Patents

Literature

83results about How to "Reduce the probability of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

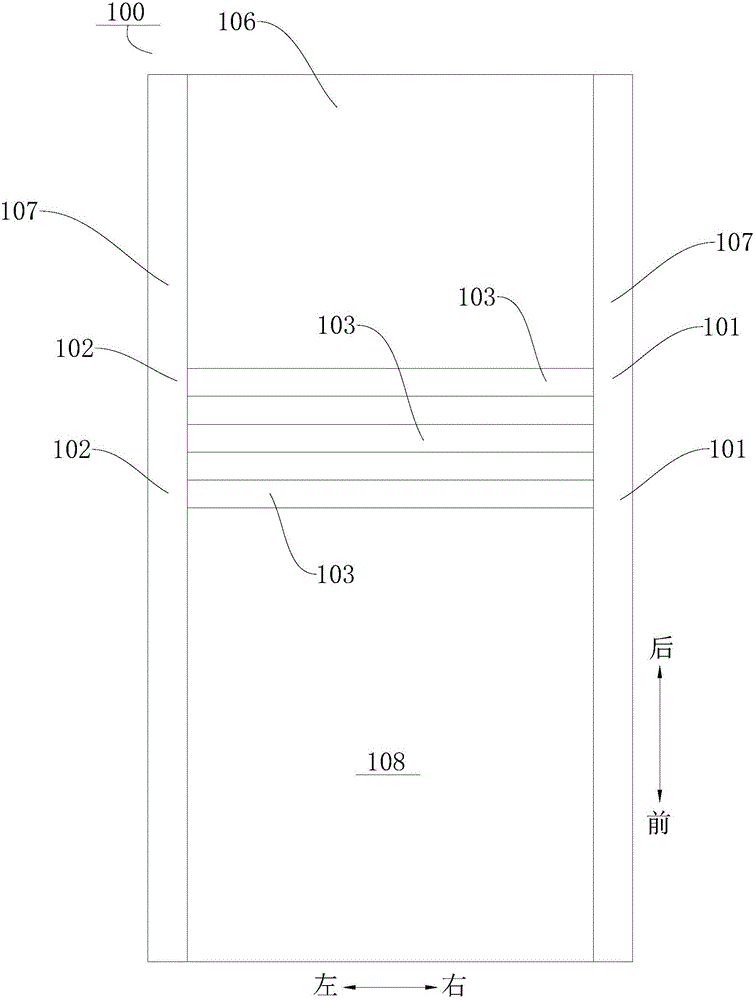

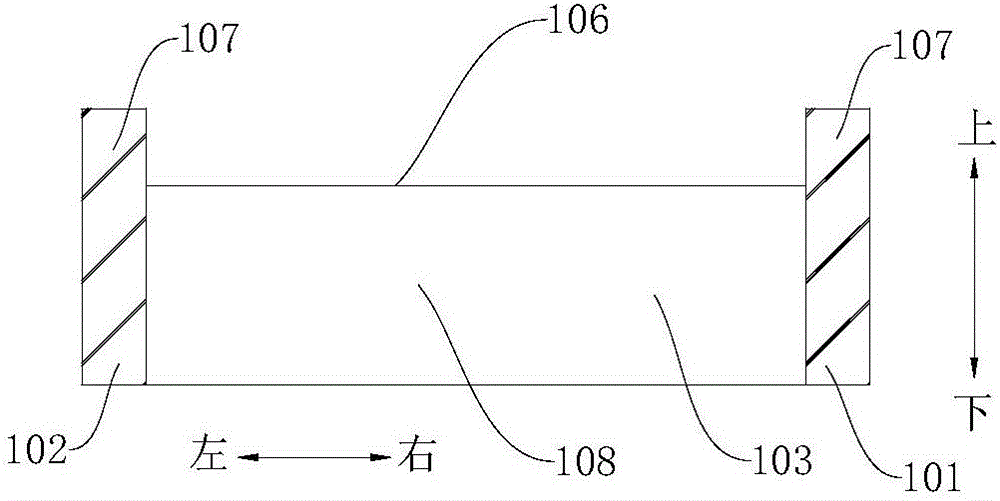

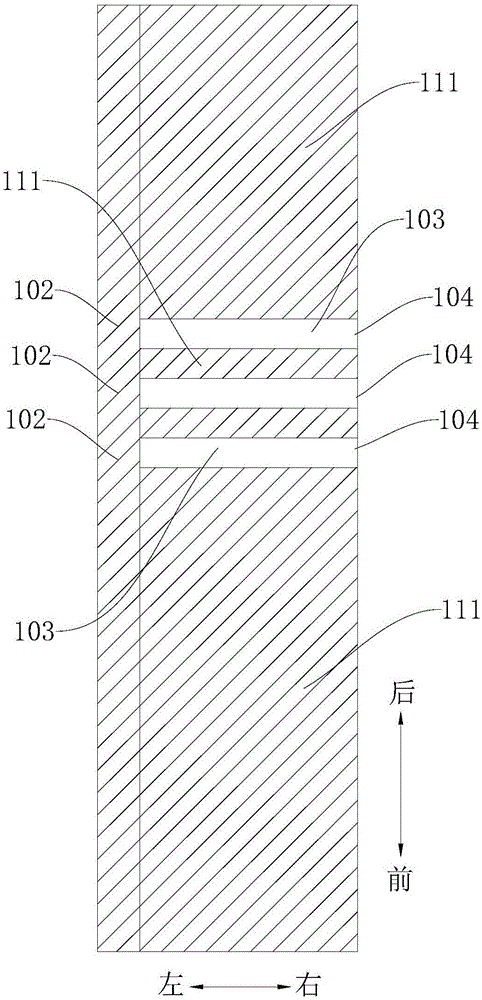

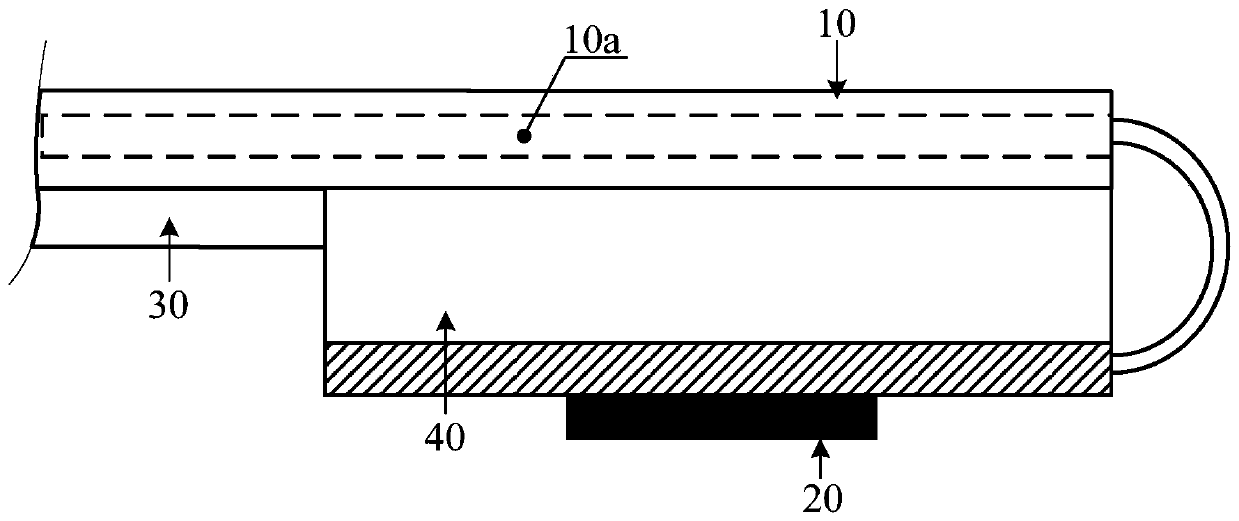

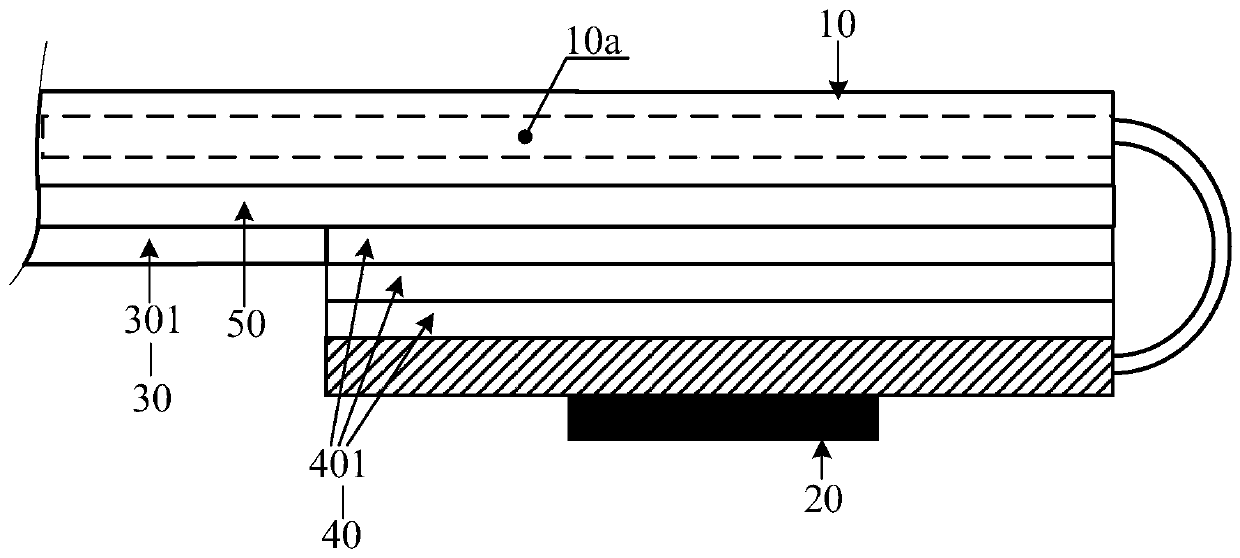

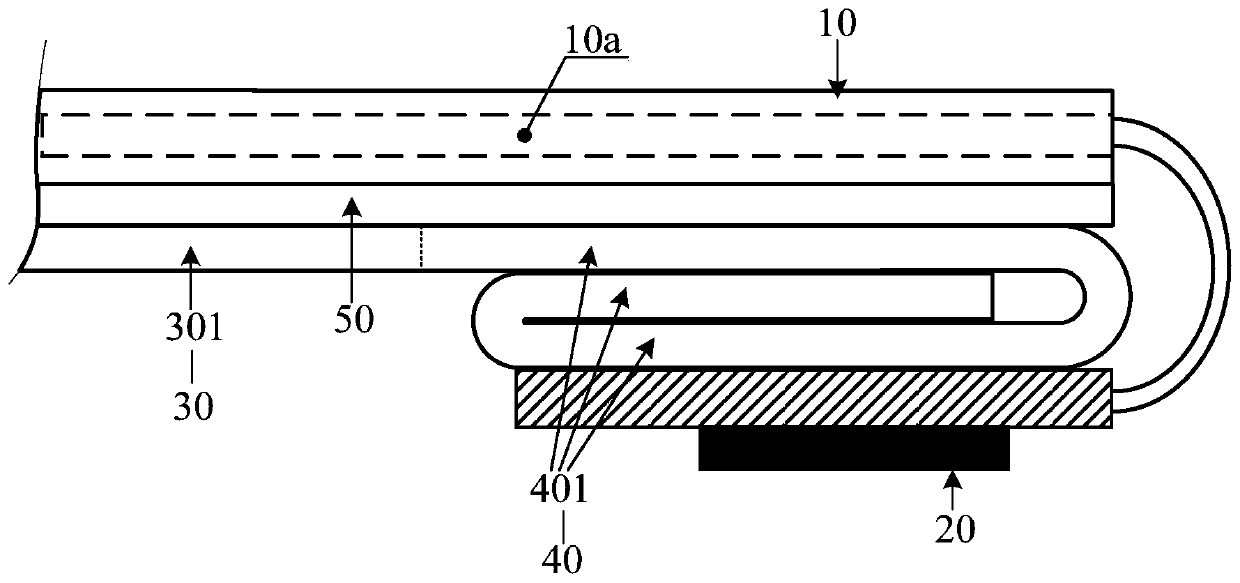

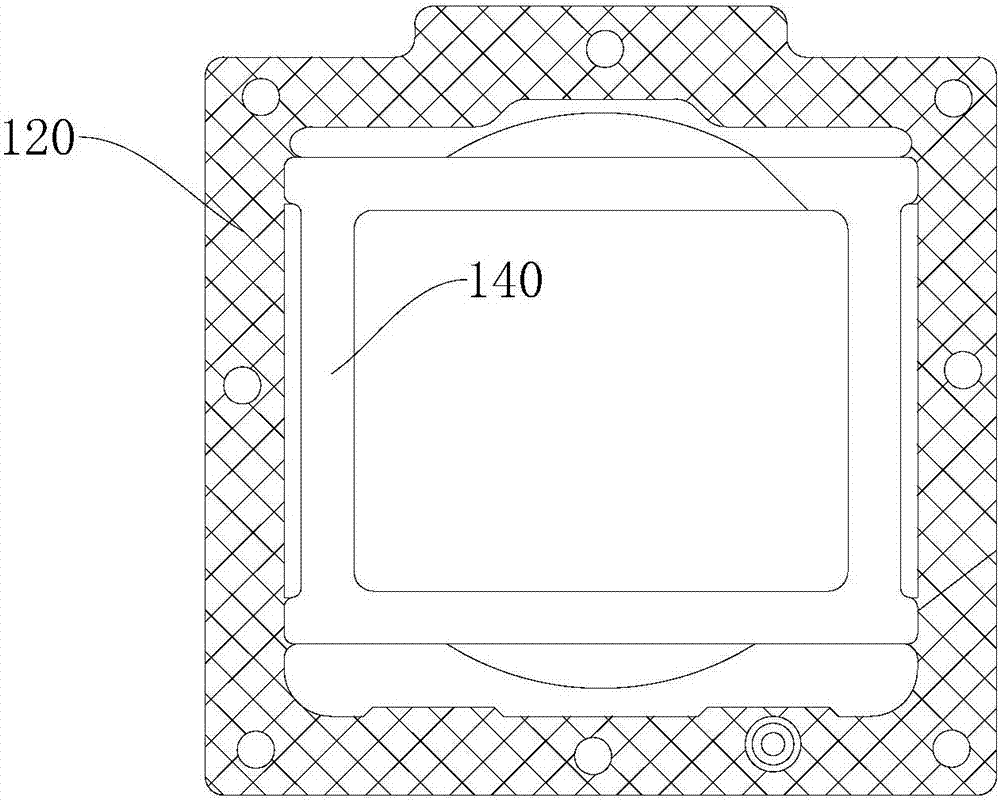

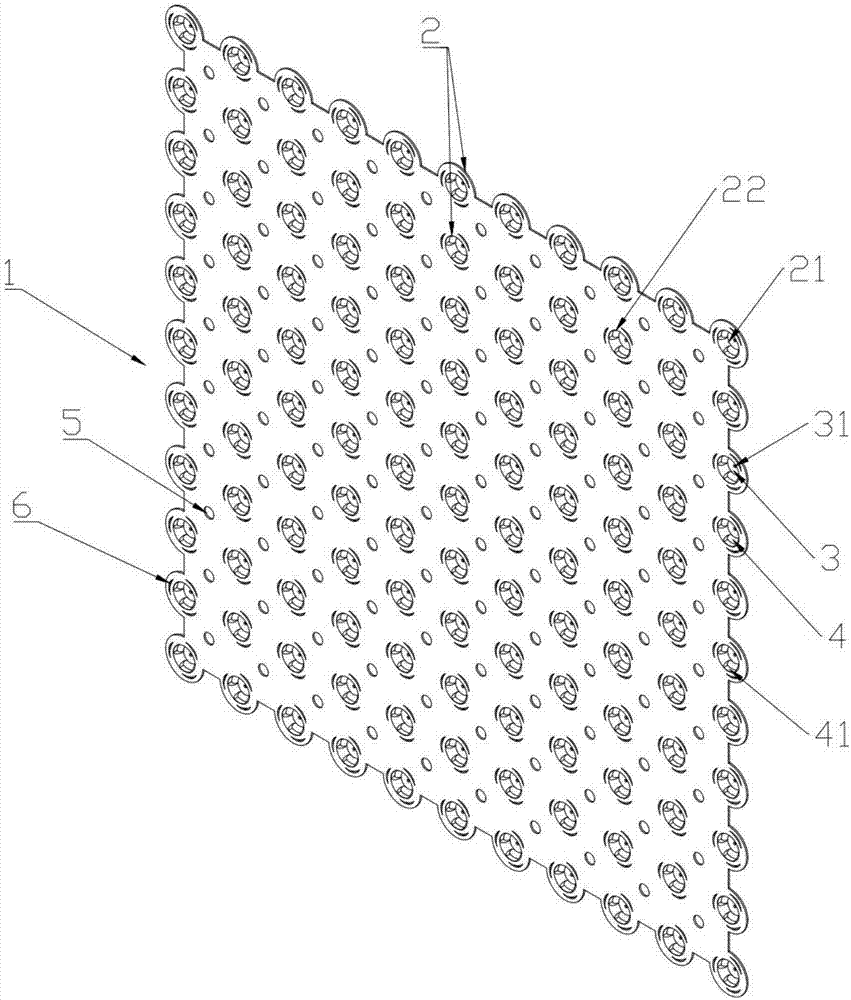

Mobile terminal, shell and manufacture method thereof

ActiveCN106163157AReduce the probability of deformationProduct deformation is smallElectrical apparatus casings/cabinets/drawersEngineeringBiomedical engineering

The invention discloses a mobile terminal, a shell and a manufacture method thereof. The manufacture method comprises the following steps of: S10, providing a base material, forming a gap penetrating the base material in a thickness direction on the base material, and making the base material have a first enclosing segment and a second enclosing segment for enclosing both ends of the gap; S20, removing the first enclosing segment so as to open one side of the gap; S30, embedding a fixed member from the opening side of the gap; S40, filling the gap with a filler; and S50, performing cutting so as to form the shell, and dividing the shell into a plurality of spacing regions by the gap, wherein the gap in the shell will be fully filled by the filler. According to the manufacture method of the shell of the mobile terminal, the structure intensity at the gap is enhanced by using the fixed member, the probability that the gap structure deforms in a filling process is reduced, and the product deformation is decreased and the whole intensity of products is ensured. Thus the defective rate of the products is reduced, and furthermore the product quality is improved and the production cost is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

