Patents

Literature

56results about How to "Rapid emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AKD emulsion and preparation method thereof

ActiveCN104499363AImprove emulsifying performanceRapid emulsificationWater-repelling agents additionWaxEmulsion

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Enzyme-containing cleaning agent

InactiveCN105602742AQuick removalRapid emulsificationNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentBiology

The invention discloses an enzyme-containing cleaning agent which is characterized by consisting of the following ingredients in percentage by mass: 3-5% of nonionic surfactant, 1-2% of enzyme, 2-3% of chelating agent, 2-3% of corrosion inhibitor, 1-4% of bactericide and the balance of water. The invention provides a cleaning agent mainly featured by the addition of a nonionic surfactant, an enzyme and a bactericide; the cleaning agent can effectively decompose and clear fat and proteins in blood stains; due to the relatively good sterilization component, the overall cleaning ability of the product can be effectively improved, and the cleaning effect of the product is enhanced; and the enzyme-containing cleaning agent has the advantages of no corrosion, low foam content, high wettability, low cost, safety and good cleaning effect.

Owner:NANJING JUSHA DISPLAY TECH

High performance on-site mixed emulsified explosive

InactiveCN101475423AImprove oxygen balanceImprove powerExplosive working-up apparatusExplosive AgentsEmulsion explosive

The invention relates to a high-performance emulsion explosive mixed and loaded on the spot. Ammonium nitrate and sodium nitrate are thrown into a crusher, are crushed, are sent to a melting pot filled with water according to mixture ratio, are heated to a temperature of between 70 and 80 DEG C and are kept at the temperature to prepare a water phase solution; an emulsifier, diesel oil and engine oil are pumped to a mixing tank and are fully stirred to prepare an oil phase solution; an explosive mixing and loading vehicle is driven to a blasting scene and is hung with a power takeoff device; when the pressure of a hydraulic pump is not less than 10 MPa, the water phase solution and the oil phase solution are automatically pumped to an emulsifier of the explosive mixing and loading vehicle according to proportion of 94:6; after emulsification, a sensitizing agent is added into a mixing device according to mixture ratio and is mixed to form medicine slurry; the medicine slurry is pressed to a hose reel by the pressure of a screw pump; the density and the temperature of the explosive are measured; and after the density and the temperature are qualified, the explosive is loaded to a blast hole for blasting. The high-performance emulsion explosive has high efficiency and a simple formula, reduces a packaging link, has low production cost and low blasting cost, reduces labor intensity of operators and field workers and is safe and reliable.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

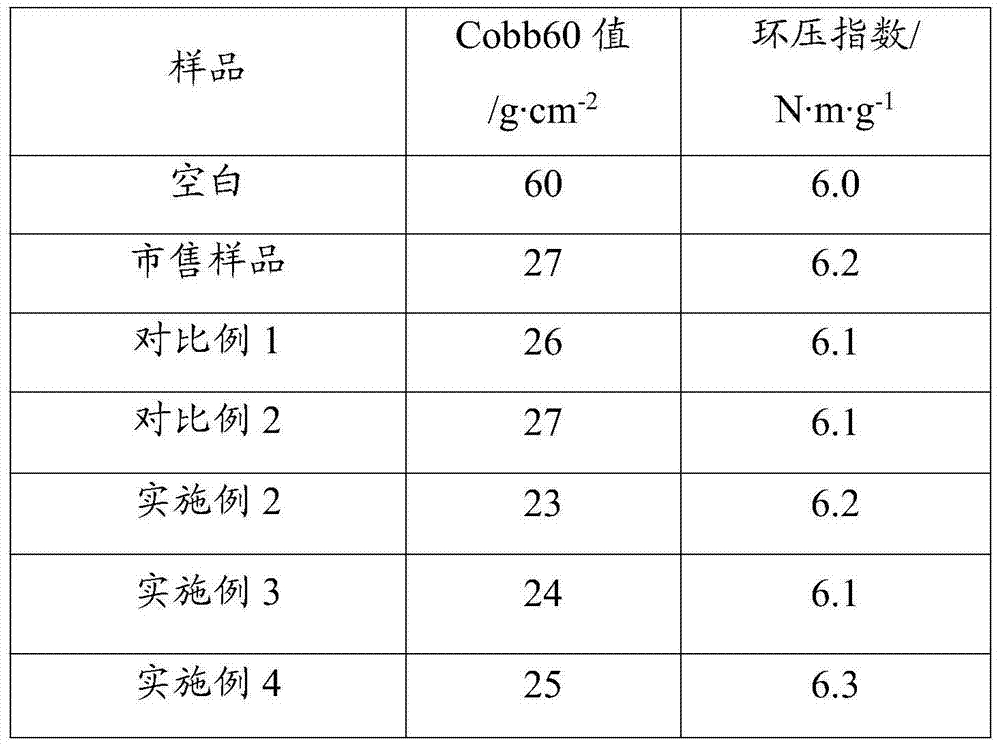

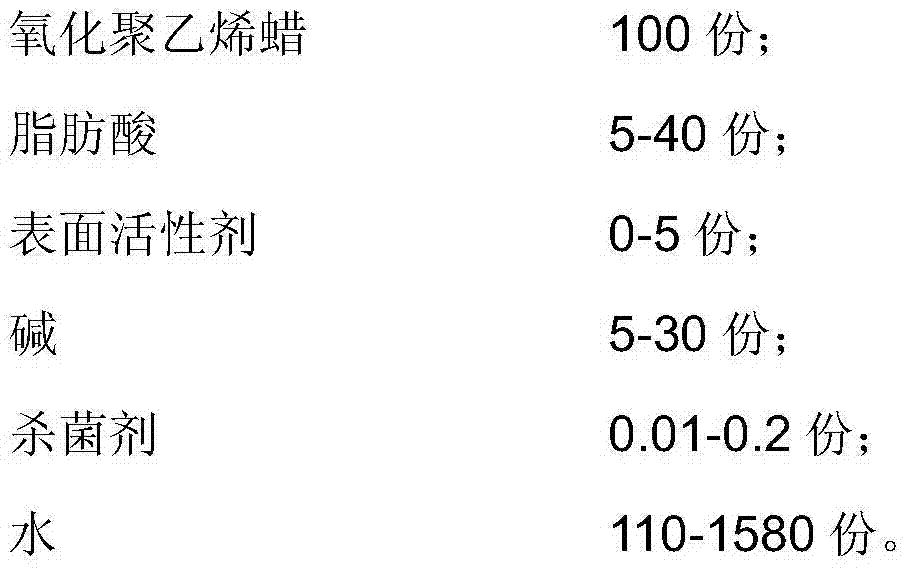

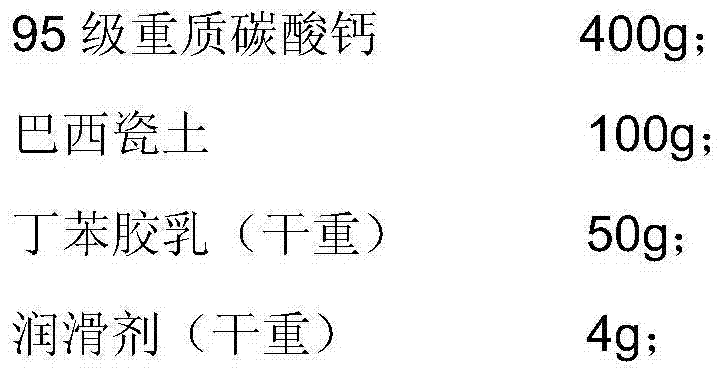

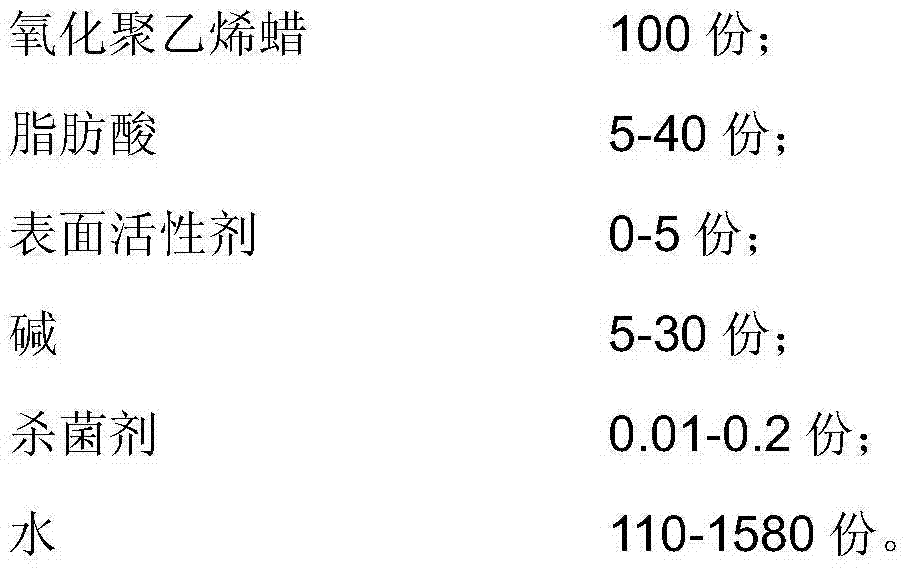

Aqueous lubricant used for papermaking, preparation method and application thereof

The invention provides an aqueous lubricant used for papermaking, a preparation method and an application of the aqueous lubricant in paper coating. The preparation method is characterized in that oxidized polyethlene wax, fatty acid, alkali, a surfactant, a bactericide and water are mixed to obtain an aqueous polymer. The aqueous lubricant used in a papermaking paint for coated paper is capable of obviously increasing smoothness of coated paper and improving the glossiness of paper, paper whiteness is not influenced, and preparation technology is simple.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Basic enzyme-containing detergent and preparation method thereof

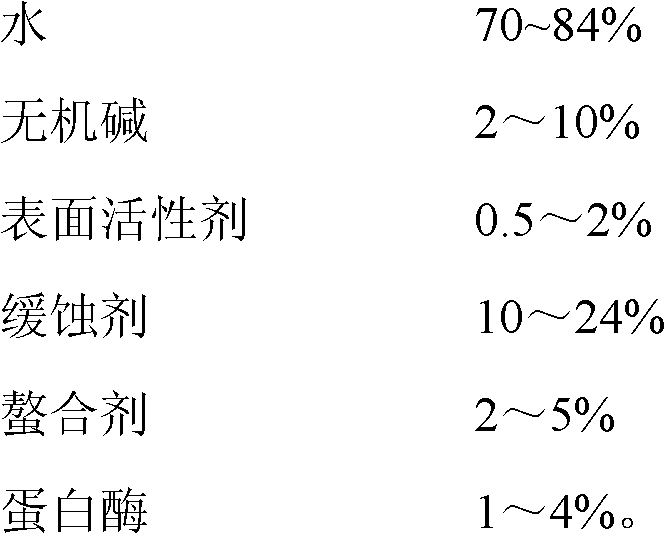

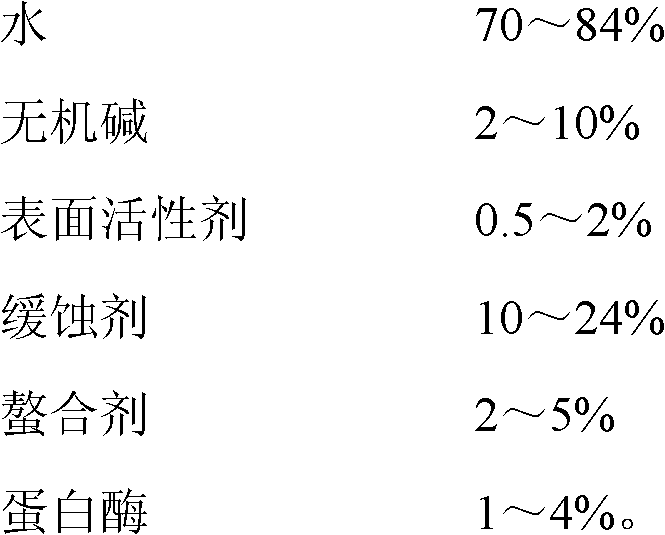

InactiveCN102329696AQuick removalRapid emulsificationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProteinase activitySURFACTANT BLEND

The invention belongs to the technical field of medical detergent, and relates to a basic enzyme-containing detergent and a preparation method thereof. The basic enzyme-containing detergent is composed of the following components in percentage by mass: 70-84% of water, 2-10% of inorganic base, 0.5-2% of surfactant, 10-24% of corrosion inhibitor, 2-5% of chelating agent and 1-4% of protease. The basic enzyme-containing detergent has the characteristics that the protease added in the basic enzyme-containing detergent can decompose fat and has good protein removal effect in alkalescent environment, thus the cleaning effect is improved; and the basic enzyme-containing detergent has the advantages of no corrosion, low foam amount, high wettability, low cost, high safety and good cleaning effect. The preparation method of the basic enzyme-containing detergent is simple and feasible, and is easy to implement and control.

