Patents

Literature

281results about How to "Improve sound insulation and noise reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection-molded type TPO (thermoplastic polyolefin) compound for sound-insulating pads for automobiles as well as preparation method of compound

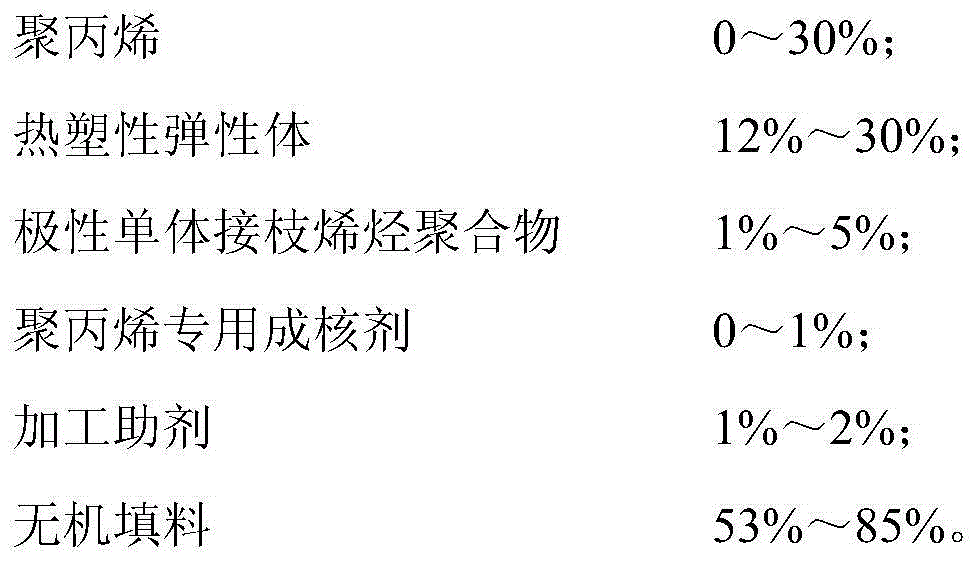

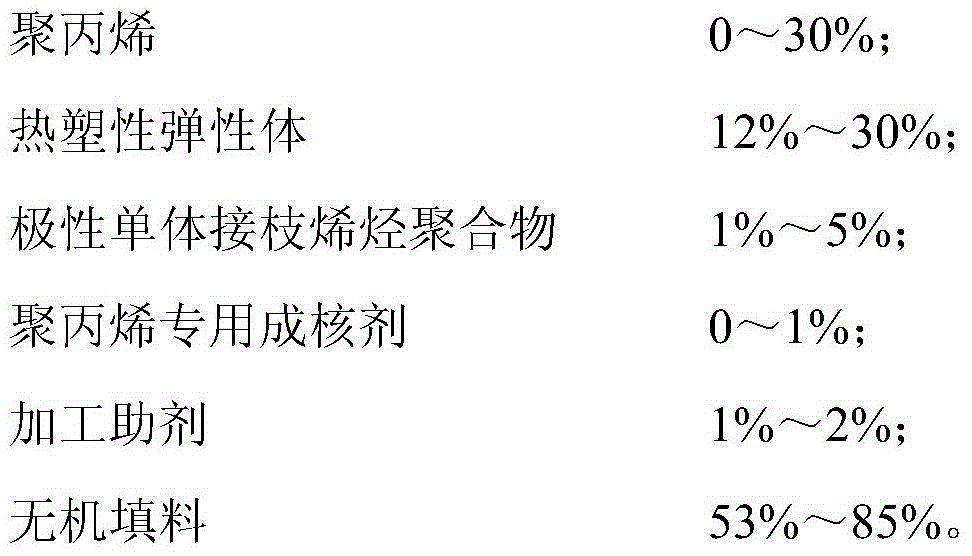

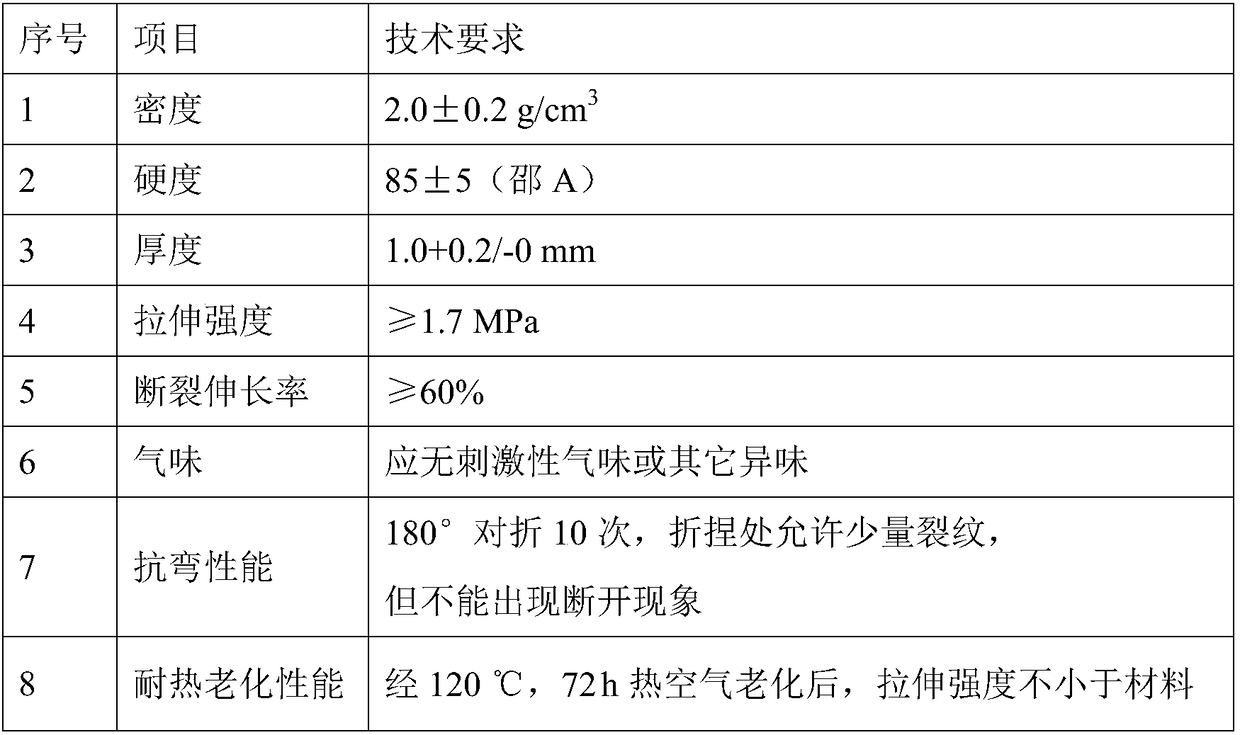

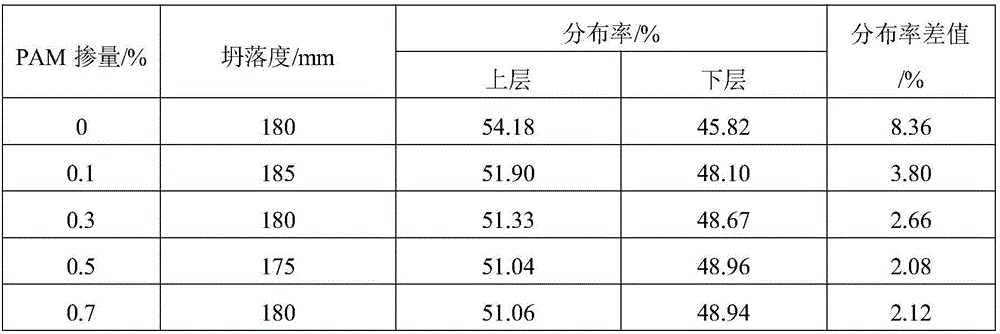

The invention discloses an injection-molded type sound-insulating pad heavy TPO (thermoplastic polyolefin) compound capable of meeting the automobile interior emission requirement as well as a preparation method of the compound. The sound-insulating pad TPO compound consists of 0-30wt% of PP (polypropylene), 12-30wt% of a thermoplastic elastomer, 1-5wt% of a polar monomer grafted olefin polymer, 0-1wt% of a special nucleating agent for PP, 1-2wt% of a processing aid and 53-85% of inorganic filler. The preparation method comprises steps as follows: the PP, the thermoplastic elastomer, the polar monomer grafted olefin polymer, the special nucleating agent for the PP and the processing aid are molten, mixed and dispersed in a twin-screw extruder, inorganic powder is added to the twin-screw extruder through a weight-loss type measuring scale in a side feeding manner, extrusion and granulation are performed, and the compound is obtained finally. The material has the characteristics of good sound-insulating and noise-reducing effect and low emission, the performance requirement for sound-insulating pad materials for automobiles is met, and injection molding of the heavy TPO material is realized.

Owner:SHANGHAI KINGFA SCI & TECH +1

Modified asphalt waterproof coating, preparation method for modified asphalt waterproof coating and use method thereof

ActiveCN106957601AAvoid reunionTechnical effect of avoiding subsidenceBituminous coatingsBituminous waterproofingSlurry

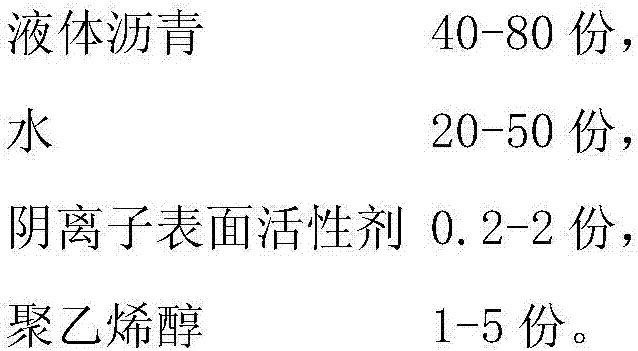

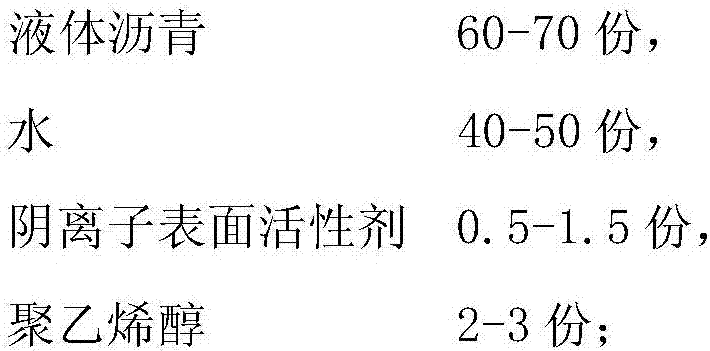

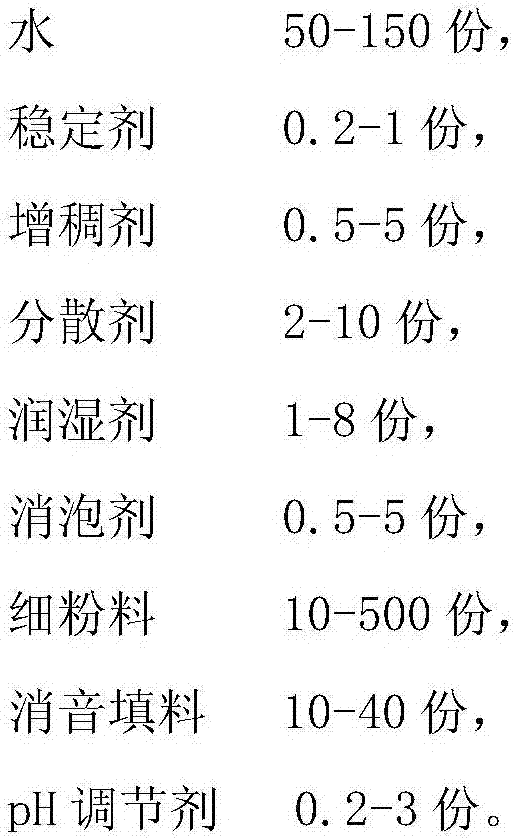

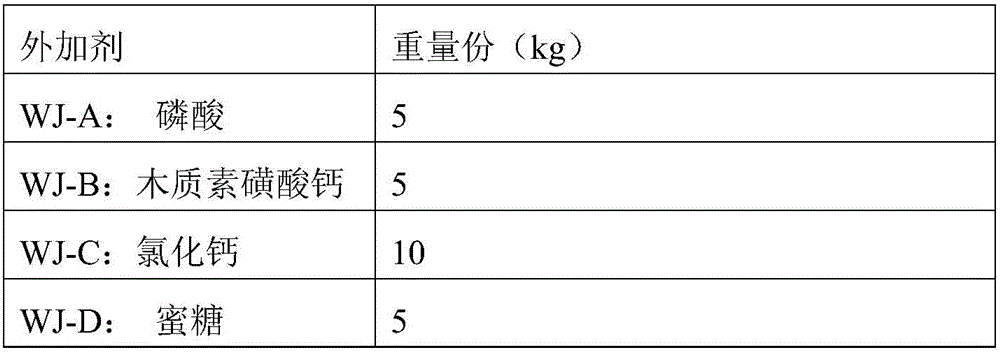

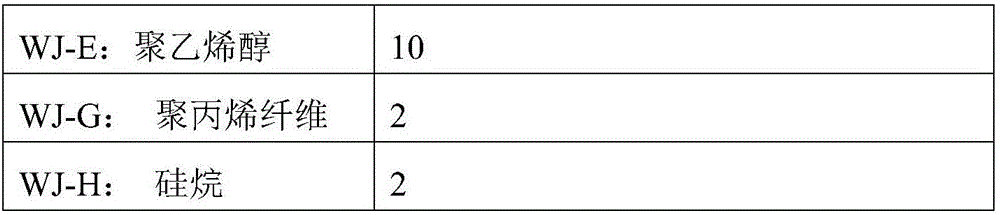

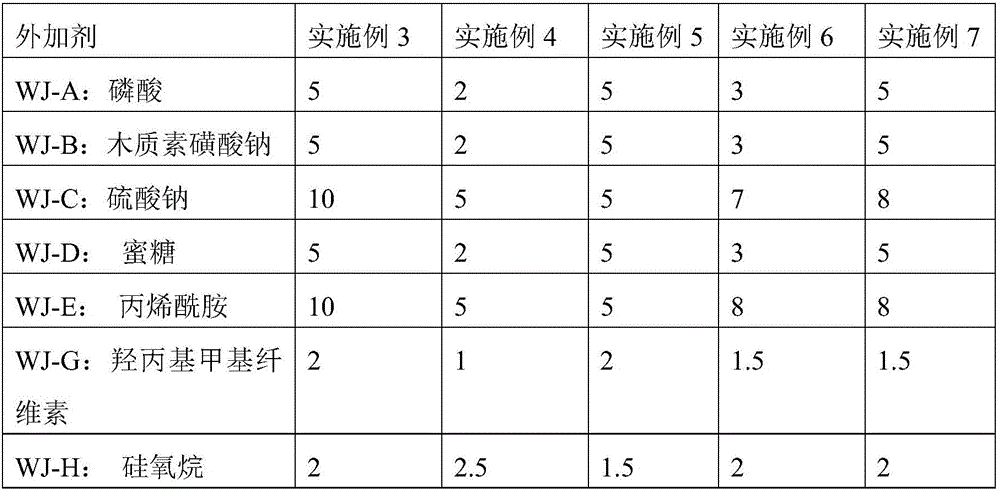

The invention discloses a modified asphalt waterproof coating, a preparation method for the modified asphalt waterproof coating and a use method thereof and relates to the field of building materials. The problems of sound insulation and noise reduction of the waterproof coating film can be solved. The preparation method for the modified asphalt waterproof coating disclosed by the invention comprises the following steps: preparing the modified asphalt waterproof coating from a component A and a component B; mixing and uniformly stirring anion emulsified asphalt, polymer emulsion and slurry, thereby acquiring the component A; and uniformly mixing water with curing agent, thereby acquiring the component B, wherein the slurry is prepared according to the following steps: adding water, stabilizer, dispersing agent, wetting agent, de-foaming agent, fine powder and pH regulator into a dispersing device, dispersing for the first time, adding a silencing filling material soaked with a silane coupling agent solution after ending the dispersing for the first time, and then adding a thickening agent, dispersing for the second time and then ending the dispersing for the second time, thereby acquiring the slurry. The modified asphalt waterproof coating disclosed by the invention has excellent effects of sound insulation and noise reduction on the basis of excellent waterproof property.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Magnesium oxysulfate cement foamed bricks and preparation method therefor

InactiveCN105859243ALow densityHigh mechanical strengthCeramic shaping apparatusCeramicwareBrickAbsorption rate

The invention relates to the field of building ware and particularly relates to magnesium oxysulfate cement foamed bricks and a preparation method therefor. The magnesium oxysulfate cement foamed bricks disclosed by the invention are prepared from the raw materials in parts by weight: 100 parts of magnesium sulfate, 50-200 parts of magnesia, 0-500 parts of filler and 30-350 parts of water, 8-50 parts of hydrogen peroxide and an admixture, wherein the addition level of the admixture is 0.1% to 5% the weight of magnesium oxysulfate cement. The magnesium oxysulfate cement foamed bricks disclosed by the invention are low in density, high in mechanical strength, small in coefficient of thermal conductivity, low in water absorption rate and good in humidity resistance and has a good fireproof effect. The preparation method for the magnesium oxysulfate cement foamed bricks disclosed by the invention is simple and is applicable to large-scale popularization and application.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