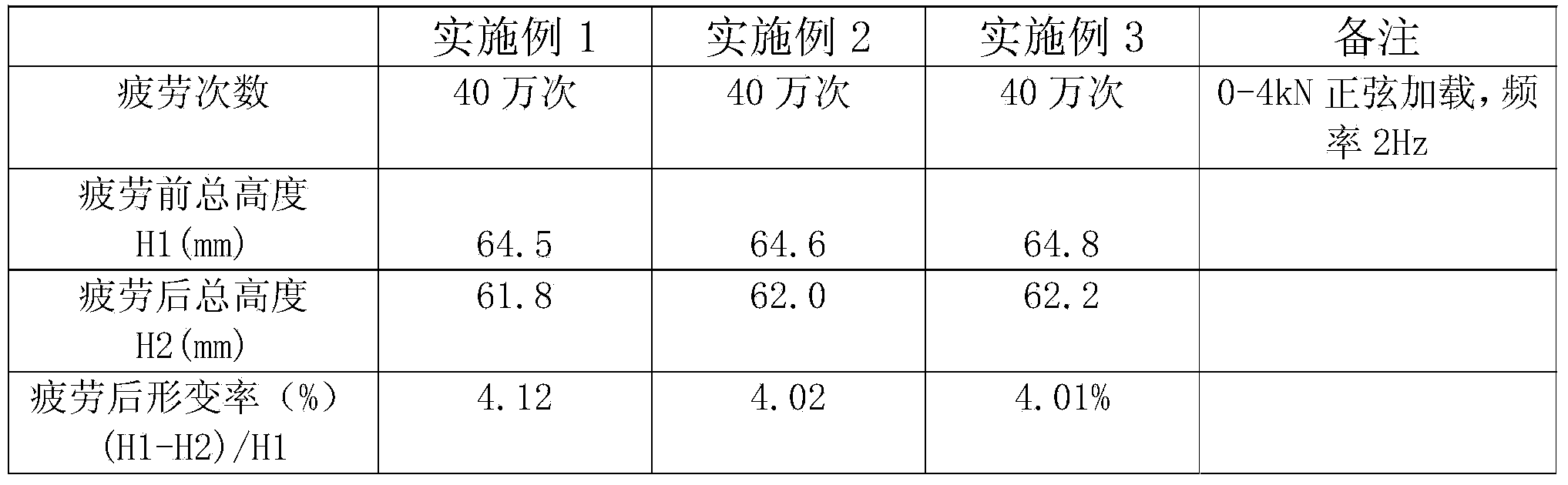

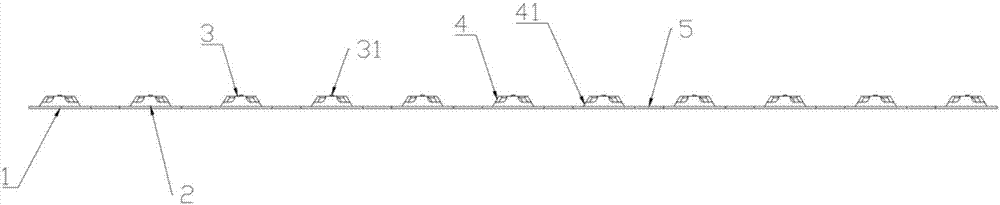

Method for preparing low-deformation polyurethane damping bumper block

ActiveCN104341579AIncreased chemical crosslinkingReduce deformation ratePrepolymerIsocyanate compound

The invention relates to a method for preparing a low-deformation polyurethane damping bumper block. The method is used for solving the technical problem in the prior art that the deformation rate is high after the polyurethane bumper block for an automobile is subjected to dynamic fatigue, and is used for improving the safety and comfort of the bumper block in a continuous working environment. The method comprises the processing steps: (1) pretreating isocyanate; (2) preparing a prepolymer; (3) preparing a chain extender; (4) blending; (5) carrying out cast molding; (6) carrying out post-vulcanization. The prepared low-deformation polyurethane damping bumper block has the advantage that the deformation rate of the fatigued bumper block is lowered on the premise that the dynamic fatigue performance and comprehensive performance of the bumper block are maintained. According to the method disclosed by the invention, modified MDI and macromolecular and polyfunctional ether polyalcohol are adopted to react, and a microporous elastomer material, of which both hard segment phase and soft segment phase contain certain chemical crosslinking, is prepared, so that the requirements of current medium- and high-end automobiles on bumper blocks which have low deformation after dynamic fatigue are met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

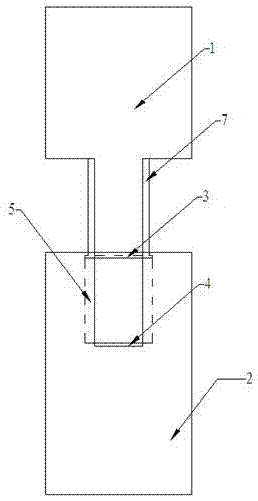

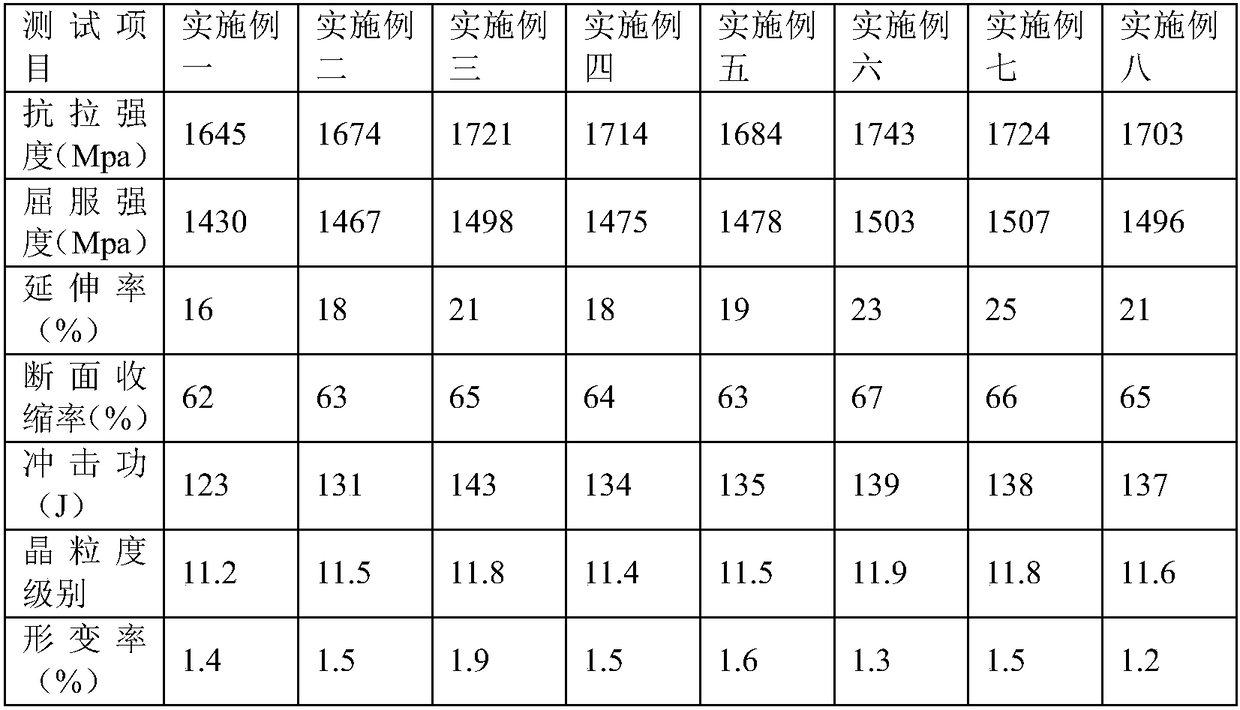

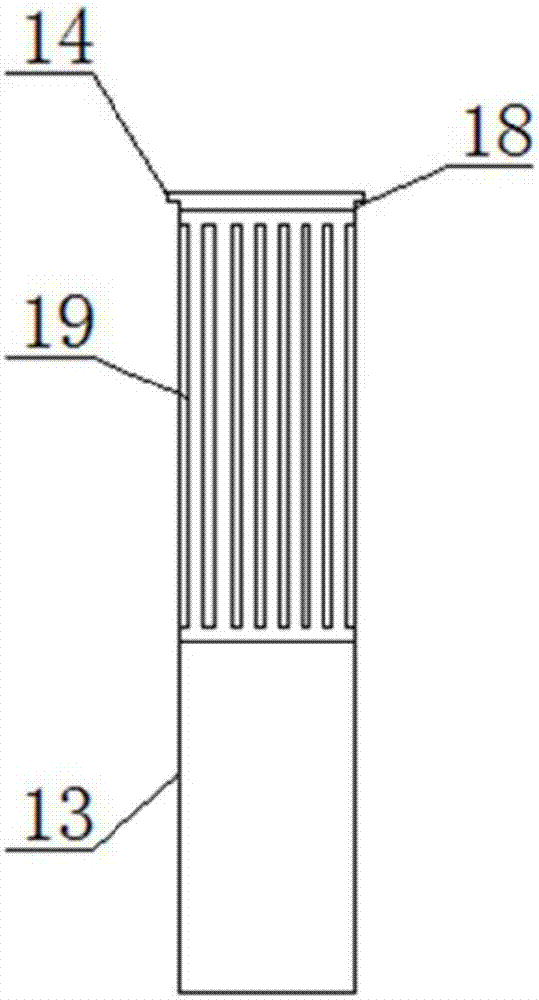

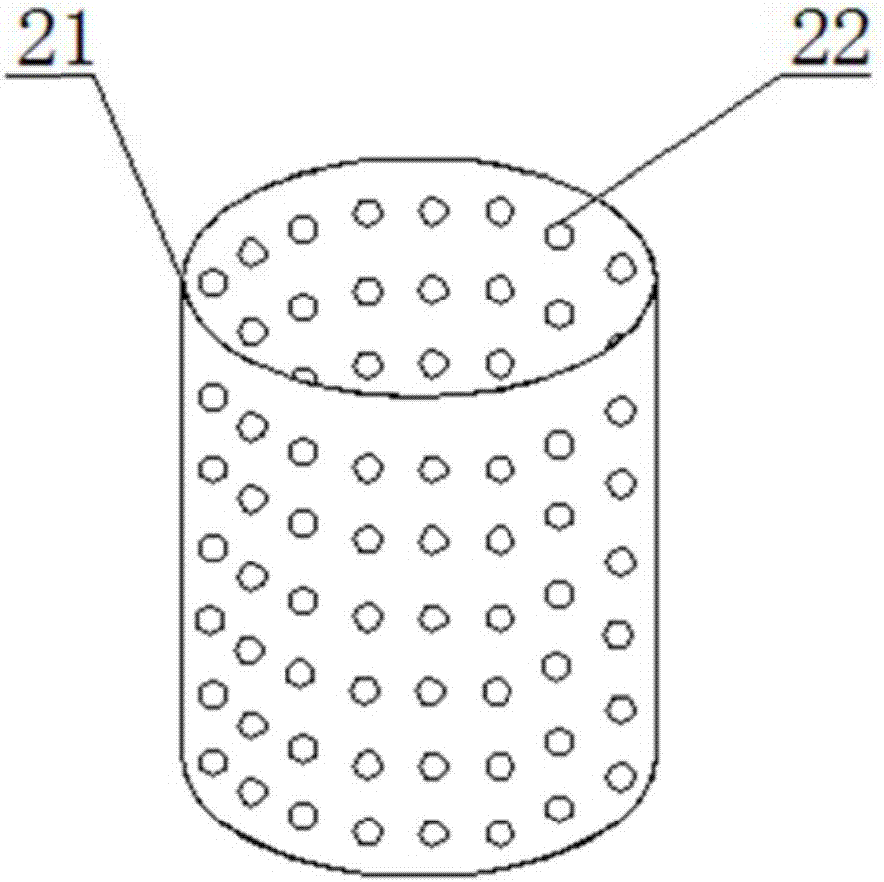

Durable die guide pillar

InactiveCN103586355AReduce the probability of deformationExtended service lifeShaping toolsEngineeringMagnet

The invention discloses a durable die guide pillar comprising a first guide pillar rod, a second guide pillar rod, a first magnet and a second magnet. The first guide pillar rod is connected with the second guide pillar rod; the first magnet is connected with the bottom end of the first guide pillar rod; the second magnet is connected with the bottom surface of the inner end of the second guide pillar rod; a sliding rib groove is formed in the side face of the inner end of the second guide pillar rod; and a stopper is arranged at the top end of the sliding rib groove. By the means, the durable die guide pillar has a buffer capacity in use, so that probability of deformation of the durable die guide pillar is lowered, and service life of the durable die guide pillar is prolonged.

Owner:SUZHOU YIQUN MOLD

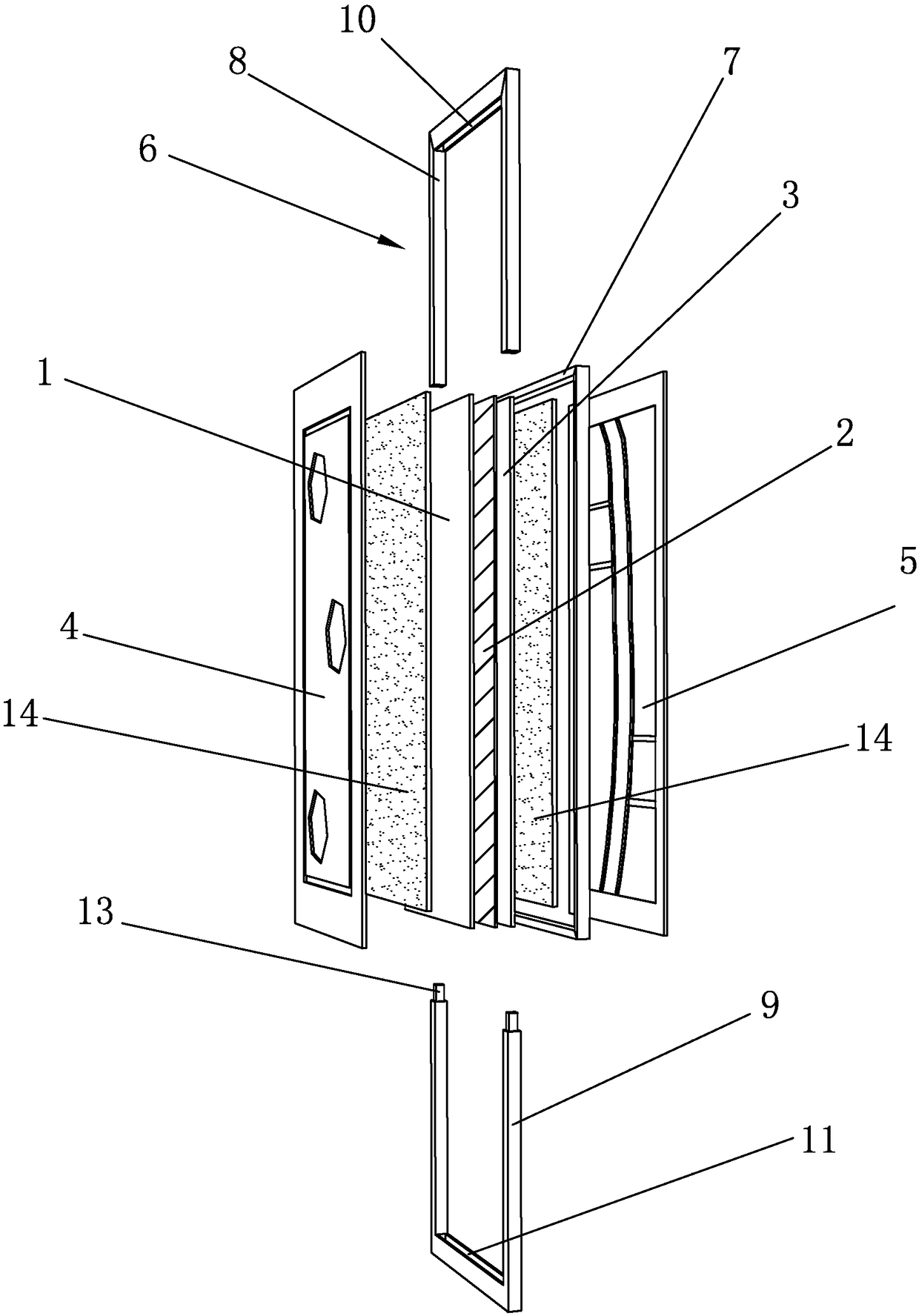

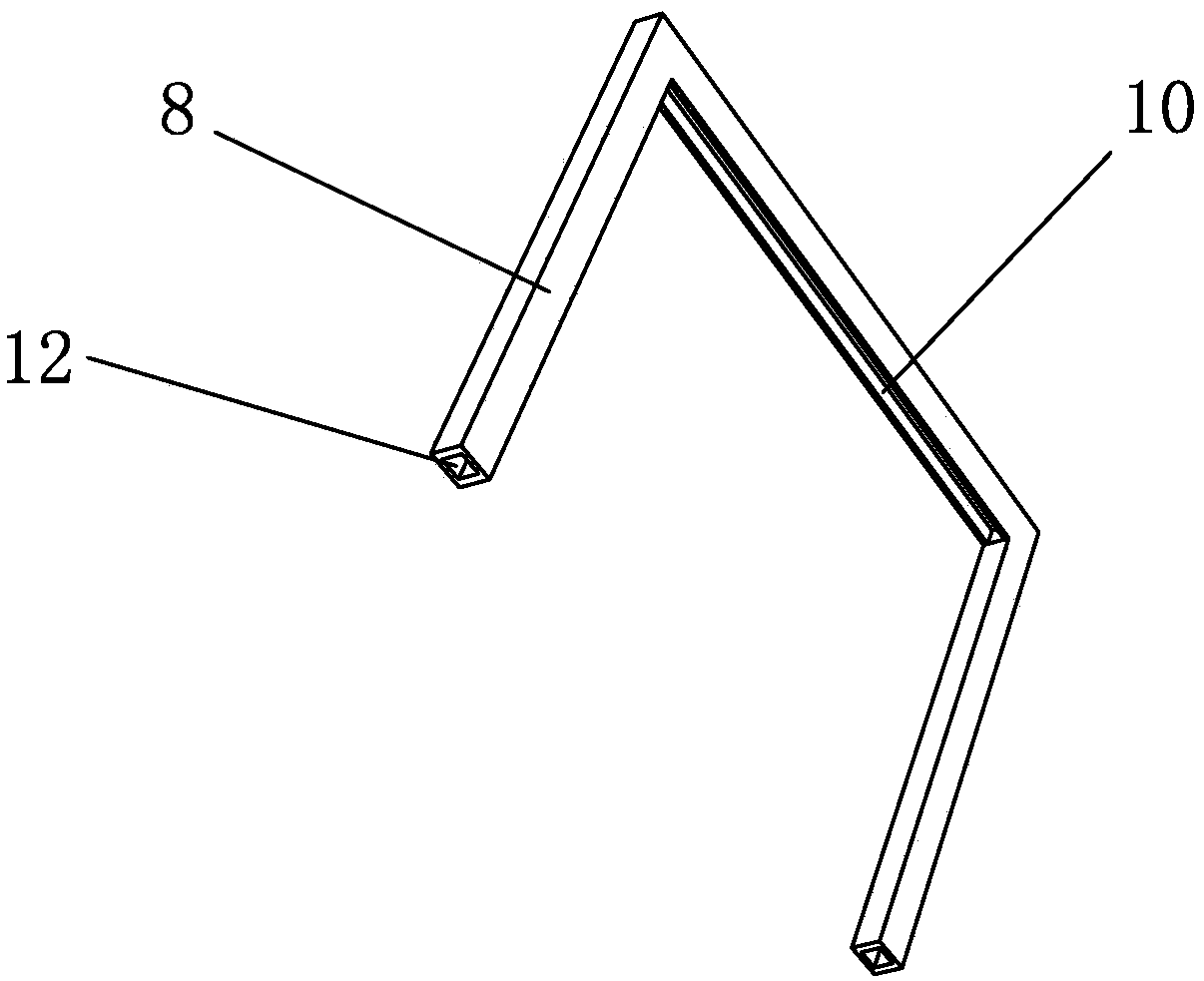

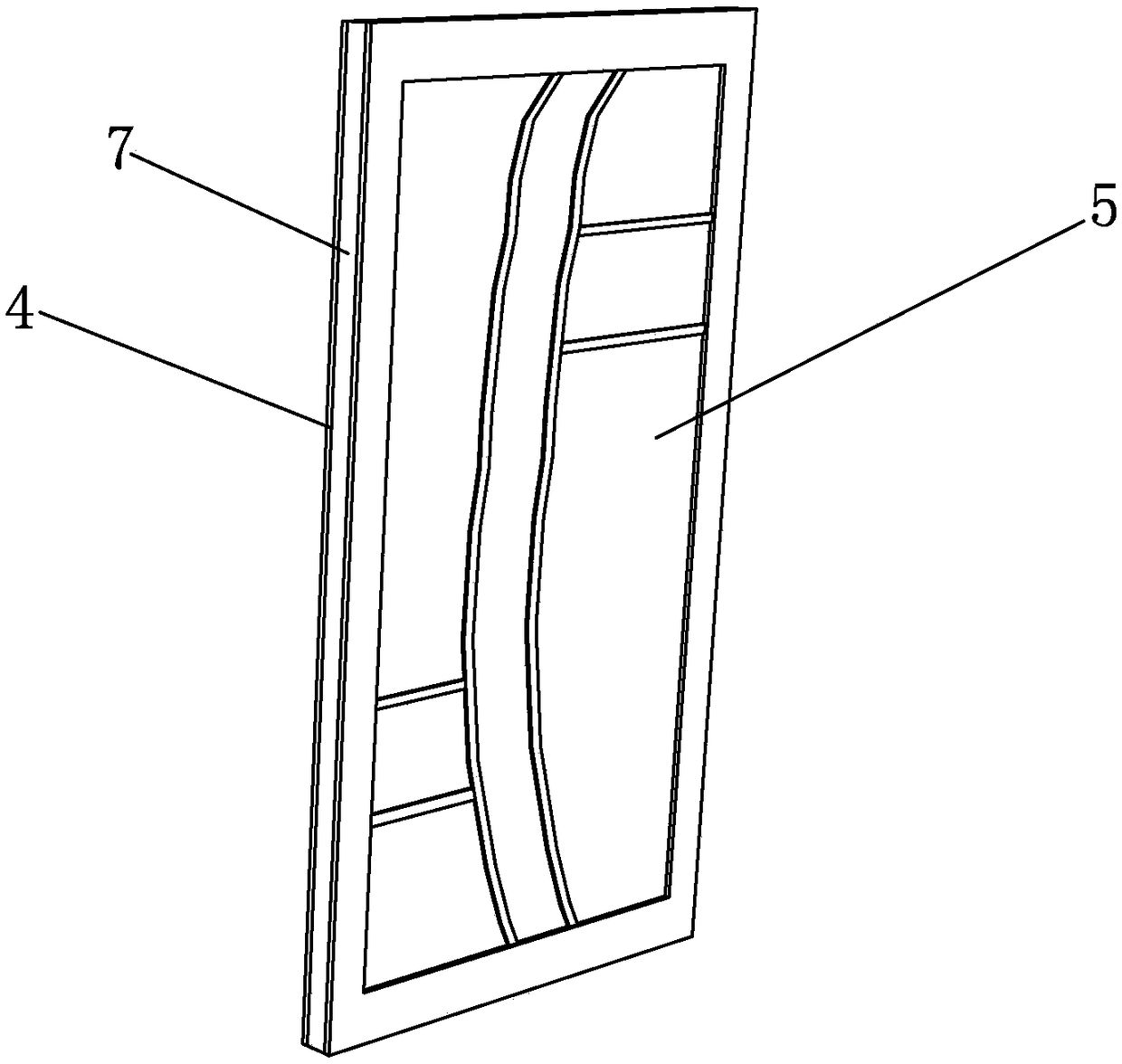

Assembled wooden door and manufacturing method thereof

ActiveCN108798398AStable structureCompact and reasonable structureFireproof doorsNoise insulation doors/windowsFixed frameUltimate tensile strength

