Patents

Literature

437 results about "Mohs scale of mineral hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Mohs scale of mineral hardness (/moʊz/) is a qualitative ordinal scale characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material. Created in 1812 by German geologist and mineralogist Friedrich Mohs, it is one of several definitions of hardness in materials science, some of which are more quantitative. The method of comparing hardness by observing which minerals can scratch others is of great antiquity, having been mentioned by Theophrastus in his treatise On Stones, c. 300 BC, followed by Pliny the Elder in his Naturalis Historia, c. AD 77. While greatly facilitating the identification of minerals in the field, the Mohs scale does not show how well hard materials perform in an industrial setting.

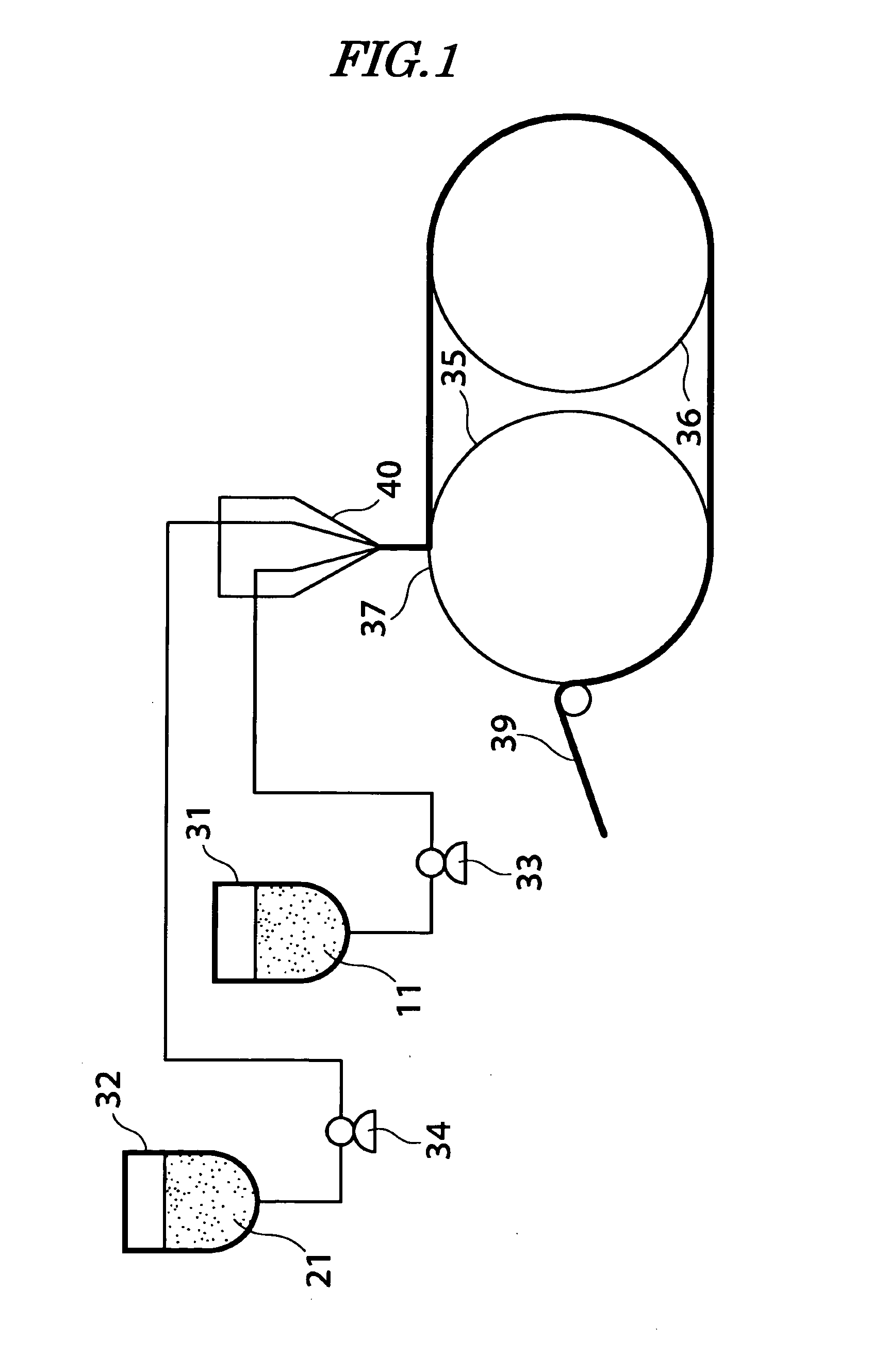

Magnetic recording medium, magnetic signal reproduction system and magnetic signal reproduction method

ActiveUS20100246073A1Excellent electromagnetic characteristicExcellent running durabilityMagnetic materials for record carriersTape carriersMohs scale of mineral hardnessHardness

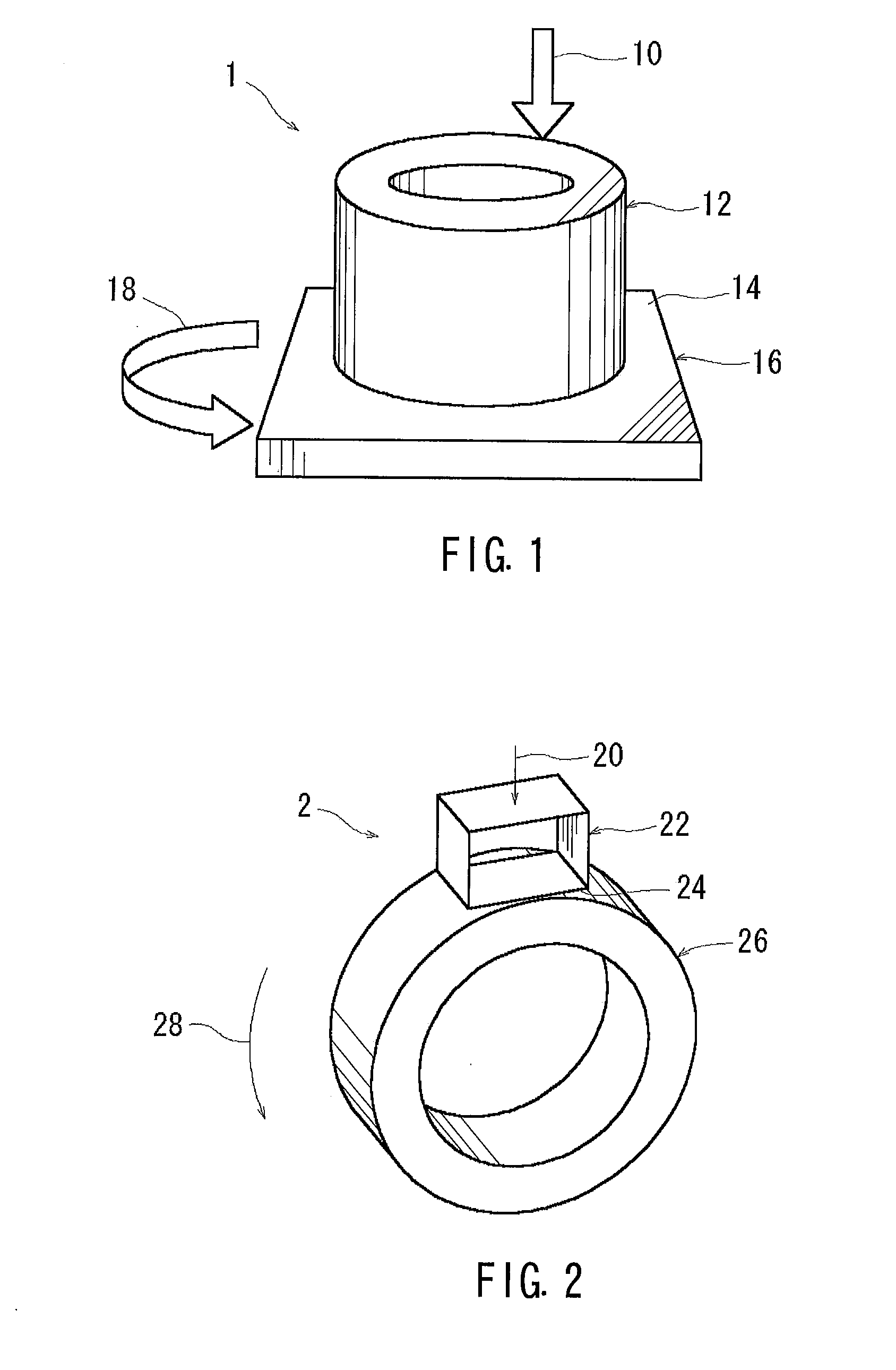

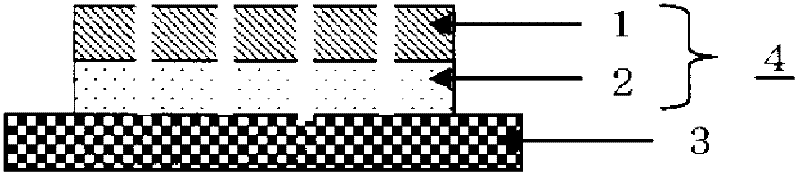

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support. A height of protrusions with a protrusion density of 0.002 protrusion / μm2 or lower on a surface of the magnetic layer as measured by AFM is 40 nm or lower; a density of protrusions that are 15 nm or higher in height on the surface of the magnetic layer as measured by AFM ranges from 0.01 to 0.18 protrusion / μm2; and the protrusions that are 15 nm or higher in height include protrusions formed of carbon black and protrusions formed of a substance with a Mohs' hardness exceeding 7, and an average height of the protrusions formed of carbon black is greater than an average height of the protrusions formed of the substance with a Mohs' hardness exceeding 7.