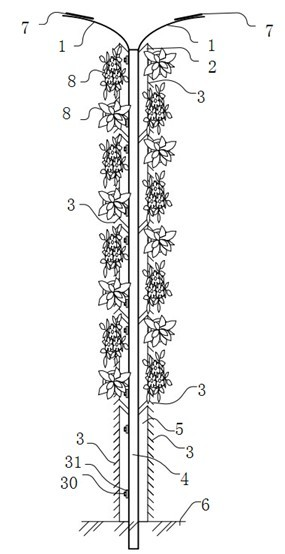

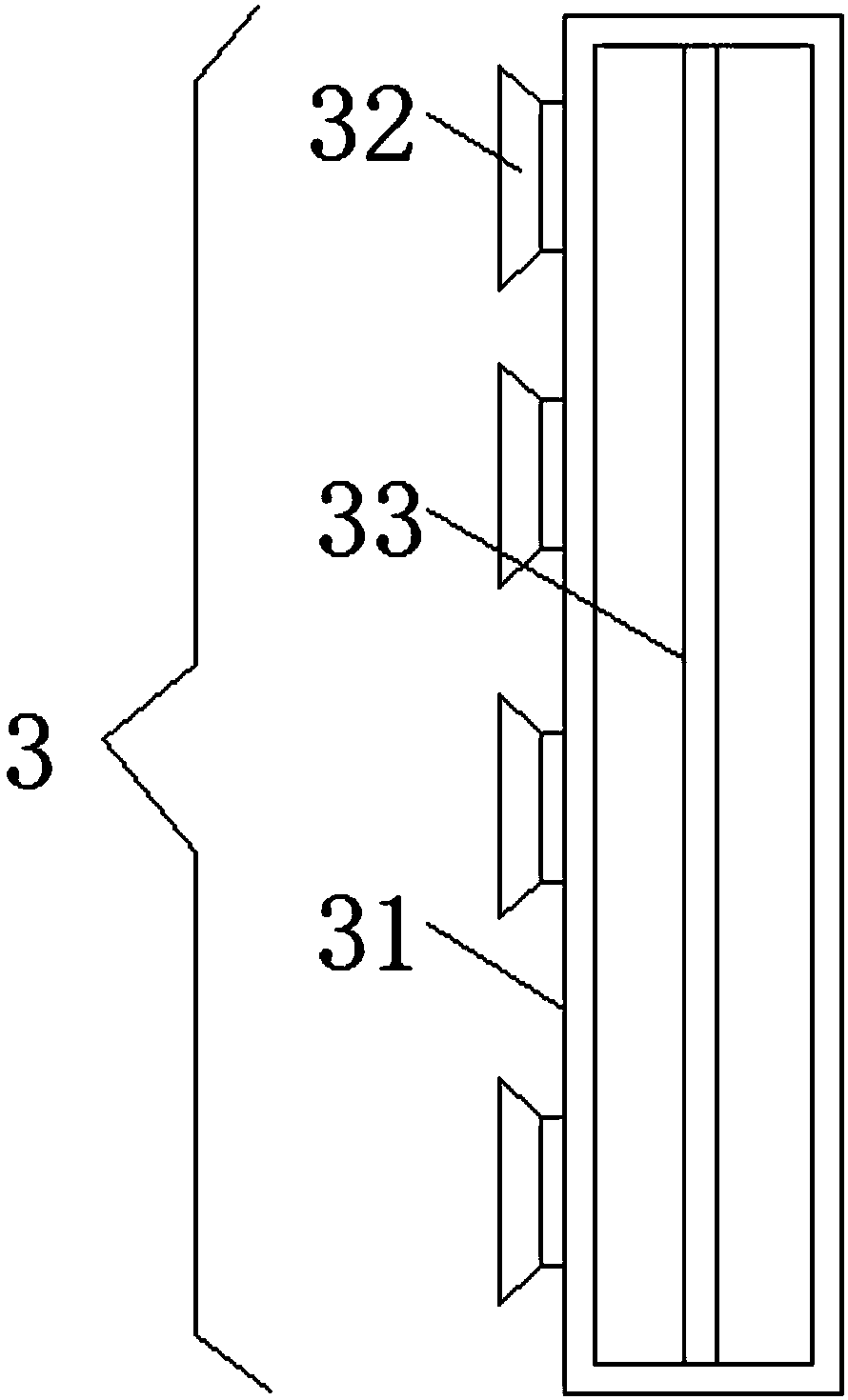

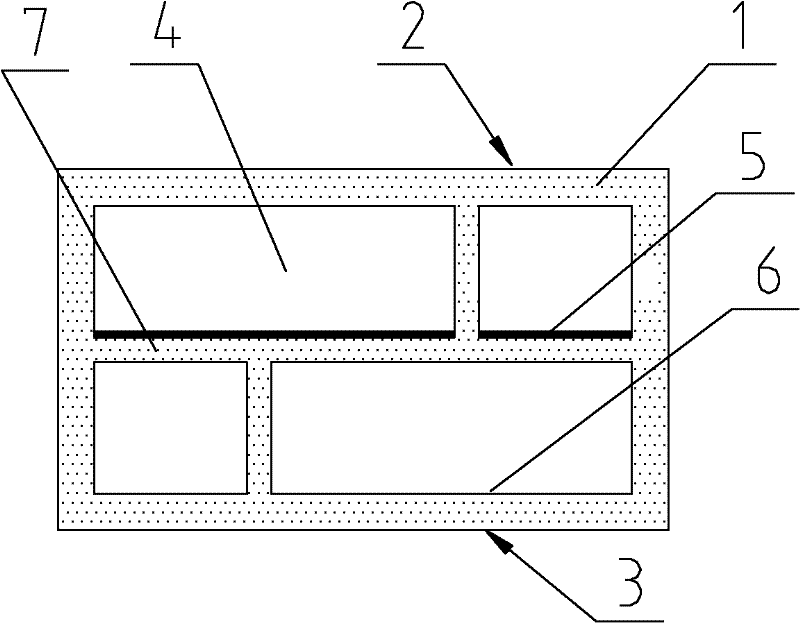

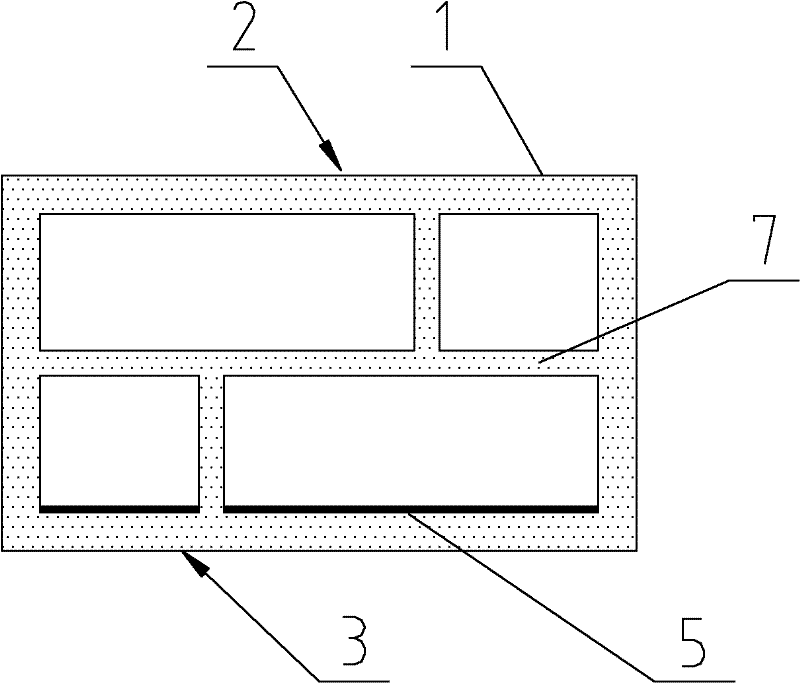

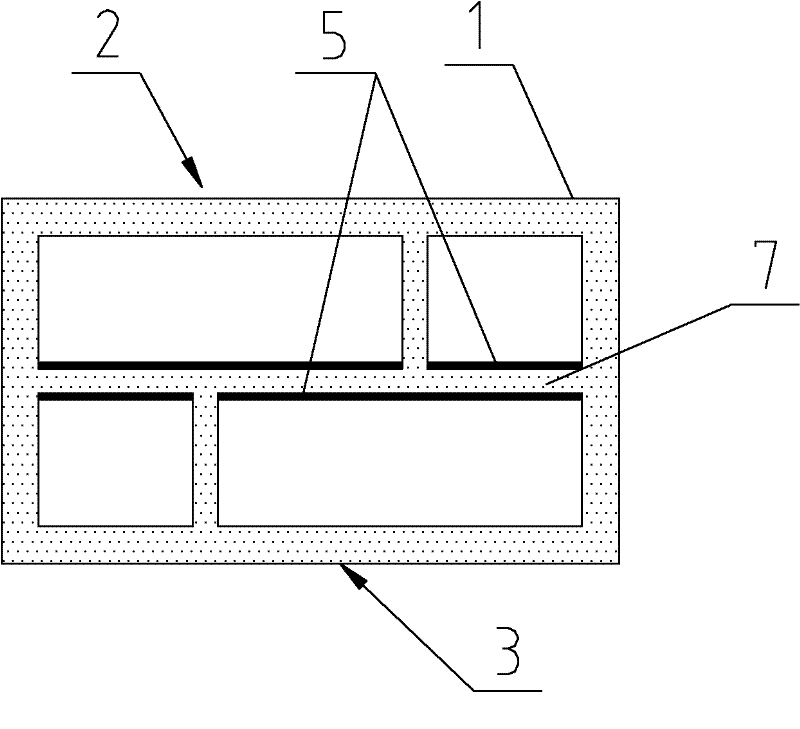

Plant noise barrier

InactiveCN102409625AReduce pollutionAvoid visual fatigueNoise reduction constructionPlant stemNoise barrier

The invention relates to a plant noise barrier, which comprises a bracket upright column (4), wherein one or more plant cultivation boxes (2) are fixed on the bracket upright column (4); a plurality of sound insulation fins (3) are arranged outside the plant cultivation boxes (2); and an inclined angle is formed between each sound insulation fin (3) and the horizontal plane. The plant noise barrier has the effects of beautifying roads, preventing visual fatigue and absorbing carbon dioxide and harmful gases, can insulate sound and reduce noise by coacting the sound insulation fins and complexoverlapped plant stems and leaves, greatly reduces automobile and other noise pollution, and has better sound insulation and noise reduction effects than the traditional single noise barrier. Moreover, because each sound insulation fin has a noise reduction structure and is more effective than a wall which insulates sound and reduces noise through plants singly, the defects that the wall hardly has sound insulation and noise reduction effects in the absence of plants are overcome.

Owner:四川融熠科技有限公司

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

Car spare tire cover plate manufacturing method

The invention discloses a car spare tire cover plate manufacturing method which comprises the following steps: delivering PP (polypropylene) engineering plastic particles into a charging barrel above a blow molding machine; heating and delivering the plastic particles to an extrusion die head by virtue of an extrusion screw rod; fixing a punched non-woven fabric on the fixed die cavity plate of a blow molding die; extruding molten plastic from the die head through the extrusion die head, thus forming a primary blank; sealing the lower end of the primary blank through a sealing device, starting the die head for blowing, thus forming the blank with needed dimension through blowing expansion, and starting die assembly; when the die assembly is in place, starting an oil cylinder on a supporting plate instantaneously so as to push a reinforcing rib forming push plate on a fixing plate to extrude the blank, delaying for 1-2 seconds, retreating the oil cylinder, and simultaneously starting a blowing needle for blowing; carrying out blowing forming and cooling; and carrying out die sinking when preset forming and cooling time is achieved, and taking out the finished product. The spare tire cover plate manufactured by the method is light in mass, good in sound-insulating effect, large in bearing force and good in attaching effect of the body and the fabric.

Owner:NINGBO SUNLIGHT MOTOR PARTS

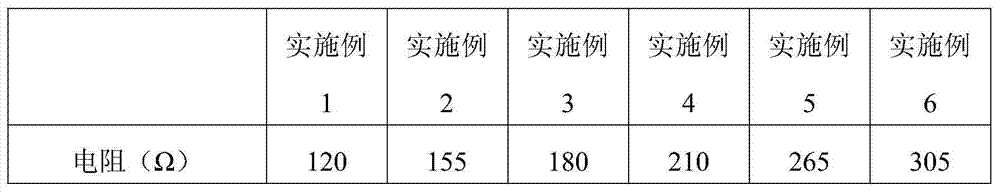

Multifunctional wallpaper capable of shielding Wi-Fi signals and production method thereof

InactiveCN103924758AConductiveWith sound insulation and noise reductionAntifouling/underwater paintsLamination ancillary operationsWater basedElectricity

The invention relates to multifunctional wallpaper capable of shielding Wi-Fi signals and a production method thereof. The multifunctional wallpaper comprises a base, a multifunctional layer on the base, and a pattern layer printed on the multifunctional layer. The production method of the multifunctional wallpaper includes the steps of selecting base material; preparing material of the multifunctional layer; preparing evenly-dispersed slurry; preparing uniform water-based paint; preparing the multifunctional layer; printing the multifunctional layer; producing a finished product. The multifunctional wallpaper has the functions of shielding Wi-Fi signals, conducting electricity, insulating, decreasing noise, inhibiting bacteria, preventing molds, proofing moisture and the like, human, equipment and information security can be protected, and application range of the wallpaper is widened.

Owner:宋旭 +1

Preparation and construction process for bottom-coating used for mineral cotton ceiling floor

InactiveCN101565580AHas a three-dimensional textureUnique three-dimensional textureLiquid surface applicatorsStarch dervative coatingsMildewUltimate tensile strength

The invention discloses a preparation and a construction process for a bottom-coating used for a mineral cotton ceiling floor. The bottom-coating used for the mineral cotton ceiling floor is a liquid-type layer material. The construction process comprises five procedures of testing substrate plates, spraying and coating the bottom-coating, high-temperature baking, re-spraying bottom-coating and re-baking at high temperature. The bottom-coating used for the mineral cotton ceiling floor has the advantages of strong stereoscopic feeling, strong decoration, excellent fireproof and moisture-proof function, reinforcing the tensile strength of the plate, mildew resistance, reducing noise, long service life, yellowing resistance, low VOC, convenient construction, etc. The bottom-coating used for the mineral cotton ceiling floor is matched with the mineral cotton ceiling floor, has unique stereoscopic feeling, can change the visible effect of the room space and is applicable to the decoration of the ceiling decorative surfaces of various top-grade buildings.

Owner:鳄鱼制漆(上海)有限公司

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

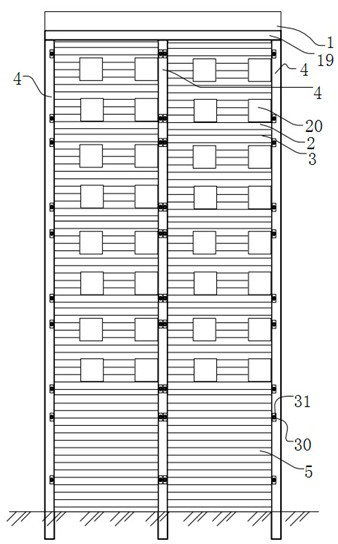

High-strength composite corrugated fiber foam cement heat insulation material

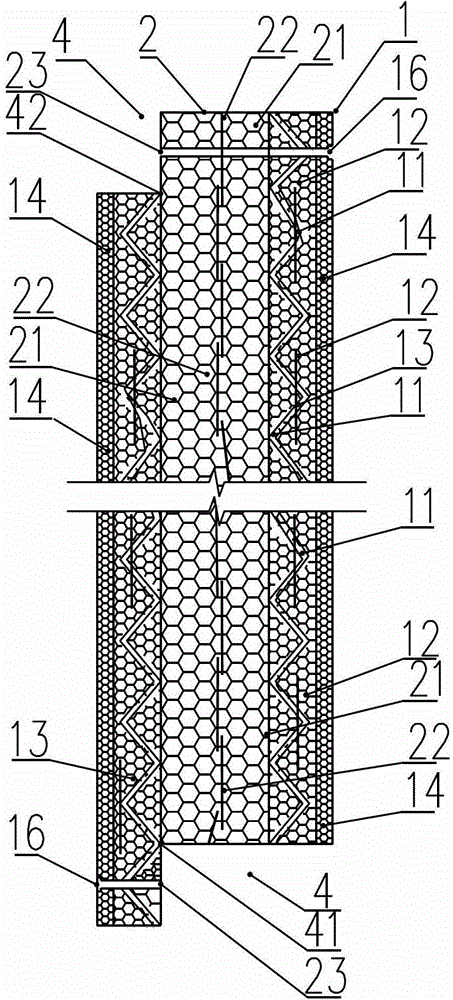

InactiveCN103334504AImprove sound insulation and noise reductionImprove thermal insulation performanceHeat proofingWater-setting substance layered productEnvironmental resistanceFiber

The invention discloses a high-strength composite corrugated fiber foam cement heat insulation material. Aiming at the defects that organic materials such as polyphenyl, extruded sheet and polyurethane, belonging to petroleum extractant, are complicated in structure, easy to age, inflammable, easy to crack, easy to seep and are short in service life, and inorganic materials such as a foam cement heat insulation board cannot reach the use strength of a wall body, the invention designs the high-strength composite corrugated fiber foam cement heat insulation material. The heat insulation material comprises corrugated fiber cement heat insulation material, composite foam cement heat insulation material, a fixed connecting support component, and concave-convex or male-female connecting mortise and tenon joints. The design purposes of meeting the use strength of a building outer wall and reducing the cost are realized by utilizing the performances of low heat conductivity coefficient, non-inflammability, high compression resistance and breaking strength of the foam cement, foamed ceramics and corrugated fiber cement plate and a pouring extrusion and foam technique. The high-strength composite corrugated fiber foam cement heat insulation material has the characteristics that the performances of heat preservation and insulation, non-inflammability and fireproofing, sound insulation and noise reduction, lightweight earthquake and acid rain resistance can be improved, and the material has the advantages on performance that the structure is simple, the material is saved, the mounting and dismounting are convenient, the construction efficiency is high, the service life is long, the cost is low, the material can be used as a finished wall body and recycled, and is energy-saving and environmental-protection.