The invention discloses an assembled wooden door comprising a wooden door base plate and a fixing frame. The wooden door base plate is connected into the fixing frame in a clamped mode and comprises afirst side base plate body, an inner core plate and a second side base plate body. The inner core plate is located between the first side base plate body and the second side base plate body. A firstdecorating layer is arranged on one side of the fixing frame. A second decorating layer is arranged on the other side of the fixing frame. The fixing frame comprises a limiting frame and an anti-collision frame. The limiting frame is connected into the anti-collision frame in a clamped mode and comprises an upper limiting frame body and a lower limiting frame body. A manufacturing method of the assembled wooden door comprises the following steps that (1) the wooden door base plate is prepared; (2) the fixing frame is prepared; (3) sound insulation pads are prepared; (4) the decorating layers are prepared; and (5) the wooden door is assembled. The assembled wooden door is ingenious and reasonable in overall structural design, the structural strength and stability of the wooden door are improved, droop deformation of the wooden door is effectively prevented, meanwhile, the four side edges of the wooden door can be protected through the design of the fixing frame, the service life of thewooden door is prolonged, and the comprehensive utilization rate is increased.

Owner:浙江图森定制家居股份有限公司

Display device

ActiveCN110767092AImprove reliabilityReduce the probability of breakageIdentification meansComputer hardwareDrop tests

The invention discloses a display device, and belongs to the technical field of display. The display device comprises a display panel, a chip, a panel supporting component and a chip protecting component; and the thickness of the chip protecting component is greater than the thickness of the panel supporting component. When the display device performs a drop test or a user presses the display device, a flexible structure (ie, the display panel) in the display device can squeeze the chip protecting component after deformation, and the thickness of the chip protecting component is large, so thatthe rigidity of the chip protecting component is high, and the probability of deformation of the chip protecting component is low. Since the chip protecting component that has not been deformed doesnot exert pressure on the chip, the chip protecting component can reduce the probability of chip breakage and effectively improve the reliability of the display device.

Owner:BOE TECH GRP CO LTD +1

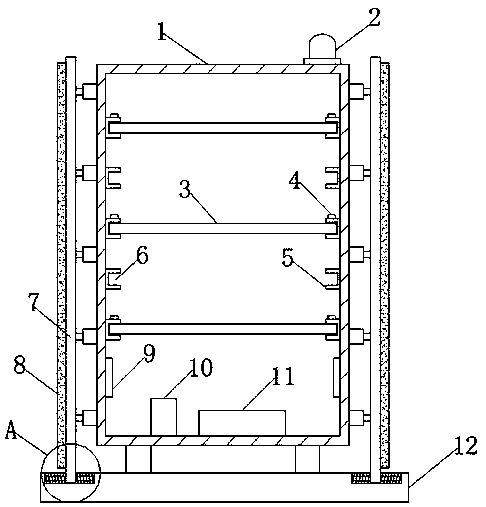

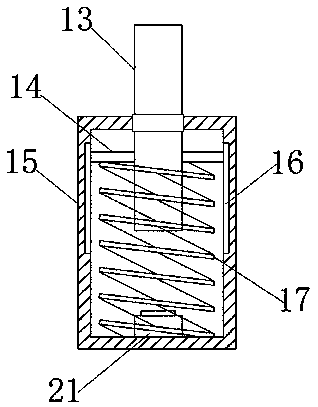

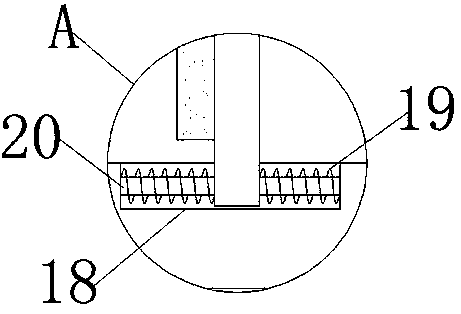

Anti-collision outdoor electrical cabinet

InactiveCN109714921AAvoid deformationEnsure safetyNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringPower equipment

The invention belongs to the technical field of power equipment and particularly relates to an anti-collision outdoor electrical cabinet. The cabinet comprises a cabinet body and a base. The cabinet body is fixedly mounted on the base. Movable plates in the vertical direction are arranged on the two sides of the cabinet body. The surfaces of one sides, close to the cabinet body, of the movable plates are fixedly connected with a plurality of connecting rods at equal intervals. The outer wall of the cabinet body is fixedly connected with protection blocks. One end of each connecting rod extendsinto the corresponding protection block. A pressure sensor is mounted on the inner wall of each protection block. A moving plate is fixedly connected to the outer side of each connecting rod. The outer side of each connecting rod is sleeved with a first spring. The two ends of each first spring are fixedly connected with the inner wall of the corresponding protection block and the corresponding moving plate correspondingly. One side, away from the cabinet body, of each movable plate is fixedly connected with a protection plate. The defects in the prior art are overcome and the electrical cabinet is protected. The deformation probability of the electrical cabinet is reduced. When the electrical cabinet is subjected to strong impact, the power supply of the electrical cabinet is cut off. The safety accidents caused by open circuit are avoided.

Owner:合肥智鼎电控自动化科技有限公司

Novel buffer pad

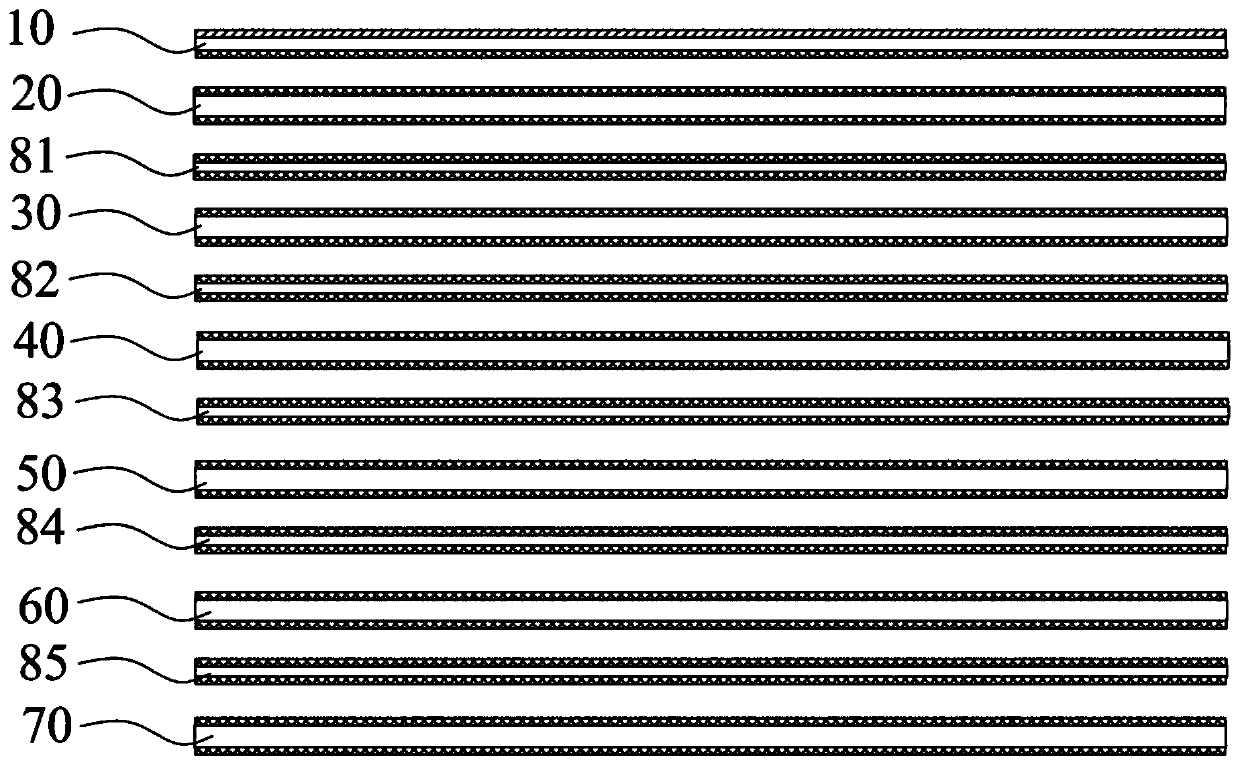

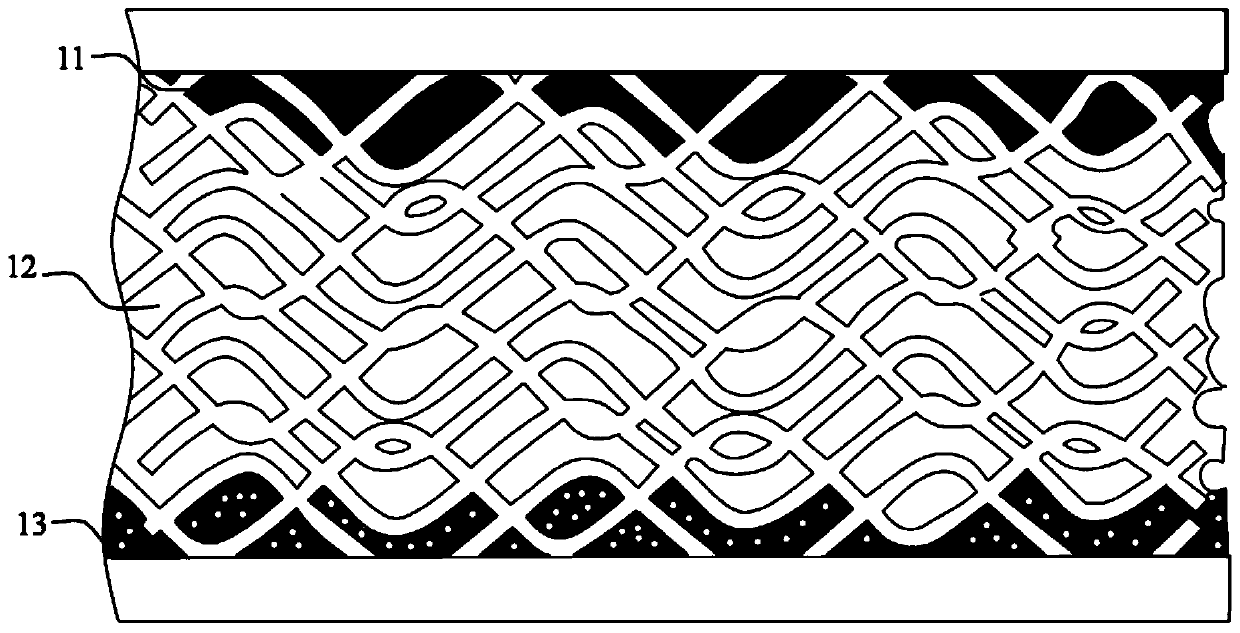

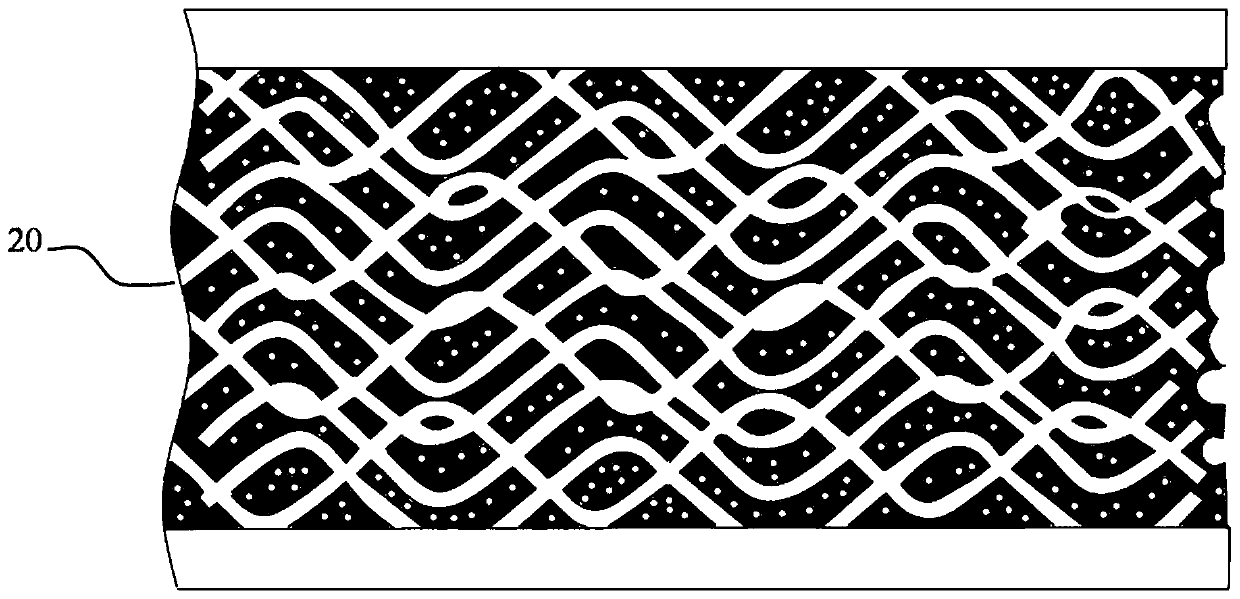

PendingCN110757919AImprove buffering effectImprove heat resistanceSynthetic resin layered productsLaminationGlass fiberPolymer science

The invention discloses a novel buffer pad which sequentially comprises a surface layer, a first thick cloth layer, a first thin cloth layer, a second thick cloth layer, a second thin cloth layer, a third thick cloth layer, a third thin cloth layer, a fourth thick cloth layer, a fourth thin cloth layer, a fifth thick cloth layer, a fifth thin cloth layer and a sixth thick cloth layer from top to bottom, wherein the surface layer comprises a polytetrafluoroethylene layer, a glass fiber cloth layer and a fluorine rubber layer containing pores in the fluorine rubber layer; the first thick cloth layer is prepared by dipping glass fiber cloth into liquid fluororubber and curing the glass fiber cloth; and the first thin cloth layer is made of fluororubber with air holes inside. The novel bufferpad is composed of the glass fibers and the fluororubber containing the air holes, has the outstanding advantages of being excellent in buffering performance, good in heat resistance (capable of beingused for a long time at the high temperature of 240 DEG C), low in deformation rate and the like, and is a high-performance buffer pad material superior to a traditional pressing pad and kraft paper.

Owner:江苏泰斯鸿科技有限公司

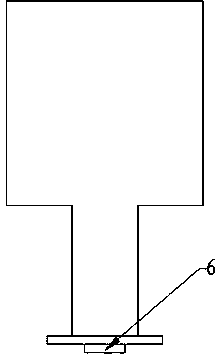

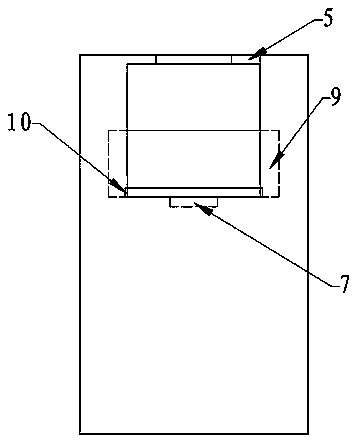

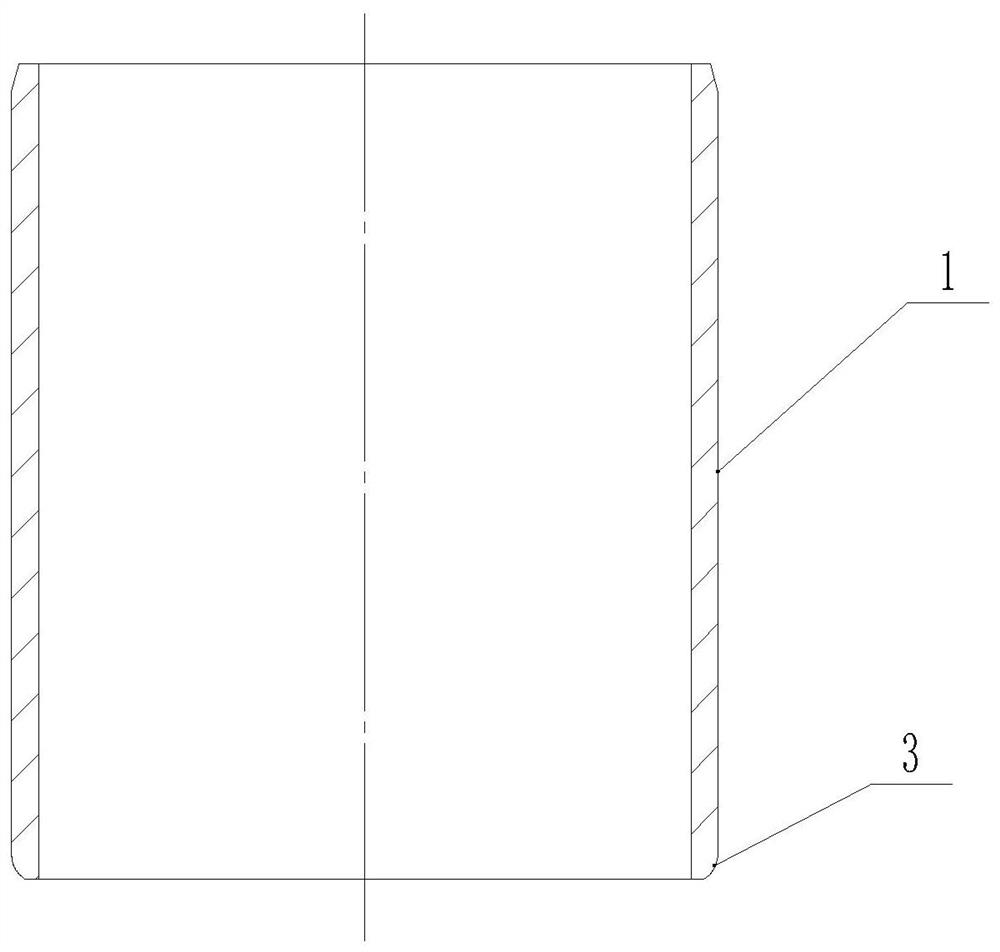

Production process for stainless steel clamping and pressing type pipe fitting equal-diameter tee joint

InactiveCN112917107AHigh hardnessReduce the probability of deformationBranching pipesPunchingPipe fitting

The invention provides a production process for a stainless steel clamping and pressing type pipe fitting equal-diameter tee joint , and relates to the technical field of pipe fitting production processes. The production process for the stainless steel clamping and pressing type pipe fitting equal-diameter tee joint comprises the following steps of S1, feeding, laser cutting and chamfering; S2, water swelling forming; S3, punching; S4, high-frequency heating; S5, drawing; S6, opening flattening; S7, pipe fitting cleaning; S8, bright solution annealing; S9, polishing and grinding; S10, sealing ring mounting and S11, pipe fitting testing. According to the production process for the stainless steel clamping and pressing type pipe fitting equal-diameter tee joint, different temperatures are each kept for a period of time, so that different elements can be well distributed at the different temperatures. During annealing, double media are used for rapid cooling, the annealing effect is better, the hardness and stress of a material pipe are reduced, and the deformation rate and the reject ratio of produced rusted steel clamping and pressing type pipe fittings are reduced.