Owner:FUJIFILM CORP

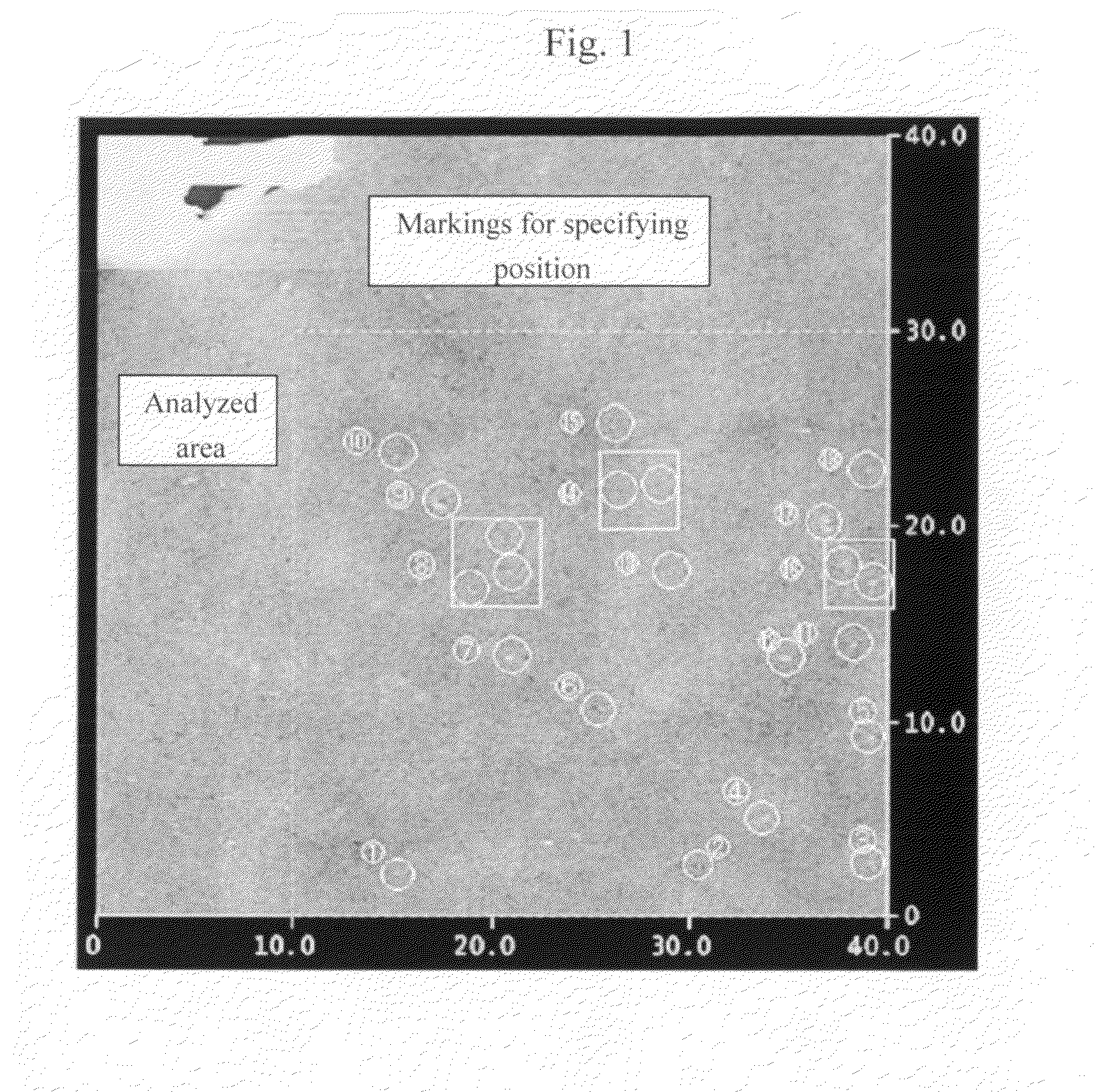

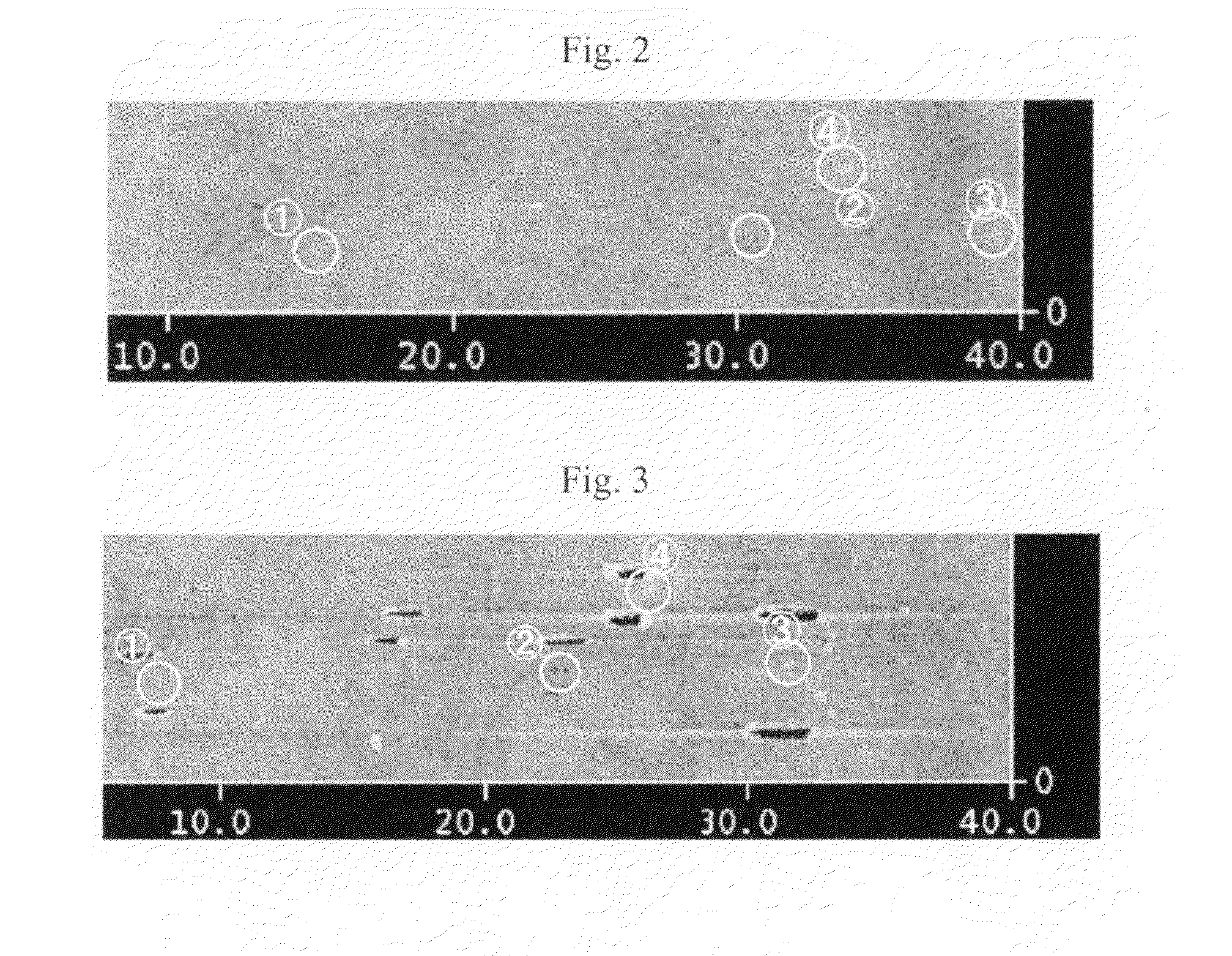

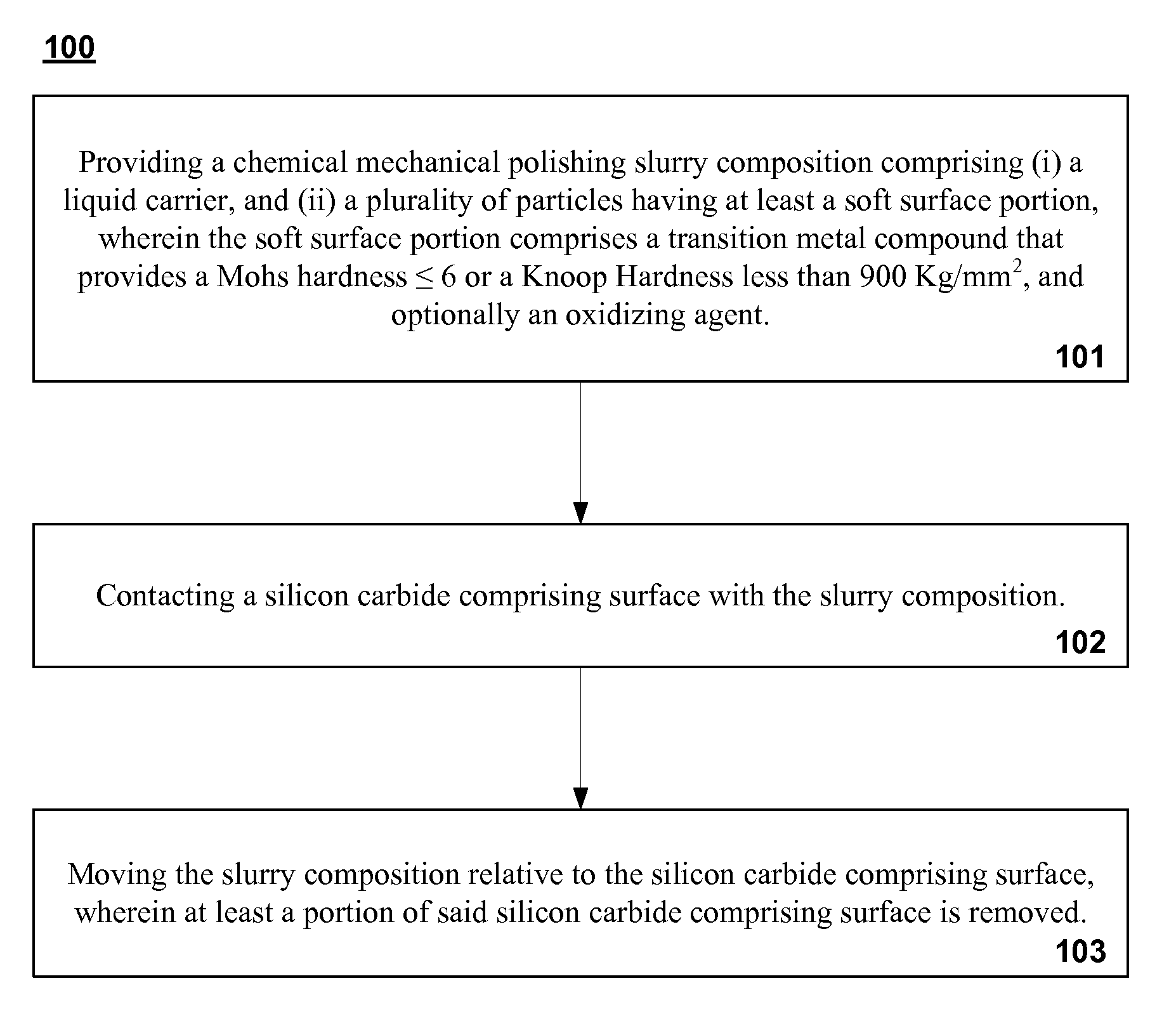

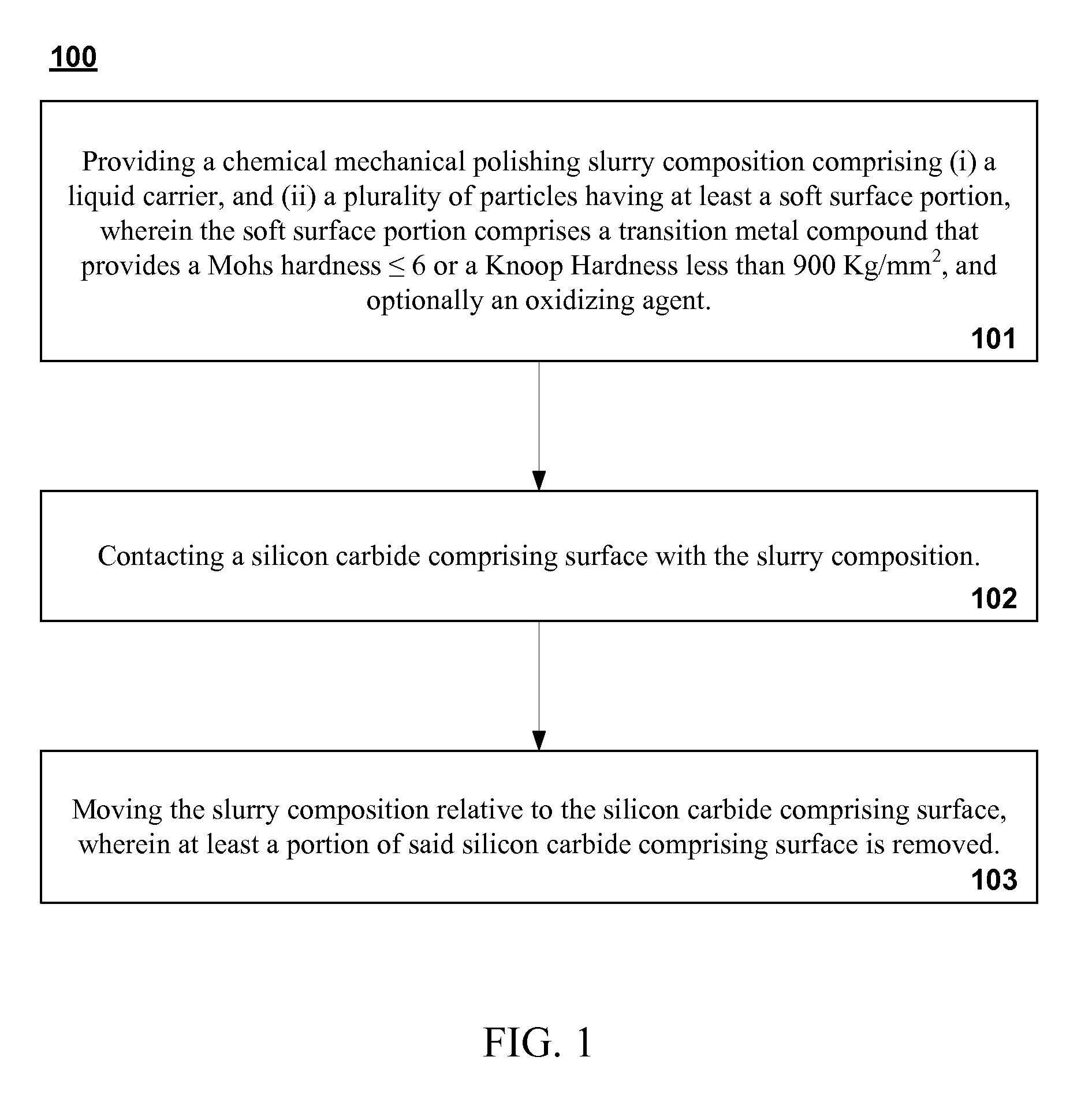

Chemical mechanical polishing of silicon carbide comprising surfaces

ActiveUS20100258528A1High polishing rateReduce sub-surface damageOther chemical processesDecorative surface effectsMohs scale of mineral hardnessSlurry

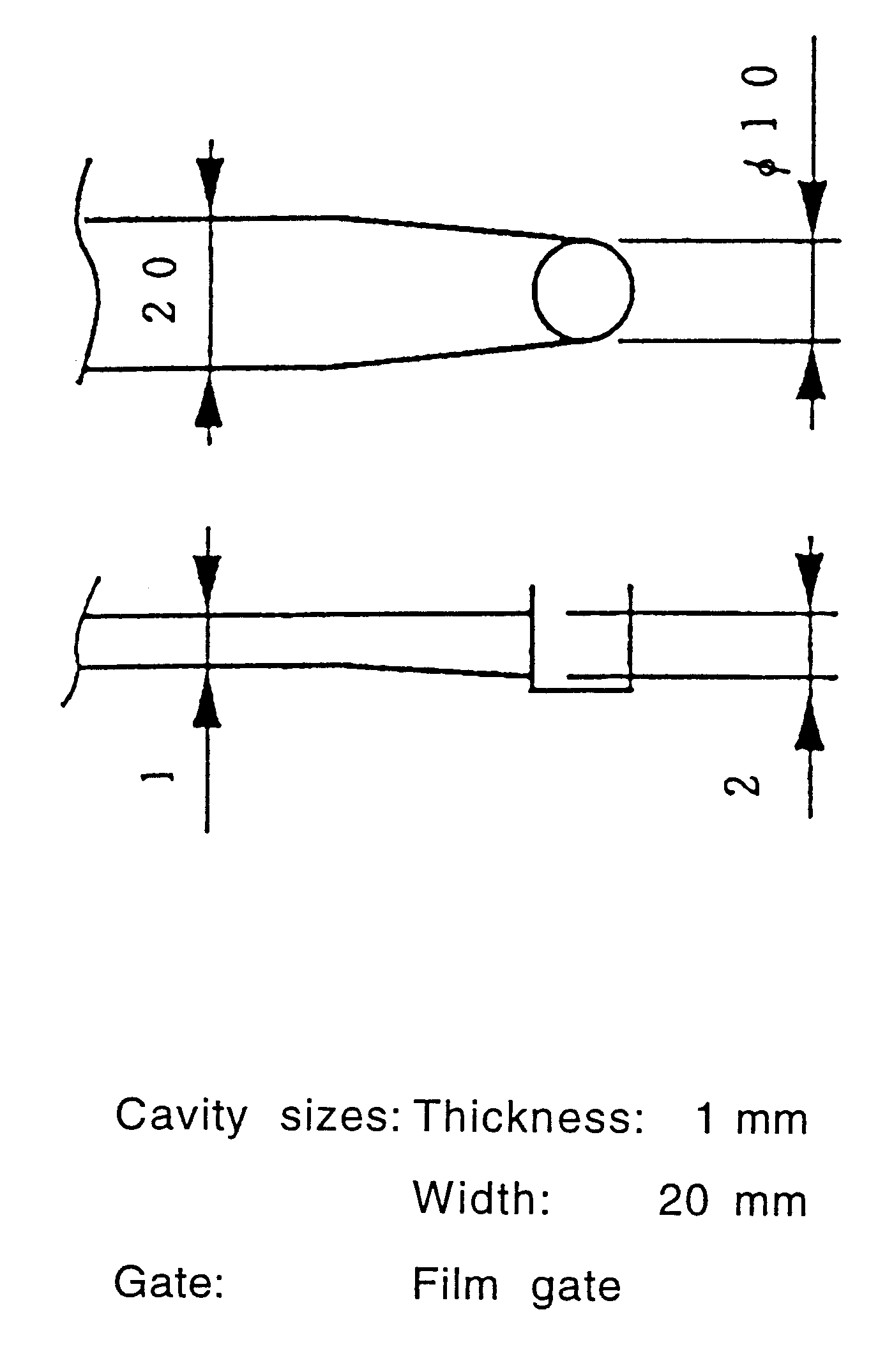

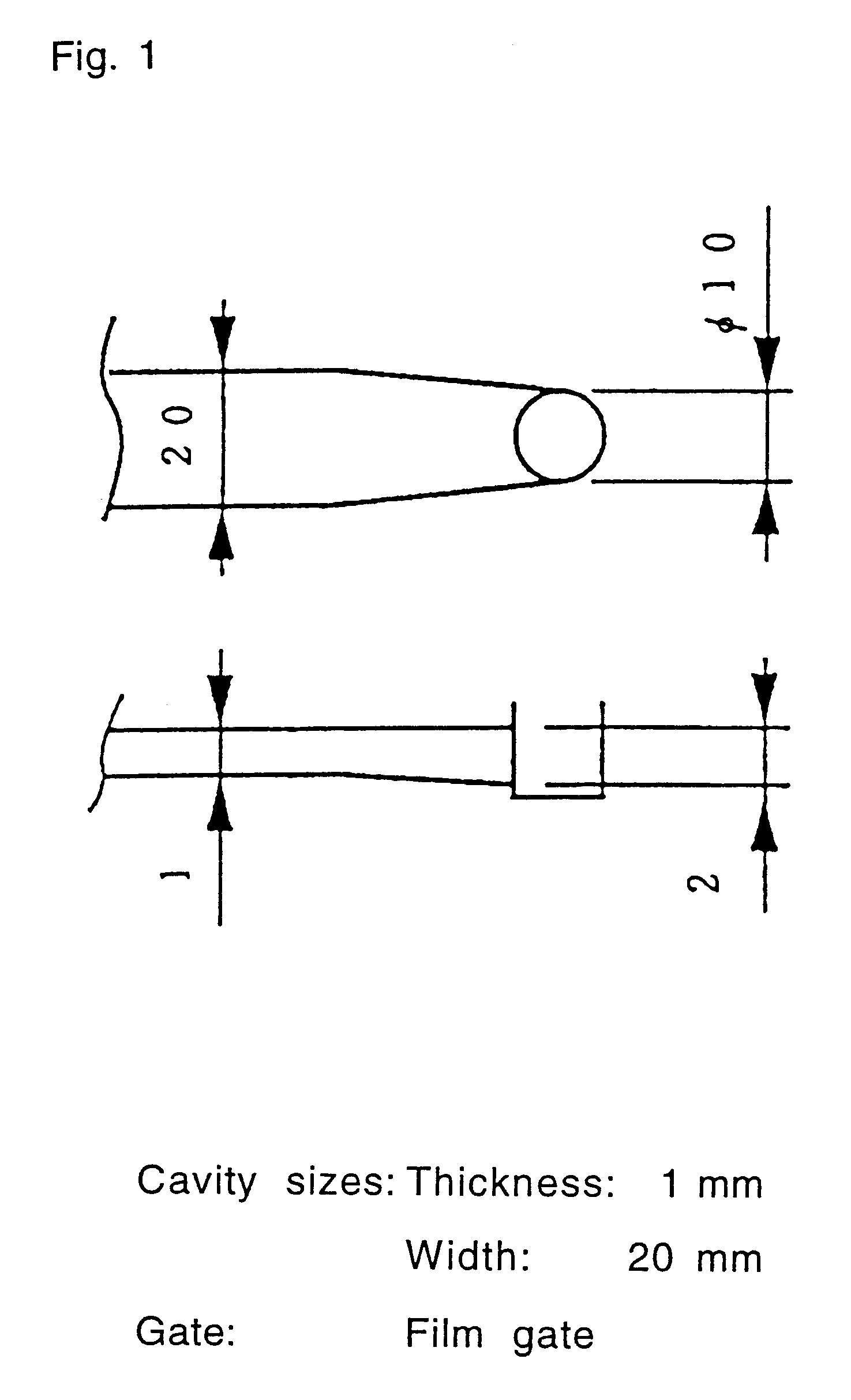

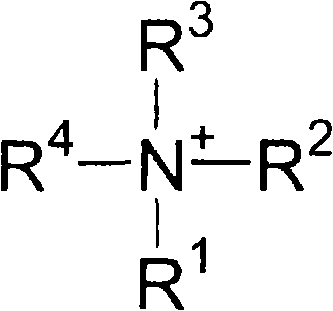

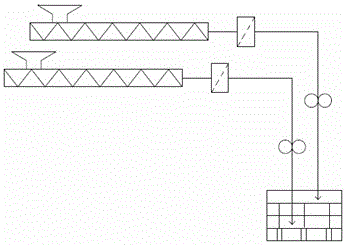

Slurry compositions and chemically activated CMP methods for polishing a substrate having a silicon carbide surface using such slurries. In such methods, the silicon carbide surface is contacted with a CMP slurry composition that comprises i) a liquid carrier and ii) a plurality of particles having at least a soft surface portion, wherein the soft surface portion includes a transition metal compound that provides a Mohs hardness ≦6, and optionally iii) an oxidizing agent. The oxidizing agent can include a transition metal. The slurry is moved relative to the silicon carbide comprising surface, wherein at least a portion of eth silicon carbide surface is removed.

Owner:ENTEGRIS INC +1

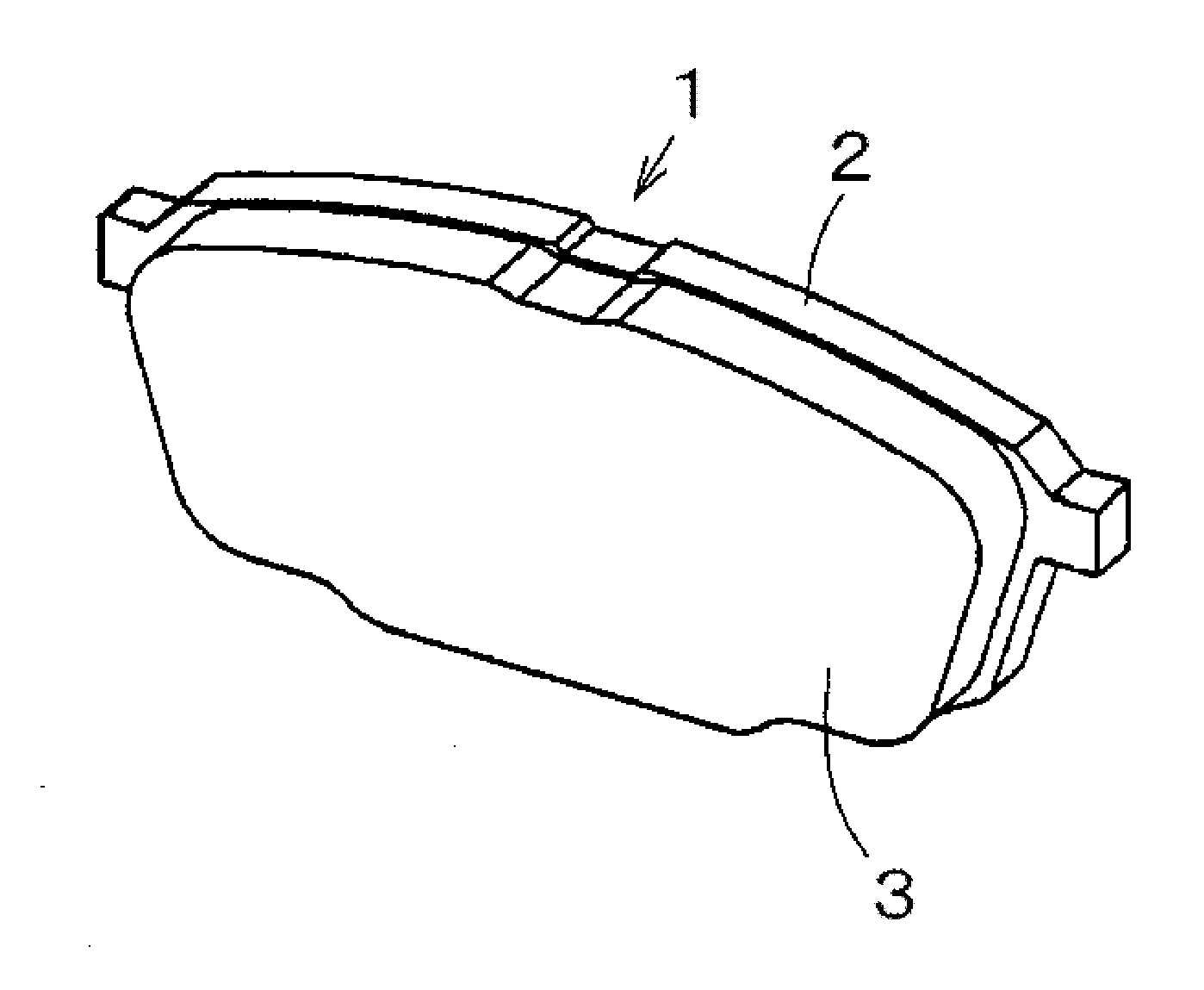

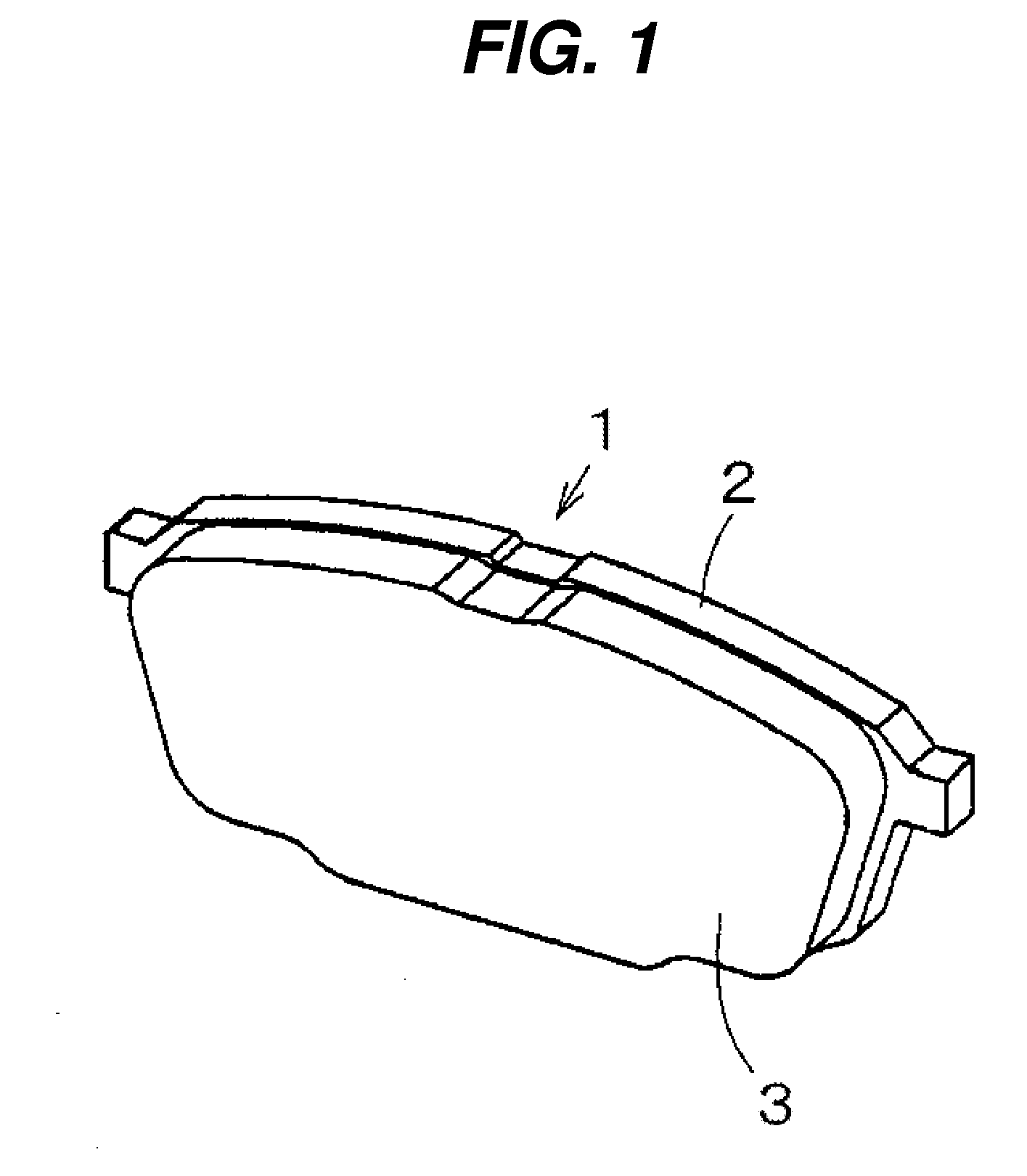

Friction material

InactiveUS20050004258A1Good brake feelingImprove effectivenessBraking element arrangementsOther chemical processesMohs scale of mineral hardnessHardness