Owner:BENXI NATURAL ICE PREPARATION ENG

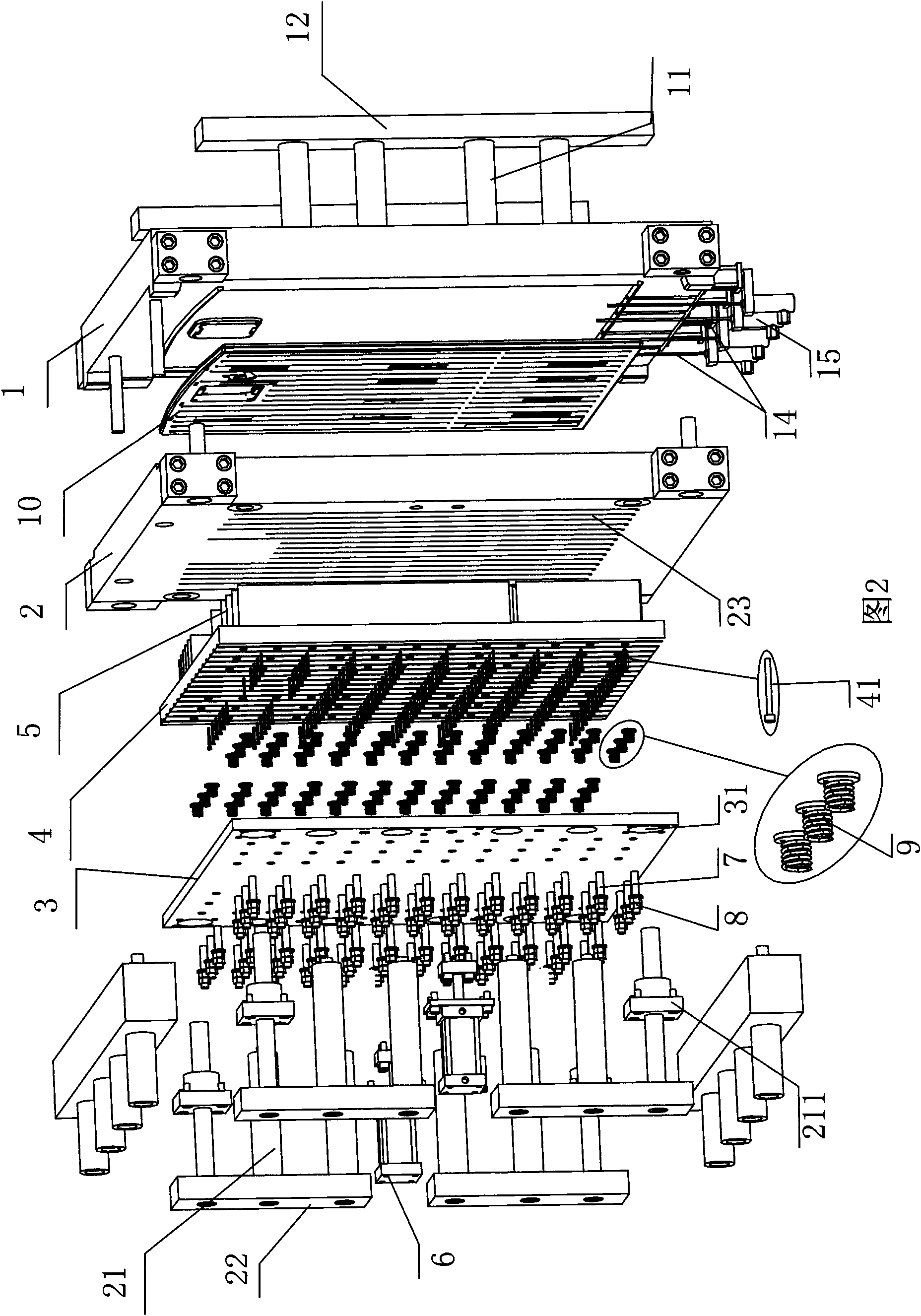

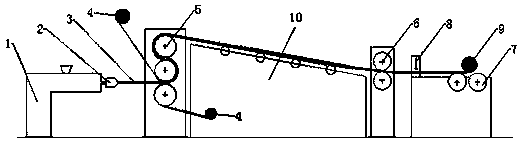

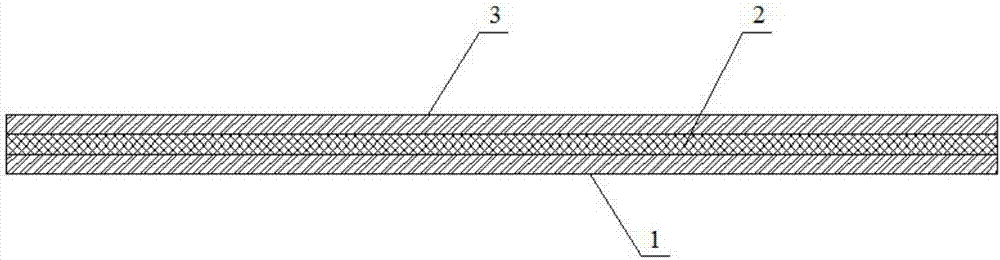

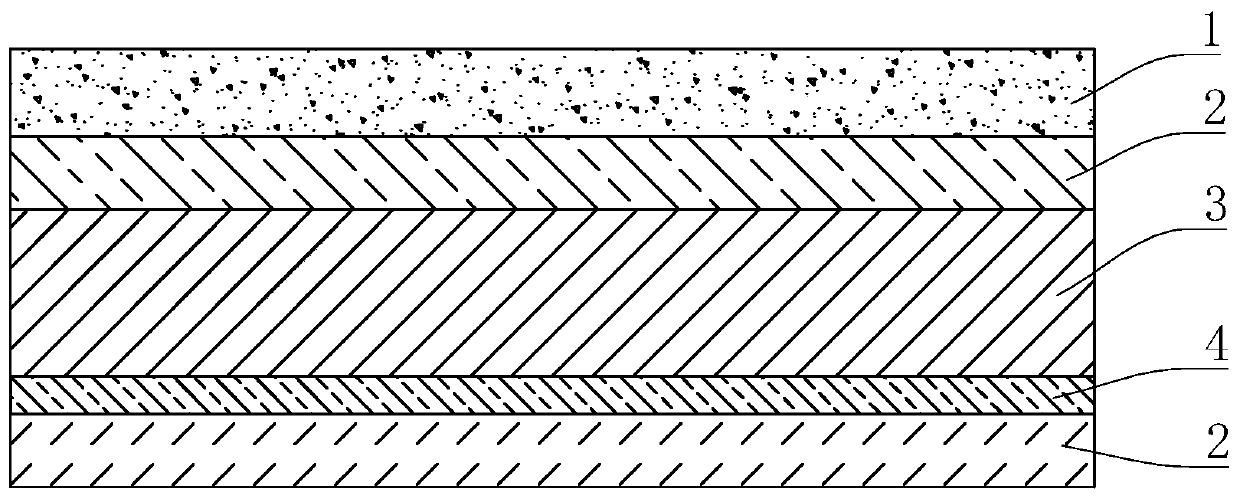

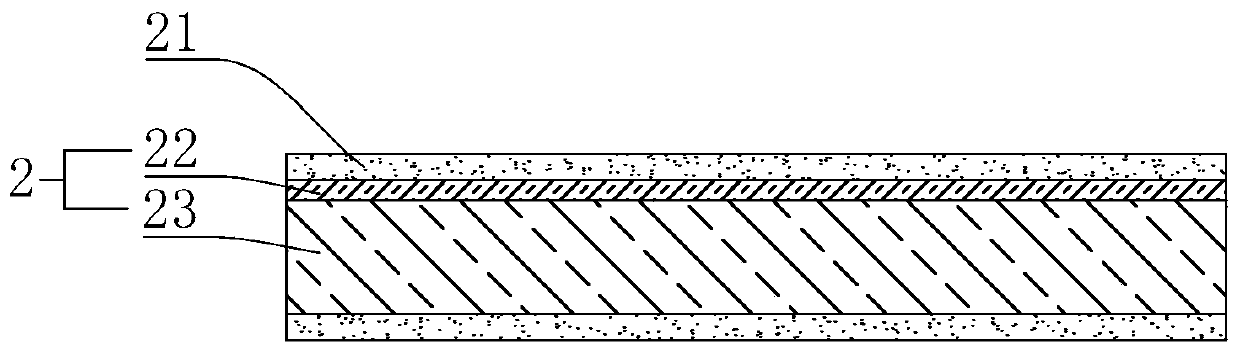

PVC (polyvinyl chloride) double side compound sound-proof felt and preparation method thereof

PendingCN108128005AImprove sound insulation and noise reductionOptimize layoutPositive displacement pump componentsSynthetic resin layered productsFiberCompound structure

The invention discloses PVC (polyvinyl chloride) double-side compound sound-proof felt and a preparation method of the felt. The PVC double-side compound sound-proof felt is in an A-B-A layered structure; the A-B-A layered structure comprises a PVC heavy layer, and fiber punched felt compounded on the upper surface and the lower surface of the PVC heavy layer. The novel PVC sound-proof felt adoptsa compound structure; a sound-proof component for an air conditioner compressor can be conveniently arranged and quickly mounted; the sound-proof felt can achieve the best sound-proof, noise reduction, damping and shock absorption effects; in addition, the sound-proof felt further has effects of effectively protecting harnesses and copper pipes against oscillation wear and removing abnormal sloshing sound; and the sound-proof felt is environment-friendly and stable in performance. The preparation method is simple, and adopts hot-melt rolling compounding, and the product is free from lamination and has good practicability.

Owner:ZHENJIANG MEIDA PLASTICS CO LTD

Rubber aggregate concrete

InactiveCN106045388AImprove mechanical propertiesImprove sound insulation and noise reductionSolid waste managementAnhydrous ethanolPolymer science

The invention discloses a rubber aggregate concrete which is prepared by mixing cement, water, fly ash, gravel, sand, rubber aggregate, a polycarboxylic acid high efficiency water reducing agent and an organosiloxane defoaming agent by a common concrete mixing method. The weight ratio of water to cement is 0.40-0.5. The rubber aggregate is modified by anhydrous ethanol. The modification process comprises the following steps: (1) immersing rubber aggregate in anhydrous ethanol for 23-25 hours, and filtering; (2) cleaning the immersed rubber aggregate granule surface with tap water; and (3) drying the cleaned rubber aggregate at 60-70 DEG C. The rubber aggregate concrete overcomes the defect of reduction of the concrete strength and uniformity after the rubber is added in the traditional concrete, ensures the concrete to have the strength and uniformity characteristics of the traditional concrete on the premise of ensuring favorable elastic damping, noise reduction, sound insulation, ductility and toughness of the ensure, and further promotes the recycling of the waste rubber.

Owner:CHONGQING CONSTR RESIDENTIAL ENG

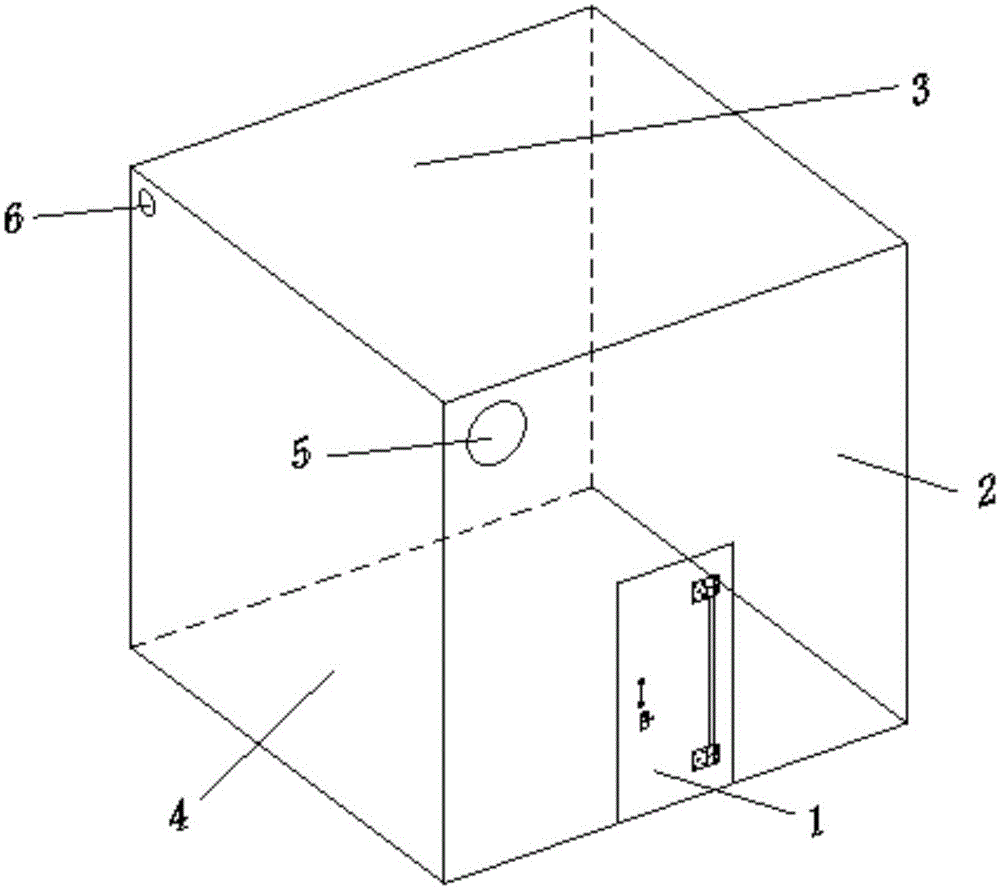

Safe refuge for families

ActiveCN104153628AEnsure the safety of life and propertyEffective isolation of radioactive contaminationSolid waste managementProtective buildings/sheltersNuclear radiationEngineering

The invention provides a safe refuge for families. The safe refuge is arranged in a building and comprises an anti-explosion wall, an anti-explosion door, an anti-explosion ceiling and an anti-explosion bottom plate, wherein the anti-explosion door is arranged on one side of the anti-explosion wall; the anti-explosion ceiling is positioned on the top of the anti-explosion wall; the anti-explosion bottom plate is positioned on the bottom of the anti-explosion wall; and the anti-explosion wall, the anti-explosion door, the anti-explosion ceiling and the anti-explosion bottom plate form closed space. The safe refuge for the families can simultaneously defend or partially defend the following damage events: earthquake disasters, occasional terrorist attacks (light weapon and explosion of a small amount of explosives), violent burglary, 'nuclear radiation weapons' and even nuclear explosion.

Owner:江苏爵格工业集团有限公司

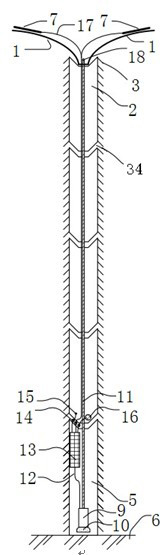

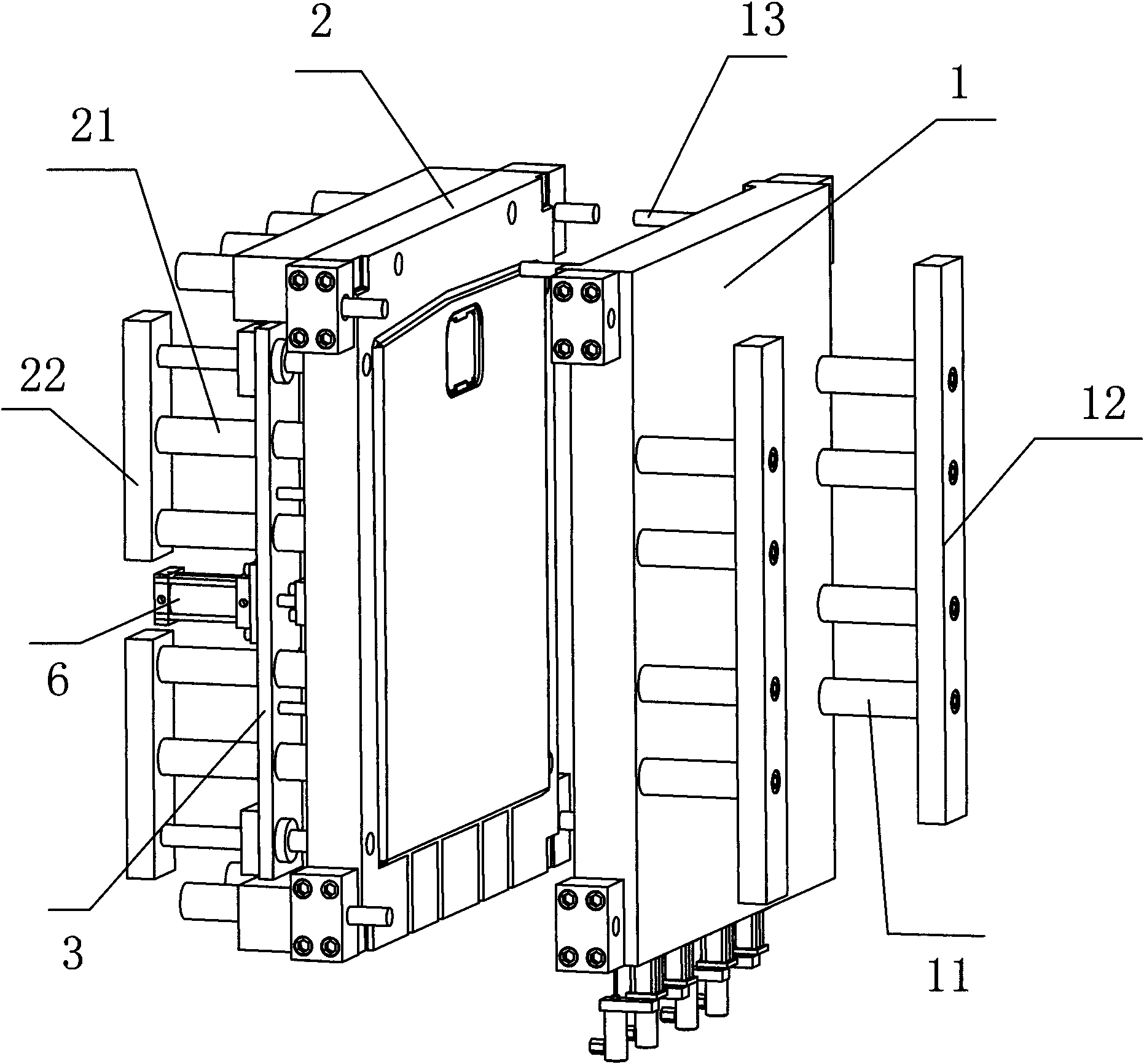

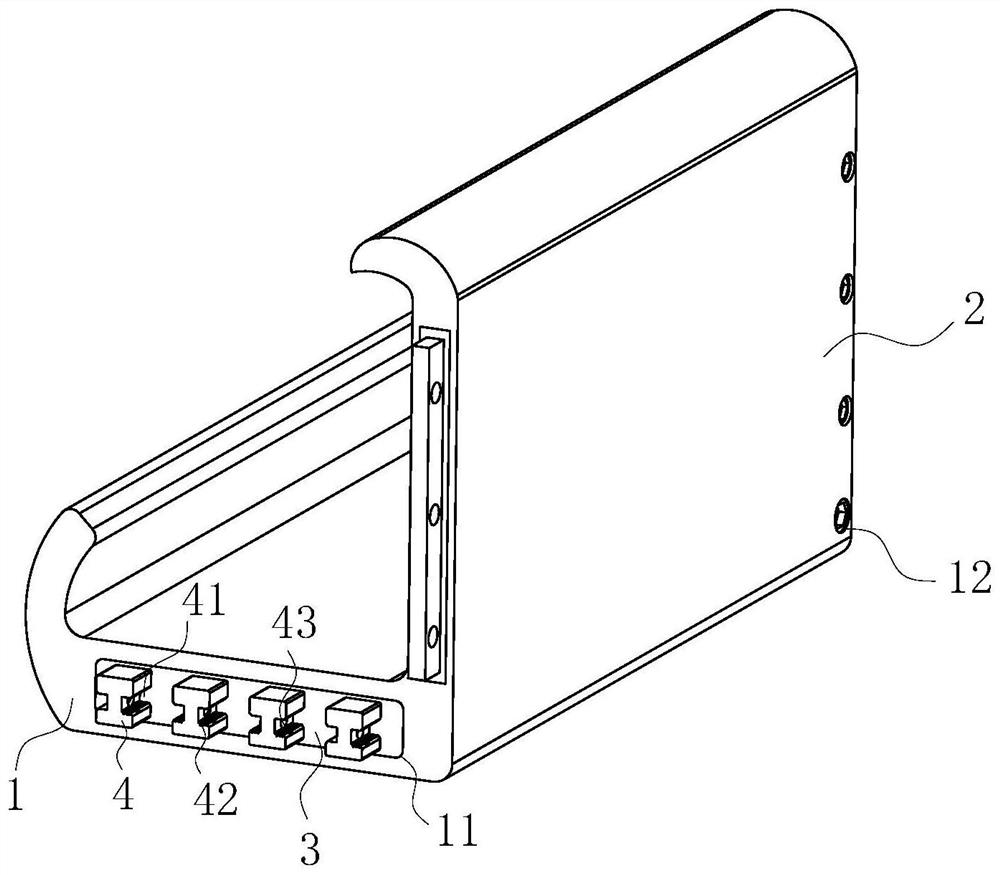

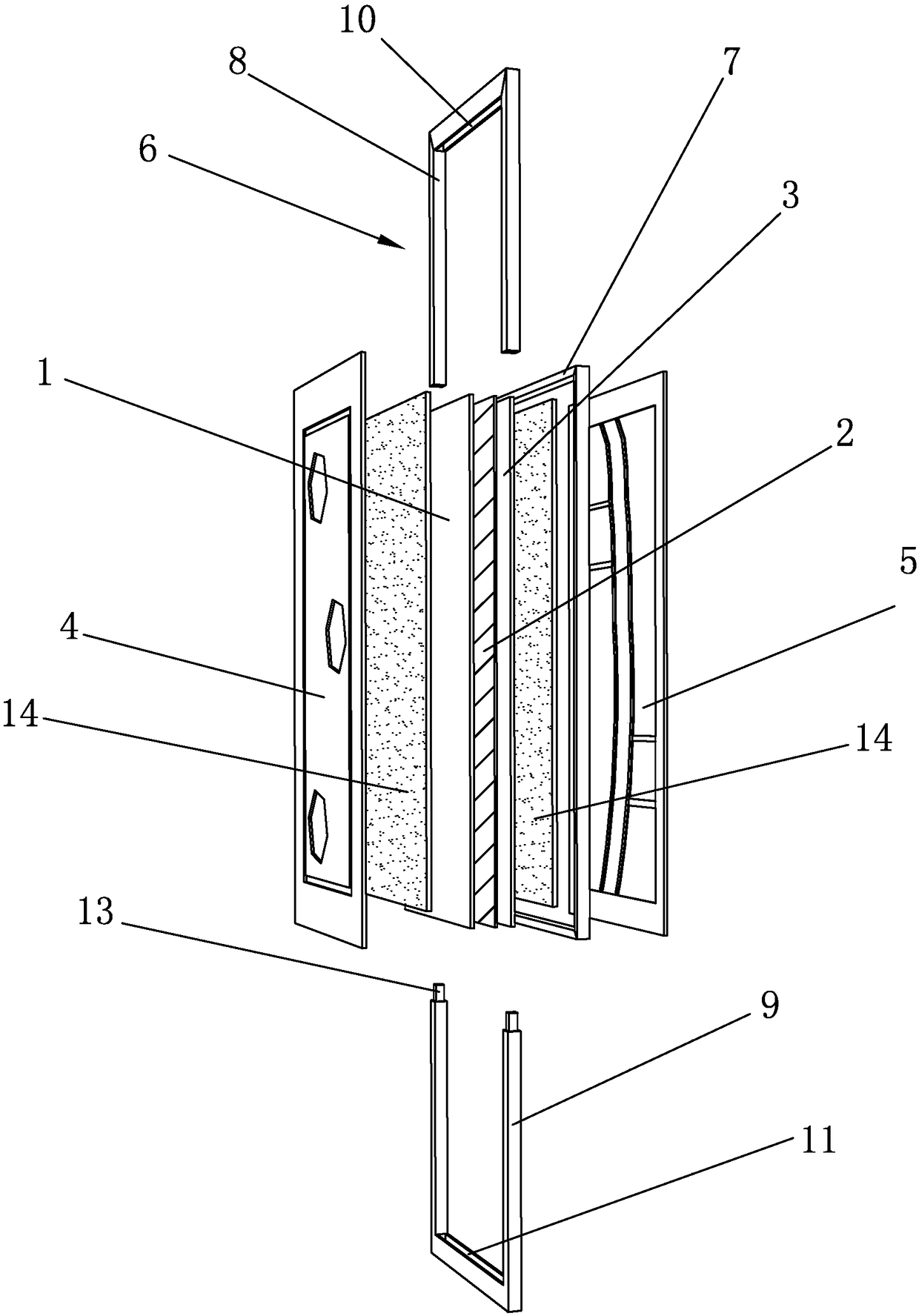

Sound barrier for highways

InactiveCN108611998AReduce construction difficultyEasy to transportNoise reduction constructionSound barrierEngineering

