Patents

Literature

205results about How to "Improve lateral strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

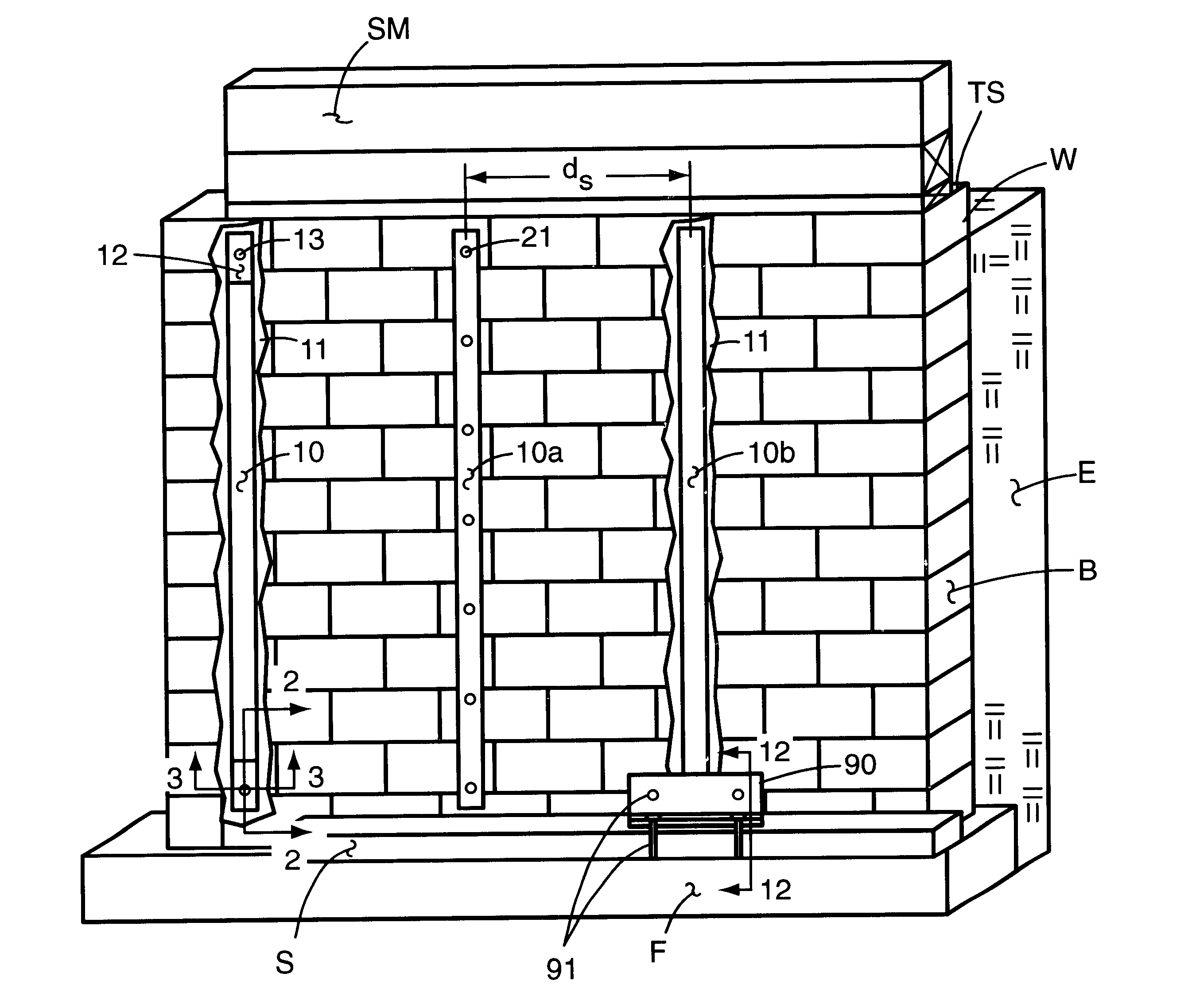

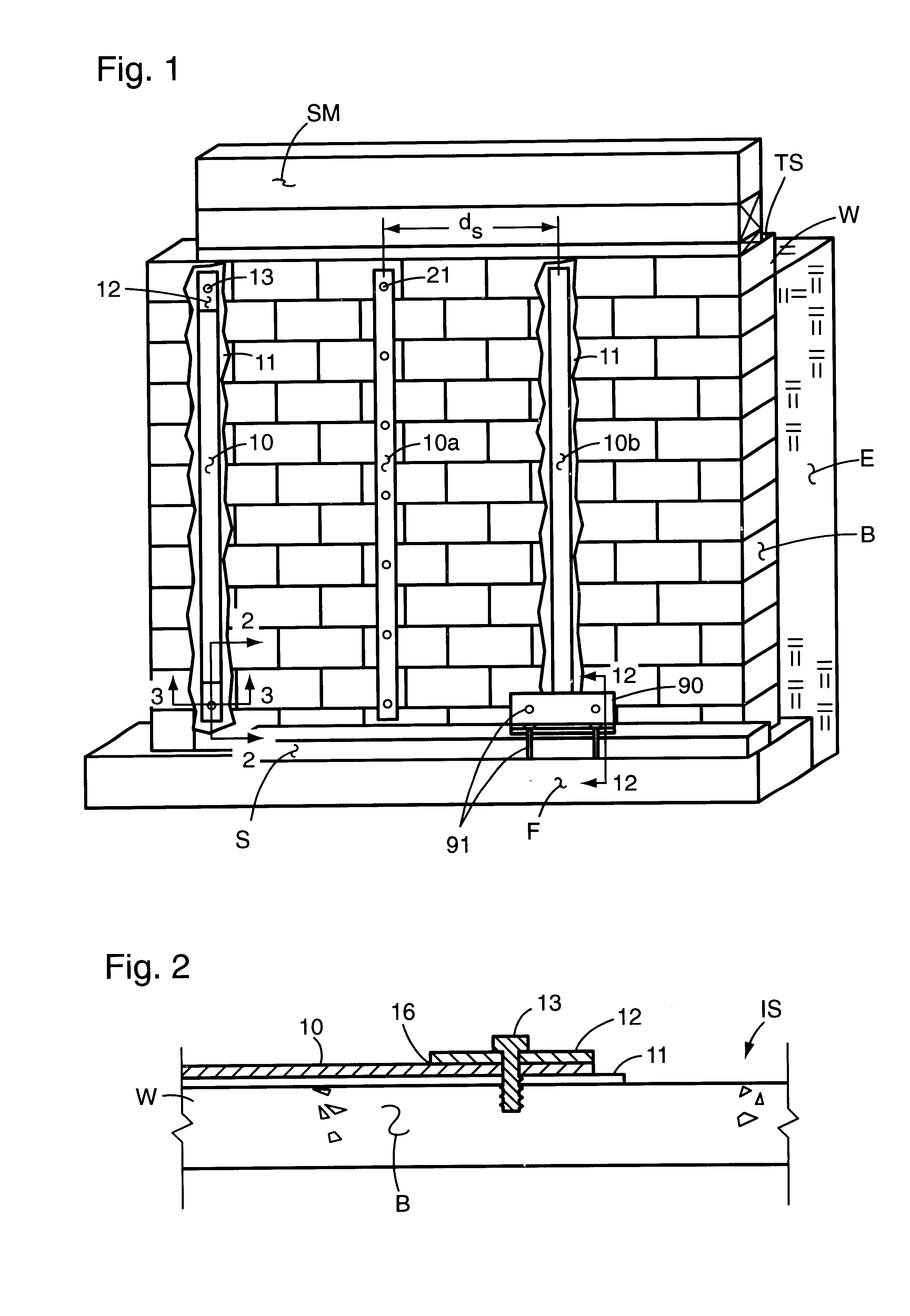

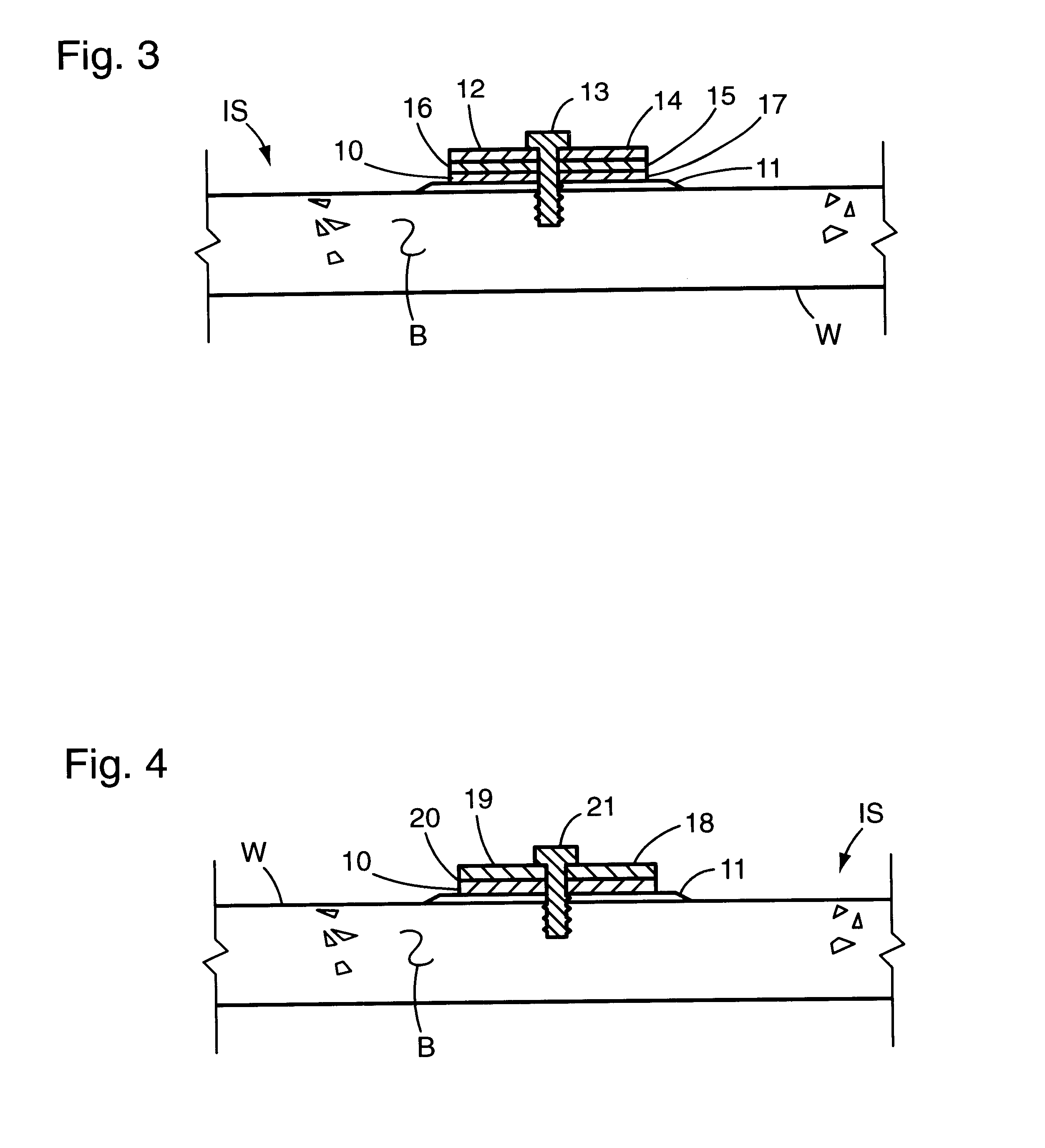

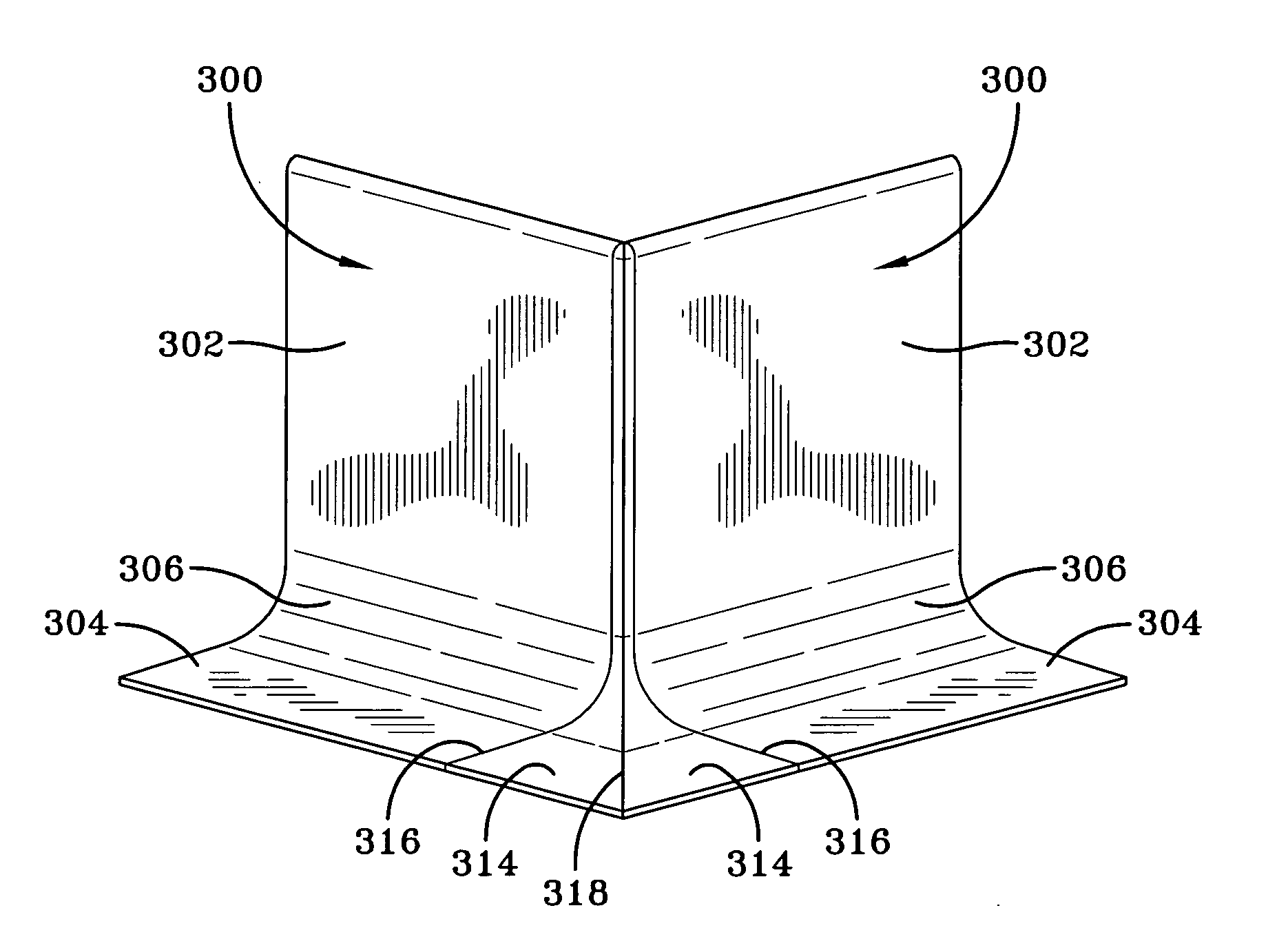

Wall reinforcement apparatus and method using composite materials

A wall reinforcing method including reinforcing members adhered to the wall. The reinforcing members are either pre-cured composite plates or composite members formed in situ, that is, a fabric of reinforcing fibers that is saturated with an adhesive to form the matrix of the composite and to adhere the reinforcement to the wall. The in situ members are either strips of fabric or wide sheets that cover most of the wall. The spacing of the reinforcing members is determined, in one embodiment, by an array of spacing distances. The array, which is preferably in table form, is consulted by the installer who first measures some of the wall parameters and environmental characteristics.

Owner:ENGINEERED COMPOST SYST +1

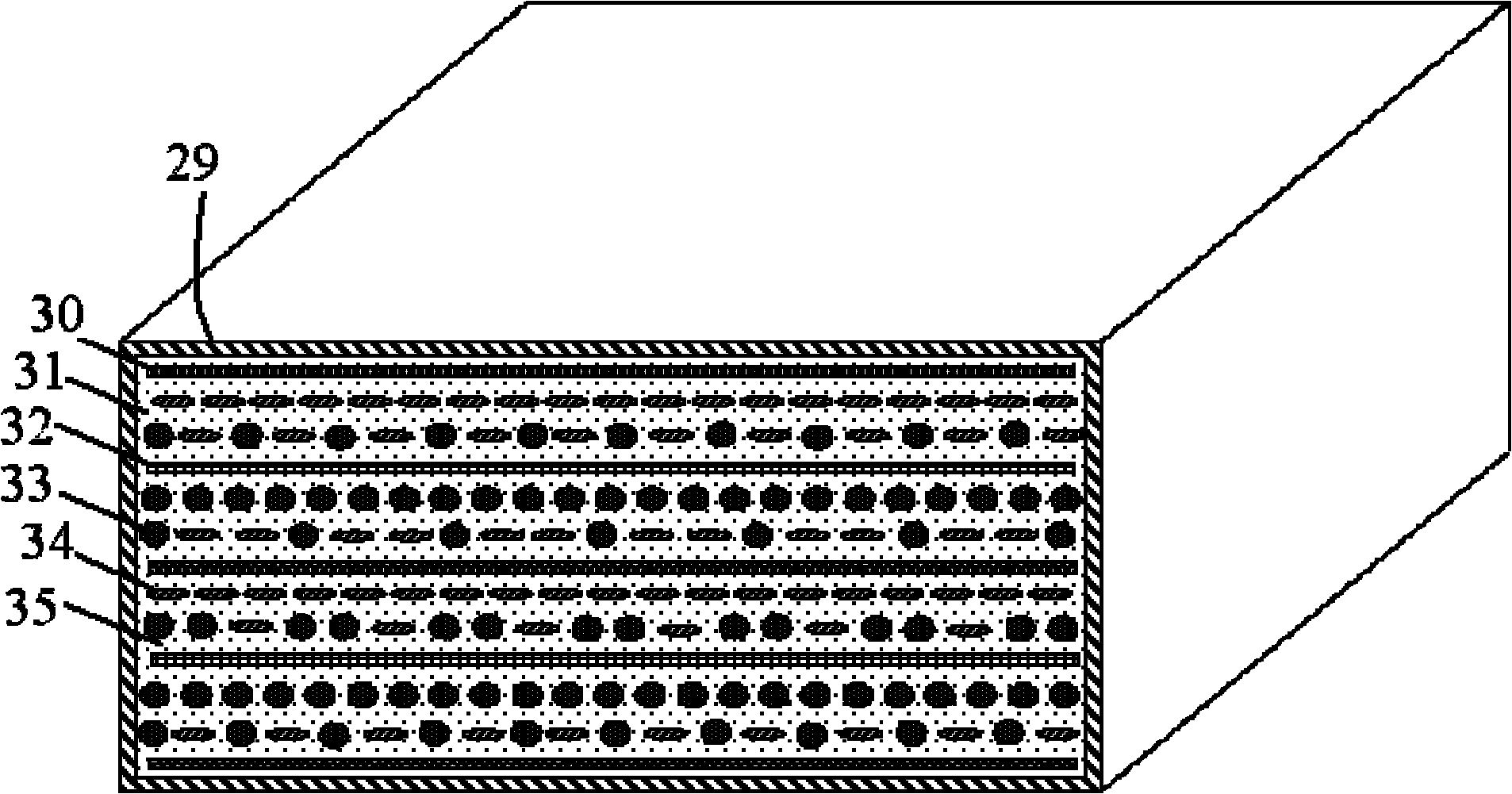

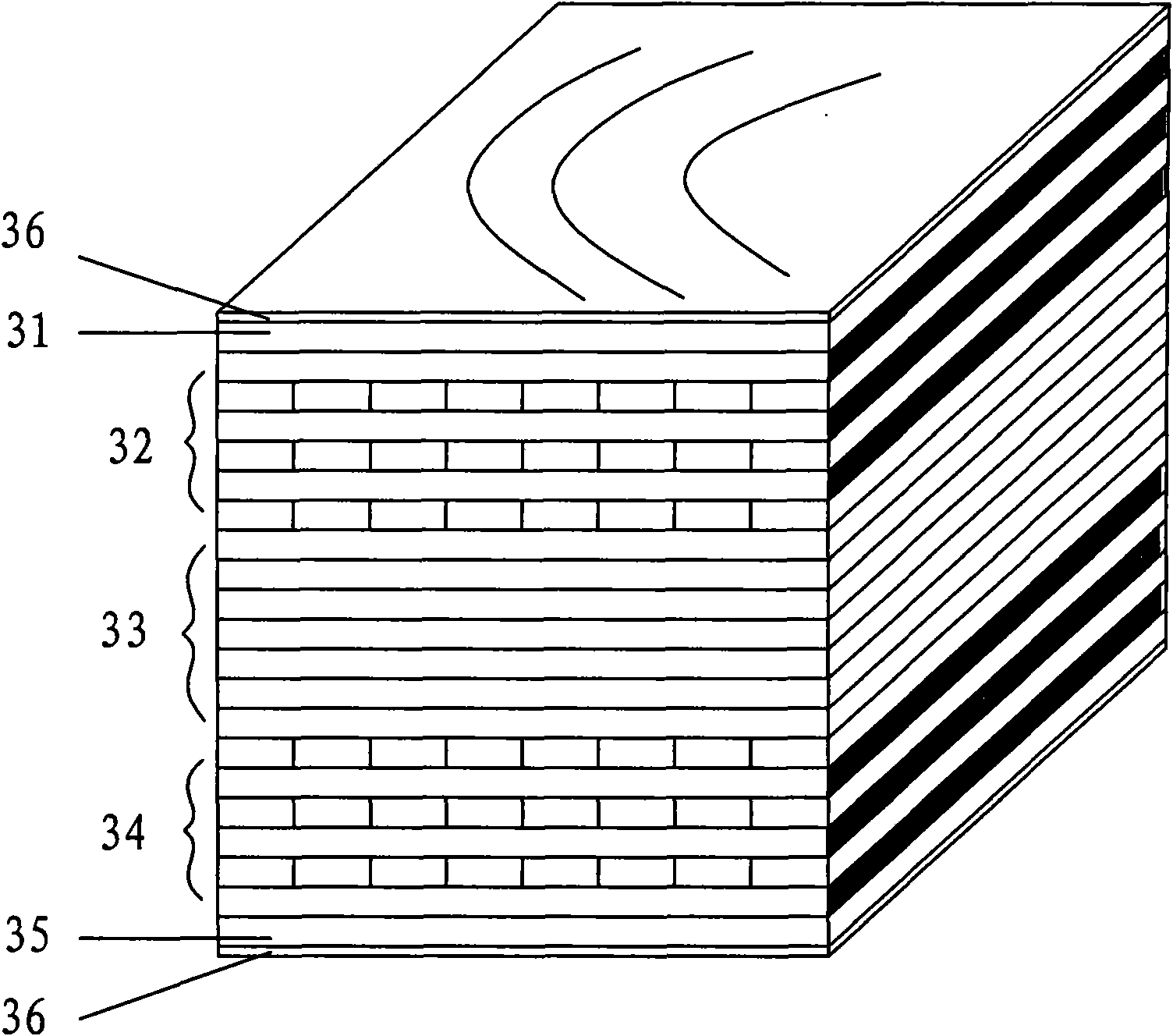

Combined fiber reinforced water-blown polyurethane hard foam composite board, production method and production equipment thereof