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

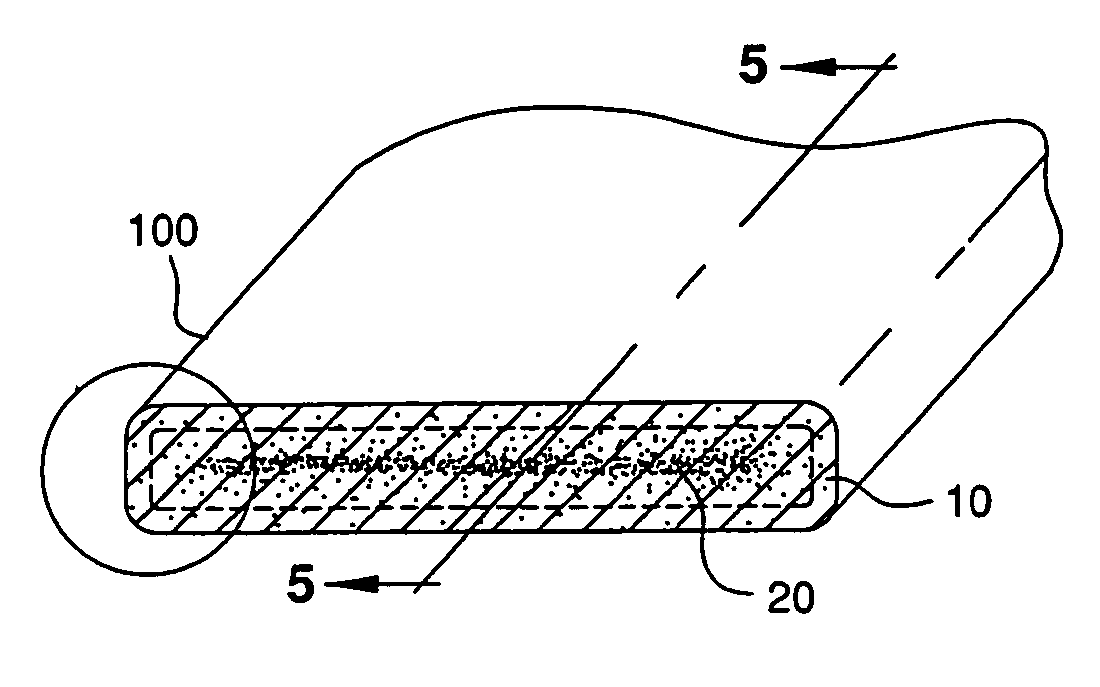

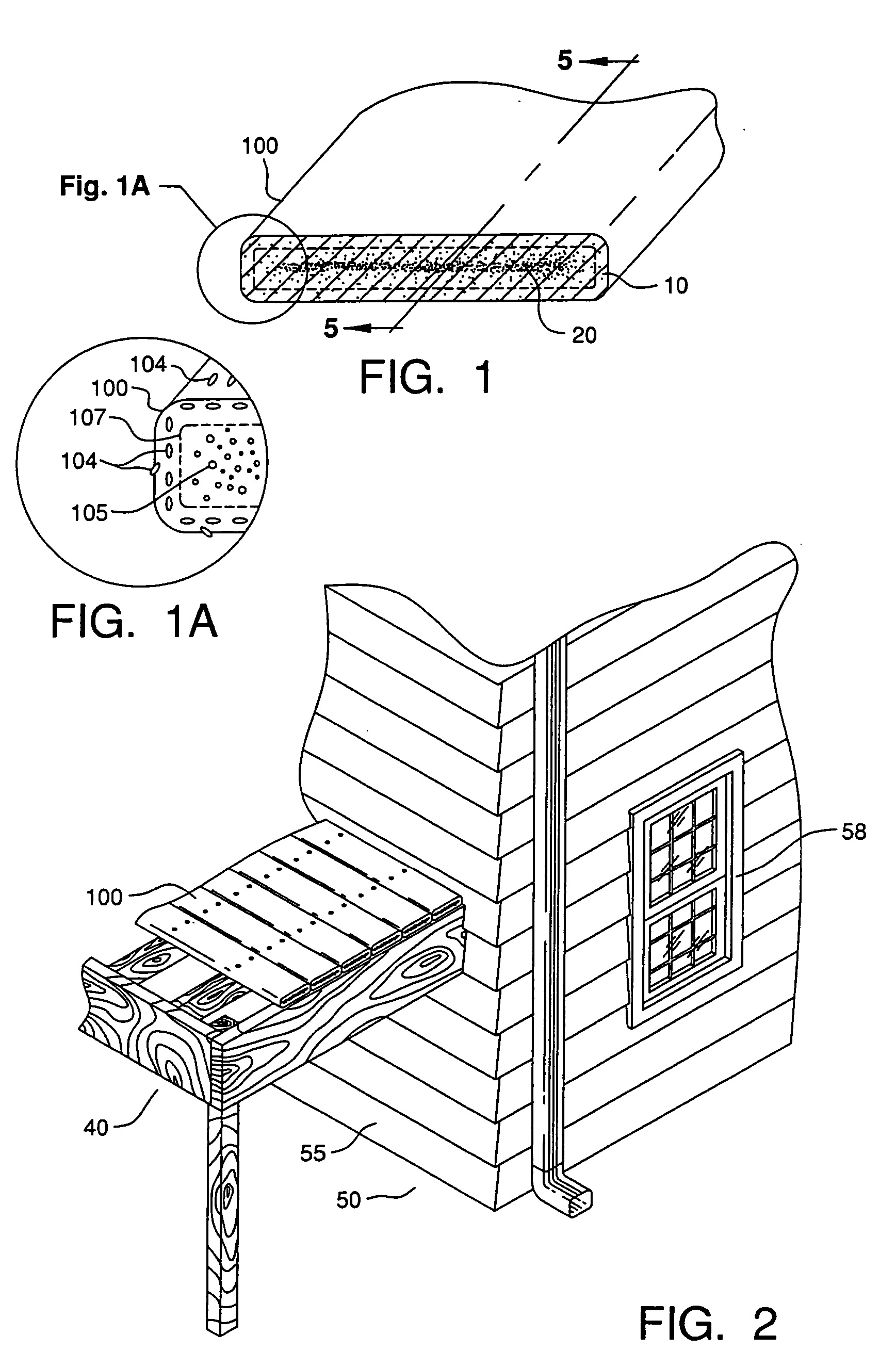

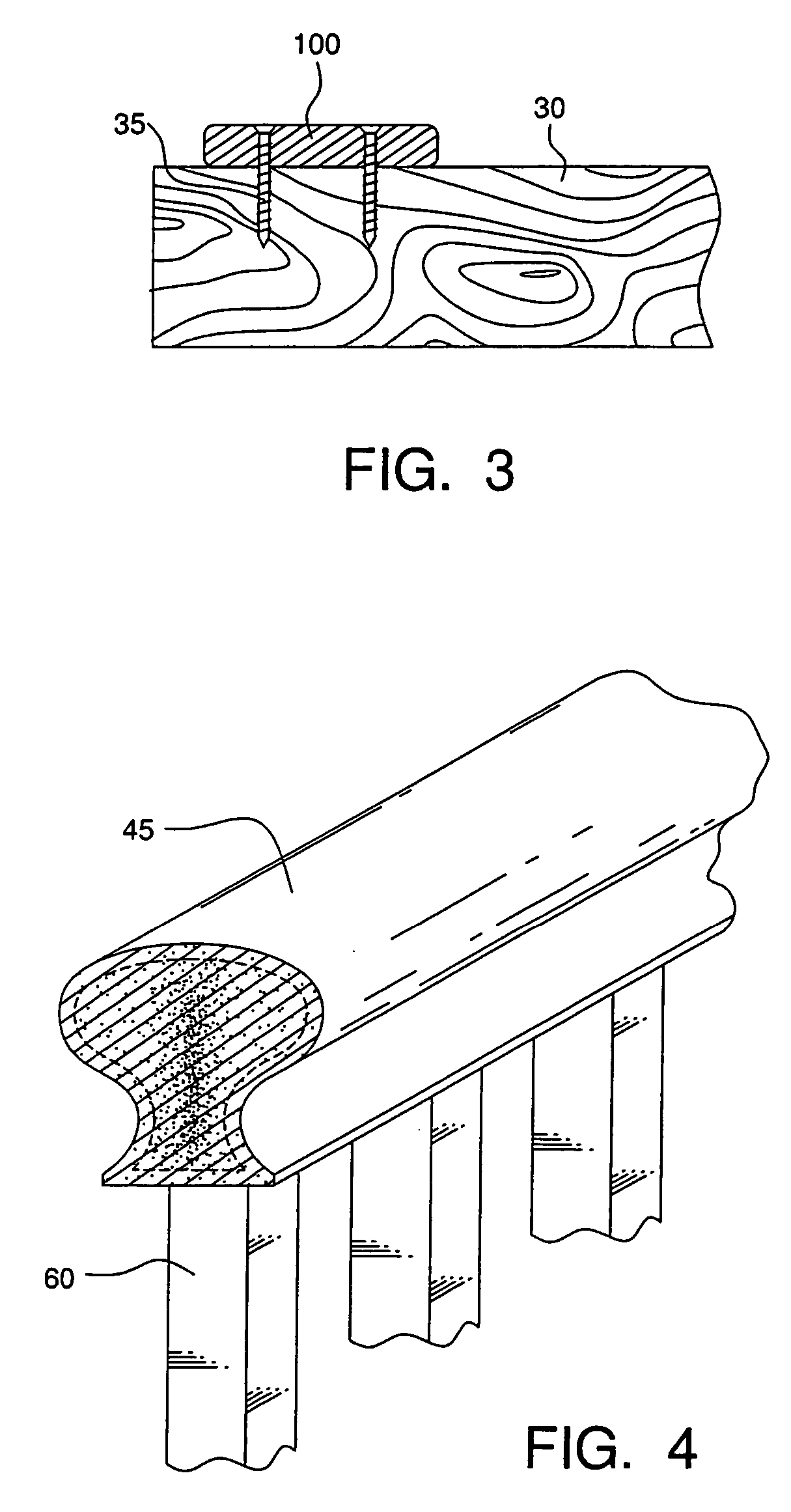

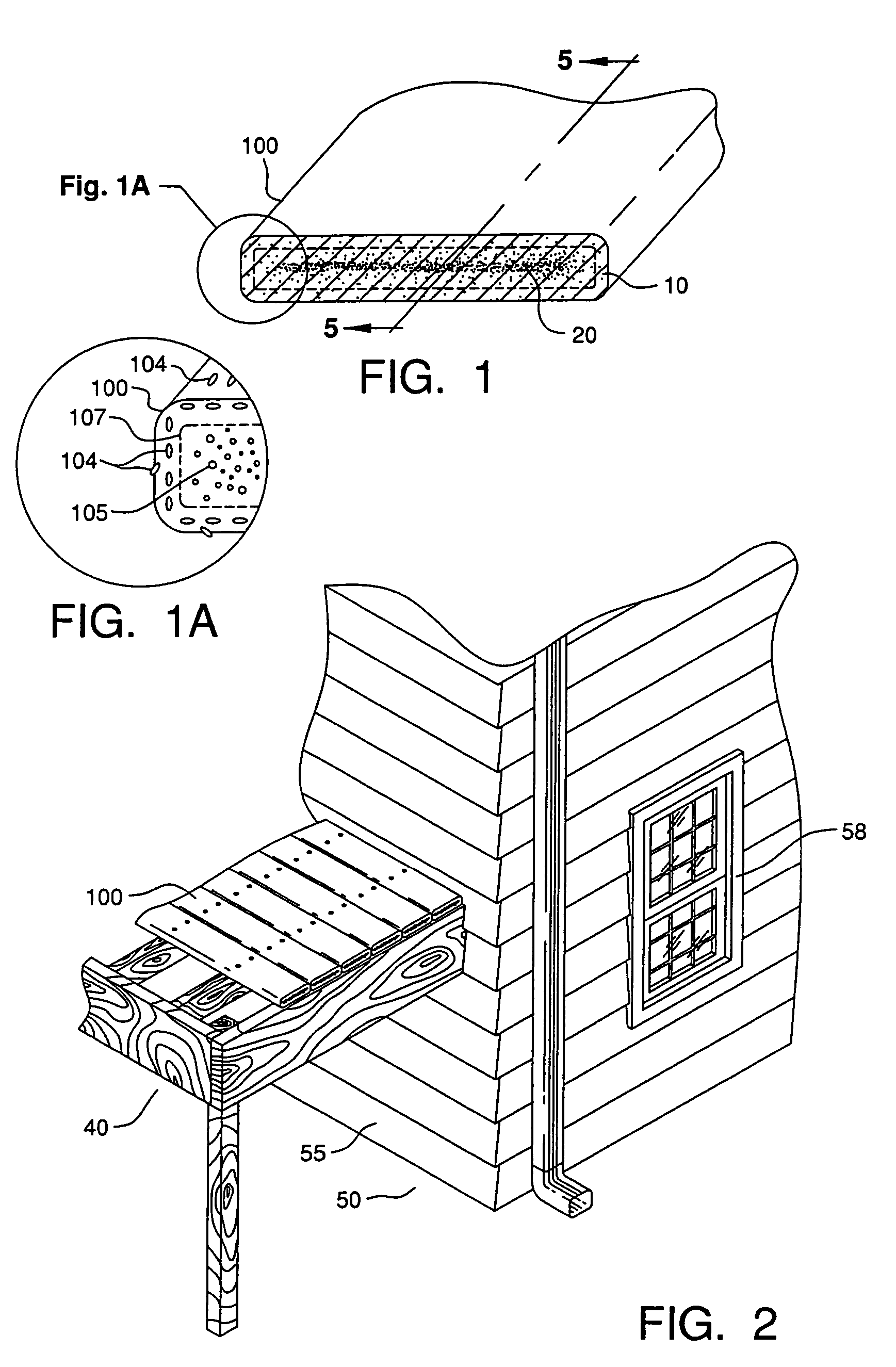

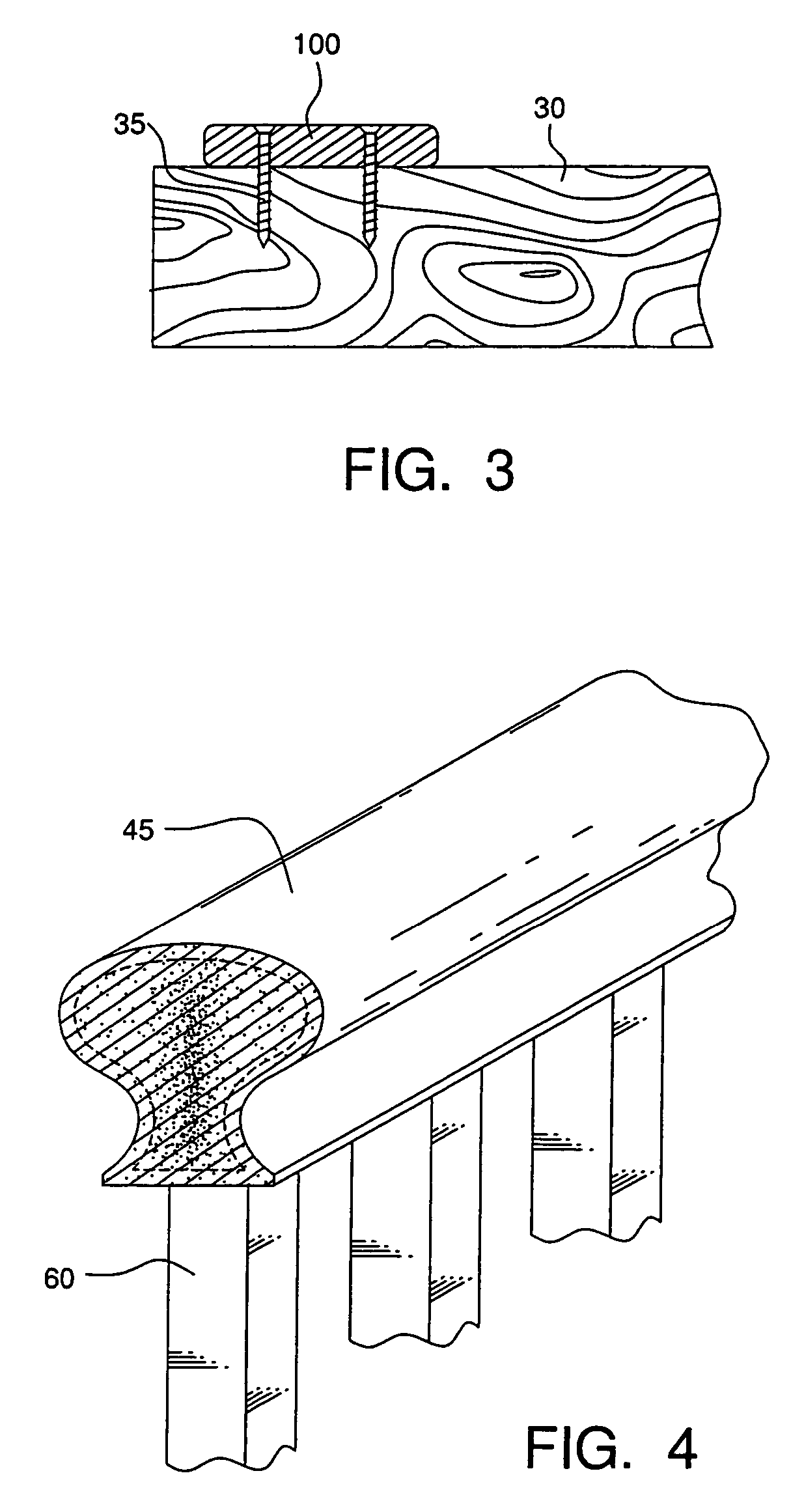

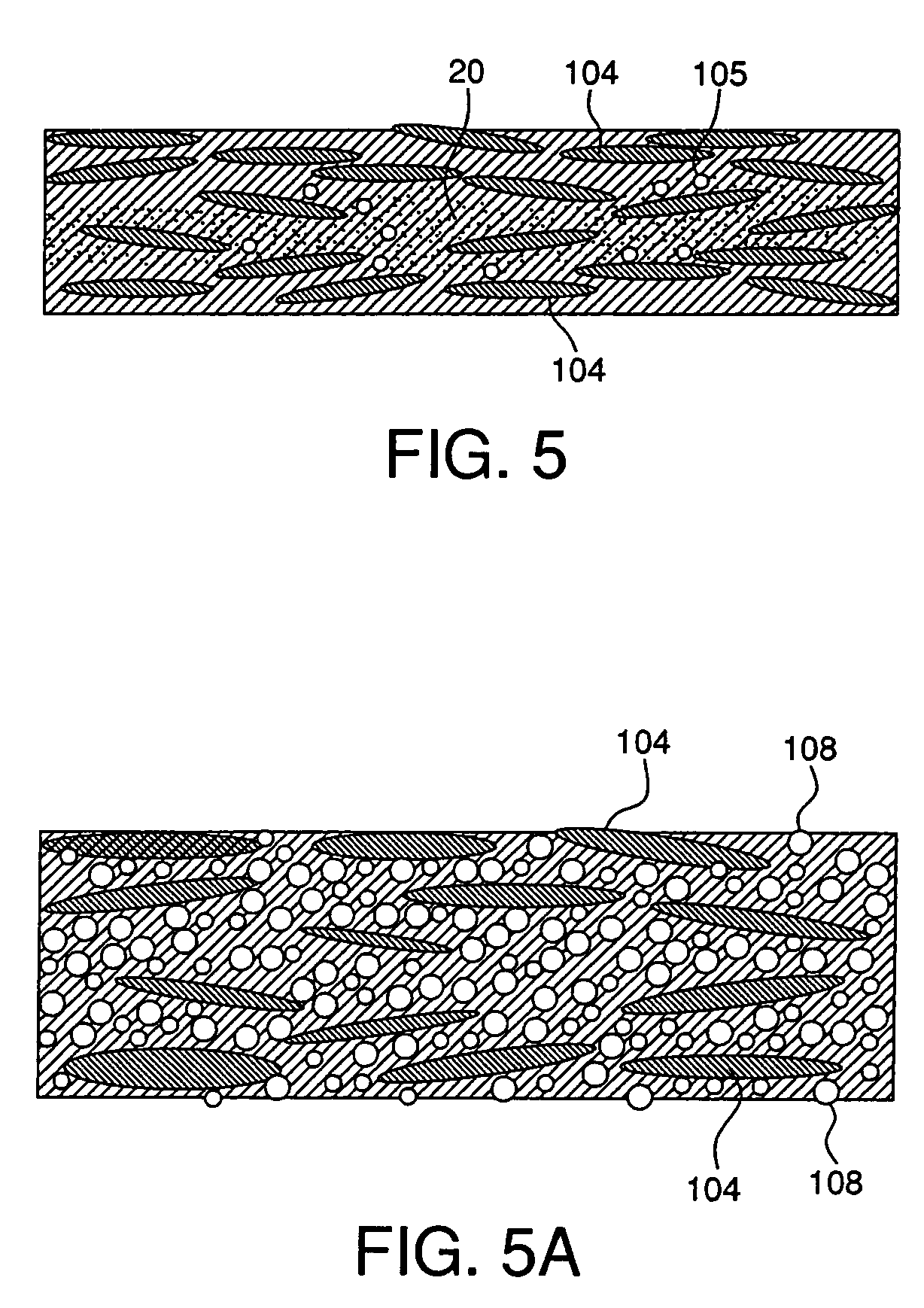

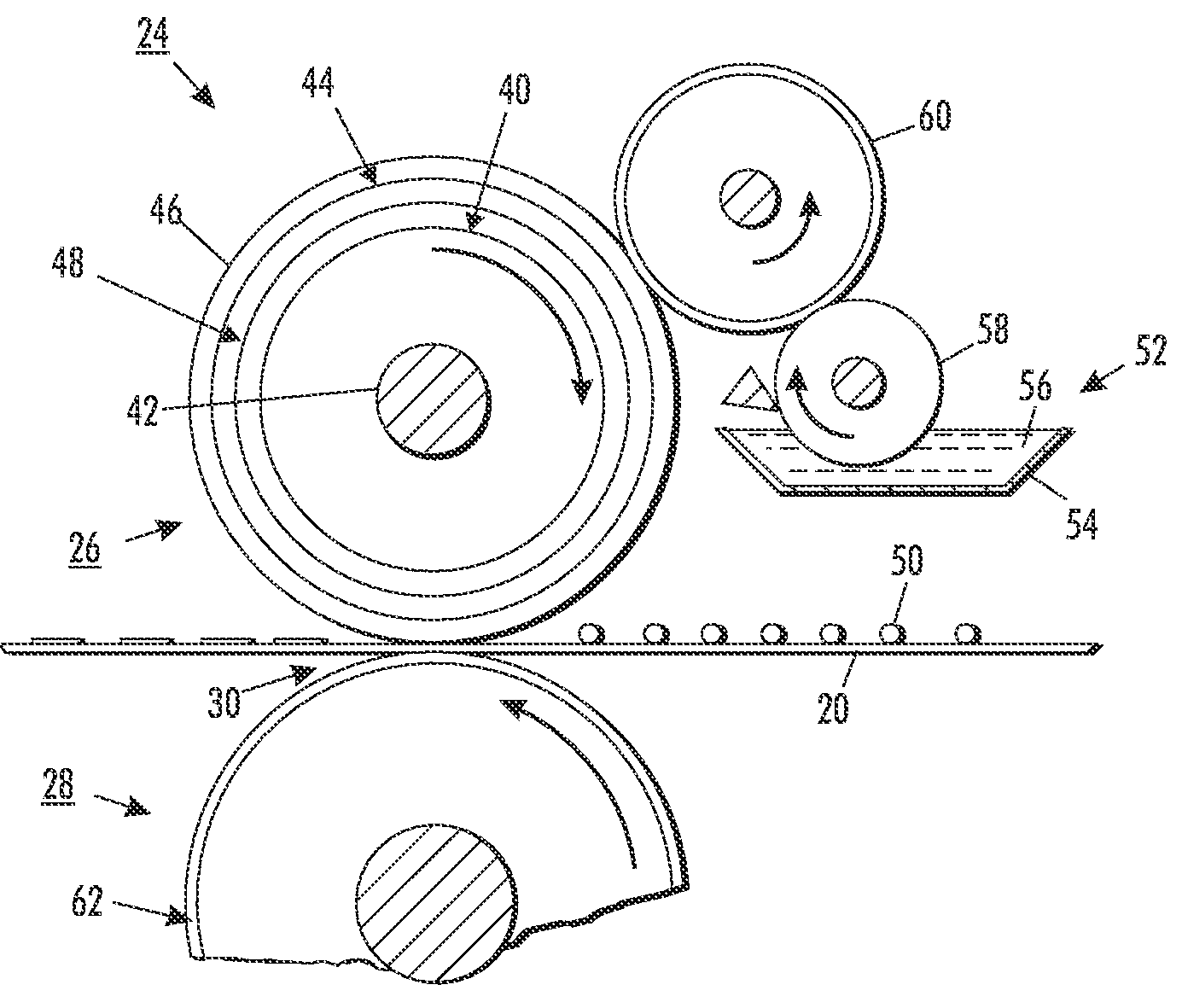

Polymer-fiber composite building material with bulk and aesthetically functional fillers

ActiveUS20060099405A1Reduce resin usageResist attackSynthetic resin layered productsCeramic layered productsFiberMohs scale of mineral hardness

Polymer composite building materials are provided which contain resin, and about 20-75 wt. % fillers and additives, in which the fillers contain at least one bulk filler for reducing the amount of resin needed to make the building material, and at least one aesthetically functional filler for providing the building material with an aesthetic appearance. The bulk filler and the aesthetically functional filler of this embodiment are non-toxic, resistant to microbial attack, and have a Mohs hardness of less than about 5.

Owner:BARRETTE OUTDOOR LIVING INC

Mixed-abrasive polishing composition and method for using the same

The invention provides a polishing composition comprising (i) an abrasive comprising (a) about 5 to about 45 wt. % of first abrasive particles having a Mohs' hardness of about 8 or more, (b) about 1 to about 45 wt. % of second abrasive particles having a three-dimensional structure comprising aggregates of smaller primary particles, and (c) about 10 to about 90 wt. % of third abrasive particles comprising silica, and (ii) a liquid carrier. The invention also provides a method of polishing a substrate, which method comprises the steps of (i) providing the above-described polishing composition, (ii) providing a substrate having a surface, and (iii) abrading at least a portion of the substrate surface with the polishing composition to polish the substrate.

Owner:CMC MATERIALS INC

Resin-bonded grinding tool for processing sapphire crystals and preparation method for resin-bonded grinding tool

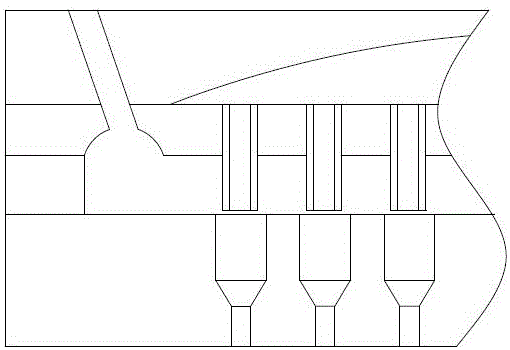

The invention discloses a resin-bonded grinding tool for processing sapphire crystals and a preparation method for the resin-bonded grinding tool. The resin-bonded grinding tool for processing the sapphire crystals is obtained by mixing, hot-pressing, post-curing and post-trimming forming materials and a matrix, wherein the forming materials include diamond abrasives, thermosetting resin powder, filling agents, silicon carbide whiskers and wetting agents. The silicon carbide whiskers with the Mohs hardness of 9.5 grades are added into the resin-bonded grinding tool, so that the grinding tool for grinding the sapphire crystals is high in efficiency and long in service life, and the surface smoothness of the sapphire crystals can be improved by means of the polishing function of the silicon carbide whiskers.