Owner:卡狮管业(上海)有限公司

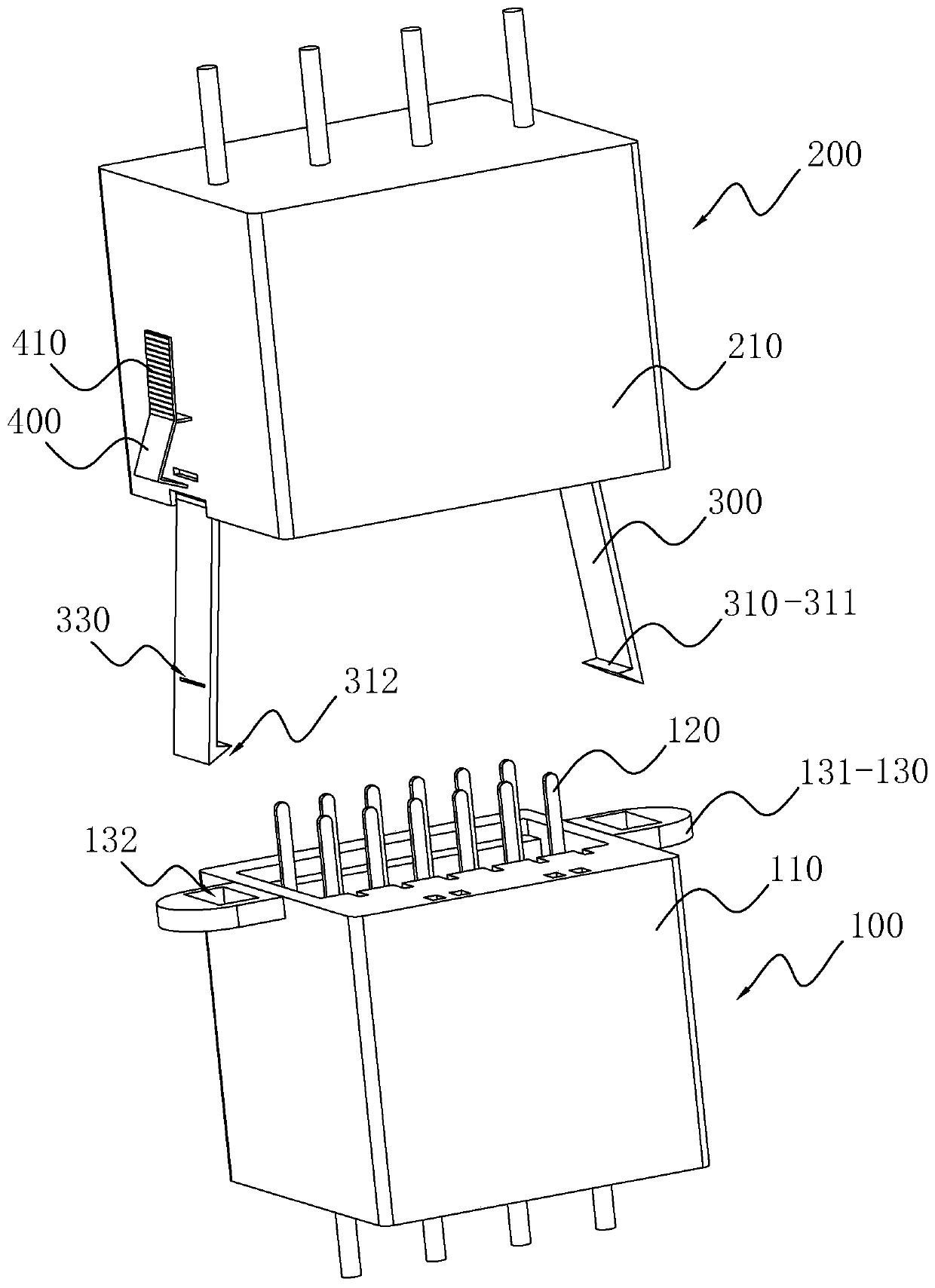

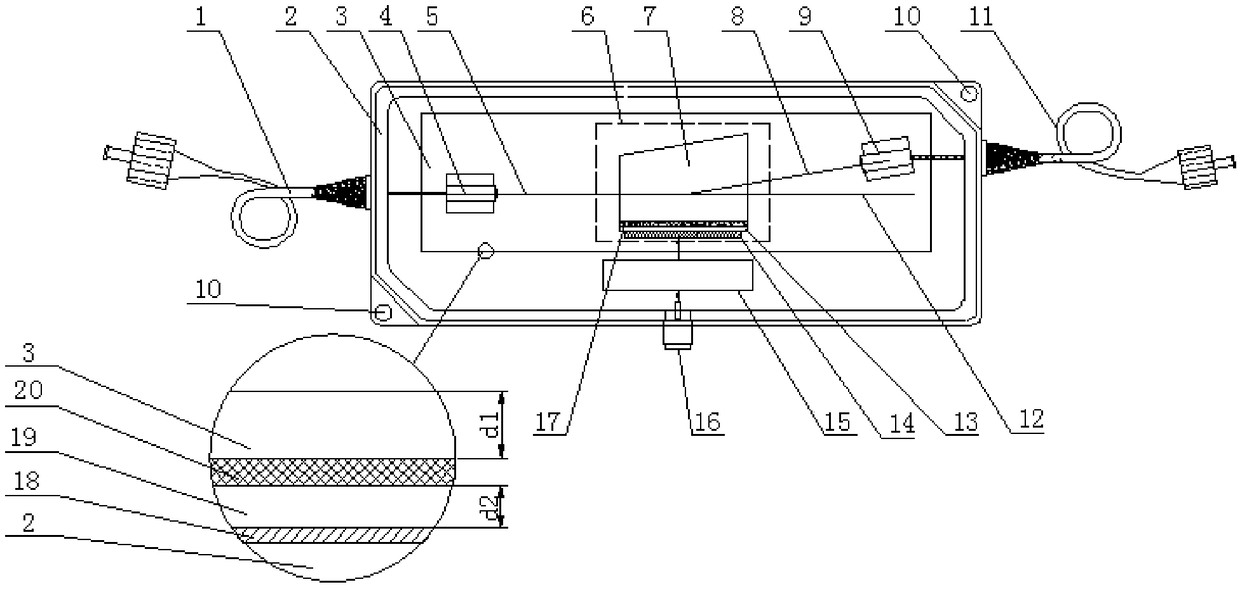

Connector for automobile data transmission

ActiveCN111244690AReduce the probability of deformationEasy to plug inVehicle connectorsCoupling device detailsAnimal scienceZoology

The invention relates to the technical field of data transmission parts. The invention discloses a connector for automobile data transmission. The connector comprises a male head and a female head, the male head comprises a male shell and a PIN terminal arranged in the male shell, the female head comprises a female shell and a port arranged in the female shell and matched with the PIN terminal inan inserted mode, guide pieces are symmetrically arranged on the two opposite sides of the female shell, and the guide pieces are connected with the female shell in a sliding mode in the inserting andpulling direction of the female shell; a connecting part is arranged at one end, facing the male shell, of the guide pieces, and a mounting part connected with the connecting part is arranged on oneside, facing the female shell; and an unlocking structure for unlocking the connecting part and the mounting part is also arranged on the female shell. Through the arrangement of the guide pieces, themale head and the female head can move along the direction of the guide pieces during plugging and unplugging, the probability of deformation of the PIN terminal under the action of external force isreduced, and meanwhile, the male head and the female head are convenient to plug.

Owner:LAUNCH DESIGN INC LTD

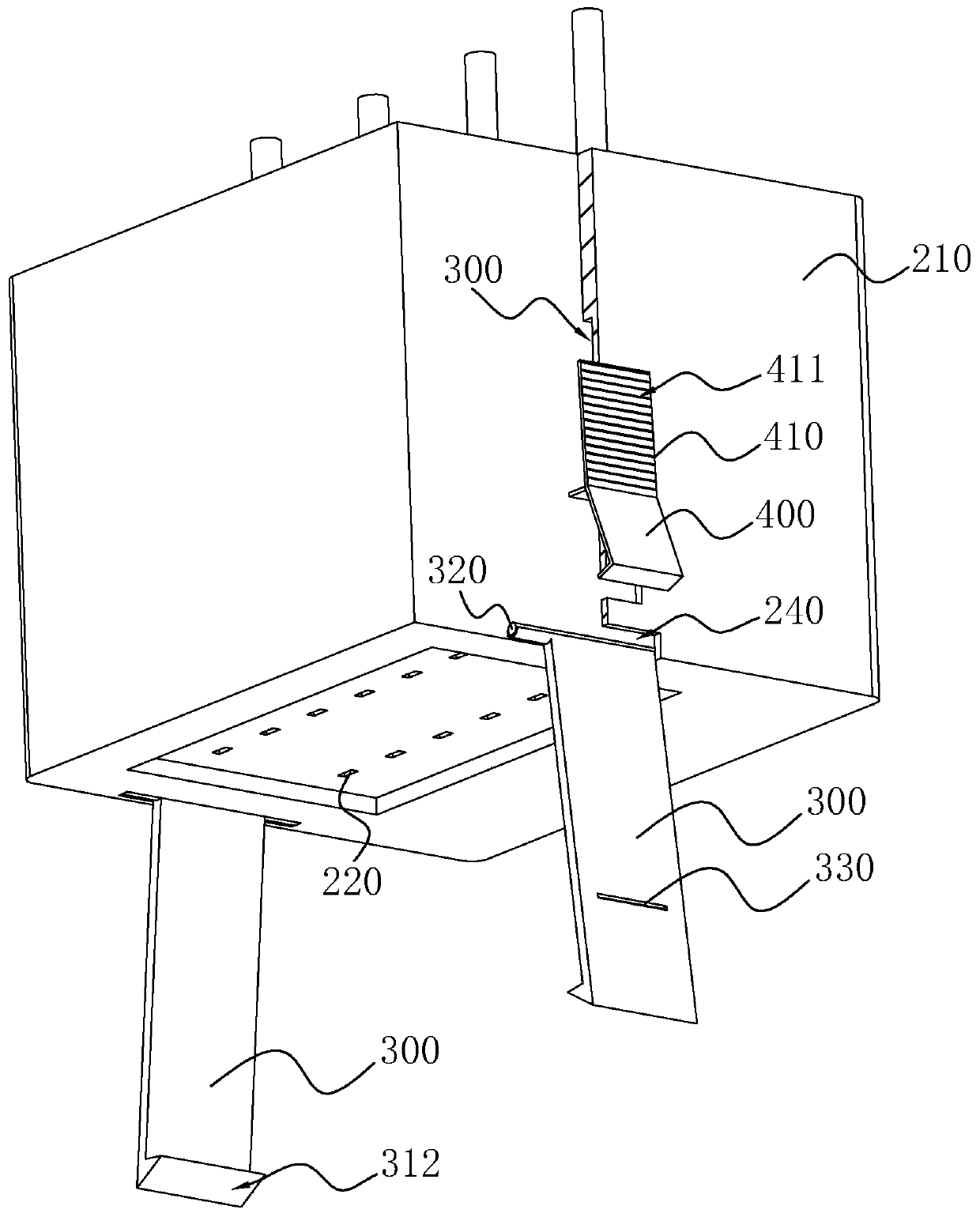

Construction method of traffic door opening in bridge road overline construction

ActiveCN111335089AHigh strengthAvoid cutsRoadwaysBridge erection/assemblyArchitectural engineeringStringer

The invention provides a construction method of a traffic door opening in bridge road overline construction, which comprises a mounting step and a dismounting step, and the mounting step comprises thefollowing steps: mounting a plurality of supporting steel pipes on two sides of a road; a loading and unloading device is arranged on the supporting steel pipe and comprises an upper support capableof moving up and down; the preset height of the upper support is adjusted, longitudinal beams are arranged on the upper support, and the longitudinal beams are arranged on the supporting steel pipes on the same side of the road; installing cross beams on the longitudinal beams, wherein the cross beams are arranged on the longitudinal beams on the two sides of the road; and a formwork is laid on the cross beam, and concrete is poured. The unloading device is arranged between the supporting steel pipe and the longitudinal beam, the upper support of the unloading device is used for supporting thelongitudinal beam when being located at a high position, and when the upper support is located at a low position, the upper support and the longitudinal beam can be quickly separated, time is saved,and efficiency is improved.

Owner:GUANGZHOU ENG CO LTD OF CHINA RAILWAY 19TH BUREAU GRP

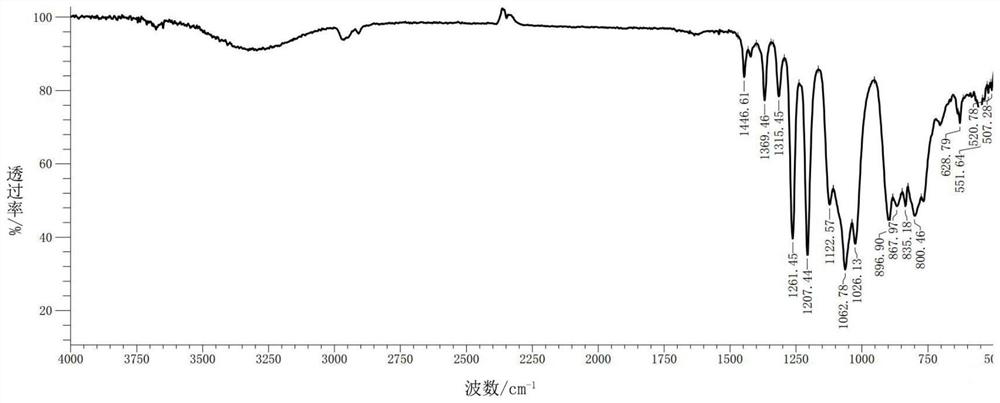

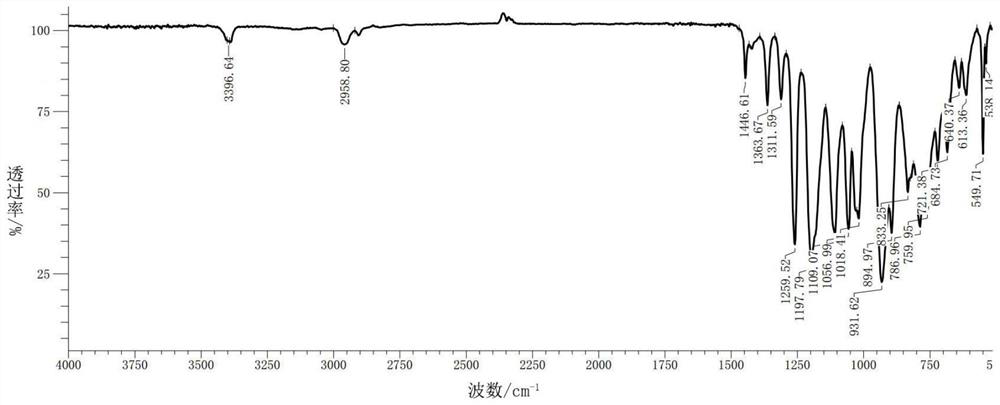

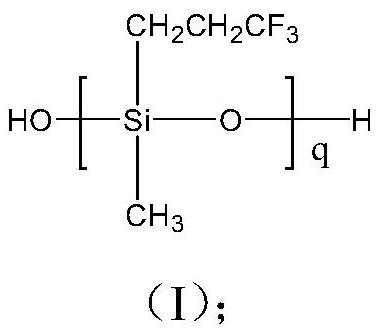

Engine oil-resistant low-pressure-change addition type liquid fluorinated silicone rubber and preparation method thereof

The invention relates to engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber and a preparation method thereof. The engine oil-resistant low-pressure-change addition type liquid fluorosilicone rubber comprises the following components in parts by weight: 100 parts of fluorosilicone base rubber; 10 to 20 parts of fumed silica; 10-20 parts of precipitated white carbon black; 1-3 parts of hydroxyl fluorosilicone oil; 2 to 5 parts of trifluoropropyl methyl cyclosilazane; 0.1 to 0.3 part of divinyl tetramethyl disilazane; 1-3 parts of distilled water; 0.1 to 0.3 part of a heat-resistant additive; 1.3 to 2.9 parts of a cross-linking agent; 0.3 to 0.6 part of a platinum catalyst; and 0.05 to 0.2 part of an inhibitor. According to the preparation method, fluorosilicone treating agents such as low-molecular-weight hydroxyl fluorosilicone oil and trifluoropropyl methyl cyclosilazane are used, the fumed silica and the precipitated silica are compounded to achieve a synergistic effect, and the specific cross-linking agent and the preparation method are matched, so that the compression set of the addition type liquid fluorosilicone rubber is greatly reduced, and the service life of the addition type liquid fluorosilicone rubber is prolonged. Even if the lubricating oil is soaked in high-temperature engine oil for a long time, the system cannot be damaged, the lower deformation rate can still be kept, and the oil pressure change resistance is very excellent.