Owner:SHINVA MEDICAL INSTR CO LTD

Self-emulsification rosinyl surfactant emulsion and preparation method thereof

InactiveCN102039099AAchieve self-emulsificationIncrease added valueTransportation and packagingMixingEmulsionPolymer science

The invention discloses a self-emulsification rosinyl surfactant emulsion and a preparation method thereof. The preparation method comprises: esterfying polyethylene glycol of low molecular weight with rosin or modified rosin to prepare rosinyl polyethylene glycol diacrylate; in the presence of emulsification-assistant agent, emulsifying the rosinyl polyethylene glycol diacrylate to prepare emulsion of which the solid content is 30-60% with a high shear apparatus. The prepared self-emulsification rosinyl surfactant emulsion has smaller parameter diameter reaching 112nm, and good stability. The emulsion has strong surface activity, raw materials are cheap and easy to obtain, and environmentally-friendly water serves as dissolvent, thus the emulsion is biodegradable. The emulsion is an environmentally-friendly surfactant emulsion and can serve as emulsifier, dispersant and accessory ingredient in oil fields.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

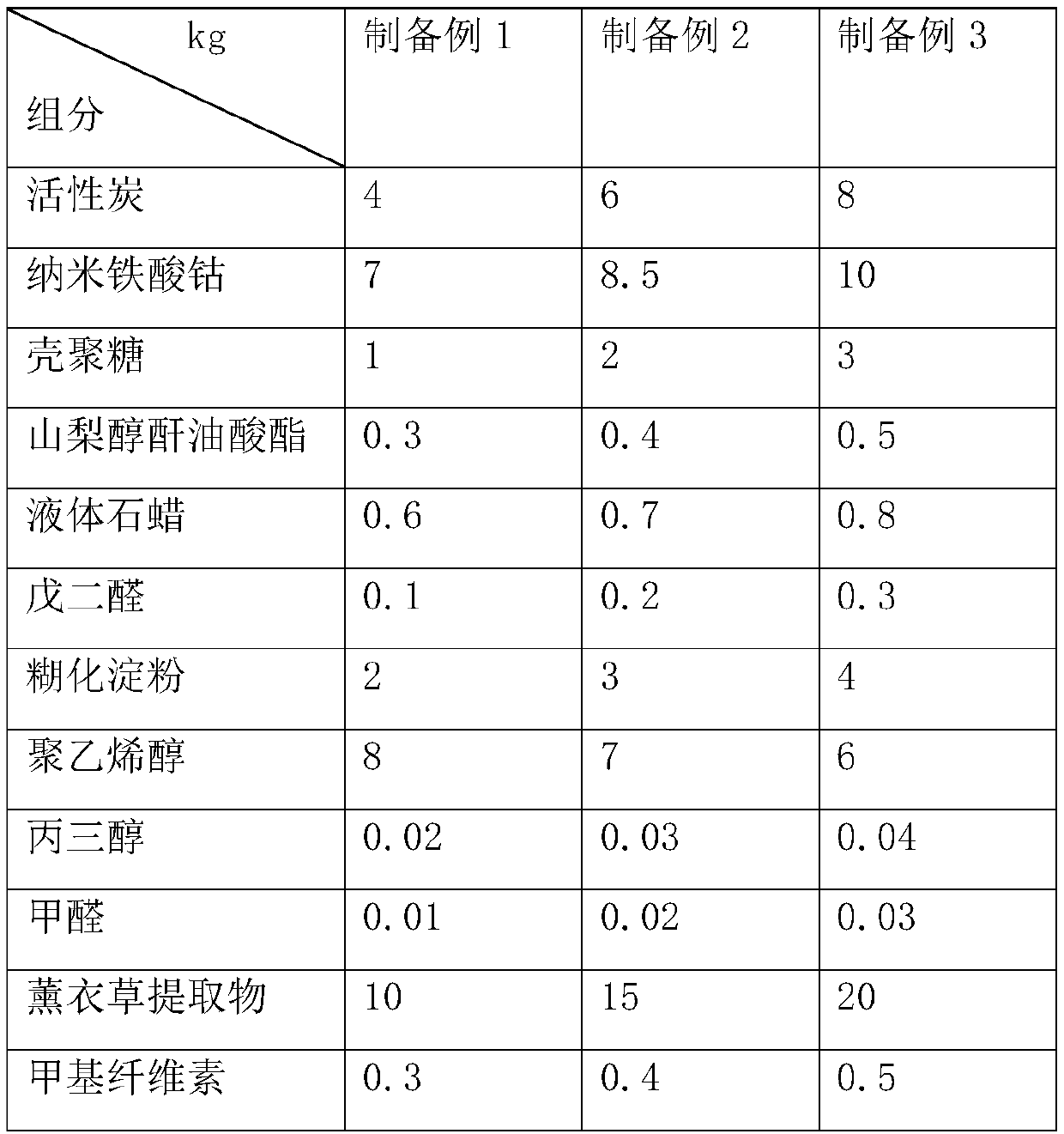

Production process of melamine-formaldehyde resin foam sponge

The invention discloses a production process of melamine-formaldehyde resin foam sponge. The production process comprises the following steps: melamine and paraformaldehyde are taken and mixed evenly; the mixed material is conveyed into a first screw machine by a material pump, and lye is added at a feed inlet of the first screw machine; an auxiliary material solution is added to the feed end, the middle position or the tail end of the first screw machine; transparent resin extruded from an outlet of the first screw machine enters a second screw machine to be subjected to a polymerization reaction continuously in the second screw machine; the transparent resin discharged out of the tail of the second screw machine enters a third screw machine after passing through a cooling device; a foaming agent, an emulsifier, a stabilizer and a curing agent are fed from the middle of the third screw machine and mixed with the resin uniformly; the resin mixed uniformly is introduced into a microwave foaming furnace for foaming, and the melamine-formaldehyde resin foam sponge with high aperture ratio is formed. The production process of the melamine-formaldehyde resin foam sponge has high utilization rate and high yield, the melamine-formaldehyde resin foam sponge with stable production quality can be produced continuously, and the aperture ratio is high.

Owner:郑州峰泰纳米材料有限公司

High-efficiency thick oil viscosity reducer and preparation method thereof

PendingCN110144205AStrong penetrating powerHigh affinityDrilling compositionOil viscositySurface-active agents

The invention discloses a high-efficiency thick oil viscosity reducer and a preparation method thereof, and belongs to the technical field of fossil fuel exploitation. A catalytic additive for preparing the high-efficiency thick oil viscosity reducer is prepared by taking zeolite as a raw material, and catalytic hydrogenation is carried out on a colloid to destroy the three-dimensional associationnetwork structure of the colloid, so that viscosity-reducing substances can well permeate. A surface active agent for preparing the high-efficiency thick oil viscosity reducer is prepared by taking chloropropyl trichlorosilane as a raw material, and the obtained siloxane and quaternary ammonium salt monomers are used for quick oil-in-water emulsification. A steric hindrance expanding additive forpreparing the high-efficiency thick oil viscosity reducer increases dispersion performance, so that viscosity reduction efficiency of thick oil is improved. According to the invention, acrylamide, acrylic acid and monomer alkyl acrylamide are added, so that the viscosity reducer has relatively good salt resistance and temperature resistance. The colloid in the thick oil is subjected to catalyticcracking through the catalytic additive, so that usability of the thick oil viscosity reducer in a high-mineralization state is improved. The invention solves the problem that viscosity reduction efficiency of an existing thick oil viscosity reducer is low.

Owner:陈光辉

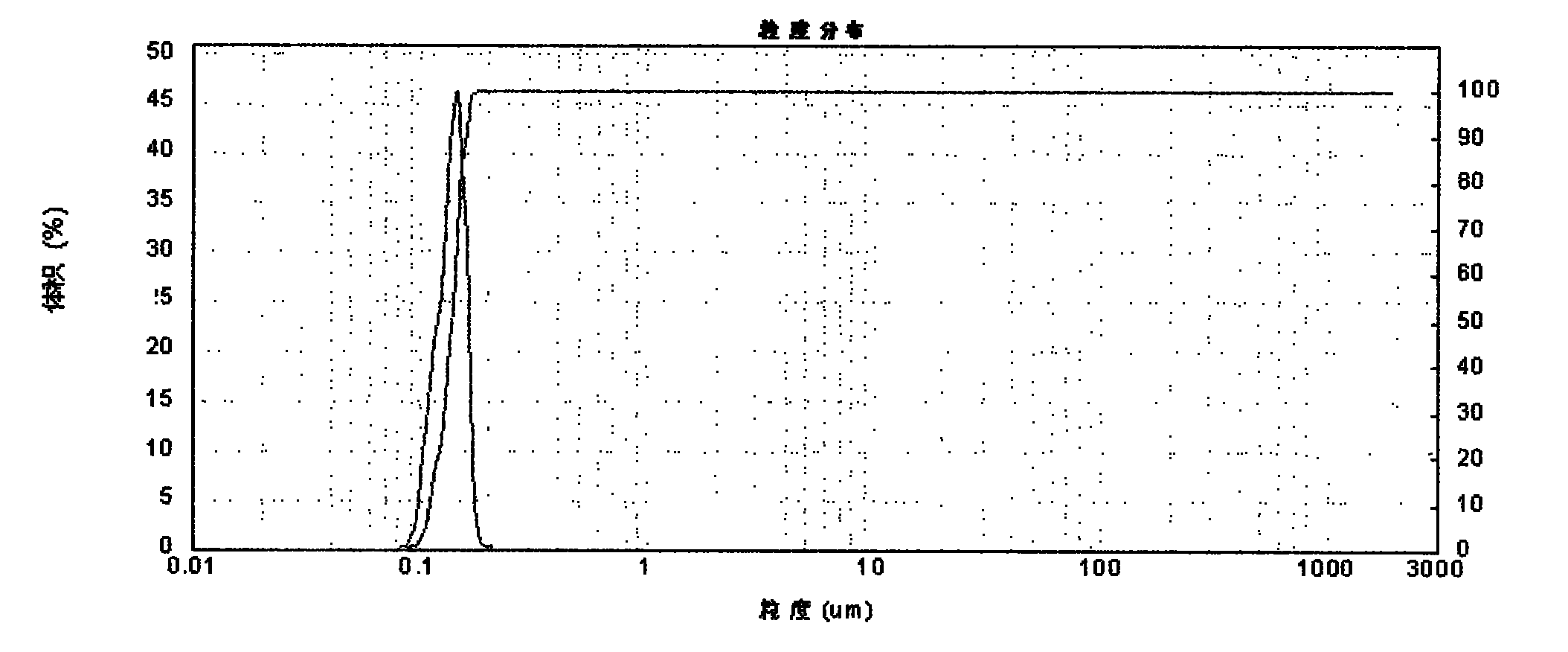

Manufacture of stable low particle size organopolysiloxane emulsion

ActiveUS7745533B2Shorten the timeEasy to adaptMaterial nanotechnologyOther chemical processesPolymer scienceEmulsion

Stable high viscosity organopolysiloxane emulsions with particle sizes up to 150 nanometer may be made in a simple and cost-effective manner employing a standard homogenizer, and optional subsequent polymerization of the organopolysiloxan at controlled temperature. A combination of non-ionic emulsifier together with an at least one anionic emulsifier is employed, having an HLB value 12-15, while maintaining a temperature up to 50° C.

