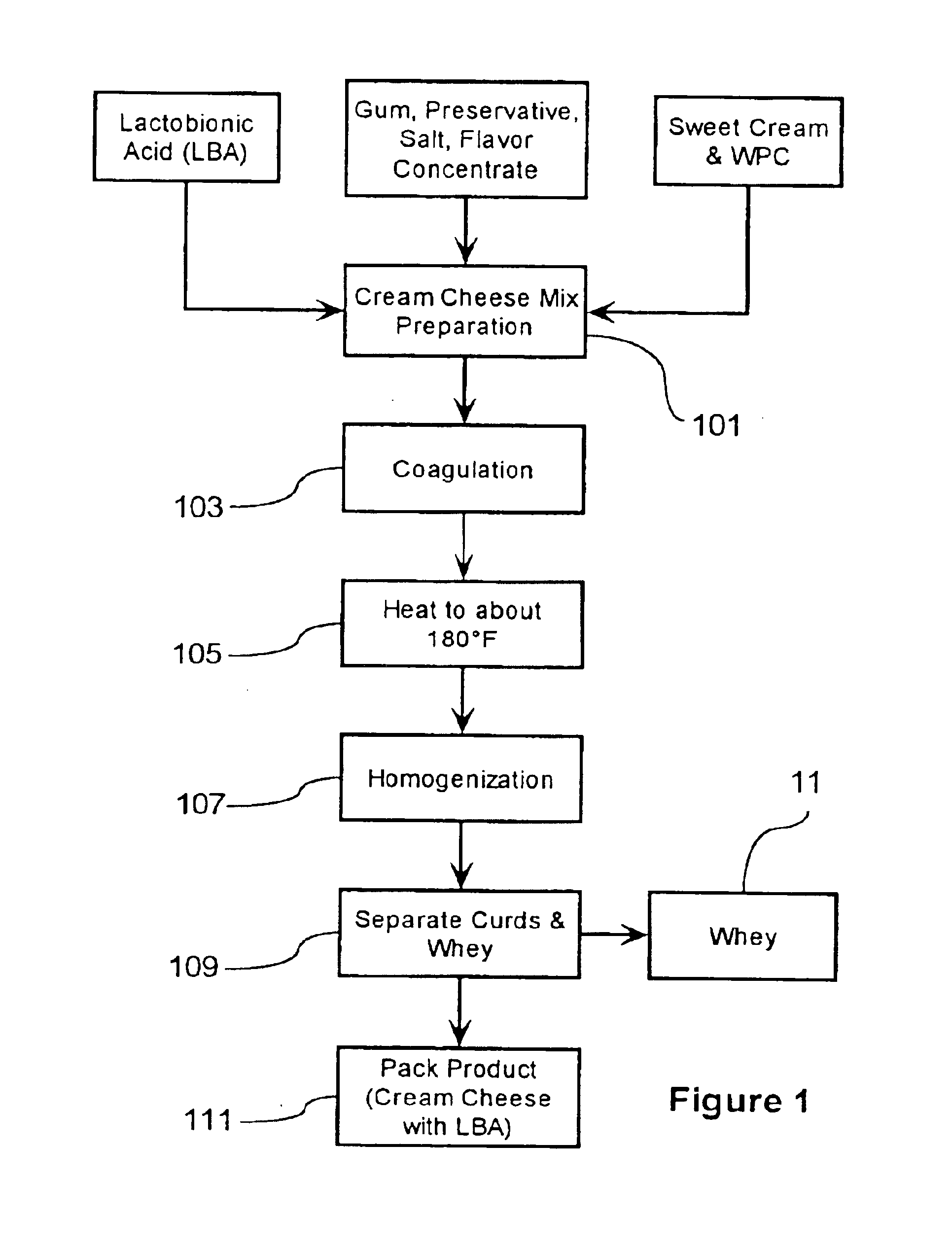

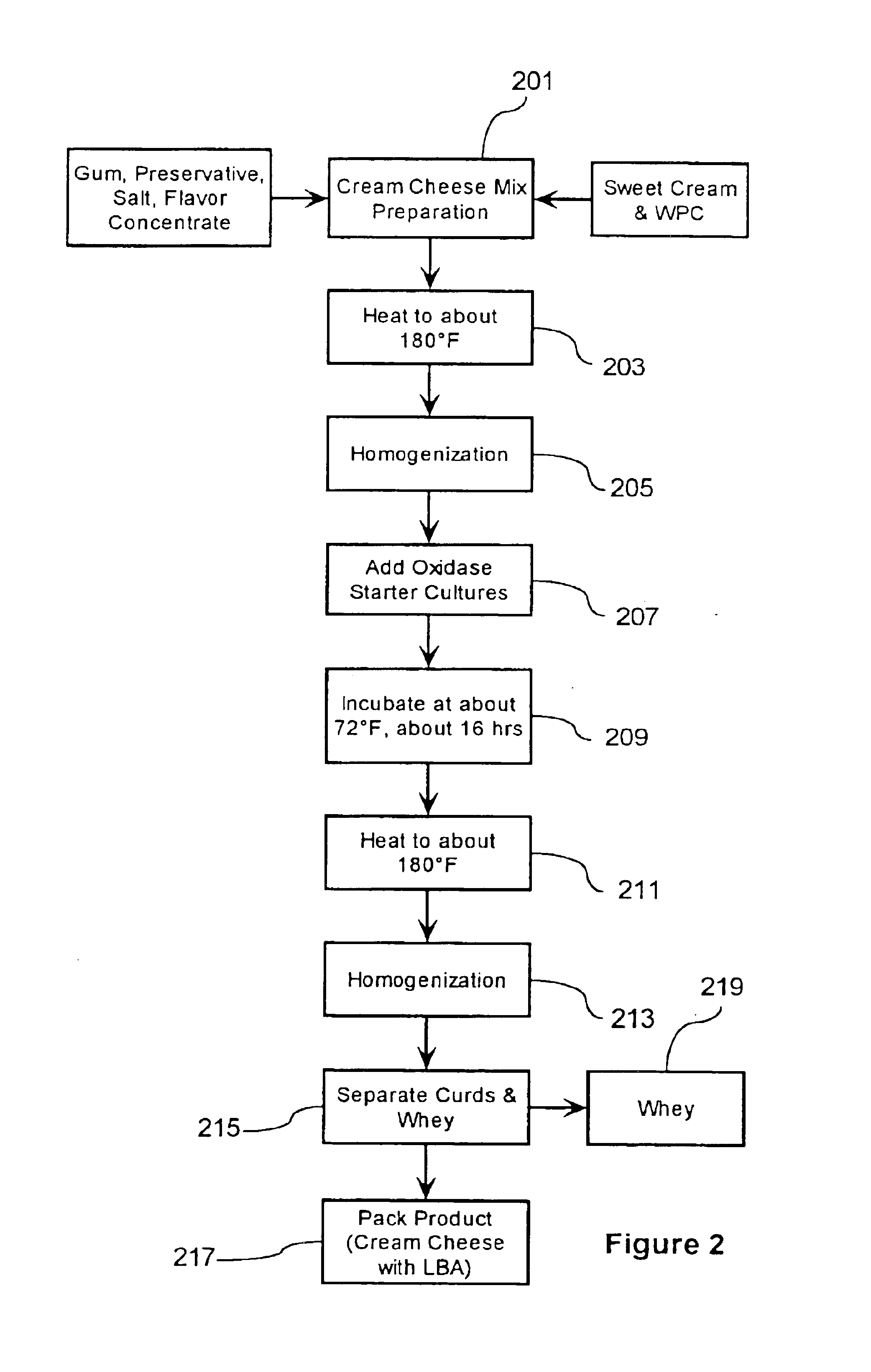

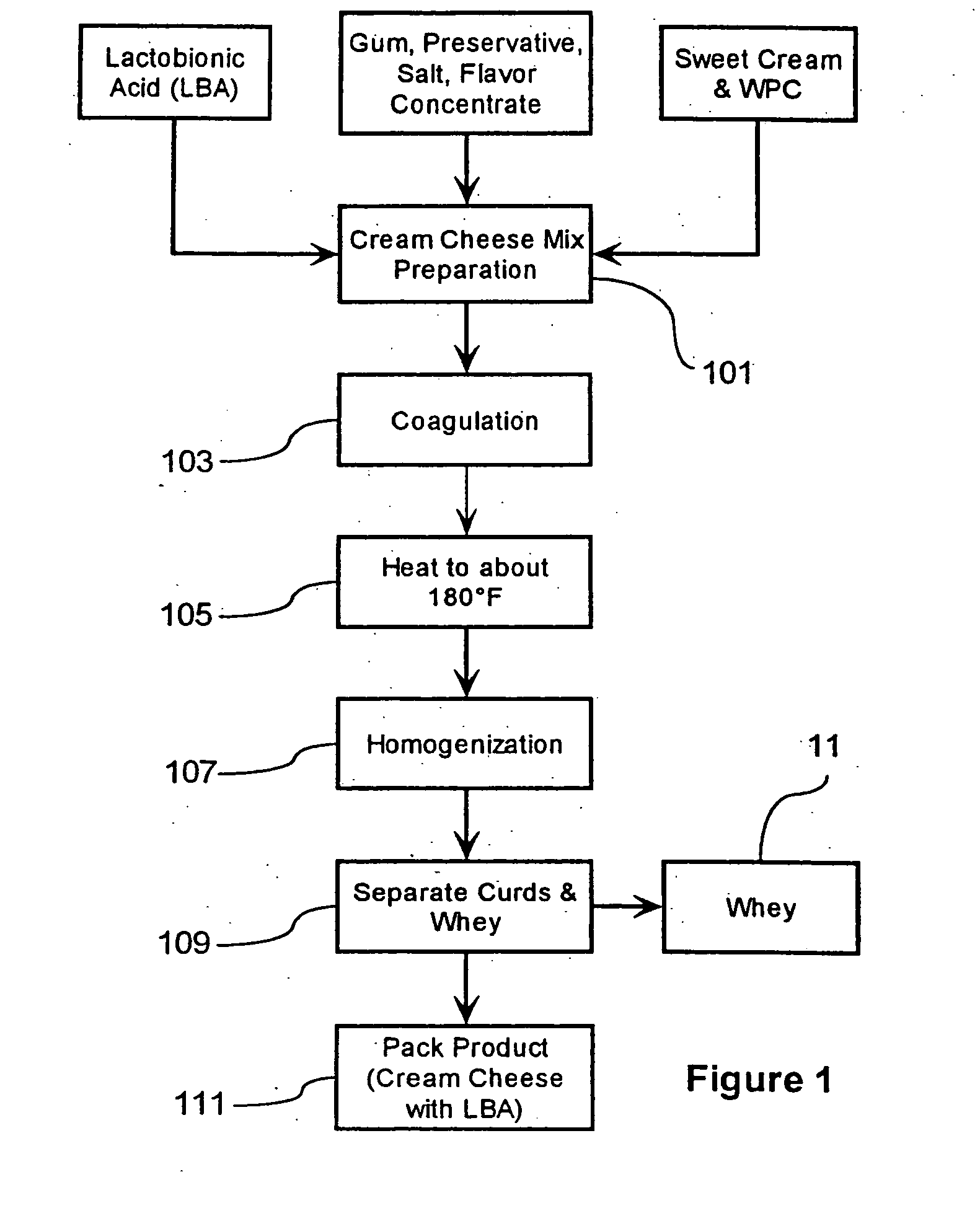

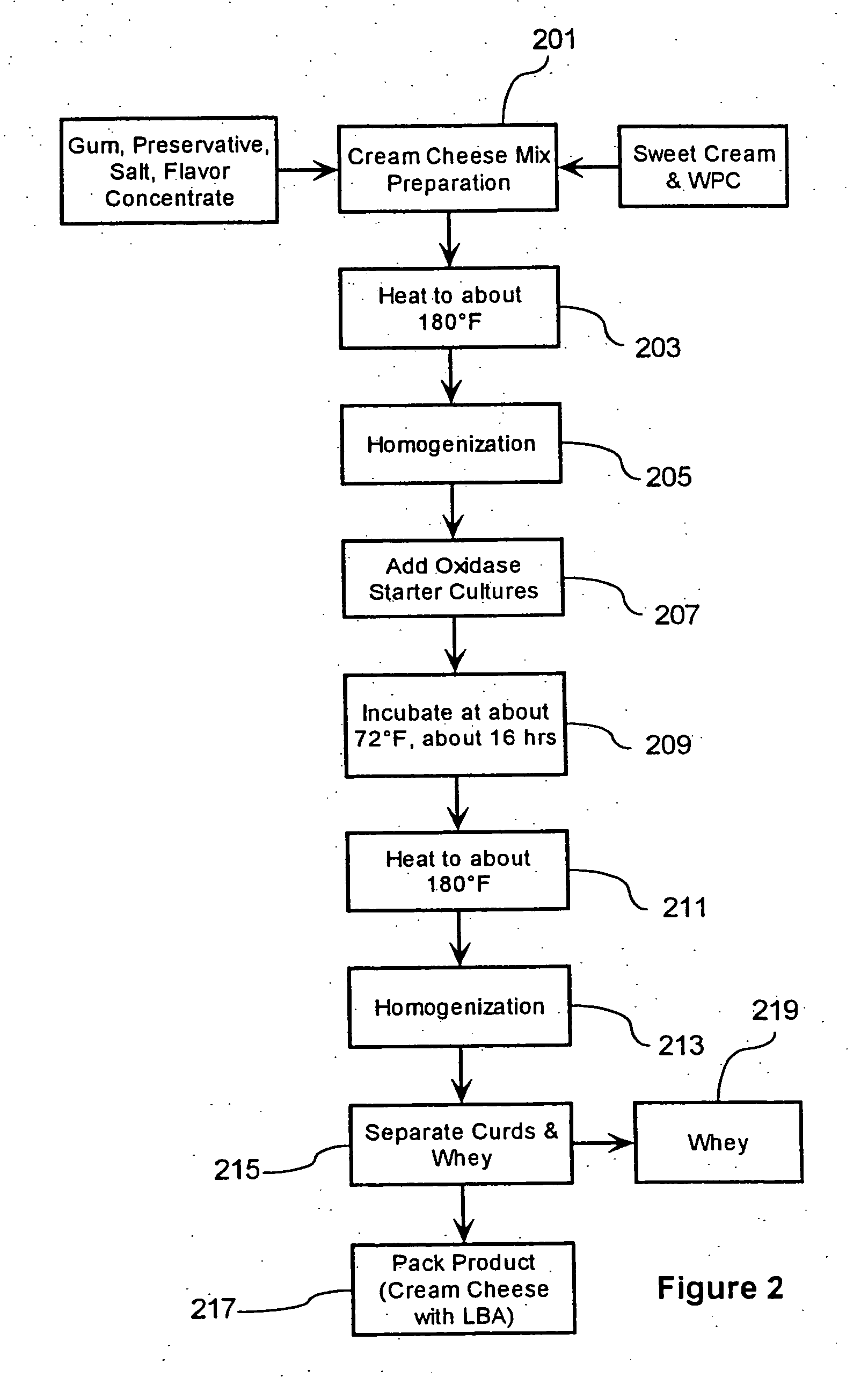

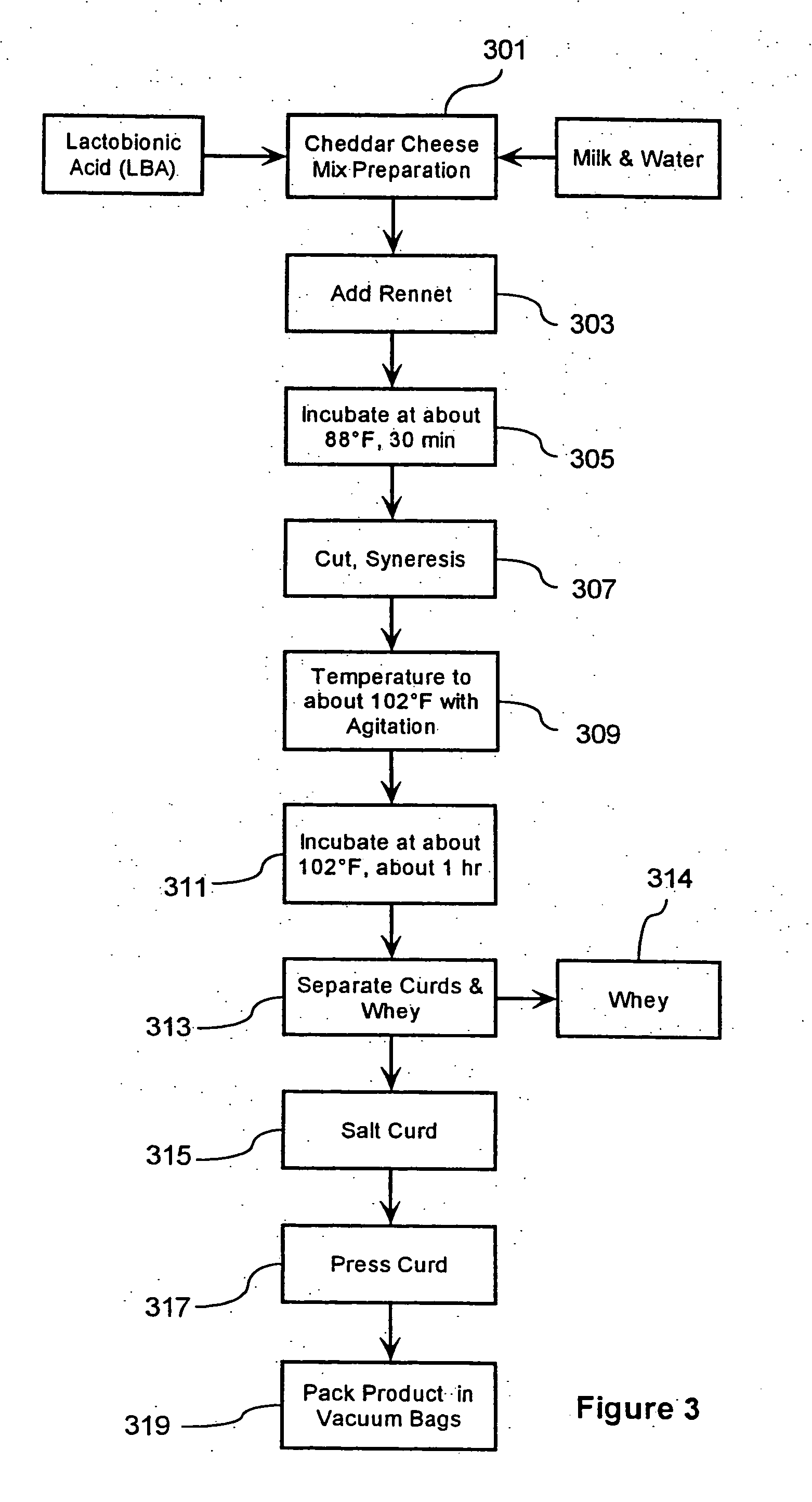

Process for manufacturing cheeses and other dairy products and products thereof

InactiveUS6916496B2Increased versatilityAcceptable tasteMilk preparationOxidoreductasesLactose oxidaseAdditive ingredient

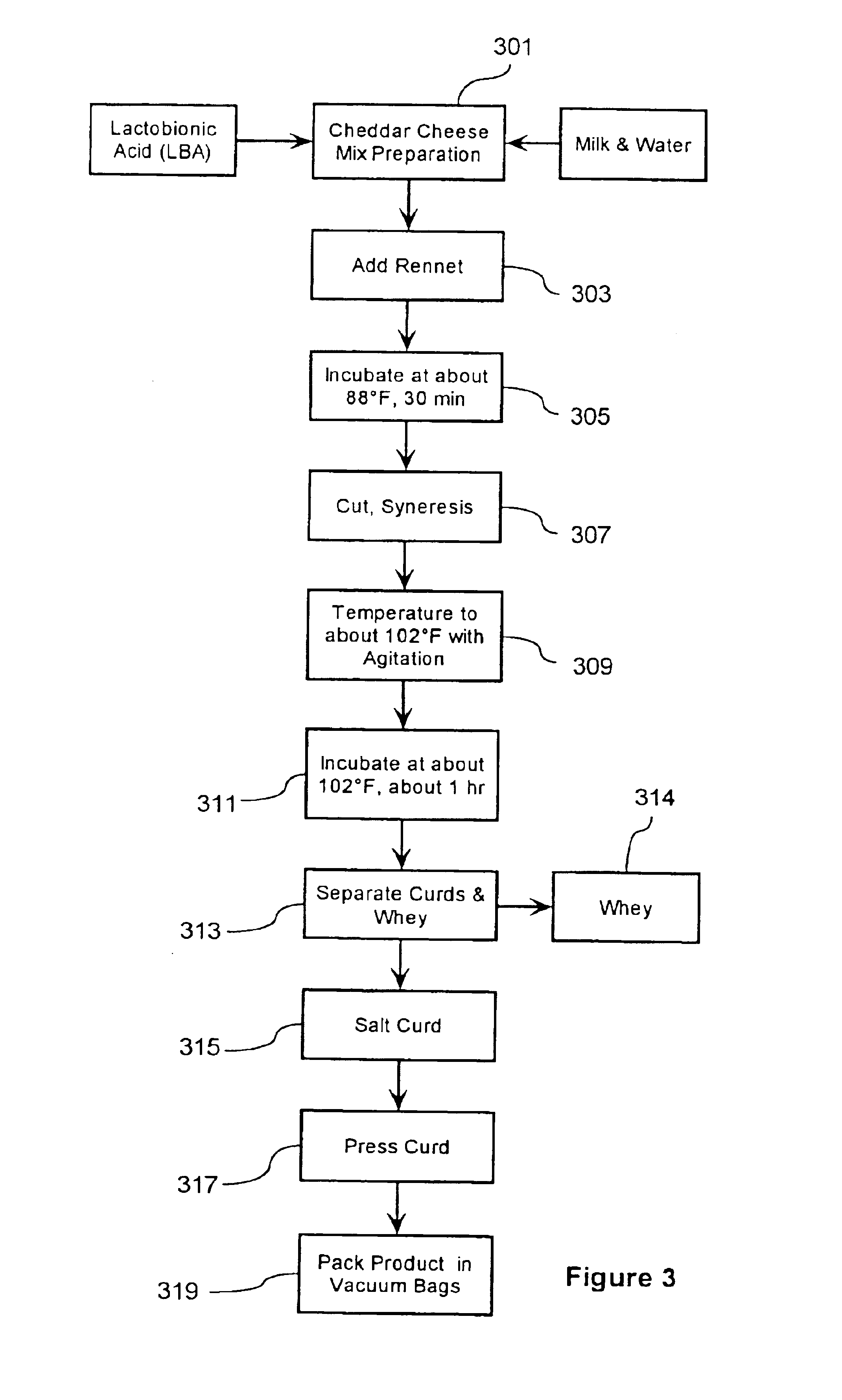

Process for manufacturing cheeses and other dairy products, and the resulting products, in which lactobionic acid is added, or generated in situ, in combination with a dairy component in the course of the process. The lactobionic acid can be used as the sole acidulent for direct acidification of the cheese, or in conjunction with reduced amounts of lactic acid culture. When the lactobionic acid is generated in situ during cheese manufacture according to the invention, a lactose oxidase is used in one embodiment to convert lactose intrinsically present in the dairy liquid ingredient(s) into lactobionic acid. The organoleptic attributes of the cheeses made using lactobionic acid as an ingredient are satisfactory and fully suitable. The process can be applied to the production of a wide variety of cheeses, including, for example, cream cheeses, hard cheeses such as cheddar, UF cheeses, process cheeses, cheddar cheeses, and so forth.

Owner:KRAFT FOODS GRP BRANDS LLC

Dilute cream cheese and preparation method thereof

The invention provides a dilute cream cheese and a preparation method thereof. Raw materials for preparing the dilute cream cheese comprise 60-95% of dilute cream and 5-30% of a lactoprotein raw material, and the total water content of the raw materials is 40-60%. The dilute cream cheese has the advantages of full treatment of the raw materials in the production process, no need of elimination of whey without the use of a stabilizer in the production process, stable structure, no whey precipitation, and effective reservation of whey proteins in the raw materials. The invention also provides a preparation method of the dilute cream cheese. The preparation method comprises the following steps: mixing and dissolving the dilute cream and the lactoprotein raw material, and sequentially homogenizing, disinfecting, inoculating and fermenting to prepare the dilute cream cheese. There is no need to eliminate whey in the preparation method, and the produced dilute cream cheese has a stable structure and has no whey precipitation.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