Owner:新元化学(山东)股份有限公司 +1

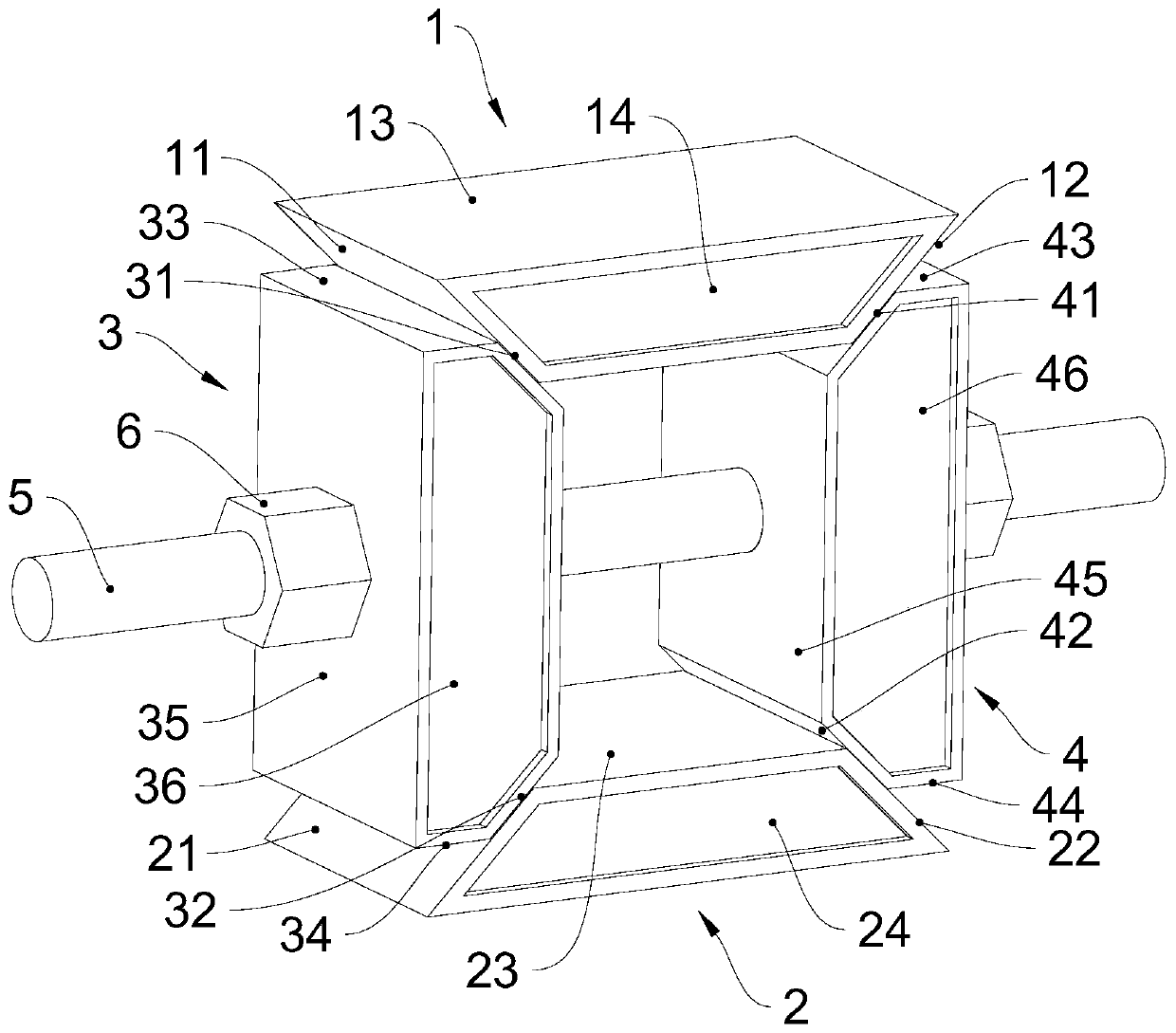

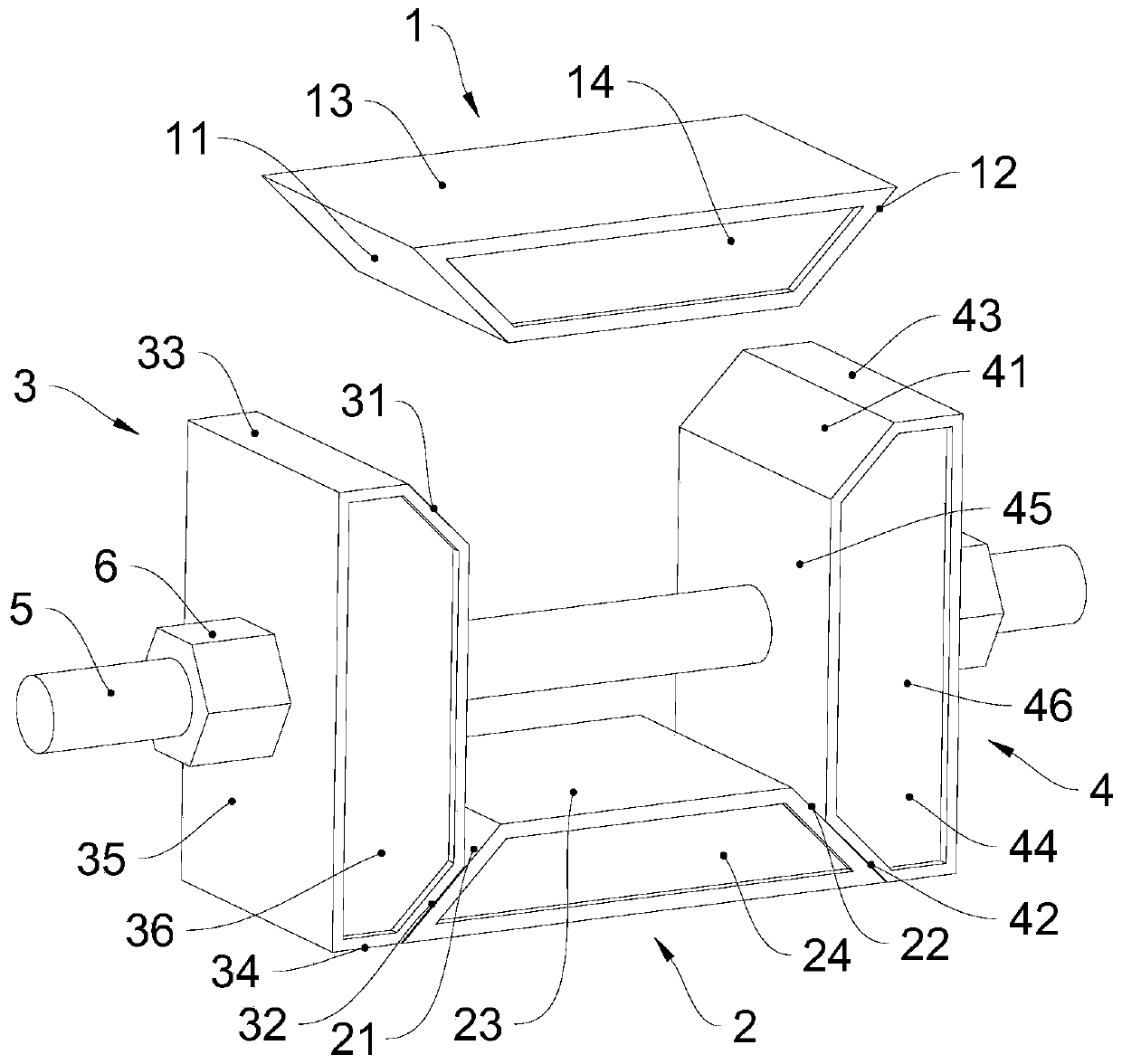

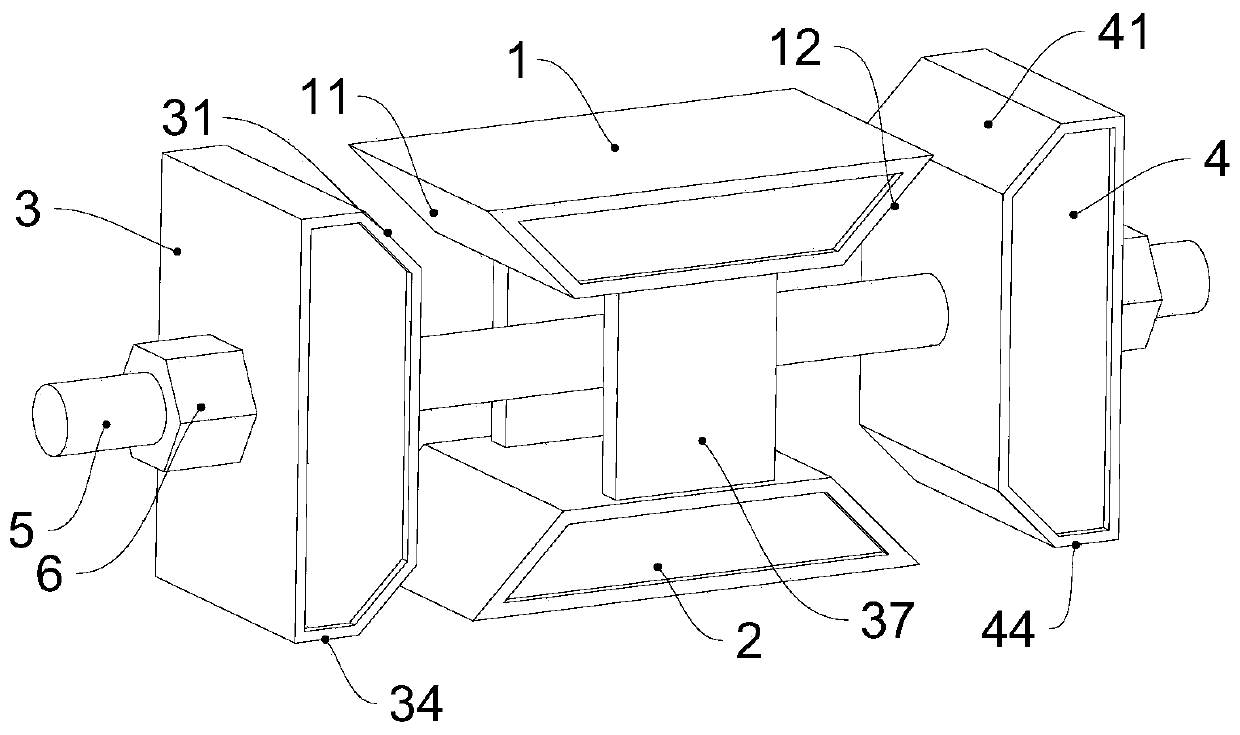

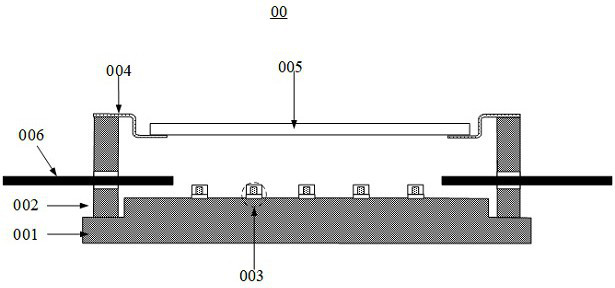

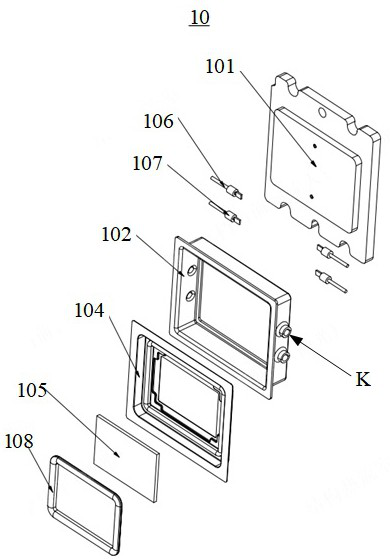

Laser

ActiveCN113451875AReduce internal stressReduce the probability of deformationSemiconductor laser arrangementsLaser arrangementsErbium lasersEngineering

The invention discloses a laser, and belongs to the technical field of photoelectricity. The laser comprises a bottom plate, a frame body, a plurality of light-emitting assemblies, a cover plate and a light-transmitting sealing layer; the frame body is arranged on the bottom plate in a surrounding mode and forms a containing space, and the light-emitting assemblies are all located in the containing space and fixed to the bottom plate; the frame body is in a thin plate shape, the upper portion of the frame body is folded outwards to form a first folded edge, and the first folded edge is fixed to the outer edge area of the cover plate; the light-transmitting sealing layer is fixed with the inner edge area of the cover plate and covers the opening of the cover plate; and the lower portion of the frame body is folded inwards or outwards to form a second folded edge, and the second folded edge is fixedly connected with the bottom plate. The assembly difficulty of the laser can be reduced, and the light emitting effect of the laser can be ensured.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

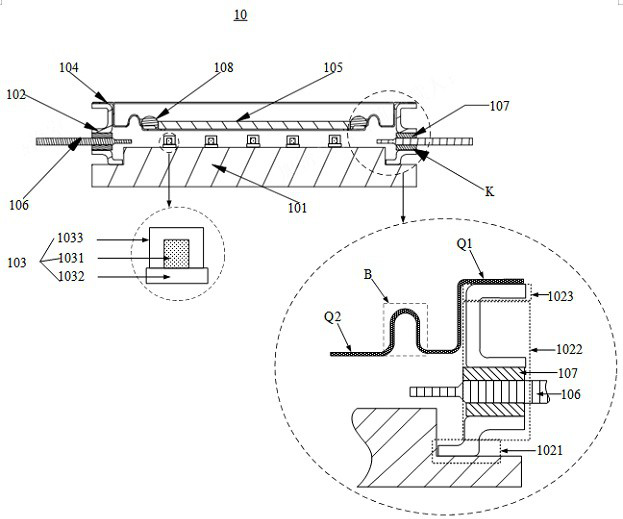

Optical fiber acoustic-optic device with high-performance stability

InactiveCN109164606ASmall coefficient of thermal expansionReduce the probability of deformationNon-linear opticsAcousto-opticsPlastic optical fiber

The invention relates to an optical device, in particular to an acoustic-optic device for the optical fiber field, belongs to the technical field of the photoelectron, and specifically relates to an optical fiber acoustic-optic device with high-performance stability. The optical fiber acoustic-optic device comprises an input optical fiber, a metal box, and an output optical fiber; the input optical fiber and the output optical fiber are connected at two ends of the metal box; a mounting plate is fixed in the metal box; an input end collimator, an acoustic-optic crystal and an output end collimator are orderly fixed on the mounting plate; the input optical fiber is connected the input end collimator, and the output end collimator is connected with the output optical fiber. By adopting the arrangement of the mounting plate, the deformation influence of the metal box can be effectively eliminated, and the problem that the performance of the optical fiber acoustic-optic device is reduced after being used for a certain time is solved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Mold guide column

InactiveCN103464623AReduce the probability of deformationExtended service lifeShaping toolsMechanical engineeringEngineering

Owner:SUZHOU YIQUN MOLD

Steering knuckle and bushing push-free process

ActiveCN111922631AReduce resistanceImprove integrityMetal working apparatusStructural engineeringMachine

The invention provides a steering knuckle and bushing push-free process. The process comprises the following steps that S1, a bushing is placed in a numerically controlled lathe, and an excircle guideangle at the bottom of the bushing is turned and formed; S2, a steering knuckle is fixed in a vertical machining center, and main pin holes of an upper lug and a lower lug of the steering knuckle arebored and formed through rough boring, chamfering and fine boring by adopting a fine machining process; S3, pretreatment before press-in is carried out, specifically, the bushing is placed in a liquid nitrogen environment to be treated for 2-3 hours; and S4, press fitting of the bushing is carried out, the bushing is pressed into the main pin holes in the two sides by adopting a press fitting machine. According to the process, the improvements in three aspects of processing technology, structure and mounting operation of the bushing and the steering knuckle are adopted, which are different from the prior art that an ironing rod needs to be used for ironing and pushing the interior of the bushing, so that the steering knuckle and bushing push-free process is realized, the bushing is smallin deformation, free of bulges, good in coaxiality and complete and attractive in inner hole surface of the bushing after pressing, and finally, the purpose of prolonging the service life of the steering knuckle, the bushing, a main pin and even the whole front axle is achieved.

Owner:HUBEI TRI RING FORGING

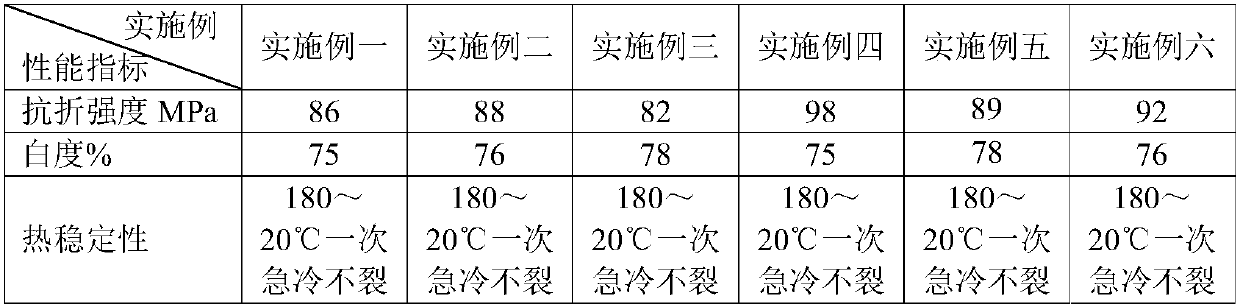

High-feldspathic ceramic green body material and preparation method thereof and method for preparing ceramic products by high-feldspathic ceramic green body material

InactiveCN107805047AImprove deformation resistanceHigh strengthClaywaresThermal stabilityUltimate tensile strength

The invention discloses a high-feldspar ceramic blank material, a preparation method thereof, and a method for preparing ceramic products by using the same, belonging to the technical field of ceramics. The high-feldspar ceramic body material includes a base material and additives, and the preparation method of the high-feldspar ceramic body material includes the following steps: material preparation, ball milling, dehydration, vacuum mud refining and aging, and the high-feldspar ceramic body material is used. The method for preparing a ceramic product from a green body material includes the following steps: forming, glazing and firing. The raw materials of the invention are easy to obtain, moderate in price, high in product strength, strong in anti-deformation performance, and strong in thermal stability. sustainable development.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