ActiveCN102059833AHigh strengthImprove rigiditySynthetic resin layered productsGlass/slag layered productsGlass fiberCarbon fibers

The invention provides a combined fiber reinforced water-blown polyurethane hard foam composite board, a production method and continuous production equipment thereof. In the combined fiber reinforced water-blown polyurethane hard foam composite board, one or mixtures of more of long glass fibers or long glass fibers and carbon fibers, glass fiber cloth, carbon fiber cloth or short-cut glass fibers are used as fiber reinforced bodies which are alternately distributed in a polyurethane foaming raw material matrix in a layered form. The combined fiber reinforced water-blown polyurethane hard foam composite board has the advantages of high strength, good rigidity and better size stability and high-temperature resistance. In the invention, the continuous production equipment is adopted, thereby the production efficiency and the product quality stability are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

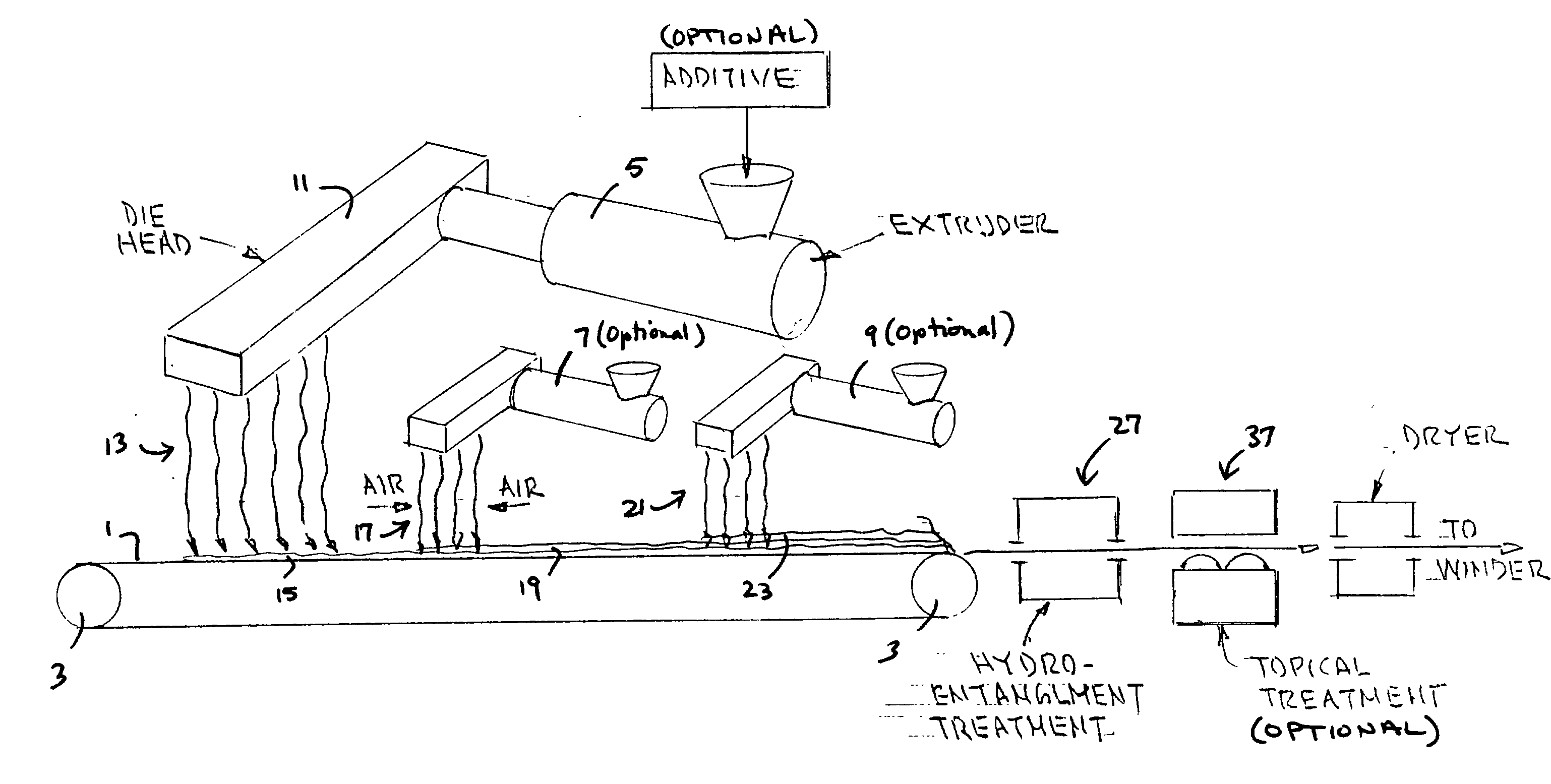

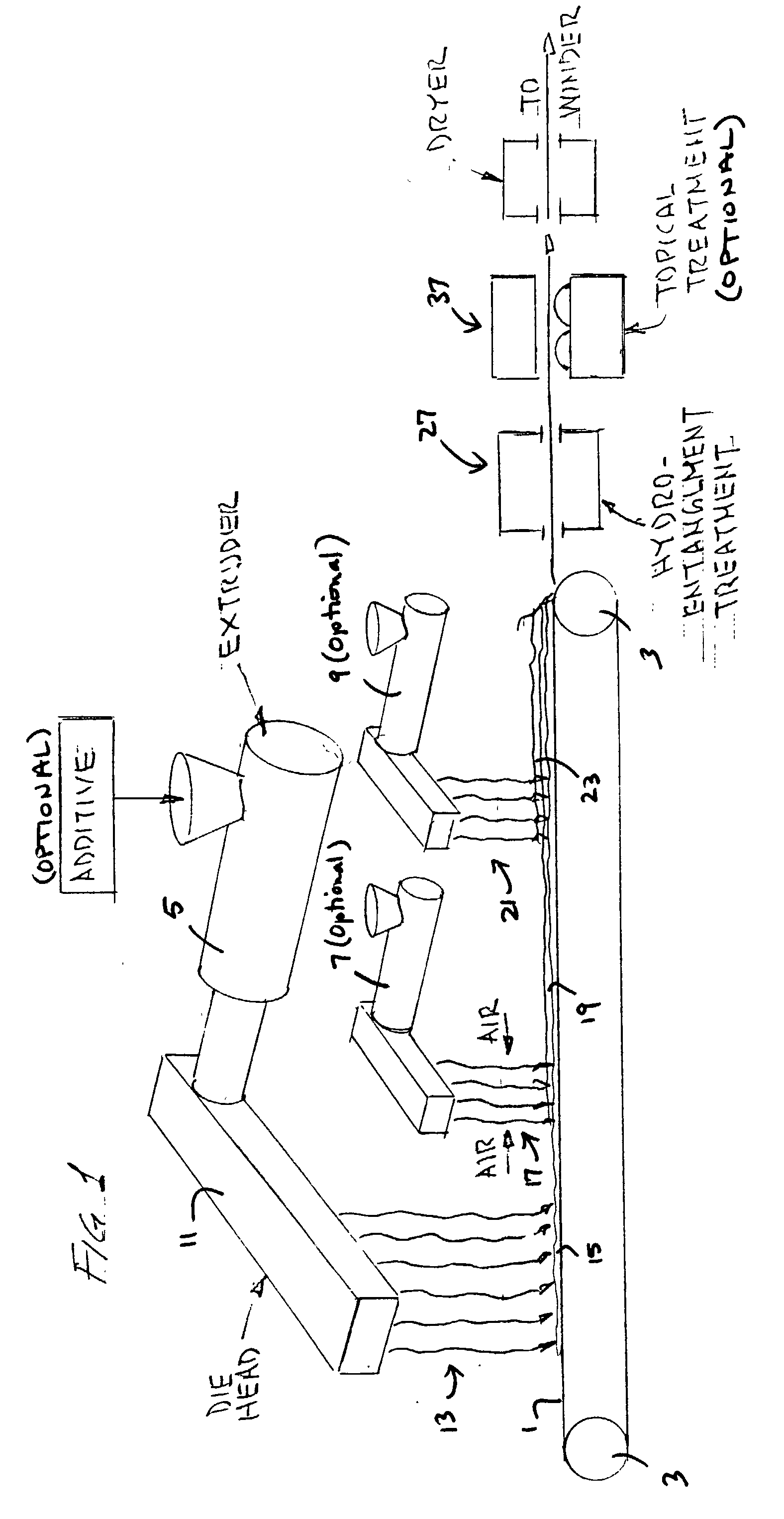

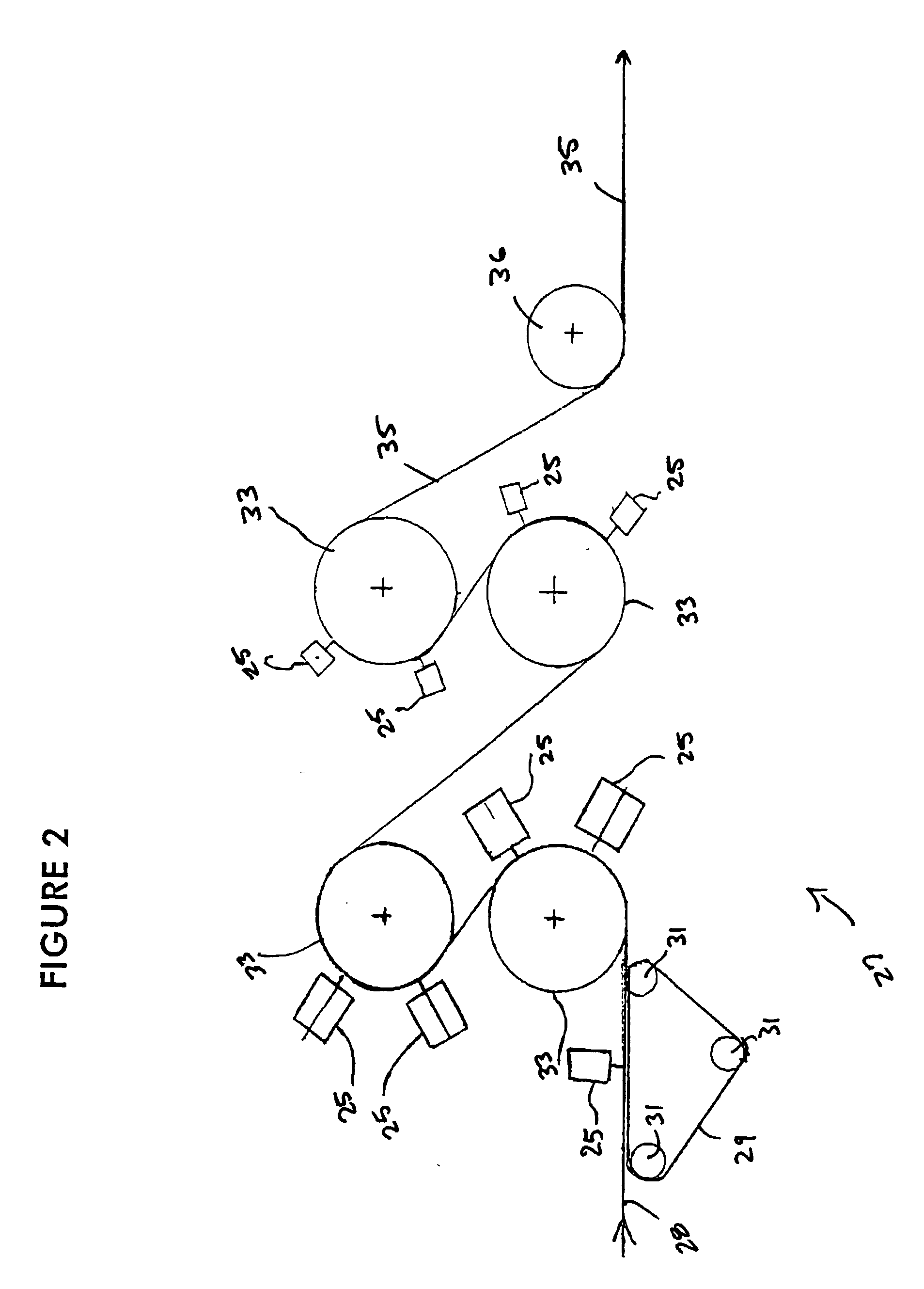

Method for making a hydroentangled nonwoven fabric and the fabric made thereby

InactiveUS20040010894A1Wet strength propertyHigh strengthPattern makingNeedling machinesTopical treatmentNonwoven fabric

A process for making a single layer or multi-layer nonwoven material having improved cross-directional strength and feel, and the nonwoven material made thereby, is described. The process provides a nonwoven material including at least one layer formed of polymeric continuous filaments. The layer(s) are formed in a continuous sequential manner, i.e., a subsequent layer being formed on top of a preceding layer or layers. Thereafter, in the absence of any prebonding, the layer(s) are subjected to hydroentanglement. The basis weight of the nonwoven material is from about 17 to 150 gsm. The nonwoven material has improved properties based on treating the layer(s) by hydroentanglement. Varying the number of water jets and the pressure of the water allows variance in the properties obtained in the final product. Other physical properties can also be imparted to or changed in the nonwoven material by inclusion of an additive in a polymer melt during formation of the filaments, or by topical treatment following treatment of the layers of the nonwoven material by hydroentanglement.

