Flap valve structure of pressure-maintaining coring device

A technology of flap valve and coring device, which is applied in the direction of extracting undisturbed core devices, wellbore/well valve devices, wellbore/well components, etc. Failure and other problems, to achieve the effect of improving the pressure holding capacity, reliable sealing performance, and preventing valve leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

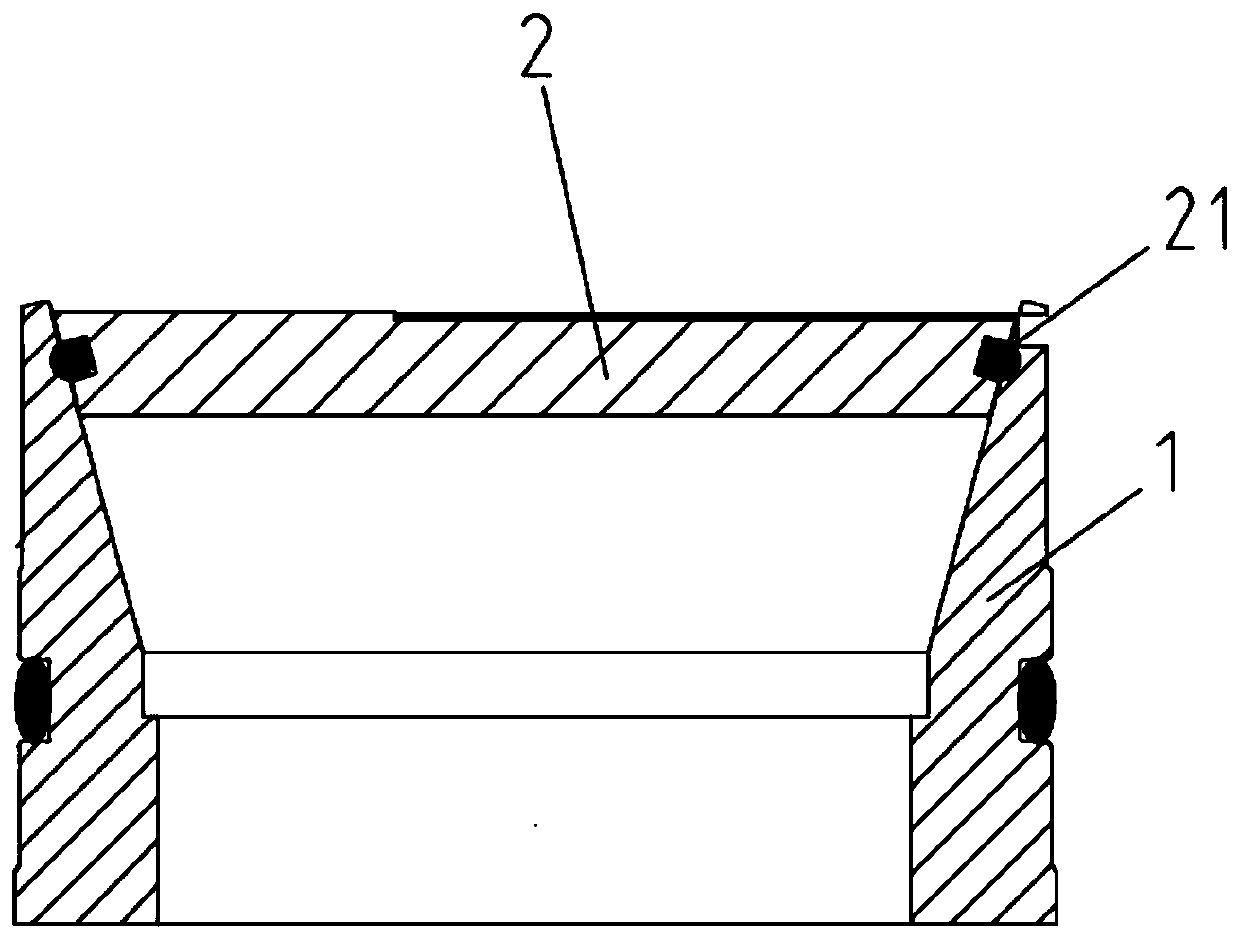

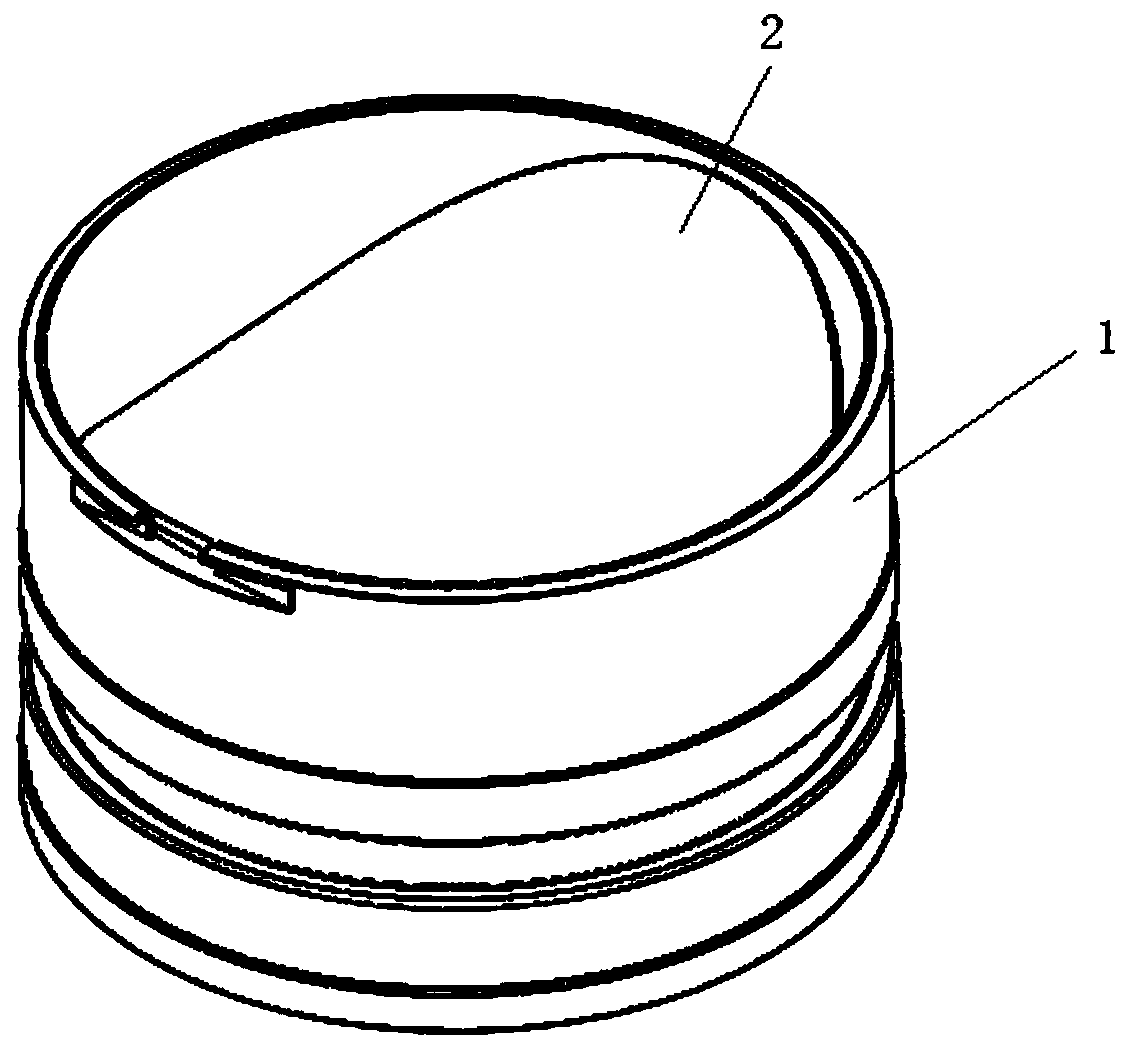

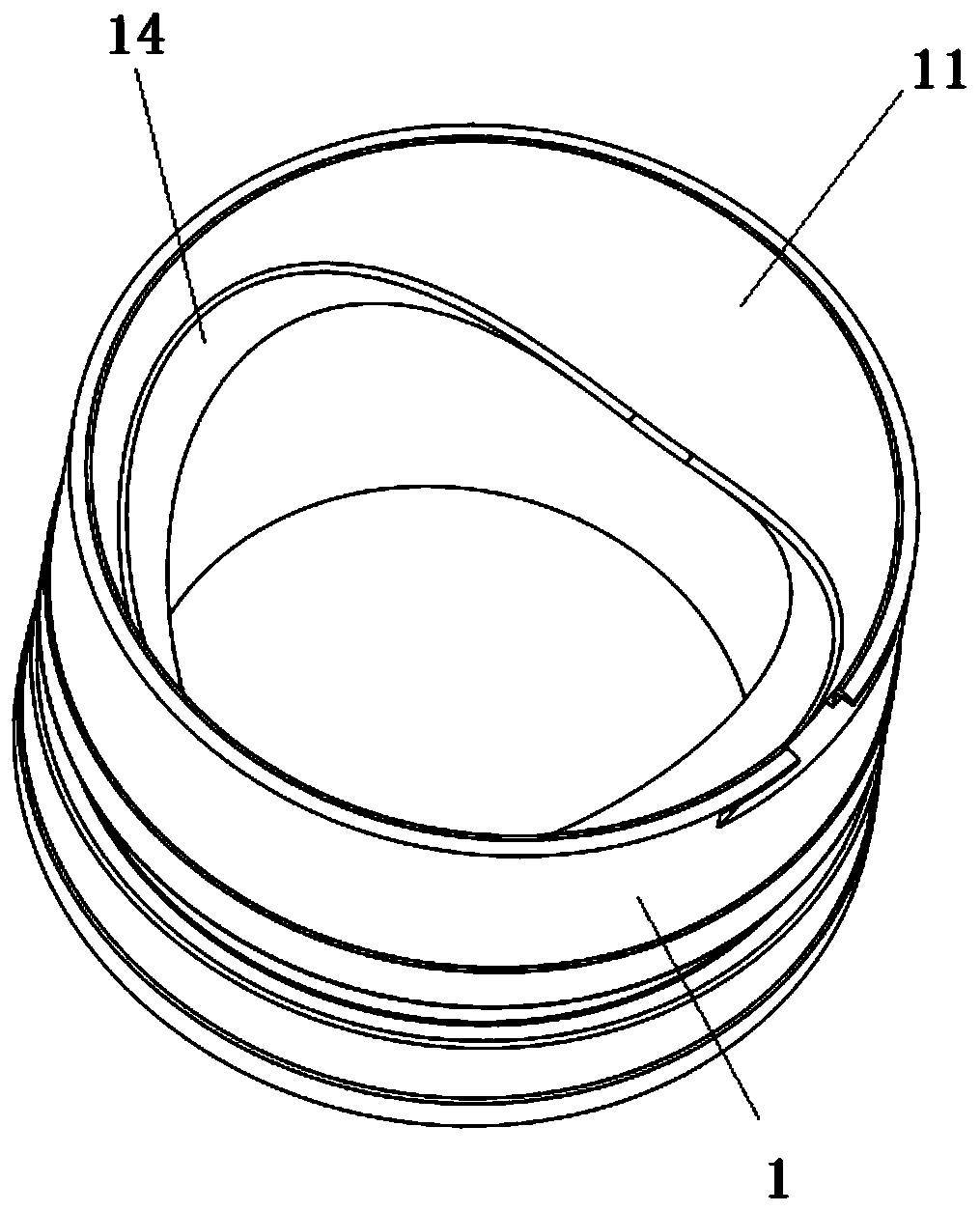

[0038] Such as figure 2 , 3 As shown in , 4, the pressure-maintaining coring device flap valve structure disclosed in this embodiment includes a valve seat 1 and a valve disc 2, one end of the valve disc 2 is movably connected with the upper end of the valve seat 1, and the top of the valve seat 1 is connected to the valve disc 2. Matching valve port sealing surface 11, the valve port sealing surface 11 is a conical surface, the valve disc 