Composite porous isolating film and electrochemical device

A technology of separator and porous substrate, which is applied in the field of electrochemistry, can solve the problems of reducing the energy density of electrochemical devices, reducing the thickness of ceramic coatings, and being unable to suppress the expansion of pole pieces, so as to improve low-temperature kinetic performance and cycle performance , Improve energy density, increase low-temperature discharge rate and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

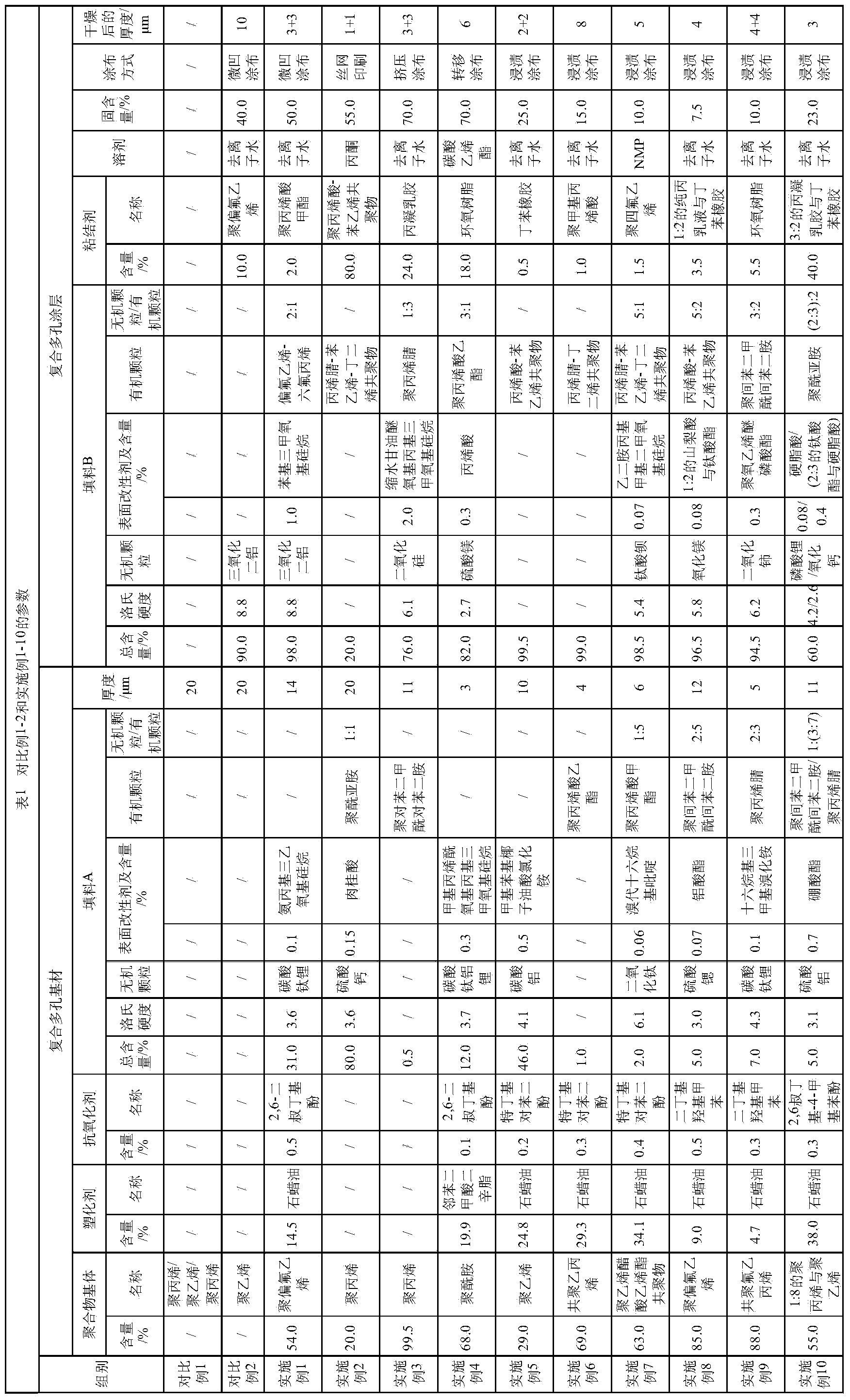

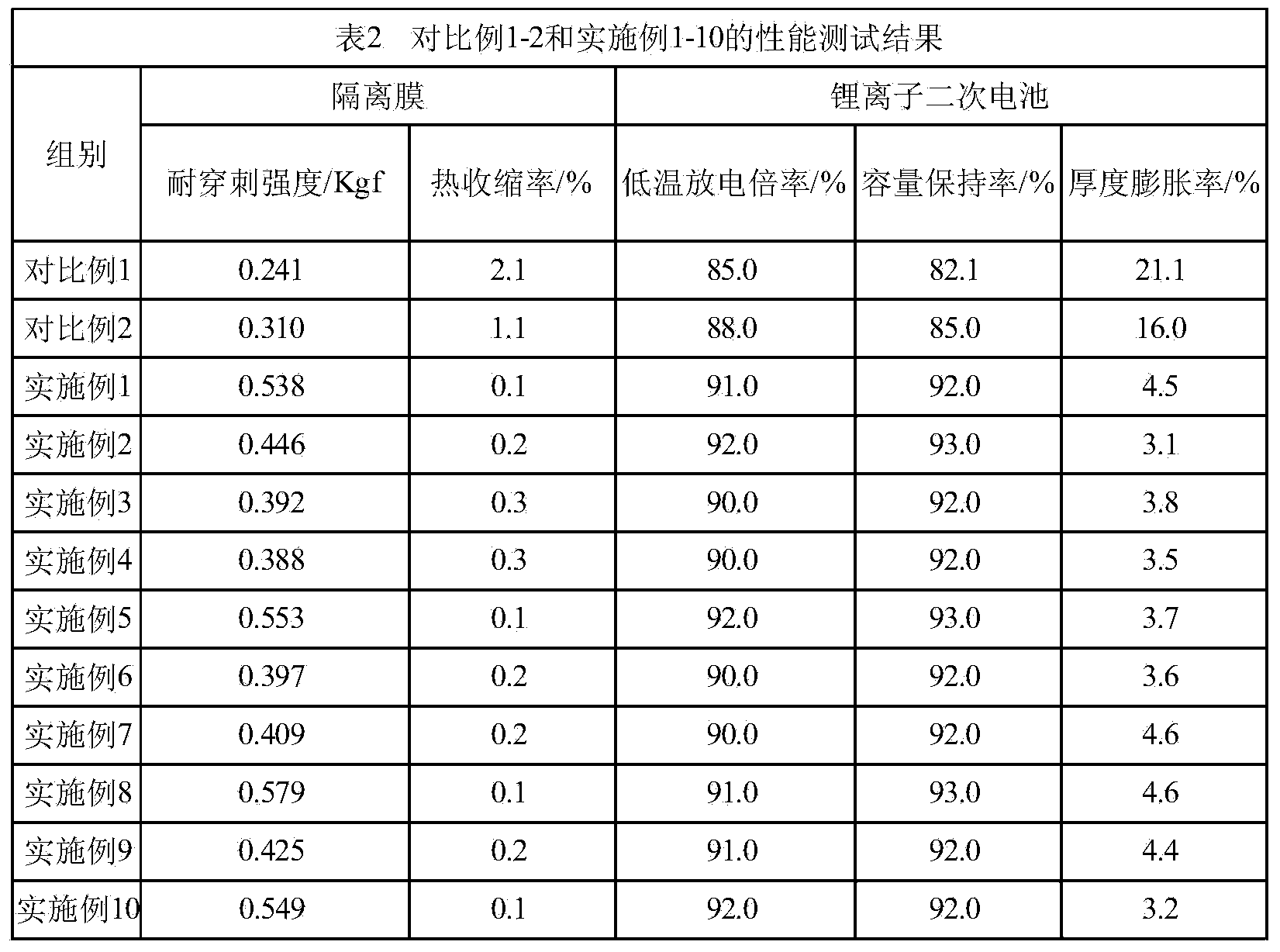

[0032] According to the second aspect of the present invention, the preparation method of the first composite porous isolation membrane includes the steps of: mixing the polymer matrix, plasticizer, antioxidant, and filler A and then extruding through a twin-screw extruder, and performing the first horizontal and then longitudinal Stretch to form a base film, then immerse the stretched base film in an extractant to extract the plasticizer, and then undergo heat setting treatment to obtain a composite porous substrate; mix filler B, binder and solvent evenly Make a slurry, and make the solid content of the slurry reach a specified value, then evenly coat the slurry on at least one surface of the composite porous substrate to obtain a wet film, and dry the wet film in an oven to obtain a composite porous isolation membrane .

[0033] In the preparation method of the first composite porous isolation membrane according to the second aspect of the present invention, the plasticizer...

Embodiment 1

[0058] A lithium-ion secondary battery was prepared according to the method of Comparative Example 1, except that in the preparation of the separator (i.e. in step (3)),