Owner:AVGOL

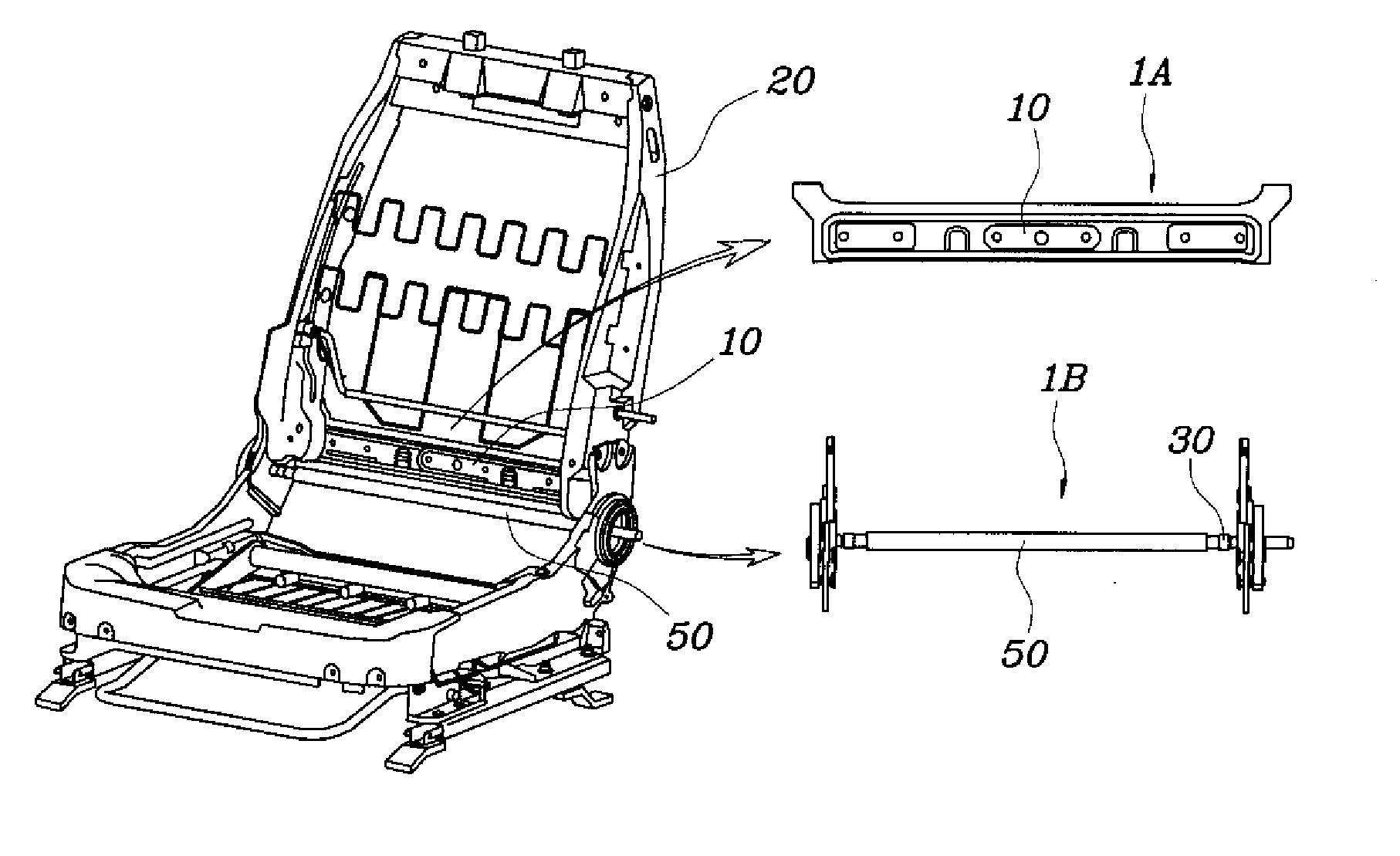

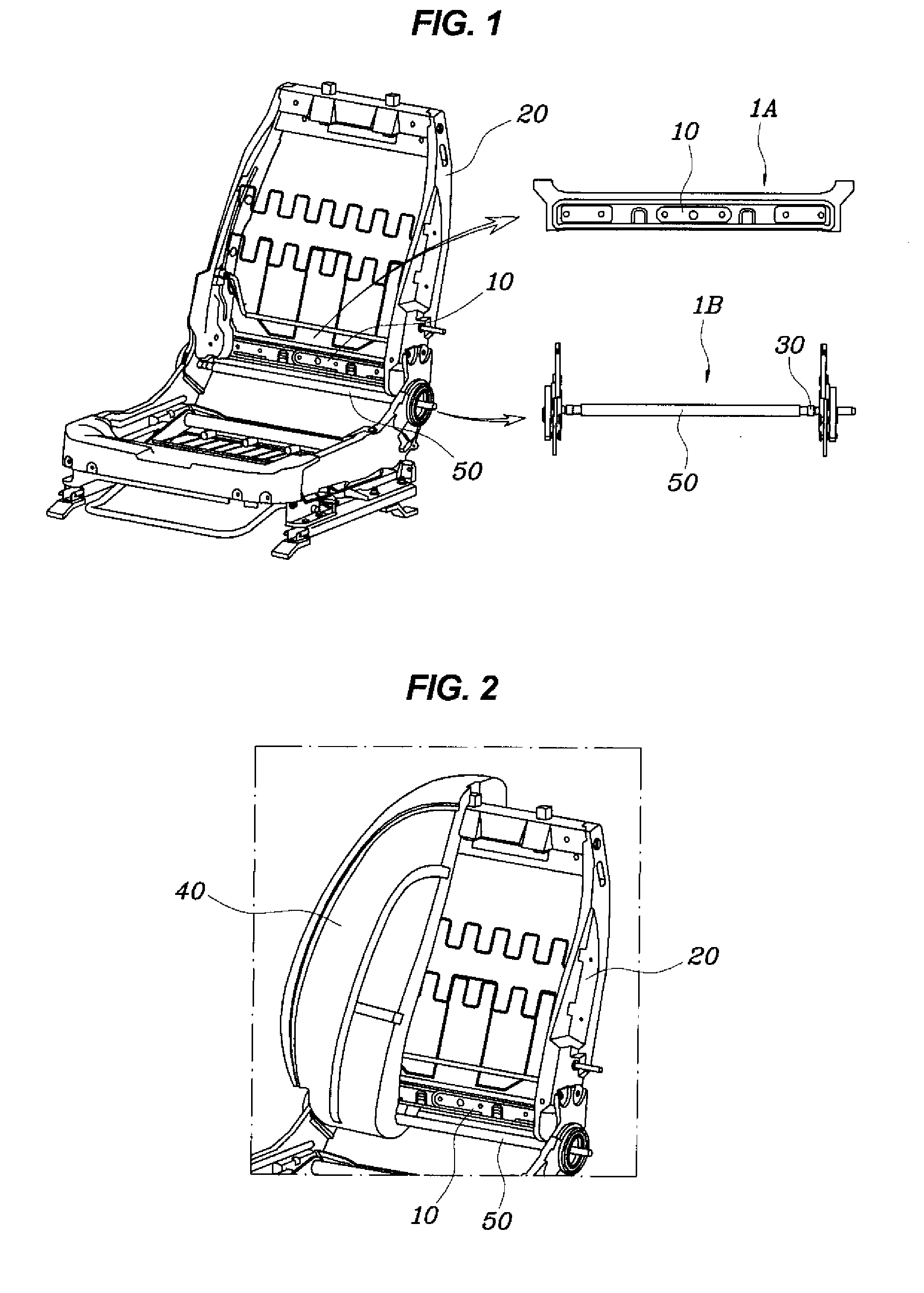

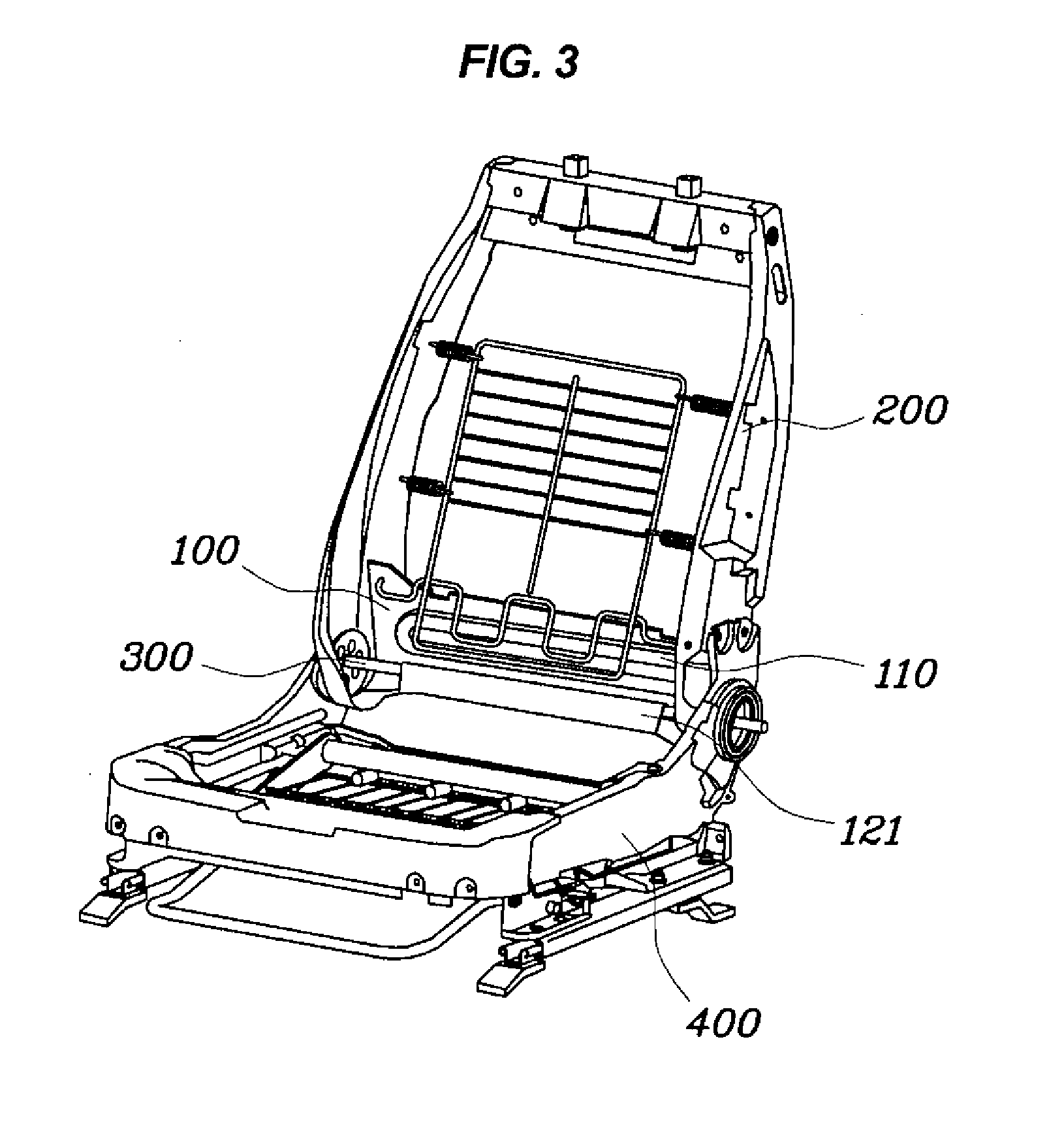

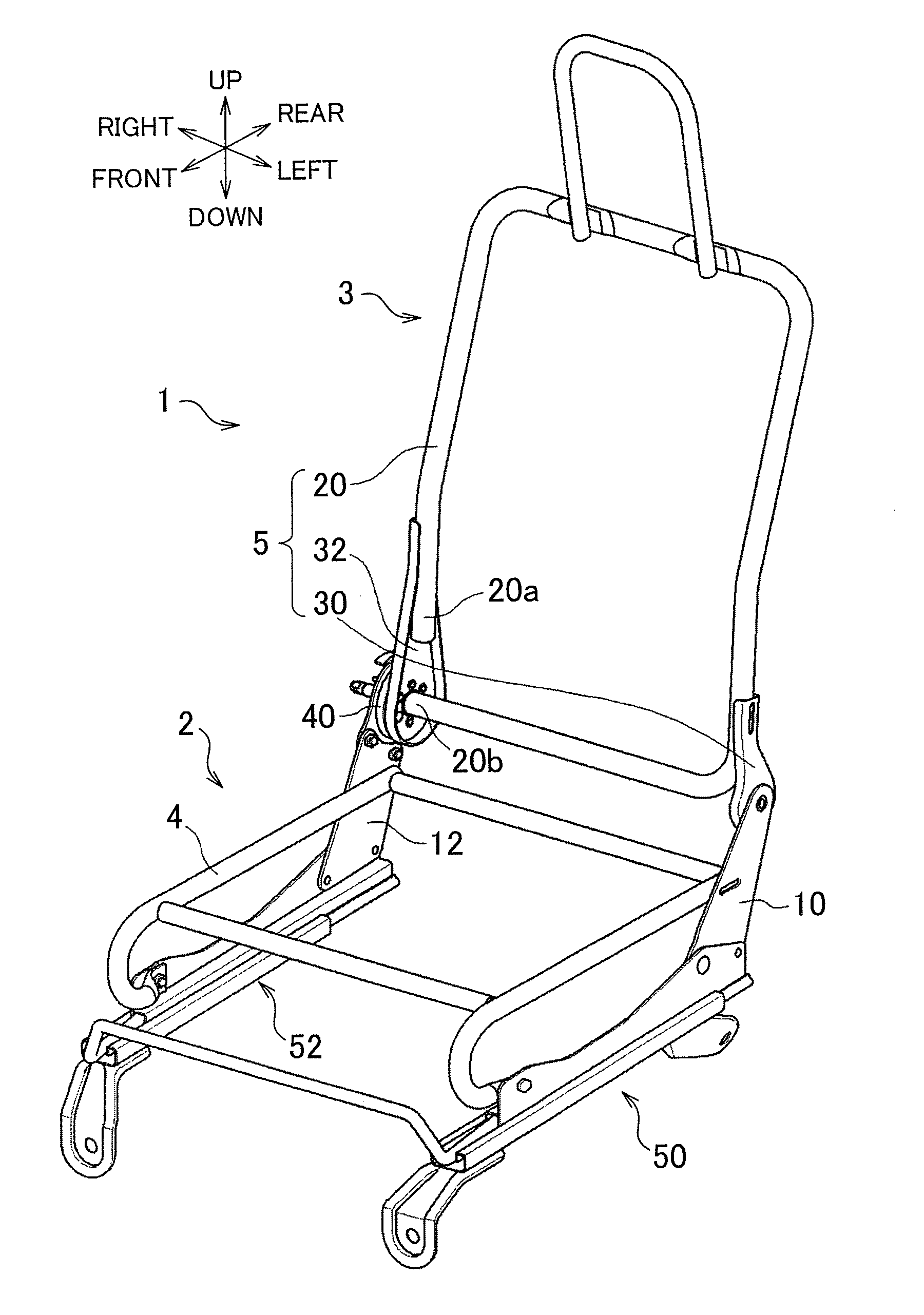

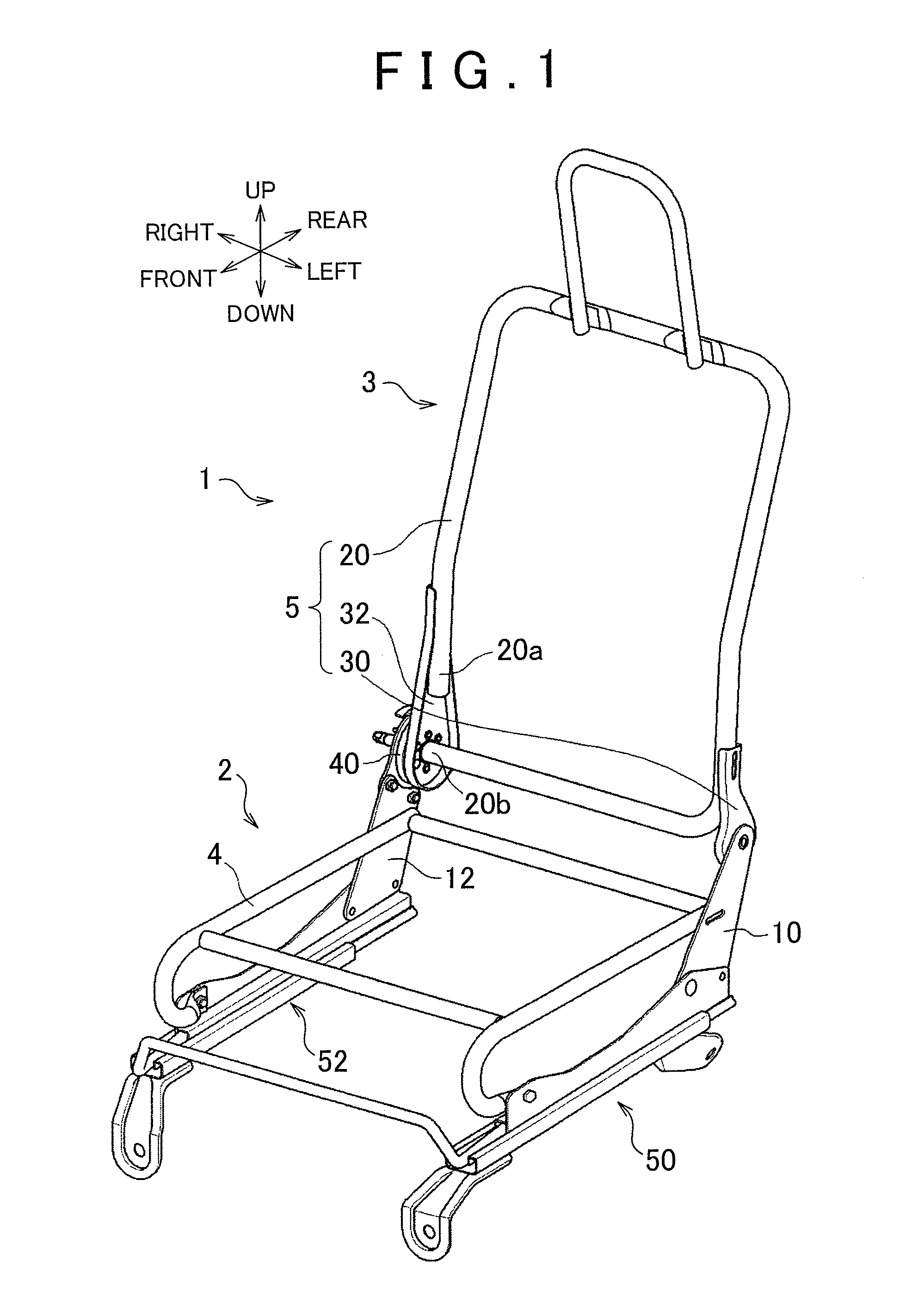

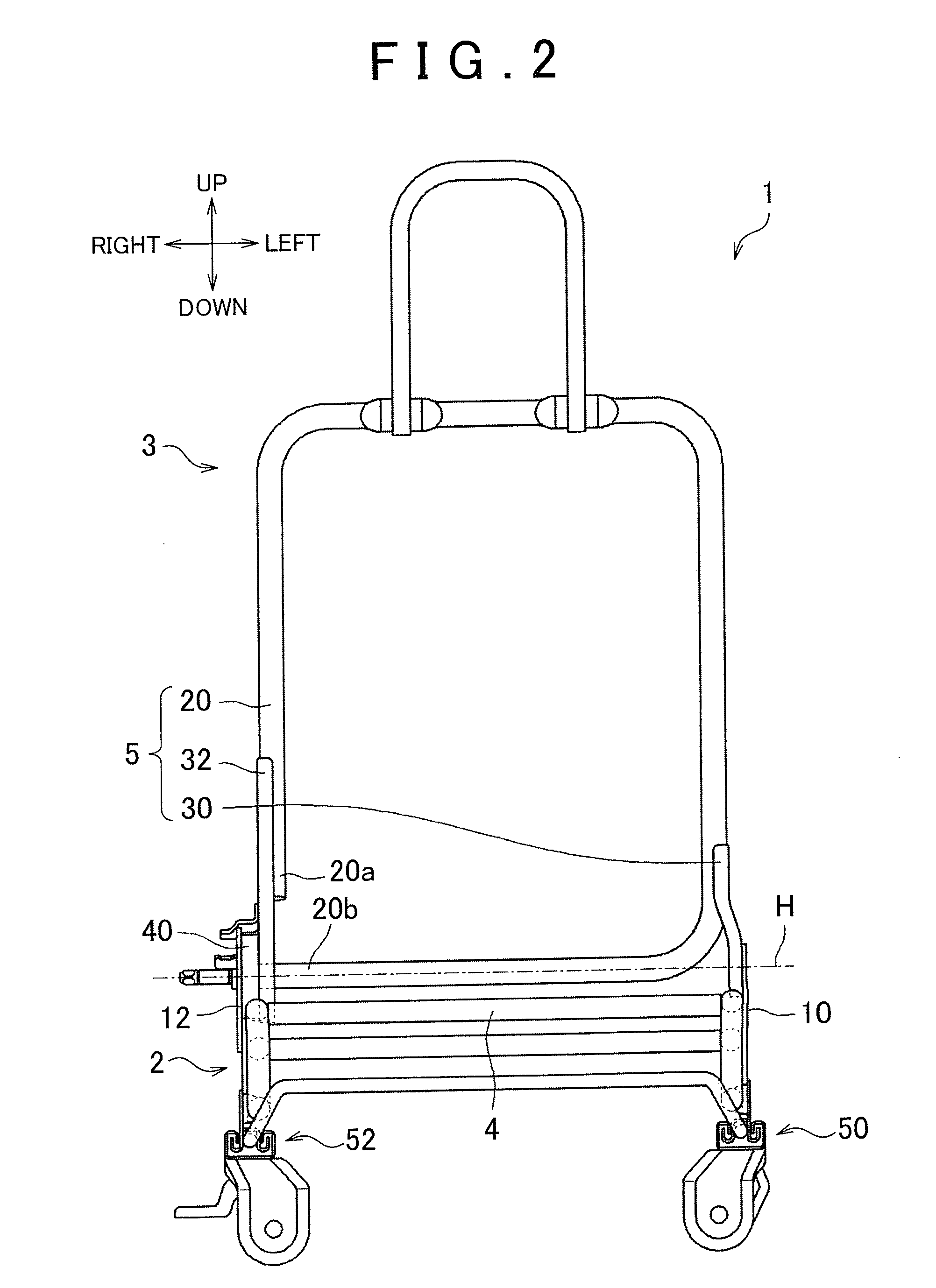

Seatback Frame for Vehicles

ActiveUS20090152928A1Improve lateral strengthOvercome problemsSeat framesStoolsMechanical engineeringHinge angle

Owner:HYUNDAI MOTOR CO LTD +1

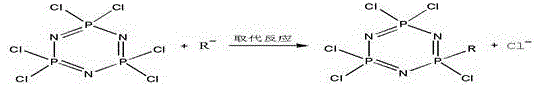

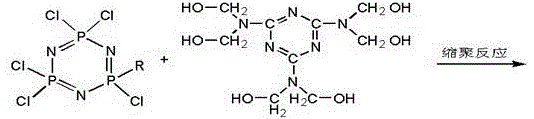

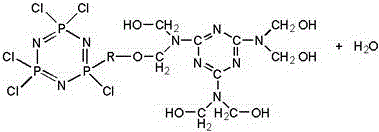

Edible soy protein casing film and preparation method thereof

ActiveCN101715870AImprove film formationImprove lateral strengthVegetable proteins working-upGlycerolPolyvinyl alcohol

The invention discloses an edible soy protein casing film, which is prepared from the following raw materials in percentage by weight: 10 to 20 percent of water, 40 to 45 percent of soy protein, 25 to 30 percent of collagen, 4 to 8 percent of glycerol, 5 to 10 percent of polyvinyl alcohol, 3 to 6 percent of edible fiber, and 0.3 to 0.8 percent of glutaraldehyde. The process for preparing the casing film comprises the following steps: 1) extracting and refining the soy protein; 2) blending and modifying the soy protein; 3) extruding and shaping the soy protein; and 4) curing, drying and plastifying the soy protein. The soy protein casing has high nutritive value, high tensile strength, high elongation, steam resistance, good product quality, and meets the requirements of stuffing sausages in various flavors.