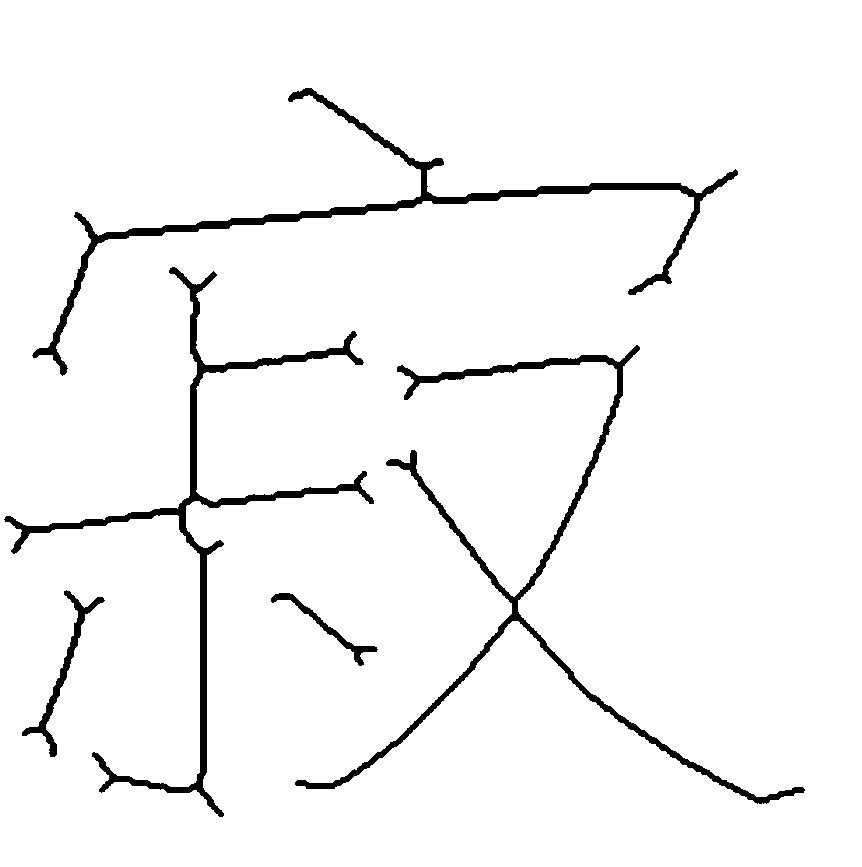

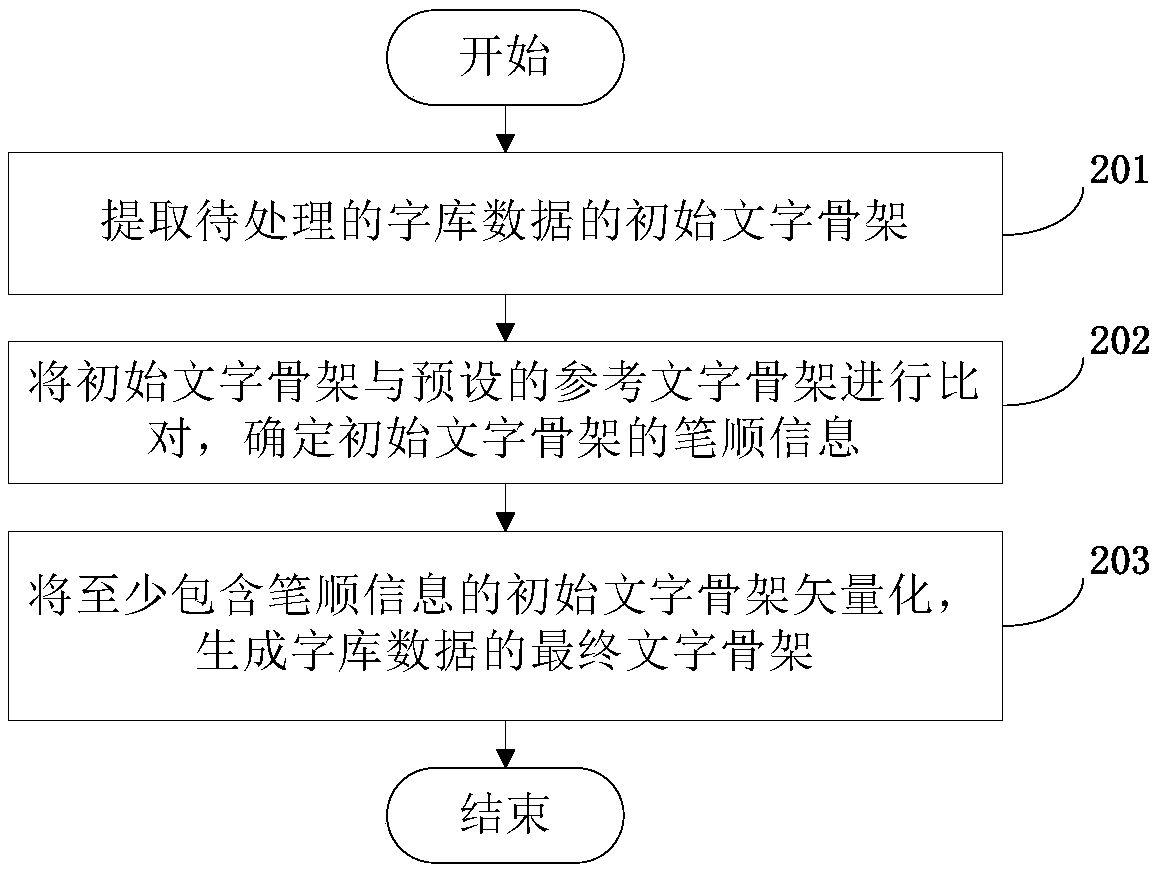

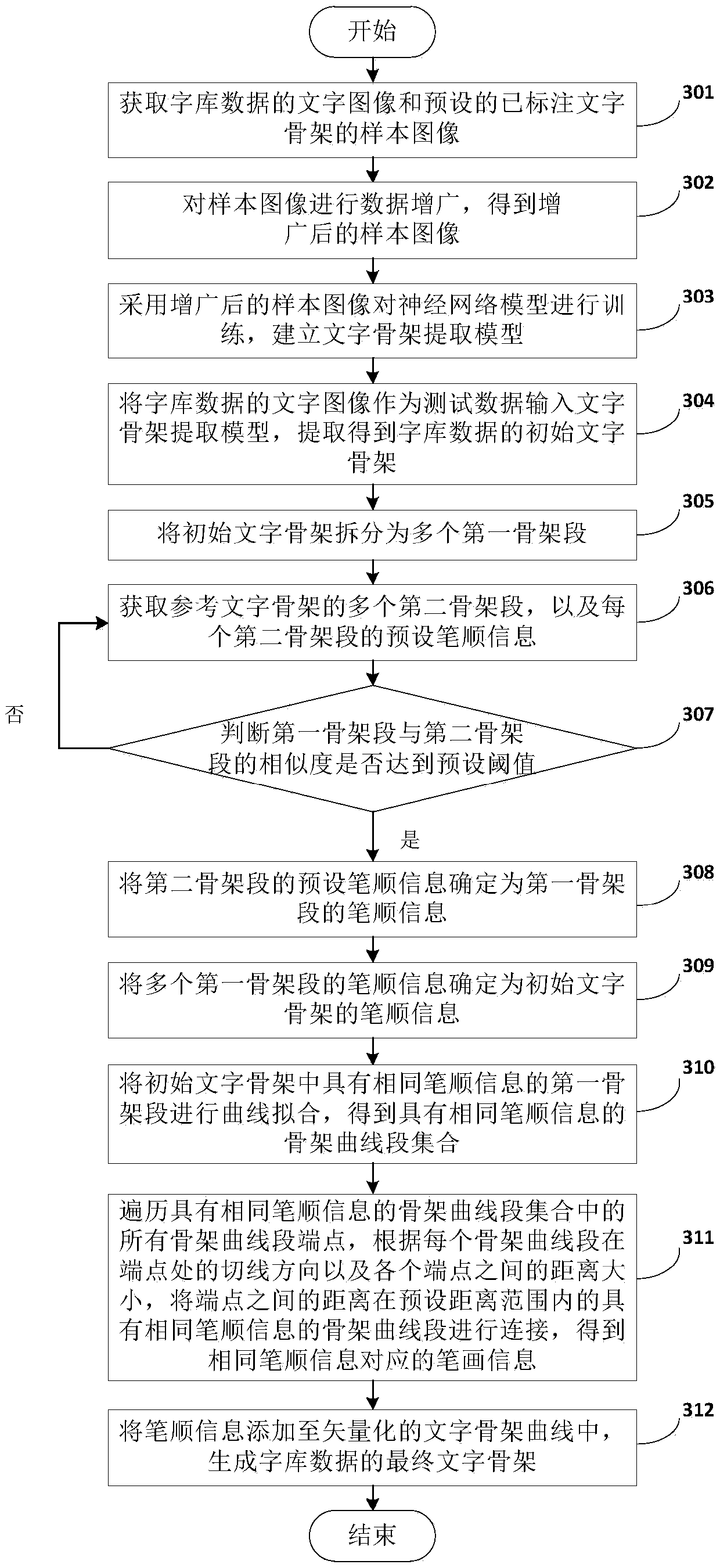

Character skeleton extraction method and device, equipment and computer readable storage medium

ActiveCN110909563AImprove extraction efficiencyReduce the probability of deformationCharacter and pattern recognitionEnergy efficient computingAlgorithmEngineering

The invention provides a character skeleton extraction method and device, equipment and a computer readable storage medium. The method comprises the following steps: extracting an initial character skeleton of to-be-processed character library data; comparing the initial character skeleton with a preset reference character skeleton, and determining stroke order information of the initial characterskeleton; vectorizing the initial character skeleton at least containing the stroke order information to generate a final character skeleton of the font library data. The scheme solves the problems in the prior art that the skeleton of the stroke cross position cannot be ensured to follow the character writing rule due to the fact that the font library data does not have stroke cross informationis solved, and the bifurcation in the character skeleton can be basically eliminated, so that the stroke cross position deformation rate is reduced, the stroke order information of the character skeleton is recovered, and the character skeleton extraction efficiency is improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

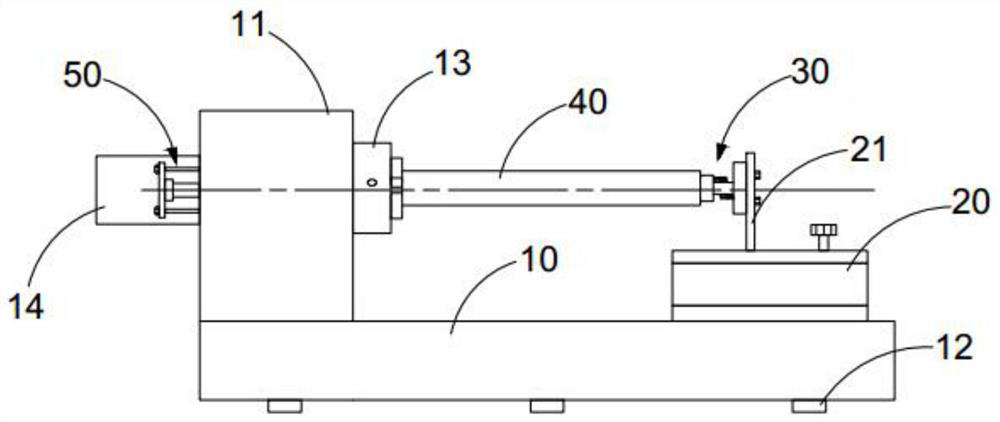

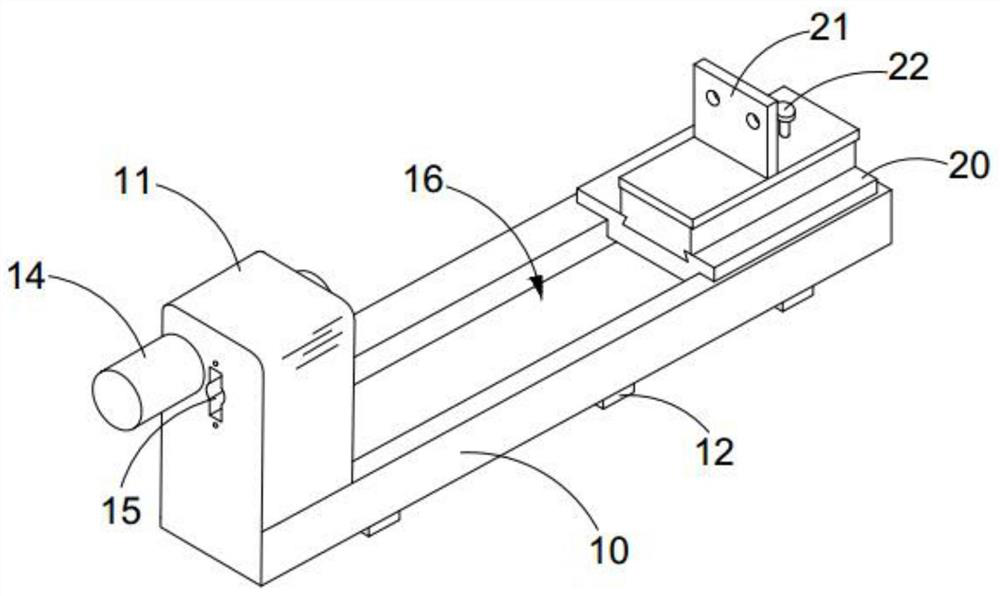

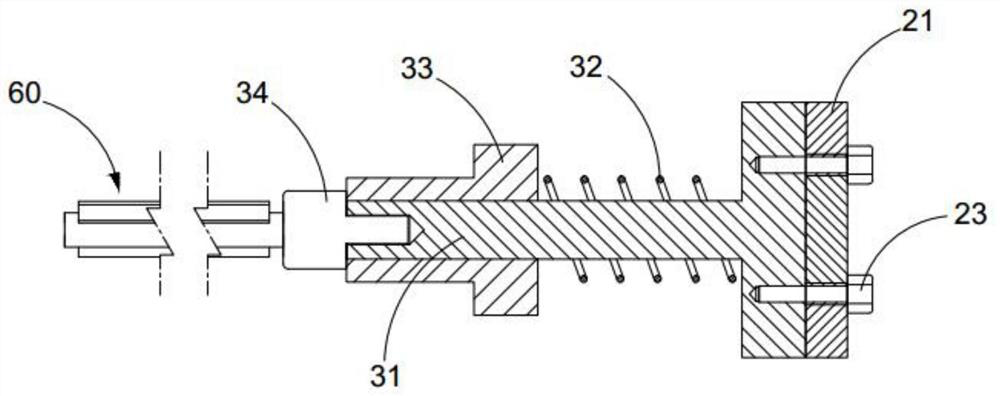

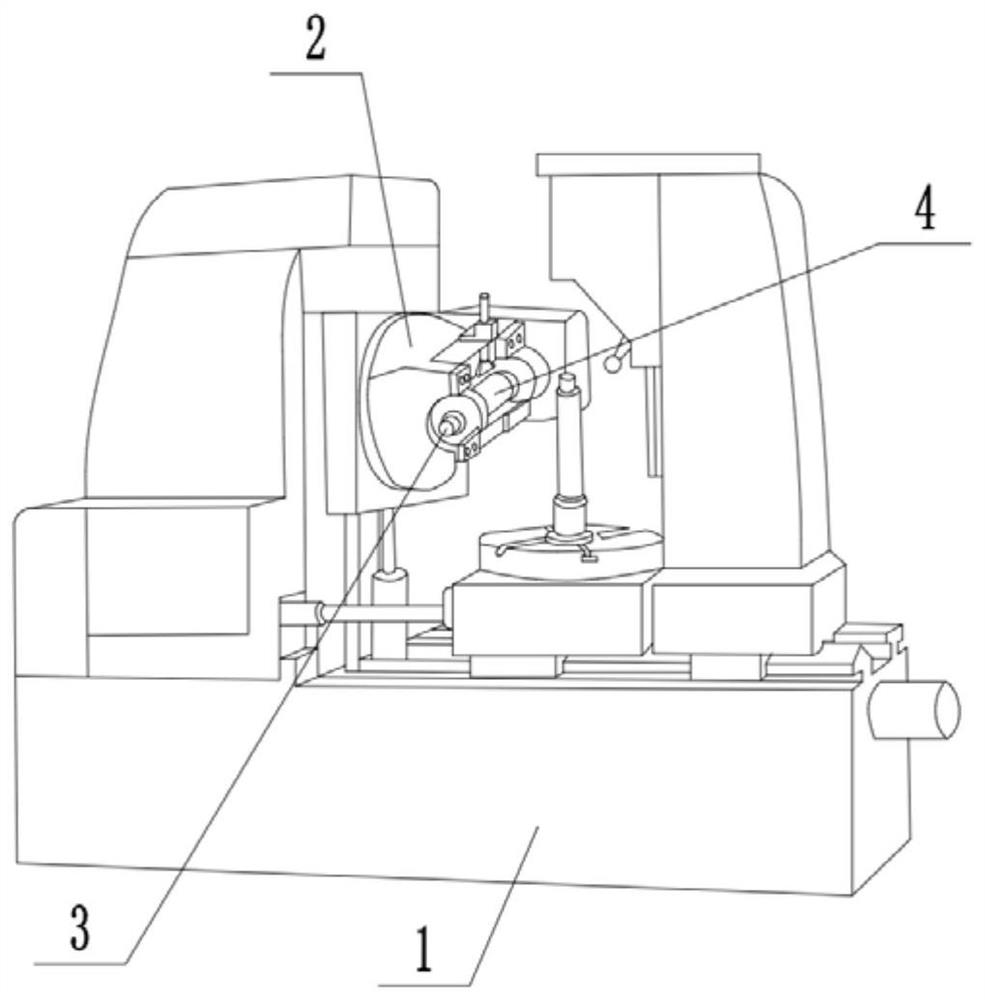

A rubber parts manufacturing automatic processing fixture

ActiveCN111390665BMeet manufacturing requirementsAvoid bending deformationEdge grinding machinesRevolution surface grinding machinesPipe fittingTailstock

The invention discloses a jig for automatic processing of rubber parts, which belongs to the technical field of jigs and jigs. The jig of the invention includes a bed. Frame, the first limit component, installed on the tailstock, the upper part of the tailstock is provided with a support connecting plate perpendicular to the horizontal plane, the support connecting plate is assembled with the first limit component on the opposite surface of the three-jaw chuck, the first limit component It includes the limit main part with a cylindrical structure, and the bottom of the cylindrical structure is provided with an assembly base plate that is connected with the support connecting plate; the limit component is sleeved with a limit accessory, and the limit accessory is a cylindrical sleeve structure. A limiting ring is arranged on the outer surface, a first spring is arranged between the limiting auxiliary part and the limiting main part, and the cylinder end of the limiting main part is connected with a grinding assembly through the connecting base. The fixture of the present invention is used to process the hole wall of the rubber part of the pipe fittings to obtain better surface roughness, the deformation rate of the rubber part during the processing is low, and the yield of the finished product is high.

Owner:HUANGSHAN SHANGYI RUBBER & PLASTIC PRODS

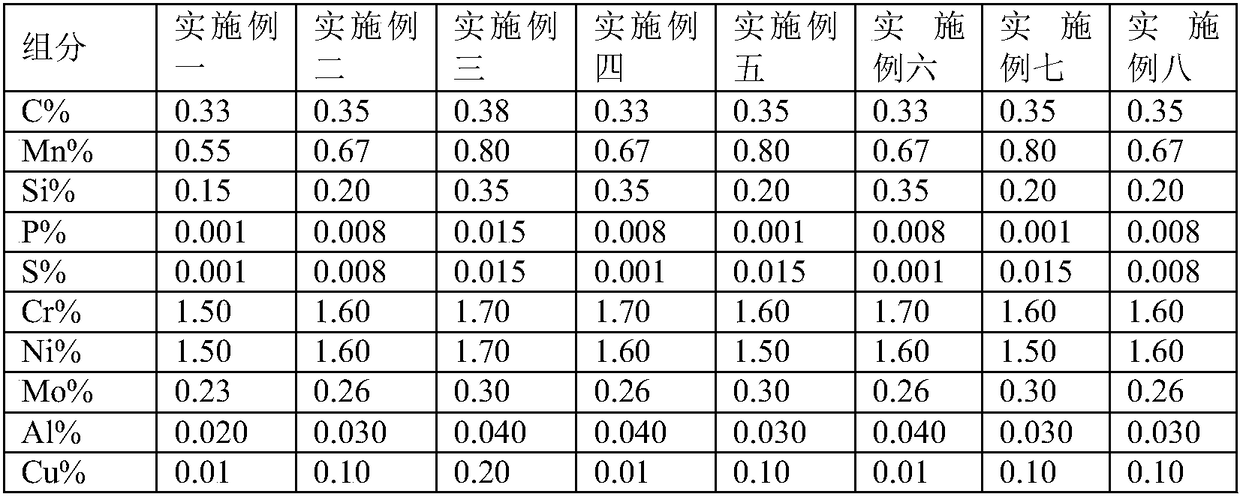

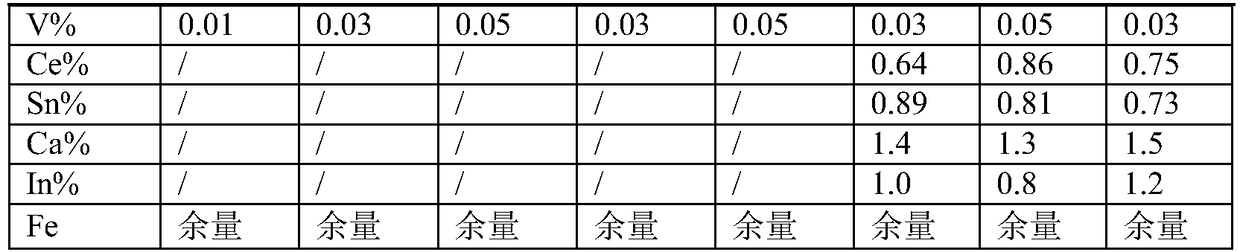

Alloy steel forged steel round bar for heavy-duty gear and preparation method thereof

The invention discloses an alloy steel forged steel round bar for a heavy-duty gear, solves the problems of a large deformation rate and poor mechanical property of carburizing and quenching and relates to the field of alloy. The alloy steel forged steel round bar is prepared from the ingredients in mass percent: 0.33 to 0.38% of C, 0.55 to 0.80% of Mn, 0.15 to 0.35% of Si, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, 1.50 to 1.70% of Cr, 1.50 to 1.70% of Ni, 0.23 to 0.30% of Mo, 0.020 to 0.040% of Al, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.05% of V and the balance of Fe and unavoidable impurities. The alloy steel forged steel round bar has a small deformation rate in carbonizing and quenching, the mechanical property is stronger, and the alloy steel forged steel round bar is suitable for producing gears; furthermore, the preparation method of the alloy steel forged steel round bar is more convenient and more suitable for scale production.