The invention provides a sound barrier for highways. The sound barrier comprises a plurality of uprights and sound barrier units disposed between the uprights, the uprights are of an H-shaped structure and the tops of the uprights are in an arc shape. Inserting slots are formed in both sides of the uprights, the sound barrier unit is disposed between the two corresponding uprights, the left end ofthe corresponding sound barrier unit is connected into the right inserting slot of the left upright in a clamped mode and is in flexible connection with nuts through a plurality of bolts; and the right end of the sound barrier unit is connected into the left inserting slot of the right upright and is in flexible connection with nuts through a plurality of bolts. The construction difficulty is reduced, transportation is convenient, during installing, the uprights are firstly installed on a foundation, then a lower composite sound insulation board, a middle layer composite sound insulation board and a top layer composite sound insulation board of the corresponding sound barrier unit are sequentially installed between the two uprights, and the lower composite sound insulation board, the middle layer composite sound insulation board and the top layer composite sound insulation are spliced to each another; and connection is stable by cooperate splicing of grooves and protrusions, and noiseabsorption and sound insulation are combined to realize a good effect of sound reduction and sound insulation.

Owner:JIANGSU JINYANG TRAFFIC ENG

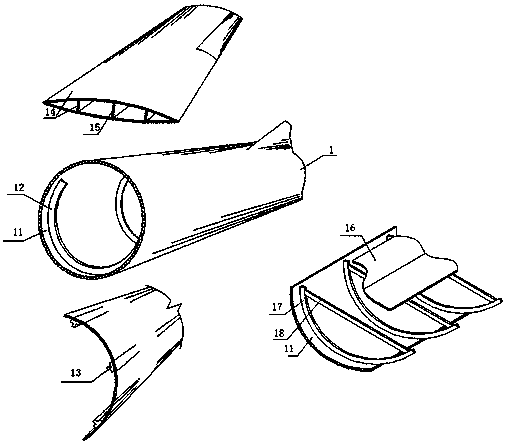

Aerial vehicle structure

An air vehicle structure comprises a framework structure and a skin connected with the framework structure, wherein at least one of the framework structure and the skin is made of plate metal; the plate metal comprises a first panel, a second panel as well as a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubesand the first panel as well as between the hollow tubes and the second panel; a turning edge is arranged at at least one end of the hollow tubes. The aerial vehicle structure has the advantages of being small in self-weight, high in strength, stable in structure, high in impact resistance, capable of insulating sound and reducing noise, resistant to high temperature, corrosion and vibration, longin service life, capable of being carried and spliced and the like.

Owner:张跃

Indoor decoration health material

InactiveCN1715589AGood for healthImprove thermal insulation performanceCovering/liningsPlant ingredientsIndoor air qualityChrysanthemum Flower

The indoor decoration health material is used in wall and ceiling in living room, office, bed room, dinning room, stand, reading room and book stack room. The decoration health material for living room and office includes cordate houttuynia, wild chrysanthemum flower and cubeba fruit; that for bed room includes common valeriana, grassleaved sweetflag and cubeba fruit; that for dinning room includes fennel seed, nutagrass flatsedge rhizome, dried orange peel, clove and cubeba fruit; and that for stand, reading room and book stack room includes rue, climbing groundsel and cubeba fruit. The indoor decoration health material of the present invention can ensure indoor air quality and release matter beneficial to human health continuously.

Owner:廖振兴

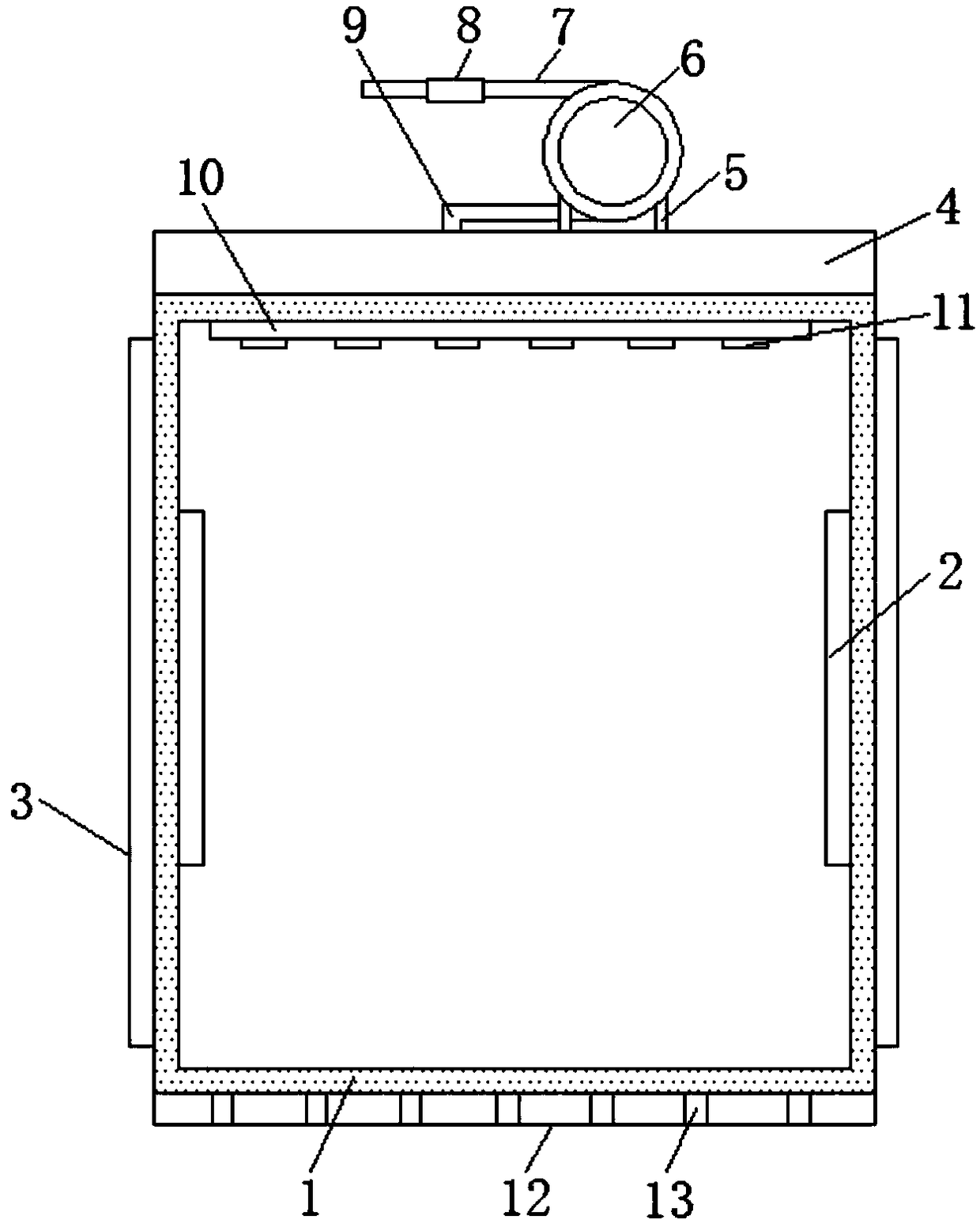

Intelligent building with good sound insulation and noise reduction effects

InactiveCN108285082AImprove sound insulation and noise reductionImprove the ride experienceLighting and heating apparatusBuilding liftsAgricultural engineeringNoise reduction

The invention provides an intelligent building with good sound insulation and noise reduction effects, and relates to the technical field of intelligent buildings. The intelligent building with the good sound insulation and noise reduction effects comprises a lift car, wherein sound-absorbing cottons are fixedly arranged on two sides of an inner wall of the lift car; sound insulation devices are fixedly arranged on two sides of the lift car; a door header is fixedly arranged on the top part of the lift car; an installation support is fixedly arranged on the top part of the door header; and a fan is fixedly arranged on the top part of the installation support. According to the intelligent building with the good sound insulation and noise reduction effects, the sound-absorbing cottons are fixedly arranged on the two sides of the inner wall of the lift car and can absorb noise produced during the operation of the lift car, meanwhile, through the cooperation of the sound insulation device,a sound-absorbing box, sound-absorbing covers and a sound insulation plate, the sound-absorbing covers can absorb the noise produced during the operation of the lift car into the sound-absorbing box,and meanwhile, the sound insulation plate can block and absorb for eliminating the noise, so that a box-type lift of the intelligent building has the good sound insulation and noise reduction effects, and is favorable for improving the riding experience of people.

Owner:绍兴快晴贸易有限公司

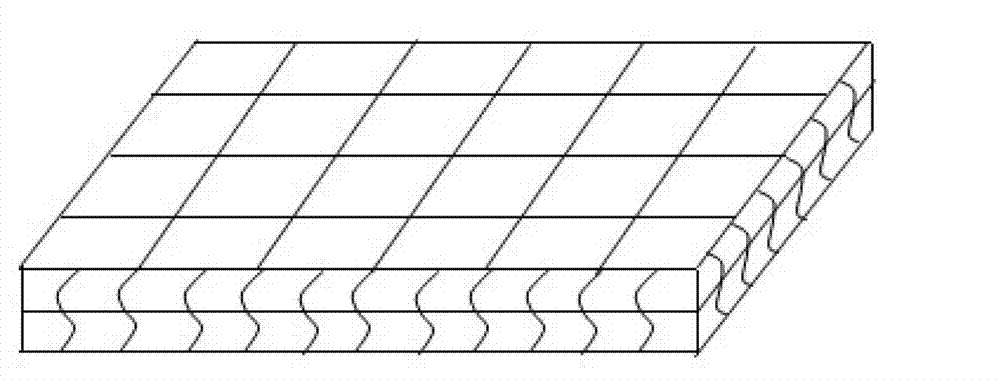

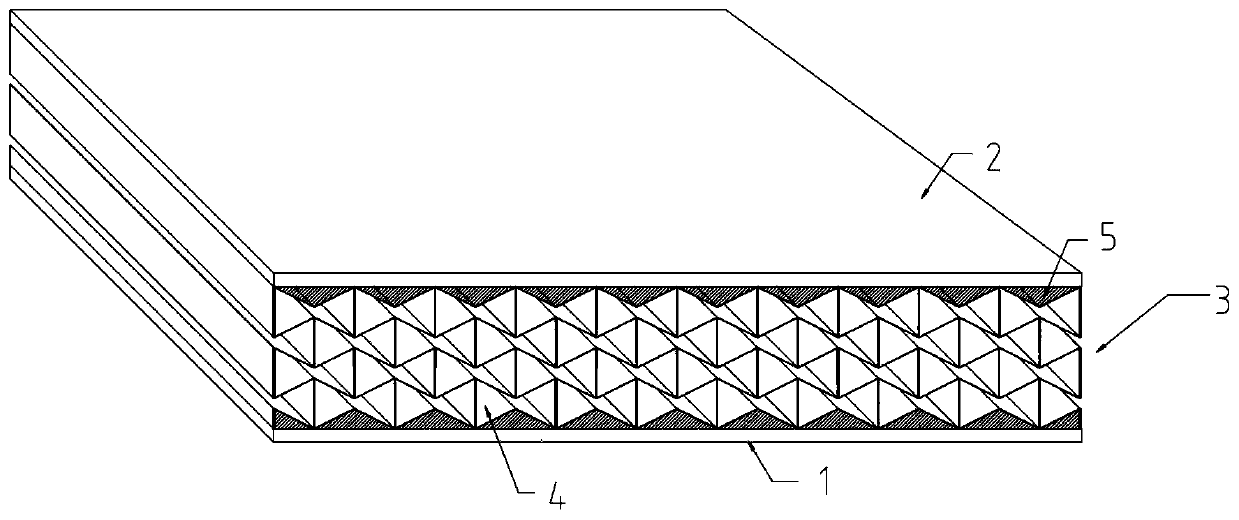

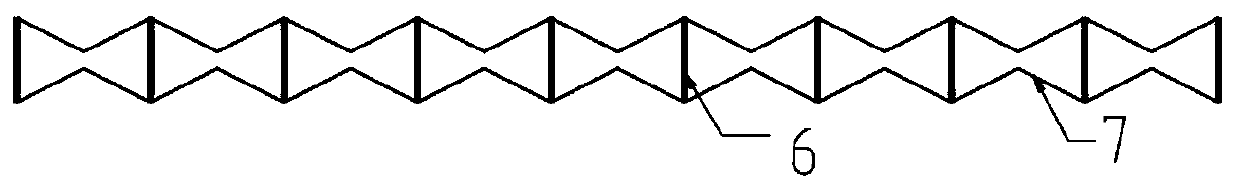

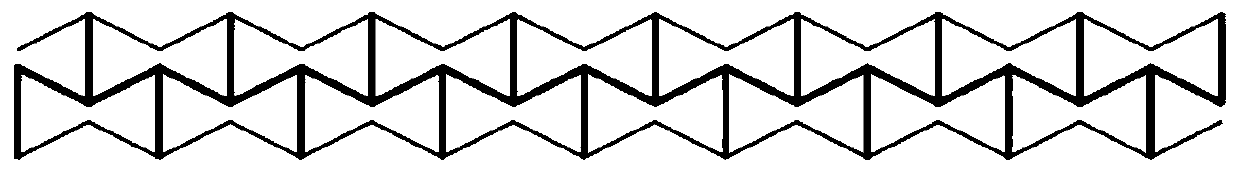

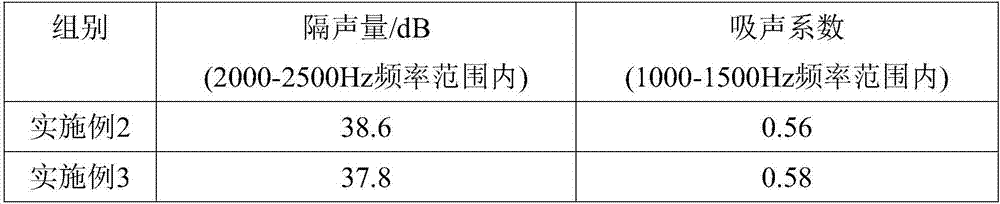

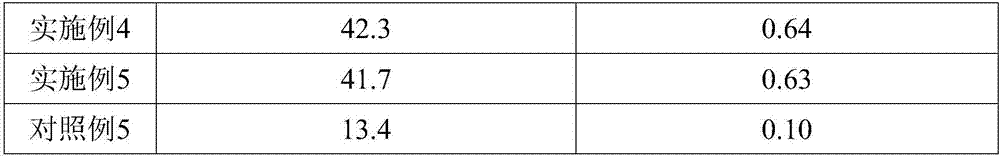

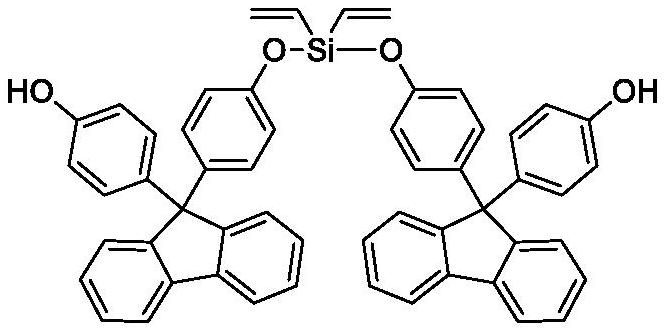

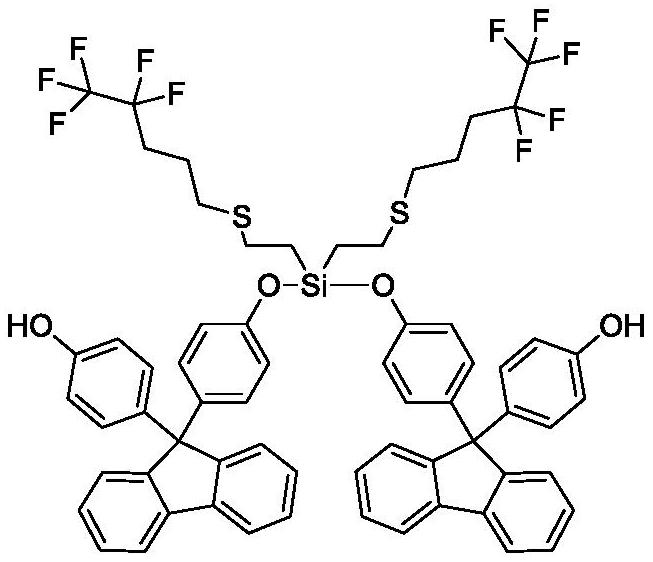

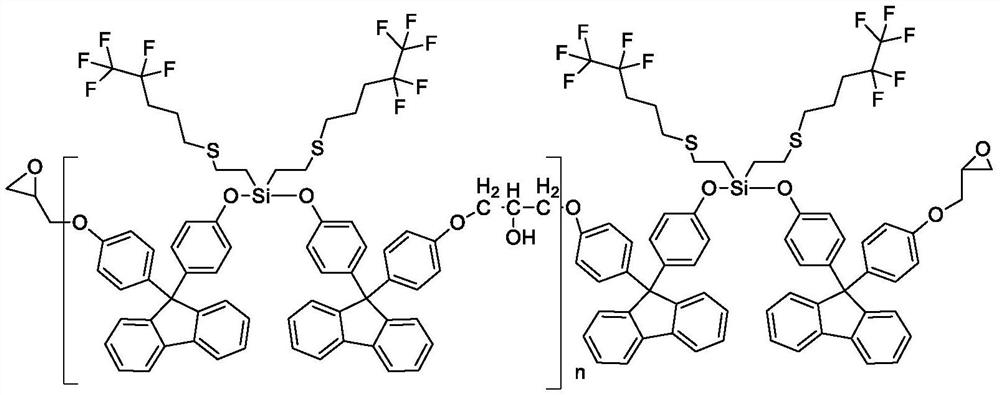

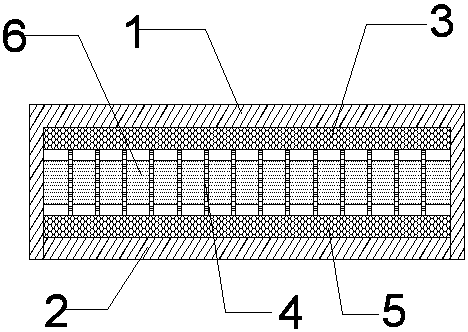

Sound insulation and noise reduction composite material and preparation method thereof