Owner:山东冠华蛋白肠衣有限公司

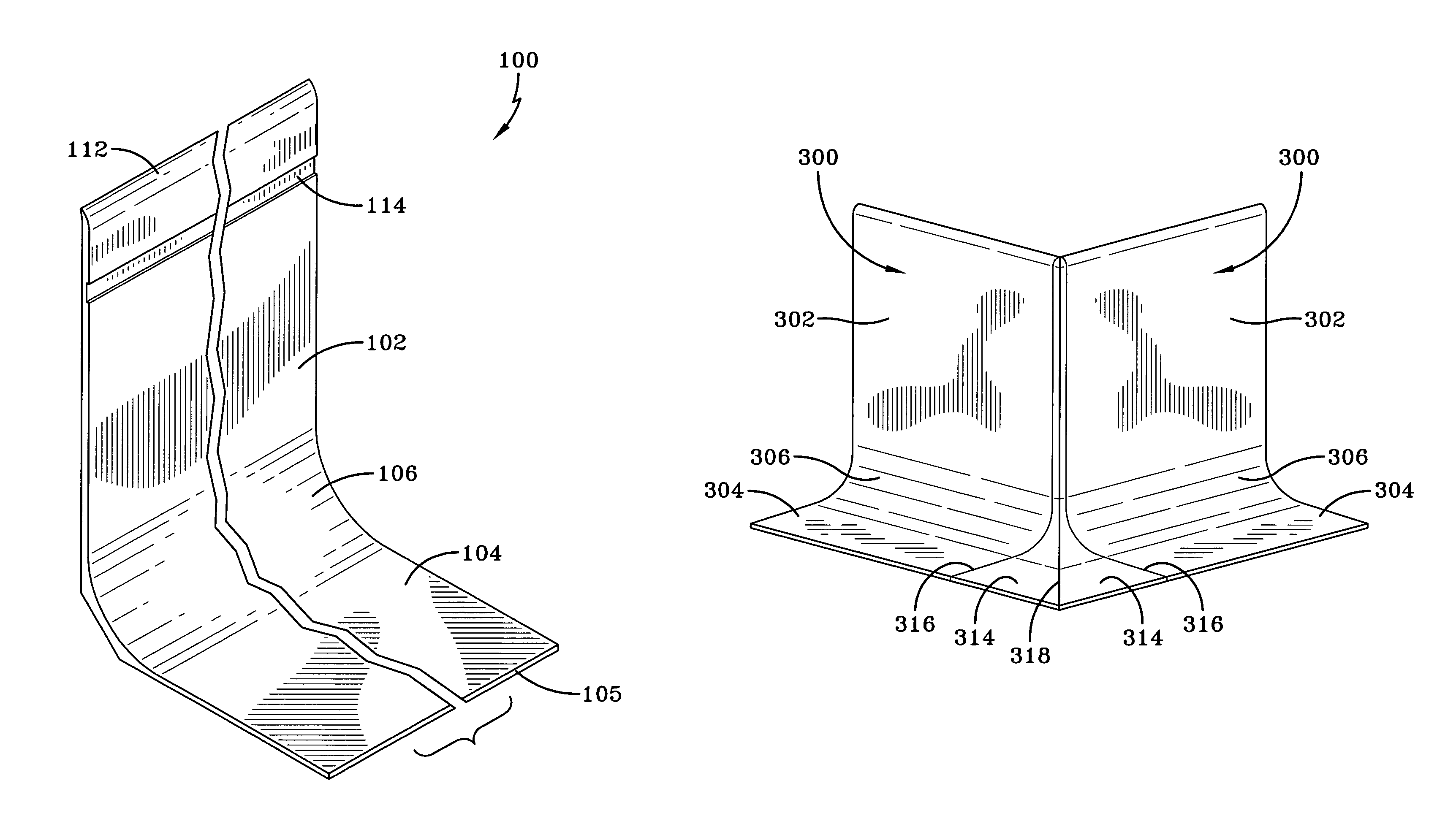

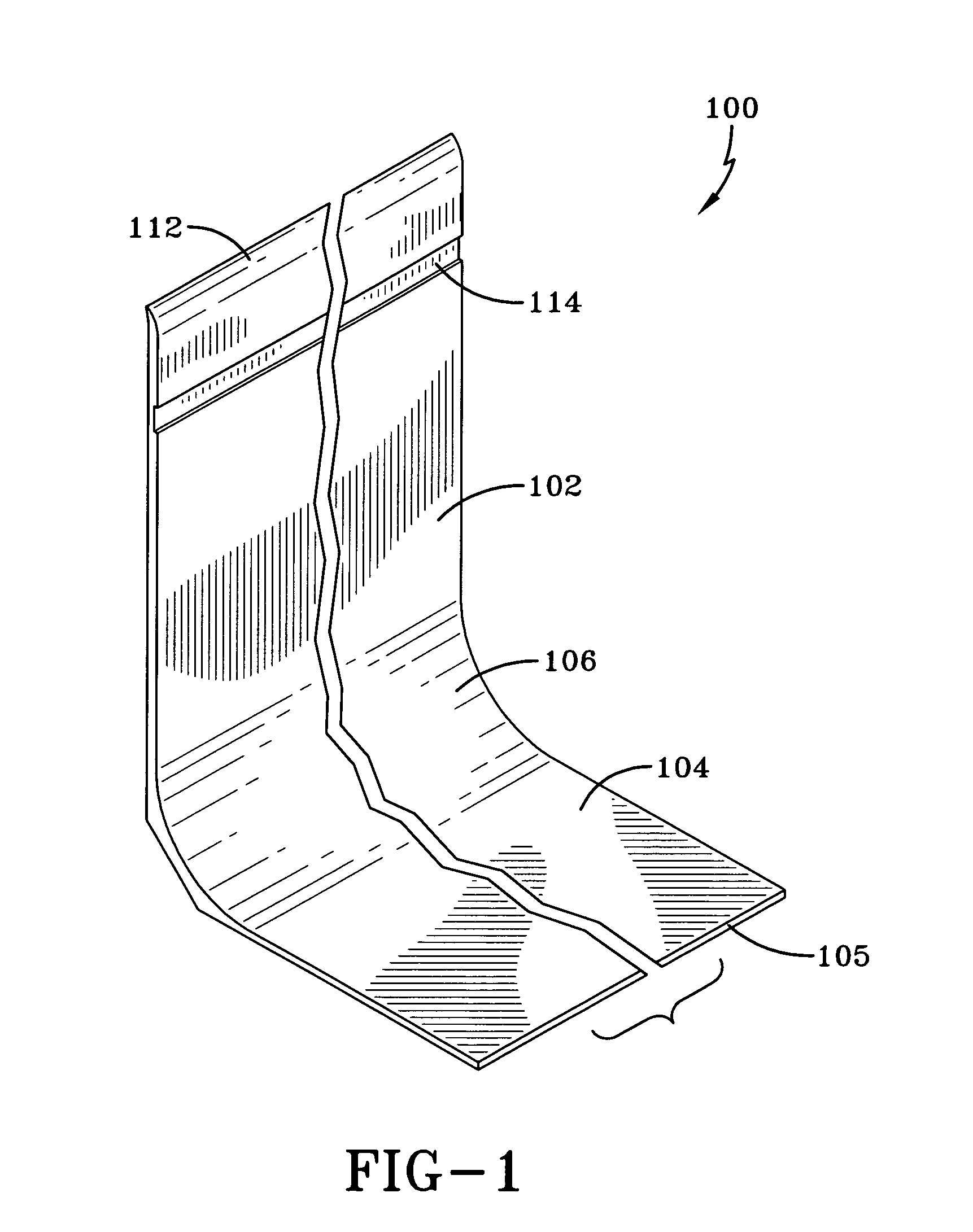

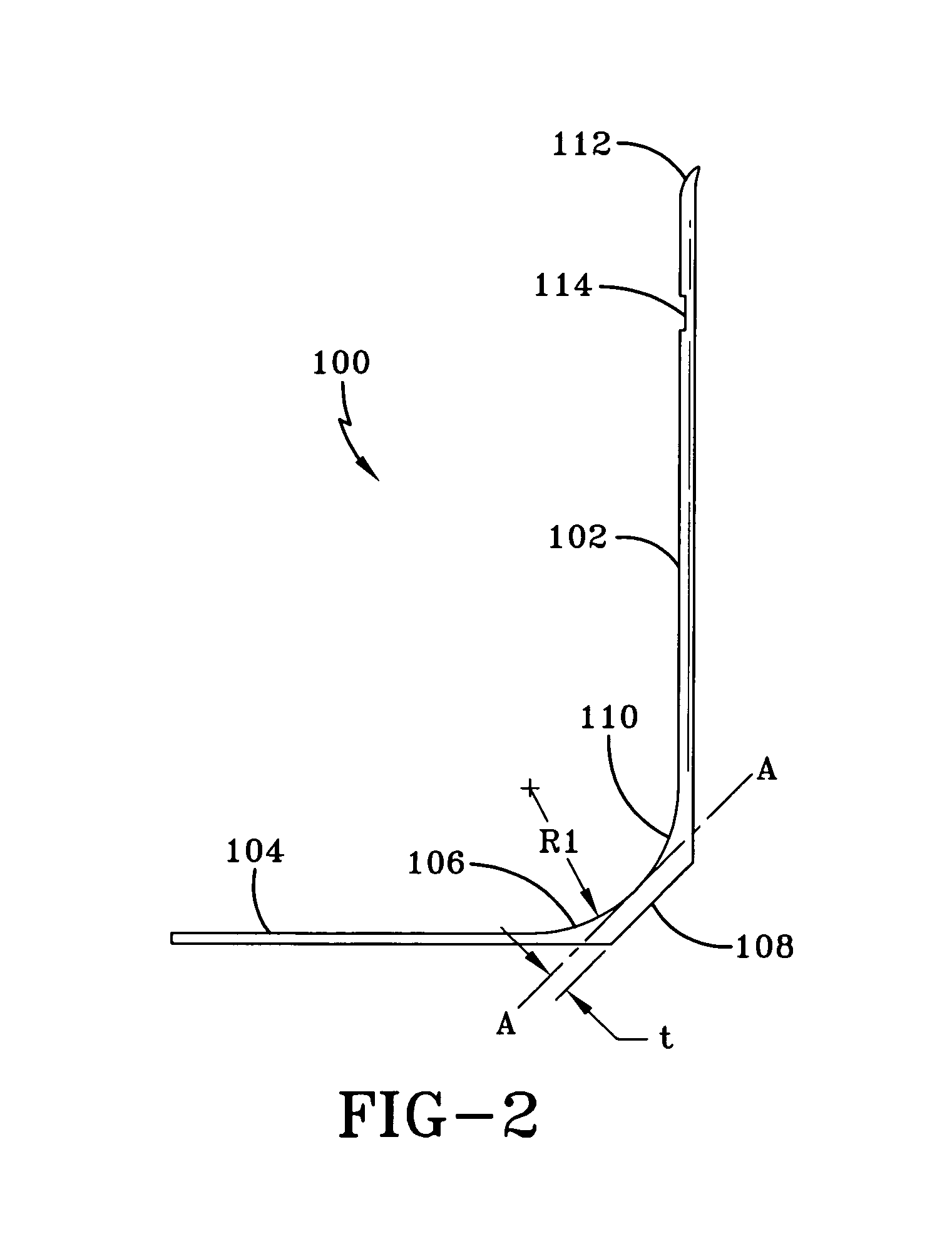

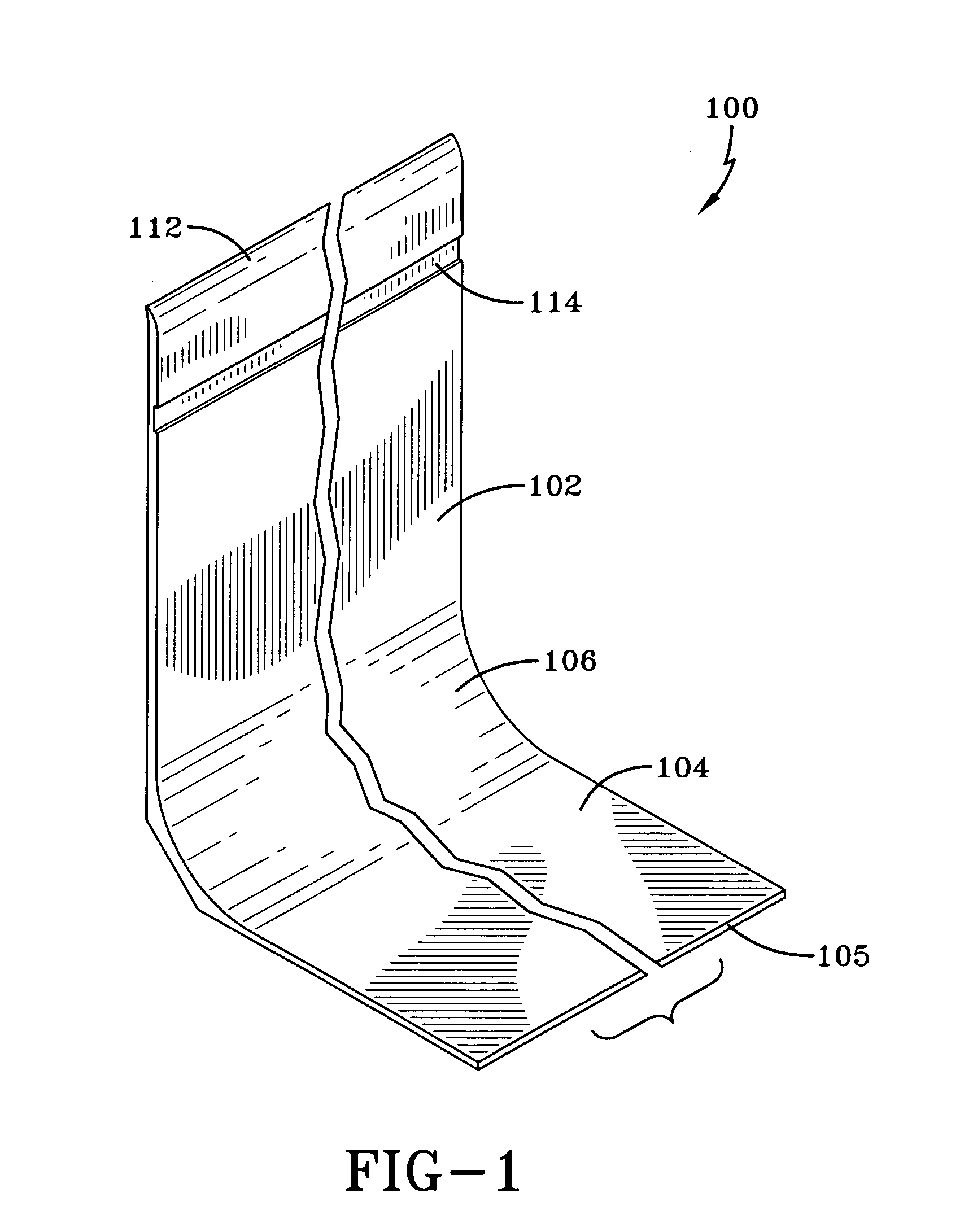

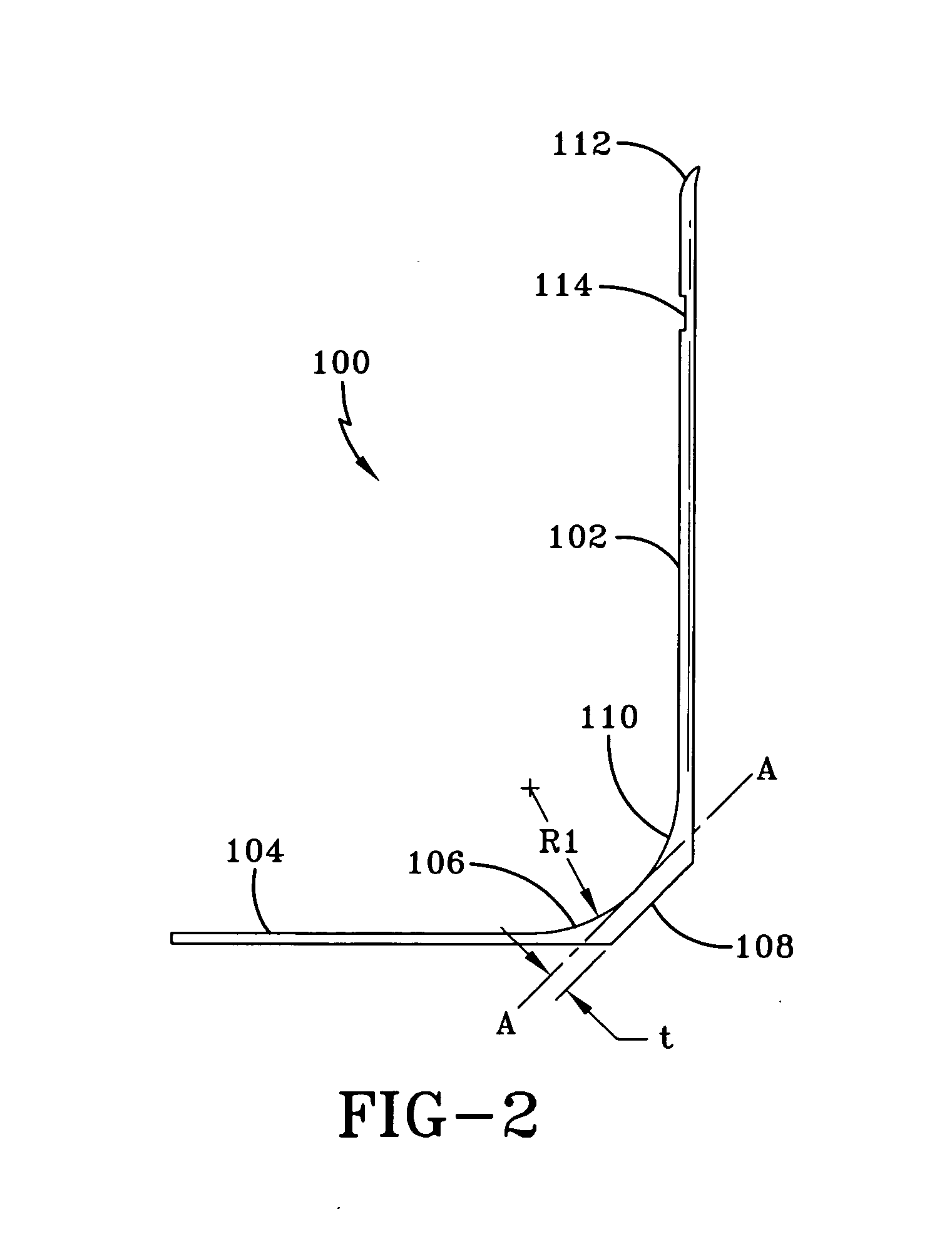

Integral wall base and flash cove

An integral wall base and flash cove having a wall portion, an elongated toe and a concave cove interconnecting the wall portion and the elongated toe in smooth transition. The integral wall base and flash cove can be wrapped around inside and outside corners without the need for a separate molded corner. The integral wall base and flash cove can be installed without required a cove stick or top cap moulding.

Owner:TARKETT USA

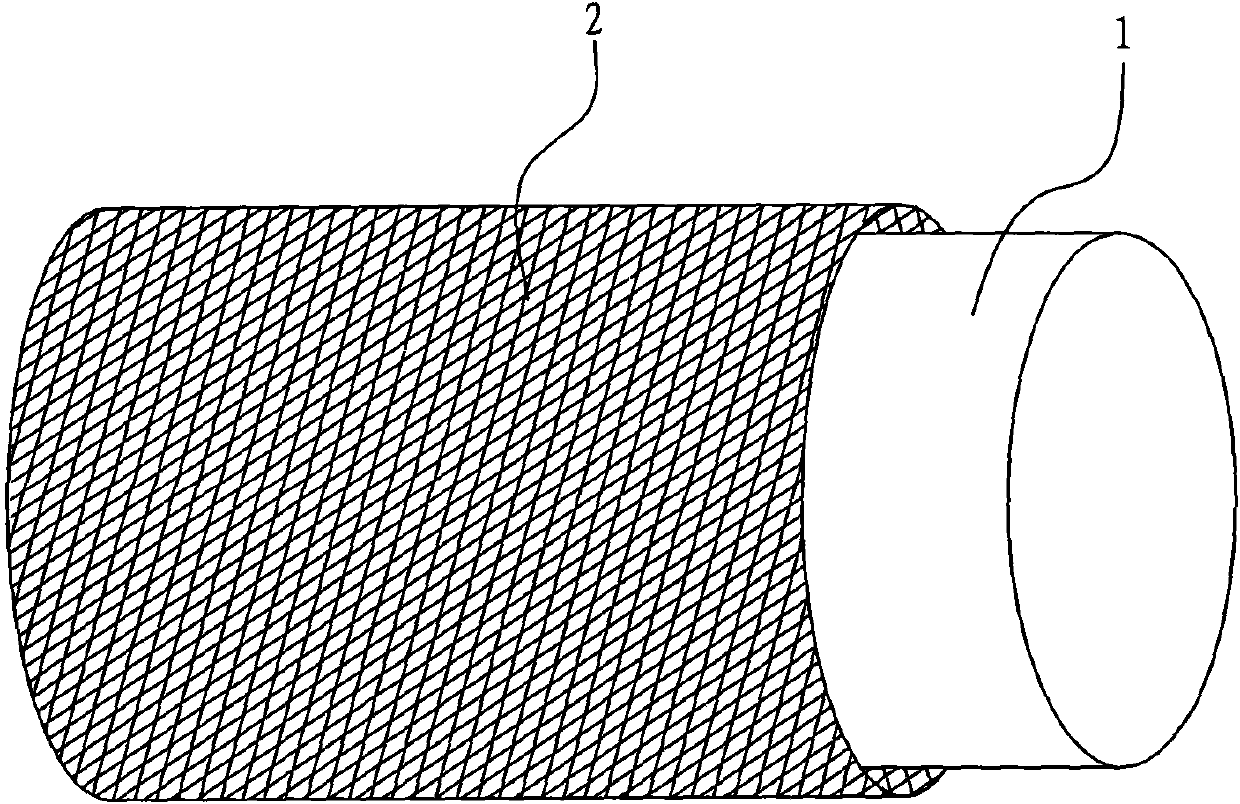

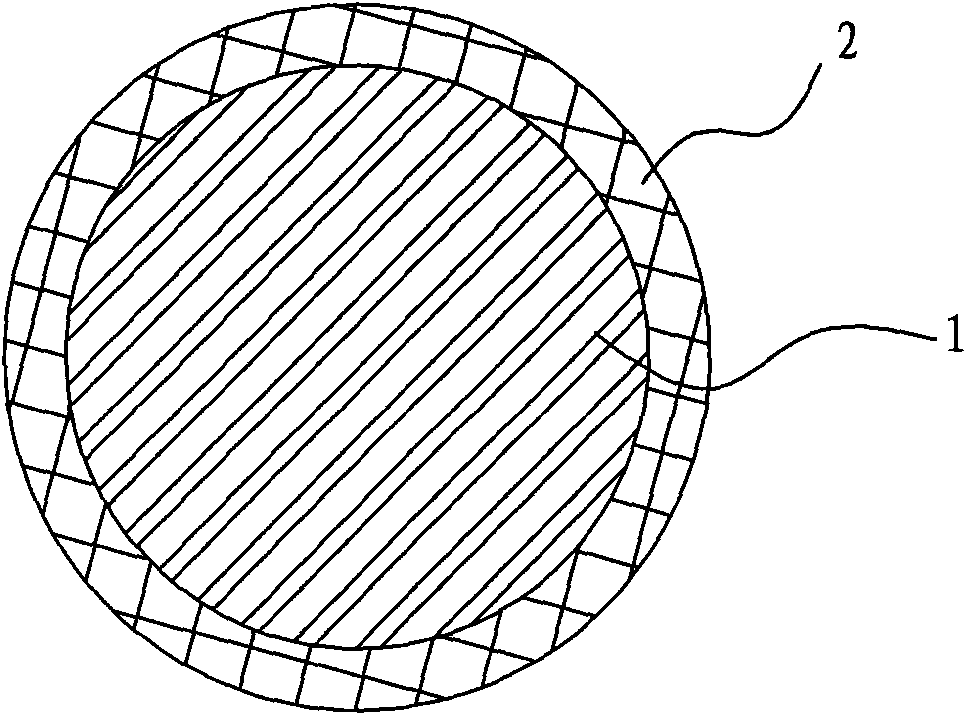

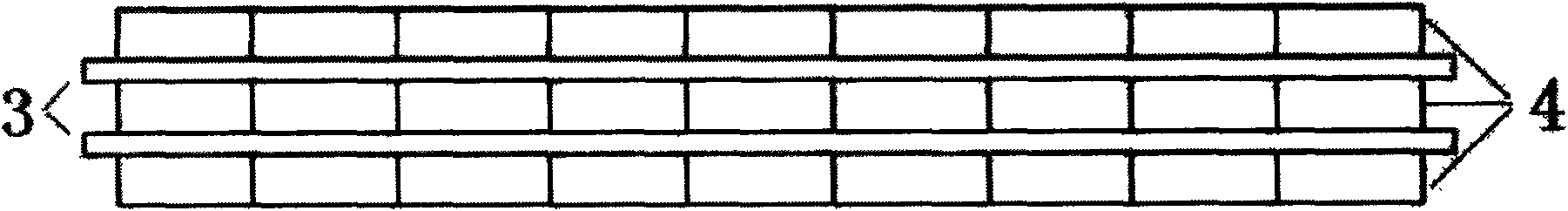

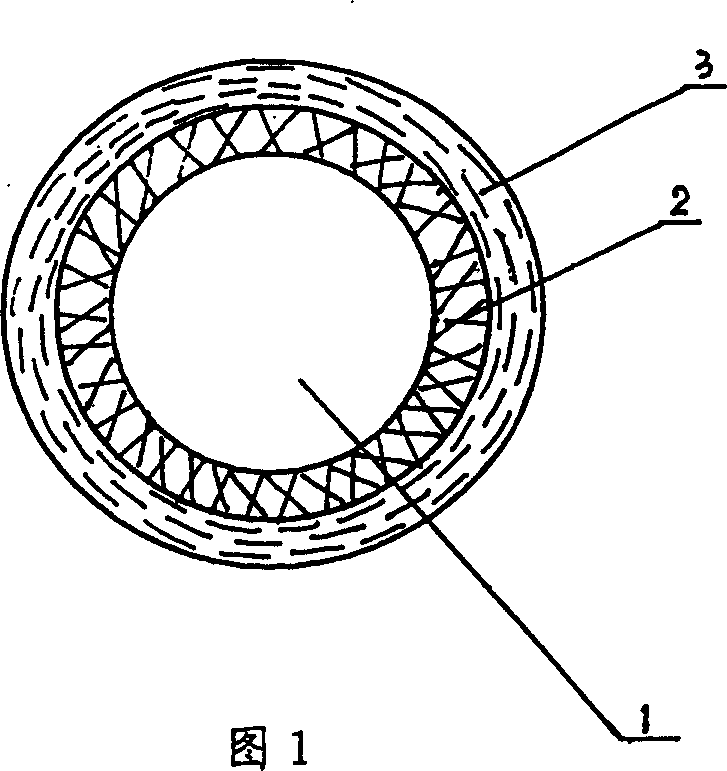

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517AImprove lateral strengthImprove fatigue resistance and fatigue resistanceInsulated cablesCable/conductor manufactureElectrical conductorFiber bundle

