Assembled wooden door and manufacturing method thereof

An assembled wooden door technology, which is applied in the direction of manufacturing tools, door leaves, windows/doors, etc., can solve the problems of shortened service life of wooden doors, easy impact of wooden doors, floor damage and other problems, so as to improve the effect of sound insulation and noise reduction, and simplify the installation steps , Improve the effect of stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

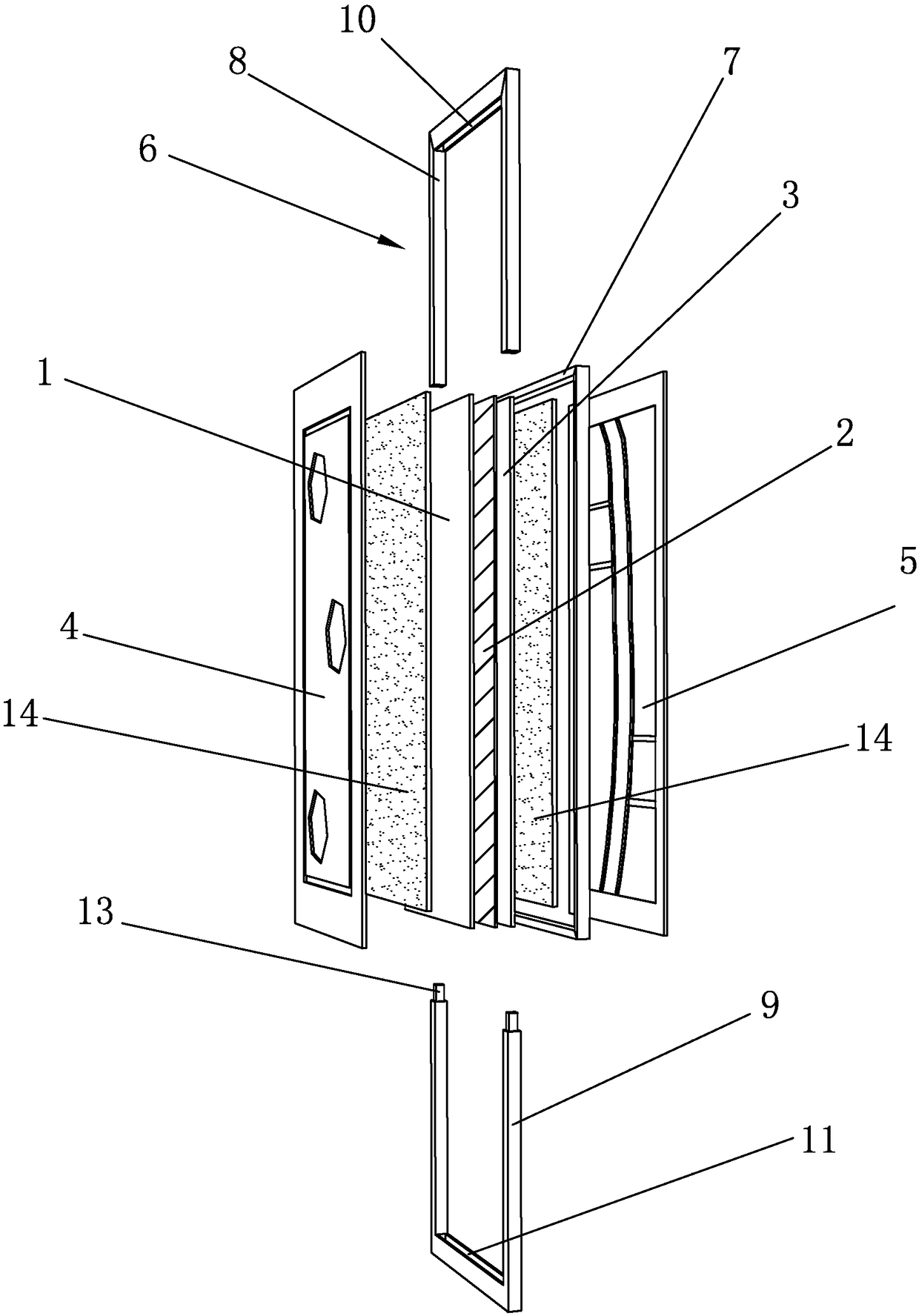

