High-fat animal milk cream cheese and preparation method thereof

A cream cheese and animal milk technology, applied in the food field, can solve problems such as patent publications that have not yet been found, and achieve the effect of enriching product flavor, enriching flavor, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

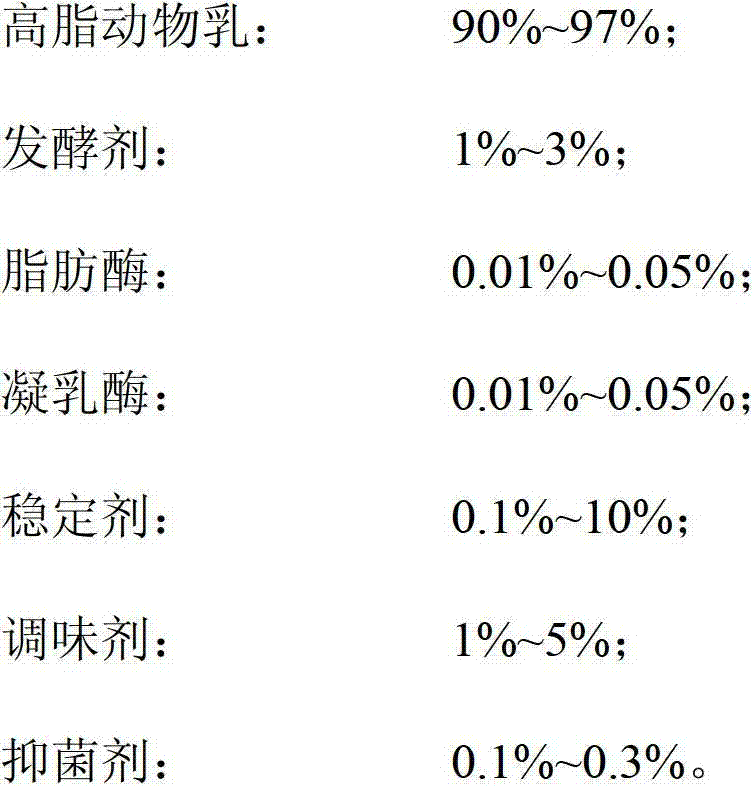

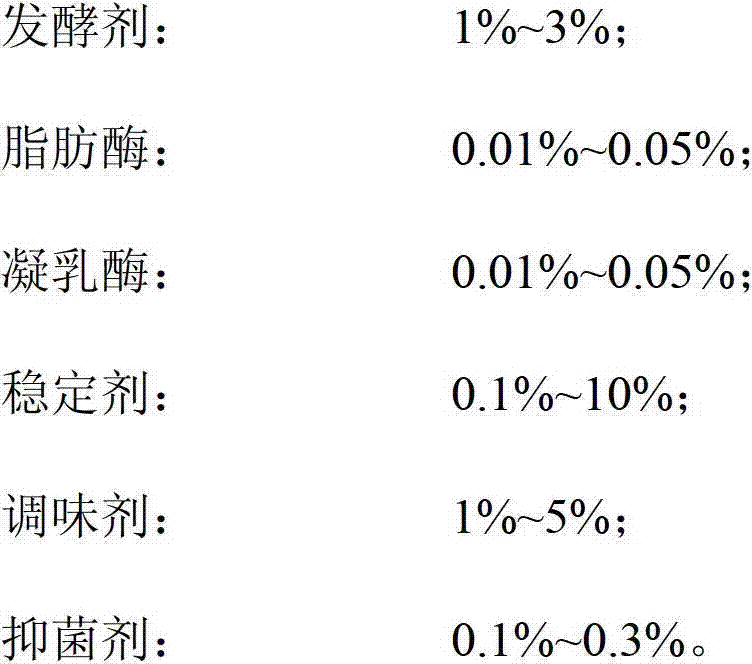

[0044] The preparation method of the above-mentioned high-fat animal milk cream cheese, the steps are as follows:

[0045] 1. Use a milk cleaner to purify high-fat animal milk to become raw milk, pasteurize it at a temperature of 70~75°C, keep it for 5~10 minutes, and quickly cool the raw milk to 15~35°C for later use;

[0046] 2. Inoculate the starter according to 1%~3% of the total mass of raw materials. While inoculating the mixed starter of lactic acid bacteria, add lipase and rennet respectively at 0.01~0.05% of the total mass of raw materials; the fermentation temperature is 15°C, The fermentation time is 10-24 hours, the pH value reaches 4.9-4.6, and the raw milk becomes continuous curd;

[0047] 3. Transfer the curd to the upper feeding separator or disc separator to separate the whey at a speed of 1500~2000r / min for 1-5 minutes to obtain a centrifuged paste;

[0048] 4. Transfer the centrifugally separated paste to a heating and shearing mixer, add seasoning, stabili...

Embodiment 1

[0054] Yak Milk Cream Cheese

[0055] Main ingredients: yak milk (95.38%), mixed strains of Streptococcus creis and Streptococcus diacetylensis (3%), yeast lipase (0.01%), mold rennet (0.01%), salt (1 %), guar gum (0.5%) and nisin (0.1%), the above percentages are mass percentages.

[0056] The preparation method of the above-mentioned high-fat animal milk cream cheese, the steps are as follows:

[0057] 1. Use a milk cleaning machine to purify yak milk to become raw milk, pasteurize it at 73°C, keep it for 5 minutes, and quickly cool the raw milk to 15°C for later use;

[0058] 2. Preparation of lactic acid bacteria mixed working starter: mix the two strains of Streptococcus milkis and Streptococcus diacetyl with a mass ratio of 1:1, and inoculate them into skim milk powder reconstituted milk with an inoculation amount of 3%. culture medium at 32°C for 24 hours, and after curdling, a lactic acid bacteria mixed working starter was obtained for later use.

[0059] 3. Inocula...

Embodiment 2

[0067] Buffalo Milk Cream Cheese

[0068] Main ingredients: buffalo milk (95.08%), mixed strains of Streptococcus crealis and Leuconostoc citricophilus (3%), yeast lipase (0.01%), mold rennet (0.01%), salt ( 1%), spices (0.5%), gelatin (0.3%) and nisin (0.1%), the above percentages are mass percentages.

[0069] The preparation method of the above-mentioned high-fat animal milk cream cheese, the steps are as follows:

[0070] 1. Use a milk cleaner to purify buffalo milk as raw milk, pasteurize it at 70°C for 5 minutes, and quickly cool the raw milk to 15°C for later use;

[0071] 2. Preparation of lactic acid bacteria mixed working starter: mix the two strains of Streptococcus milkis and Leuconostoc citricophilus with a mass ratio of 1:1, and inoculate the sterilized Culture medium composed of skim milk or skim milk powder reconstituted milk, cultivated at 32°C for 3-24 hours, after curdling, a mixed working starter of lactic acid bacteria was obtained, and it was set aside;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com