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. As the fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

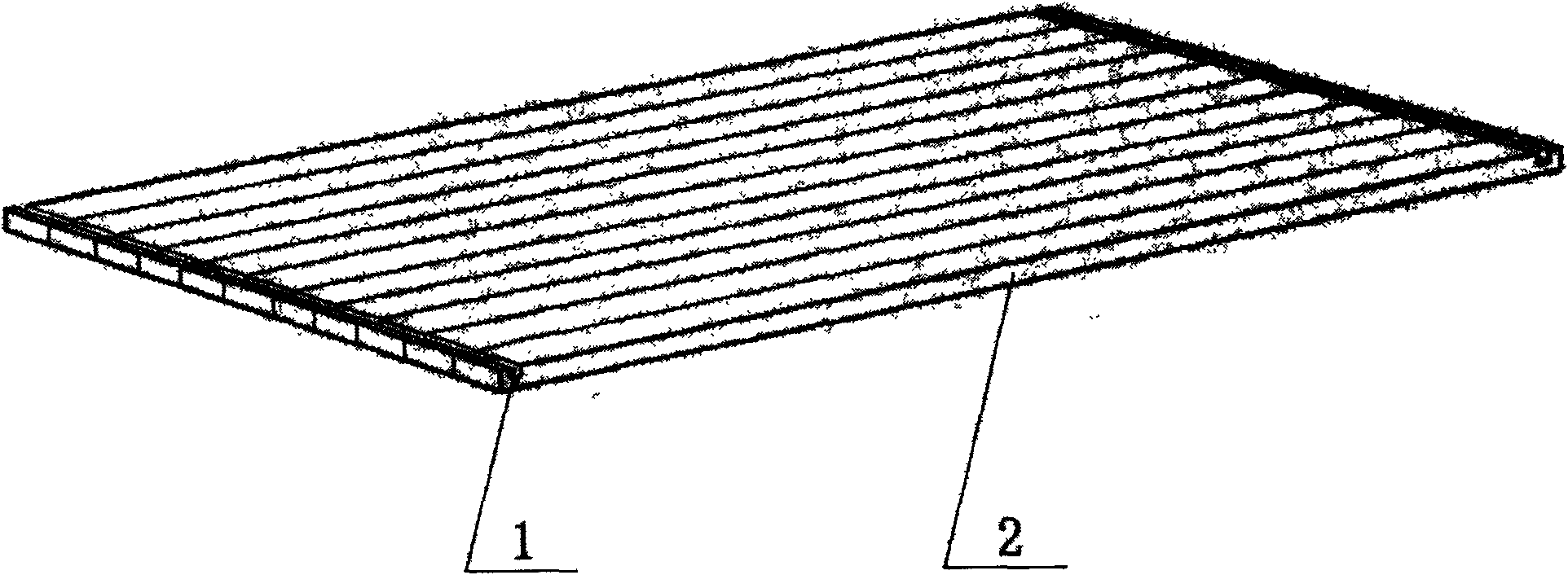

Short-fiber-reinforced pultrusion composite material solar energy assembly frame and preparation method thereof

ActiveCN104761880AImprove efficiencyImprove lateral strengthPhotovoltaicsPhotovoltaic energy generationUltimate tensile strengthFiber orientation

The invention discloses a short-fiber-reinforced pultrusion composite material solar energy assembly frame, which is characterized by being produced through a pultrusion method and being composed of following components, by volume: 5-10% of short fibers, 50-80% of continuous fibers and 10-40% of resin. The invention also discloses a preparation method of the solar energy assembly frame. In the method, a short fiber reinforcement body is added for solving a problem of insufficient strength in the vertical direction of the fiber when a continuous reinforced pultrusion composite material is used as the solar energy assembly frame. The continuous fiber is impregnated in the resin mixture, in which 5-10% by volume of the short fibers is dispersed homogeneously, and then the impregnated continuous fiber is injected into a die for obtain the solar energy assembly frame through pultrusion. The short fibers can form an overlap joint structure among the continuous fiber so that the performance in the vertical direction of the fibers in the material can be improved. Not only is the excellent performance in the direction in parallel with the fibers ensured, but also an excellent mechanical performance in the vertical direction of the fibers can be ensured at the same time.

Owner:哈尔滨生材新材料科技发展有限公司

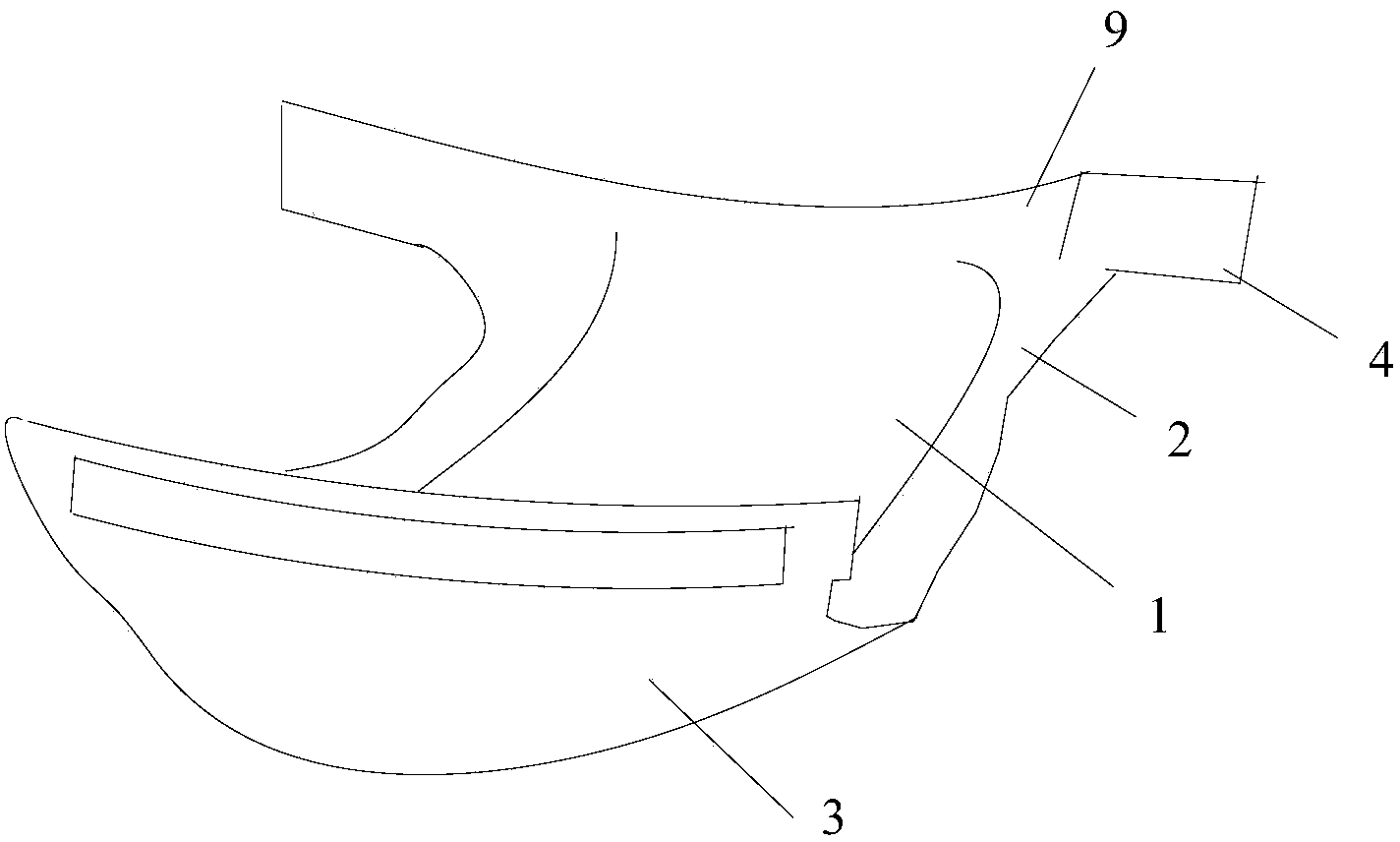

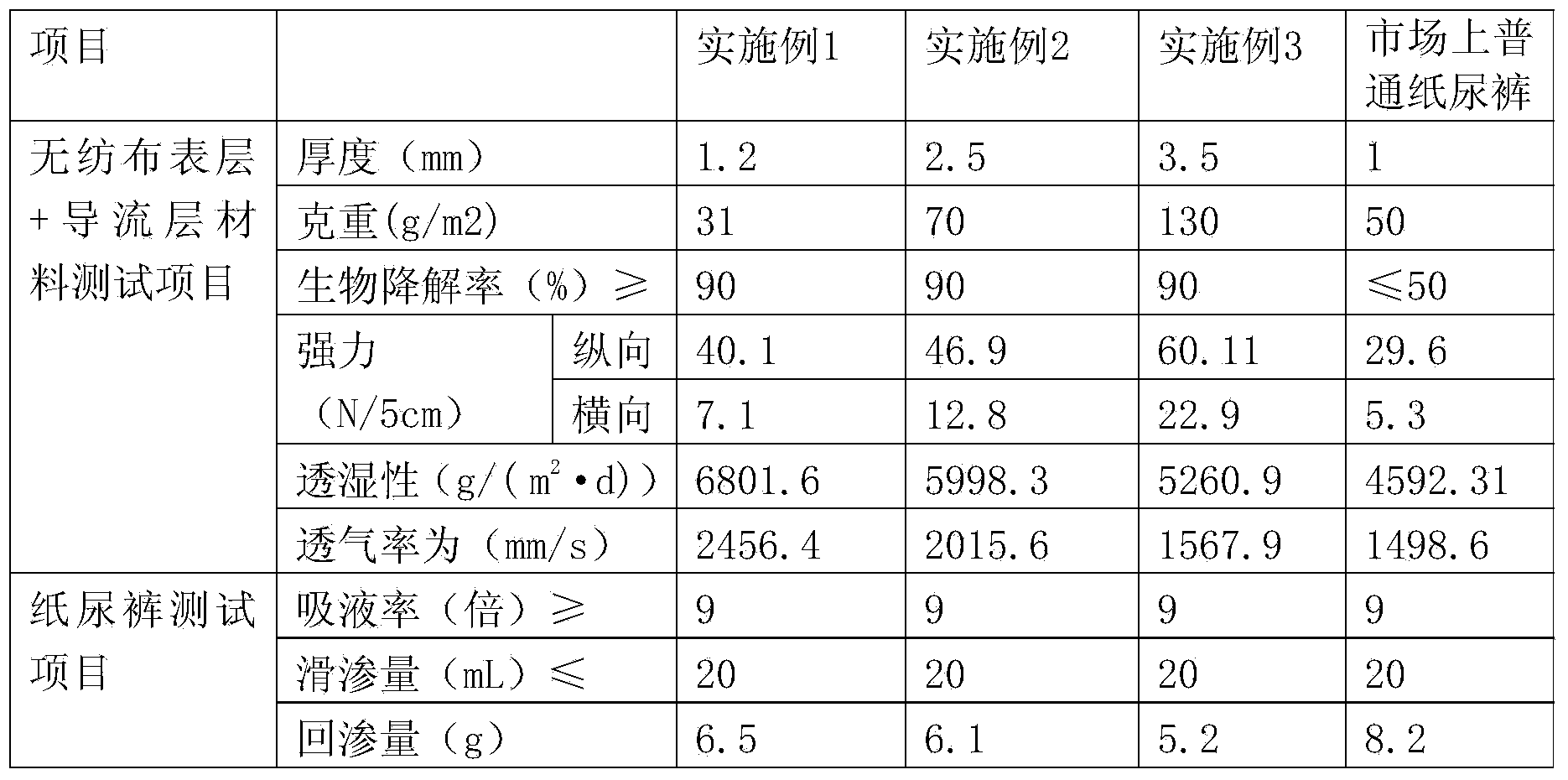

PLA (polylactic acid) non-woven fabric diaper with high breathability and preparation method thereof

ActiveCN104138310AImprove breathabilityGood moisture managementAbsorbent padsNon-woven fabricsSurface layerEngineering

The invention discloses a PLA (polylactic acid) non-woven fabric diaper with high breathability. The PLA non-woven fabric diaper comprises a surface material, a water absorption core layer and a bottom membrane from inside to outside, wherein the surface material adopts a three-layer structure consisting of an upper layer, a middle layer and a lower layer, PLA short fiber webs are arranged on the upper layer and the lower layer, PLA long fiber non-woven fabric is arranged on the middle layer, and guide holes with pore diameters of 10-30 meshes are distributed on the PLA long fiber non-woven fabric. According to the diaper with the high breathability, upper-layer PLA short fiber non-woven fabric in three-layer PLA fiber webs is adopted as a surface layer, lower-layer PLA short fiber non-woven fabric is adopted as a guide layer, middle PLA filament non-woven fabric is adopts as an isolated layer, the three layers are bonded into integral non-woven fabric in a hot melting compound manner, the method for compounding the guide layer and the non-woven fabric on the surface layer through glue spraying in the production process of conventional diapers is not required, and the breathability between the surface layer and the non-woven fabric on the guide layer is greatly improved.

Owner:马鞍山同杰良生物材料有限公司

Preparing composite of modifing glass fiber reinforced plastics pultrusion section bar and preparation method thereof

The invention is a combination for preparing modified glass fibre reinforced plastic pull-extrude (GFRP) sectionbar including unsaturated polyester resin 92.6-64 (wt.%), nano silicon dioxide 0.5-4, calcium carbonate 5-20, benzoyl peroxide 0.2-2, methyl ketone peroxide 0.2-2, demoulding agent 0.5-2 and mill base 1-6. Batching in the above weight percents, selecting a ultrasonic wave dispersive apparatus to fully disperse the nano silicon dioxide in 2Kg resin; dispersing and blending, where the glue soluting temperature is controlled at 30 plus or minus 2 deg.C and the fully blending and dispersing time is 1 hour; adding in other additives in proportion in turn, fully blending until the mixture is uniform and meets the preset viscosity number; prepring structural sections: pouring the well-prepared glue soluting in a presoaking glue tank and keep constant temperature at 25 plus or minus 2 deg.C; placing the glass yarn felts ccording to a sectionbar perform guiding device to enter in the glue tank for fully soaking with the glue; making the yarn felts soaked with resin glue soluting enter in a well-heated mould for solidification moulding, and pulling into products by a hydraulic drag device, and at last cutting for fixed size.

