Aqueous lubricant used for papermaking, preparation method and application thereof

A lubricant and water-based technology, which is applied in the field of papermaking, can solve problems such as complex processes, and achieve the effects of simple preparation process, improved gloss, and improved smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

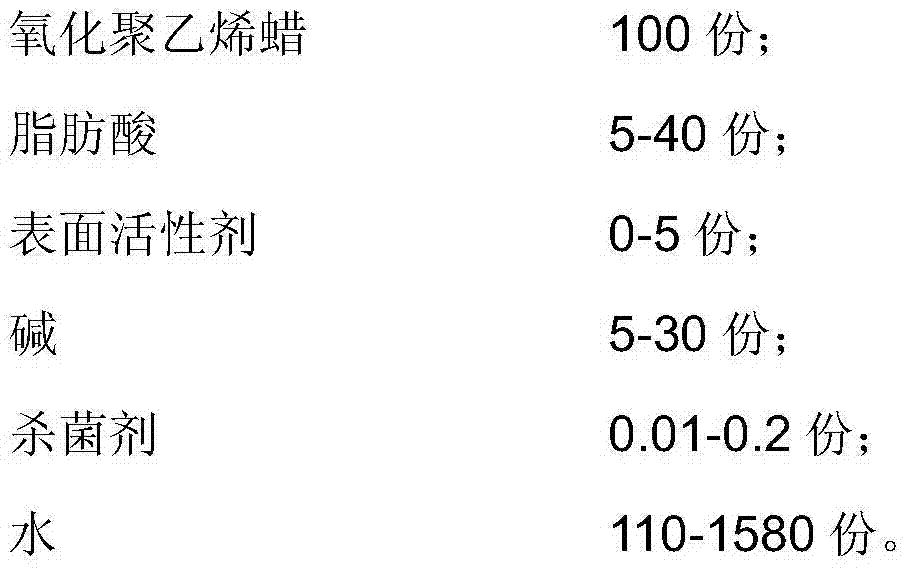

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment provides a water-based lubricant for papermaking, which is obtained according to the following steps:

[0029] (1) Add 5g of oleic acid, 5g of sodium hydroxide and 110g of deionized water into the reaction kettle, stir evenly, heat up to 98°C, and set aside;

[0030] (2) Add 100g of oxidized polyethylene wax into the reaction kettle at 130°C, melt for 0.2 hours, and set aside;

[0031] (3) Add (2) into (1) and mix evenly at 98°C while stirring, and keep warm for 0.2 hours;

[0032] (4) Cool down to 25° C., filter, add 0.01 g of bronopol, continue to stir for 10 minutes, and filter the material with a 100-mesh sieve.

[0033] The obtained water-based lubricant has a weight solid content of 49.8 wt%, a viscosity of 460 mPa·s (measured by a viscometer selected from NDJ-1), and a pH value of 6.15 (measured by a PHS-3C precision pH meter).

Embodiment 2

[0035] The present embodiment provides a water-based lubricant for papermaking, which is obtained according to the following steps:

[0036] (1) Add 40g of stearic acid, 30g of diethanolamine, 5g of sodium lauryl sulfate and 1574.8g of deionized water into the reaction kettle, stir evenly, heat up to 80°C, and set aside;

[0037] (2) At 90°C, add 100g of oxidized polyethylene wax into the reaction kettle, melt for 2 hours, and set aside;

[0038] (3) Add (2) into (1) and mix evenly at 80°C while stirring, and keep warm for 2 hours;

[0039] (4) Cool down to 25° C., filter, add 0.2 g of 2-methyl-4-isothiazolin-3-one, continue stirring for 10 minutes, and filter the material through a 100-mesh sieve.

[0040] The obtained water-based lubricant has a weight solid content of 10.2 wt%, a viscosity of 10 mPa·s (measured by a viscometer selected from NDJ-1), and a pH value of 9.83 (measured by a PHS-3C precision pH meter).

Embodiment 3

[0042] The present embodiment provides a water-based lubricant for papermaking, which is obtained according to the following steps:

[0043] (1) 20g of palmitic acid, 10g of triethanolamine, 5g of potassium hydroxide, 2g of sodium dodecylbenzenesulfonate, 1g of polyoxyethylene (20) sorbitan monooleate (Tween 80) and 532g of Add ionized water into the reaction kettle, stir evenly, heat up to 90°C, and set aside;

[0044] (2) At 110°C, add 100g of oxidized polyethylene wax into the reaction kettle, melt for 2 hours, and set aside;

[0045] (3) Add (2) into (1) and mix evenly at 90°C while stirring, and keep warm for 2 hours;

[0046] (4) Cool down to 25°C, filter, add 0.07g 5-chloro-2-methyl-4-isothiazolin-3-one, 0.05g 2-methyl-4-isothiazolin-3-one, continue stirring After 10 minutes, filter the material with a 100-mesh sieve.

[0047] The obtained water-based lubricant has a weight solid content of 20.3 wt%, a viscosity of 35 mPa·s (measured by a viscometer selected from NDJ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com