Owner:WACKER CHEM GMBH

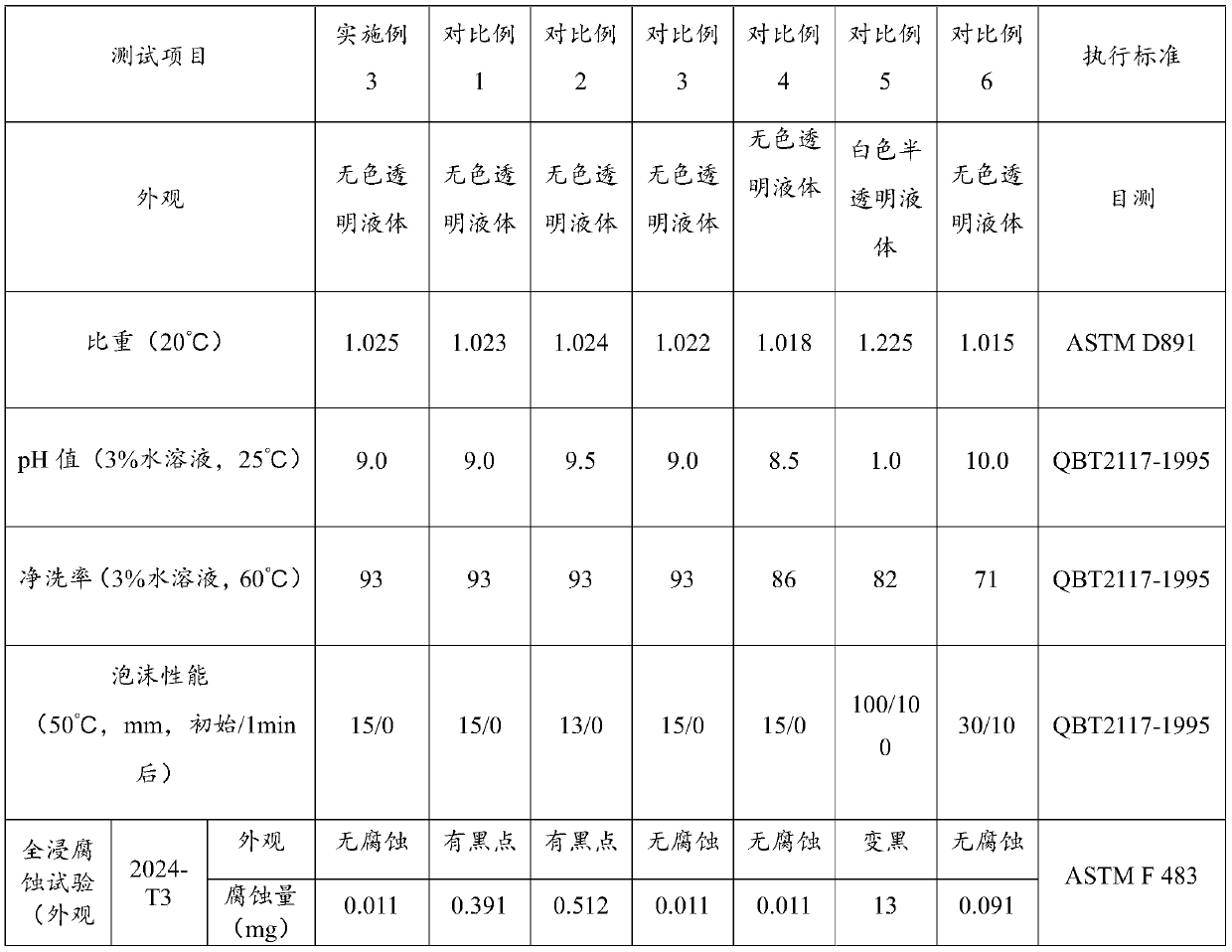

Multifunctional cleaning agent for aviation aluminum material and preparation method

The embodiment of the invention provides a multifunctional cleaning agent for an aviation aluminum material and a preparation method. A metal corrosion inhibition system in the multifunctional cleaning agent can provide powerful protection for the aviation aluminum material, an adopted surfactant system can rapidly strip and emulsify oil stains, an adopted auxiliary system can organically combinetwo contradictory systems of cleaning and corrosion inhibition so that all the system components in the product system can effectively play respective roles, multiple cleaning modes such as spray cleaning, ultrasonic cleaning and bubbling cleaning can be adopted for use, the application range is wide, the application method is flexible and diversified, the cleaning agent has a good cleaning effecton grinding oil, cutting fluid, metal dust and the like in the production and machining process of various metal equipment, subsequent surface treatment is not affected, and a certain antirust function is achieved.

Owner:长沙艾森设备维护技术有限公司

Process for producing melamine foam sponge

The invention discloses a process for producing melamine foam sponge, comprising the steps of mixing well melamine and paraformaldehyde; pumping the mixture to a first screw unit by a material pump, and adding alkali liquid to a feed port of the first screw unit; adding auxiliary solution to the feed end, middle or tail end of the first screw unit; feeding to a second screw unit, transparent resin extruded from an outlet of the first screw unit, and continuing polymerization in the second screw unit; allowing transparent resin from the tail of the second screw unit to pass through a cooling device and then enter a third screw unit; introducing a foaming agent, an emulsifying agent, a stabilizer and a curing agent from the middle of the third screw unit, and mixing well with the resin; introducing the mixed resin to a microwave foaming furnace for foaming to form high-porosity melamine foam sponge; the process of the invention makes high use of materials, has high yield, and can provide continuous production of melamine foam sponge with stable quality and high porosity.

Owner:郑州峰泰纳米材料有限公司

Skin cleaning composition as well as preparation method and application thereof

The invention discloses a skin cleaning composition as well as a preparation method and application thereof. The skin cleaning composition comprises the following components in parts by weight: 10-30 parts of natural grease, 10-80 parts of synthetic ester, 10-80 parts of polyhydric alcohols and 0.5-5 parts of an emulsifier. The cleansing composition disclosed by the invention can realize temperature-sensitive makeup removal, is fresh and non-irritant, has strong makeup removal capability, is convenient to use, has the advantages of moisture retention after washing, does not have bitter taste similar to EO-series surfactants in commercially available makeup removal products, is soft in taste, and can be safely applied to faces, eyes and lips. When the skin cleaning composition is smeared, the skin is slightly massaged, the temperature of the skin is raised, so that pores are opened, the skin fitting effect is good, cosmetics are rapidly dissolved and dirt in the pores is thoroughly removed by utilizing the rolling-up effect of gel, the skin cleaning composition can be rapidly emulsified and extremely easy to wash when being wetted by adding water, and the dirt and cosmetics residues are rapidly taken away through water flow and are completely removed.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Emulsifier making AKD glue fast cured

InactiveCN105088861AGood gelGood film formingWater-repelling agents additionAluminium chlorohydrateEmulsion

The invention discloses an emulsifier making AKD glue fast cured. The emulsifier is composed of 2-8% of modified starch, 15-25% of aluminium polychlorid, 20-35% of modified polyamide epichlorhydrin resin, 30-45% of acrylamide, 1-2% of PH modifier and 2-4% of anti-sticking cross-linking agent. Compared with the prior art, the emulsifier has the advantages that safety is achieved, toxins do not exist, the environment cannot be polluted, intermediate-alkaline glue can be fast emulsified, the curing speed is higher, the water resistance is enhanced, and the stability and the gluing efficiency of a prepared AKD emulsion are obviously improved.

Owner:HEFEI LONGFA PACKING CO LTD

Thick oil emulsifying viscosity breaker for tracing steam, and preparation method and application method thereof

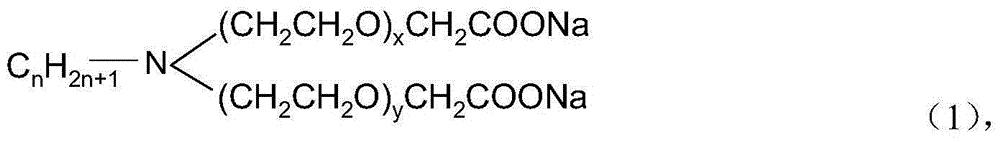

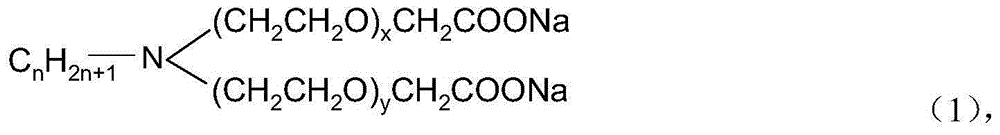

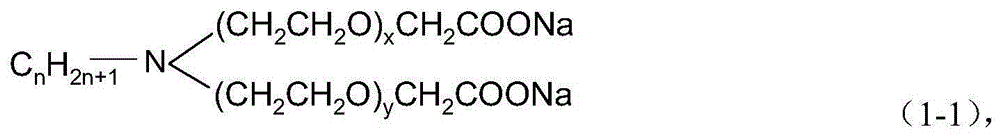

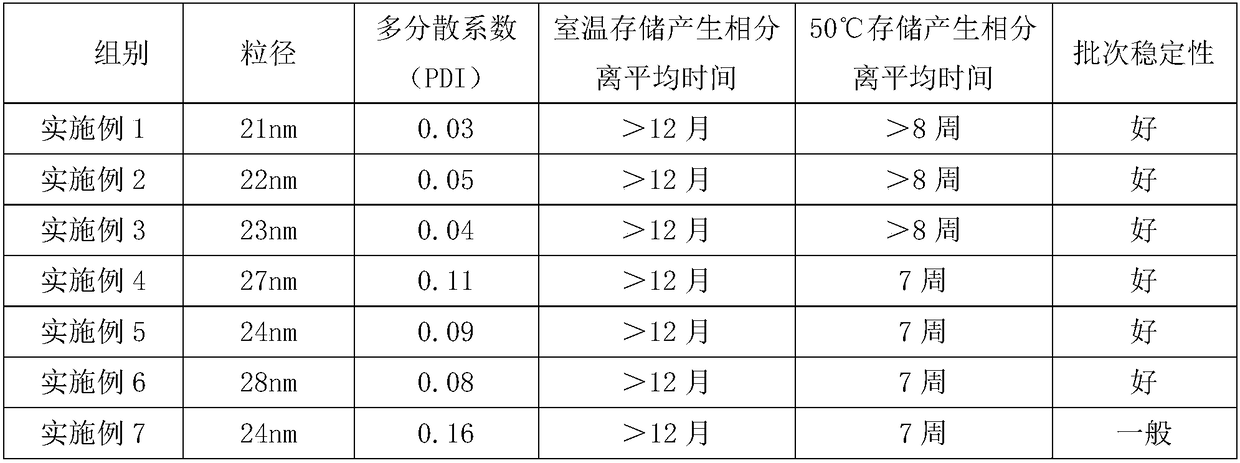

The invention discloses a thick oil emulsifying viscosity breaker for tracing steam, and a preparation method and application method thereof. The viscosity breaker comprises the following components in parts by weight: 75-80 parts of sodium fatty amine polyethenoxy ether carboxylate, 10-15 parts of alkaline assistant and 1-5 parts of small molecule alcohol. The molecular formula of the sodium fatty amine polyethenoxy ether carboxylate is disclosed as Formula (1), wherein n is any whole number ranging from 12 to 18, x is any whole number ranging from 2 to 5, and y is any whole number ranging from 2 to 5. The thick oil emulsifying viscosity breaker for tracing steam is compounded from the main agent sodium fatty amine polyethenoxy ether carboxylate, the synergist alkaline assistant and the penetrant small molecule alcohol with water. The obtained viscosity breaker has high temperature resistance and salt resistance, can quickly emulsify the thick oil with higher colloid asphalt content, has the advantages of favorable viscosity breaking effect and the like, and can be automatically demulsified. The thick oil emulsifying viscosity breaker for tracing steam satisfies the viscosity breaking requirements for high-temperature high-salinity high-colloid-asphalt super-thick oil, and is suitable for tracing steam injection in steam soak and steam displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

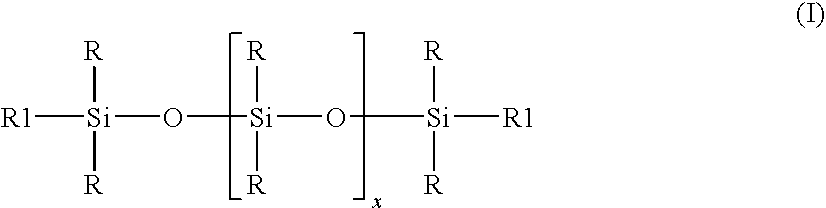

Amino silicone oil emulsion and preparation method thereof

ActiveCN108752935AFast preparationRapid preparation of small particle sizesPolyethylene glycolCocamidopropyl betaine

The invention discloses an amino silicone oil emulsion. The amino silicone oil emulsion comprises, by mass, 42-58% of amino silicone oil, 31-47% of deionized water, 6-10% of a surfactant, 3-1.1% of distearyl phosphatidyl glycerol and 0.5-5% of a pH adjuster. The surfactant comprises, by mass, 10-30% of polyethylene glycol 4000 monooleate, 40-60% of polyoxyethylene sorbitan monolaurate and 20-40% of cocamidopropyl betaine. The viscosity of the amino silicone oil is 2000-15000 mPa.s. The ammonia value is 0.2 to 0.8. The pH of the amino silicone oil emulsion is 6.5 to 7.0. The amino silicone oilemulsion is prepared from glass beads through a double-center mixing disperser, has high content of silicone oil, small particle size distribution and good storage stability and can be used in fabrictreatment.