[0059] The polymer matrix polyvinylidene fluoride with a mass percentage of 54%, the plasticizer paraffin oil with a mass percentage of 14.5%, and the antioxidant 2,6-di-tert-butylphenol with a mass percentage of 0.5% and lithium titanium carbonate (Rockwell hardness 3.6) with a mass percentage content of 31% (filler A, surface-modified by the surface modifier aminopropyltriethoxysilane, the surface modifier accounts for 10% of the mass of lithium titanium carbonate 0.1%) are mixed and extruded through a twin-screw extruder, stretched horizontally and then vertically to form a base film, and then the stretched base film is immersed in the extractant dichloroethane to extract the plasticizer paraffin oil After coming out, it is then heat-set to obtain a composite porous substrate with a thickness of 14 μm;

...

Embodiment 2

[0062] A lithium-ion secondary battery was prepared according to the method of Comparative Example 1, except that in the preparation of the separator (i.e. in step (3)),

[0063] The polymer matrix polypropylene with a mass percentage of 20% and calcium sulfate (Rockwell hardness 3.6) with a mass percentage of 80% (modified by surface modifier cinnamic acid, the surface modifier accounted for calcium sulfate The mixture of 0.15% of the mass) and polyimide (mass ratio 1:1, filler A) is melt-extruded through a twin-screw extruder, stretched horizontally and then longitudinally, and then heat-set to obtain a thickness of 20μm composite porous substrate;

[0064] Add the acrylonitrile-styrene-butadiene copolymer (filler B) with a mass percentage of 20% and the binder polyacrylic acid-styrene copolymer with a mass percentage of 80% into the solvent acetone and mix uniformly to prepare Form a slurry and make the solid content of the slurry 55%, and then use screen printing to evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com