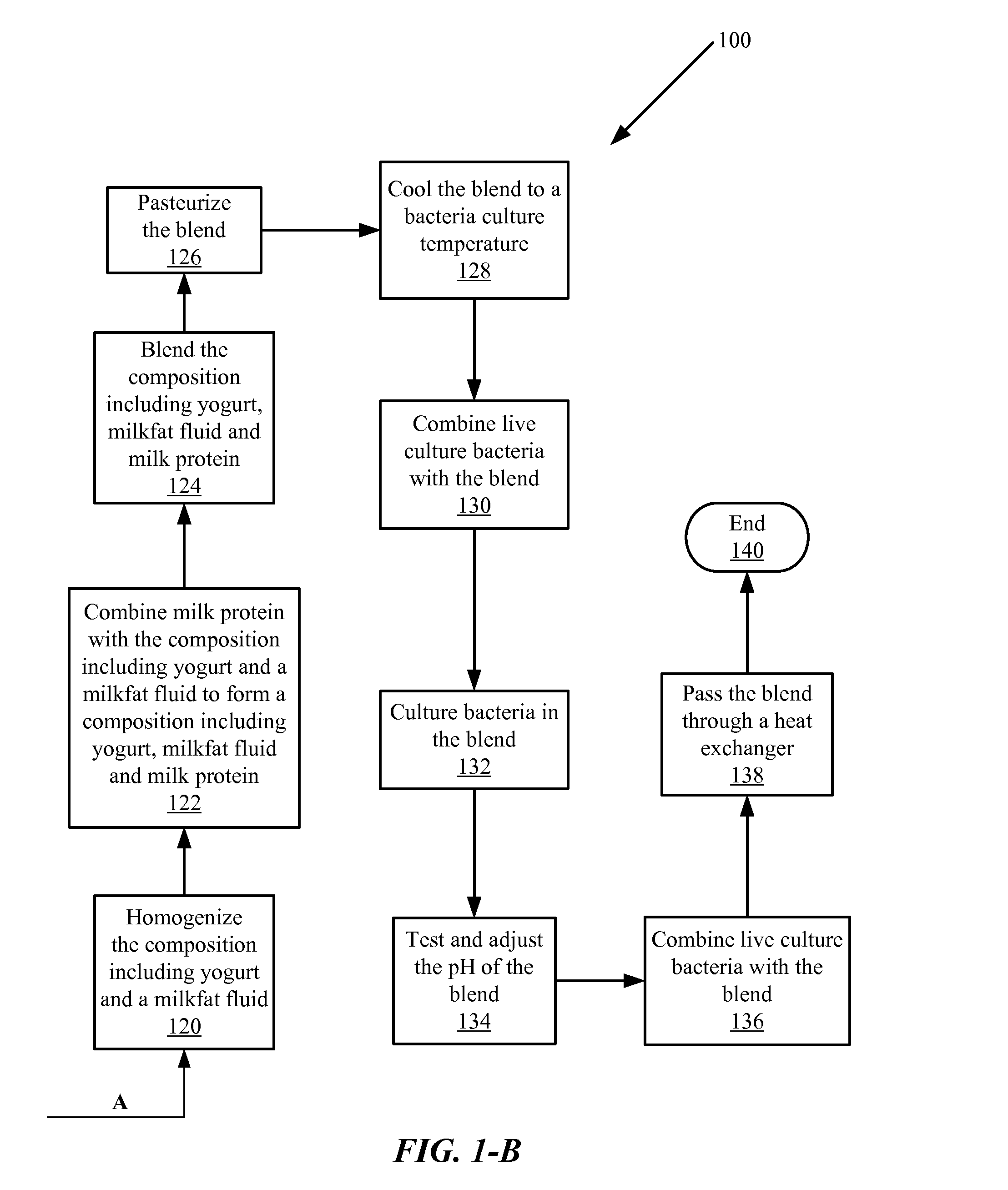

Process for making yogurt cream cheese, and the resulting products

Techniques for making a yogurt cream cheese product comprising steps of providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid to produce a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to produce a combined precursor; and homogenizing and acidifying the combined precursor; wherein the acidification is completed within about three hours following production of the combined precursor; producing a yogurt cream cheese product. Techniques wherein the combined precursor is cooled to retard bacteria activity prior to the acidifying. Techniques for making a whipped yogurt cream cheese product. Yogurt cream cheese products produced by the processes.

Owner:FRLIN FOODS HLDG

Pre-mix formulations comprising ingredients for dairy products

Compositions and methods of using the compositions to prepare dairy food products are disclosed. The ingredients may include milk protein concentrates, fat containing powders and other mixtures including sweeteners, flavorings, preservatives, salt and emulsifiers. Food products prepared according to the invention include yogurt, cheese, soft cheese, spreads, nutritional bars, cream cheese, dairy desserts and yoghurt.

Owner:FONTERRA COOP GRP LTD

Acid whey texture system

ActiveUS7150894B2Process economyExemption stepsMilk preparationWhey manufacturePresent methodCream cheese

The present invention relates to a method for directly using acid cheese whey and / or its by-products from conventional cheese production to make additional food products. More particularly, the present method provides an economical way to profitably utilize a traditional waste or by-product in the manufacture of cream cheese or other high-value added products without re-culturing, without combining with cheese curd, without neutralizing, and without the disposal or recycling costs common in the industry.

Owner:KRAFT FOODS GRP BRANDS LLC

Processed dairy products

InactiveUS6503553B1Powder deliveryPeptide/protein ingredientsAdditive ingredientRefrigeration temperature

A range of products and methods are based on a creamy base of cream, artificial cream, thickened cream, cream cheese, mixtures thereof and mixtures with compatible incidental ingredients, the creamy base being aerated while cold and intimately mixed with a hot aqueous gelatin solution typically around 80° C. and providing 1-3% gelatin in the mixed product and the overrun in the aeration being typically in the range of 10-40%. Various further components are included or introduced with further processing selected from methods including heating the product with a further component to boiling point whereby de-aeration and enhanced shelf life is found in the resultant product. An alternative method is where flavor components are added prior to de-aeration. Another application is as a carrier for a pharmaceutical agent which is incorporated into the creamy base and protected with the gelatin matrix, a powder being formed ready for packaging in pharmaceutical doses. Another embodiment which does not require heating is incorporating a flavoring agent and food acid to obtain a pH of 3.0 to 4.2 an adding a large volume of water which has the effect of ensuring a low viscosity and the elimination of aeration whereby a pourable sauce-like product can be achieved at refrigeration temperatures.

Owner:AUSTRALIAN COOP FOODS

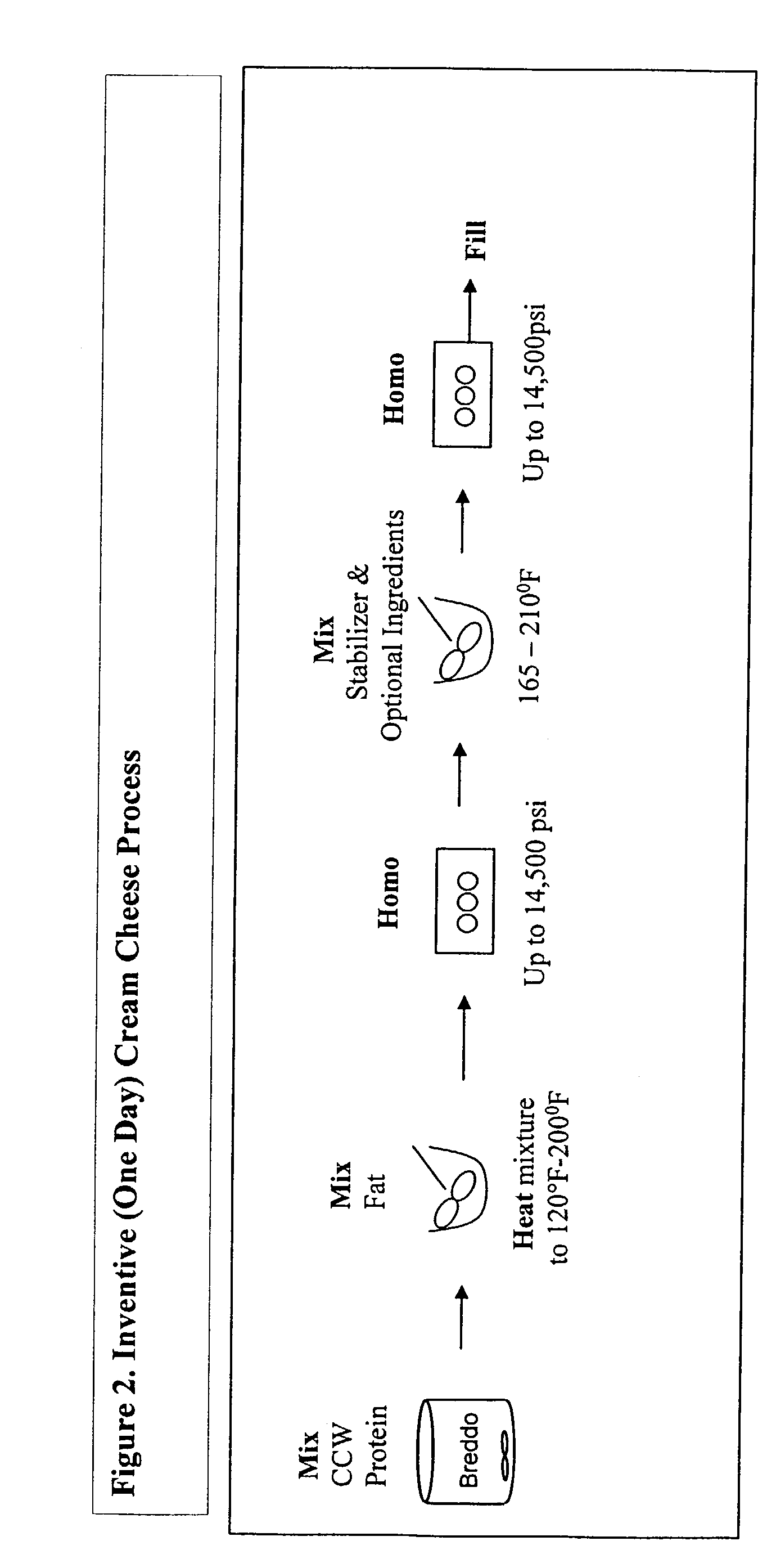

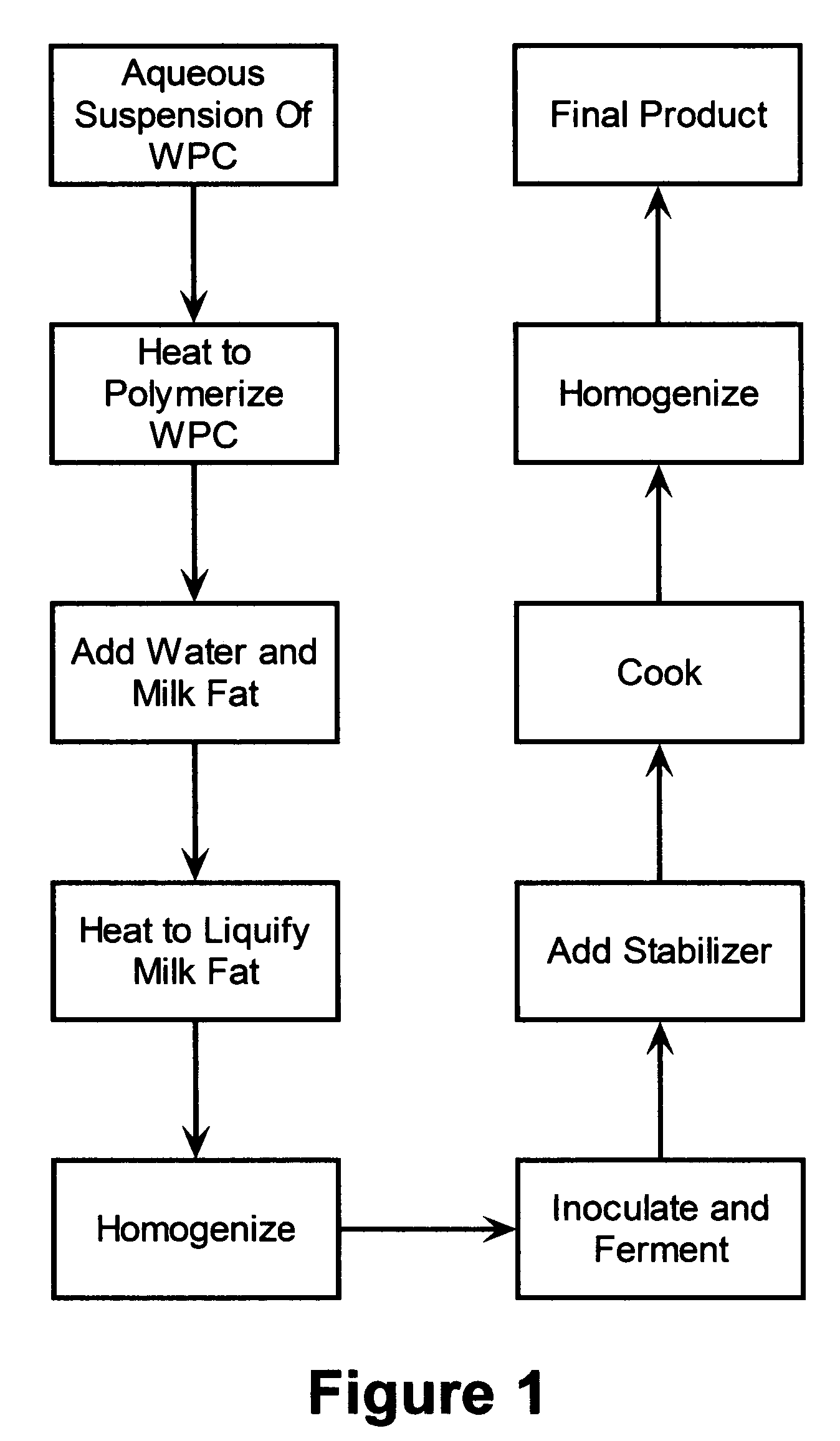

Cream cheese made from whey protein polymers

ActiveUS7250183B2Low production costAvoids cumbersome and expensiveMilk preparationWhey manufacturePresent methodWhey protein

This invention relates to a cheese product and a novel method for preparing a cheese product. More specifically, this invention relates to cream cheese product prepared using an edible fat and polymerized whey protein, as a protein source, obtainable from a whey protein concentrate. A cream cheese product prepared according to the present method exhibits an unexpected increase in firmness and has excellent syneresis properties.