Owner:江门市润祥纺织科技有限公司

Self-emulsification rosinyl surfactant emulsion and preparation method thereof

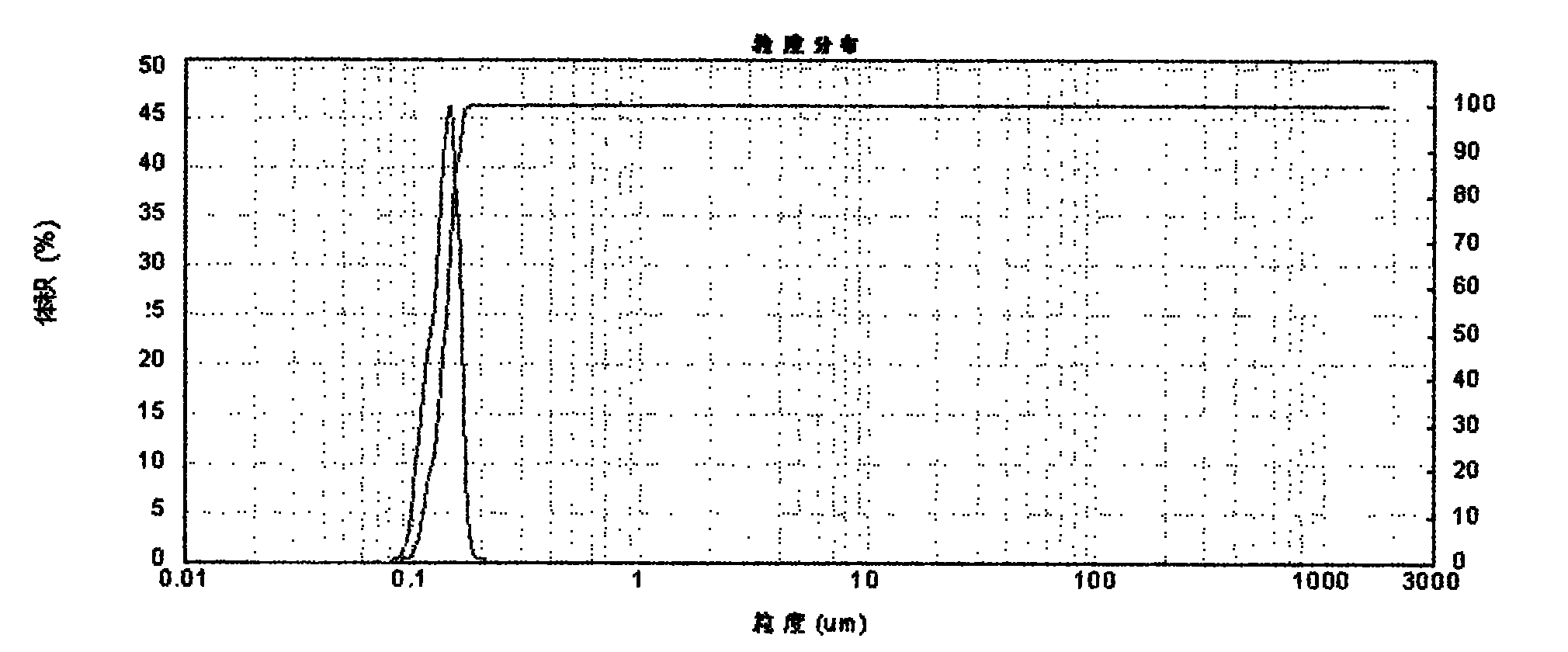

InactiveCN102039099BRapid emulsificationEasy to processTransportation and packagingMixingEmulsionPolymer science

The invention discloses a self-emulsification rosinyl surfactant emulsion and a preparation method thereof. The preparation method comprises: esterfying polyethylene glycol of low molecular weight with rosin or modified rosin to prepare rosinyl polyethylene glycol diacrylate; in the presence of emulsification-assistant agent, emulsifying the rosinyl polyethylene glycol diacrylate to prepare emulsion of which the solid content is 30-60% with a high shear apparatus. The prepared self-emulsification rosinyl surfactant emulsion has smaller parameter diameter reaching 112nm, and good stability. The emulsion has strong surface activity, raw materials are cheap and easy to obtain, and environmentally-friendly water serves as dissolvent, thus the emulsion is biodegradable. The emulsion is an environmentally-friendly surfactant emulsion and can serve as emulsifier, dispersant and accessory ingredient in oil fields.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Range hood cleaning agent and preparation method thereof

InactiveCN110317682AGood degreasing effectLess corrosiveNon-ionic surface-active compoundsOrganic detergent compounding agentsAlkylphenolCleansing Agents

The invention discloses a range hood cleaning agent and a preparation method thereof. The range hood cleaning agent is prepared from, by weight, 10-15 parts of sodium alcohol ether sulphate, 10-15 parts of alkylphenol ethoxylate, 20-25 parts of coconutt diethanol amide, 1-10 parts of octadecanol, 5-30 parts of ethylene glycol monobutyl ether, 1-10 parts of ethanol, 1-10 parts of a penetrating agent BX, 1-10 parts of sodium alpha-olefin sulfonate, 1-3 parts of D-limonene, 1-5 parts of triethanolamine, 1-5 parts of ethylenediamine tetraacetic acid disodium and 200-250 parts of deionized water. Compared with existing range hood cleaning agents, the range hood cleaning agent can rapidly swell and emulsify oil dirt and quickly remove dust, oil dirt, stains, iron rust and the like attached to kitchen appliances such as a range hood through the synergistic function of all the components, the appliances are not damaged, the corrosion is small, and the cleaning effect is good; moreover, after use, there is no chemical residues on the range hood, and the cleaning agent is non-toxic and harmless to the human body.

Owner:广州三乐环保科技有限公司

Special biodegradable cleaning agent for building roof and preparation method thereof

ActiveCN108048234AAvoid pollutionEasily biodegradableOrganic detergent compounding agentsPolymeric surface-active compoundsEmulsionCleansing Agents

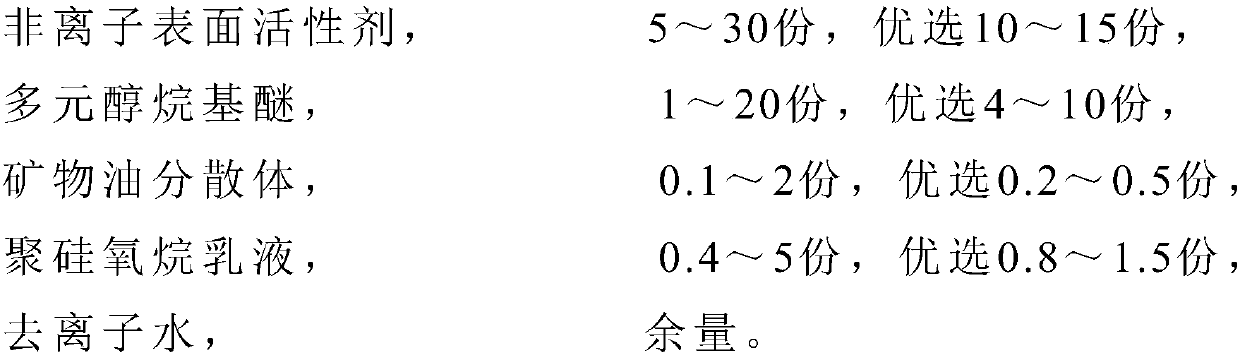

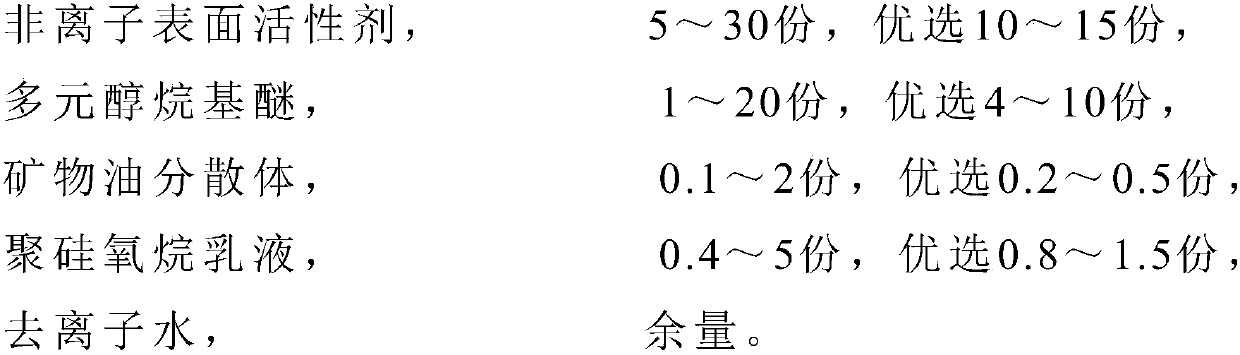

The invention provides a special biodegradable cleaning agent for a building roof and a preparation method thereof. The cleaning agent is prepared from a nonionic surfactant, polyol alkyl ether, mineral oil dispersoid, a polysiloxane emulsion, an anionic surfactant, components of hydramine compounds, and deionized water. The special biodegradable cleaning agent can rapidly and effectively remove oily dirt required to be washed in a targeted manner, can be rapidly emulsified, dispersed and dissolved in water, is nontoxic or low-toxic, does not have pungent smell, is green and environmentally friendly, has biodegradability, and is convenient to operate.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