Owner:天津市金锚科技发展有限公司

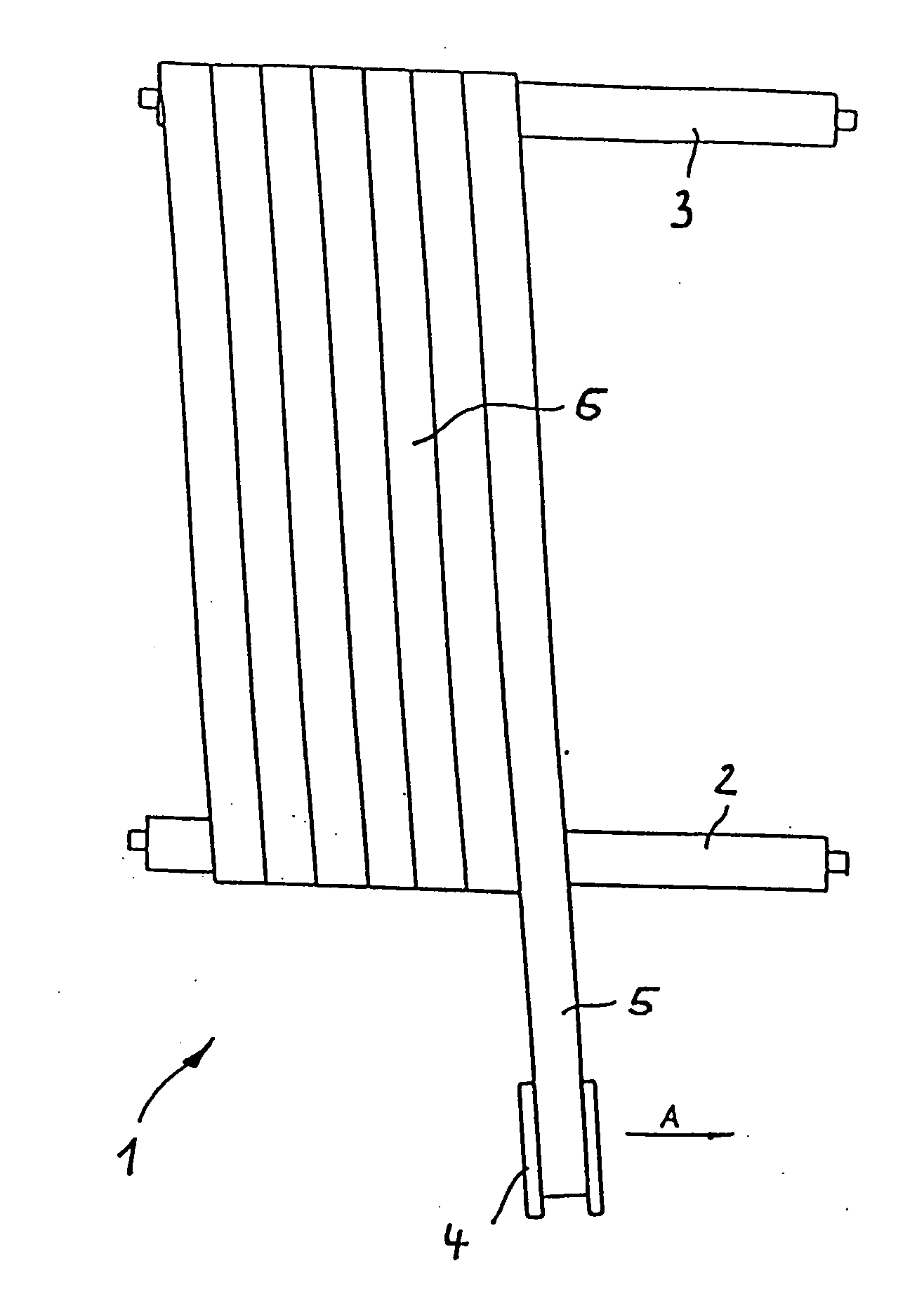

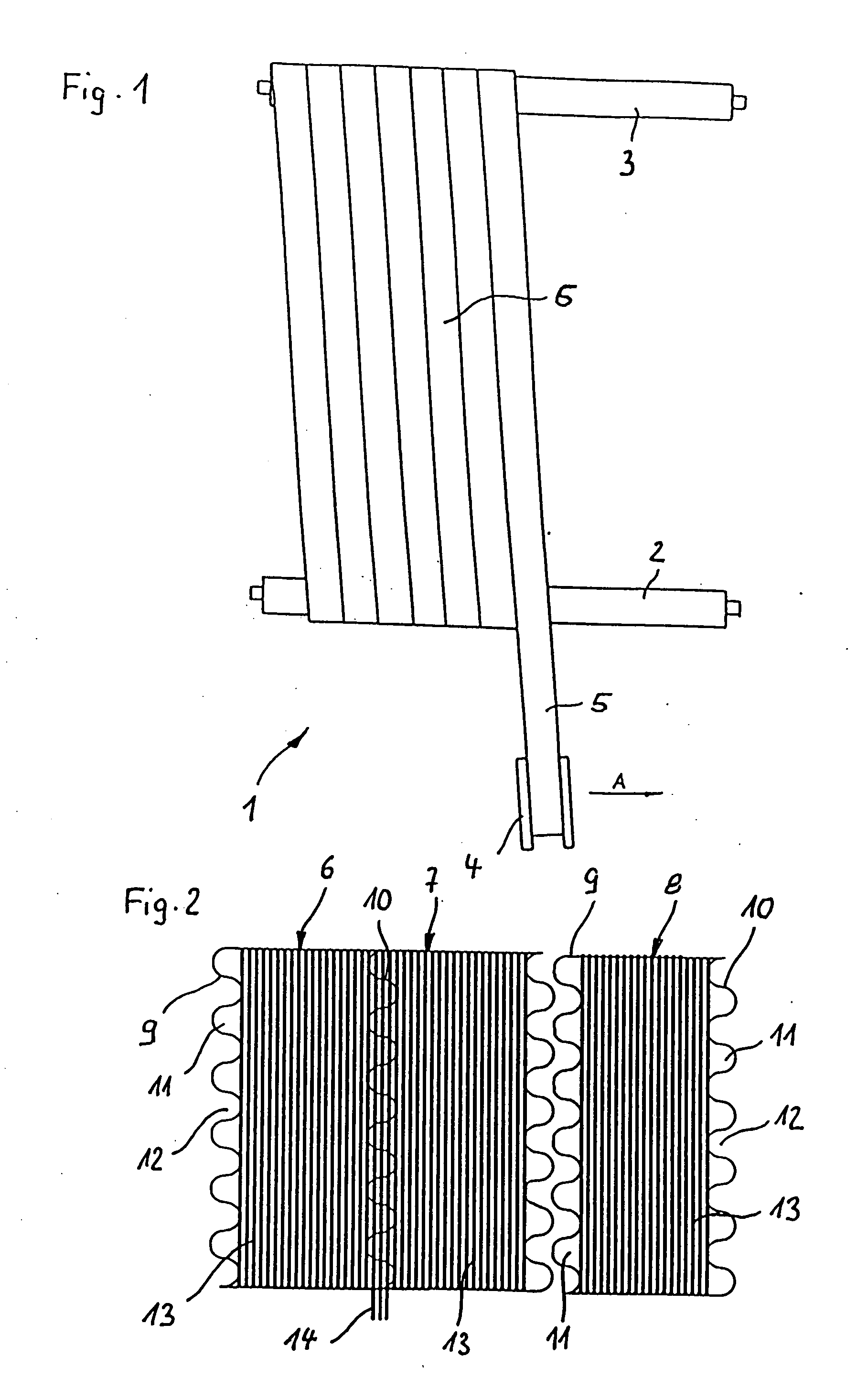

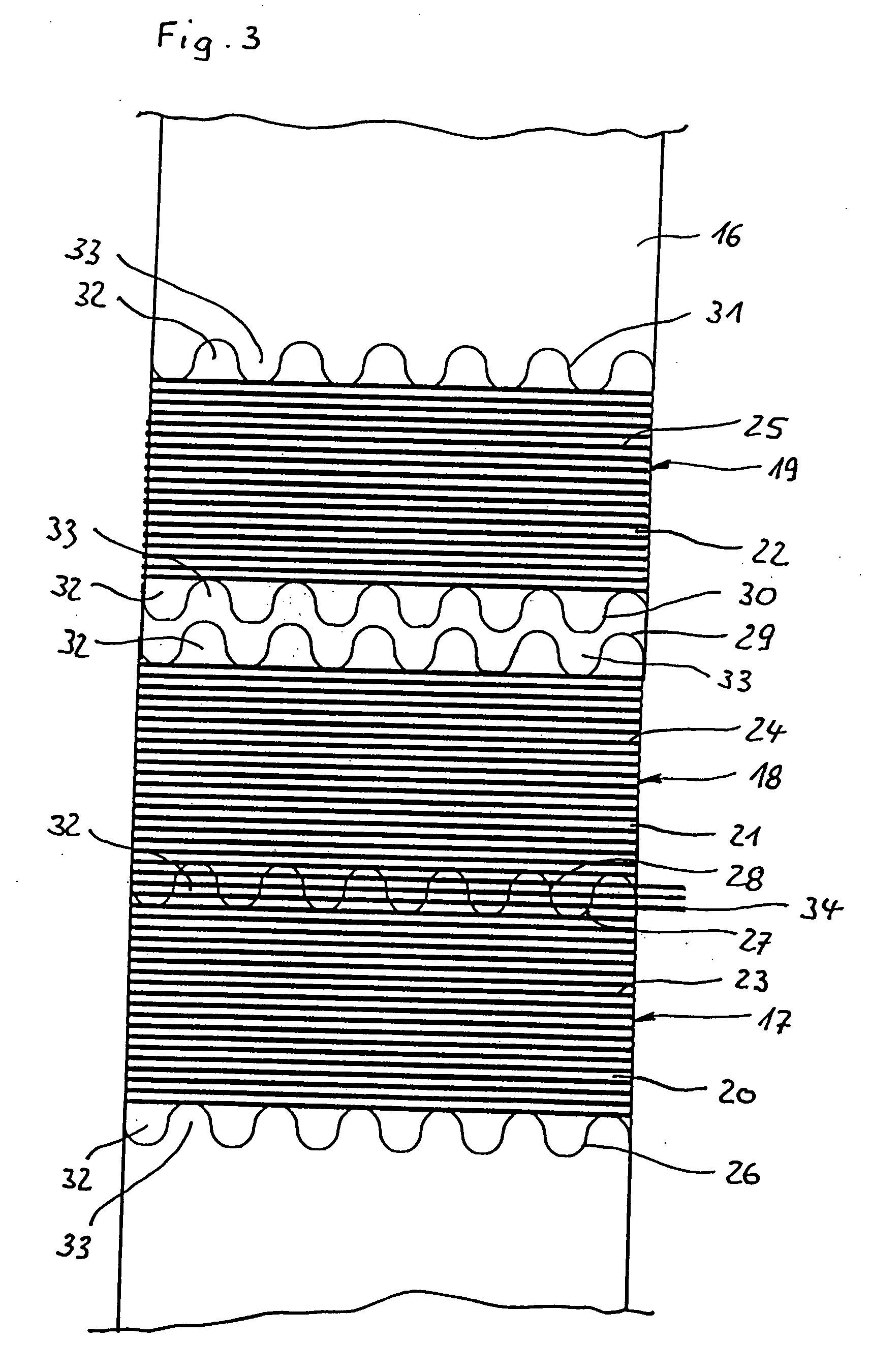

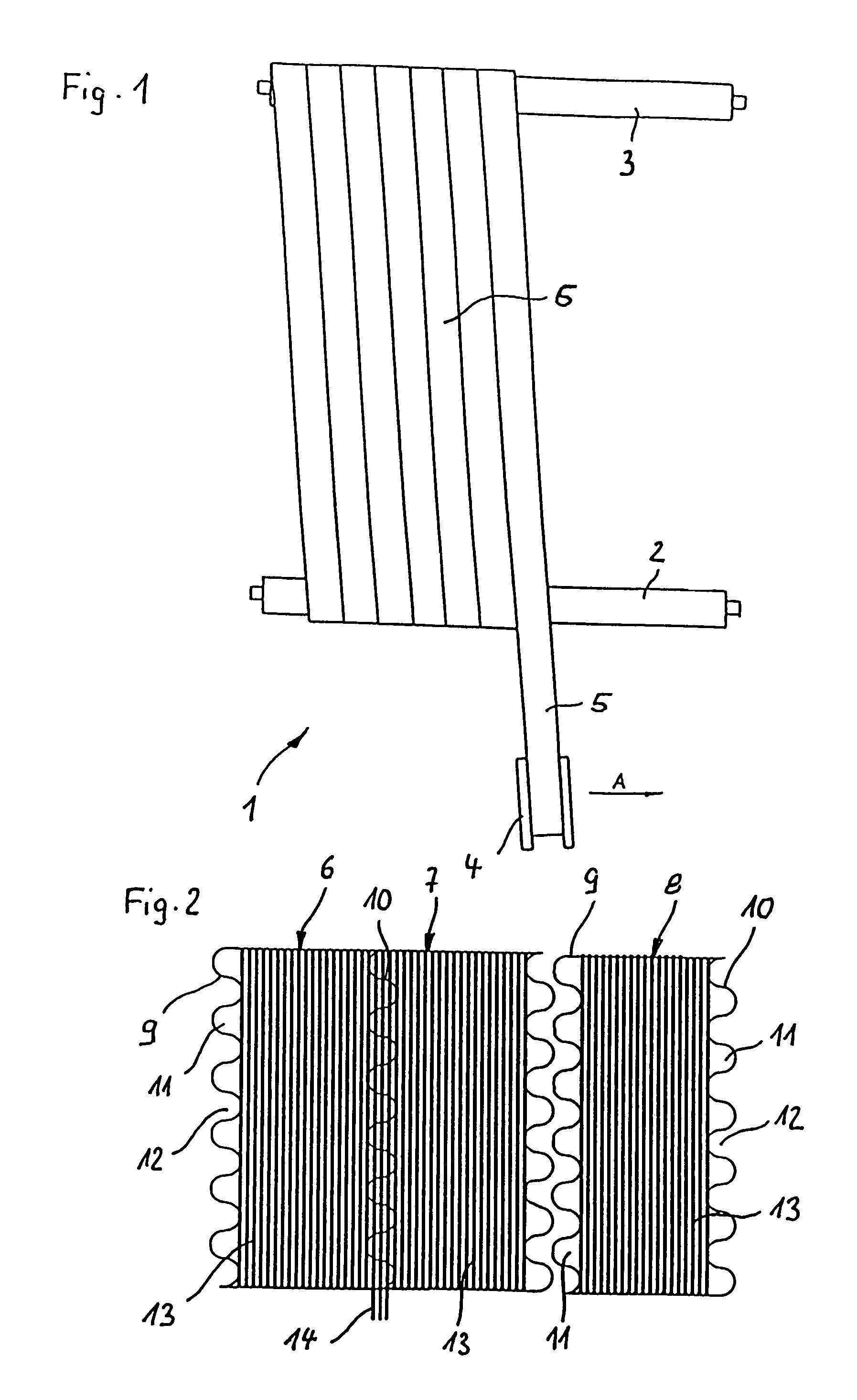

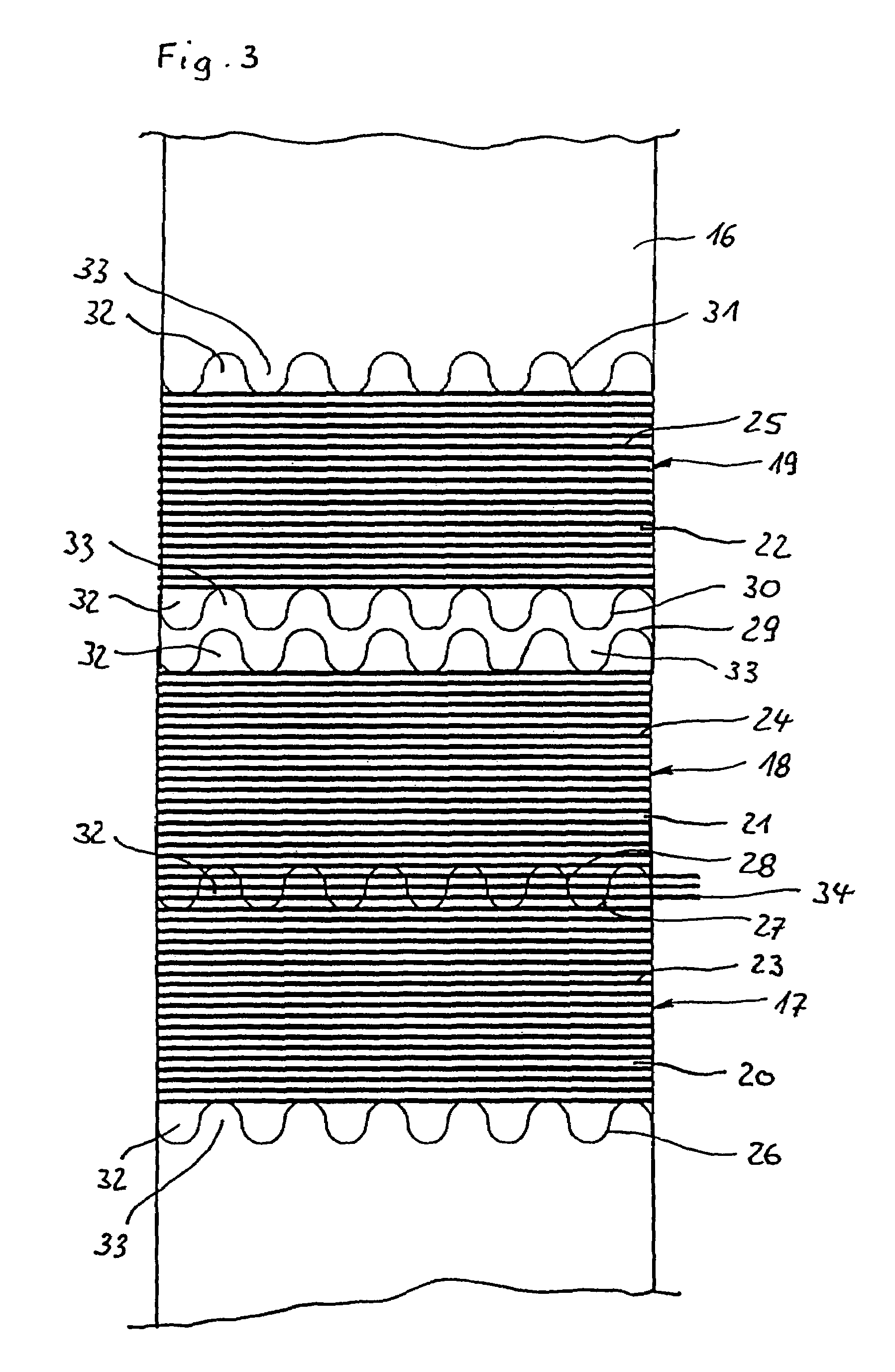

Method for manufacturing a felt belt, and felt belt

ActiveUS20070235155A1Economical fashionImprove lateral strengthLamination ancillary operationsCellulosic plastic layered productsYarnFiber matrix

The invention is a method for manufacturing a felt belt having a support which is embedded in a fiber matrix and is made up of at least two yarn layers arranged one above another, at least one is a longitudinal yarn layer made up of longitudinal yarns extending in parallel fashion, and at least one is a transverse yarn layer made up of transverse yarns extending in parallel fashion, transverse yarns being present that are continuous over the width of the felt belt. For each longitudinal yarn layer, a first support module is manufactured, by means of a first auxiliary support web, at a width that is less than the width of the completed felt belt, the first auxiliary support web being wound in helical fashion, before, during, or after the application of yarns, to a width that corresponds to the width necessary for manufacture of the completed felt belt.

Owner:HEIMBACH GMBH & CO KG

Oriented polymer reeds for musical instruments

InactiveUS6087571AHigh strengthImprove lateral strengthWind musical instrumentsEngineeringPolypropylene

A synthetic reed for use in reed-blown wind instruments such as the clarinets, saxophones, oboes and bassoons may be made from an oriented thermoplastic material such as uniaxially or biaxially oriented polypropylene. The reed may be machined from an oriented-polymer blank which in turn has been cut or stamped from an oriented-polymer sheet of the appropriate thickness.