Owner:KRAFT FOODS GRP BRANDS LLC

Low protein cream cheese

ActiveUS7611743B2Lower Level RequirementsDesirable firmnessMilk preparationFrozen sweetsCarrageenanLow protein

The present invention is directed to cream cheese compositions in which the protein level is reduced to below 6.5 percent, and preferably between about 5 to about 6 percent, with acceptable baking properties. In order to obtain such a cream cheese composition with acceptable baking properties, a stabilizer composition is added to the low protein cream cheese. The stabilizer composition comprises a first stabilizer and a second stabilizer, wherein the first stabilizer is selected from the group consisting of carob gum and tara gum and the second stabilizer is selected from the group consisting of xanthan gum, carrageenan, maltodextrin, pectin, inulin, starch, gelatin, and agar.

Owner:KRAFT FOODS GRP BRANDS LLC

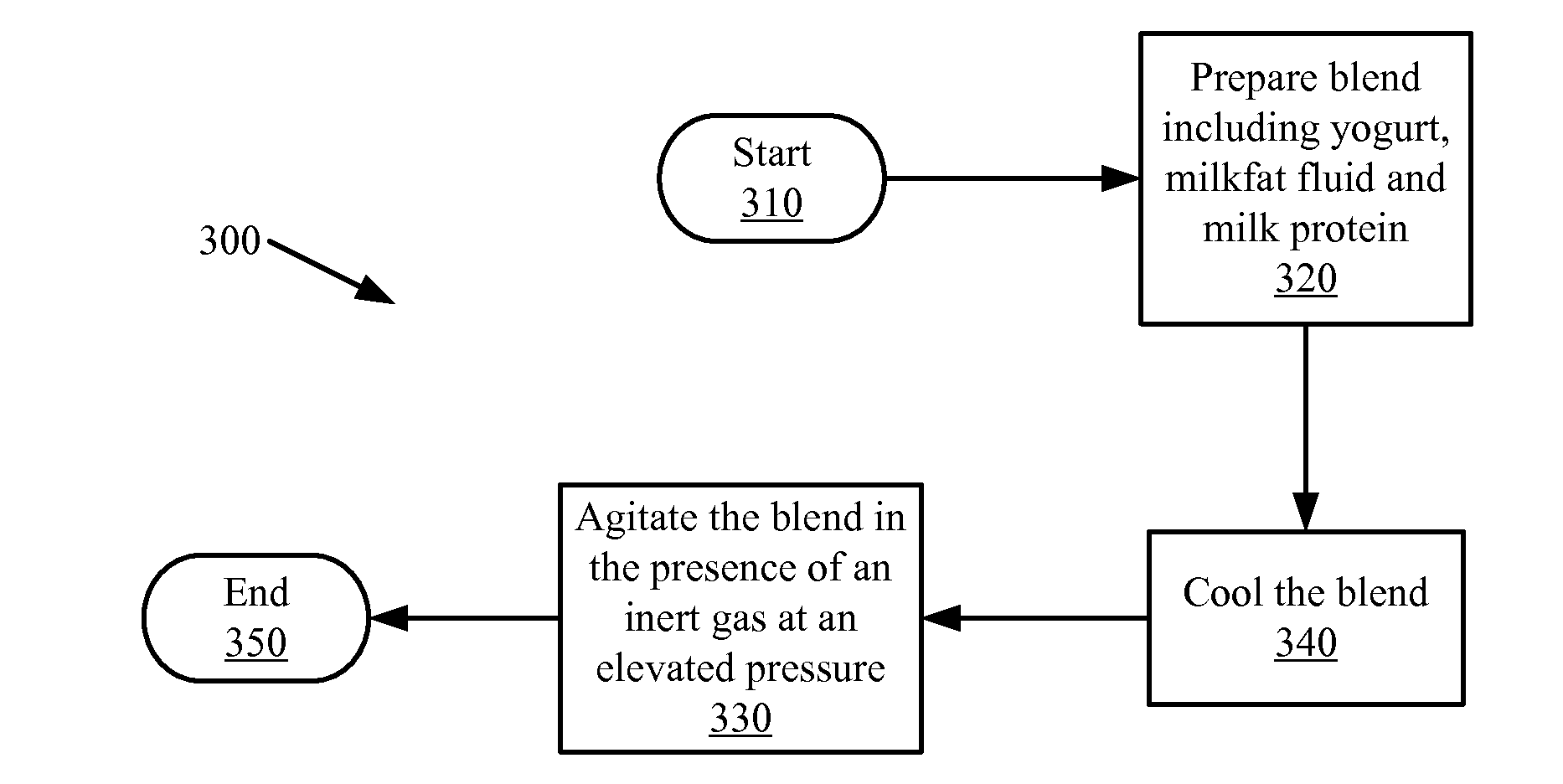

Yogurt-cheese compositions

Technique for making a Low-Fat Yogurt-Cheese Composition, including: providing a composition including a milkfat fluid; combining yogurt with the composition including a milkfat fluid to form a composition including yogurt and a milkfat fluid; combining milk protein with the composition including yogurt and a milkfat fluid; and forming a blend including the milk protein and the composition including yogurt and a milkfat fluid. Low-Fat Yogurt-Cheese Composition, including: cream cheese at a concentration within a range of between about 75% by weight and about 15% by weight; yogurt at a concentration within a range of between about 40% by weight and about 10% by weight; and milk protein at a concentration within a range of between about 45% by weight and about 15% by weight.

Owner:FRLIN FOODS HLDG

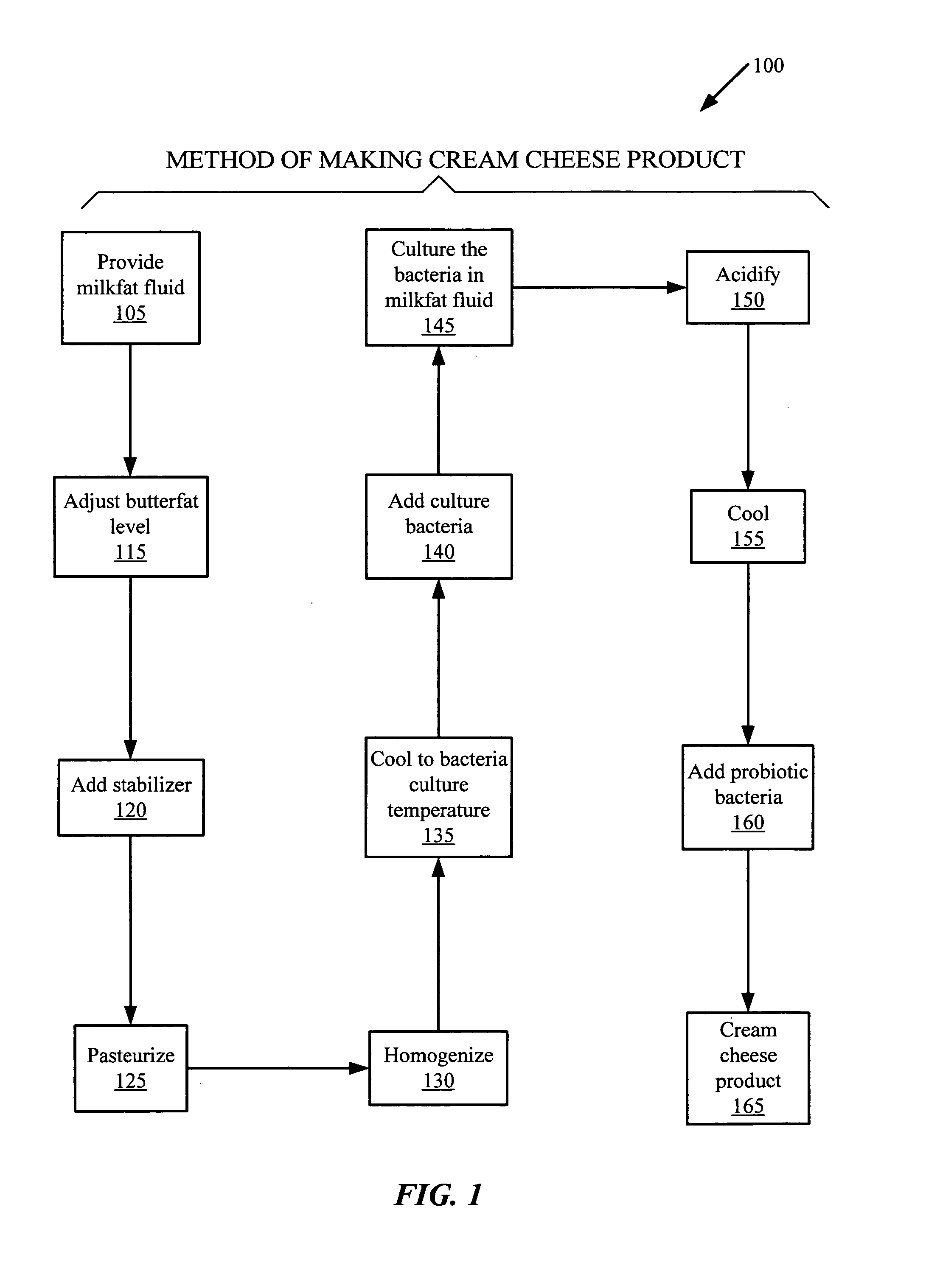

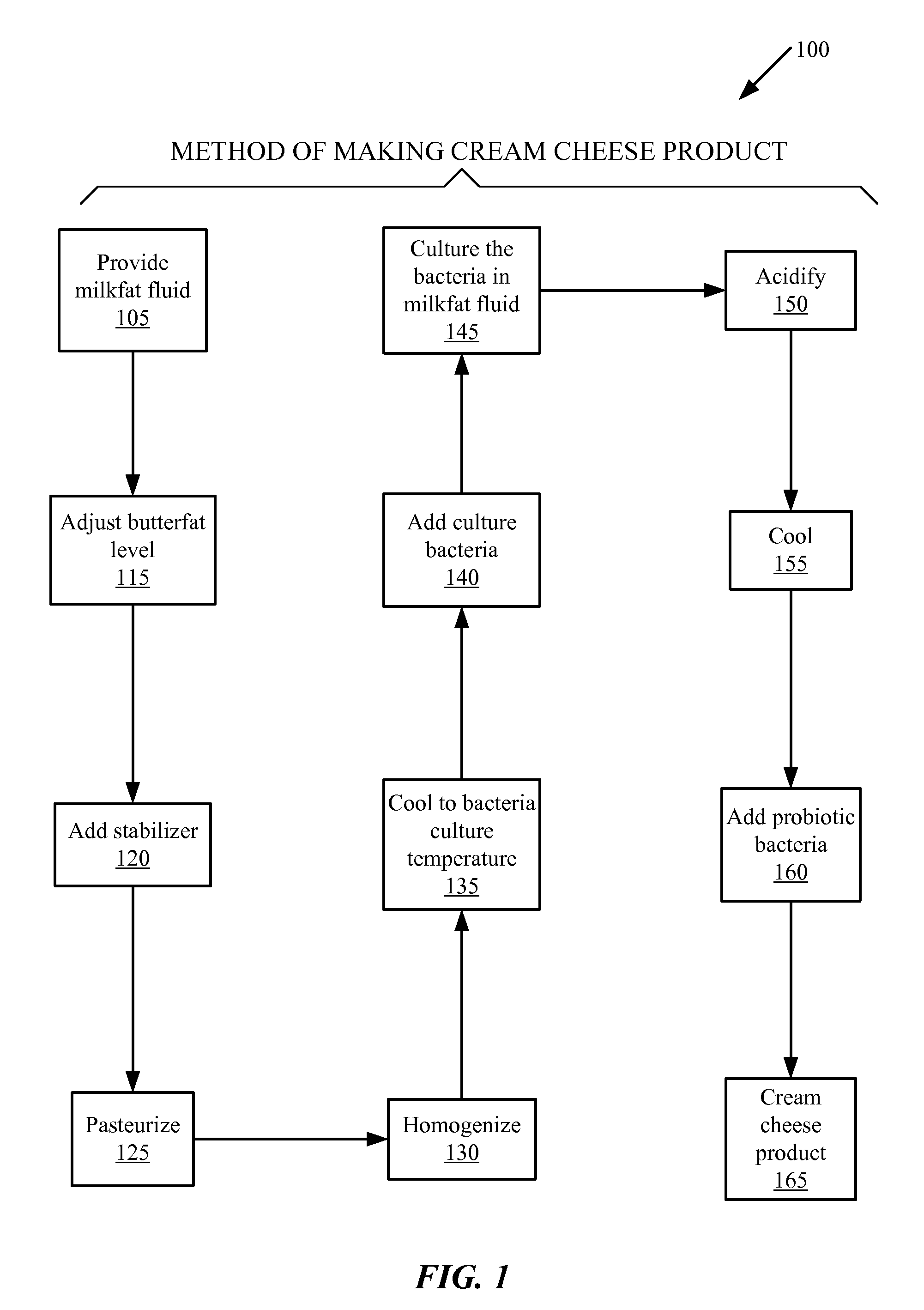

Cream cheese products and methods of making the same

Technique for making a cream cheese product comprising steps of: providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid; homogenizing the milkfat fluid; and culturing bacteria in the milkfat fluid; producing a cream cheese product comprising live probiotic bacteria cultures. Cream cheese product comprising: between about 10% by weight and about 55% by weight of total butterfat; and a live probiotic bacteria culture.