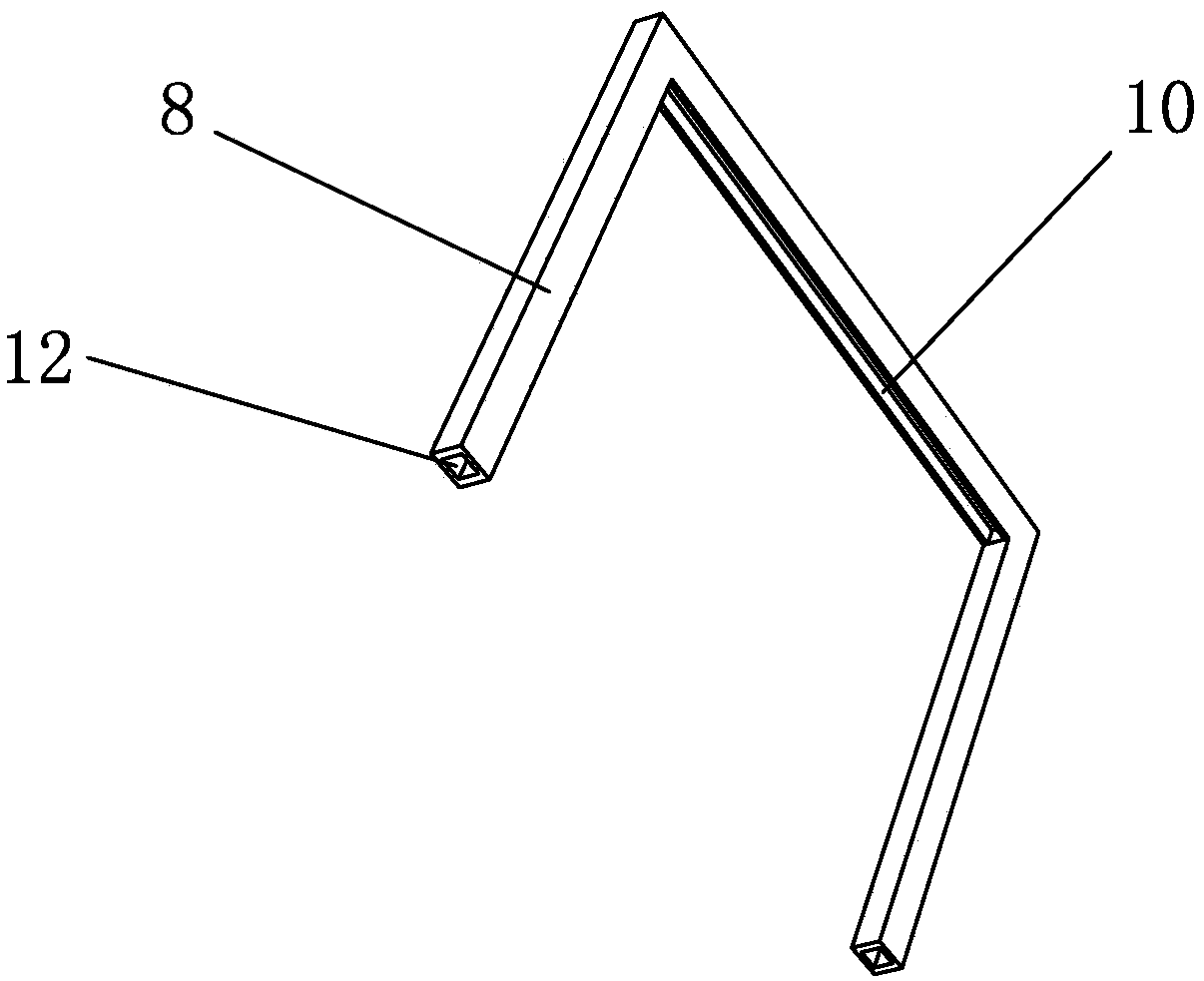

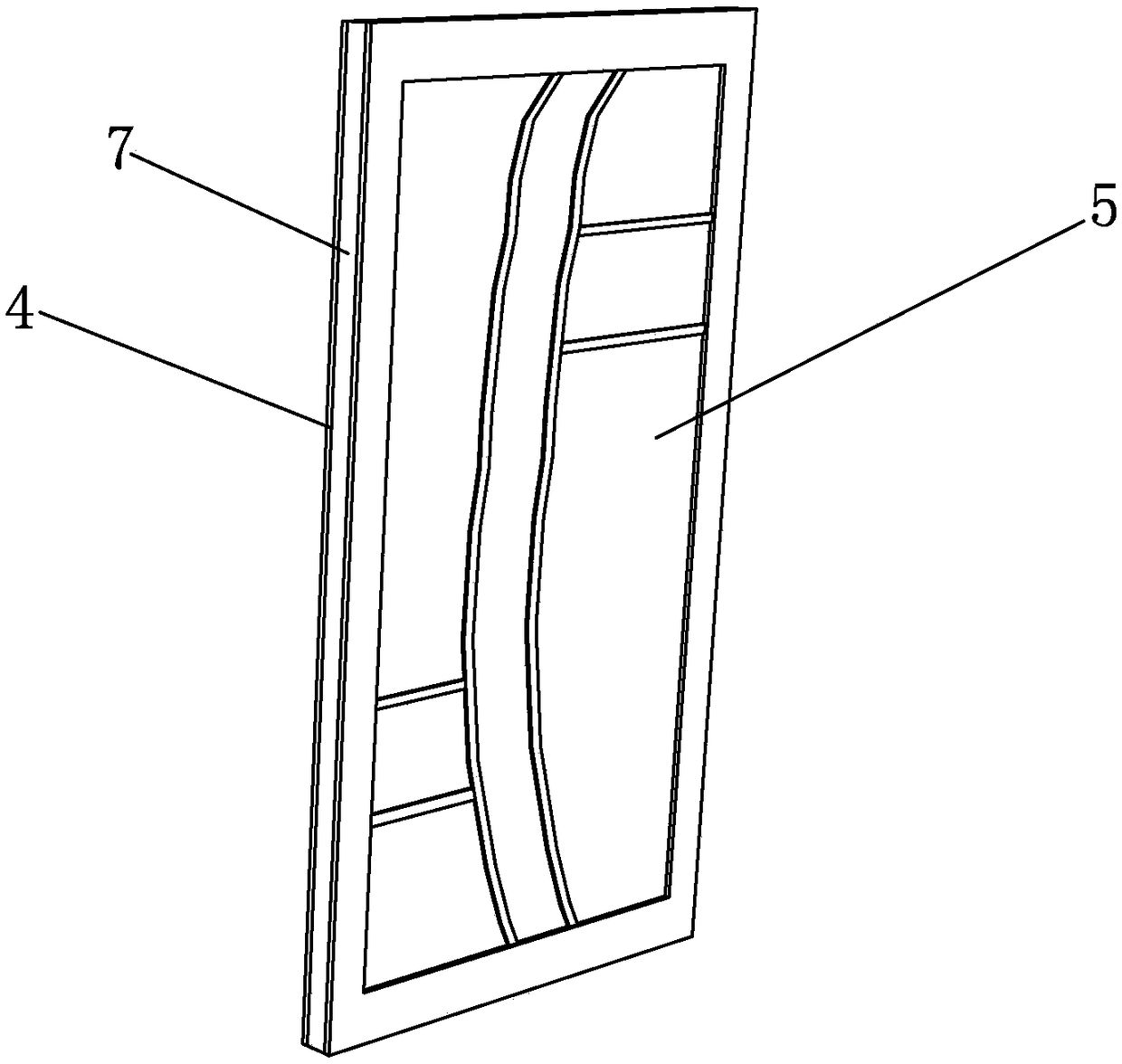

[0035] Such as Figure 1 to Figure 4 As shown, the assembled wooden door of the present invention includes a wooden door base plate and a fixed frame, and the wooden door base plate is clamped in the fixed frame. Located between the first side substrate 1 and the second side substrate 3, between the first side substrate 1 and the inner core board 2, and between the second side substrate 3 and the inner core board 2 are fixed by cloth glue, the first side The numerical ratio of the thickness of the substrate 1, the inner core panel 2 and the second side substrate 3 is 1:0.6:1. By controlling the thickness ratio of the first side substrate 1, the inner core panel 2 and the second side substrate 3, the wooden door substrate can be controlled. The overall weight and structural strength, the design is reasonable, the inner core board 2 is a rock wool board, and the density of the rock wool board is 80-180kg / m 3 The design of the inner core board 2 made of rock wool board can impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com