Owner:LEGERE REEDS

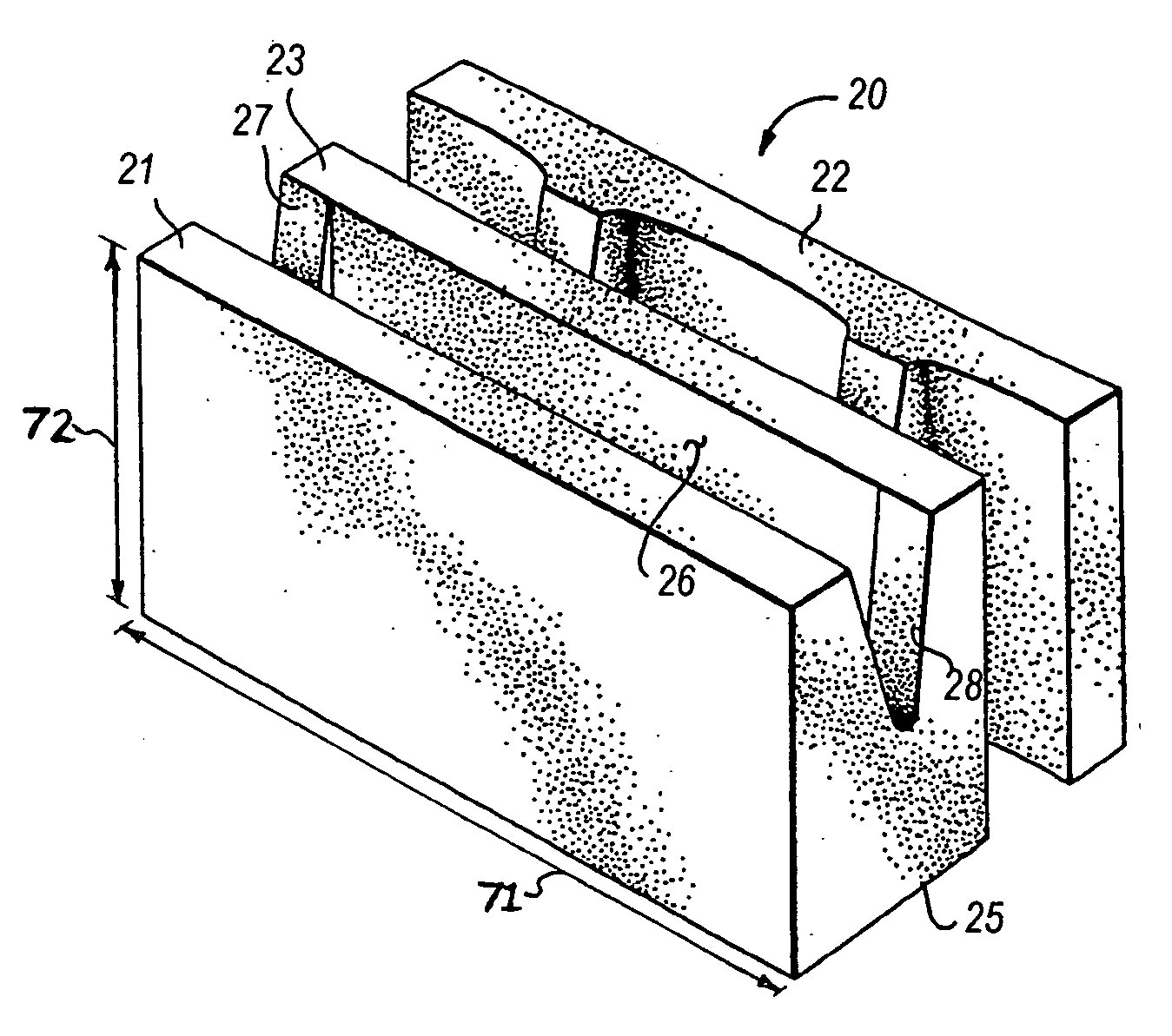

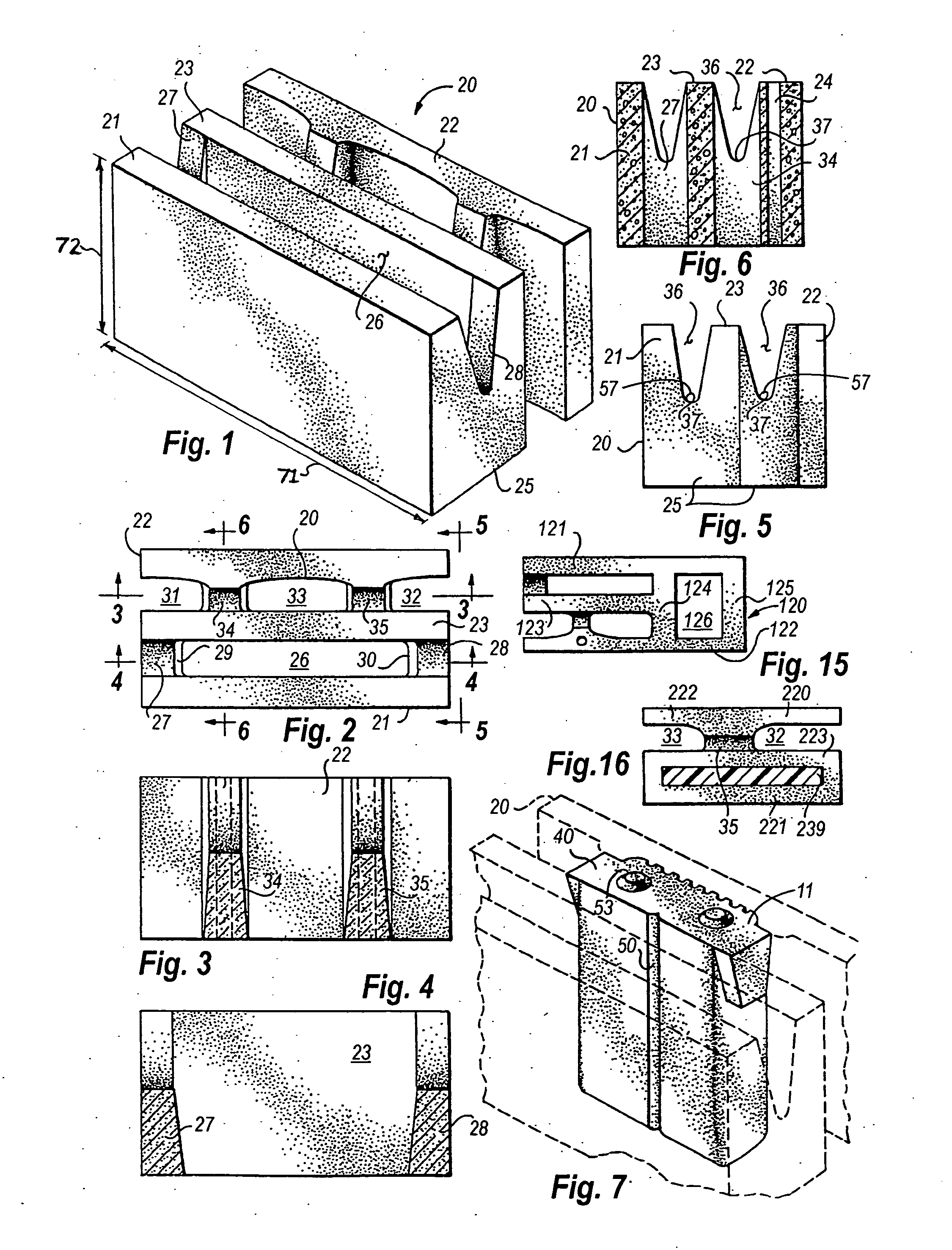

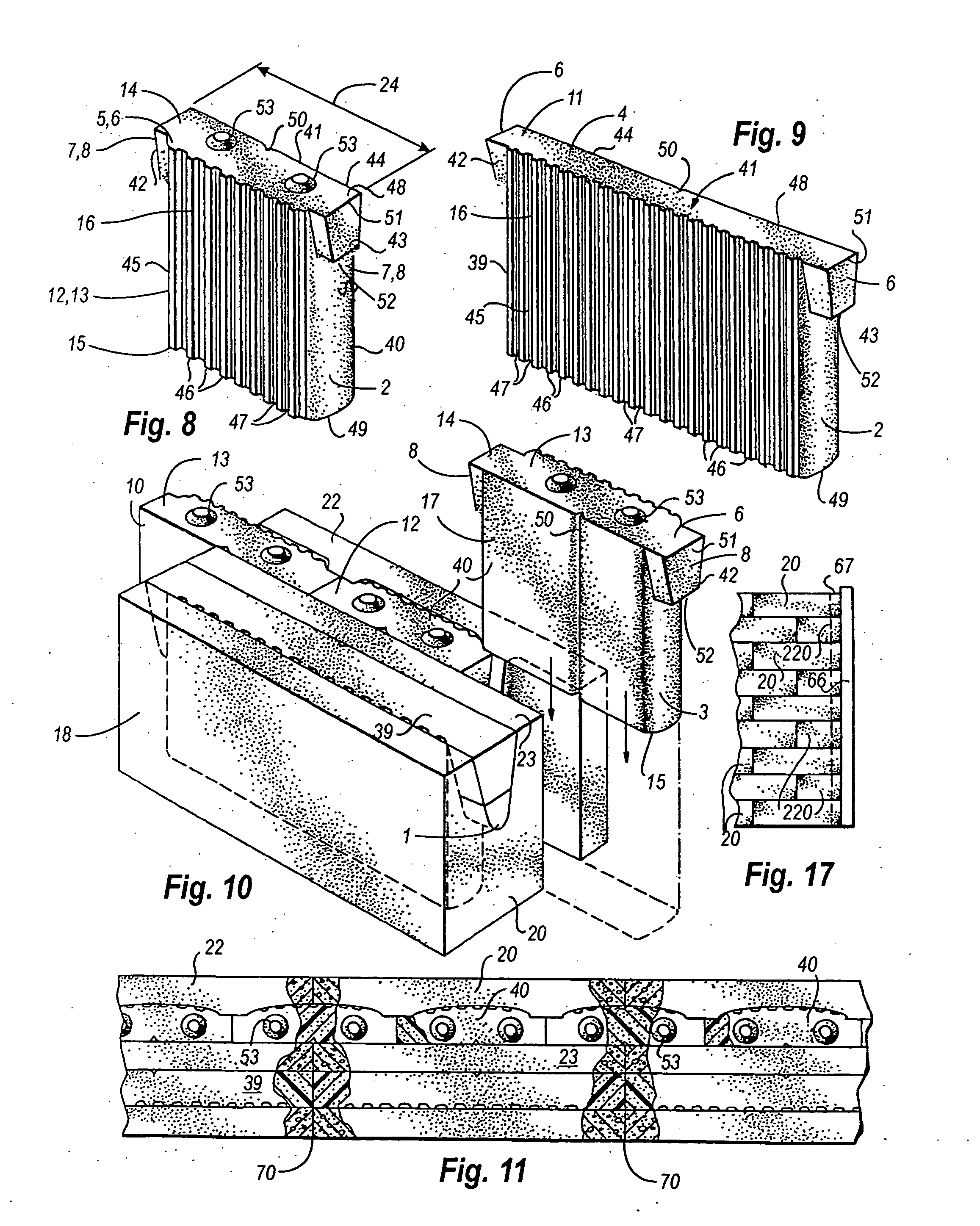

Dry stack insulated building blocks

InactiveUS20080060300A1Improve lateral strengthIncreased shear strengthConstruction materialWallsEngineering

An improved dry stack insulated building block and block wall system, the block having a first and a second side wall, a central web interposed between the side walls, a pair of end transverse webs, and a pair of intermediate transverse webs. The side walls, central web, and transverse webs define a first, a second, and a third cell. A first cell core, second cell core, and a pair of third cell cores of insulative material are inserted in the respective cells. The cell cores have trapezoidal shaped ear members which matingly fit in notches in the transverse webs, the trapezoidal shaped ear members providing for the creation of a notch gap between the base of the ear members and the notch bottom of the respective notches, thereby accommodating crumbing in the notch bottom.

Owner:BRISTOL SYST INT

Lithium ion battery diaphragm and its production method

InactiveCN1514501AHigh crystallization conversion rateLow priceCell component detailsPorosityElectrical battery

Characters of the invention are that crystal-nucleating agent of amide family compound is added into polyolefine resin. The procedure of the method includes following steps. (1) Under computer full control, hoisting system adds polyolefine resin containing 0.001-3% crystal-nucleating agent to extruder. In temperature 130-280 deg.C, the material is melted and extruded out. Then, primal flat film is rolled and obtained by using cooling roller to treat the material at temperature 40-110 deg.C. (2) The said primal flat film is fed into vertical and horizontal biaxial stretcher for stretch formability. Finally, heat customization is carried out. The selected crystal-nucleating agent possesses high crystal transformation ratio, and abundant source. Battery diaphragm provides features of high porosity, shapely hole shape, good intensity in both directions, and low cost. The invention can be applied to lithium cell, secondary cell or other type batteries after hydrophilic treatment.

Owner:XINXIANG ZHONGKE SCI&TECH

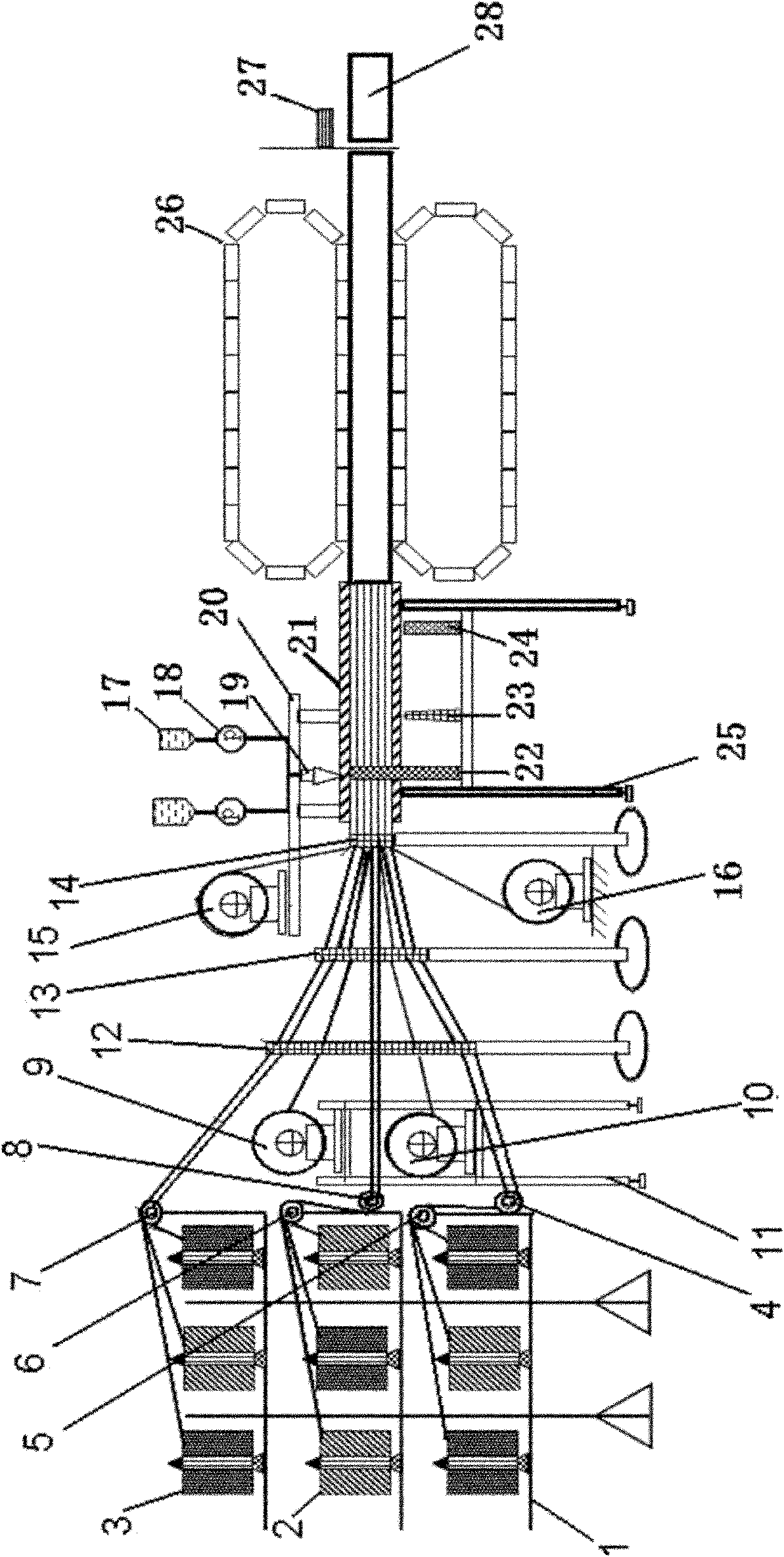

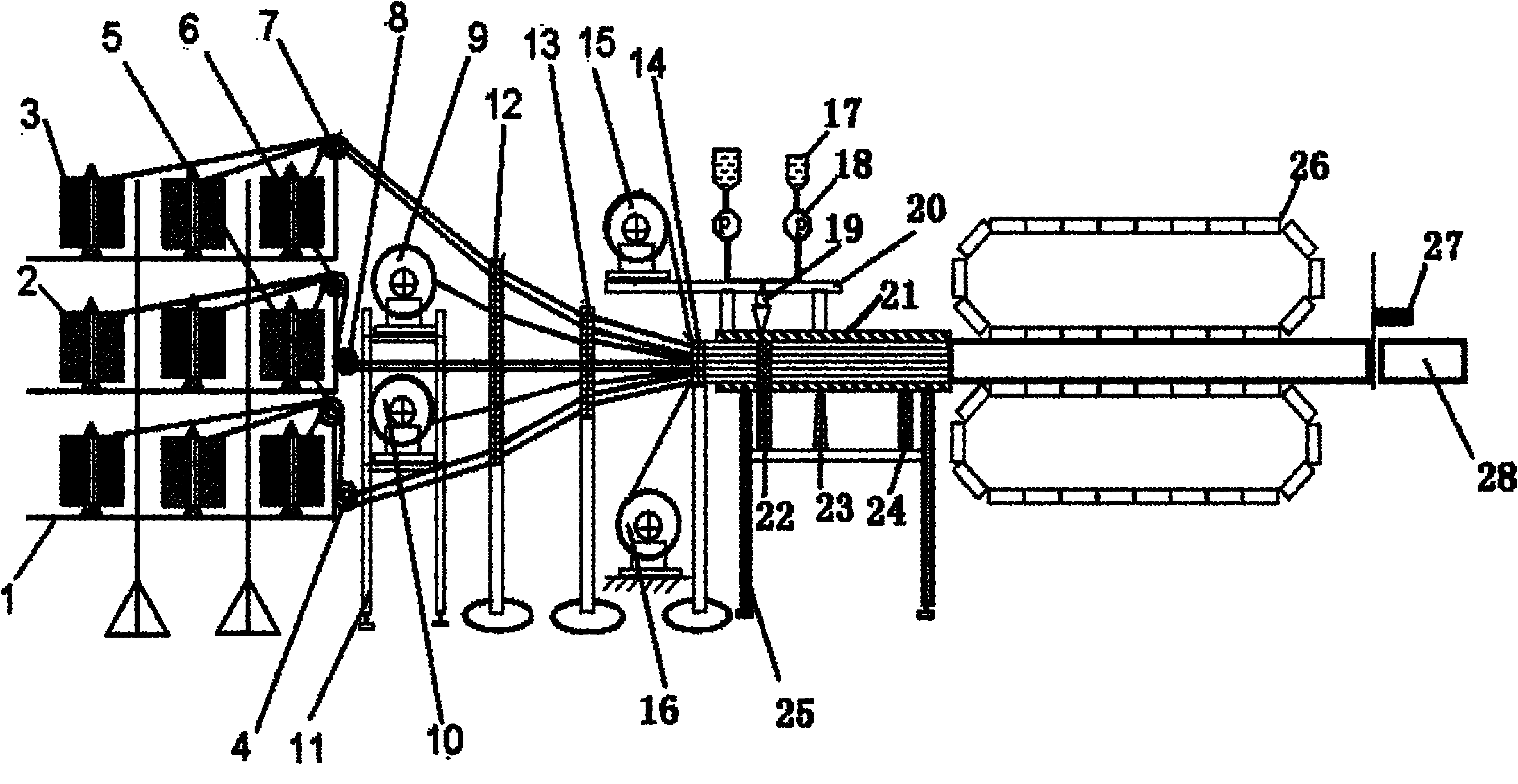

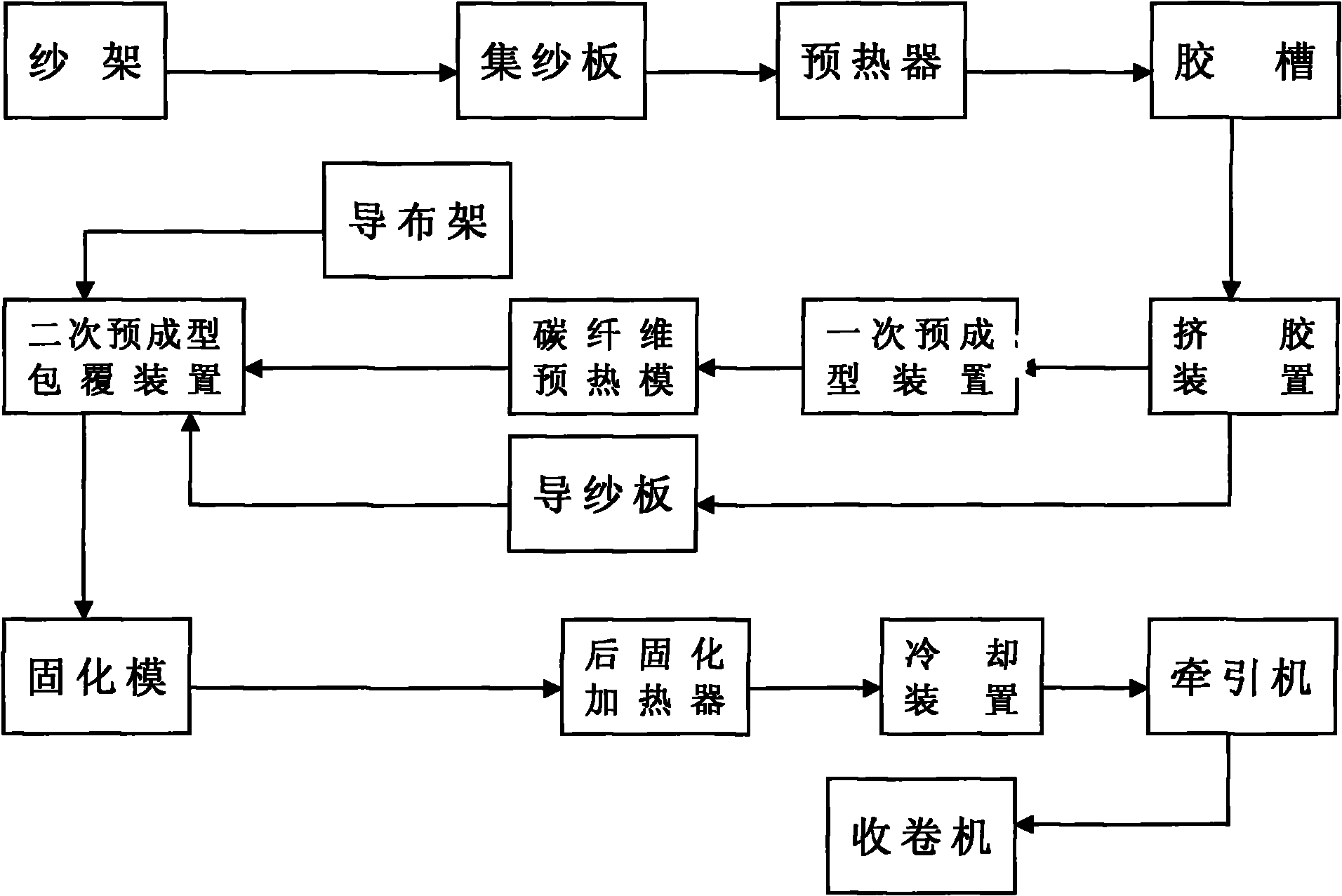

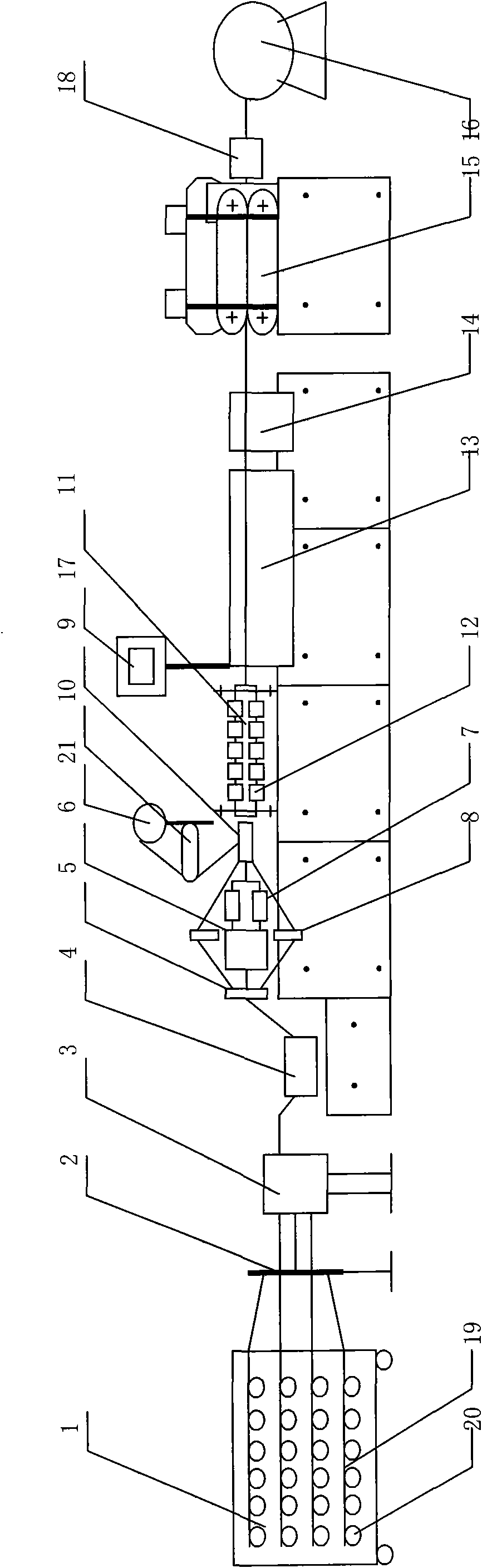

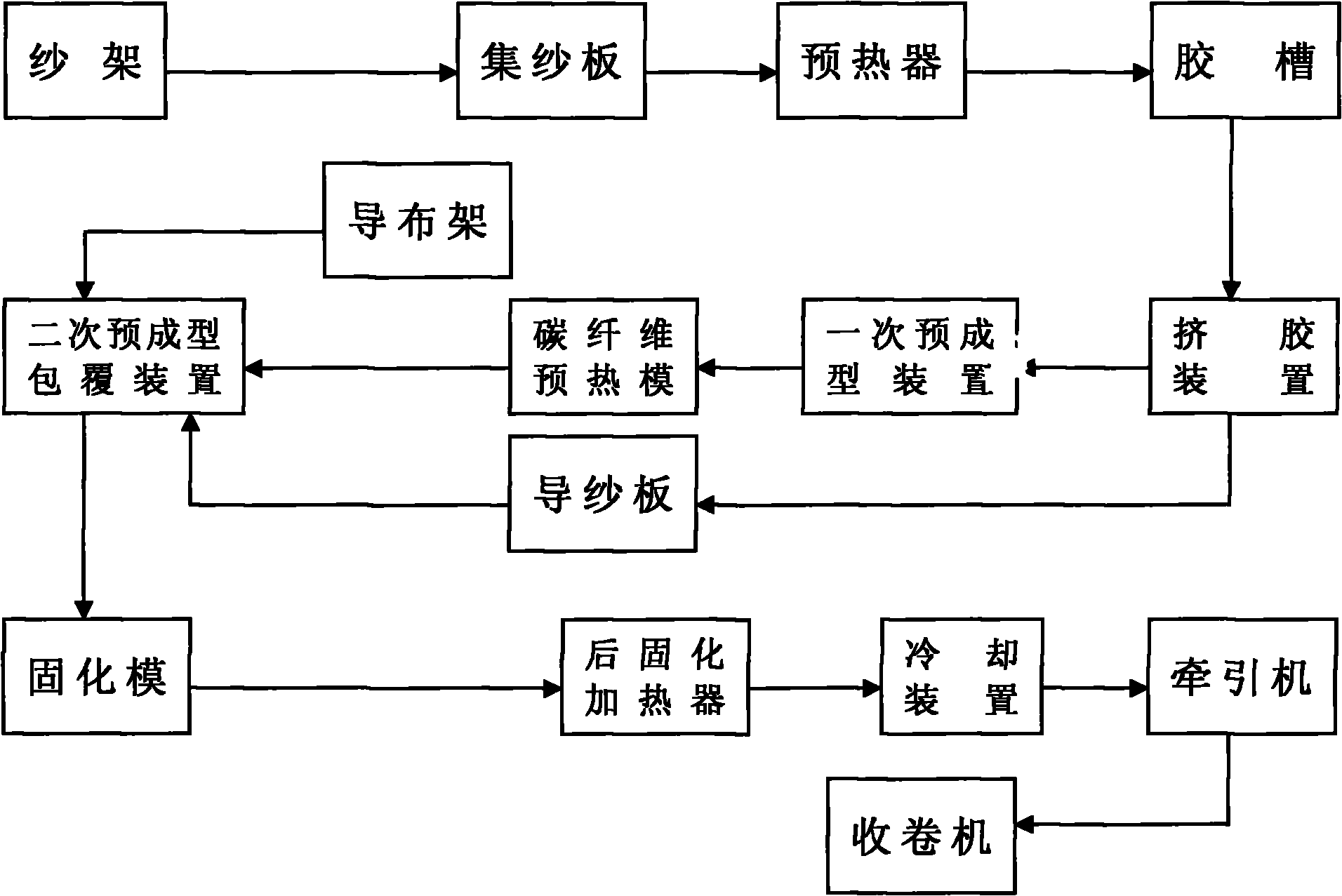

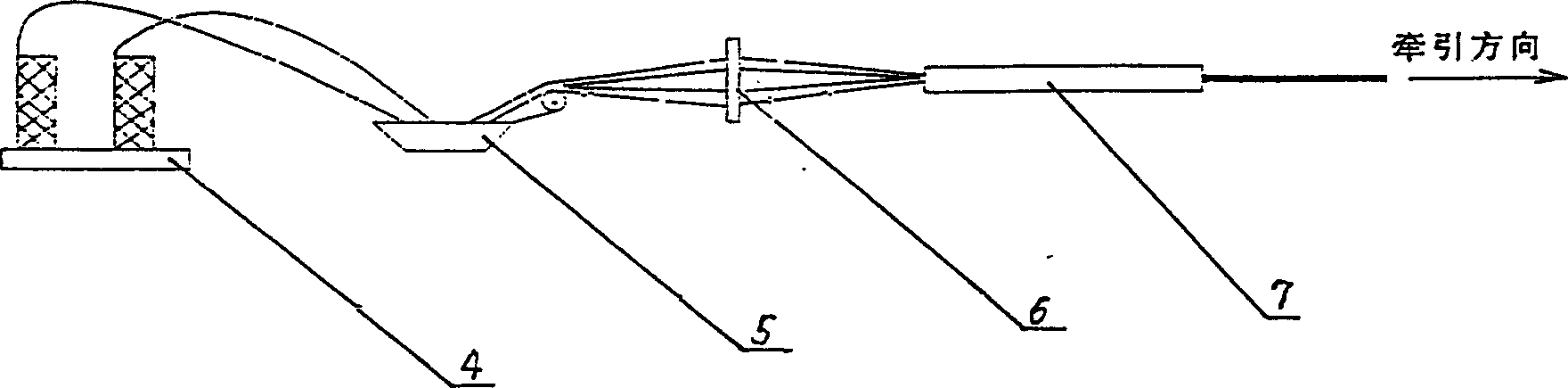

System and process for manufacturing carbon fiber composite core of electric transmission line