Owner:云南光电辅料有限公司

Polishing liquid and polishing method using the same

InactiveUS20090004863A1Excellent polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingMohs scale of mineral hardnessParticulates

The present invention provides a polishing liquid for polishing a ruthenium-containing barrier layer, the polishing liquid being used in chemical mechanical polishing for a semi-conductor device having a ruthenium-containing barrier layer and conductive metal wiring lines on a surface thereof, the polishing liquid comprising an oxidizing agent; and a polishing particulate having hardness of 5 or higher on the Mohs scale and having a composition in which a main component is other than silicon dioxide (SiO2). The present invention also provides a polishing method for chemical mechanical polishing of a semi-conductor device, the method contacting the polishing liquid with the surface of a substrate to be polished, and polishing the surface to be polished such that contacting pressure from a polishing pad to the surface to be polished is from 0.69 kPa to 20.68 kPa.

Owner:FUJIFILM CORP

Stain-resistant grout composition, dispenser therefor, and method of use

InactiveUS20050197444A1Improve workabilityPaper coatingCoatingsMohs scale of mineral hardnessPolymer resin

The invention relates to a composition useful for grouting and caulking construction materials. The composition exhibits improved stain resistance and improved clean-up properties. The composition comprises an air-dryable polymeric resin, a mineral filler, microspheres, and a stain resistant polymer. In an embodiment the composition comprising a mineral filler that has average particle size greater than about 160 micrometers and a Mohs hardness less than about 6.5 is suitable for packaging in pressurized containers.

Owner:ROANOKE GROUP

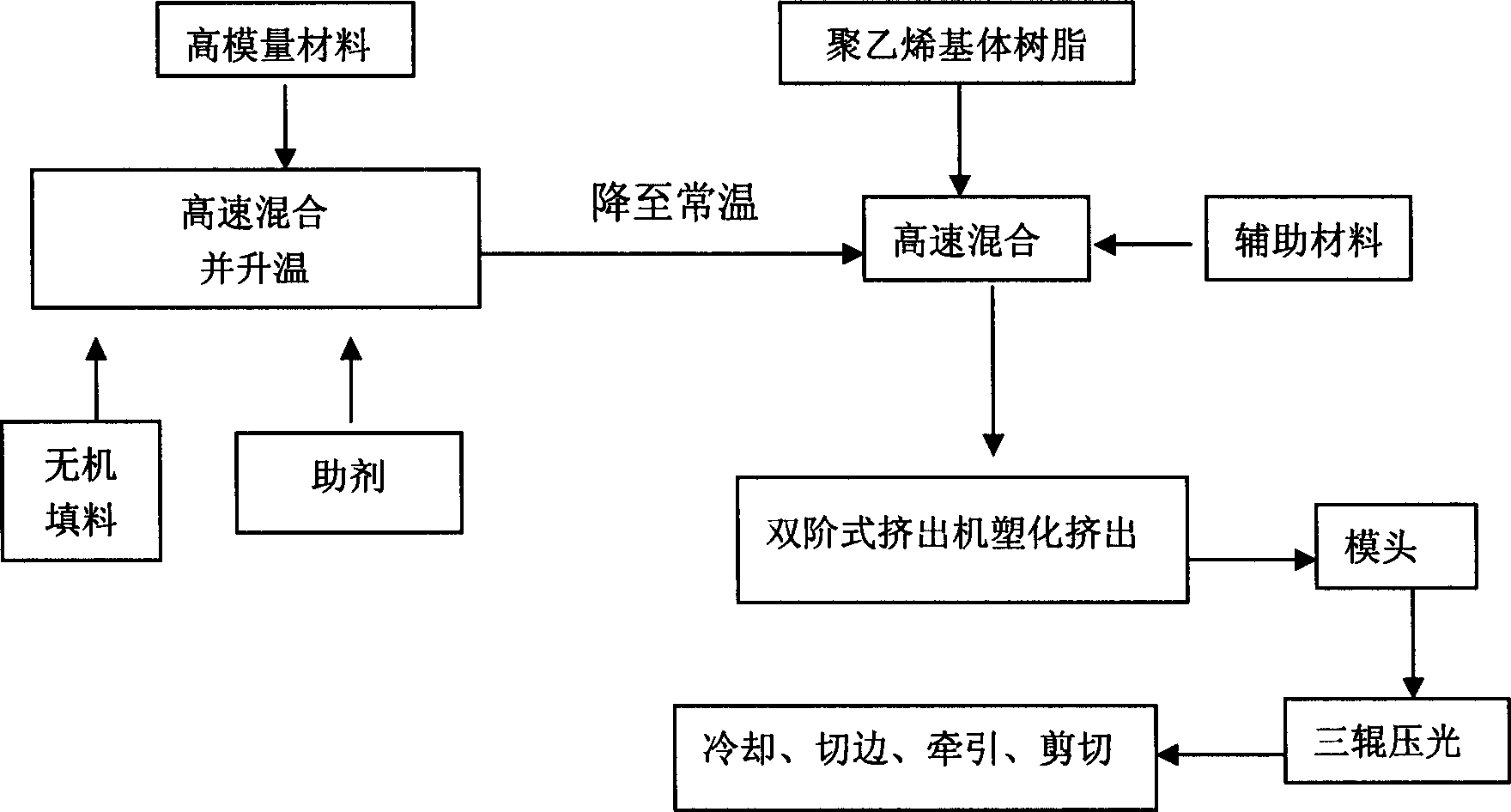

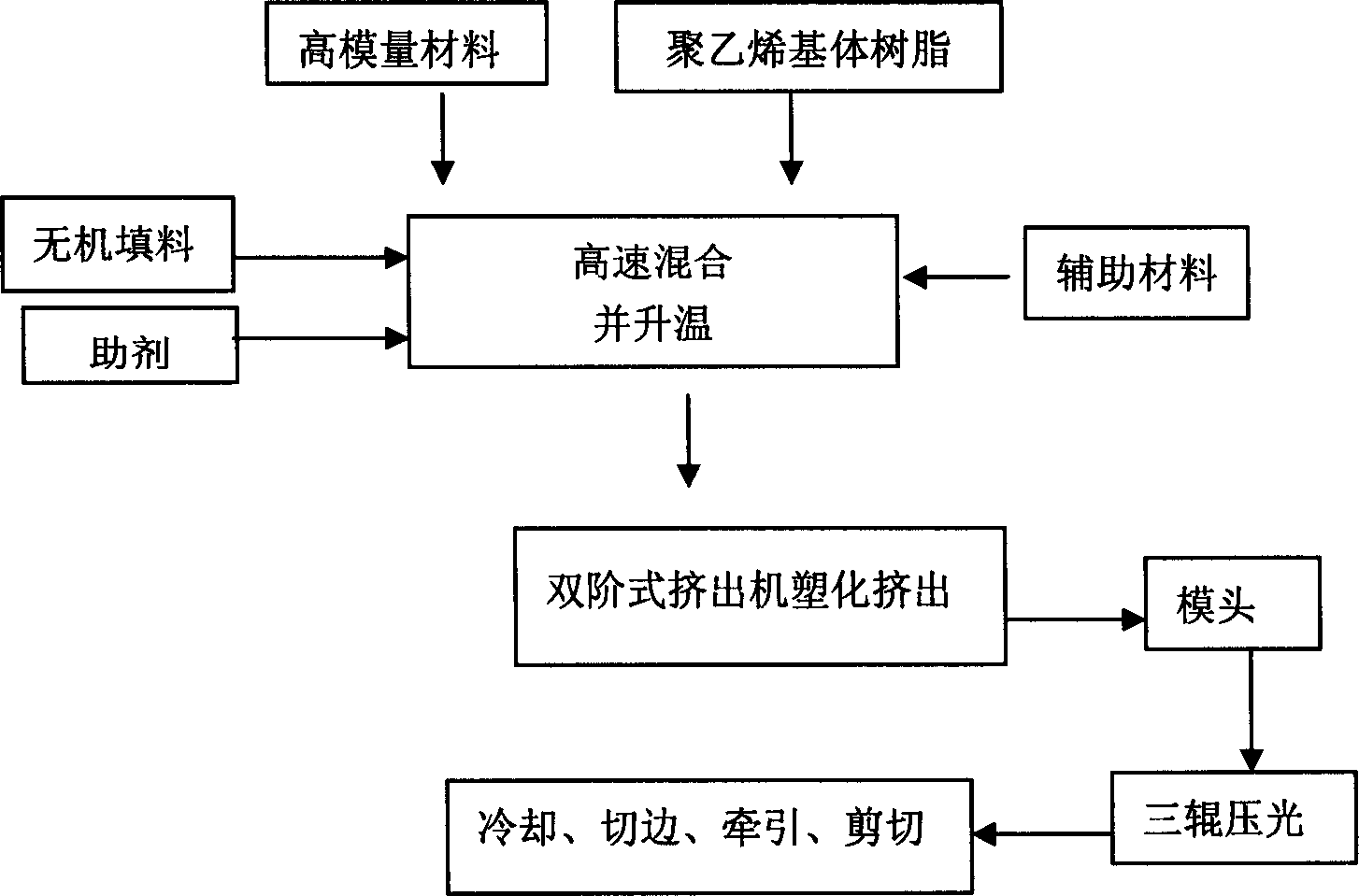

Noice insulation dumping noise reducing sheet material with high modulus material for car and preparation process thereof

InactiveCN1793211AImprove sound insulation and noise reductionExcellent vacuum thermoforming performanceSound producing devicesMohs scale of mineral hardnessPolyvinyl alcohol

The invention discloses a vehicle using high molding quantity filling sound insulation damping noise reduction sheet material and the manufacture method. It has good sound insulation and noise reduction function, and has simple technology. The raw material includes polyvinyl alcohol resin, coupler, lubricant and powder material that has Mohí»s hardness above 6 as high molding quantity material.