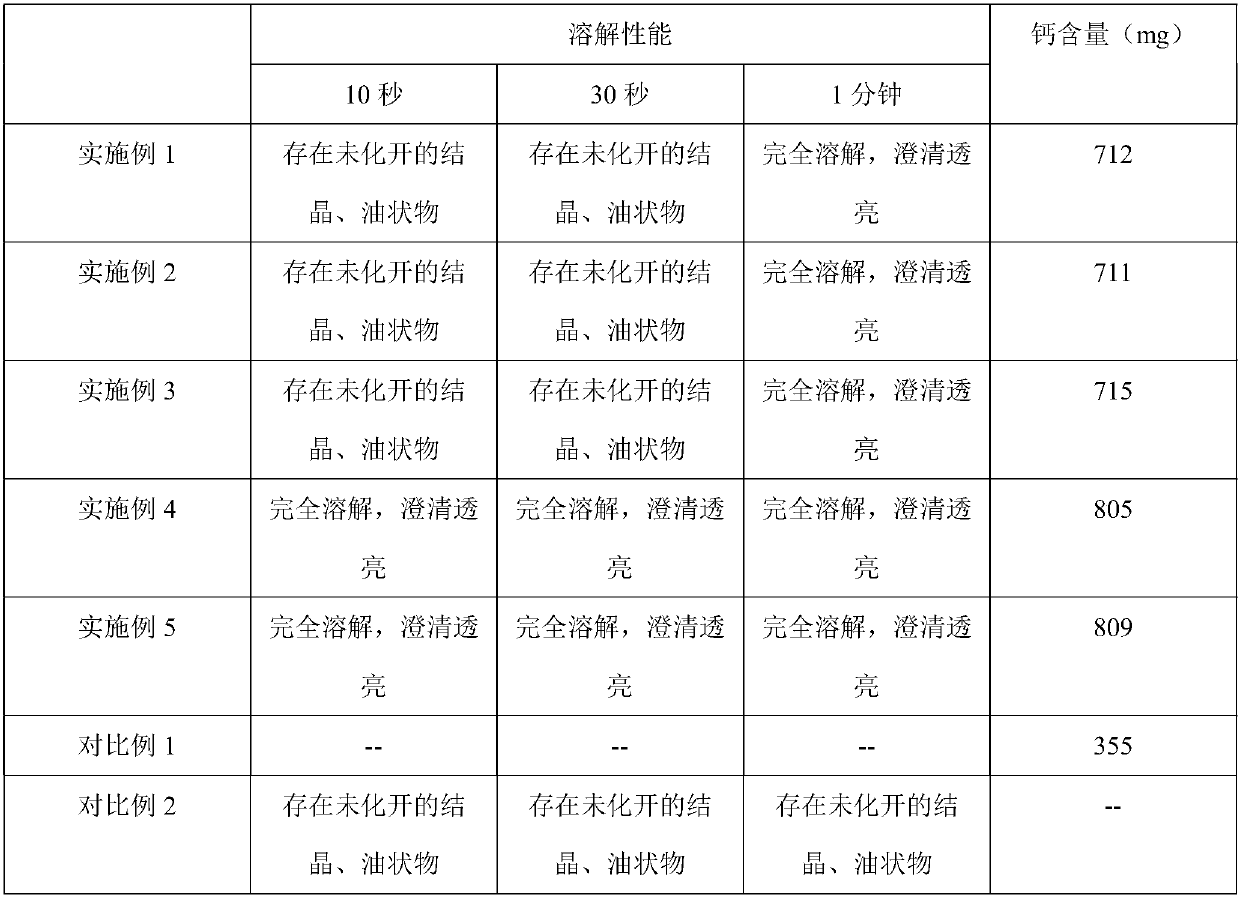

Processing technology capable of improving soup stock dissolving performance

ActiveCN111084364AGreat tasteImprove solubilityFood ingredient as taste affecting agentNatural extract food ingredientsProcess engineeringLivestock

The invention discloses a processing technology capable of improving soup stock dissolving performance. The processing technology comprises the following steps of: firstly, breaking fresh and clean livestock and poultry bones into 3-5 cm, and then, carrying out high-temperature high-pressure stewing, vacuum concentration, mixing, homogenization, sterilization, emulsification and packaging in sequence to obtain a soup stock. According to the processing technology, product dissolving performance is improved, the soup stock can quickly and completely dissolve in constant temperature water, and the taste of soup bases is improved.

Owner:临沂新程金锣肉制品集团有限公司

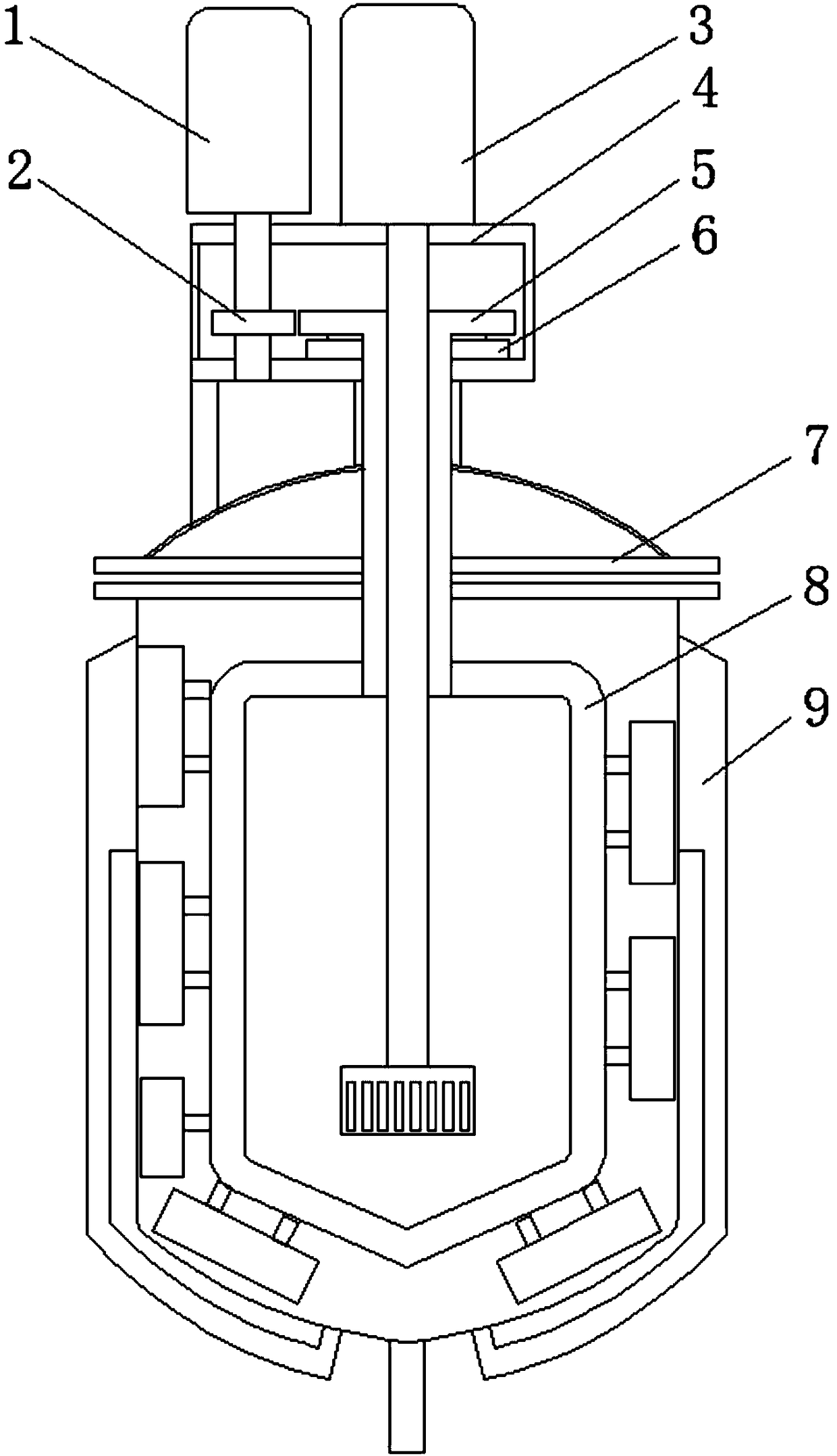

High-shear emulsifying and wall-scraping stirring device

The invention relates to a high-shear emulsifying and wall-scraping stirring device. The device comprises a reaction tank, a high-shear emulsifier, a wall-scraping stirring assembly and a stirring speed reducing motor, wherein the wall-scraping stirring assembly is arranged in the reaction tank and is connected with the stirring speed reducing motor; the high-shear emulsifier comprises an emulsifying motor and an emulsifier rotating shaft movably connected with the emulsifying motor; the wall-scraping stirring assembly comprises a stirring rotating shaft; and the emulsifier rotating shaft penetrates through the axis center of the stirring rotating shaft. Compared with the prior art, the high-shear emulsifying and wall-scraping stirring device has the advantages that the emulsifying and stirring processes are simultaneously carried out, the structure is compact, no dead corner exists in the stirring process, the mixing is relatively uniform, and the like.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

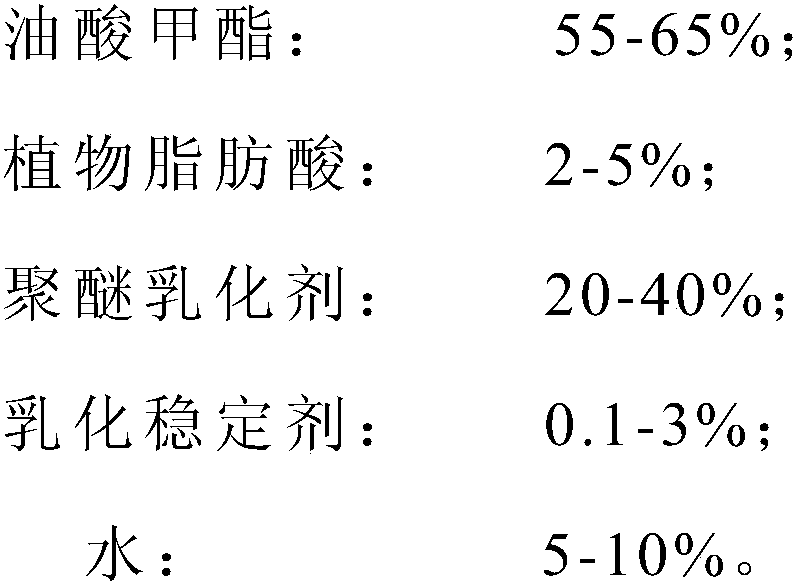

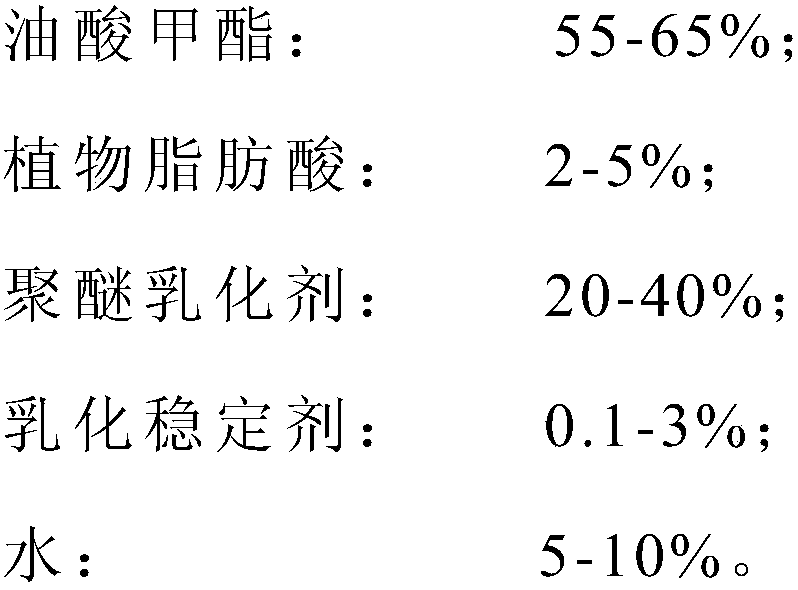

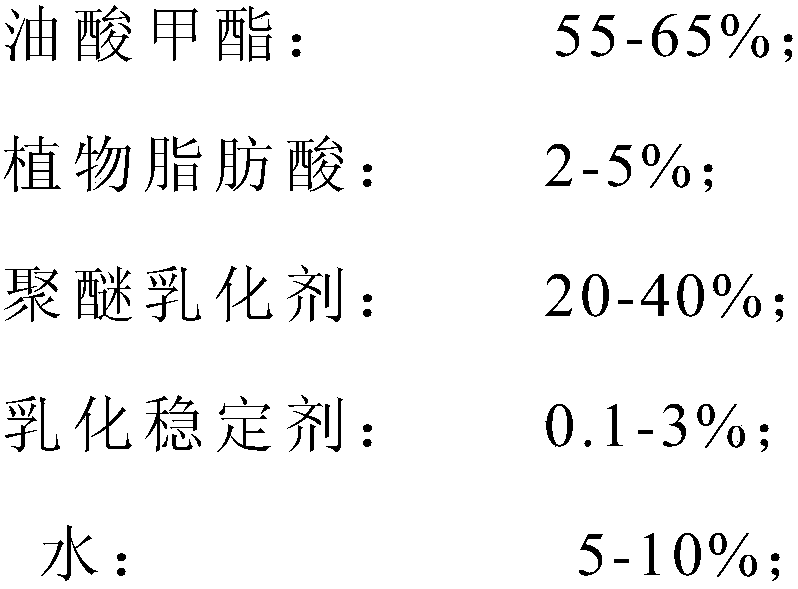

Wool lubricating oil easy to emulsify

The invention discloses wool lubricating oil easy to emulsify. The wool lubricating oil easy to emulsify is prepared from 55-65% of methyl oleate, 2-5% of vegetable fatty acid, 20-40% of polyether emulsifier, 0.1-3% of emulsion stabilizer and 5-10% of water. The wool lubricating oil has high content of methyl oleate, and has good lubricity, bundling performance, antistatic performance, easy-cleaning performance and the like; alkyl phenol surfactants are not utilized, and the wool lubricating oil is more environmentally friendly; stirring is not needed even if the wool lubricating oil is prepared with water at 0 DEG C, the wool lubricating oil is emulsified quickly, emulsified liquid is stable, and the non-delamination state can be maintained for 48 h.