Owner:FRLIN FOODS HLDG

Shelf stable cream cheese product

InactiveUS20010018087A1Reduced pHGood emulsifying effectMilk preservationAnimal fodder preservationRoom temperatureCream cheese

A cream cheese product storable at normal room temperature for at least 6 months without substantial bacteriological deterioration comprising cream cheese, including cream cheese analogs and substitutes, and an edible acid in an amount sufficient to provide a pH of less than about 4.5, and methods for producing the same.

Owner:KRAFT FOODS INC

Yogurt-cheese compositions

Technique for making a Low-Fat Yogurt-Cheese Composition, including: providing a composition including a milkfat fluid; combining yogurt with the composition including a milkfat fluid to form a composition including yogurt and a milkfat fluid; combining milk protein with the composition including yogurt and a milkfat fluid; and forming a blend including the milk protein and the composition including yogurt and a milkfat fluid. Low-Fat Yogurt-Cheese Composition, including: cream cheese at a concentration within a range of between about 75% by weight and about 15% by weight; yogurt at a concentration within a range of between about 40% by weight and about 10% by weight; and milk protein at a concentration within a range of between about 45% by weight and about 15% by weight.

Owner:FRLIN FOODS HLDG

Cream cheese product and its method of preparation

The invention relates to a cream cheese product obtainable by a process comprising the steps of: (a) acidifying a whey protein concentrate with a food grade acidulant or with starter bacteria to reduce the pH to more than 4.5 to about 5.2, (b) heating the acidified whey protein concentrate of step (a) slowly to a temperature of about 75° to about 90° C. and maintaining it for at least about 30 min to produce a 1.5 functional whey protein concentrate, (c) optionally blending the whey protein concentrate of step (b) with milk fat in a weight ratio of about 60:40 to about 100:0 wherein step (c) may be carried out before step (b), (d)=homogenizing the blend obtained in step (b) or (c) in a 2-stage high-pressure homogenizer at pressures of about 300-400 / 50-80 bar and a temperature of about 5° to about 75° C. to produce an emulsified functional whey protein concentrate, (e) blending the product of step (d) with curd the fat content of which is adjusted in accordance with the milk fat portion added in step (c) and with the desired product, and adding salt and optional stabilizers, and (f) homogenizing the product of step (e) in a 2-stage high pressure homogenizer at pressures of about 300-400 / 508-80 bar and at a temperature of about 68° to about 90° C.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