Owner:HENKEL CORP

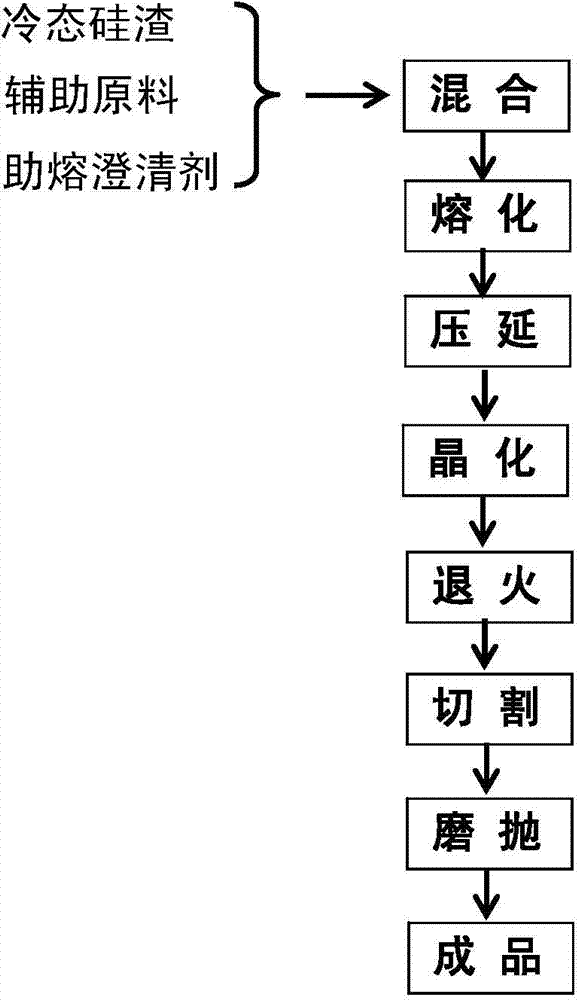

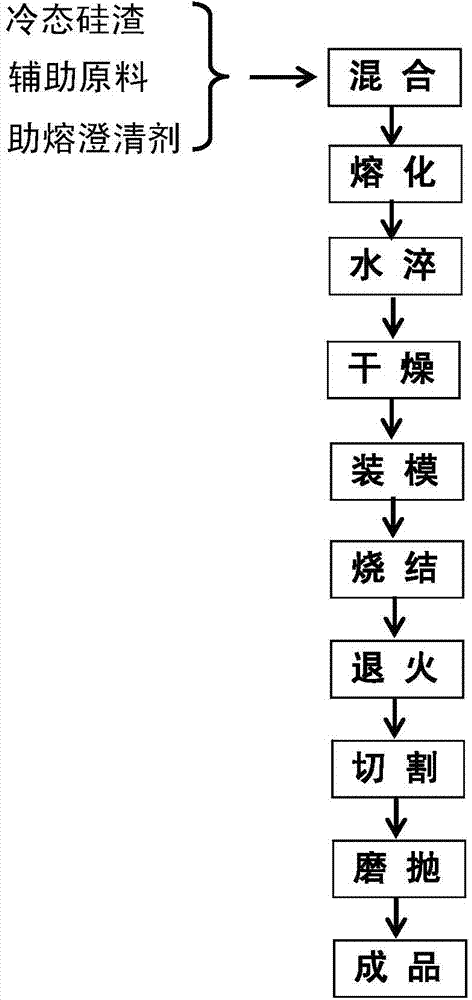

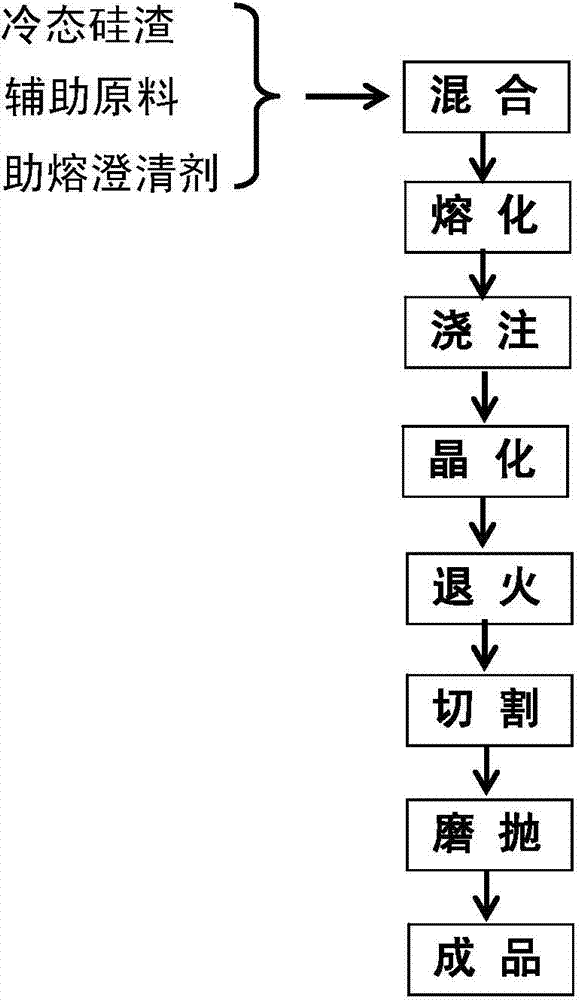

Silicon-slag microcrystalline glass and preparation method thereof

The invention relates to silicon-slag microcrystalline glass and a preparation method thereof. Silicon smelting waste slag is taken as a major raw material, and silicon dioxide or silica sand (SiO2), fluorite (CaF2), limestone or calcite (CaCO3), industrial sodium carbonate (Na2CO3), zinc oxide (ZnO) and potassium carbonate (K2CO3) are taken as auxiliary raw materials, wherein the dosage of the silicon smelting waste slag in the raw materials of the microcrystalline glass is 26.0-75.0wt%. The preparation method specifically comprises the following steps of: evenly mixing cold-state silicon slag with other auxiliary raw materials in a blender mixer to obtain a basic mixed batch, melting the basic mixed batch into qualified glass liquid in a melting furnace, and then performing calendering, casting or water quenching on the glass liquid to form a basic glass plate or granules; finally, subjecting the basic glass plate to crystallization heat treatment to obtain the microcrystalline glass. The density of the microcrystalline glass is 2.5-2.8 g / cm<3>, the rupture strength of the microcrystalline glass is 30.0-103.5 MPa, the compressive strength of the microcrystalline glass is 70.0-903.0 MPa, the Moh's hardness of the microcrystalline glass is 5-8 and the abrasive resistance of the microcrystalline glass is 0.063-0.15 g / cm<2>; the silicon-slag microcrystalline glass can be widely applied to the fields such as chemical engineering, metallurgy, architectural ornament, petroleum, mine and machinery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and preparation method thereof

InactiveCN102942303AImprove physical and mechanical propertiesSmall sizeChemical industryWear resistant

The invention discloses high-strength wear-resistant engineering microcrystalline glass prepared by using granite waste materials and a preparation method thereof. The microcrystalline glass disclosed herein comprises 10.0-55.0wt% of granite waste materials as the main raw material, and comprises SiO2, CaF2, CaCO3, ZnO, K2CO3, etc. as the auxiliary raw materials. The preparation method comprises the following steps: crushing the granite waste materials, uniformly mixing the crushed granite waste materials with other raw materials in a mixer to obtain a base mixed batch, using a tank furnace to carry out high temperature melting on the base mixed batch to obtain qualified liquid glass, carrying out calendaring, casting or water quenching on the liquid glass to form a base glass plate (or pellets), and carrying out crystallization heat treatment on the base glass plate (or pellets) to obtain the microcrystalline glass. The microcrystalline glass has a density of 2.5-2.8g / cm<3>, a flexural strength of 30.0-103.5MPa, a compressive strength of 70.0-903.0MPa, a Moh's hardness of 5-8, and a wear resistance of 0.063-0.15g / cm<2>, has the advantages of high strength, good toughness, strong wear resistance and corrosion resistance, and excellent cutting machinability, and an be widely applied in the fields of chemical industry, metallurgy, building decoration, petroleum, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

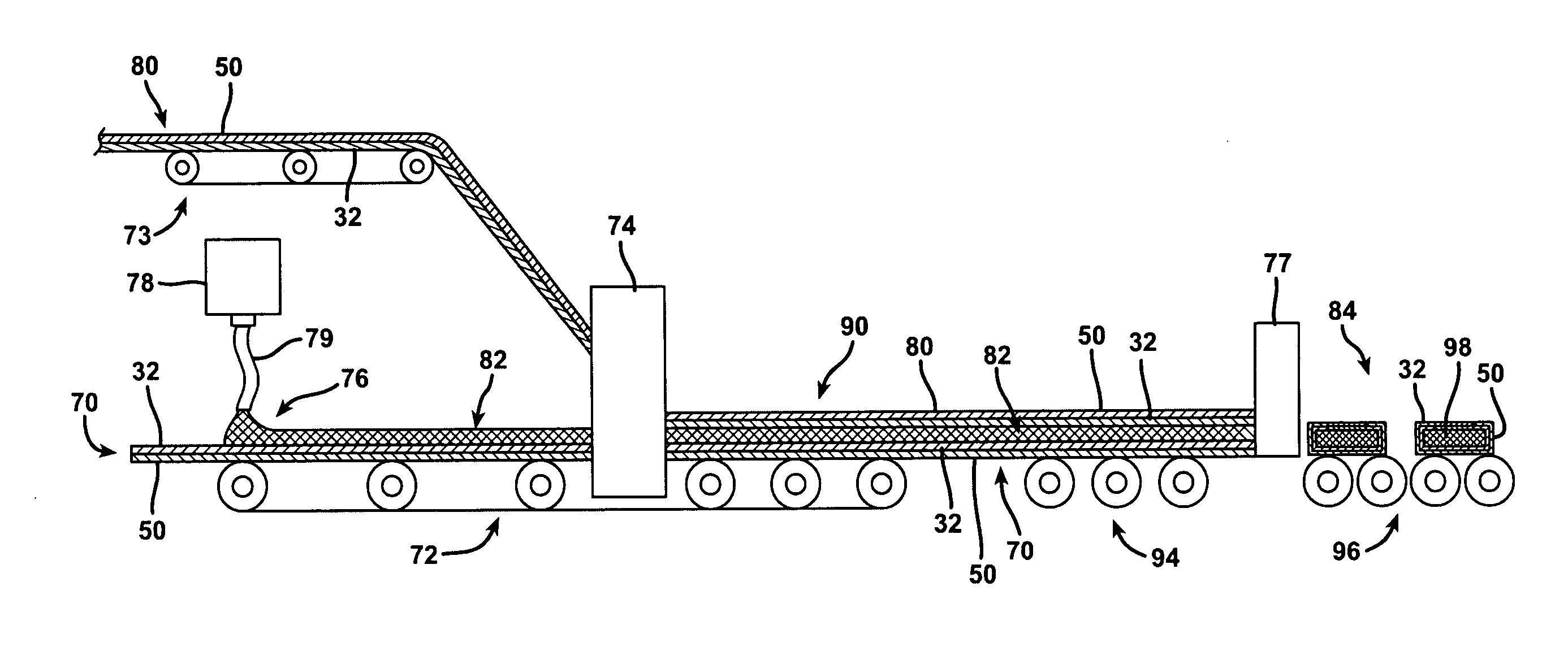

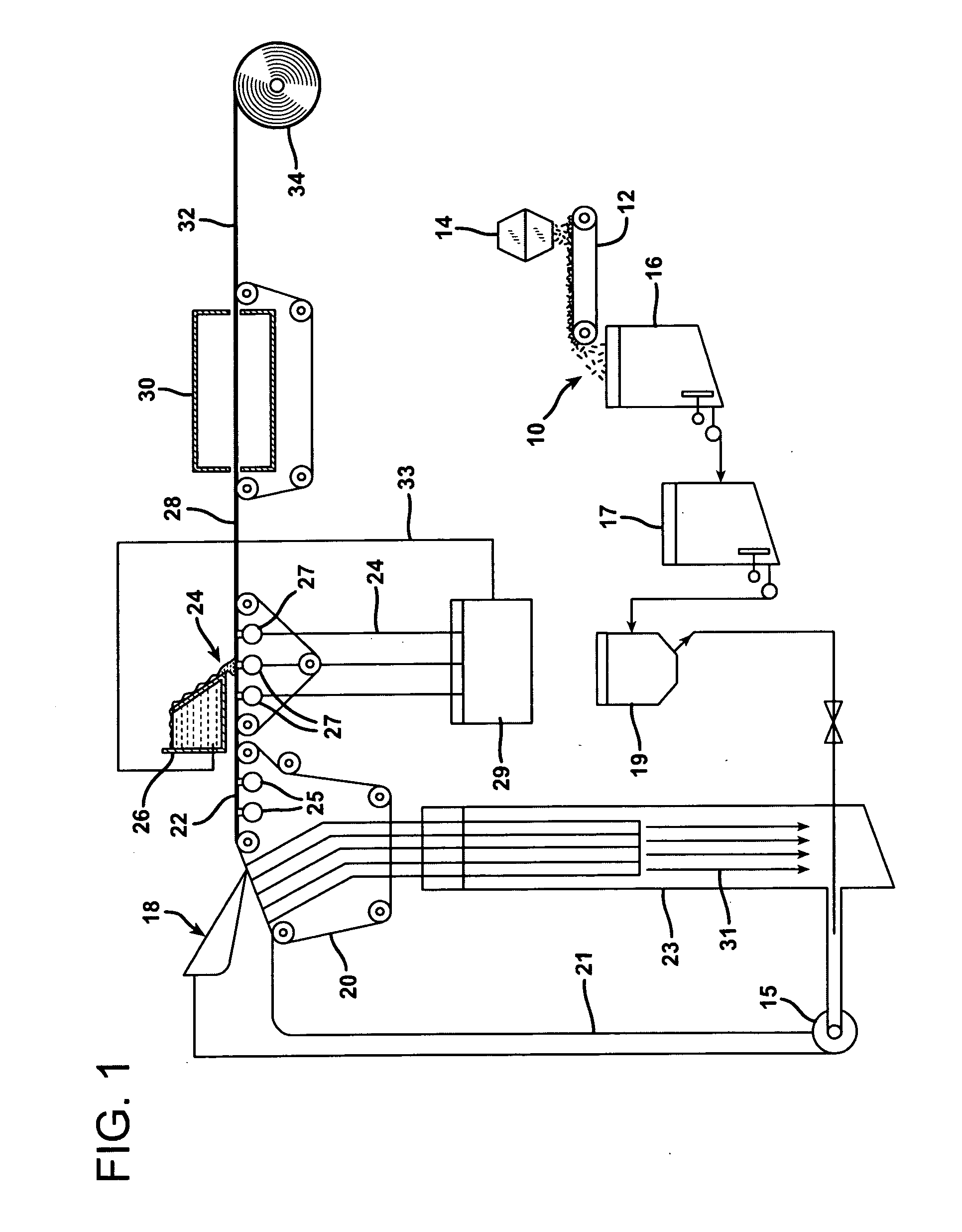

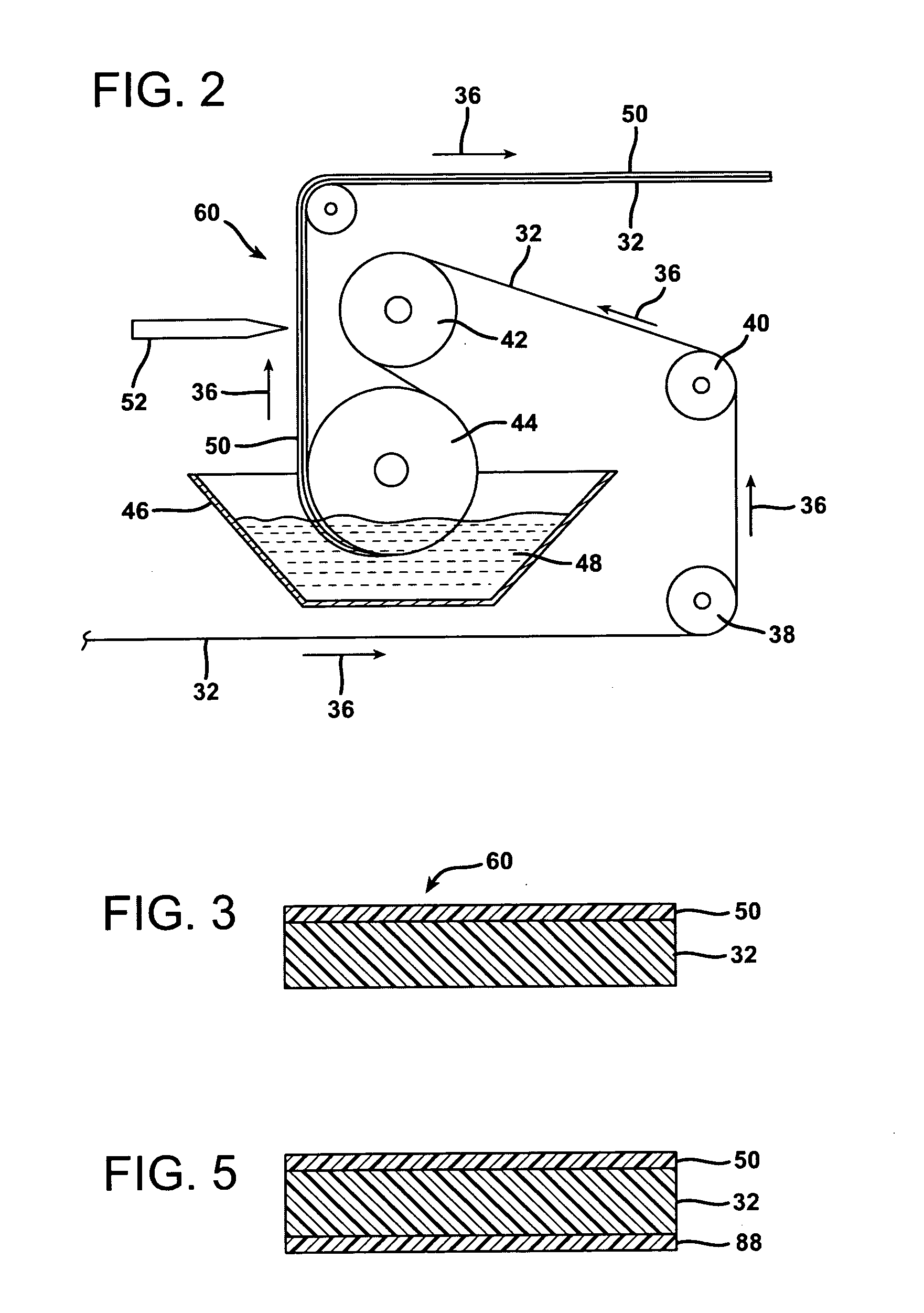

Wear resistant coating composition for a veil product

InactiveUS20070197114A1Harm reductionMore wear resistantSynthetic resin layered productsBuilding componentsMohs scale of mineral hardnessWear resistant