Owner:苏州禾川化学技术服务有限公司

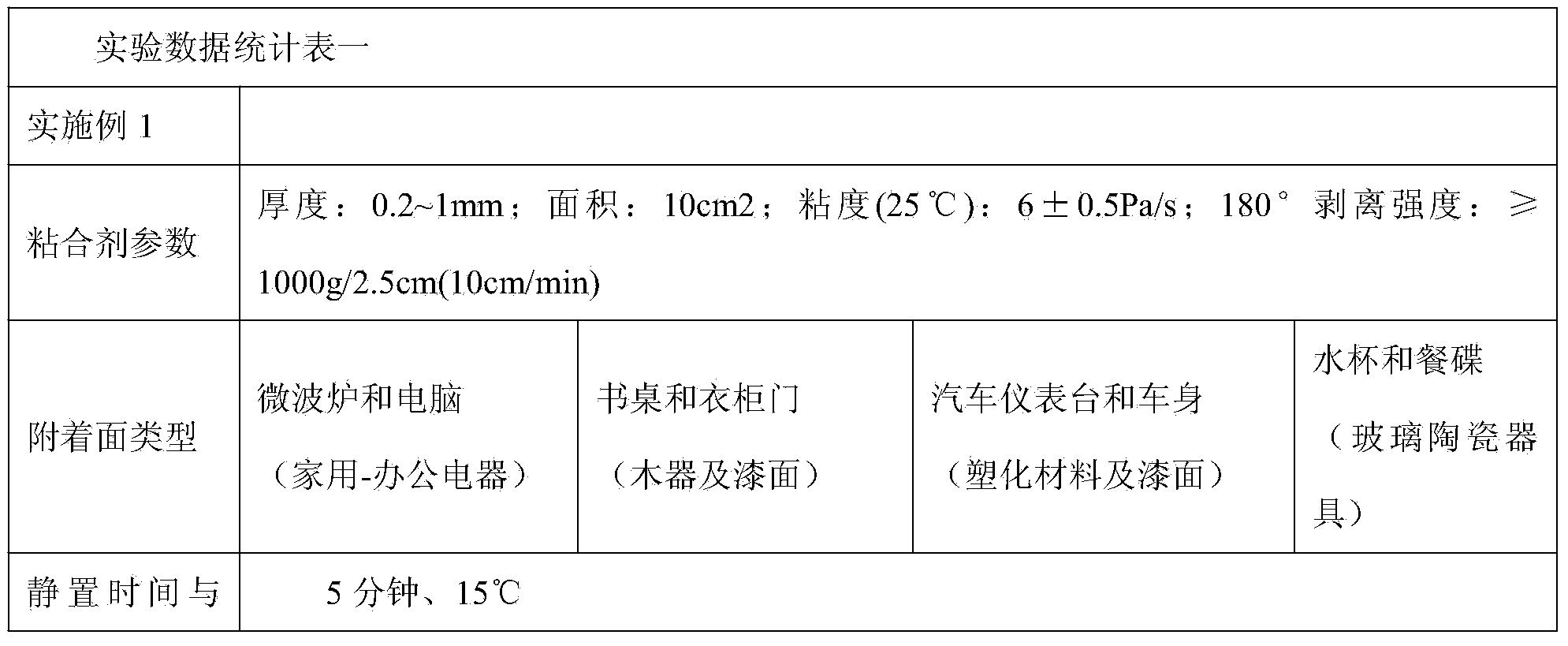

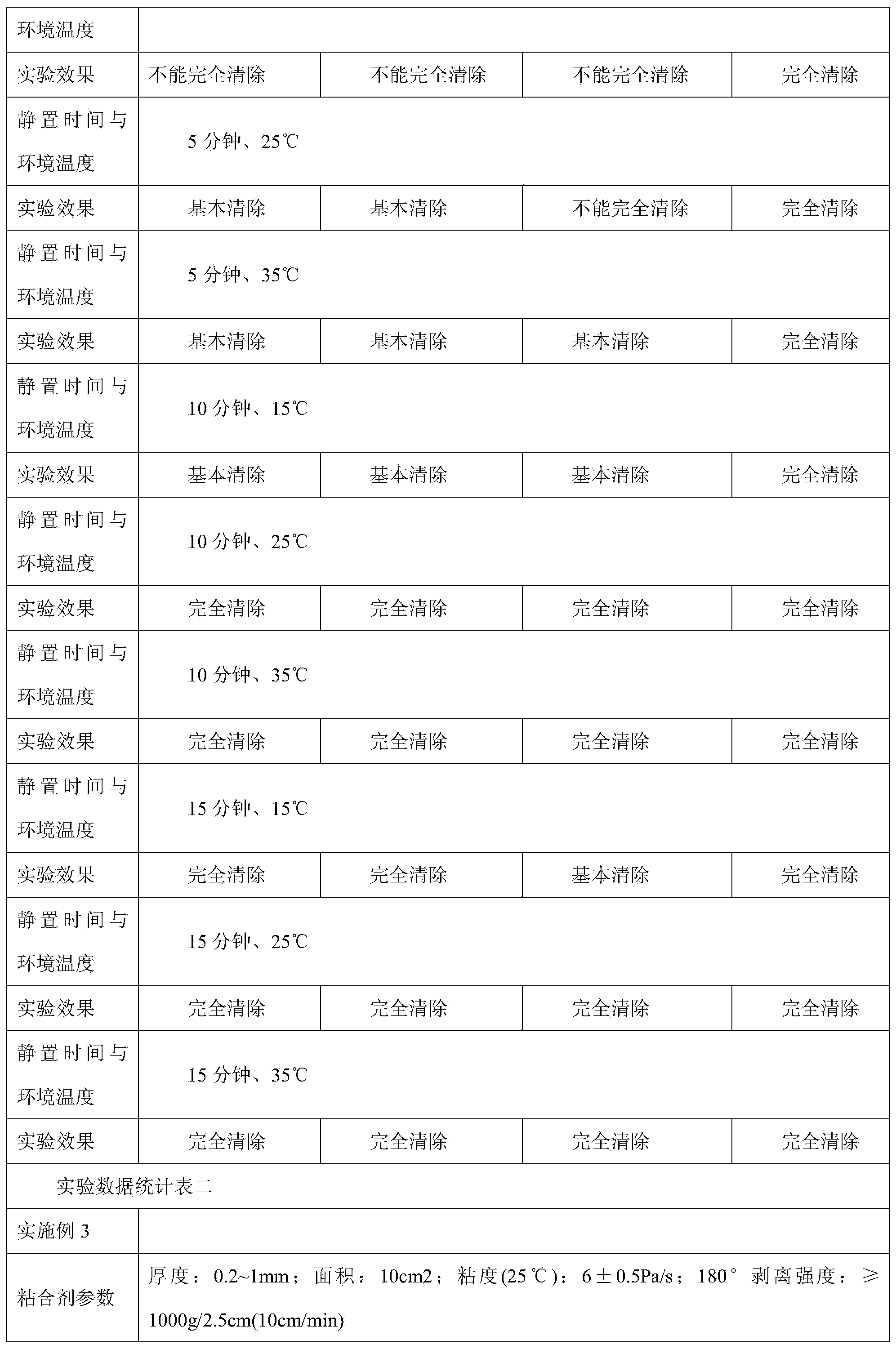

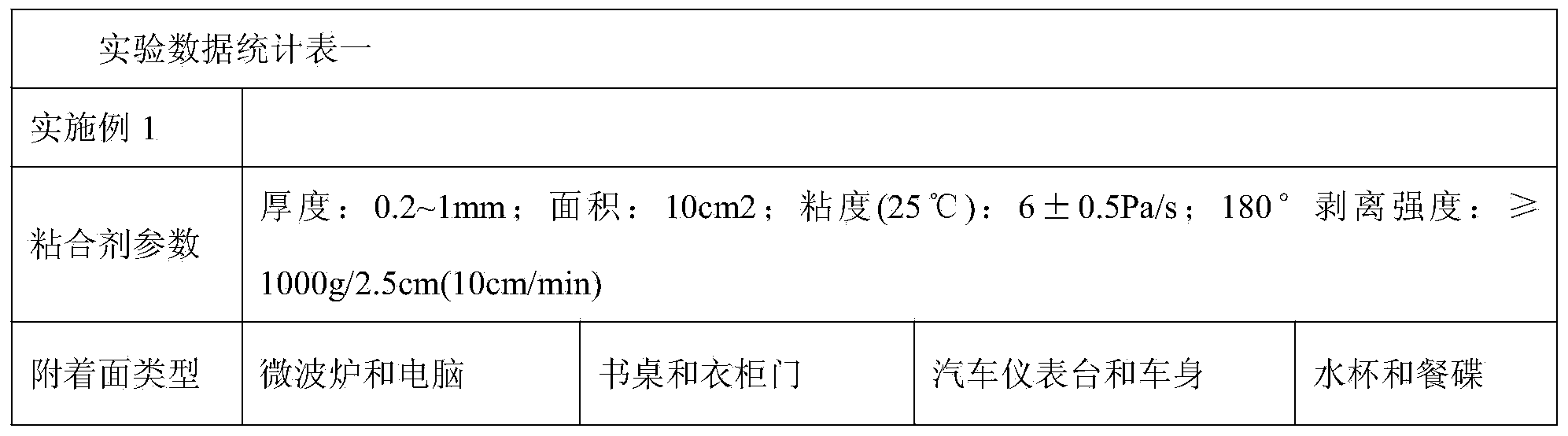

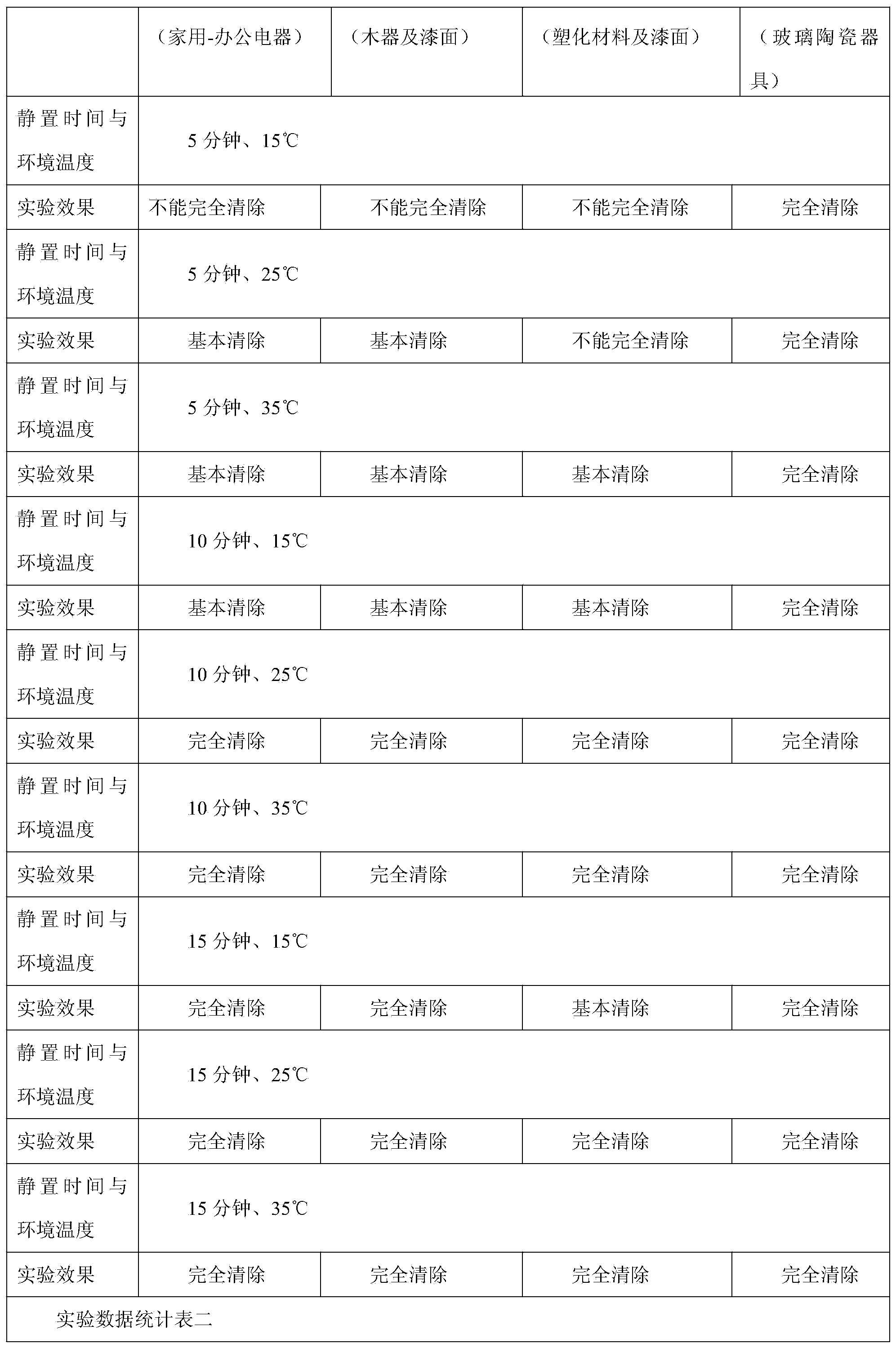

Adhesive residue detergent of adhesive sticker and production process of adhesive residue detergent