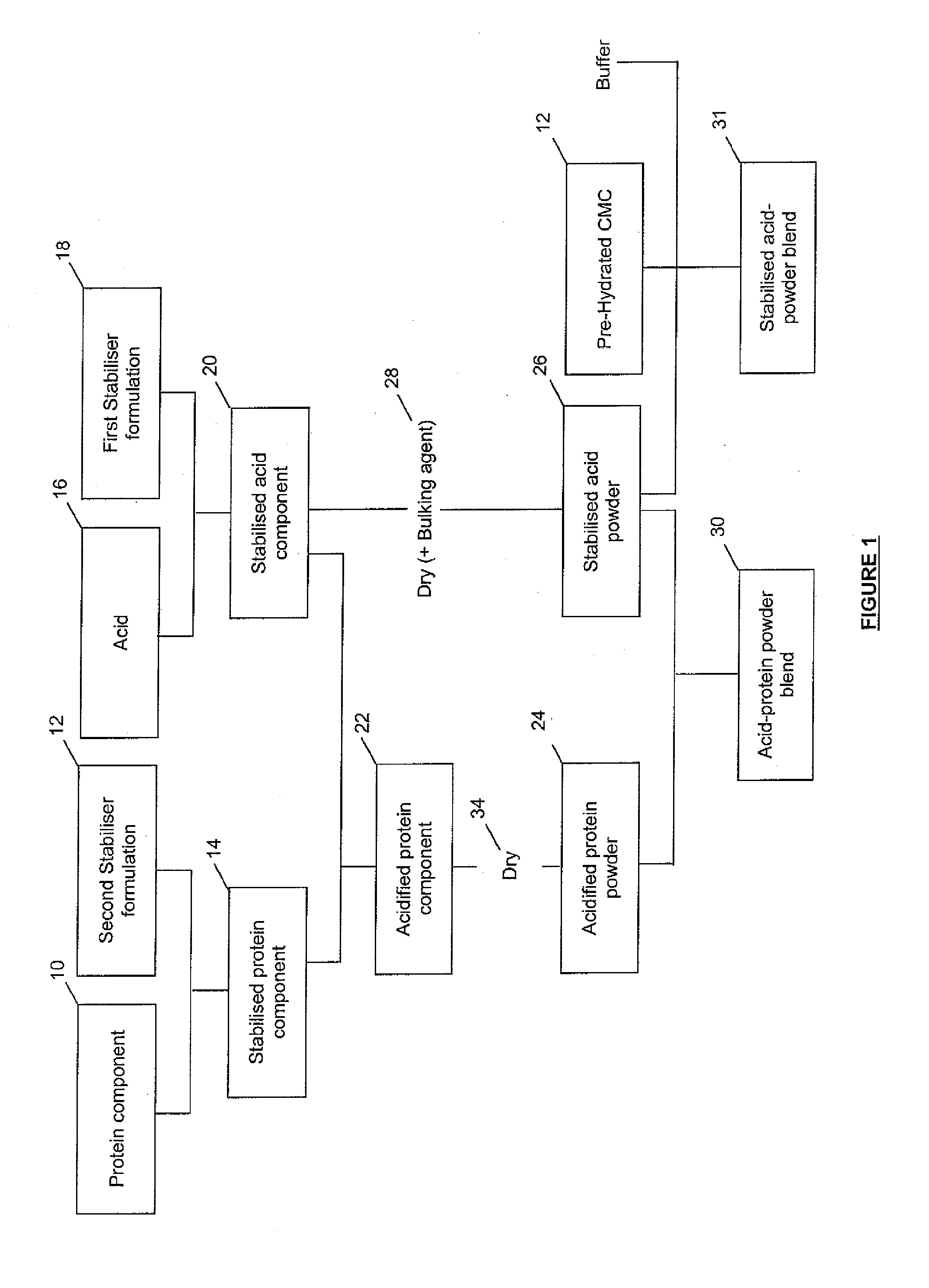

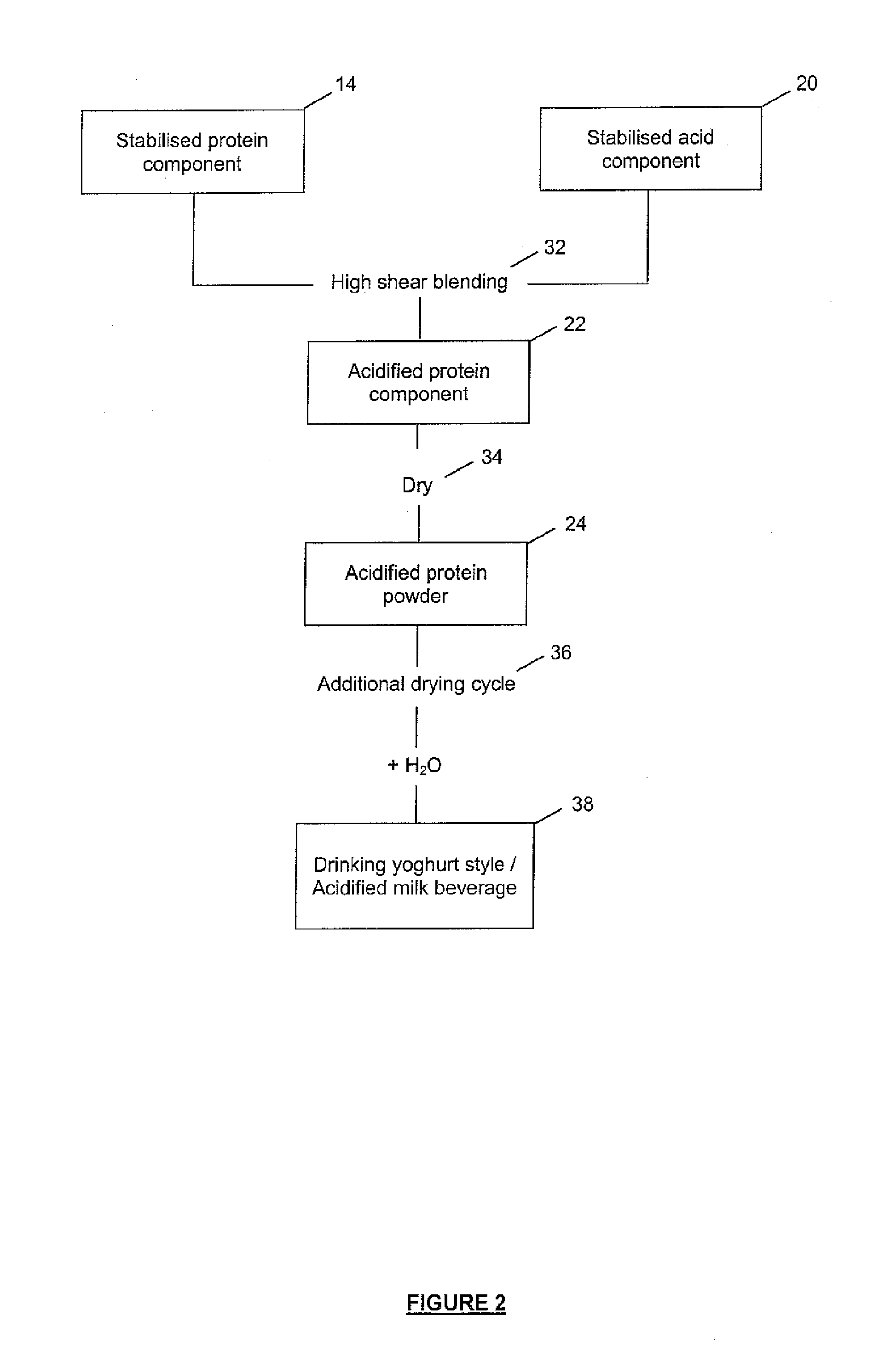

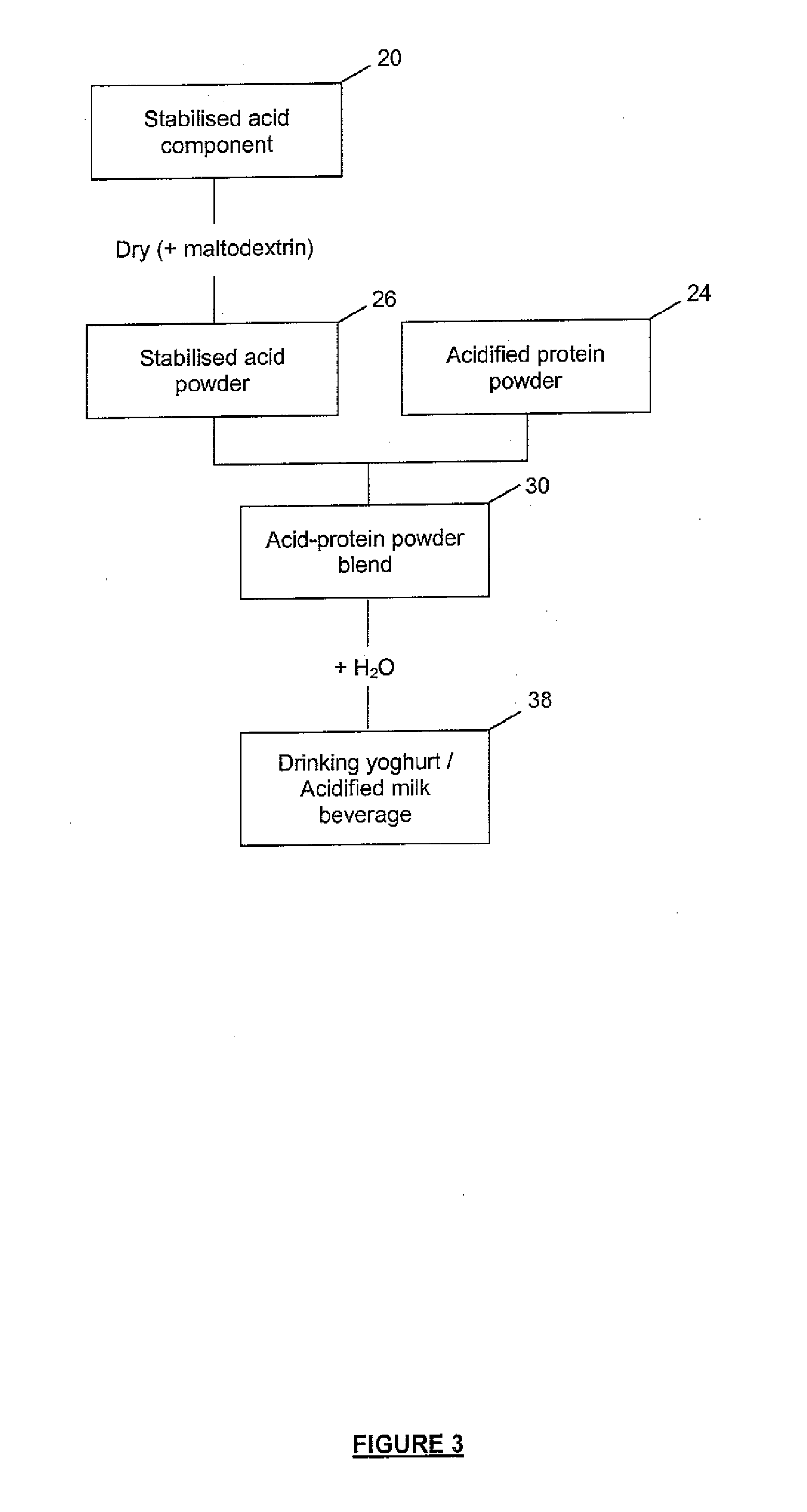

Method of Producing Acid Stable Protein Products and Products so Produced

InactiveUS20110159165A1Maximise negative chargeSufficient amountMilk preparationDough treatmentMilk proteinCream cheese

This invention relates to a method of producing powders and liquids containing milk proteins, which are stable in an acidic medium. In particular, the invention is concerned with a method of producing a powder which can be mixed with water, milk or juice to form a stable, acidified, high protein beverage. Moreover, the invention extends to a method of producing a carbonated, flavoured milk beverage or a carbonated, acidified flavoured milk beverage that is stable in an acidic medium. The invention also discloses methods of producing yoghurt style beverages and cream cheese by blending a stabilised acid component and a stabilised protein component to form an acidified protein component.

Owner:NAIRSONS FLAVOURHOUSE CC

Process for producing citric acid caseins by using yak milk dregs as raw materials

InactiveCN103073630ALow costImprove efficiencyPeptide preparation methodsAnimals/human peptidesMixed materialsCream cheese

The invention provides a process for producing citric acid caseins by using yak milk dregs as raw materials. The caseins are produced by using Cream cheeses (milk dregs), which are formed by extracting butters from yak milk by Tibetan herdsmen and fermenting and coagulating the butters, as raw materials and using citric acid as a milk coagulant; the technical process is as follows: preparing raw materials, adding alkali to dissolve the raw materials, filtering the dissolved raw materials to remove impurities, centrifugally degreasing the filtered raw materials, sterilizing the degreased raw materials for a short time at a high temperature, adding acid to the sterilized raw materials for coagulation so as to obtain curds, washing the curds, dehydrating the curds, granulating the curds, drying particles, checking qualities of the particles and obtaining finished products, wherein the dissolving of the milk dregs is adjusting the pH value of a mixed material into 9.5 by using a sodium hydroxide solution with concentration of 7.5 %; a centrifugal separator with rotation speed of 6800 rpm is used for degreasing; the sterilizing temperature is 90-95 DEG C and the sterilizing time is 2-8 seconds; and acid coagulation pH value is 3.8-4.1. The product is ivory particles with milk fragrance and no odor; and in terms of dry basis, the content of proteins is not less than 92.00 %, the content of fats is not more than 1.50 %, and the content of water is not more than 12.00 %.

Owner:香格里拉县康美乳业开发有限责任公司

Dairy-based snack products and method of manufacture of same

A portable dairy-based snack food product is provided with similar shape, appearance and convenience as a conventional candy bar where inner core is replaced with healthier more nutritional dairy based filling mixture. The dairy based filling mixture is composed of a yogurt based product and a dairy based product. The mixture is enrobed by an edible shell. The yogurt based product may be of any type, including Greek yogurt. The dairy based product is selected from the group consisting of soft cheese, cheese curd, farmers cheese, cottage cheese, ricotta cheese, cream cheese, neufchâtel cheese and mixtures thereof.

Owner:KONCHAKOVSKIY SERGEY

Cream Cheese Products and Methods of Making the Same

Technique for making a cream cheese product comprising steps of: providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid; homogenizing the milkfat fluid; and culturing bacteria in the milkfat fluid; producing a cream cheese product comprising live probiotic bacteria cultures. Cream cheese product comprising: between about 10% by weight and about 55% by weight of total butterfat; and a live probiotic bacteria culture.

Owner:FRLIN FOODS HLDG

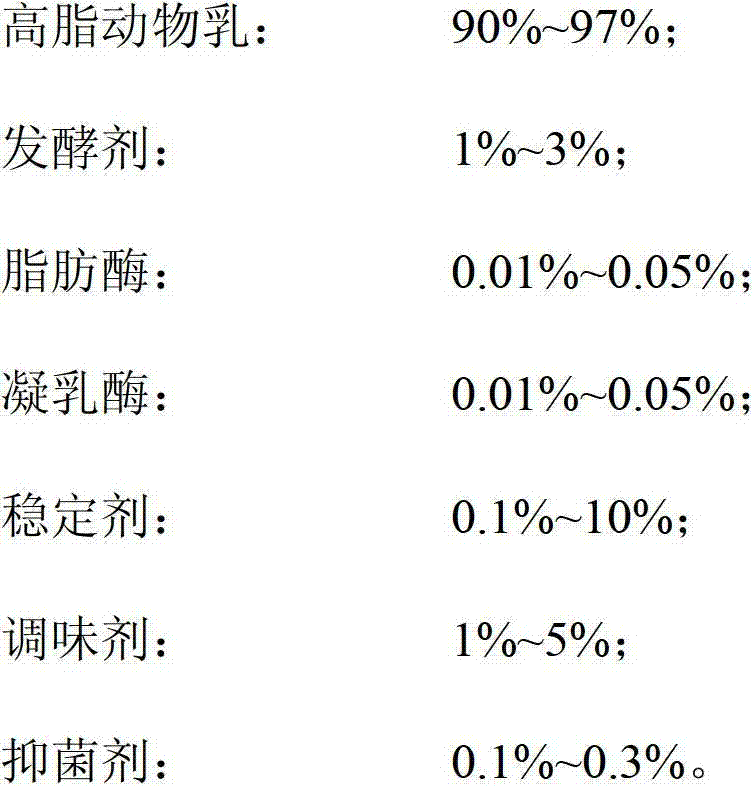

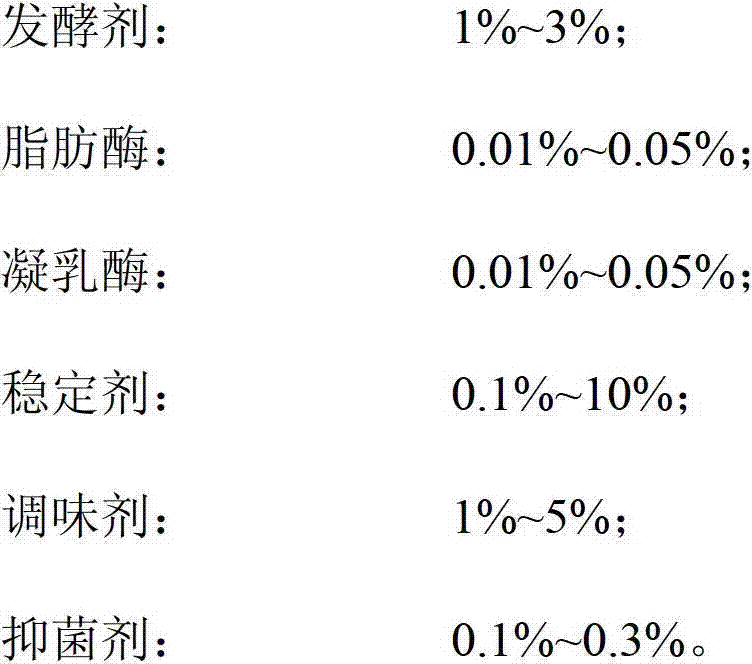

High-fat animal milk cream cheese and preparation method thereof

InactiveCN103039628AUniform and fine textureStable and continuous textureCheese manufactureHigh fatRefrigeration

The invention relates to high-fat animal milk cream cheese which comprises, by weight, 90% to 07% of high-fat animal milk, 1% to 3% of a starter culture, 0.01% to 0.05% of lipase, 0.01% to 0.05% of rennin, 0.1% to 10% of a stabilizer, 1% to 5% of a flavoring agent and 0.1% to 0.3% of a bacteriostatic agent. The cream cheese is milk white or slightly yellow, the texture is uniform and delicate, and no whey is precipitated; the content of protein is larger than 10.0%, and the content of fat is larger than 20.0%; and the stable and continuous texture is provided. Simultaneously, when the product is in a refrigeration condition of 10 DEG C, the service life of a product shelf is 60 days, and a long product shelf life is provided.