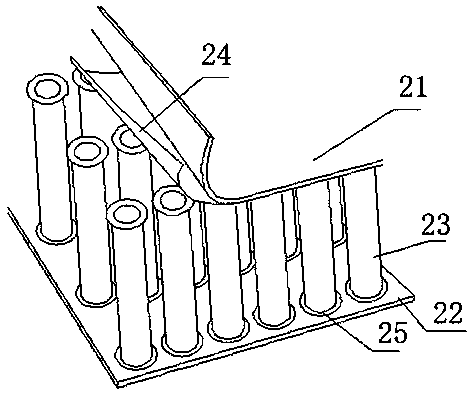

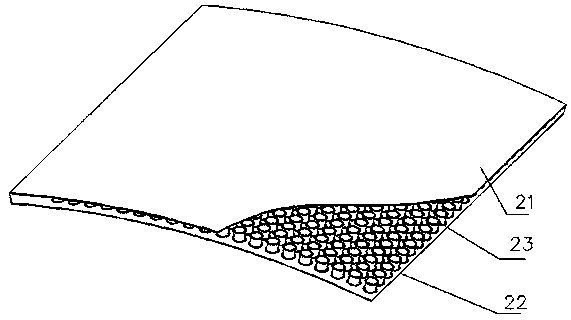

ActiveCN111114020AImprove sound insulation and noise reduction performanceHigh shear modulusLamination ancillary operationsSynthetic resin layered productsLoad resistanceSi substrate

The invention relates to the field of material science, and in particular, relates to a sound insulation and noise reduction composite material and a preparation method thereof. The sound insulation and noise reduction composite material comprises a base plate, a top plate and a sandwich layer located between the base plate and the top plate, wherein the sandwich layer is provided with a negativePoisson's ratio unit; the negative Poisson's ratio unit is mainly formed by alternately stacking and bonding a first negative Poisson's ratio unit and a second negative Poisson's ratio unit made of two different materials and having concave hexagonal structures. The sound insulation composite material has the negative Poisson's ratio unit, the sound insulation and noise reduction performance of the material can be improved, meanwhile, the shear modulus, the fracture resistance, the resilience toughness and the load resistance of the material are improved, and the application range of the material is greatly expanded.

Owner:上海众汇泡沫铝材有限公司

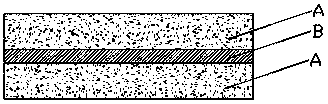

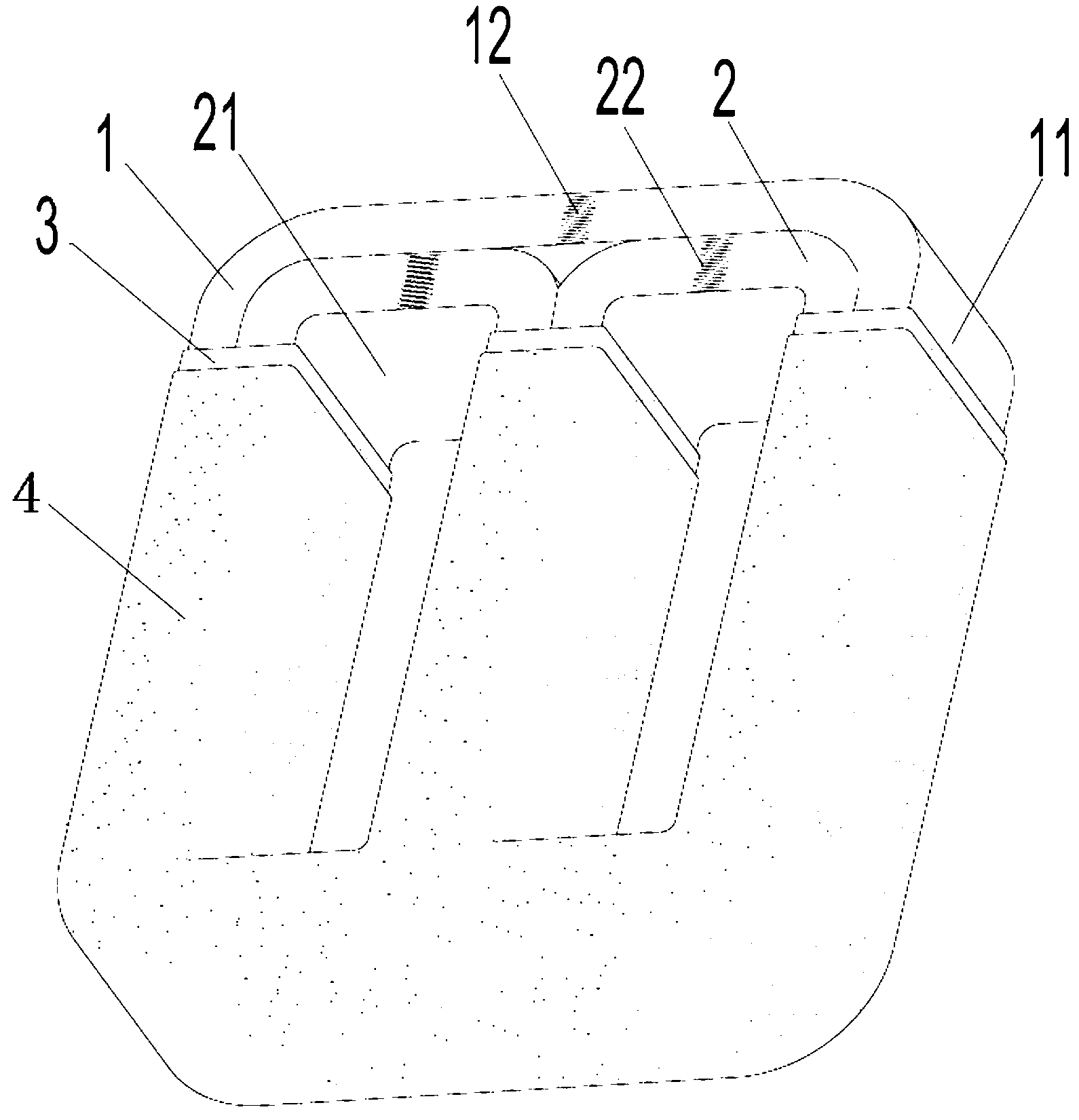

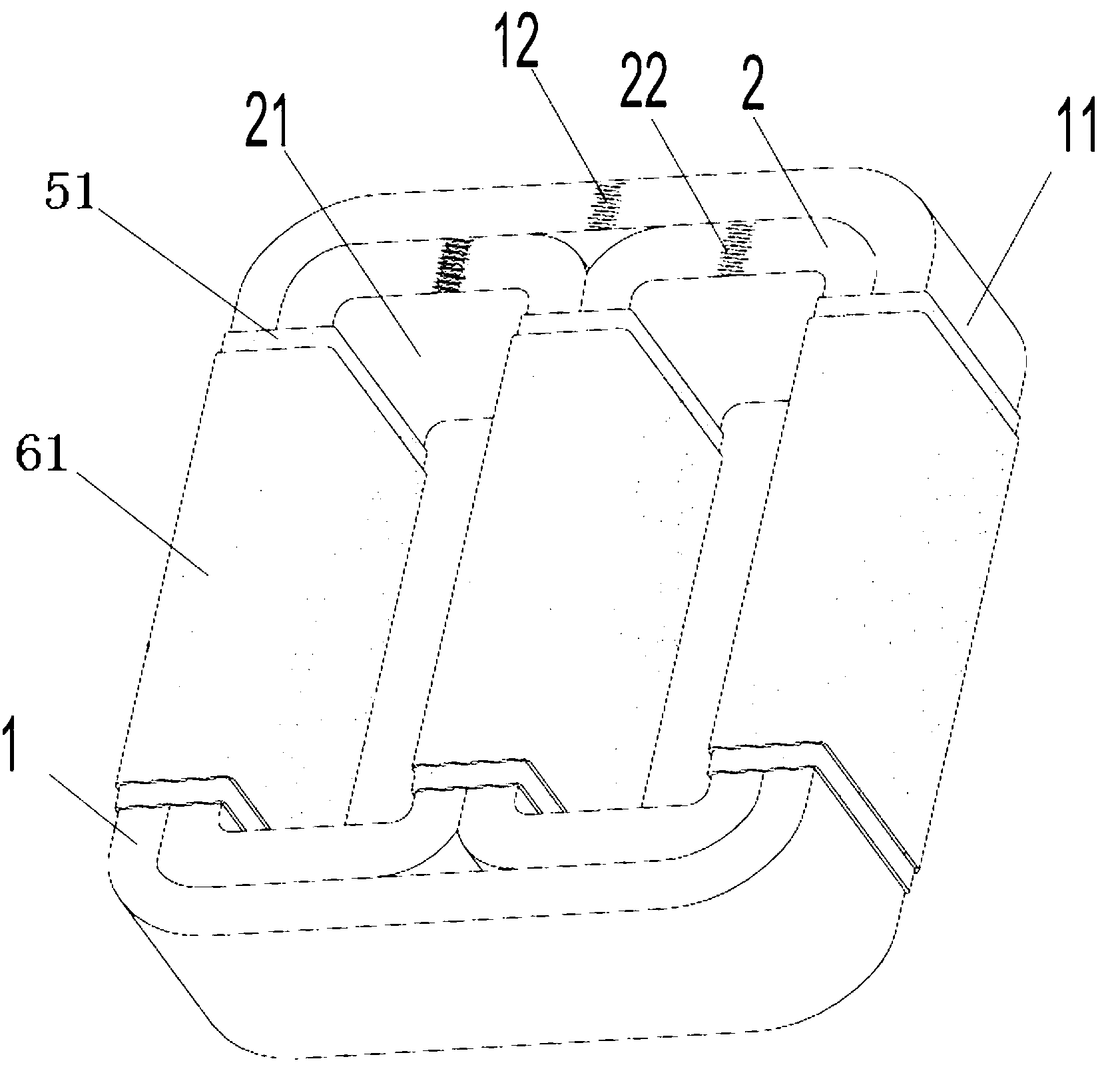

Sound insulation and noise reduction type composite bamboo fiberboard

ActiveCN107877624AImprove sound insulation and noise reductionGuaranteed physical and mechanical performanceLaminationLamination apparatusFiberNoise reduction

The invention discloses a sound insulation and noise reduction type composite bamboo fiberboard, and relates to the technical field of bamboo fiberboard processing. The sound insulation and noise reduction type composite bamboo fiberboard is composed of three layer structures of a bamboo fiber bottom board, a sound insulation and noise reduction layer and a bamboo fiber panel, and the sound insulation and noise reduction layer is arranged between the bamboo fiber bottom board and the bamboo fiber panel and is made of an asbestos wool-foamed aluminum-magnesium composite. According to the soundinsulation and noise reduction type composite bamboo fiberboard, the asbestos wool-foamed aluminum-magnesium composite serves as the sound insulation and noise reduction layer, so that the manufactured composite bamboo fiberboard has excellent sound insulation and noise reduction performance; and the sound insulation and noise reduction performance of the manufactured composite bamboo fiberboard is further enhanced by using the self-made bamboo fiber bottom board or bamboo fiber panel, meanwhile, physical and mechanical using performance of the composite bamboo fiberboard is ensured, and construction requirements of building decoration are met accordingly.