ActiveCN103849496AGood decontaminationFine foamOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsChemistrySURFACTANT BLEND

The invention discloses an adhesive residue detergent of an adhesive sticker and a production process of the adhesive residue detergent, and aims to provide the detergent which is environment-friendly, good in formula and simple in production process and can effectively eliminate adhesive residues of the adhesive sticker on various apparatuses as well as the production process of the detergent. The residual adhesive residue detergent of the adhesive sticker is technically characterized by being prepared from the following components in percentage by mass: 0.001-0.1% of gummy substance control enzyme, 50-90% of deionized water, 5-40% of sulphobetaine surfactant, 0.5-20% of cocamidopropyl dimethylamine oxide, 0.1-0.5% of preservative and 0.1-1% of essence, totaling 100%. The invention belongs to the technical field of detergents.

Owner:广州麦饭石化工技术有限公司

Preparation method for AKD gel emulsifier

InactiveCN105113327AReduce product costImprove water resistanceWater-repelling agents additionCoatingsEmulsionChemistry

The present invention discloses a preparation method for an AKD gel emulsifier. The method mainly comprises the main steps: modification of polyamide epichlorohydrin resin and reaction between modified starch and other raw materials in a specific condition to obtain the emulsifier. Compared to the prior art, the preparation method disclosed by the present invention has the following advantages that the preparation method is simple, safe and non-poisonous, so that no environmental pollution is caused; a neutral-basic gel can be emulsified rapidly, the aging speed is faster and the water resistance is strengthened, and the stability and the sizing efficiency of the prepared AKD emulsion are significantly improved.

Owner:HEFEI LONGFA PACKING CO LTD

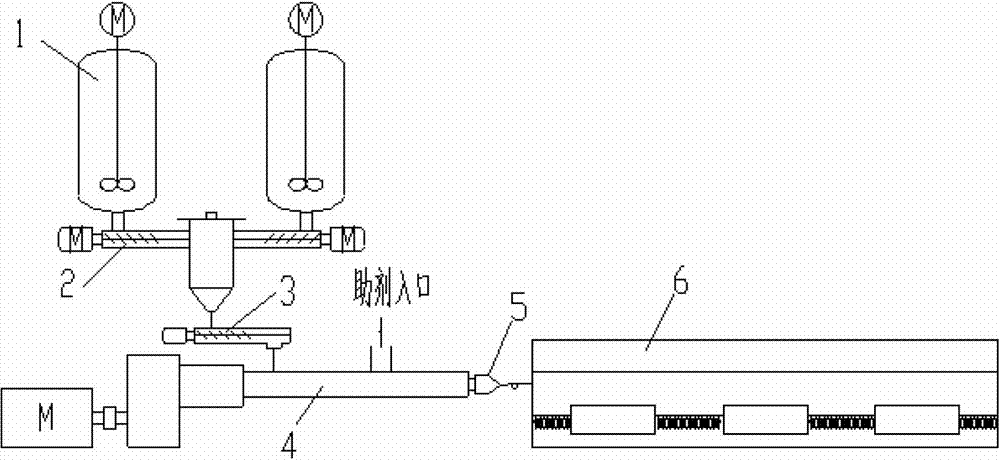

Device and process for preparation of melamine formaldehyde foam

InactiveCN104325648ATimely and effective removalContinuous productionDomestic articlesMelamine formaldehydeEngineering

The invention discloses a device and process for preparation of melamine formaldehyde foam, the device comprises melamine reactors, a single screw extruder, a metering feeder, a reaction type twin-screw extruder, a sheet machine head and a microwave foaming device, which are connected in sequence, the number of the melamine reactors is two, and the melamine reactors are arranged in parallel. The device can effectively and timely remove a large amount of heat of reaction when melamine and formaldehyde react, so that the reaction is performed in a smooth and controlled manner, and a melamine formaldehyde foam product with stable quality can be continuously produced.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Traditional Chinese medicine washing agent

InactiveCN104498224AReduce harmProtection securitySurface-active non-soap compounds and soap mixture detergentsCamellia oleiferaChemical composition

The invention relates to the field of treatment, disinfection and washing, and concretely relates to a traditional Chinese medicine washing agent. The traditional Chinese medicine washing agent comprises 300-500 parts by mass of a nanometer oil-removing emulsifier, 40-60 parts by mass of Chinese soapberry fruit, 20-30 parts by mass of fatty-oil-removed residue of camellia oleifera seed, 10-20 parts by mass of gleditsia sinensis, and 30-50 parts by mass of radix stemonae. The composition is prepared by mixing the above compositions according to the above ratio, and causes much smaller damage to human body skin compared with common washing agents in the market. Because the above compositions and ratio are employed, the prepared washing agent is capable of protecting safety of contacted people. Because multiple traditional Chinese medicine compositions are employed, the traditional Chinese medicine compositions give play to alleviating effect on damage of chemical compositions in the washing agent to human body, and also have the effect of cleaning spots.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Shampoo mousse composition and preparation method and application thereof

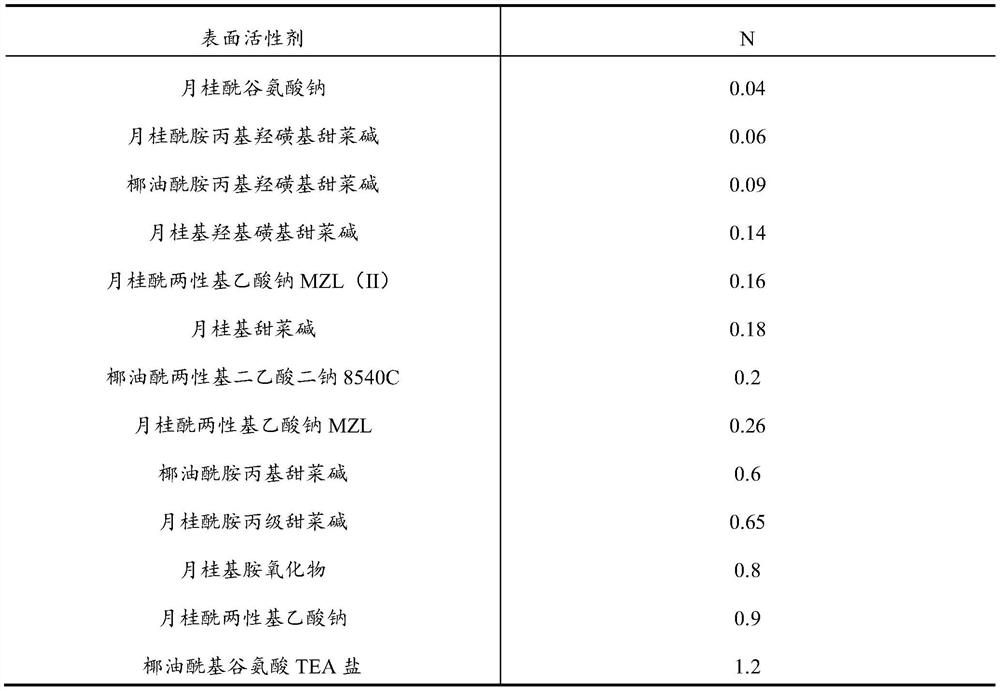

ActiveCN112370393AStir wellRapid emulsificationCosmetic preparationsHair cosmeticsCocoyl glutamateActive agent

The invention discloses a shampoo mousse composition and a preparation method and application thereof, and relates to the technical field of daily cosmetics. The shampoo mousse composition comprises asurfactant compound and an active ingredient nano-liposome, wherein the surfactant compound comprises cocamidopropyl hydroxysulfobetaine, sodium lauroyl sarcosine, sodium lauroyl glutamate, cocoyl glutamate TEA salt, cocoyl alanine TEA salt and sodium methyl cocoyl taurate; and the active ingredient nano-liposome comprises a hypecoum extract, fructan, a houttuynia cordata extract and a sodium cocoyl amino acid / sarcosine / potassium aspartate / magnesium aspartate compound. Shampoo mousse prepared from the shampoo mousse composition is free of irritation to the skin, can go deep into hair follicles and has a good repairing effect on the scalp.

Owner:泉后(广州)生物科技研究院有限公司

Adhesive sticker blot cleaning agent based on biological enzyme technology and production technology thereof

ActiveCN103834491AReduce viscosityReduce surface tensionAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsCocamidopropyl dimethylaminePreservative

The invention discloses an adhesive sticker blot cleaning agent based on a biological enzyme technology and a production technology thereof, and aims to provide a cleaning agent being environmental-friendly in formula, simple in a production technology and capable of effectively eliminating adhesive sticker blots on various appliances and the production technology thereof. The cleaning agent is technically characterized in that the adhesive sticker blot cleaning agent based on the biological enzyme technology is prepared from the following components in percentage by mass: 0.001%-0.1% of gummy substance control enzyme, 50%-90% of deionized water, 5%-40% of cocamidopropyl betaine, 0.5%-20% of cocamidopropyl dimethylamine oxide, 0.1%-0.5% of preservative and 0.1%-1% of essence, wherein the sum of the mass percent of the components is 100%. The adhesive sticker blot cleaning agent belongs to the technical field of the cleaning agent.