A coating composition that contains hard particles, a binder, and at least one thickening agent is provided. Pigment materials, a dispersant, a biocide, and a defoaming agent may also be included. The particles may have a size of about 1.0 to about 20.0 microns and a hardness of at least 5 on the Mohs Hardness Scale. The hard particles may be present in the composition in an amount from about 2.0 to about 15.0% by weight of the composition. The coating composition may be applied to a veil to form a wear resistant coating. The coated veil may then be used to form a coated gypsum product. The coating composition improves wear resistance and reduces damaging effects that may be caused by winding, workers handling the coated gypsum product during installation, and / or adverse conditions after installation. Methods of forming a coated veil and coated gypsum products are also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

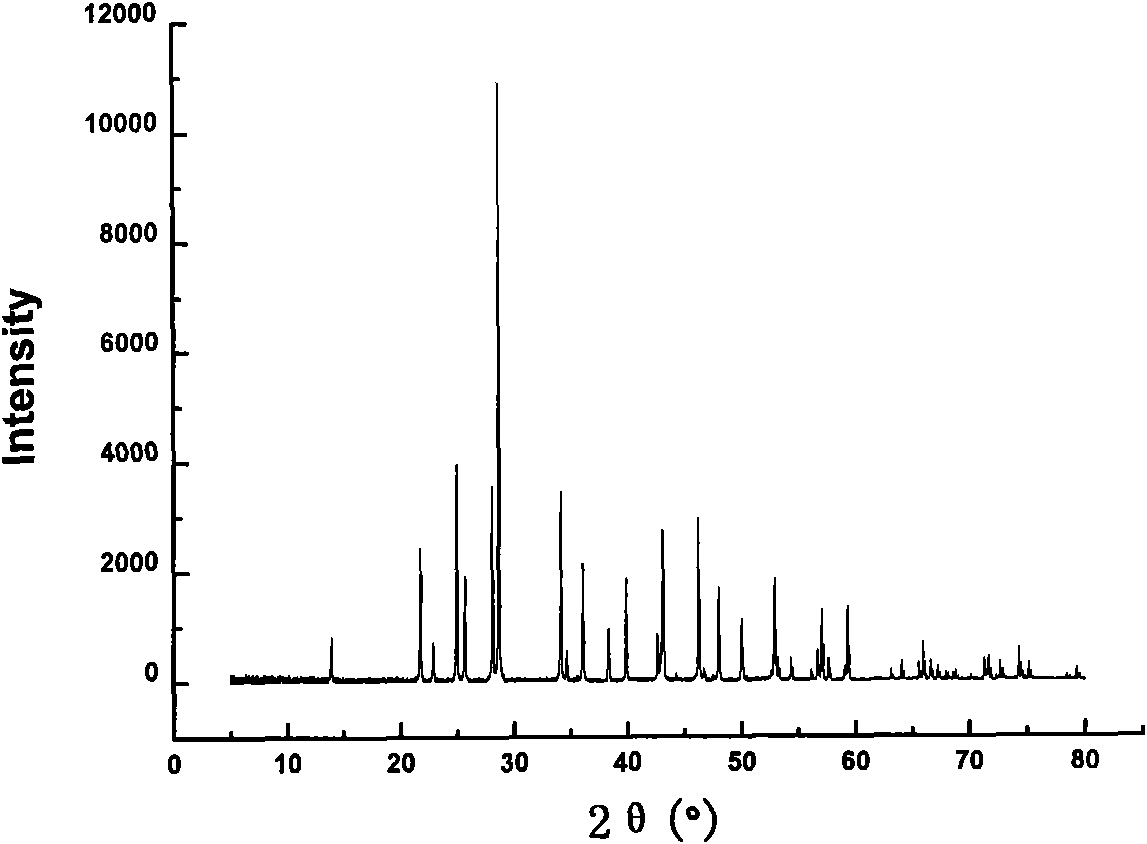

Nonlinear optical crystal of potassium borate chloride compound and preparation method as well as application thereof

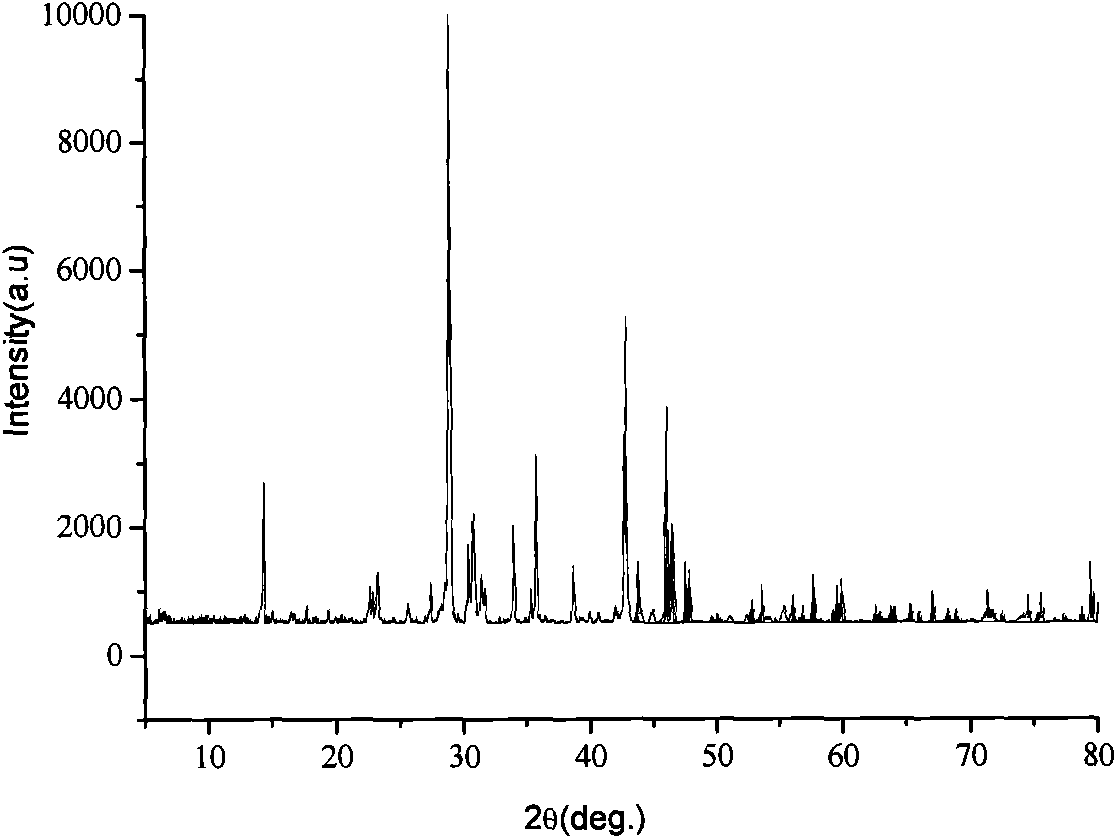

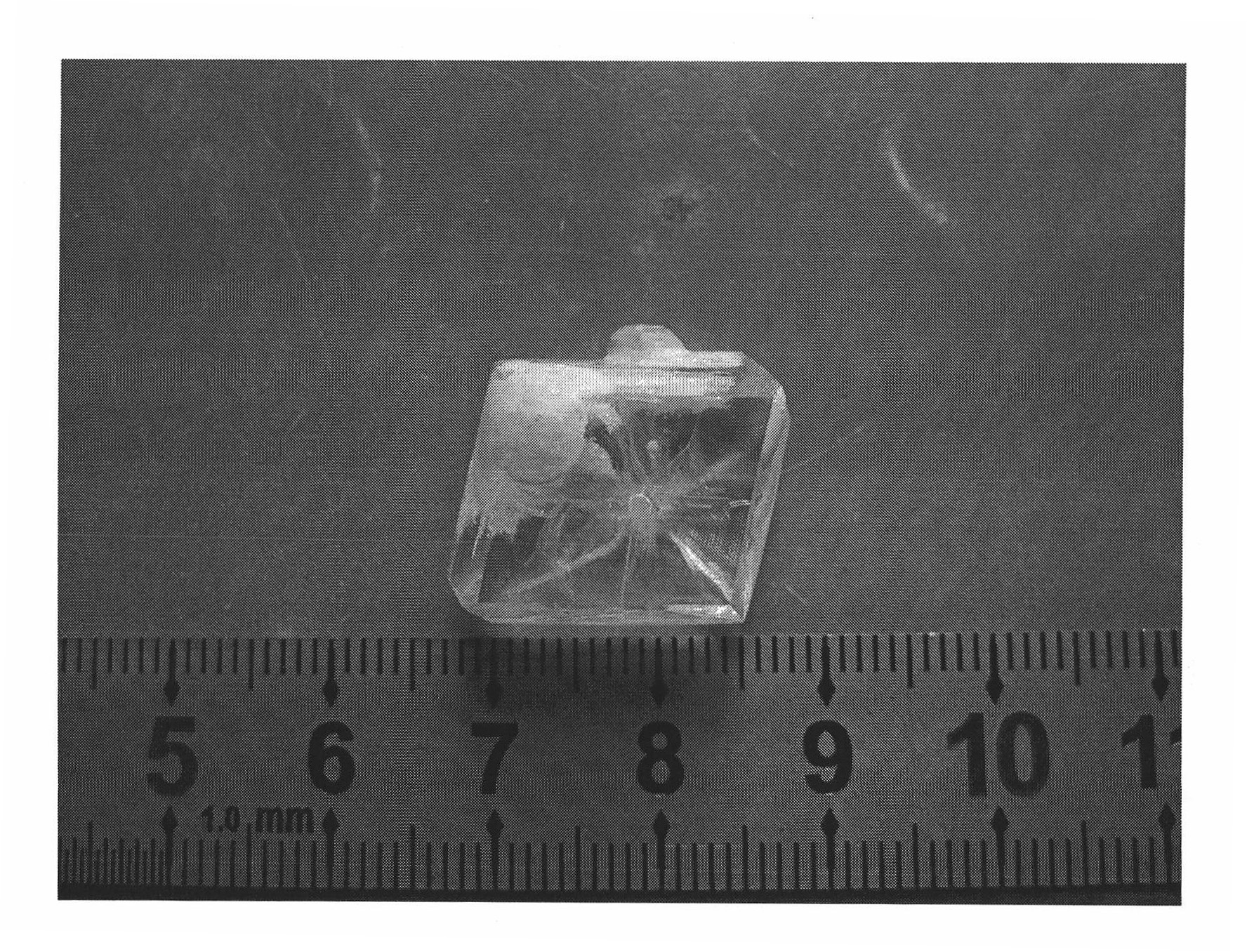

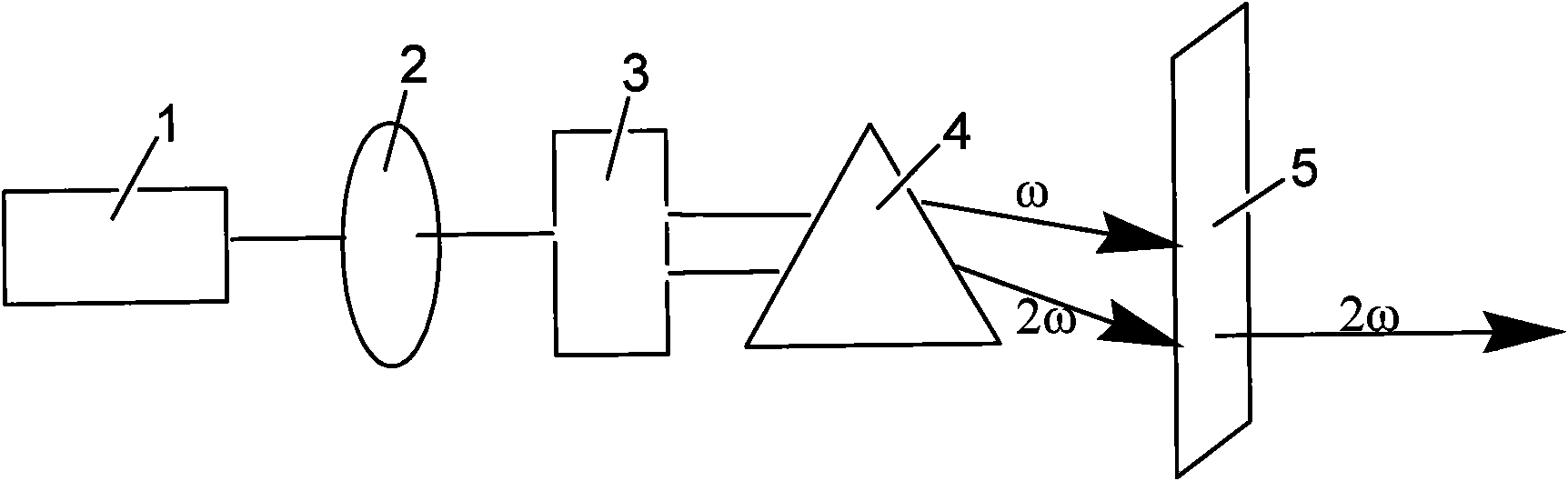

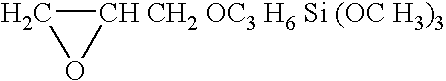

ActiveCN101914809APolycrystalline material growthFrom melt solutionsNonlinear optical crystalSpace group

The invention relates to a nonlinear optical crystal of a potassium borate chloride compound and a preparation method as well as application thereof. The chemical formula of the compound is K3B6O10Cl, and the molecular weight of the compound is 377.61. The crystal does not have a symmetric center and belongs to a trigonal system and a space group R3m, and cell parameters are as follows: a=10.0624(14), b=10.0624(14), c=8.8361(18), Z=3, and V=774.8 (2). The powder frequency-doubled effect reaches about 3 times of KDP(KH2PO4), the Mohs hardness is 4-5, and the light transmission waveband is 165nm-3460nm. A solid phase reaction method is used for synthesizing the compound, and a cosolvent method is used for growing the crystal. The crystal has the advantages of simple operation, low cost, large size, short growth cycle, few inclusion enclaves and larger mechanical hardness, and can be cut, polished, processed and saved easily. The crystal is used for generating twofold frequency or three-fold frequency or fourfold frequency or fivefold frequency harmonic light output for laser beams of which the wavelength is 1064nm.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Cellulose acylate film, cellulose acylate film with functional thin film, and method for preparation thereof

InactiveUS20040077752A1Easily brokenConvenient coatingImpression capsOther chemical processesMohs scale of mineral hardnessCellulose

The present invention relates to a cellulose acylate film having a high modulus of elasticity and a high surface hardness. The cellulose acylate film of the present invention is characterized by containing 1 vol % to 99 vol % of a metal oxide having an average particle size of 1 nm to 400 nm. The metal oxide used here is preferably a metal oxide having a Mohs hardness of at least 7, and specific examples thereof include aluminum oxide and silicon dioxide. This metal oxide may be subjected to a surface treatment. Furthermore, a functional thin film such as a hardcoat layer may be formed on the cellulose acylate film containing the metal oxide.

Owner:FUJIFILM CORP

Fluorine-containing meltable resin composition

An injection moldable fluorine-containing meltable resin composition comprising 70 to 98 wt. % of a fluorine-containing meltable resin, and 2 to 30 wt. % of a needle-shape material having an average diameter of 3 mum or less, an average aspect ratio of between 10 and 100, and Mohs hardness of between 5 and 8, which composition has good sliding and sealing properties and excellent moldability, in particular, moldability of thin wall articles.

Owner:DAIKIN IND LTD

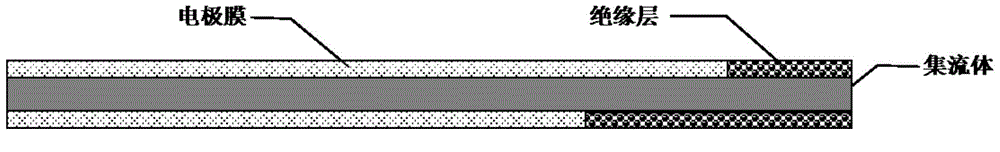

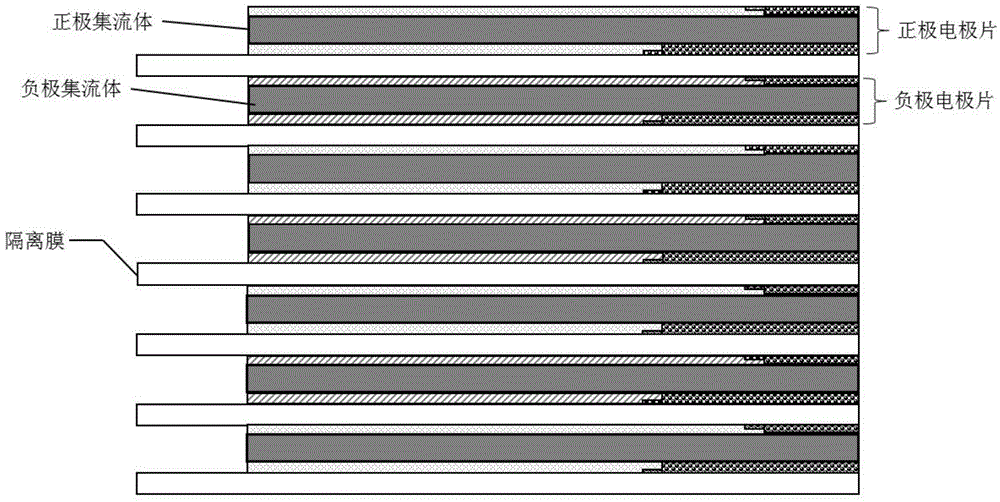

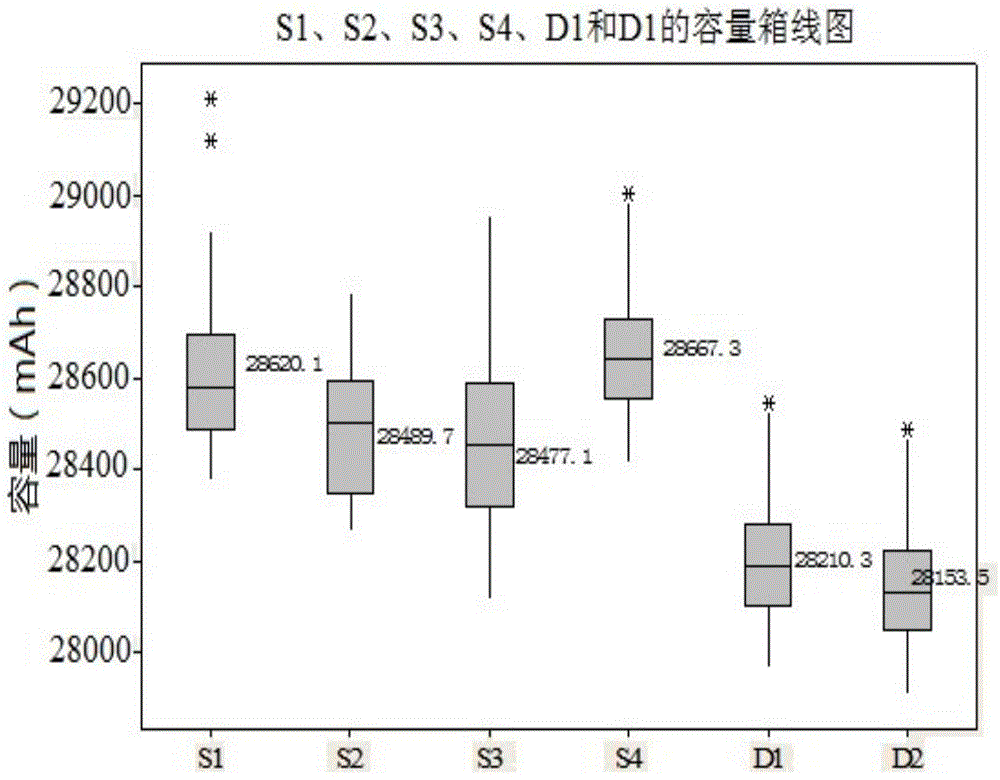

Electrode plate and lithium ion battery comprising same

ActiveCN104466097ASmooth appearanceSimple interfaceSecondary cellsNon-aqueous electrolyte accumulator electrodesCapacity lossMohs scale of mineral hardness

The invention relates to an electrode plate and a lithium ion battery comprising the same. The electrode plate comprises a current collector, an electrode diaphragm and an insulation layer; the electrode diaphragm comprises an electrode active substance; the insulation layer comprises solid insulation padding with the mohs hardness being less than or equal to 5; the insulation layer at least covers an area, which is not covered by the electrode diaphragm, of the surface of the current collector. By adopting the insulation layer, the safety problem caused by the piercing of burrs of the current collector to the diaphragm can be avoided; the insulation layer also has the good extension rate and the good effect on transferring the rolling pressure, the flat appearance of the electrode plate in rolling can be guaranteed, a good fitting interface of the electrode plate inside a cell also can be guaranteed, and the capacity loss of the lithium battery in the charging and discharging processes can be reduced.