Owner:JIANGSU ZHUHONG FORGING

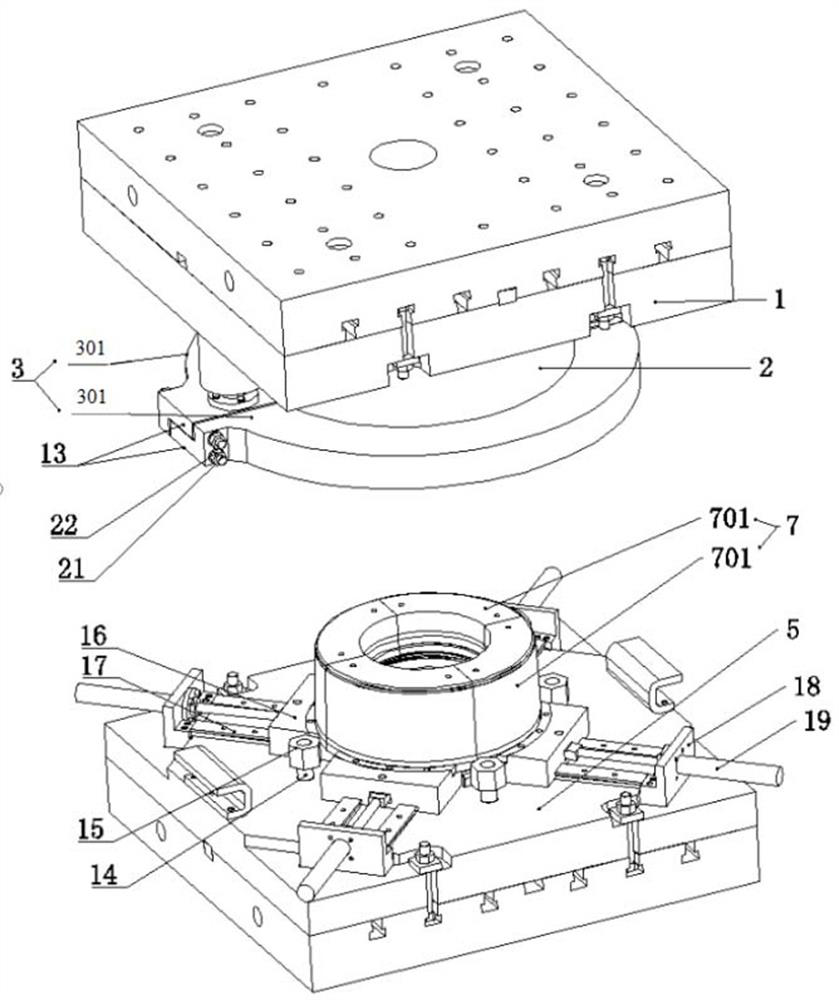

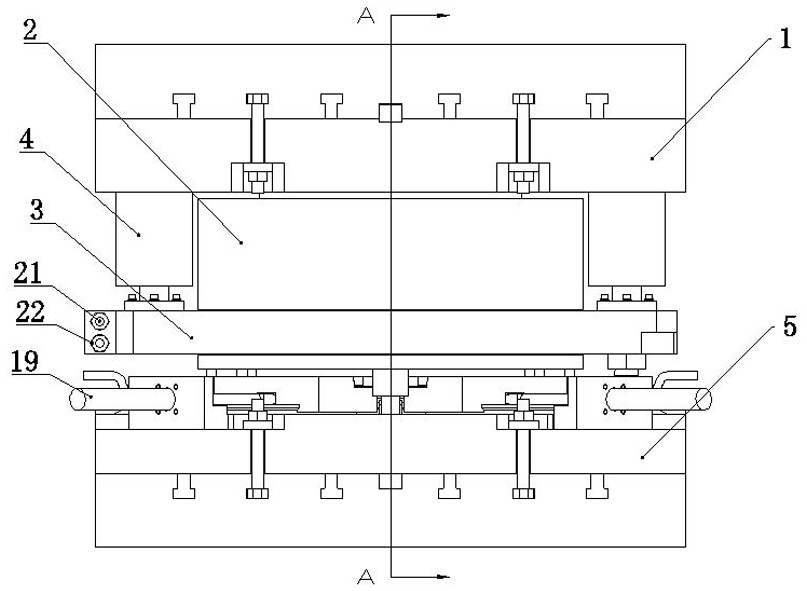

Outer guide post component for mold

InactiveCN107962808AReduce the probability of deformationExtended service lifePressesReciprocating motionEngineering

The invention discloses an outer guide post component for a mold. The outer guide post component comprises a body component and an auxiliary component; the body component comprises a lower die, a pedestal, a guide post, an end plate, a guide sleeve, an upper base and an upper die; the pedestal is detachably connected to the lower die and is positioned at the upper surface of the lower die; a steelball sleeve rolls in a steel ball groove formed in the outer sidewall of the guide post so that the friction force between the guide post and the inner surface of the guide sleeve is remarkably reduced, and thus the abrasion of the guide post and the guide sleeve is reduced; lubricating oil can flow into the steel ball sleeve by virtue of communication of an oil tank and the steel ball groove soas to maintain a steel inside the steel ball sleeve; the service life of the steel ball is prolonged; the problems that when the mold is assembled, the guide post does a reciprocating motion inside the guide sleeve to generate friction which results in reduction of the guidance precision of the guide post and the guide post loses a guidance function are solved; the guide post needs not to be replaced; and the production cost is lowered.

Owner:苏州圣亚精密机械有限公司

Manufacturing method of instrument warm box

Disclosed is a manufacturing method of an instrument warm box. Hot press molding is carried out on a sheet, and a main body of a box body and a main body of a box door are manufactured; the main body of the box body and the main body of the box door are put into corresponding foamed moulds respectively, and aluminum foil film layers are attached to the outer surfaces of core moulds of the foamed moulds; a foaming machine is used for manufacturing the box body with a warm layer and the box door with a warm layer through a polyurethane foaming technology, and then, the box body and the box door are assembled into a finished product; and the sheet is formed by sequentially arranging a C layer, a D layer and a C layer, wherein the C layers are short glass fiber reinforced unsaturated polyester resin composite material layers, and the D layer is a copper wire mesh layer with the wire diameter ranging from 0.3mm to 0.7mm.

Owner:吉林市吉化北方华丰仪表有限公司

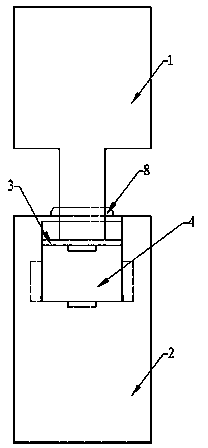

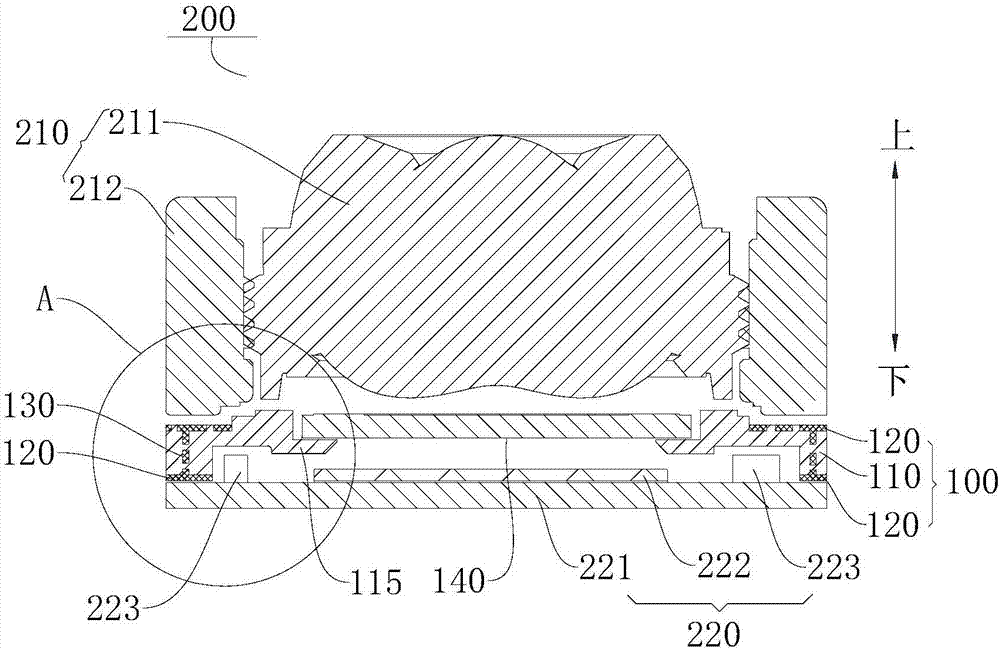

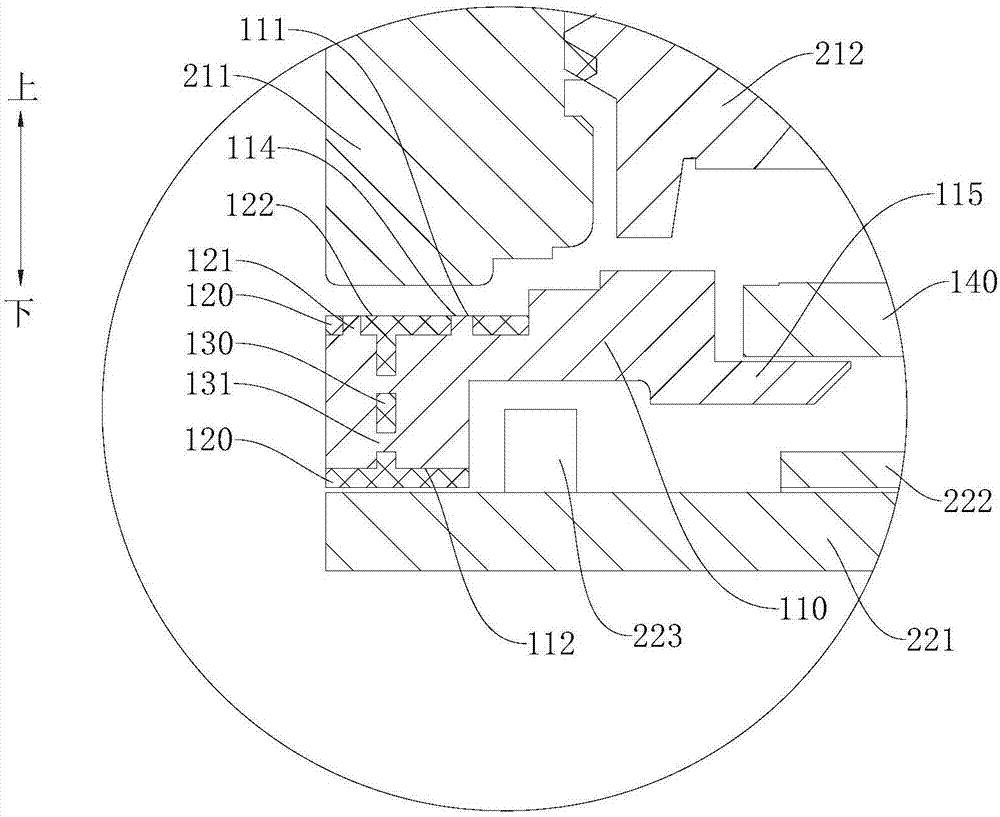

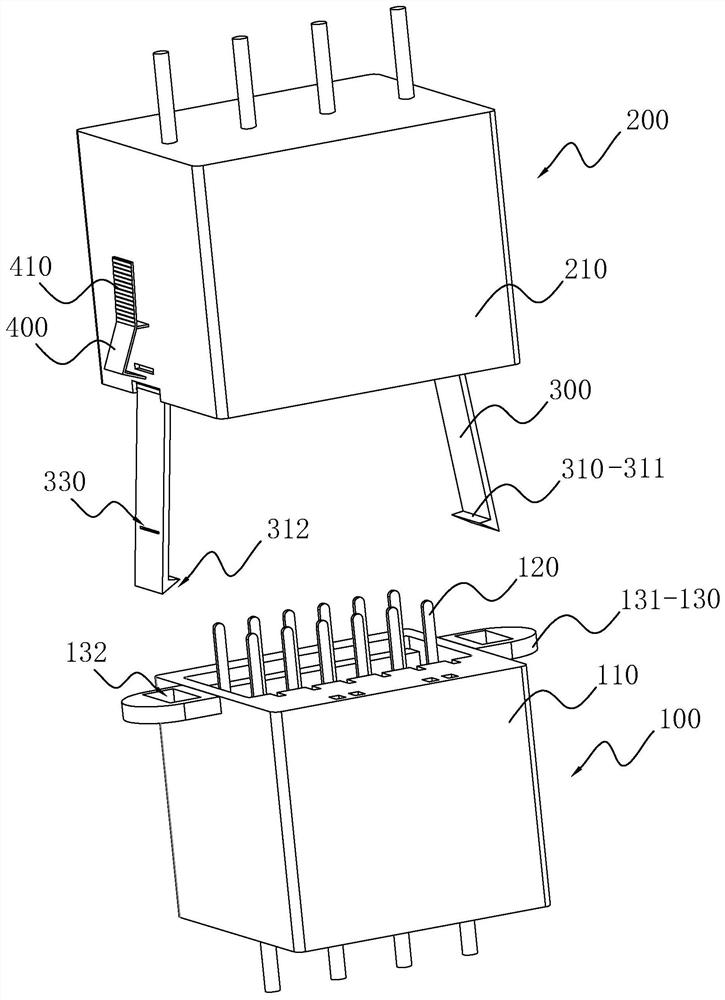

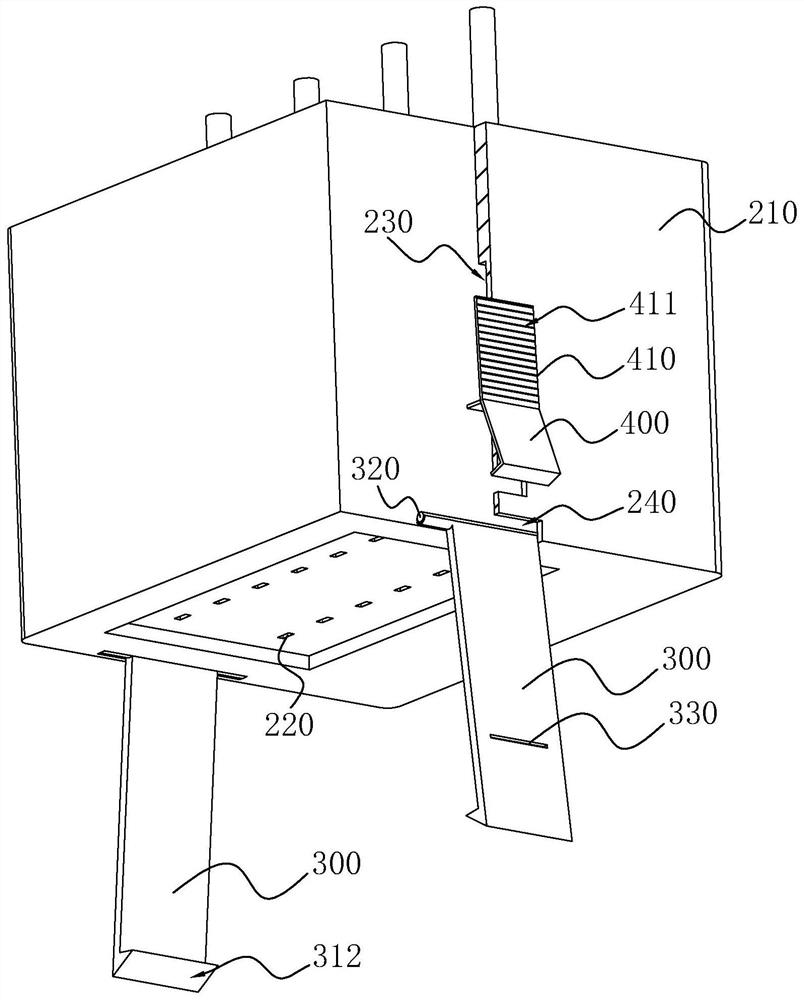

Support component, camera and electronic equipment

PendingCN107888729AImprove assembly stabilityGood assembly reliabilityTelevision system detailsColor television detailsComputer hardwareFatigue damage

The invention discloses a support component, a camera and electronic equipment. The support component is used for supporting a light passing structure of the camera, and comprises a support body and areinforcer, wherein the support body is connected with the light passing structure, and the reinforcer is embedded into the support body. According to the support component of the camera provided bythe invention, the reinforcer is arranged on the support body, the structure of the support body can be enhanced, so that assembly stability of the support body can be enhanced, the deformation probability of the support body when in use and dropping can be reduced, and the service life of the support body can also be effectively prolonged, the possibility that a fatigue damage occurs in the support body during a use process can be reduced, and thus the assembly stability and reliability of the camera can be improved, and the practicability and imaging effect of the camera can be enhanced.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