Owner:广州麦饭石化工技术有限公司

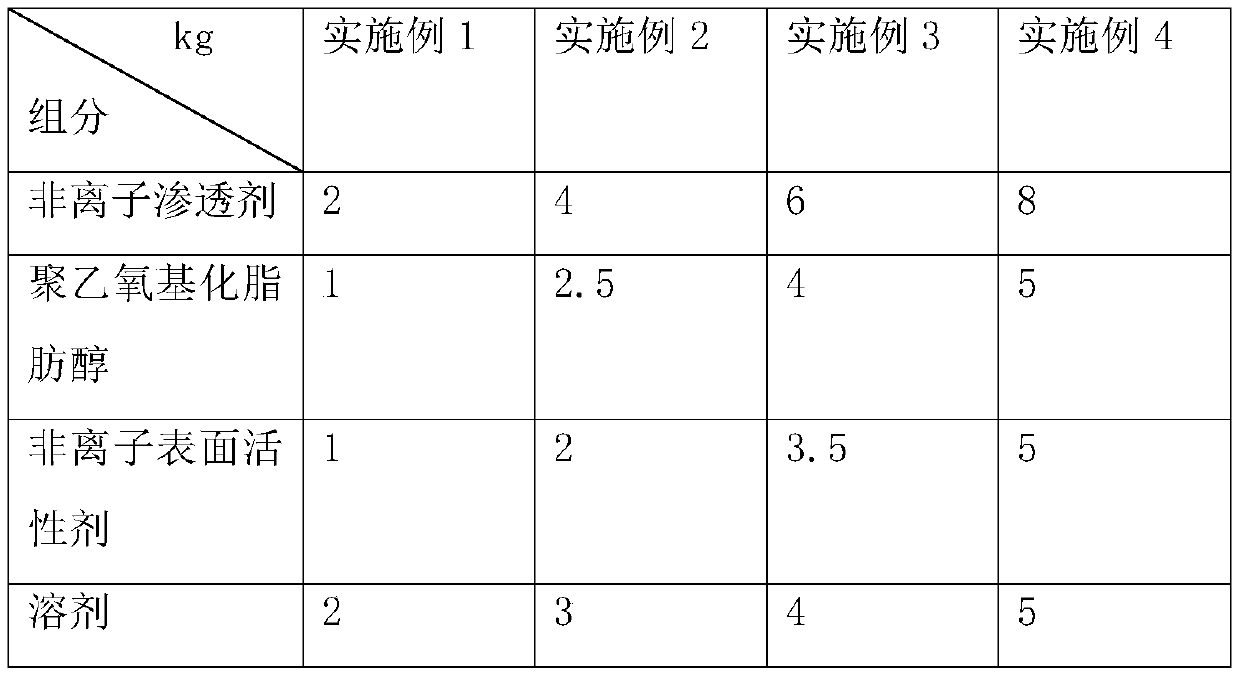

Neutral cleaning agent for range hood and preparation method thereof

ActiveCN111575120AAccelerated oil removalImprove removal efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolventActive agent

The invention discloses a neutral cleaning agent for a range hood and a preparation method thereof, and relates to the technical field of cleaning agent preparation. The neutral cleaning agent for therange hood comprises the following components in percentage by weight: 2-8% of a nonionic penetrating agent, 1-5% of polyethoxylated fatty alcohol, 1-5% of a nonionic surfactant, 2-5% of a solvent, 0.2-0.5% of sodium chloride, 0.01-0.02% of a defoaming agent, 0.1-0.3% of essence, 0.01-0.03% of a preservative, 0.01-0.03% of sodium hydroxide and the balance of softened water, wherein the nonionic penetrating agent comprises a KOC type efficient low-foam nonionic penetrating agent, the polyethoxylated fatty alcohol comprises AEO5-80, and the nonionic surfactant comprises an HSN38 type strippingagent. The neutral cleaning agent for the range hood has the advantages of mildness, no stimulation, capability of protecting the range hood and two hands from being corroded during cleaning, short effect taking time, high decontamination rate and long peculiar smell removal time.

Owner:北京金鱼科技有限责任公司

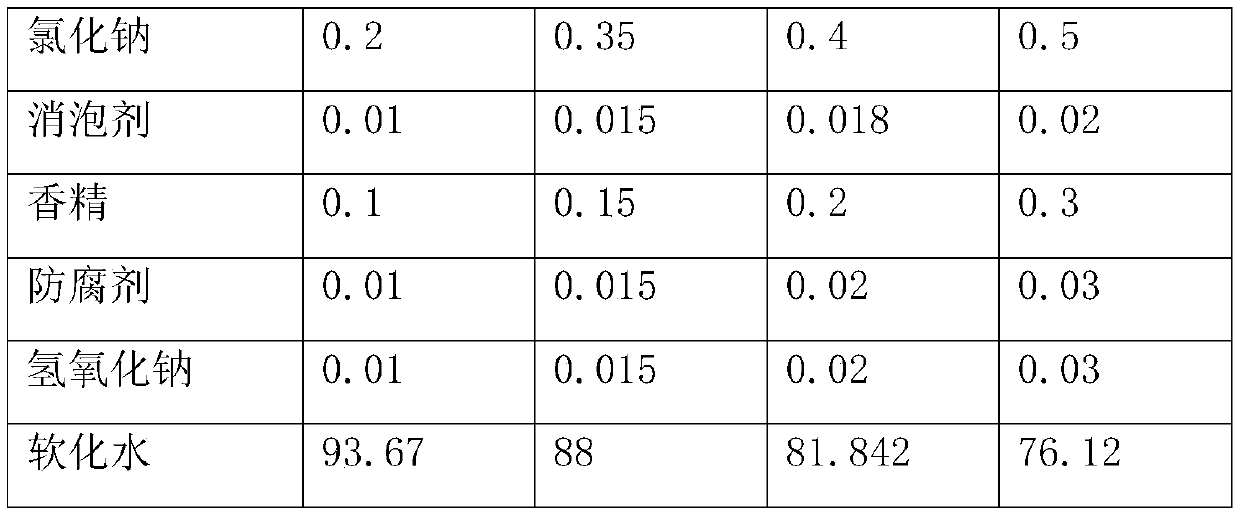

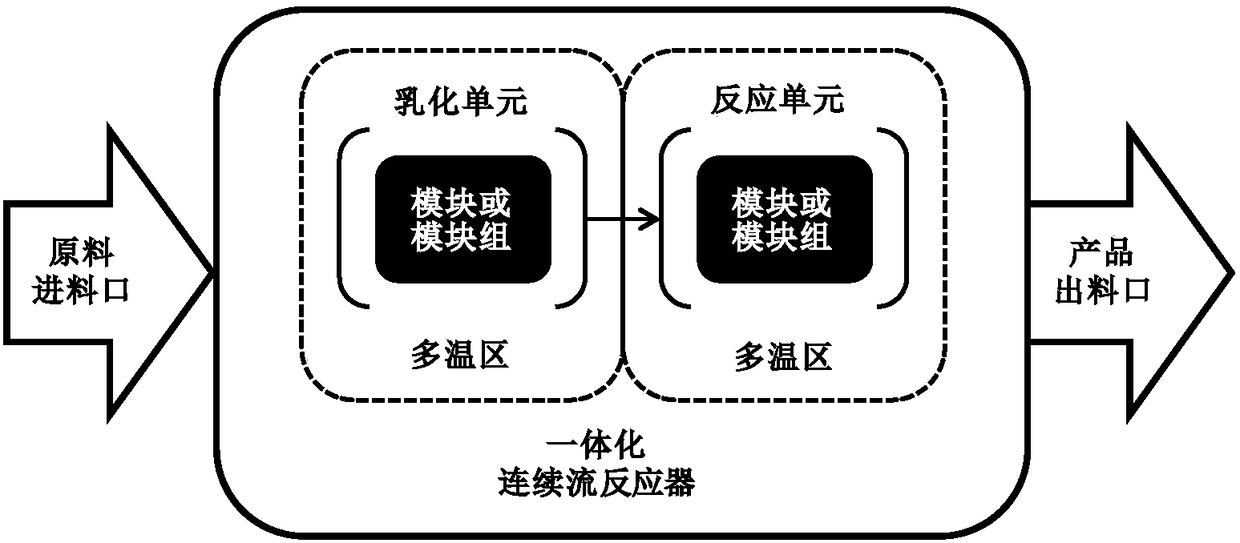

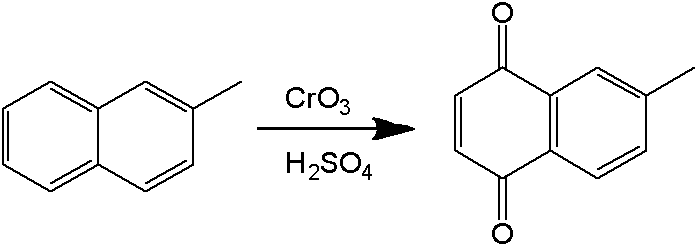

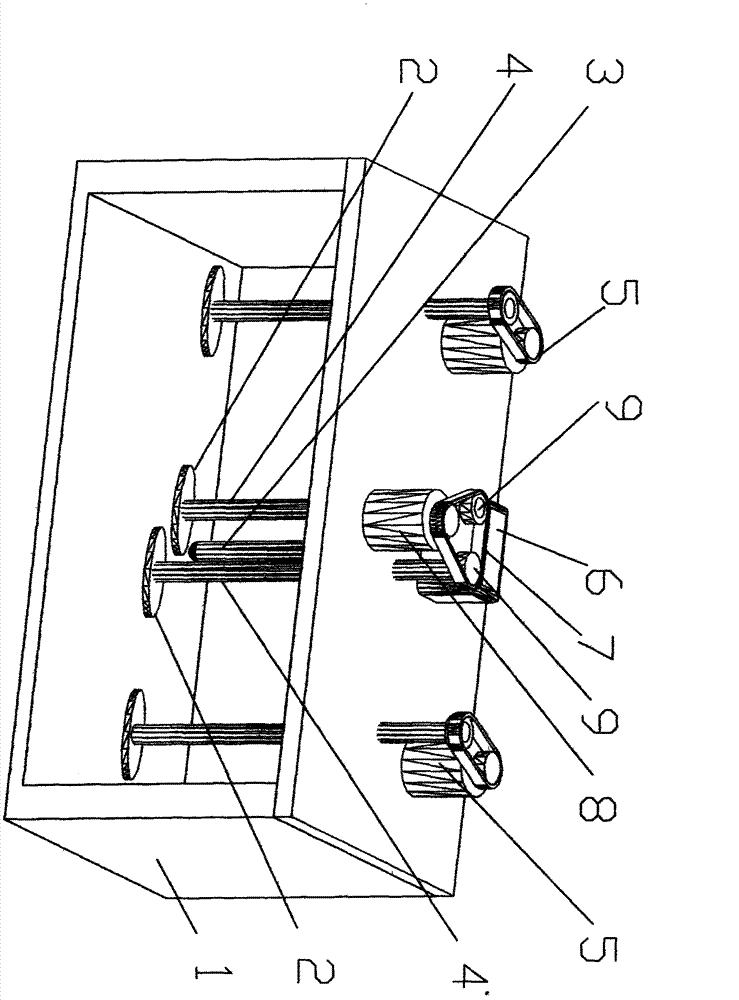

Full continuous flow synthesis process for 2-methyl-1,4-naphthoquinone

ActiveCN108299177ATotal reaction time shortenedIncrease productivityQuinone preparation by oxidationEmulsionNaphthoquinone

The invention relates to a full continuous flow synthesis process for 2-methyl-1,4-naphthoquinone and an integrated continuous flow reactor for implementing the process. According to the synthesis process, 2-methylnaphthalene, an emulsifying agent solution, a sodium dichromate solution and a sulphuric acid solution are taken as raw materials; the synthesis process is performed in the integrated continuous flow reactor; the 2-methylnaphthalene, the emulsifying agent solution, the sodium dichromate solution and the sulphuric acid solution are added into a feeding port of the integrated continuous flow reactor uninterruptedly; continuously performing transient emulsion process and oxidation process, then the 2-methyl-1,4-naphthoquinone is uninterruptedly obtained at a discharging port of theintegrated continuous flow reactor; the reaction time is less than or equal to 700 seconds. The process is a continuous synthesis process for the 2-methyl-1,4-naphthoquinone, which is quick, safe, high in efficiency and high in universality, and facilitates large-scale production.

Owner:SHANGHAI HYBRID CHEM TECH

Mud-modifying equipment with physical method

InactiveCN102777143AImprove performanceImprove solubilityRotary stirring mixersMechanical vibrations separationImpellerDrive wheel

The invention relates to mud-modifying equipment with a physical method, which is matched with petroleum drilling for use. Two stirrers are arranged in the left and the right of a mud pit, and a chemical auxiliary is added into mud. Two dispersing shafts are arranged in the middle part of the mud pit, the lower end of each dispersing shaft is provided with an impeller, and the upper end of each dispersing shaft is provided with a driving wheel. A dispersing motor is arranged on the middle part of the mud pit and is in driving fit with the two driving wheels through driving belts. Meanwhile, an ultrasonic generator is arranged on the middle part of the mud pit, and the transmitting terminal of the ultrasonic generator penetrates into the bottom of the mud pit. When the equipment works, through ultrasonic waves and the rotary impellers on the two dispersing shafts, mud is subjected to cavitation vibration in solid phase and liquid phase interfaces, so that the mud liquid is dissolved and emulsified further, and the purpose that the mud performance is improved is achieved.

Owner:马磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com