Owner:DONGGUAN AMPEREX TECH +1

Compound potassium lead borophosphate nonlinear optical crystal as well as preparation method and application thereof

InactiveCN101876772AHigh birefringenceBroaden the field of studyPolycrystalline material growthFrom frozen solutionsNonlinear optical crystalPhosphate

The invention relates to a compound potassium lead borophosphate nonlinear optical crystal as well as a preparation method and application thereof. The compound has the chemical formula of KPbBP2O8. The preparation method comprises the following steps of: after uniformly mixing a raw material containing K, Pb, B and P by adopting a solid-phase reaction method, heating for carrying out solid-phase reaction to obtain a compound of the potassium lead borophosphate; and growing a crystal on the compound by adopting a melt method to obtain the potassium lead borophosphate nonlinear optical crystal. The compound is the centimeter-grade large size nonlinear optical crystal of a tetragonal crystal system; a space group is I-42d; cell parameters comprise a=7.1764(7), b=7.1764(7), c=13.9483(13), Z=4 and V=718.35; the powder frequency doubling effect of the compound is equivalent to that of KDP (Potassium Dihydrogen Phosphate); the Mohs hardness is 4 to 5; and the potassium lead borophosphate nonlinear optical crystal has the advantages of easy cutting, polishing processing and storage, no deliquescence, high preparation speed, simple operation, low cost, good mechanical performance, difficult cracking, stable physicochemical property, and the like and is suitable for manufacturing an nonlinear optical device.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Thermally conductive resin composition

InactiveUS20150299550A1Reduce frequencySatisfactory thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesMohs scale of mineral hardnessConductive polymer

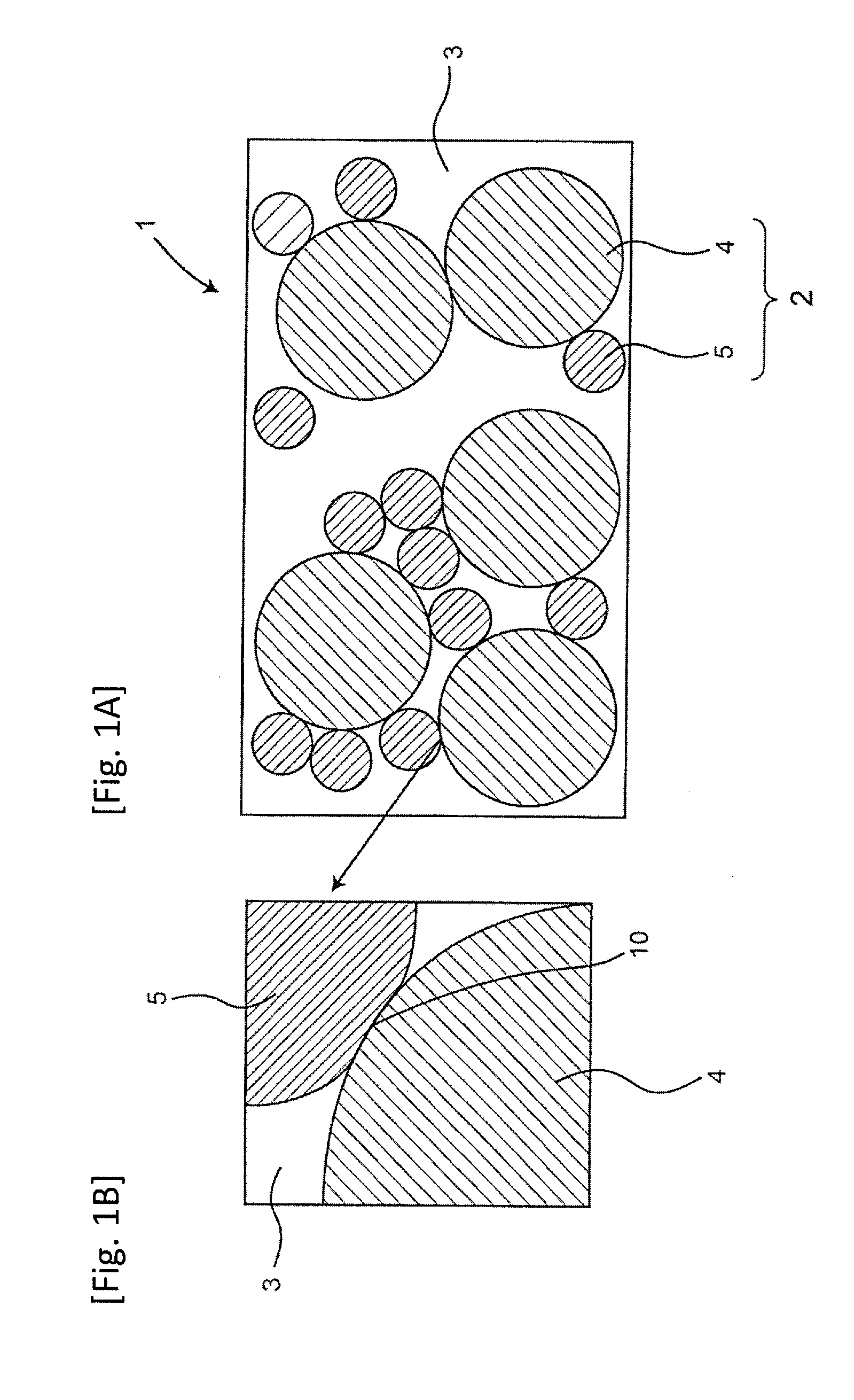

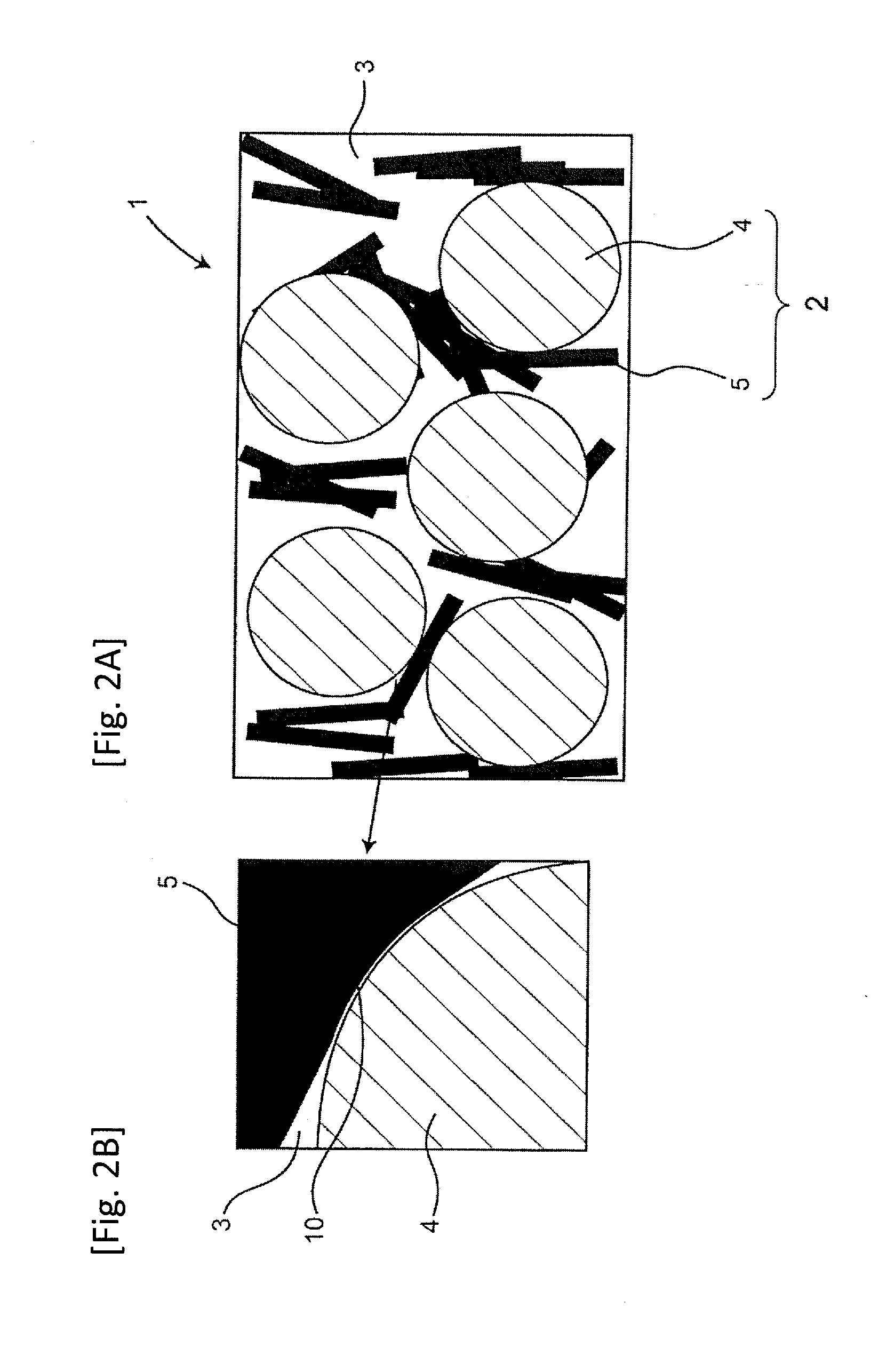

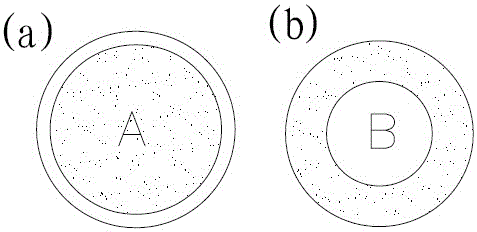

The present disclosure is directed to providing a thermally conductive resin composition which can realize high thermal conduction without increasing the content of a thermally conductive filler, and also exhibits satisfactory moldability. Disclosed is a thermally conductive resin composition, comprising:a thermally conductive filler; anda binder resin,wherein the thermally conductive filler contains:a hard filler having a Mohs hardness of 5 or more; anda soft filler having a Mohs hardness of 3 or less, andwherein when the thermally conductive resin composition is solidified to stabilize its shape, the soft filler is pressed by the hard filler in the thermally conductive resin composition so that a surface of the soft filler is deformed by the hard filler in the pressed state to provide a face contact between the soft filler and the hard filler.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Sliding Member Coating Composition

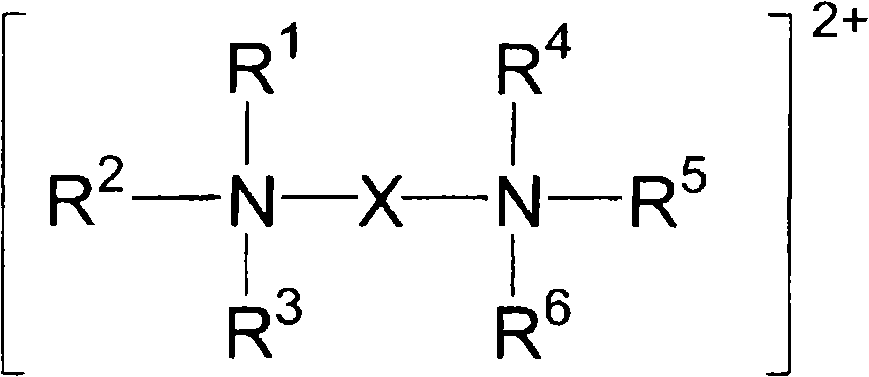

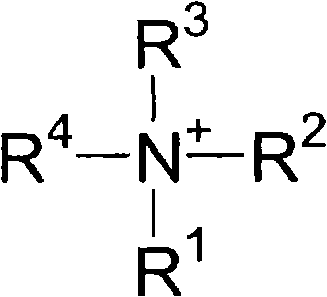

InactiveUS20120101011A1Increase surface areaIncrease in internal agglutination forceBearing componentsAdditivesMohs scale of mineral hardnessHardness

Owner:AKROS

Polishing liquid and polishing method using the same

ActiveCN101333417APolishing machinesOther chemical processesParticulatesMohs scale of mineral hardness

The present invention provides a polishing liquid for polishing a ruthenium-containing barrier layer, the polishing liquid being used in chemical mechanical polishing for a semi-conductor device having a ruthenium-containing barrier layer and conductive metal wiring lines on a surface thereof, the polishing liquid comprising an oxidizing agent; and a polishing particulate having hardness of 5 or higher on the Mohs scale and having a composition in which a main component is other than silicon dioxide (SiO2). The present invention also provides a polishing method for chemical mechanical polishing of a semi-conductor device, the method contacting the polishing liquid with the surface of a substrate to be polished, and polishing the surface to be polished such that contacting pressure from a polishing pad to the surface to be polished is from 0.69 kPa to 20.68 kPa.

Owner:FUJIFILM CORP

Friction material

InactiveUS7297728B2Improve effectivenessExcellent brake feelBraking element arrangementsOther chemical processesMohs scale of mineral hardnessShell molding

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

Polymer-fiber composite building material with bulk and aesthetically functional fillers

ActiveUS7473722B2Reduce resin usageResist attackSynthetic resin layered productsGirdersFiberMohs scale of mineral hardness

Polymer composite building materials are provided which contain resin, and about 20-75 wt. % fillers and additives, in which the fillers contain at least one bulk filler for reducing the amount of resin needed to make the building material, and at least one aesthetically functional filler for providing the building material with an aesthetic appearance. The bulk filler and the aesthetically functional filler of this embodiment are non-toxic, resistant to microbial attack, and have a Mohs hardness of less than about 5.

Owner:BARRETTE OUTDOOR LIVING INC

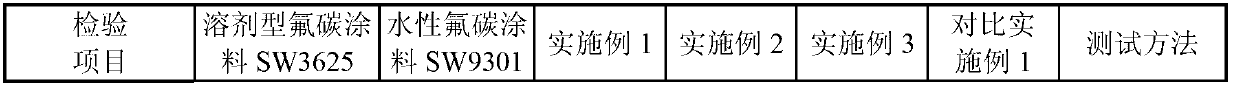

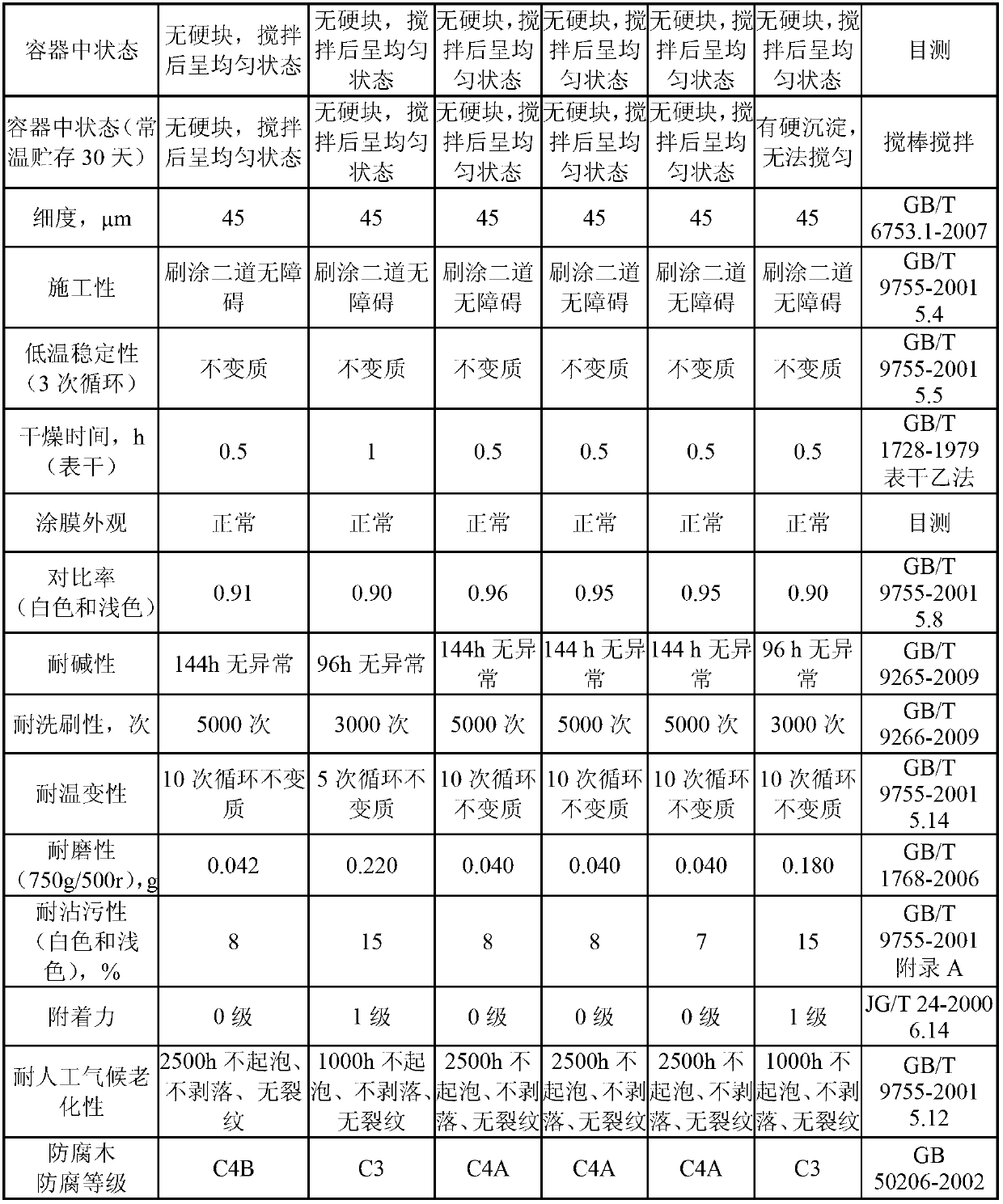

Waterborne fluorocarbon coating, and preparation method and application thereof

ActiveCN102898904AImprove wear resistanceGood alkali resistanceCoatingsMohs scale of mineral hardnessFoaming agent

The invention discloses a waterborne fluorocarbon coating, and a preparation method and application thereof. A formula for raw materials of the waterborne fluorocarbon coating comprises 13.0 to 48.0% of a waterborne fluorocarbon emulsion, 1.0 to 3.0% of hydroxyethyl cellulose, 10.5 to 18.8% of an inorganic pigment, 18.2 to 32.2% of a filling material, 5.0 to 7.0 % of wear-resistant powder, 0.6 to 2.3% of a wetting dispersant, 0.5 to 1.0% of a multifunctional auxiliary agent, 0.1 to 0.5% of a de-foaming agent, 0.4 to 4.0% of a bactericide, 0.1 to 3.2% of a thickening agent, 0.6 to 3.0% of a film forming auxiliary agent, 1.0 to 4.2% of an anti-freezing agent and 14.0 to 20.0% of water, wherein the pH value of the waterborne fluorocarbon coating is 8.0 to 9.5, and the Moh's hardness of the wear-resistant powder is more than 9.0. The waterborne fluorocarbon coating has no toxicity, no pollution and both functions of decoration and protection; a paint film formed by the coating has good wear resistance and weatherability and can improve anti-corrosive performance and wear resistance of a regenerated woodwork.