Owner:广西平乐爱森新材料有限公司

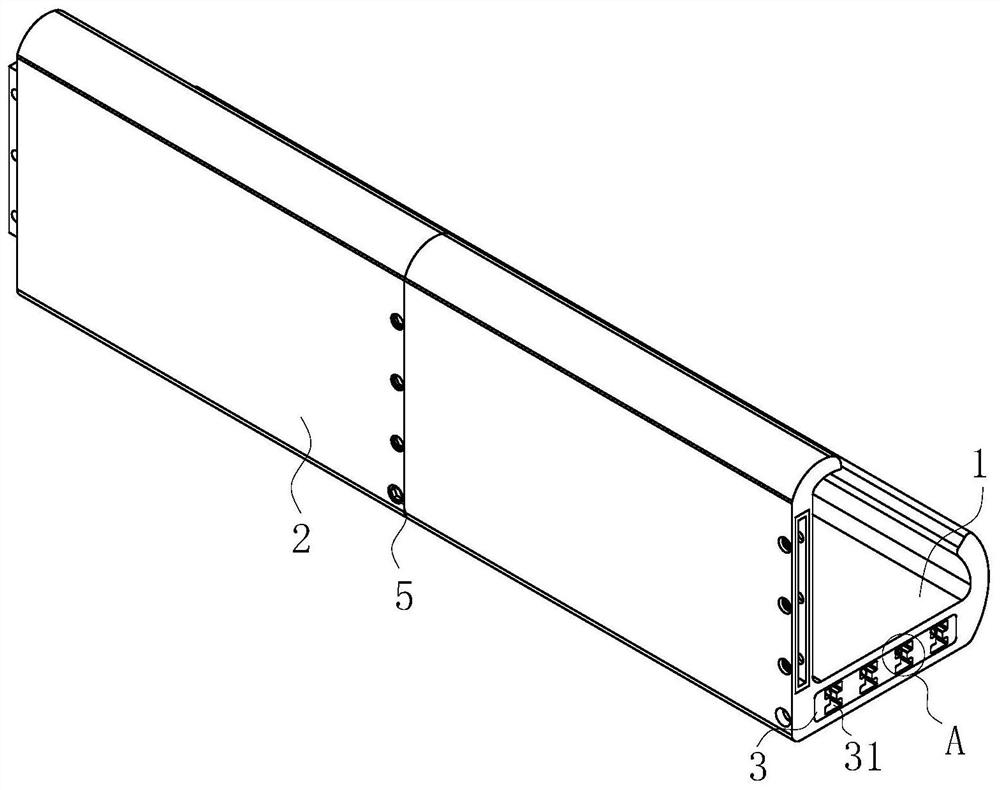

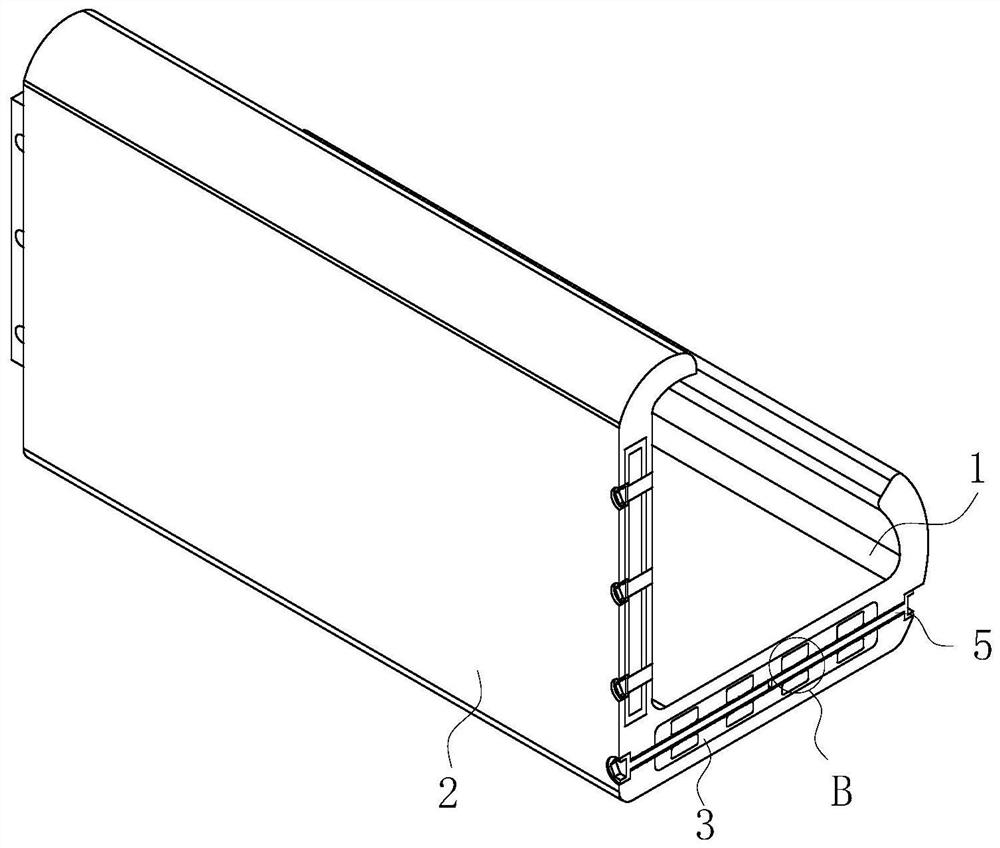

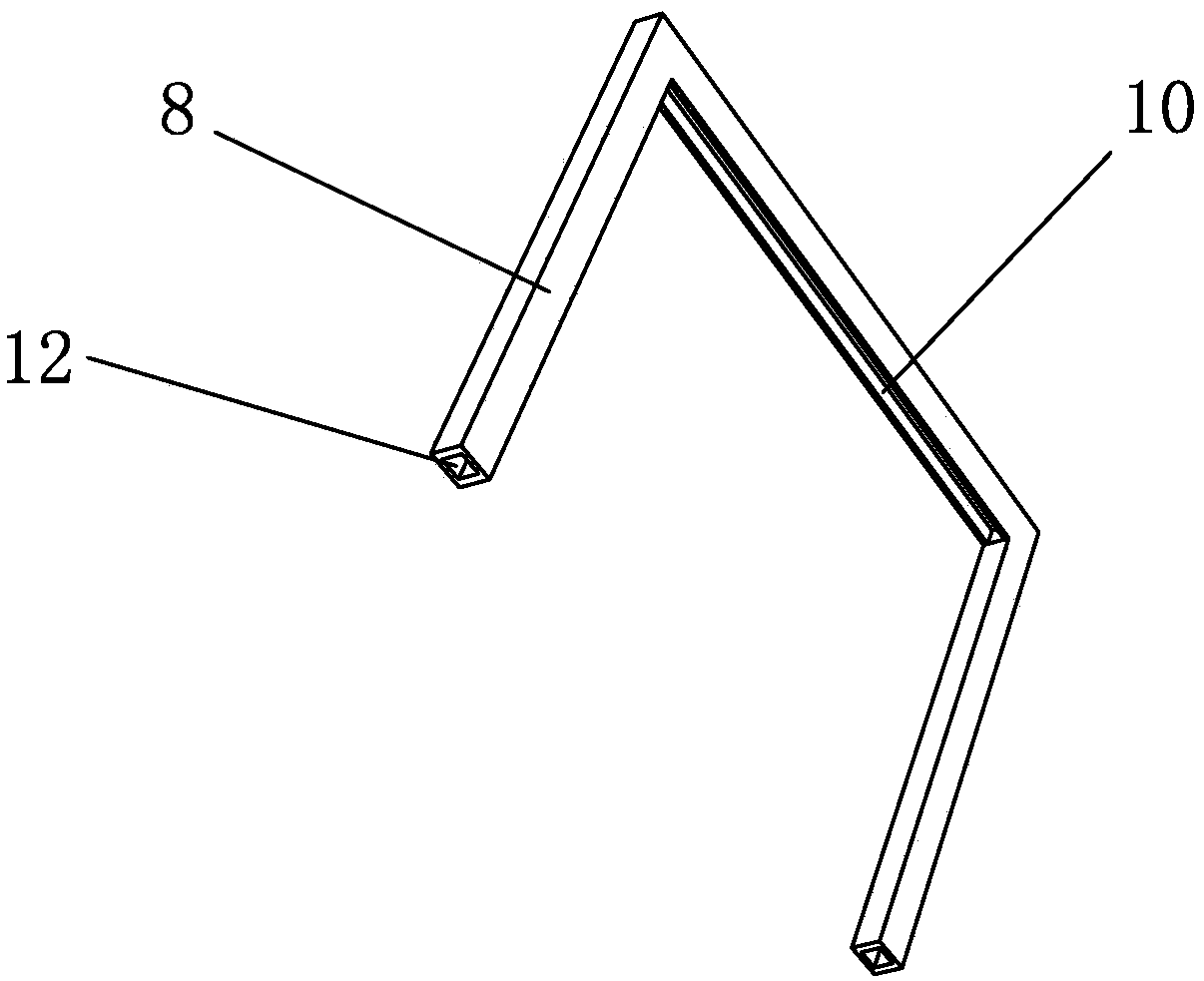

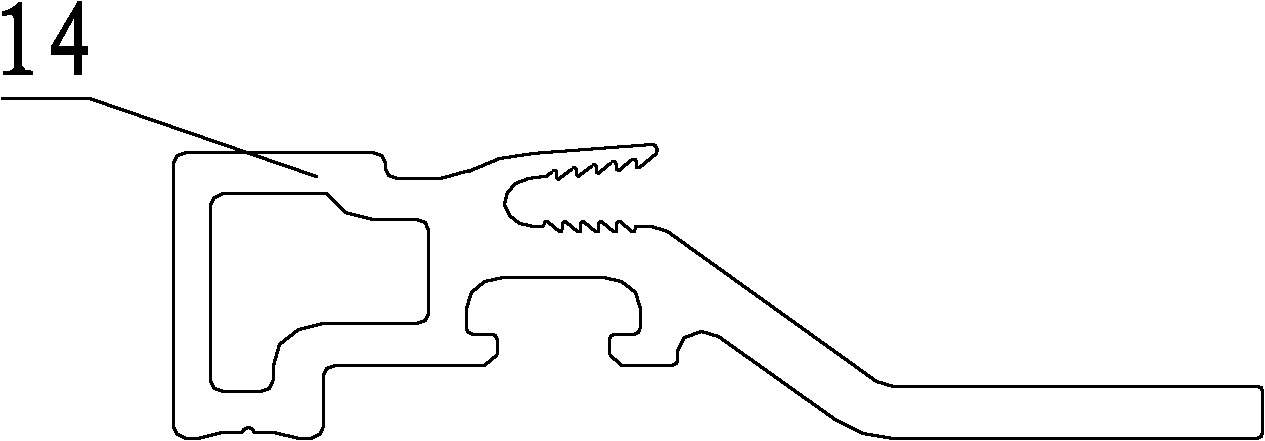

L-shaped edge sealing aluminum profile

ActiveCN111852258AImprove shock absorptionHigh yieldNoise insulation doors/windowsWing framesEngineeringMechanical engineering

Owner:池州市安安新材科技有限公司

Polyurethane sound insulation coating and production process thereof

ActiveCN113913098AImprove corrosion resistanceImprove high temperature resistanceFireproof paintsAnti-corrosive paintsEpoxyPolyester

The invention relates to a polyurethane sound insulation coating and a production process thereof, belonging to the technical field of preparation of sound insulation materials. The production process comprises the following steps: 1, mixing polyester diol, isocyanate, epoxy resin and dibutyltin dilaurate according to a formula ratio, carrying out heating to 75-90 DEG C, and performing stirring for a reaction for 1-2 hours to obtain a polyurethane prepolymer; and 2, adding N-methyl pyrrolidone into the polyurethane prepolymer, carrying out stirring and reacting for 20-60 minutes, adding triethylamine and water, conducting heating to 70-90 DEG C, performing stirring for 2-3 hours, then adding modified hollow glass beads, aminated tetrapod-like zinc oxide whiskers, a defoaming agent and a coalescing agent, and carrying out stirring and reacting at 70-80 DEG C for 1-2 hours to obtain the polyurethane sound insulation coating. According to the invention, by adding the modified hollow glass beads and the modified tetrapod-like zinc oxide whiskers, the polyurethane coating is endowed with excellent sound insulation and noise reduction performance, and the problems that an existing floor in a building of a community is poor in sound insulation effect and tedious in construction are solved.

Owner:安徽瑞联节能科技股份有限公司

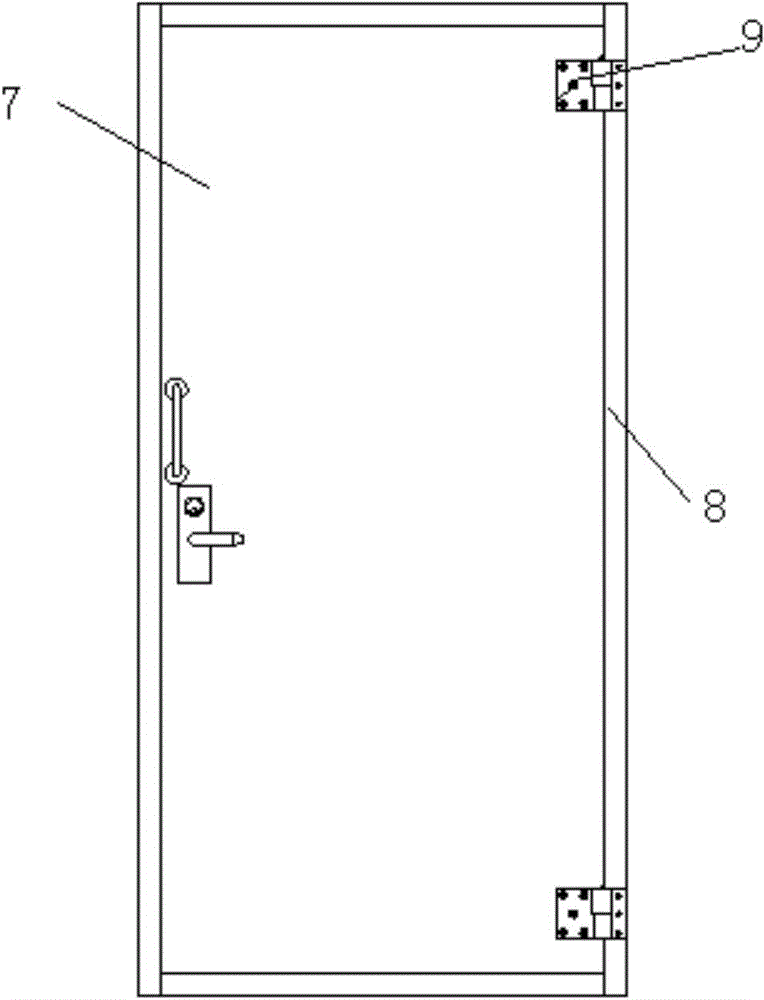

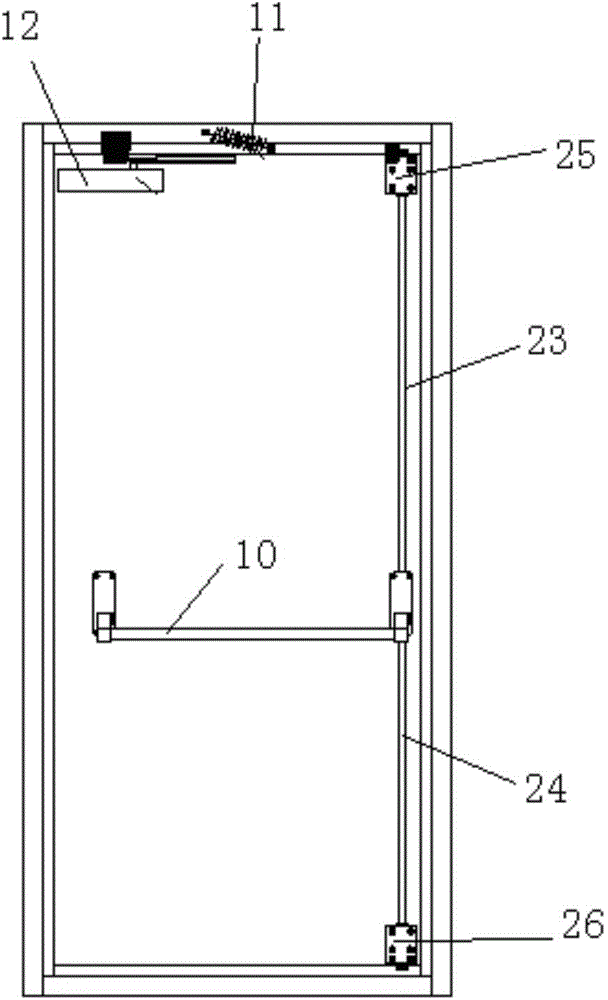

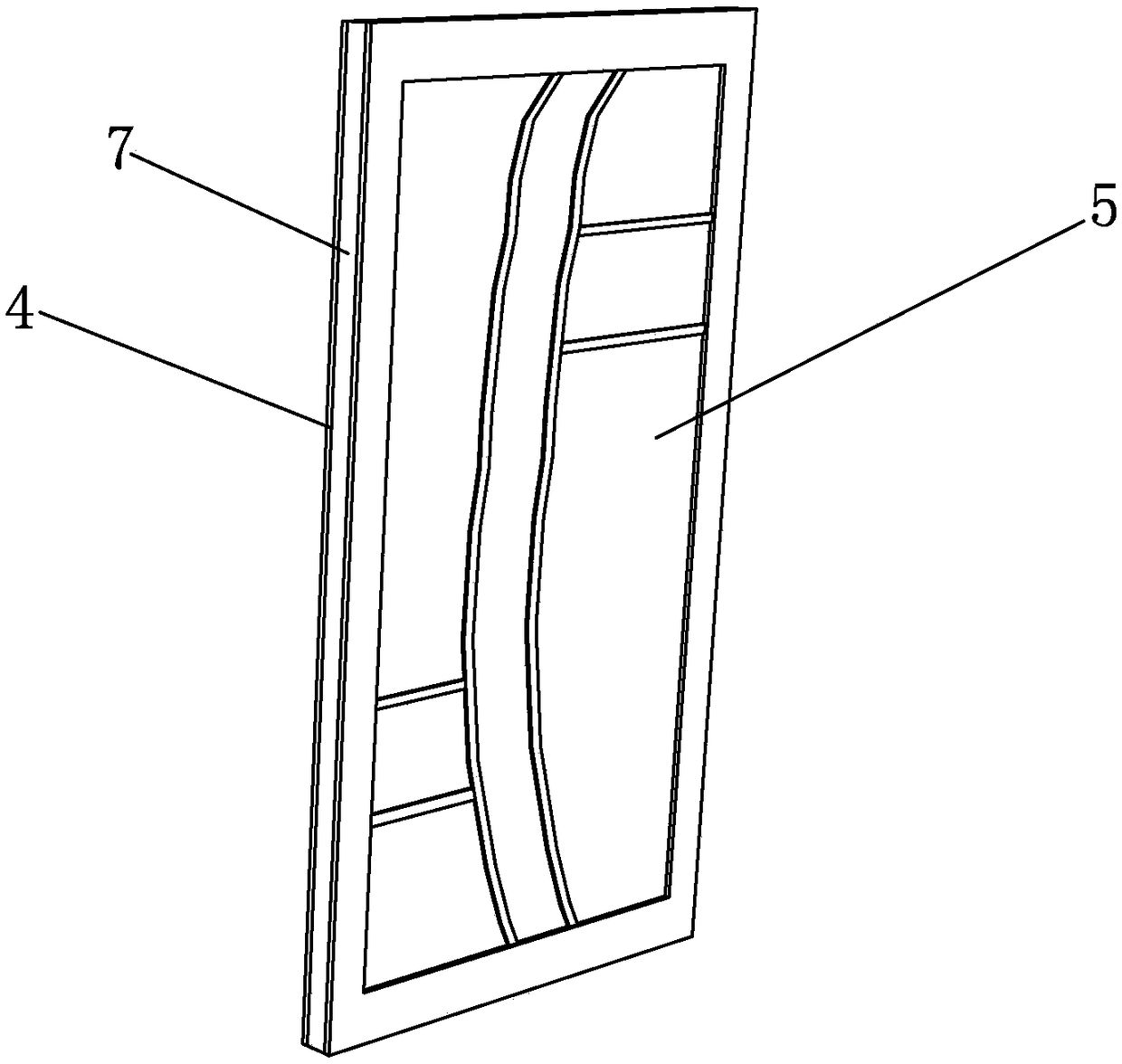

Assembled wooden door and manufacturing method thereof

ActiveCN108798398AStable structureCompact and reasonable structureFireproof doorsNoise insulation doors/windowsFixed frameUltimate tensile strength

The invention discloses an assembled wooden door comprising a wooden door base plate and a fixing frame. The wooden door base plate is connected into the fixing frame in a clamped mode and comprises afirst side base plate body, an inner core plate and a second side base plate body. The inner core plate is located between the first side base plate body and the second side base plate body. A firstdecorating layer is arranged on one side of the fixing frame. A second decorating layer is arranged on the other side of the fixing frame. The fixing frame comprises a limiting frame and an anti-collision frame. The limiting frame is connected into the anti-collision frame in a clamped mode and comprises an upper limiting frame body and a lower limiting frame body. A manufacturing method of the assembled wooden door comprises the following steps that (1) the wooden door base plate is prepared; (2) the fixing frame is prepared; (3) sound insulation pads are prepared; (4) the decorating layers are prepared; and (5) the wooden door is assembled. The assembled wooden door is ingenious and reasonable in overall structural design, the structural strength and stability of the wooden door are improved, droop deformation of the wooden door is effectively prevented, meanwhile, the four side edges of the wooden door can be protected through the design of the fixing frame, the service life of thewooden door is prolonged, and the comprehensive utilization rate is increased.

