High-feldspathic ceramic green body material and preparation method thereof and method for preparing ceramic products by high-feldspathic ceramic green body material

A ceramic body, feldspar technology, applied in the field of ceramics, can solve problems such as reducing product performance, and achieve the effects of improving performance, increasing glass phase, and reducing firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

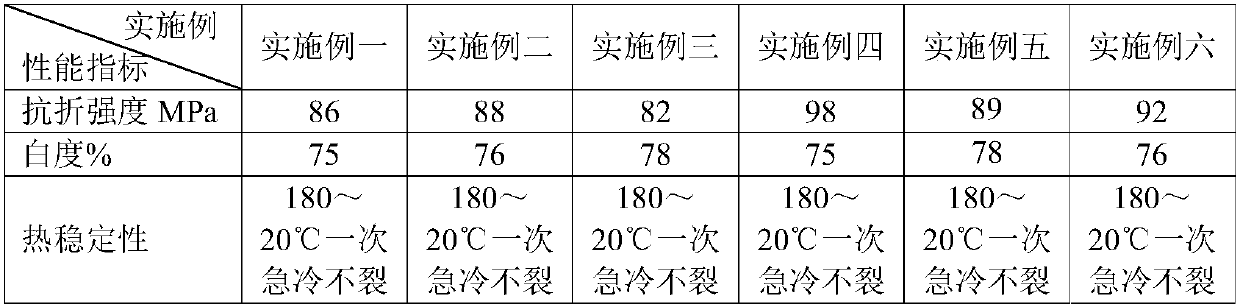

Examples

Embodiment 1

[0041] The high-feldspar ceramic body material is characterized in that it includes a base material and an additive, and the mass ratio of the base material and the additive is: 100:5, wherein the base material includes the following components by weight percentage: Potassium feldspar 30%, albite 15%, Longyan kaolin 20%, lithium feldspar 10%, Guangxi white mud 22%, calcined talc 3%, the total is 100%.

[0042] Wherein, the additive is a thickening and anti-reflection agent, and the thickening and anti-reflection agent is boron frit.

[0043] The method for preparing the high-feldspar ceramic green body material comprises the following steps:

[0044] S11. Prepare materials:

[0045] Mix the potassium feldspar, albite, lithium feldspar, calcined talc and Guangxi white mud uniformly according to the mass ratio to obtain the first proportioning material, and mix the Longyan kaolin and additives according to the mass proportion Mix evenly to obtain the second proportioning mater...

Embodiment 2

[0065] The high-feldspar ceramic body material is characterized in that it includes a base material and an additive, and the mass ratio of the base material and the additive is: 100:8, wherein the base material includes the following components by weight percentage: Potassium feldspar 35%, albite 15%, Longyan kaolin 18%, lithium feldspar 13%, Guangxi white mud 18%, calcined talc 1%, the total is 100%.

[0066] Wherein, the additive includes the following components in terms of weight percentage: 50% of the thickening and antireflection agent, 50% of the glass phase thickening agent, the described thickening and antireflection agent is boron frit, and the glass phase thickening agent For white carbon black.

[0067] The method for preparing the high-feldspar ceramic green body material comprises the following steps:

[0068] S11. Prepare materials:

[0069] Mix the potassium feldspar, albite, lithium feldspar, calcined talc and Guangxi white mud uniformly according to the mas...

Embodiment 3

[0089] The high-feldspar ceramic body material is characterized in that it includes a base material and an additive, and the mass ratio of the base material and the additive is: 100:5, wherein the base material includes the following components by weight percentage: Potassium feldspar 30%, albite 18%, Longyan kaolin 20%, lithium feldspar 11%, Guangxi white mud 20%, calcined talc 1%, the total is 100%.

[0090] Wherein, the additive includes the following components in terms of weight percentage: 40% of the thickening and antireflection agent, 60% of the glass phase thickening agent, the described thickening and antireflection agent is boron frit, and the glass phase thickening agent For white carbon black.

[0091] The method for preparing the high-feldspar ceramic green body material comprises the following steps:

[0092] S11. Prepare materials:

[0093] Mix the potassium feldspar, albite, lithium feldspar, calcined talc and Guangxi white mud uniformly according to the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com