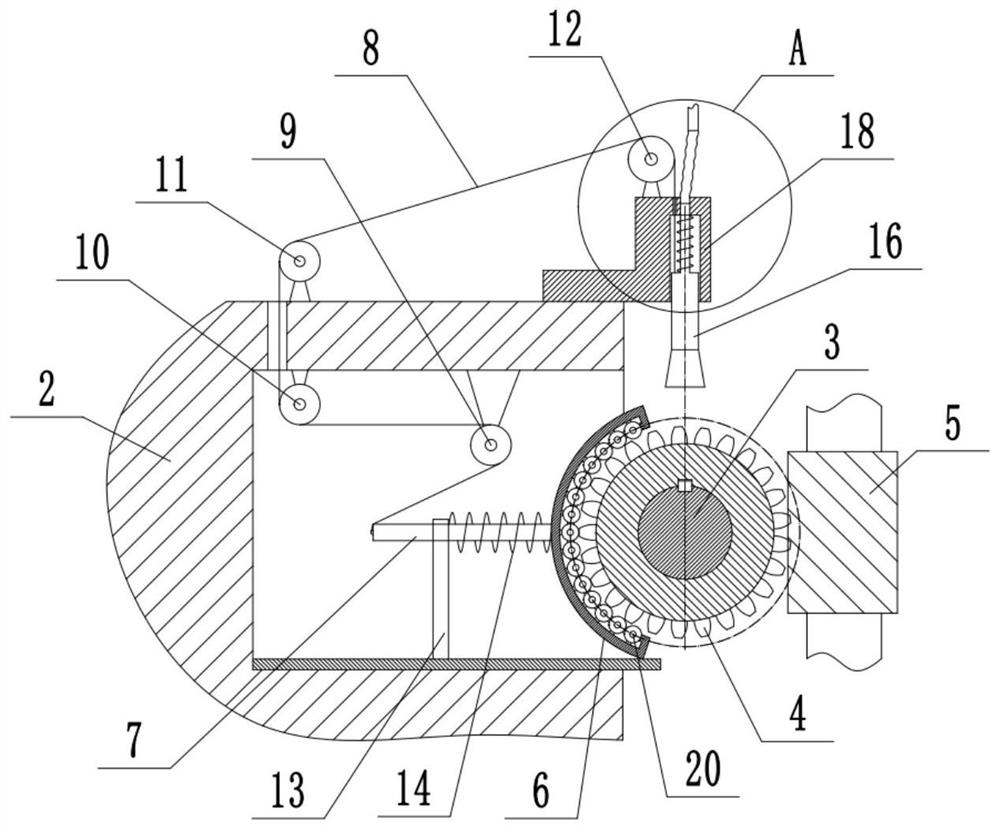

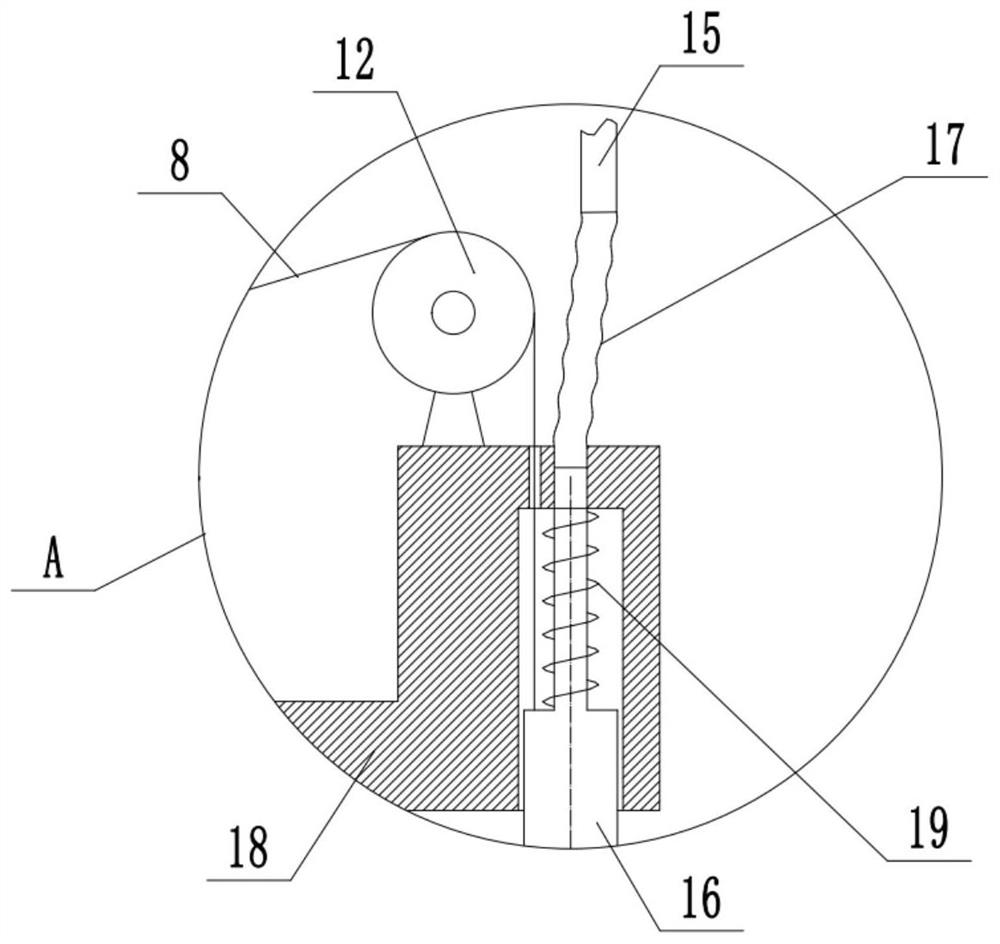

Gear forming device

PendingCN112191950AGood cooling effectGood lubrication and coolingGear-cutting machinesMaintainance and safety accessoriesMoulding deviceRadial motion

The invention relates to the technical field of gear machining equipment, and discloses a gear forming device. The gear forming device comprises a cutter fixing seat and a hob shaft rotationally connected to the cutter fixing seat, wherein a hob is detachably connected to the hob shaft, an arc-shaped plate is slidably connected to the cutter fixing seat in the radial direction of the hob shaft, the arc-shaped plate and the hob shaft are coaxially arranged, and a first elastic piece is arranged between the arc-shaped plate and the cutter fixing seat; and a cooling assembly facing the hob shaftis slidably connected to the cutter fixing seat, a connecting mechanism used for driving the cooling assembly to move along with the arc-shaped plate is connected between the cooling assembly and thearc-shaped plate, and under the transmission action of the connecting mechanism, the cooling assembly and the arc-shaped plate are the same in the radial movement trend relative to the hob shaft. According to the gear forming device, the connecting mechanism is arranged so that the distance between the cooling assembly and the hob shaft can be changed along with the change of the size of the replaced hob, and the problem that in the prior art, a cooling pipe cannot provide stable cooling for hobs with different sizes after the hob is replaced is solved.

Owner:CHONGQING RUNYUE MACHINERY CO LTD

Lithium ion battery pack convergence board

InactiveCN107171149ALow resistivityReduce the probability of deformationCoupling device connectionsVehicle connectorsEngineeringLithium ion battery pack

The invention belongs to the technical field of an electric automobile lithium ion battery pack and specifically relates to a lithium ion battery pack convergence board. The lithium ion battery pack convergence board comprises a convergence board body, a plurality of welding through holes arranged on the convergence board body, and a plurality of convergence sheets. The convergence sheets and the welding through holes are not located on the same plane. The convergence sheets and the welding through holes are same in number, shape and axle center. A plurality of connecting parts are arranged at peripheries of the convergence sheets equidistantly. The connecting parts and the welding through holes are connected. The lithium ion battery pack convergence board provided by the invention is low in cost, low in density, low in cost and firm in welding, has suitable resistivity and is easy to process.

Owner:江苏艾鑫科能源科技有限公司

Preparation method of SU8 mold

InactiveCN106066582AReduce deformationReduce rateSemiconductor/solid-state device manufacturingPhotosensitive material processingFiberLaboratory oven

Owner:BEIJING ZHONGKEZIXIN TECH

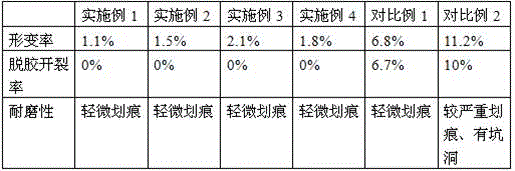

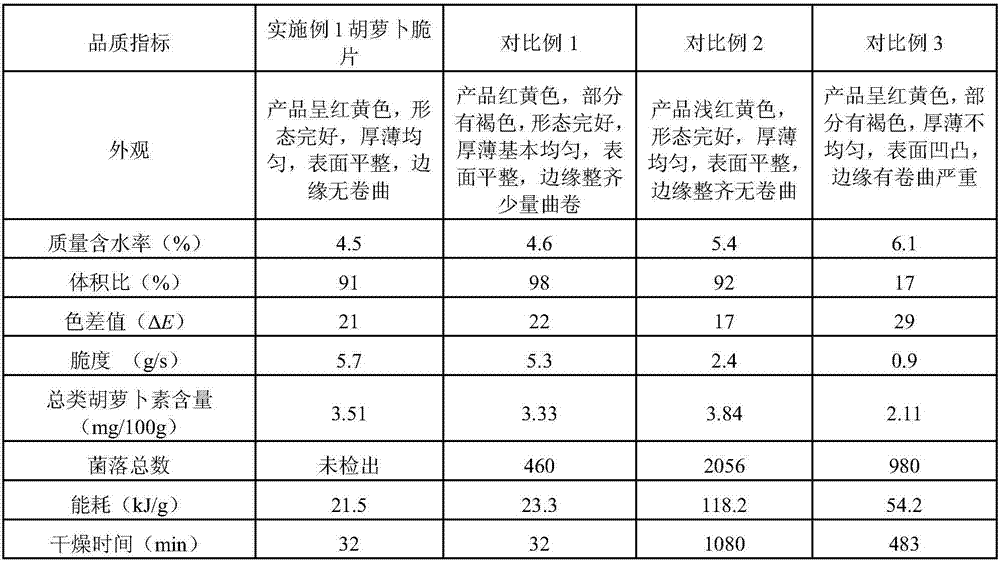

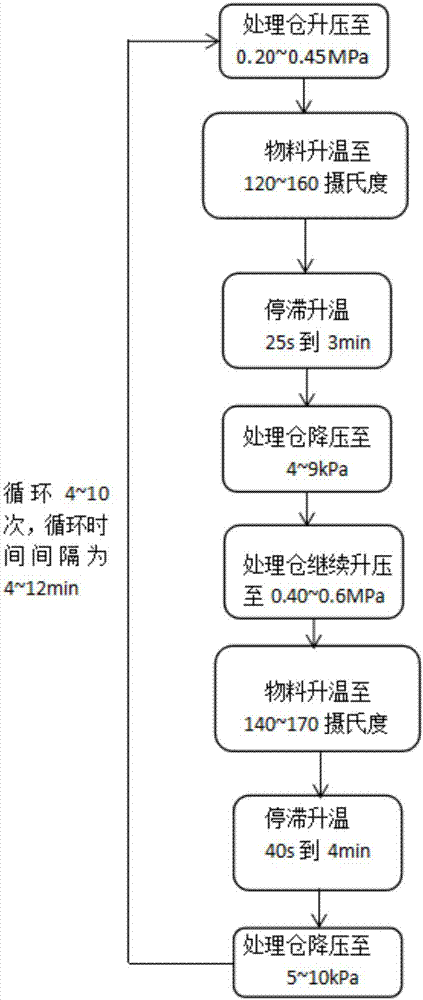

Method for preparing crisp carrot slices, the crisp carrot slices and full nutrition carrot powder

InactiveCN107279832AReduce operating energy consumptionReduce energy consumptionClimate change adaptationFood dryingFreeze-dryingDifferential pressure

The present invention discloses a method for preparing crisp carrot slices. The method comprises the following steps: carrot slices are subjected to an solar energy combined vacuum heat pump drying treatment, at the same time an instantaneous pulse strong magnetic field coordinated with pulsation controllable instantaneous differential pressure treatment is used, a cycle treatment is conducted, in each of a cycle, a pressure in a treatment chamber rises firstly, a temperature of materials rises instantly to be 110 DEG C-150 DEG C, the pressure in the treatment chamber then drops instantaneously, besides, in each of the cycle, when a pressure relief of the treatment chamber begins, the instantaneous pulse strong magnetic field is loaded at the same time at an intensity of 60-80 T, and then when the pressure relief of the treatment chamber is ended, the loading stops. The present invention discloses the crisp carrot slices and full nutrition carrot powder. The preparation method solves problems that oil bathed carrot products are high in an oil content, quality of the products dried by traditional hot air drying is low, a vacuum freeze-drying is high in energy consumption, a dehydration efficiency is low, etc. The prepared products are obviously improved in a preservation rate of carrot carotenoids.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

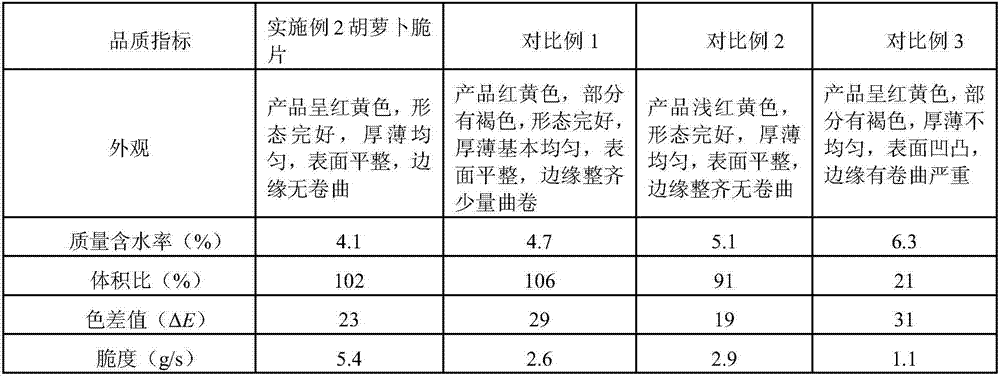

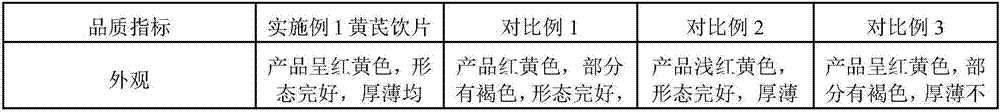

Method for drying astragalus mongholicus medicinal slices through vacuum heat pump

InactiveCN107957165AReduce operating energy consumptionReduce energy consumptionDrying solid materials without heatLavatory sanitoryEngineeringPressure difference

The invention discloses a method for drying astragalus mongholicus medicinal slices through a vacuum heat pump. The method comprises the steps that the astragalus mongholicus medicinal slices are subjected to vacuum heat pump drying treatment and pulse instantaneous pressure-difference cycle treatment, in each cycle, the pressure of a treatment bin is increased firstly, the temperature of a material is instantaneously increased to be 110-150 DEG C, the temperature increasing time is stagnated for 25 s-3 min, the pressure of the treatment bin is instantaneously decreased to be 4-9 kPa, the number of the cycle times is 3-9, the time interval between every two adjacent cycles is 2-8 min, and finally, the astragalus mongholicus medicinal slices are treated till the water content is smaller than or equal to 8%. According to the method for drying the astragalus mongholicus medicinal slices through the vacuum heat pump, the problems that the water content of raw astragalus mongholicus is high, the quality of products dried by traditional hot air is low, and vacuum freezing drying is high in energy consumption and low in dehydration efficiency are solved.

Owner:张善辉

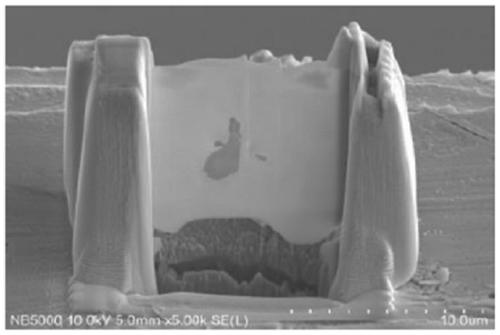

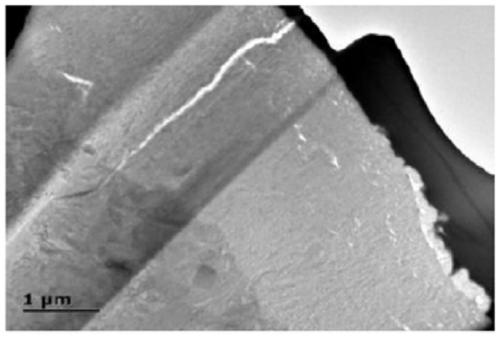

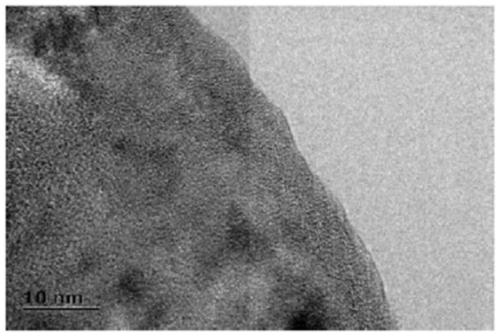

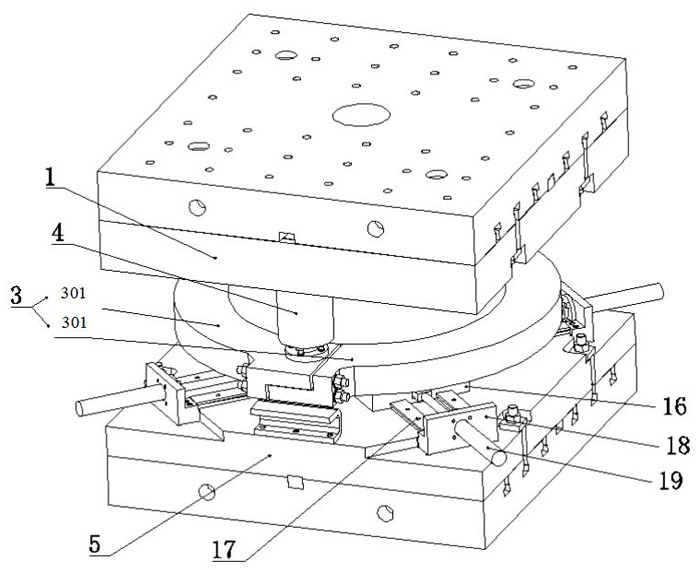

Method for controlling deformation generated in transmission electron microscope sample preparation

PendingCN111474196AReduce the probability of deformationImprove sample preparation efficiencyMaterial analysis by transmitting radiationMaterial analysis using radiation diffractionPhysicsTransmission electron microscopy

The invention relates to preparation of an electron microscope sample, and provides a method for controlling deformation generated in transmission electron microscope sample preparation. The method comprises the following steps of providing an electronic component sample placed on a substrate based on a focused ion beam system, performing pre-thinning treatment, thinning the electronic component sample to a first thickness of 1.3-1.7 microns, conducting first thinning treatment, thinning the electronic component sample to a second thickness at a tilt angle of + / -(0.5 degrees to 1.5 degrees) and a first diaphragm hole, the second thickness being 700 nanometers to 900 nanometers, conducting second thinning treatment, thinning the electronic component sample to a third thickness of 250-350 nanometers according to the tilt angle and a second diaphragm hole, and conducting a third thinning process of thinning the electronic component sample to a fourth thickness of less than or equal to 100nanometers according to the tilt angle and a third diaphragm hole, the first diaphragm hole being larger than the second diaphragm hole, and the second diaphragm hole being larger than the third diaphragm hole.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Forging die for formed hub

PendingCN114012017AAvoid squeezing gapsReduce wasteUpsetting pressesSwagging pressesStructural engineeringMechanical engineering

The invention relates to the technical field of dies, and discloses a forging die for a formed hub. The forging die comprises an upper die and a lower die, the lower die comprises a lower die plate, a lower die core installed on the lower die plate and a lower die body fixedly connected to the lower die core in a sleeving mode, the upper die comprises an upper die plate and an upper die core located over the lower die core, a forging cavity is formed among the upper die core, the lower die core and the lower die body during die assembly, the lower die body comprises at least two die body assemblies which can be far away from the lower die core or form a circular closed ring to be attached to the outside of the lower die core after being attached to each other, the die body assemblies get close to each other or get away from each other under the control of a first driving mechanism, a tightening ferrule clamped outside the attached die body assembly during die closing is vertically arranged on the upper die plate in a lifting mode, and lifting of the tightening ferrule is controlled by a second driving mechanism fixed to the upper die plate. The die remarkably improves demolding convenience after hub forging, raw material waste caused in the forging stage is remarkably reduced, and subsequent blank spinning procedures are reduced, so that the production cost of the hub is remarkably reduced.

Owner:宁波润程智能科技有限公司

A connector for automotive data transmission

ActiveCN111244690BReduce the probability of deformationEasy to plug inVehicle connectorsCoupling device detailsData transmissionMechanical engineering

The invention relates to the technical field of data transmission parts, and discloses a connector for automotive data transmission, including a male head and a female head, the male head includes a male shell and a PIN terminal arranged inside the male shell, and the female head includes a female shell and a female head The port that is set inside the female housing and mated with the PIN terminal, the opposite sides of the female housing are symmetrically provided with guide pieces, and the guide pieces are slidingly connected with the female housing along the plugging and pulling direction of the female housing; the guide piece faces one end of the male housing A connecting part is provided, and the male housing is provided with a mounting part connected with the connecting part toward the side of the female housing; the female housing is also provided with an unlocking structure for unlocking the connecting part and the mounting part. Through the setting of the guide piece, the male connector and the female connector can move along the direction of the guide piece when plugging and unplugging, which reduces the probability of deformation of the PIN terminal under the action of external force and facilitates the insertion of the two.

Owner:LAUNCH DESIGN INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com