Forging die for formed hub

A wheel hub forging mold and mold body technology, which is applied in the direction of manufacturing tools, swaging presses, wheels, etc., can solve the problems of reducing the forging thickness of the spokes, easy demoulding, and increasing the thickness of the hub, so as to reduce waste, reduce production costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

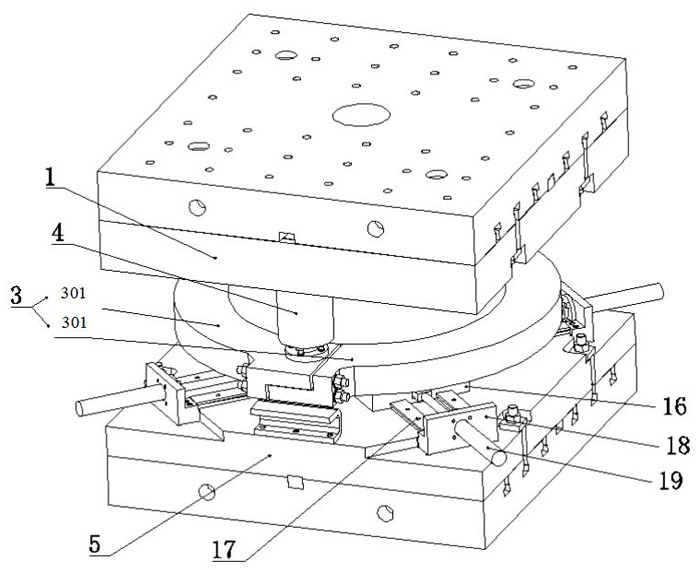

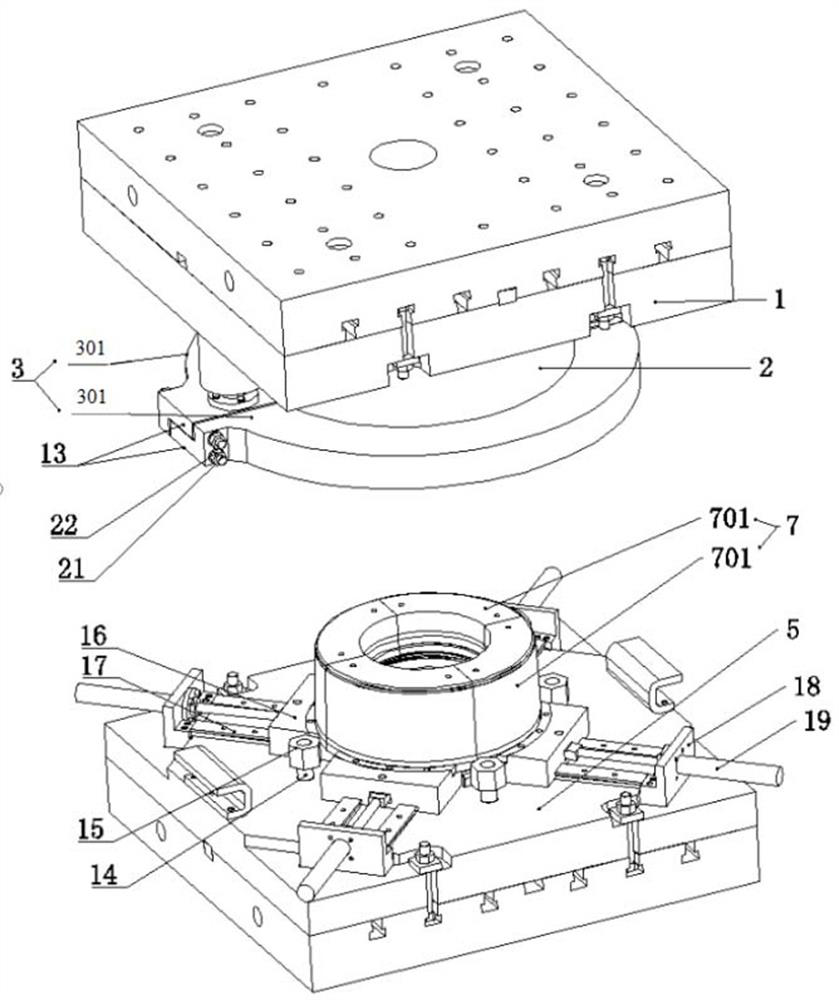

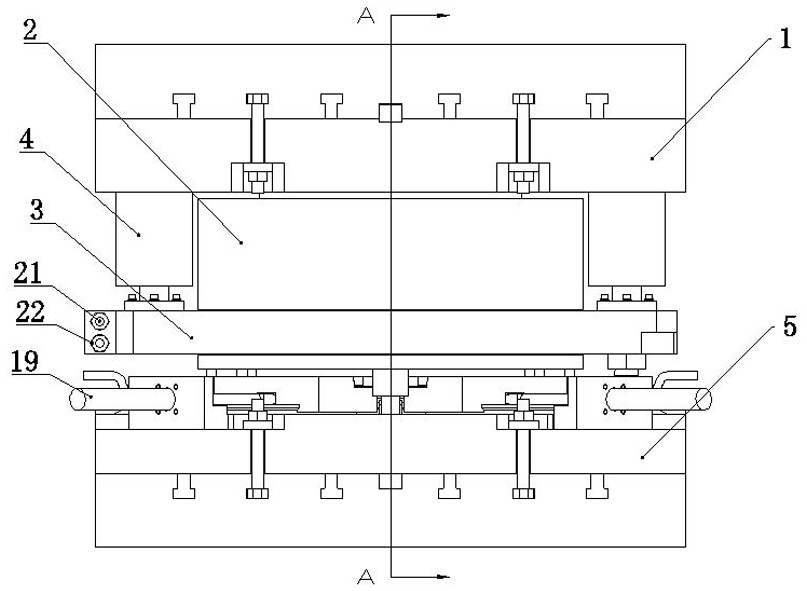

[0044] A kind of forming wheel hub forging mold, refer to Figure 1-Figure 6 Shown, comprise upper mold and lower mold, upper mold comprises upper formwork 1, upper mold core 9 that is fixed on upper formwork 1 and upper mold body 8 that is fixed on upper formwork 1 and wraps outside upper mold core 9, lower The mold includes a lower template 5, a lower mold core 6 installed on the lower template 5 and directly below the upper mold core 9, and a lower mold body 7 fixedly sleeved on the lower mold core 6, the upper mold core 9, the lower mold core 6 A forging cavity 20 is formed between the lower mold body 7 and the lower mold body 7 when the mold is closed. The center of the lower end surface of the upper mold core 9 is an offset forging part 10. The center of the lower mold core 6 is raised and lowered to be provided with a lifting part 11. The lifting part 11 The lift is controlled by a jacking cylinder (not shown), the jacking cylinder is fixed on the lower template 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com