Owner:TIANJIN UNIV OF SCI & TECH

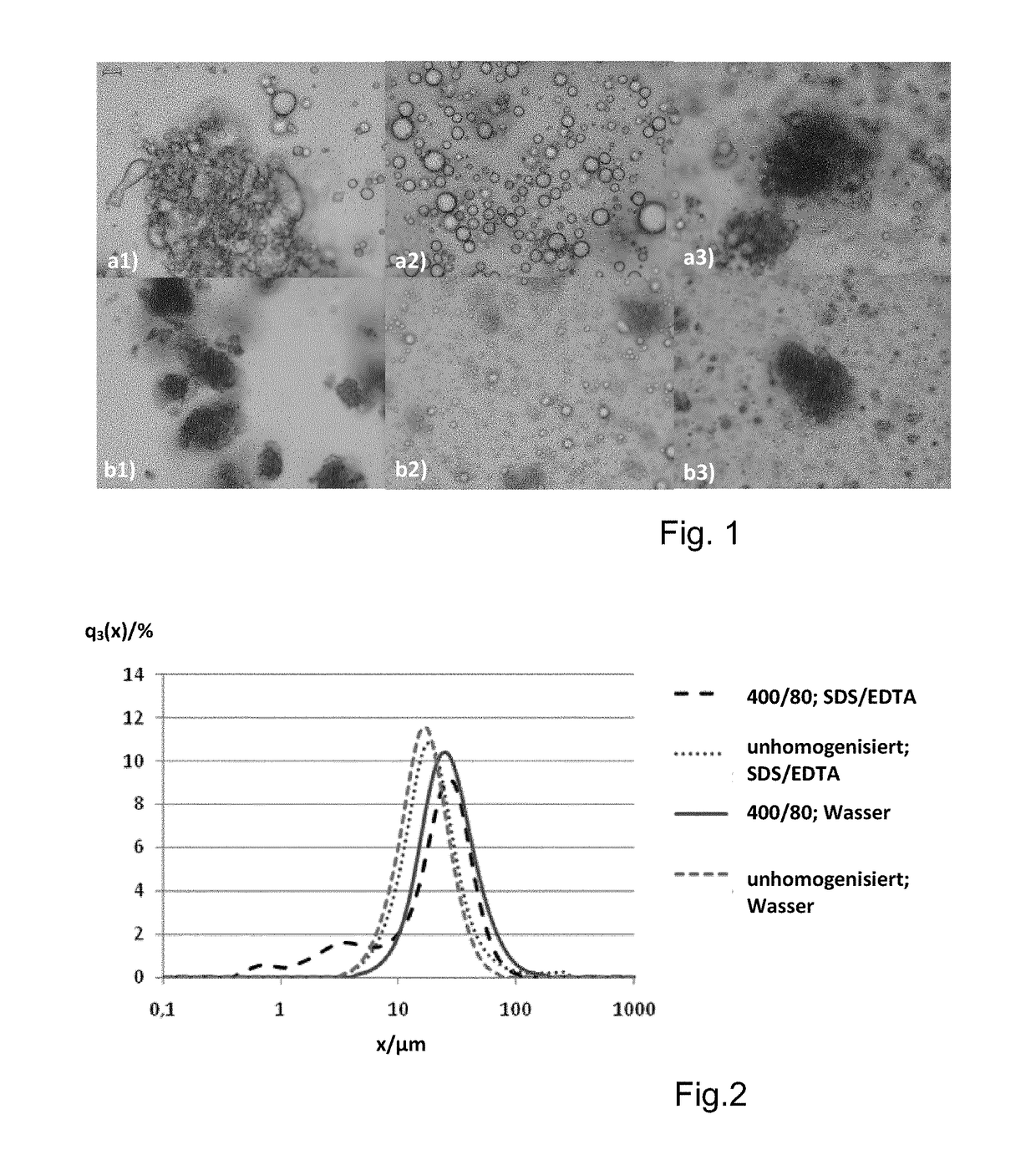

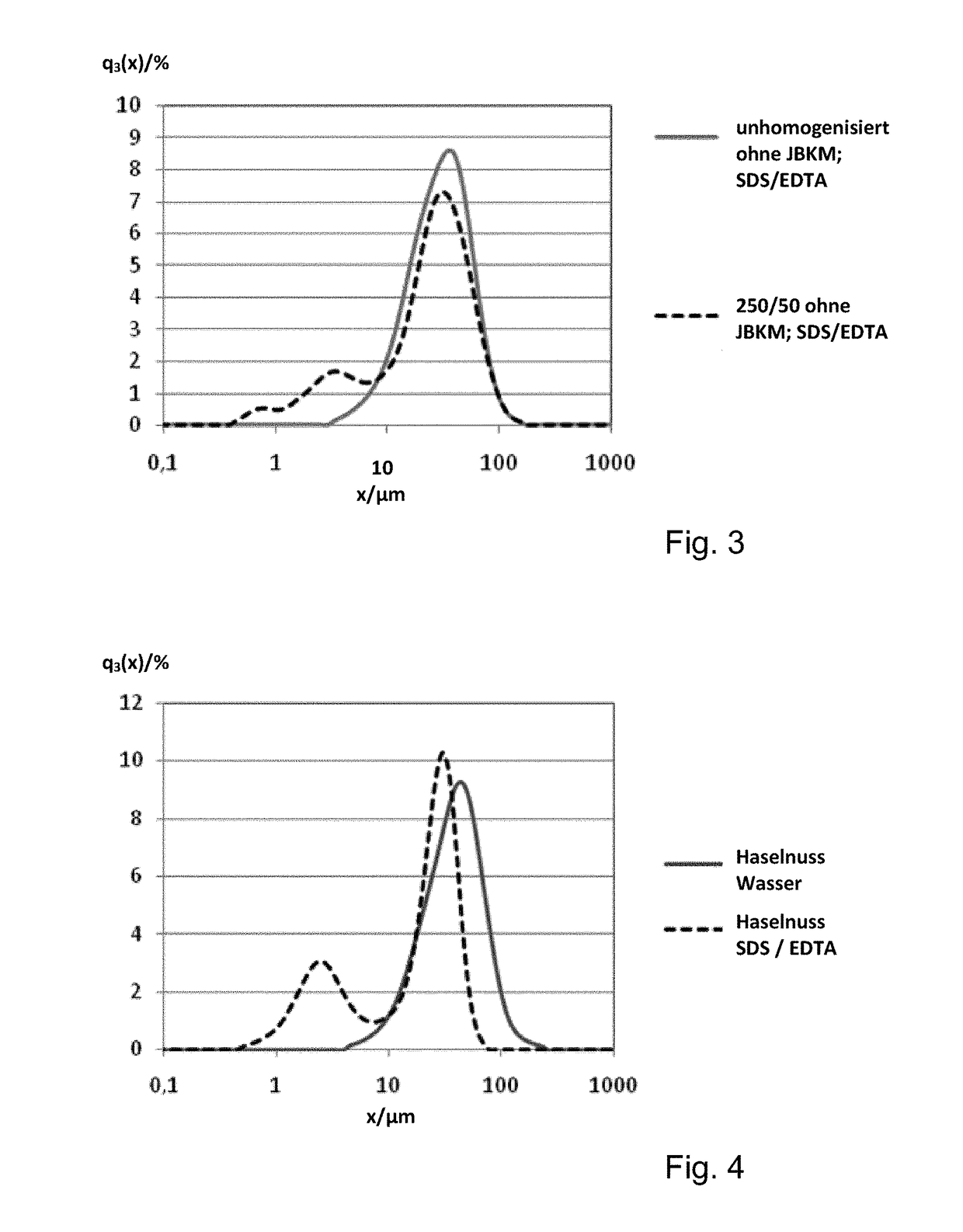

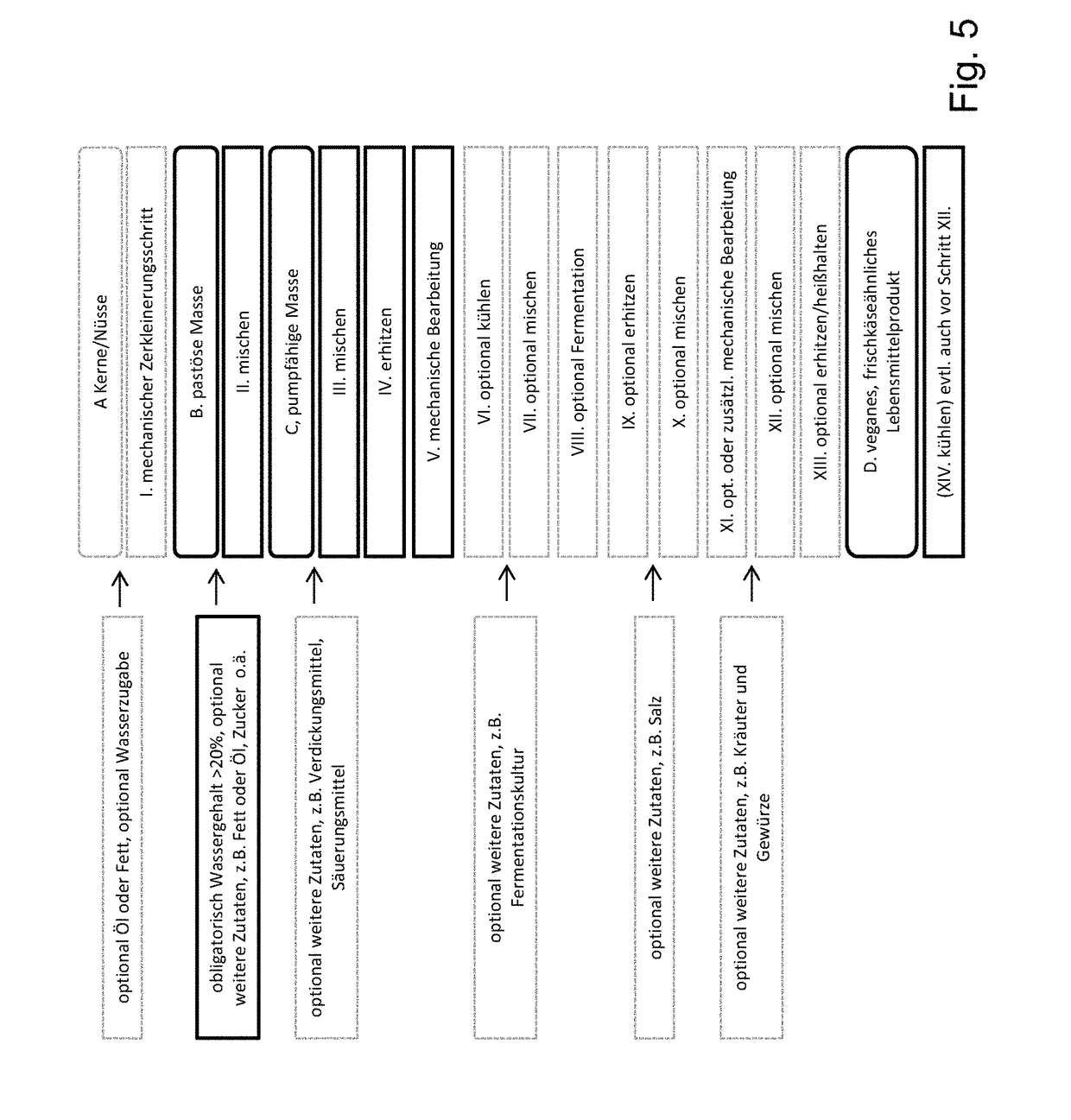

Cream cheese-like food product and production method

A method for producing a cream cheese-like, in particular vegan food product, in particular having a solidity in a value range between 0.2 N and 7.0 N measured at 10° C., and a corresponding food product, wherein the in particular cream cheese-like food product has a particle size distribution in a non-macerated state, with a particle size distribution, measured in distilled water, with an average particle diameter x50,3<100 μm, preferably between 10 and 40 μm, and with at least one peak, in particular a global maximum, at a particle diameter x3>10 μm, and in that, in a partially macerated state obtained by mixing one part by weight of the food product with 9 parts by weight of an SDS-EDTA solution (0.25% SDS, 0.25% EDTA), the food product has a particle size distribution with at least one additional peak at a particle diameter x3<10 μm in relation to the non-macerated state.

Owner:HOCHLAND SE

Process for manufacturing cheeses and other dairy products and products thereof

InactiveUS20050244541A1Improve production stabilityMilk preparationOxidoreductasesAdditive ingredientLactose oxidase

Process for manufacturing cheeses and other dairy products, and the resulting products, in which lactobionic acid is added, or generated in situ, in combination with a dairy component in the course of the process. The lactobionic acid can be used as the sole acidulent for direct acidification of the cheese, or in conjunction with reduced amounts of lactic acid culture. When the lactobionic acid is generated in situ during cheese manufacture according to the invention, a lactose oxidase is used in one embodiment to convert lactose intrinsically present in the dairy liquid ingredient(s) into lactobionic acid. The organoleptic attributes of the cheeses made using lactobionic acid as an ingredient are satisfactory and fully suitable. The process can be applied to the production of a wide variety of cheeses, including, for example, cream cheeses, hard cheeses such as cheddar, UF cheeses, process cheeses, cheddar cheeses, and so forth.