Owner:浙江图森定制家居股份有限公司

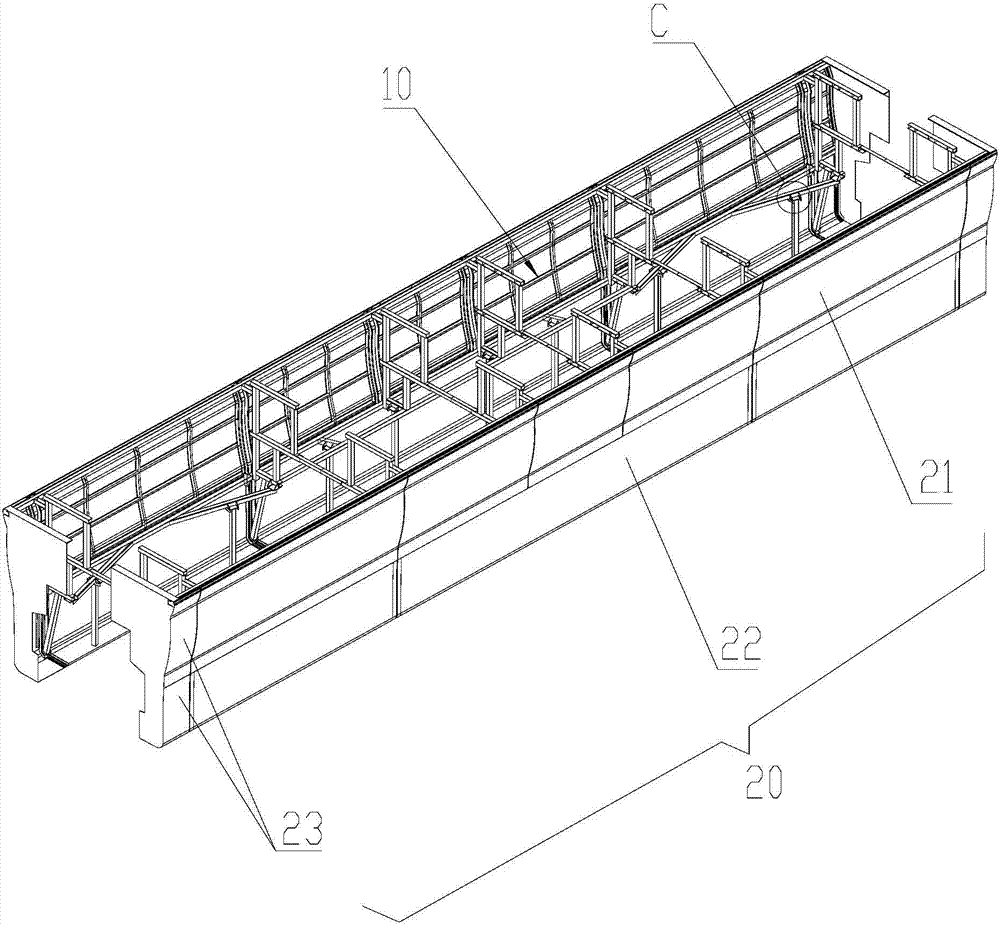

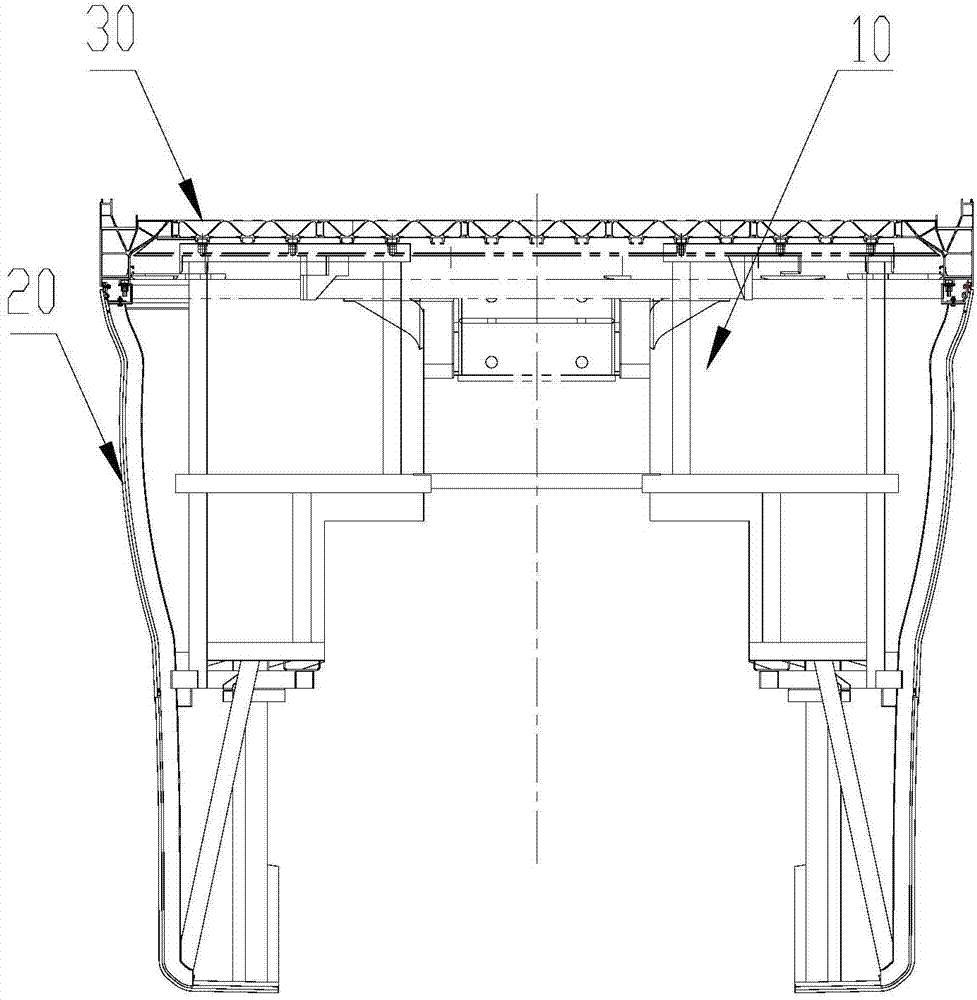

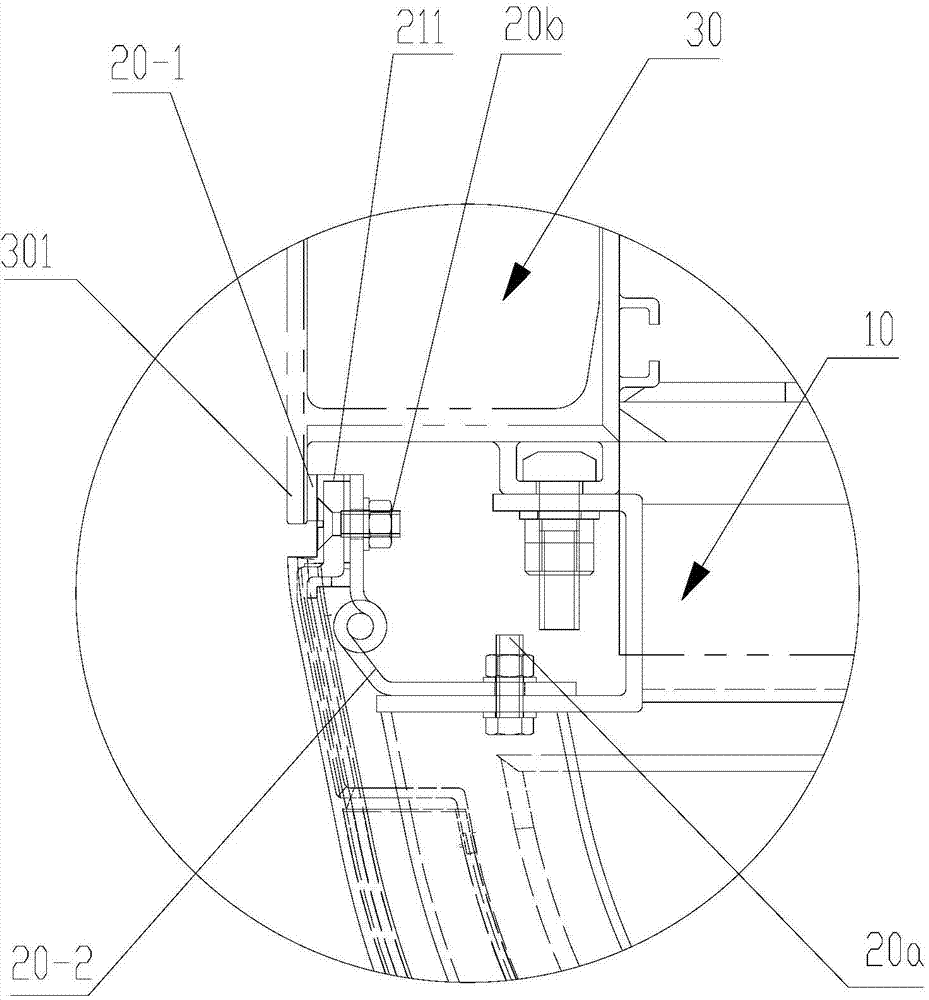

Straddle type monorail vehicle body

ActiveCN104742923AImprove sound insulation and noise reductionUnderframesRailway transportSkeleton as a wholeEngineering

The invention discloses a straddle type monorail vehicle body. The straddle type monorail vehicle body comprises a bottom skeleton and apron board structures connected with the bottom skeleton. The apron board structures extend from one end of the vehicle body to the other end of the vehicle body, each apron board structure comprises an upper-layer apron board and a lower-layer apron board, and the tops of the upper-layer apron boards are connected with the skeleton in a rotating mode so that the upper-layer apron boards can be overturned outwards. The apron board structures wrap the two sides of the vehicle body skeleton as a whole, noise of the vehicle body is offset in the apron board structures wrapping the whole skeleton, in this way, a good sound insulation and noise reduction effect is achieved, and the whole vehicle body forms a complete shell; in addition, the upper layer and lower layer separation mode meets the requirements for appearance uniformity and continuity of the apron board structures extending from one end to the other end, guarantees connection with the outer side wall of the vehicle body and lowers manufacturing difficulty. The overall height of the vehicle body can be reduced in maintenance by disassembling the lower layers, so that the workshop requirement and operating difficulty are lowered. The upper-layer apron boards can be overturned, so that maintenance is facilitated for technicians.