Owner:上海三银涂料科技股份有限公司

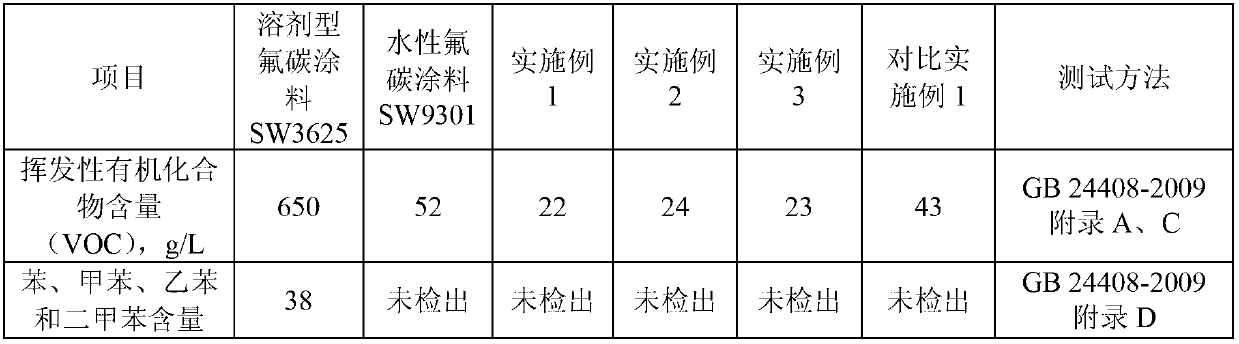

Detergent resin composition for shaping apparatus

InactiveCN101245290AImprove removal effectOrganic detergent compounding agentsMohs scale of mineral hardnessHardness

The invention provides a cleaning agent resin composite which is suitable for being used as a cleaning agent for a thermosetting resin forming machine, in particular to a cleaning agent resin composite which is used for a forming machine; wherein, 100 weight parts (A) of non-crystalline resin comprise 20 to 200 weight parts (B) of inorganic fillers with the mohs hardness of 3 to 8; depending on needs, the composite comprises 1 to 10 weight parts (C) of surfactants and the proportion of the composite is 1.15 to 2.5.

Owner:DAICEL POLYMER LTD

Environment friendly heat resistant opal crystalline glass and its prepn process

InactiveCN101066837AUniform chemical compositionReduce dosageGlass furnace apparatusGlass blowing apparatusMohs scale of mineral hardnessSmelting process

The present invention discloses one kind of environment friendly heat resistant opal crystalline ceramic glass and its preparation process. The opal crystalline ceramic glass is prepared with base material, supplementary material and additive and through one electric smelting process at 1480-1520 deg.c. It consists of SiO2 67.0-78.0 wt%, Al2O3 5.0-7.5 wt%, CaO 1.0-1.5 wt%, MgO 1.5-2.0 wt%, Na2O 4.0-6.0 wt%, F- 3.0-5.0 wt%, ZnO 1.3-1.5 wt%, B2O3 2.2-4.0 wt%, BaO 1.0-1.5 wt%, and K2O 3.0-4.0 wt%. It has thermal expansion coefficient not higher than 7.0x10<-6> / deg.c, Mohs hardness up to 6.5, thermal shock resisting temperature higher than 150 deg.c and high water resistance, and is ideal substitute for traditional porcelain.

Owner:JIANGSU AOBO CRYSTALLINE GLASS SOI TECH

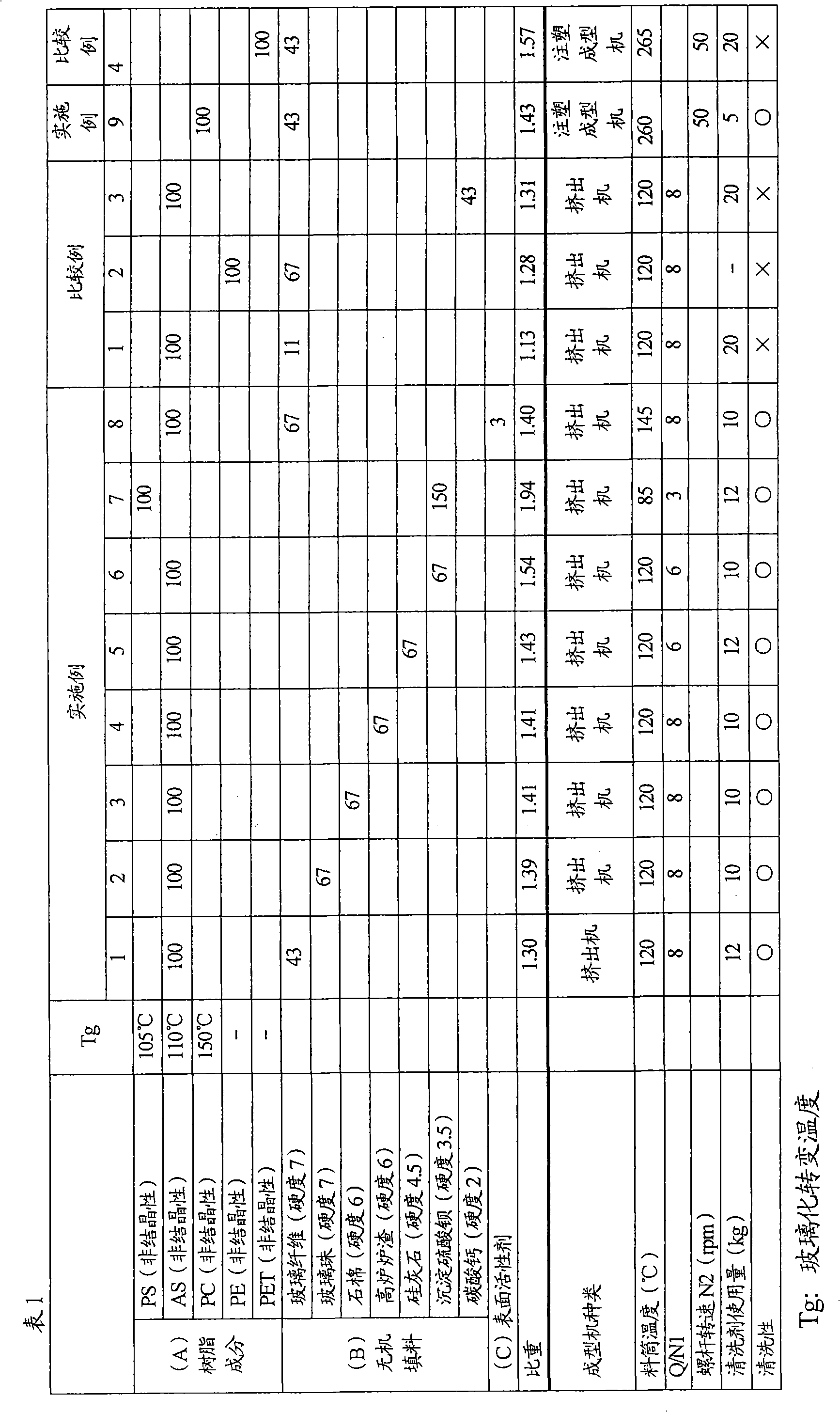

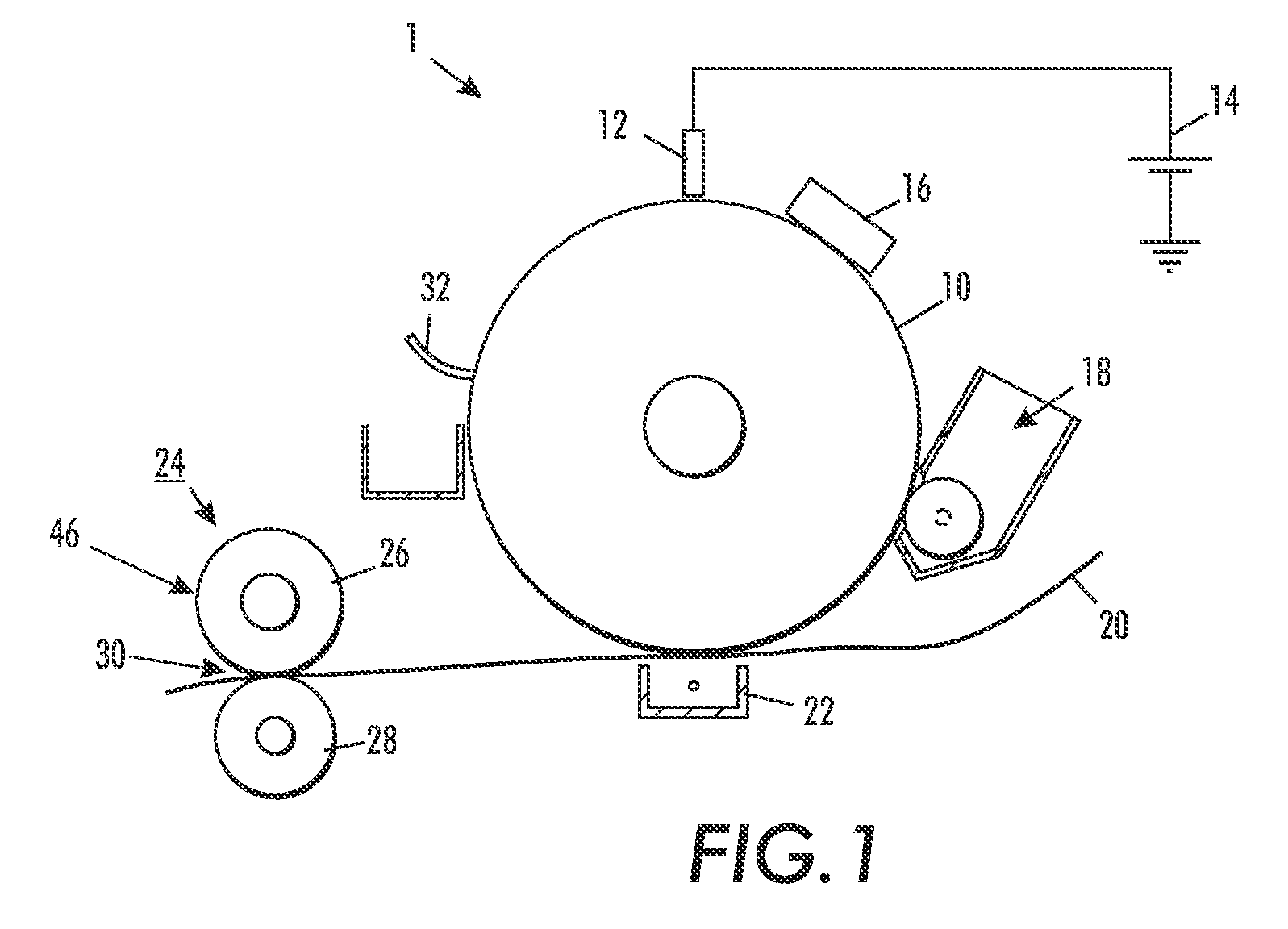

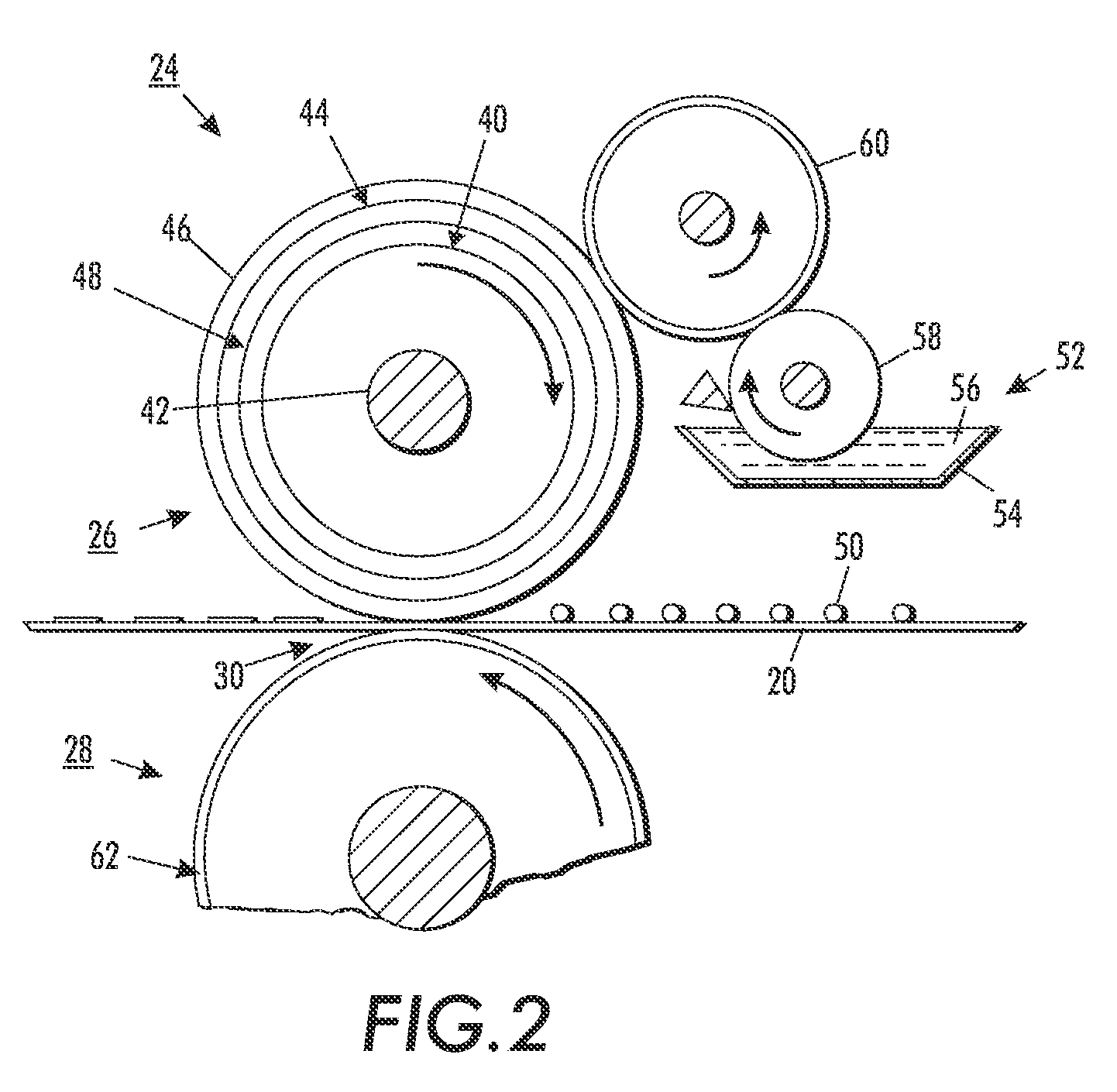

Fuser member with nano-sized filler

A fuser member suited to use in a fusing apparatus of an electrostatographic image rendering device includes a substrate and an outer layer over the substrate. The outer layer includes a matrix material and filler particles dispersed in the matrix material. an outer layer comprising a halopolymer and filler particles. The filler particles have a particle size of less than about 1 micrometer and a particle hardness of greater than about 3 on a Mohs hardness scale and form no more than about 3 percent by volume of the outer layer. The outer layer comprising filler particles nonetheless may provide improved wear of the fuser member.

Owner:XEROX CORP

High thermal conductivity membrane adhesive, adhesive composition and semiconductor package using the adhesive and manufacturing method thereof

ActiveCN102676105AReduce wear rateExcellent adhesionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsMohs scale of mineral hardnessEpoxy

The invention provides a high thermal conductivity membrane adhesive, an adhesive composition and a semiconductor package using the adhesive and a manufacturing method thereof. The high thermal conductivity membrane adhesive composition is characterized by including epoxy resin (A), an epoxy hardener (B), an inorganic filler (C) and phenoxy resin (D). The inorganic filler (C) meets all the flowing conditions of (i)-(iii) and the content of the inorganic filler (C) is 30-70 volume%: (i) a mean grain size being 0.1-5.0 [mu] m; (ii) moh 's hardness being 1-8; (iii) thermal conductivity being above 30 w / (m.k).

Owner:FURUKAWA ELECTRIC CO LTD

Cutting-resistant ultra high molecular weight polyethylene fiber, preparation method and application thereof

ActiveCN106350882AImprove cut resistanceExcellent processabilitySpinnerette packsWet spinning methodsFiberMohs scale of mineral hardness

The invention relates to cutting-resistant ultra high molecular weight polyethylene fiber, a preparation method and application thereof. The cutting-resistant ultra high molecular weight polyethylene fiber is endless tow or / and short fiber in morphology; the matrix of the polyethylene fiber comprises rodlike particles; the Moh's hardness of each rodlike particle is of grade 3 and above (one with high hardness is preferred); the length-diameter ratio of each rodlike particle is greater than or equal to 2 micrometers; the diameter of each rodlike particle is smaller than 30 micrometers. By adopting the cutting-resistant ultra high molecular weight polyethylene fiber, the cutting resistance of high molecular weight polyethylene fiber and a fabric of the high molecular weight polyethylene fiber can be improved, the fiber has post processing properties prior to those of conventional cutting-resistant fiber of a same grade and fabrics of the conventional cutting-resistant fiber, and the cost can be lowered.

Owner:CHANGSHU SUPERFIBER

Disc brake pad

ActiveUS20110259686A1Effective formabilityEffective resistanceBraking membersFriction liningFiberMohs scale of mineral hardness

To provide a disc brake pad for a disc brake equipped with a metal disc rotor, having a friction material that includes a fiber base material, a binder, an abrasive material, and a frictional wear modifier, which effectively minimizes a sticking problem of the friction material and the disc rotor and simultaneously provides effective fading resistance, wear resistance, and formability. The friction material includes the fiber base material, binder, abrasive material, and frictional wear modifier, and friction material has the binder of 4.5-7.0 weight % relative to the gross friction material amount, aralkyl modified phenolic resin of at least 50 weight % relative to the binder amount, inorganic particles of 1-3 weight % as the abrasive material with 6-8 of Moh's hardness and average particle diameter of 10-200 μm. Furthermore, the friction material includes alkali metal titanate and / or alkali earth metal titanate of 20-30 weight %.

Owner:NISSHINBO BRAKE INC

High hardness transparent glass-ceramic and preparation method thereof

The present invention provides a high hardness transparent glass-ceramic and a preparation method thereof, wherein the high hardness transparent glass-ceramic comprises, by weight, 55.0-70.0% of SiO2, 15.0-20.0% of Al2O3, 0-10.0% of MgO, and 0-12.5% of ZnO, and must contain one of MgO and ZnO, and the crystallized glass contains the micro-crystal of the spinel crystal. According to the present invention, the suitable precursor glass is used to carry out the heat treatment and the micro-crystal is subjected to crystallization precipitation from the glass matrix so as to prepare the high hardness transparent glass-ceramic, wherein the Mohs hardness is more than 7, and the 1 mm glass visible light transmittance is greater than 80%; and the high hardness transparent glass-ceramic overcomes the easy scratching problem f the common optical glass, and can be used as mobile phone protection panels, optical instruments, and protection lens, magnetic disk substrates, liquid crystal display device panels r other optoelectronic device protection lens and the like on communication equipment.

Owner:CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com