Owner:KRAFT FOODS GRP BRANDS LLC

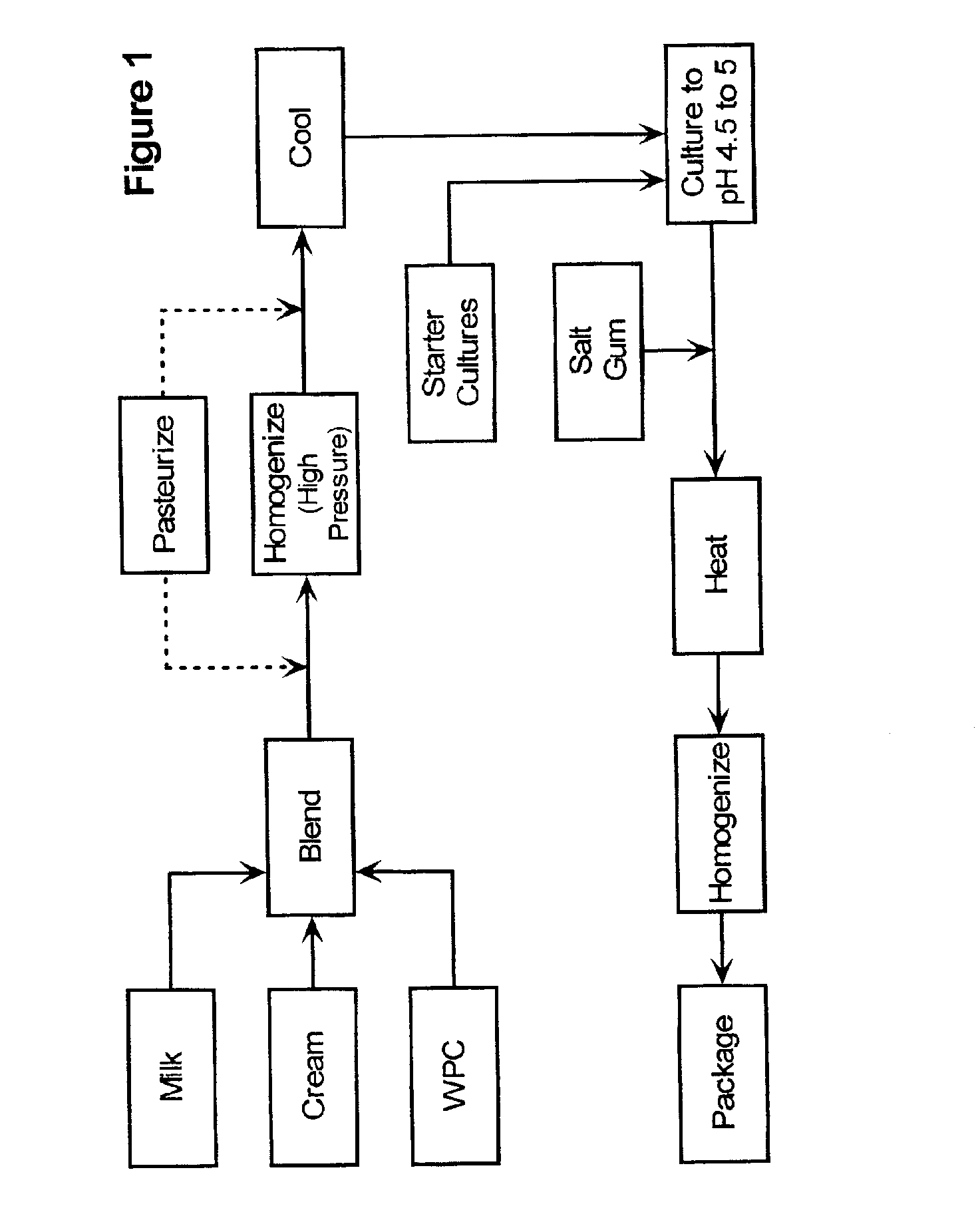

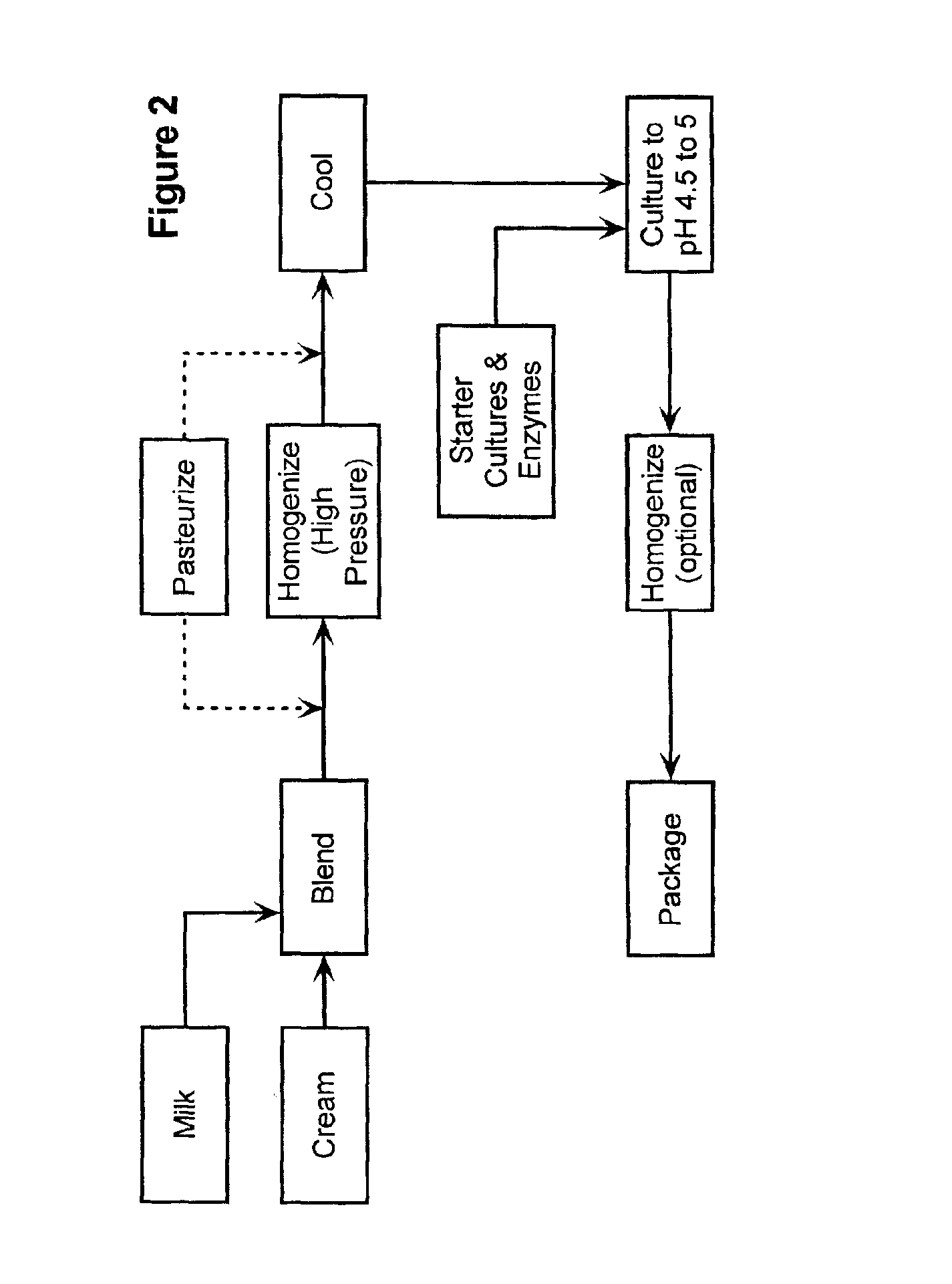

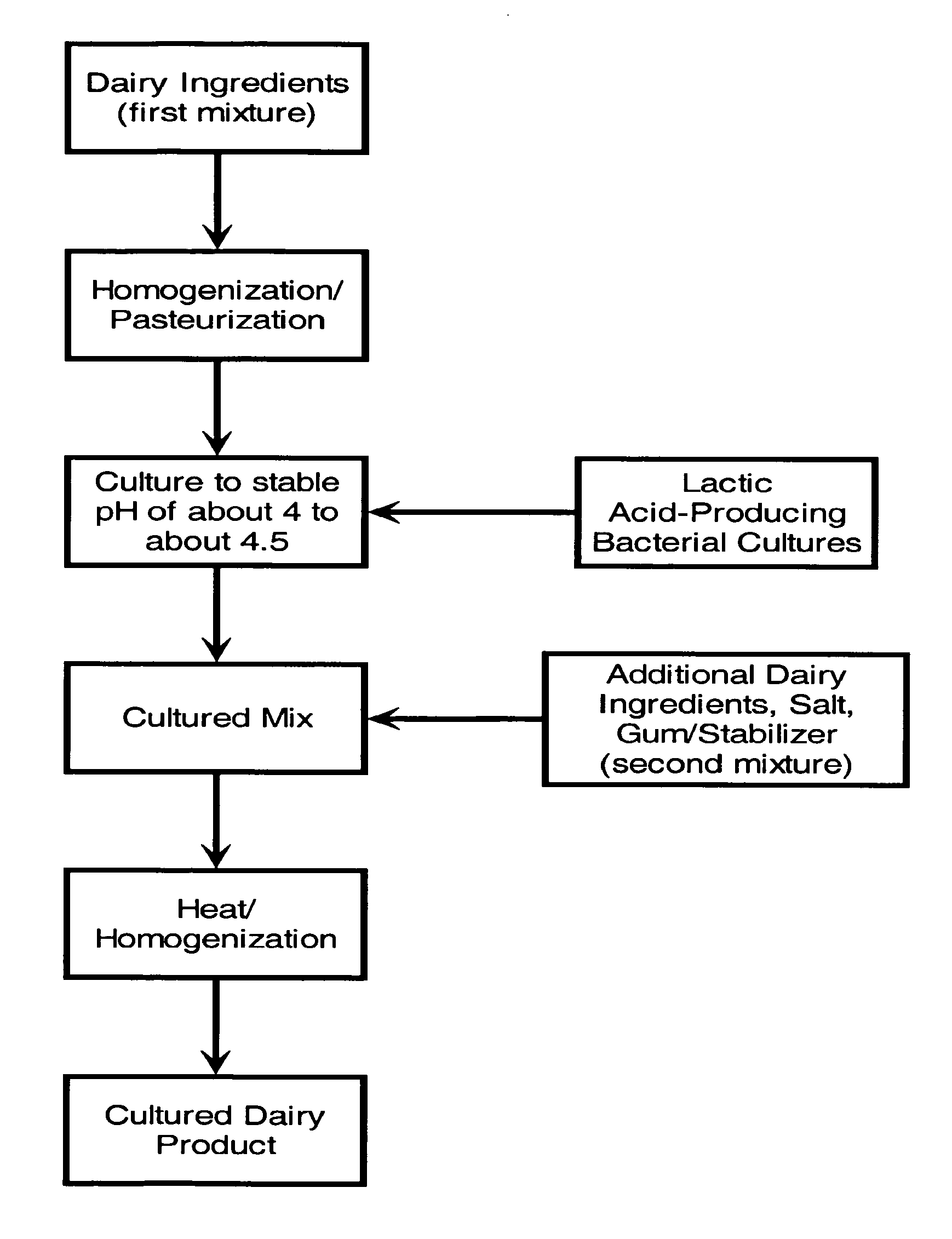

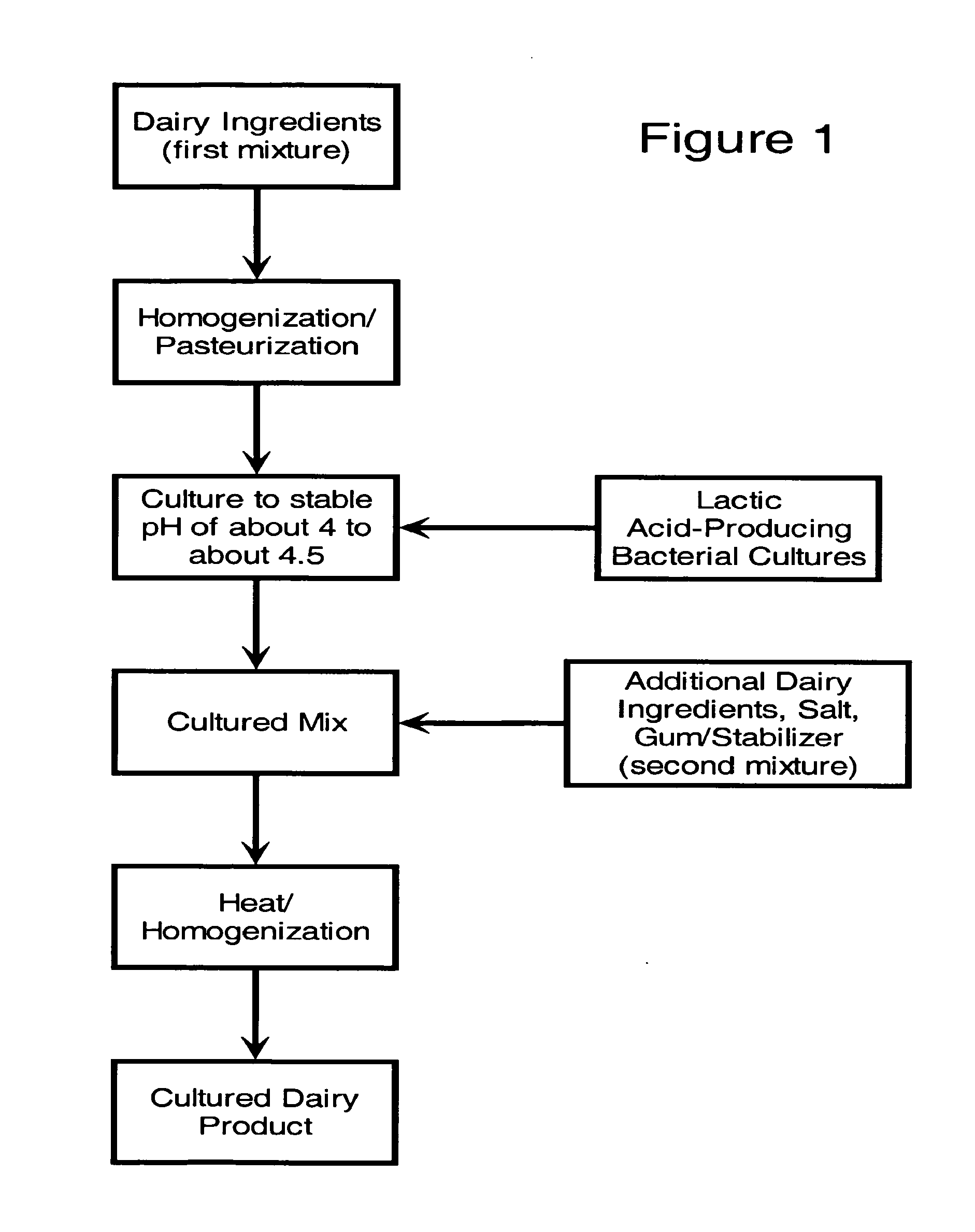

Cultured Dairy Products and Methods of Manufacture

InactiveUS20090047386A1Improve the level ofConsistent pH levelMilk preparationOther dairy technologyBiotechnologyButterfat

The present invention is directed to cultured dairy products and more particularly to cultured cream cheese compositions which are prepared without a whey-separation step and which have reduced levels of cultured dairy materials. The present invention also relates to methods of making such cultured dairy or cream cheese products. The cultured dairy or cream cheese products contain a considerable quantity of non-cultured dairy material (generally greater than about 60 percent, and preferably about 70 to about 80 percent, of the total dairy protein).

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com