AKD emulsion and preparation method thereof

An emulsion and solution technology, applied in the direction of adding water repellent, can solve the problems of long production cycle, cumbersome process, and low aging rate, and achieve the effect of shortening time consumption, ensuring sizing effect, and reducing the degree of hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

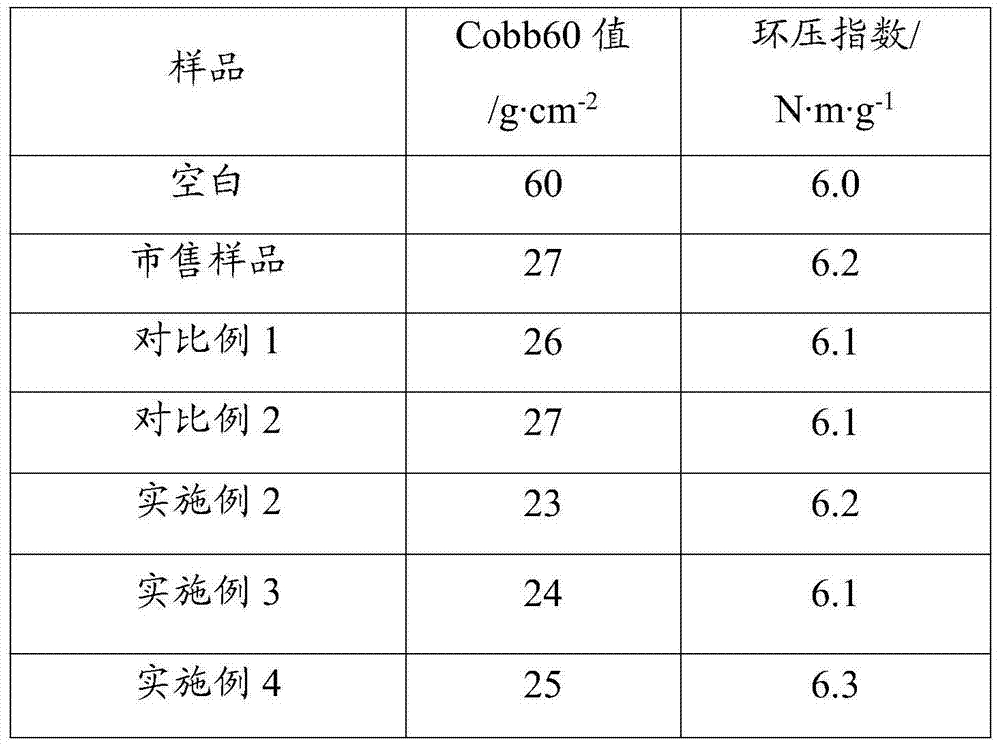

Examples

Embodiment 1

[0031] A kind of preparation method of AKD emulsion of the present embodiment comprises the steps:

[0032] (1) Put 400 parts of hot water into the reactor, keep the temperature at 75°C, start stirring, put 110 parts of AKD wax powder, 11 parts of cationic starch, and 2 parts of dispersant into the reactor at the same time, stir for 15 minutes, and release Lotion;

[0033] (2) Pour into the homogenizer for homogenization, pass 2 times; the homogenization pressure is 30MPa;

[0034] (3) Then pass the emulsion into 470 parts of frozen water, and add 2 parts of stabilizer and 5 parts of curing agent;

[0035] (4) Continue stirring until the emulsion is cooled to room temperature, and filter to obtain the AKD emulsion.

[0036] The preparation method of described cationic starch comprises the steps:

[0037] A. Put tapioca starch in a reaction vessel, add catalyst (sodium hydroxide) and etherification agent (2,3-epoxypropyltrimethylammonium chloride), stir and heat up to 60°C, ...

Embodiment 2

[0044] A kind of preparation method of AKD emulsion of the present embodiment comprises the steps:

[0045] (1) Put 500 parts of hot water into the reactor, keep the temperature at 80°C, start stirring, put 100 parts of AKD wax powder, 30 parts of cationic starch, and 4 parts of dispersant into the reactor at the same time, stir for 15 minutes, and release Lotion;

[0046] (2) Pour into the homogenizer for homogenization, pass 2 times; the homogenization pressure is 35MPa;

[0047] (3) Then pass the emulsion into 350 parts of frozen water, and add 6 parts of stabilizer and 10 parts of curing agent;

[0048] (4) Continue stirring until the emulsion is cooled to room temperature, and filter to obtain the AKD emulsion.

[0049] The cationic starch used in this embodiment is the same as the preparation method of embodiment 1.

[0050] The solid content of the obtained AKD emulsion is about 15%, the particle size of the emulsion is 2-3um, and the emulsion does not change when ce...

Embodiment 3

[0052] A kind of preparation method of AKD emulsion of the present embodiment comprises the steps:

[0053](1) Put 280 parts of hot water into the reactor, keep the temperature at 85°C, start stirring, put 130 parts of AKD wax powder, 28 parts of cationic starch, and 2 parts of dispersant into the reactor at the same time, stir for 15 minutes, and release Lotion;

[0054] (2) Enter the homogenizer for homogenization, and pass it 2 times; the homogenization pressure is 40MPa;

[0055] (3) Then pass the emulsion into 540 parts of frozen water, and add 2 parts of stabilizer and 18 parts of curing agent;

[0056] (4) Continue stirring until the emulsion is cooled to room temperature, and filter to obtain the AKD emulsion.

[0057] The cationic starch used in this embodiment is the same as the preparation method of embodiment 1.

[0058] The solid content of the obtained emulsion is about 18%, the particle size of the emulsion is 2-4um, and the emulsion does not change when cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com