2 has a valve disc sealing surface adapted to the valve port sealing surface 11, and the taper of the valve disc sealing surface and the valve port sealing surface 11 is the same .

[0039] There is a supporting surface for supporting the valve disc 2 on the sealing surface 11 of the valve port; when the valve disc 2 is closed, the bottom of the valve disc 2 is against the supporting surface of the valve seat 1 . The coefficient of friction of the bearing surface in this embodiment is 0.12-0.3.

[0040] When the valve clack 2 is closed, ...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that: Figure 5-8 As shown, in this embodiment, a groove 15 conformally matched with the valve flap 2 is provided on the valve port sealing surface 11 to form a supporting surface, and the bottom of the valve flap 2 has a convex portion 22 adapted to the groove 15. When the valve flap 2 is closed , the protrusion 22 is embedded in the groove 15 . The cone angle of the sealing surface 11 of the valve port is 40°-50°.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: in this embodiment, a magnet is provided on the valve seat 1 , and a magnetic material is provided on the valve flap 2 . The shape, position and quantity of the magnets are set as required. This embodiment only mentions two of them, but is not limited to these two configurations.

[0047] The first type, such as Figure 9 As shown, an annular magnet 6 is installed on the valve seat 1, and the position of the annular magnet 6 is set as required. The annular magnet 6 can be arranged below the sealing groove 16 of the valve seat, and can also be arranged above the sealing groove 16 of the valve seat.

[0048] The second type, such as Figure 10 As shown, the sheet magnets 7 are installed on the valve seat 1, and the number and positions of the sheet magnets 7 are set as required. The magnet can choose NdFeB magnet.

[0049] In this embodiment, the valve flap 2 can be magnetically attract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com