Alloy steel forged steel round bar for heavy-duty gear and preparation method thereof

A technology of alloy steel and forging circles, which is applied in the field of alloy steel forging circles for heavy-duty gears and its preparation, can solve the problems of difficult control of smelting process, influence on alloy mechanical properties, unstable grain refinement effect, etc., and achieve mechanical Improve performance, improve hardenability, reduce the effect of small deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

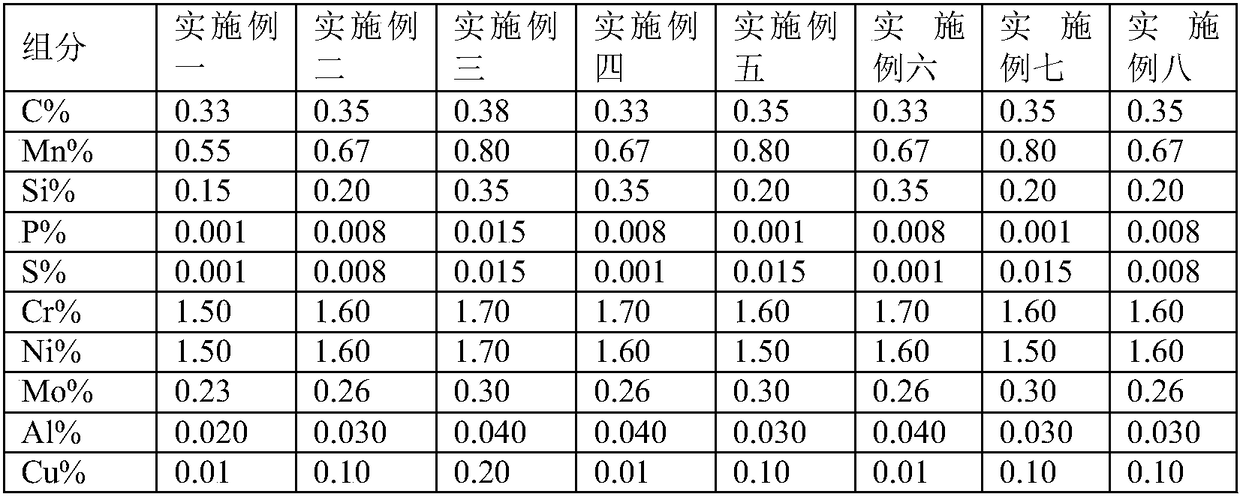

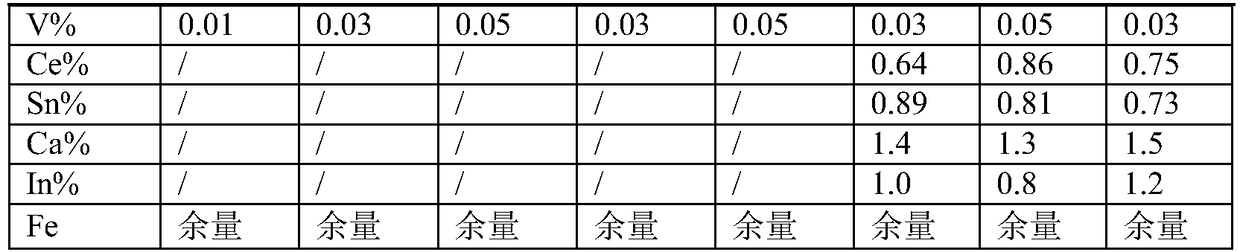

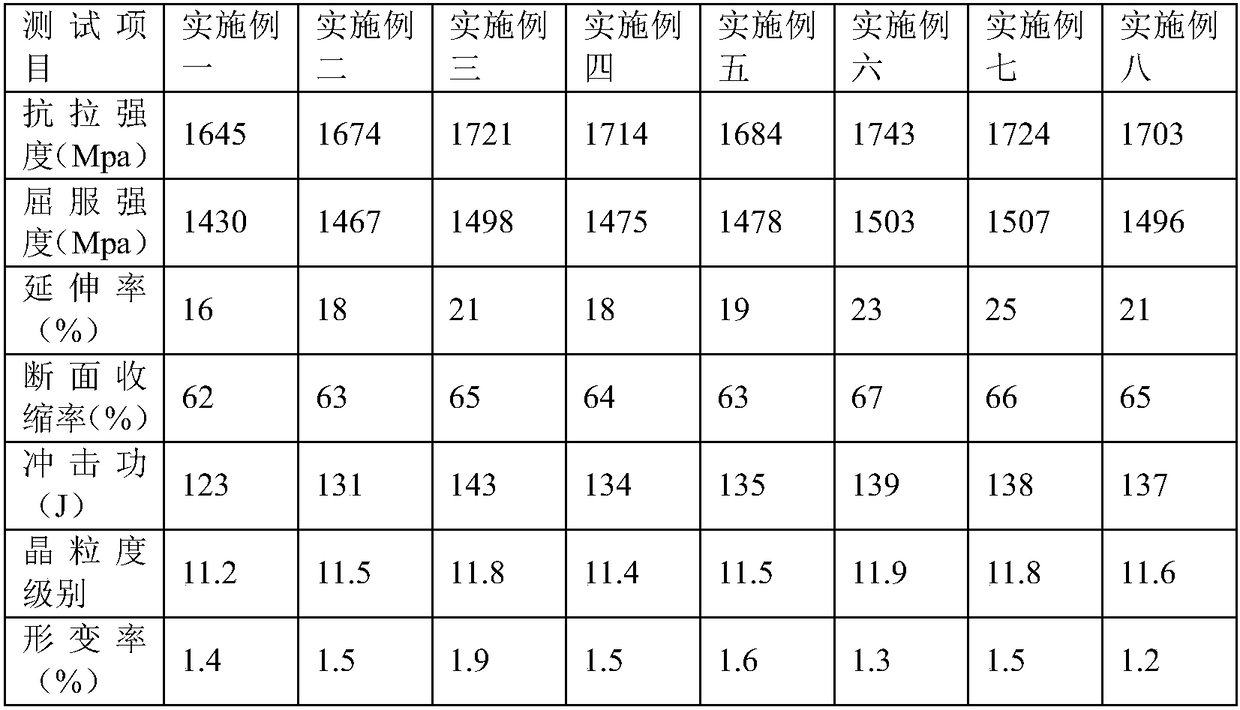

Examples

Embodiment Construction

[0036] A method for preparing an alloy for heavy-duty gears, comprising the following steps:

[0037] Step 1. Add steel containing C1.65-1.79%, Mn0.67-0.93%, P0.13-0.25%, S0.16-0.20% and A10.13-0.19% into the converter by mass fraction Carry out smelting, and then add artificial graphite, deoxidizer, copper-silicon alloy, chromium, nickel, molybdenum, aluminum, vanadium and other metal elements to the converter in sequence, and blow Ar from the bottom of the converter throughout the whole process to control the oxygen pressure ≥ 0.8Mpa, The end point of smelting is C0.56~0.64%, P≤0.016%, the temperature of molten iron reaches 1620~1645℃, and then the steel is tapped;

[0038] Step 2. The molten steel tapped in step 1 is transferred to the LF furnace for refining, and Ar is blown from the bottom of the LF furnace, and at the same time, lime, silicon carbide, calcium carbide and fluorite are added to the LF furnace for electrification and slagging. The 6-level voltage is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com