Owner:CRRC QINGDAO SIFANG CO LTD

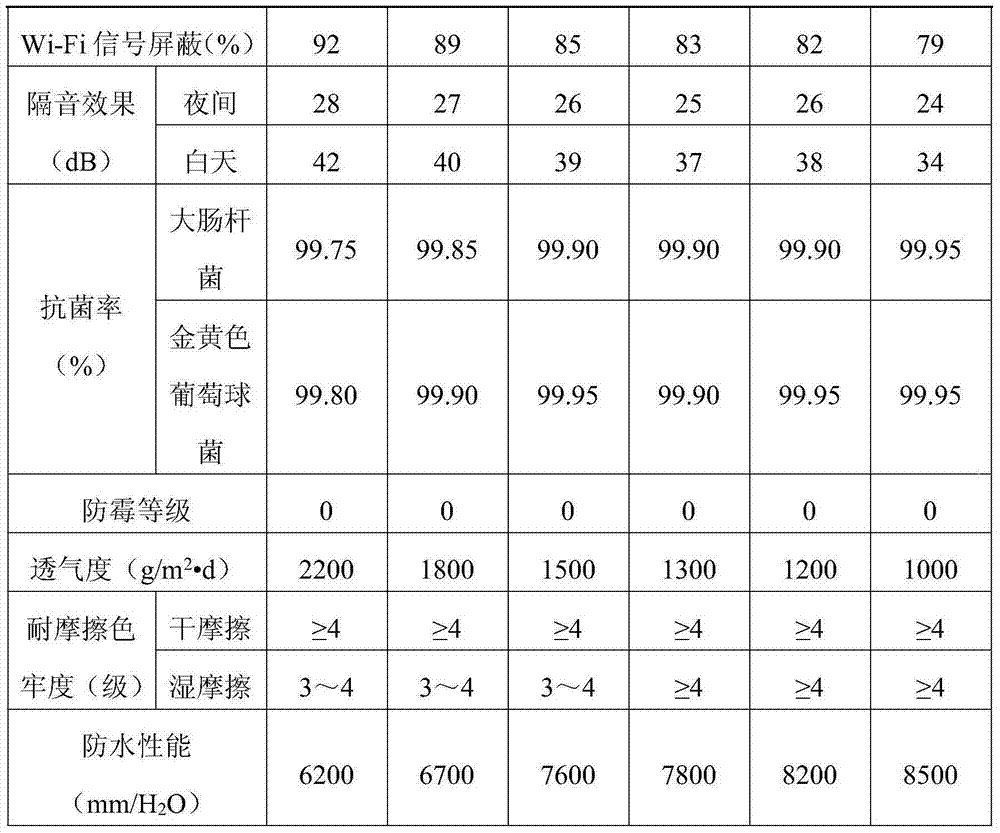

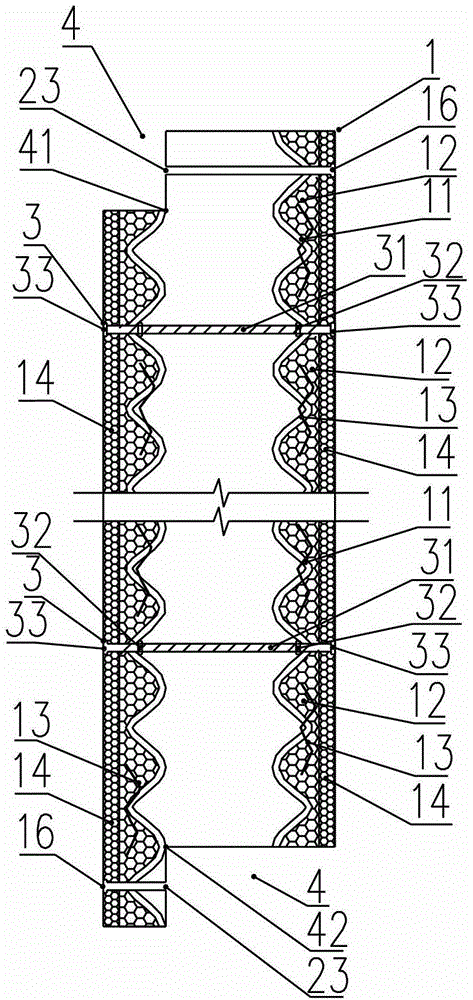

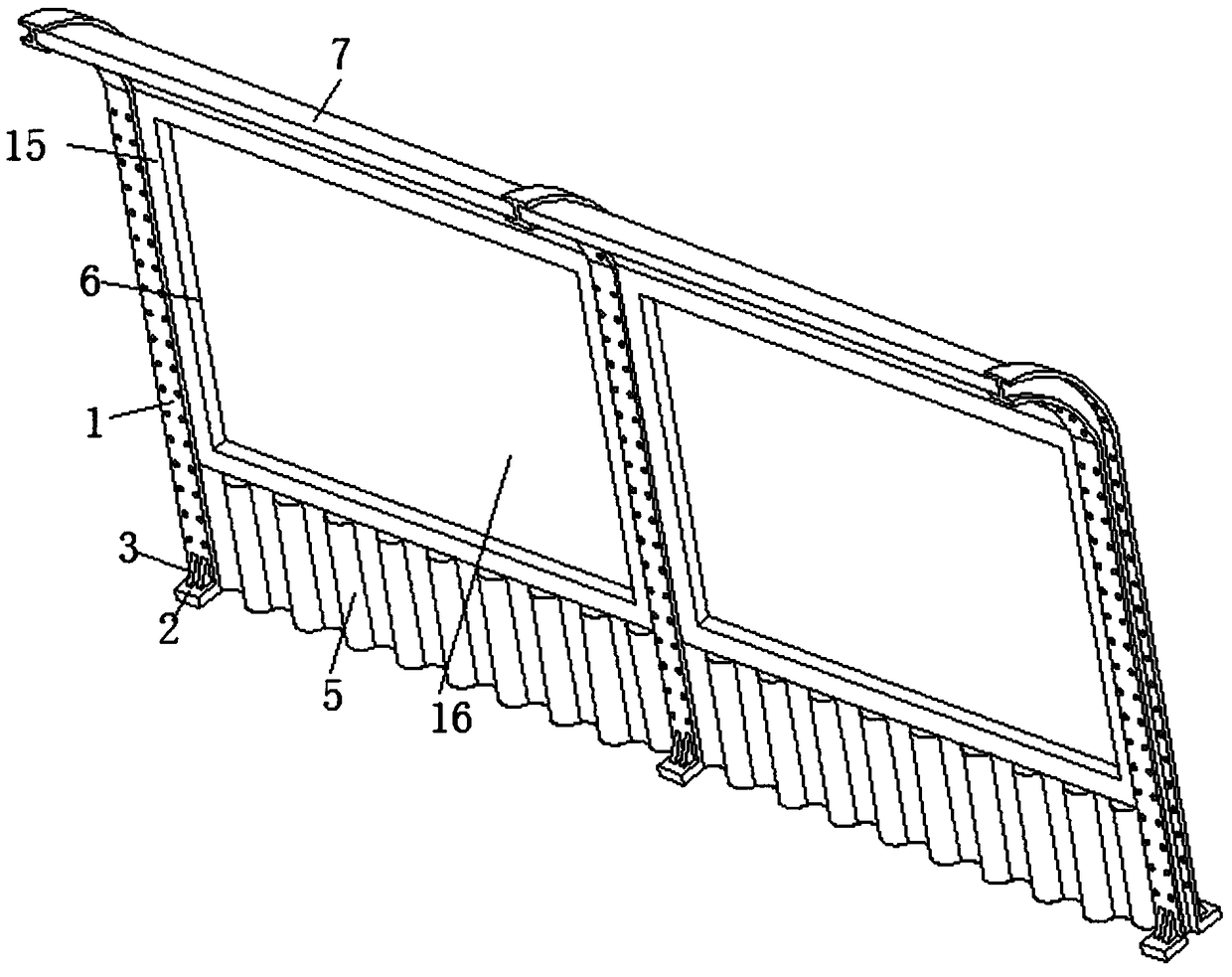

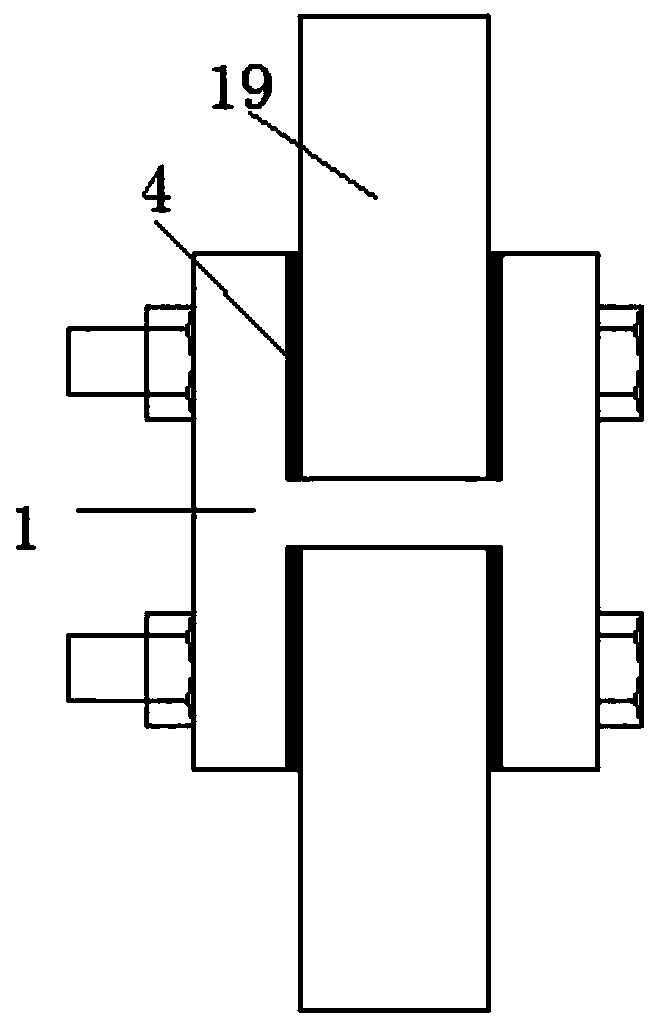

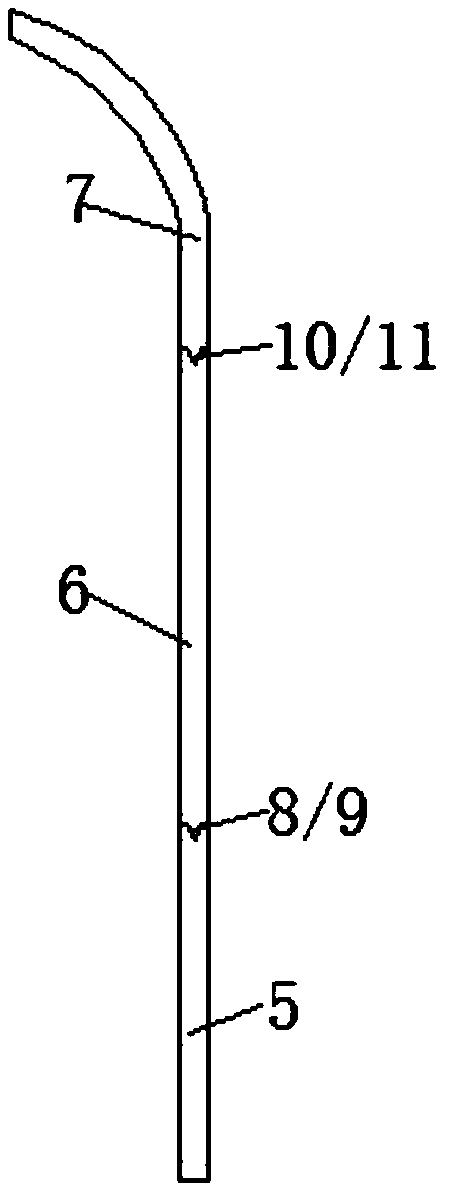

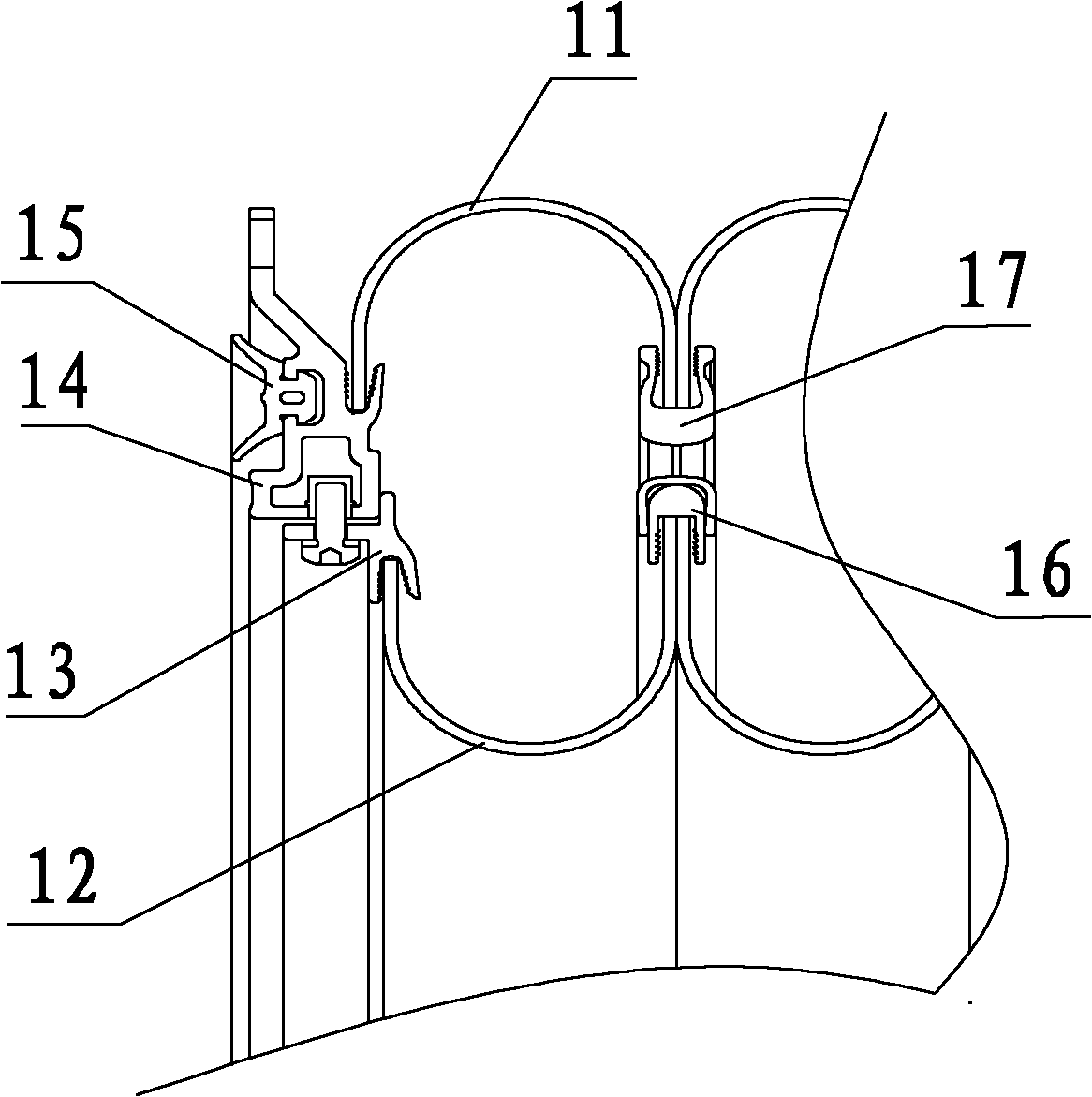

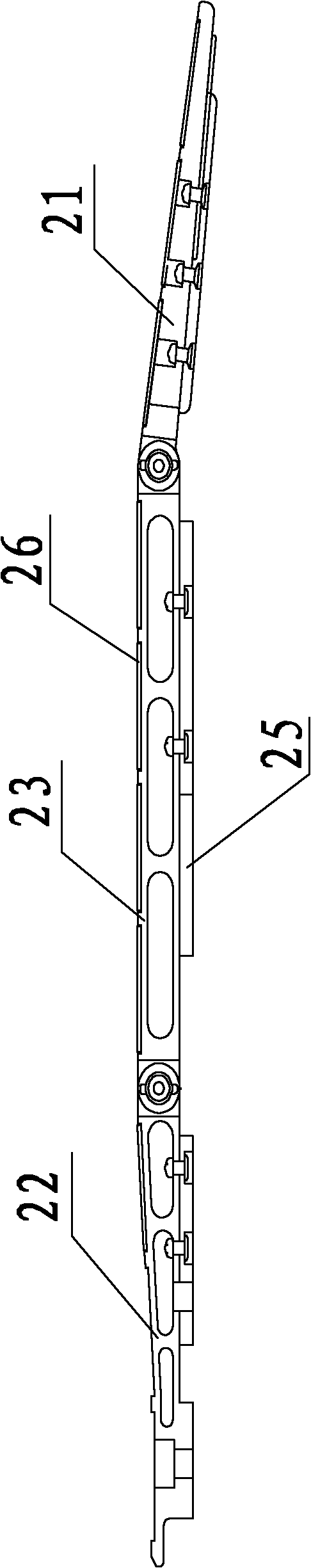

Run-through channel for track passenger trains

InactiveCN102120460AImprove fire performanceImprove sound insulation and noise reductionAxle-box lubricationRailway bodiesThermal insulationEngineering

The invention relates to a run-through channel for track passenger trains, which comprises a vestibule diaphragm body assembly, a gangway foot plate assembly, a pedal assembly and a reset plate spring assembly, wherein the vestibule diaphragm body assembly is provided with an external vestibule diaphragm body arched outwards and an internal vestibule diaphragm body arched inwards; and the end part of the internal vestibule diaphragm body is connected with a fabric inserted aluminum frame, the external vestibule diaphragm body is connected with an end-wall connecting frame, the fabric inserted aluminum frame is fixedly connected with the end-wall connecting frame, and a rubber sealing strip is embedded into the end-wall connecting frame. The internal vestibule diaphragm body is formed by connecting more than two pieces of double-layer U-shaped internal diaphragm fabric together, and the internal diaphragm fabric is made by an integral sulfidizing process with a forming die. The run-through channel provided by the invention is flexible to move, is safe and reliable and has high sound insulation, high thermal insulation and high air tightness, and can satisfy the high performance requirements of high speed track passenger trains.

Owner:CHANGZHOU HUBOLA JINCHUANG TRAFFIC EQUIP

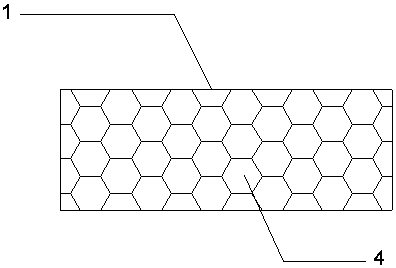

Sound insulation composite aluminum plate for curtain wall and preparation method thereof

InactiveCN111016307AImprove sound insulation and noise reductionLow densityWallsSynthetic resin layered productsFluorocarbonMacromolecule

The invention discloses a sound insulation composite aluminum plate for a curtain wall and a preparation method thereof. The composite aluminum plate comprises an upper aluminum plate,a core layer, and a lower aluminum plate from top to bottom; the upper aluminum plate and the lower aluminum plate are connected around the core layer in a closed manner; the upper end and the lower end of the core layer are bonded through macromolecule bonding films, a layer of PET composite film is laid on the outer layer of the upper aluminum plate; the PET composite film is further coated with a PVDF fluorocarbon layer, the core layer comprises an upper nonmetal composite layer, a honeycomb layer and a lower nonmetal composite layer from top to bottom, the honeycomb layer is fixedly connected with the upper aluminum plate and the lower aluminum plate, and the aluminum plate has the advantages that the sound insulation effect is excellent, and the service life of the totally-closed aluminum plate is longer.

Owner:江苏佰大幕墙科技有限公司

Environment-friendly rubber sound insulation building material and preparation method thereof

InactiveCN107298776AGood tear strength and fatigue resistanceGood weather aging resistanceWeather resistanceEnvironmental resistance

The invention discloses an environment-friendly rubber sound-insulating building material, which comprises the following raw materials in parts by weight: 50-60 parts of isoprene rubber, 20-30 parts of fluorosilicone rubber, 3-5 parts of heat stabilizer, and 0.5-0.9 parts of crosslinking agent , 5-9 parts of rare earth oxide filler, 4-8 parts of glass microspheres, 3-5 parts of vulcanizing agent PDM, 2-4 parts of silane coupling agent, 6-10 parts of ore powder. The sound-insulating building material of the present invention has excellent sound-insulating performance and good waterproof effect, is more compact in structure than traditional non-woven materials, has superior sound-insulating and noise-reducing effects, has good mechanical properties, and has strong weather resistance; meanwhile, the preparation method of the present invention , the material cost is low, the raw material is easy to obtain, and the process is simple, easy to operate and realize industrial production, and has high practical value and good application prospect.

Owner:合肥一片美环保科技有限公司

Reflective thermal insulation energy-saving brick

InactiveCN102268903AReduce deliveryImprove insulation effectConstruction materialBrickFire protection

The invention relates to a reflective heat-insulating energy-saving brick, which comprises a hollow brick body or a hollow block body provided with a plurality of through holes, each of which is a rectangular hole, and the rectangular holes of the hollow brick body or hollow block body are at least A layer of reflective heat insulating material is provided on the inner wall facing the outer wall or on the rib wall separating the through holes. The reflective heat preservation and heat insulation energy-saving brick of the present invention applies heat preservation and heat insulation principles to the interior of hollow bricks or hollow blocks. The reflective heat preservation and heat insulation energy-saving brick has no exposed flammable materials, which not only improves heat preservation and heat insulation Performance, but also improve the fire effect.

Owner:唐峰 +2

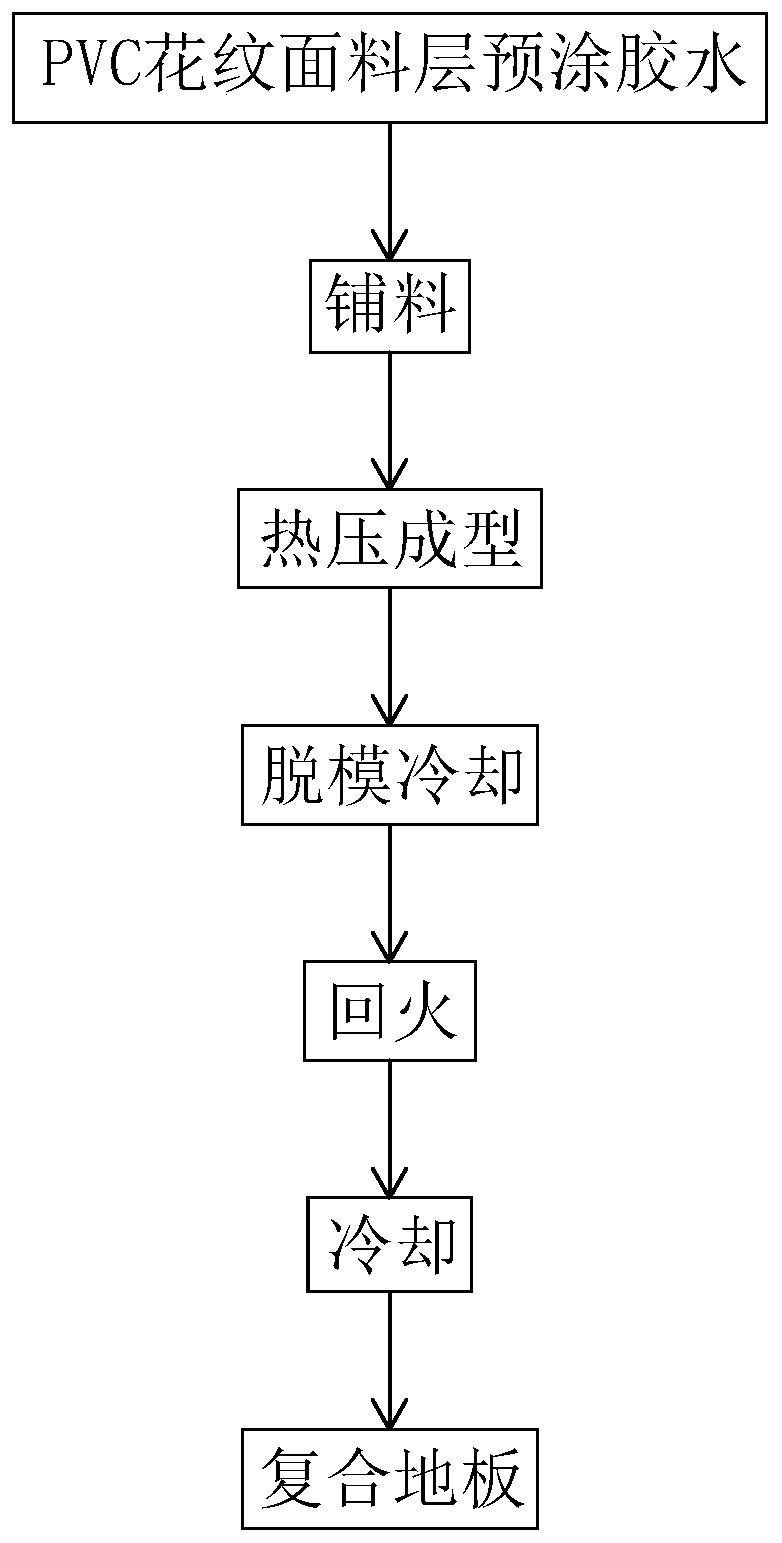

Composite floor board and manufacturing technology thereof

PendingCN110485674AImprove wear resistanceSimple structureCovering/liningsCoatingsManufacturing technologyHigh dimensional

The invention discloses a composite floor board. The composite floor board is characterized by comprising a wear resisting layer, a PVC patterned fabric layer, a base material layer, a balance layer and a mute layer which are arranged in sequence, wherein the wear resisting layer is a melamine abrasion resistant paper layer. The composite floor board has clear and vivid patterns; and in addition,the wear and scratch resistance of the composite floor board is far better than that of a regular floor board provided with a PVC wear resisting layer. Meanwhile, the invention also correspondingly discloses a manufacturing technology of the composite floor board. The manufacturing technology comprises the steps of material spreading, hot pressing, demolding and tempering; the technological stepsare simple; and in addition, the prepared composite floor board has high dimensional stability and excellent wear and scratch resistance.

Owner:JIANGSU LANGYUE NEW MATERIALS TECH CO LTD

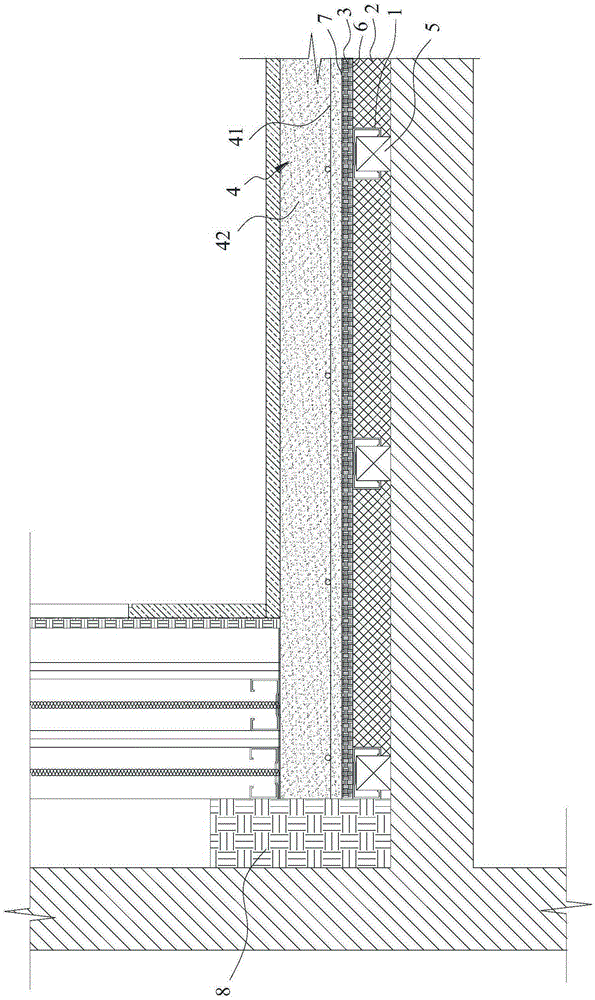

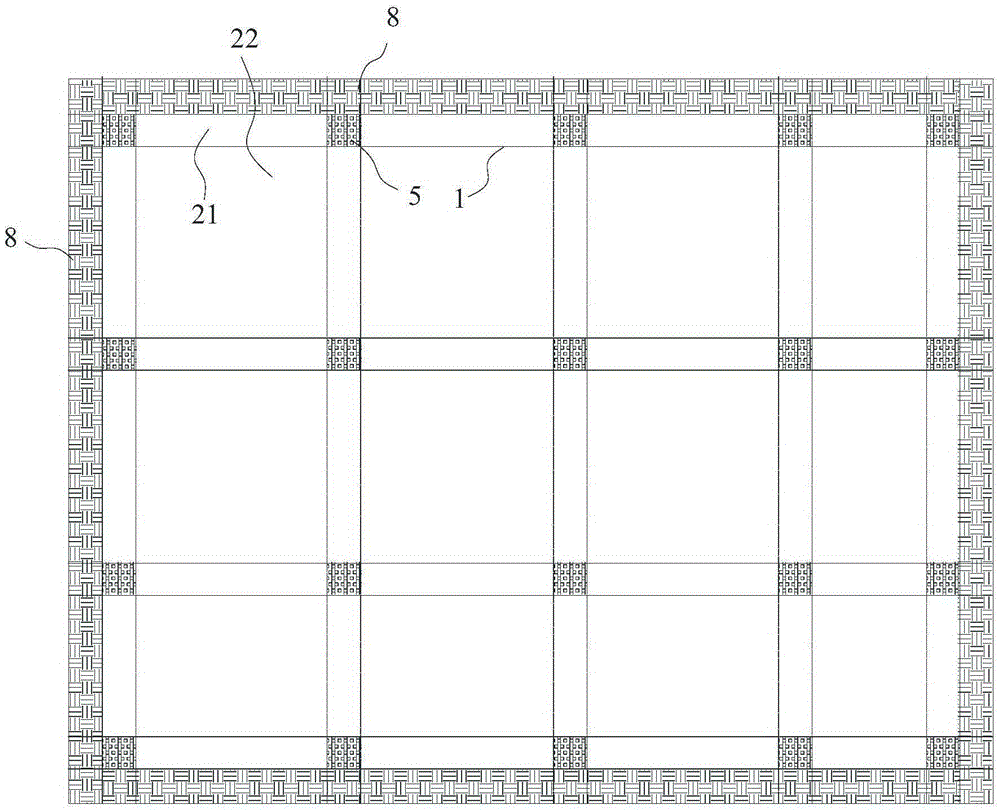

Suspended quakeproof sound-proof isolating layer structure and quakeproof sound-proof floor slab construction method

InactiveCN105256930AEffective sound insulationLabor savingFloorsSound proofingFloor slabReinforced concrete

The invention discloses a suspended quakeproof sound-proof isolating layer structure which comprises a keel frame, rock wool layers, a bamboo clamping plate, a reinforced concrete layer and a plurality of quakeproof cushion blocks, wherein the quakeproof cushion blocks are uniformly distributed at intervals; the keel frame is fixed at the side parts of the quakeproof cushion blocks in a clamping manner; each rock wool layer is paved between every two adjacent quakeproof cushion blocks and in gaps of the keel frame; the top surfaces of the quakeproof cushion blocks, the top surface of the keel frame and the top surfaces of the rock wool layers are flush, and are combined to form a tiled surface; the bamboo clamping plate is horizontally paved on the surface of the tiled surface; the reinforced concrete layer is fixedly arranged on the top surface of the bamboo clamping plate. The invention further discloses a quakeproof sound-proof floor slab construction method adopting the suspended quakeproof sound-proof isolating layer structure. According to the invention, a damping action on sound waves can be achieved, and good sound-proof and quakeproof effects are achieved.

Owner:SHENZHEN ASIANTIME INTIAONAL CONSTR CO LTD

Transformer iron core and production method thereof

InactiveCN103325534AReduce noiseNot easy to fall offTransformers/inductances magnetic coresInductances/transformers/magnets manufactureFoaming agentTransformer

The invention relates to a transformer iron core and a production method thereof. A polyurethane foam layer formed by curing reaction of polyurethane foaming agents is coated on the outer surface of the iron core; by the polyurethane foam layer, sounds, generated by vibration caused by magnetostriction, of the iron core can be reduced, and sounds generated by transformer coils can be absorbed, so that transformer noise is reduced; the polyurethane foaming agents are coated on the iron core after foaming to form the compact polyurethane foam layer attached on the iron core, and the polyurethane foam layer is not prone to shedding and durable, so that input cost is reduced.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com