InactiveCN102039681AQuality improvementSolve the difficult problem of pultrusionFiberWinding machine

The invention relates to a system and process for manufacturing a carbon fiber composite core of an electric transmission line. The invention is characterized in that the system comprises a yarn frame, a yarn-collecting board, a preheater, a double-roller constant-temperature replaceable glue tank, a glue-squeezing device, a primary preforming device, a carbon fiber preheating mold, a secondary preforming and coating device, a curing mold, a postheating oven, an air cooling device, a tractor and a winding machine which are sequentially connected, wherein a cloth guide frame is mounted above the secondary preforming and coating device, the carbon fiber preheating mold and the curing mold are respectively sheathed with a heater, and both sides of the carbon fiber preheating mold are provided with glass fiber yarn guide boards. In the preparation method provided by the invention, repeated experiments are carried out on the high-performance resin system, and the outermost layer is coated with the glass fiber cloth by fully considering characteristics of carbon fibers and high-strength glass fibers, thereby enhancing the transverse strength of the product, improving the cracking resistance of the product and realizing the feasibility of the process. Thus, the invention solves the problem that high-performance resin is difficult to pultrude.

Owner:西安联瑞科技实业有限责任公司

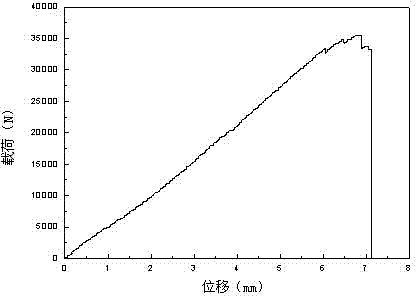

High-puncture-strength lithium ion battery diaphragm and preparation method thereof

InactiveCN103633273AImprove lateral strengthImprove puncture strengthCell seperators/membranes/diaphragms/spacersSecondary cellsLithium dendriteLithium electrode

The invention relates to the processing field of lithium ion battery diaphragms and discloses a high-puncture-strength lithium ion battery diaphragm. The high-puncture-strength lithium ion battery diaphragm consists of 75 to 99.9 weight percent of main body olefin resin and 25 to 0.1 weight percent of an auxiliary additive. The invention further discloses a method for preparing the high-puncture-strength lithium ion battery diaphragm, which comprises the following step: carrying out transverse stretching on a micropore diaphragm which is longitudinally stretched, wherein the traveling speed of the micropore diaphragm is 0.5 to 200 mm / min, the stretch temperature is 100 to 150 DEG C and the stretching multiplying power is 0.5 to 3.0. According to the invention, one step of transversely stretching is added on the basis of one-way stretching in an existing dry method; and by transverse stretching according to a certain ratio, under the condition of not influencing basic performance of the micropore diaphragm (air permeability, porosity and the like), the transverse intensity of the micropore diaphragm is improved, i.e. the puncture-resistant intensity of the micropore diaphragm is improved, so that the diaphragm can be better suitable for assembling of a battery, the micro short circuit problem caused by lithium dendrite puncture is reduced or avoided and safety of the battery is improved.

Owner:SHENZHEN SENIOR TECH MATERIAL

Method for manufacturing a felt belt, and felt belt

ActiveUS7722743B2Economical fashionImprove lateral strengthLamination ancillary operationsCellulosic plastic layered productsYarnFiber matrix

The invention is a method for manufacturing a felt belt having a support which is embedded in a fiber matrix and is made up of at least two yarn layers arranged one above another, at least one is a longitudinal yarn layer made up of longitudinal yarns extending in parallel fashion, and at least one is a transverse yarn layer made up of transverse yarns extending in parallel fashion, transverse yarns being present that are continuous over the width of the felt belt. For each longitudinal yarn layer, a first support module is manufactured, by means of a first auxiliary support web, at a width that is less than the width of the completed felt belt, the first auxiliary support web being wound in helical fashion, before, during, or after the application of yarns, to a width that corresponds to the width necessary for manufacture of the completed felt belt.

Owner:HEIMBACH GMBH & CO KG

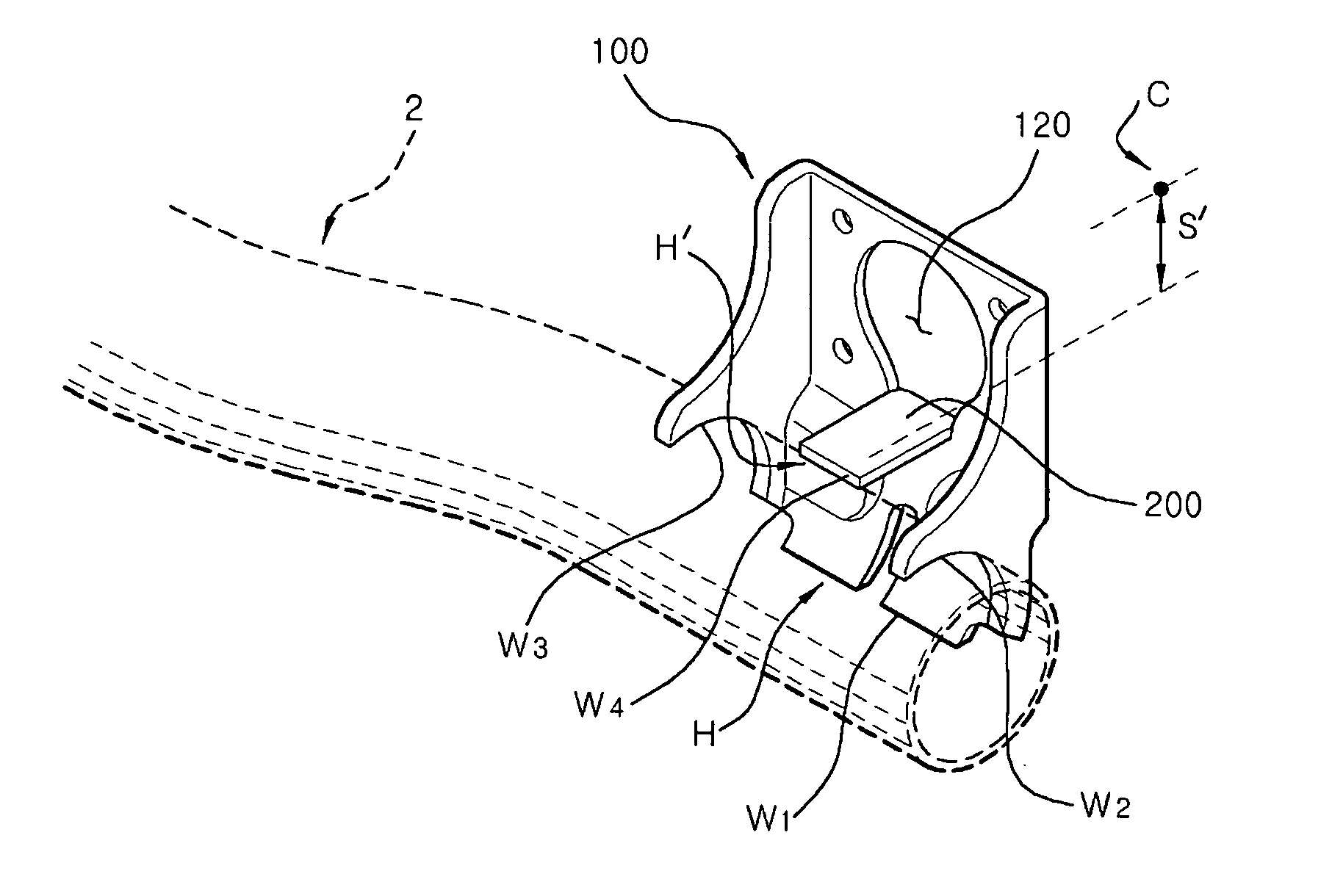

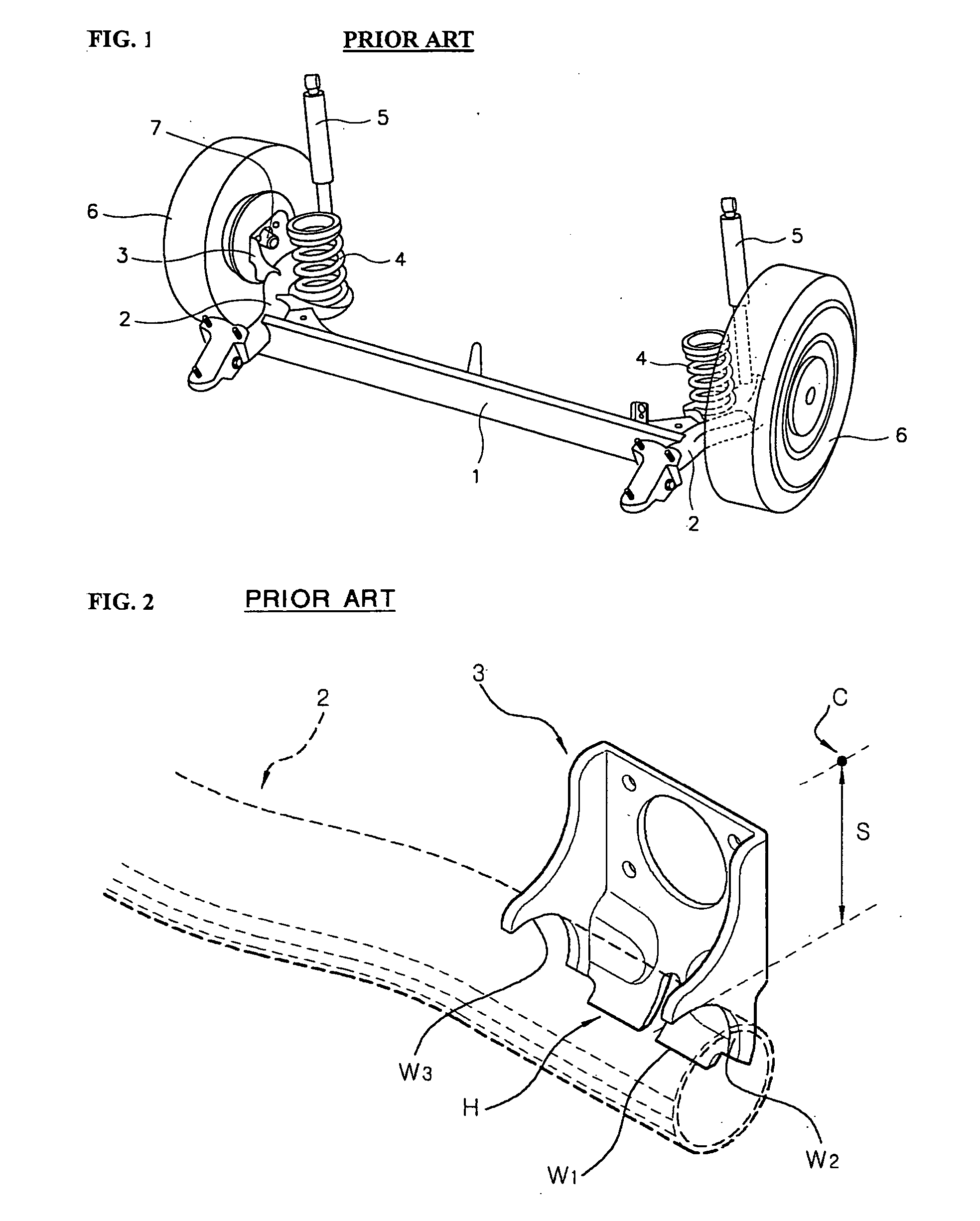

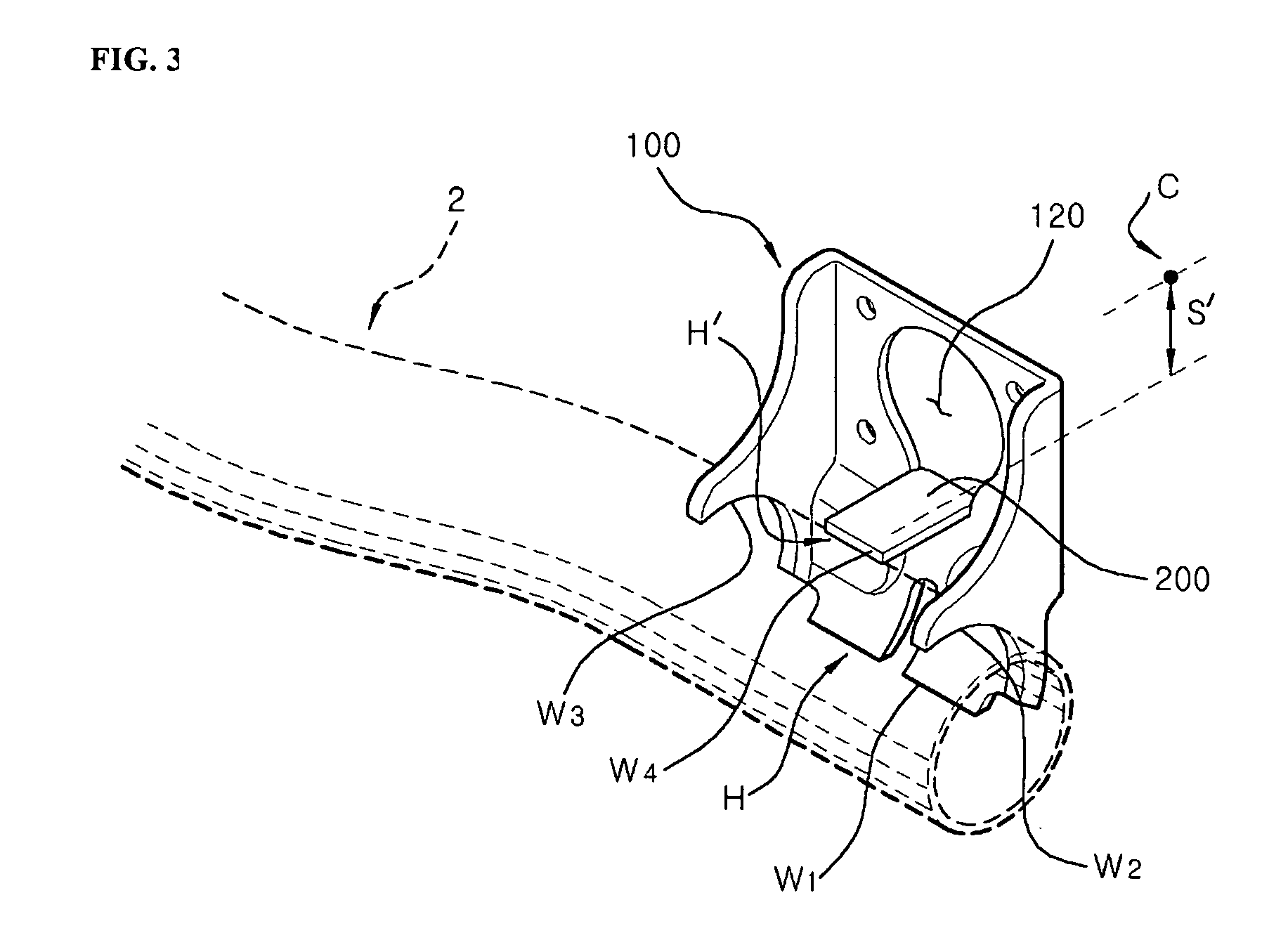

Spindle bracket for rear suspension

InactiveUS20060033303A1Increase the number ofReduce spanSteering linkagesInterconnection systemsTrailing armMechanical engineering

A spindle bracket for rear suspensions includes a bracket body welded to a trailing arm and having a mounting hole into which a spindle is inserted, and a lateral strength reinforcing piece secured between the trailing arm and the bracket body.

Owner:HYUNDAI MOBIS CO LTD

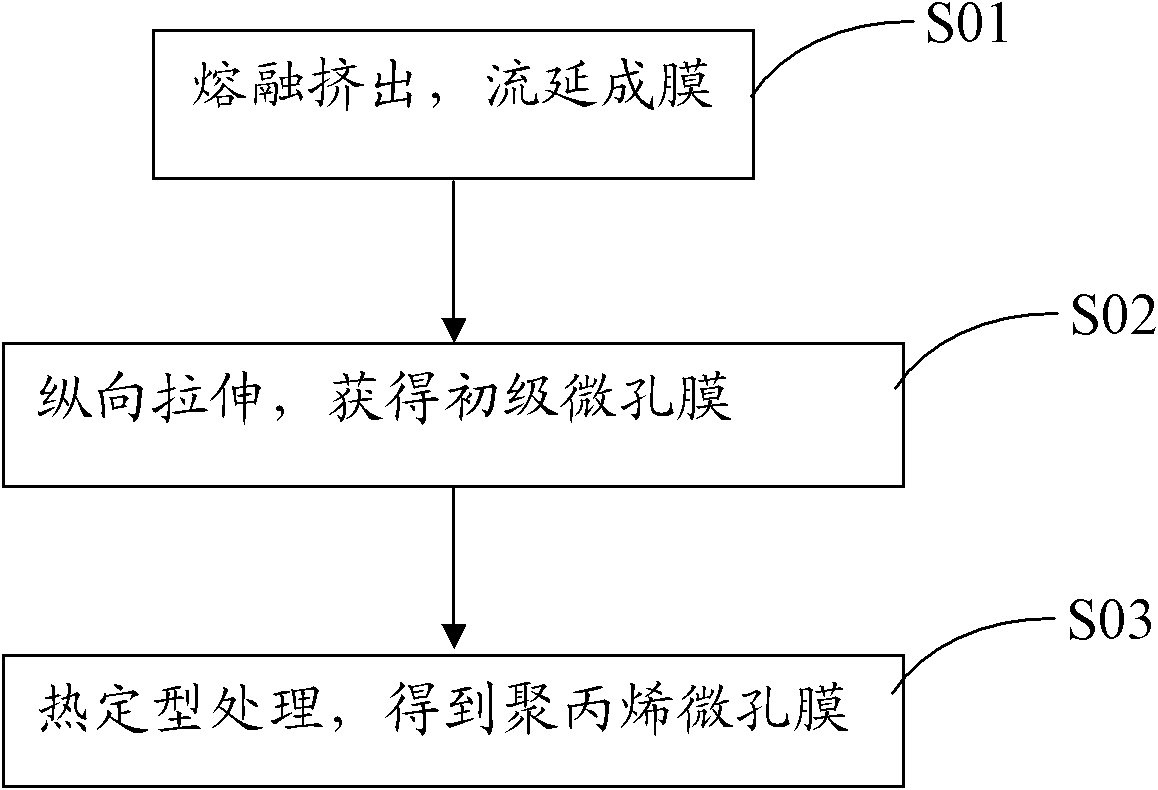

Method for forming polyolefin microporous membrane and application thereof

InactiveCN102001186AImprove breathabilityImprove lateral strengthLi-accumulatorsCell component detailsPolyolefinPolypropylene

The invention provides a method for forming a polyolefin microporous membrane, which comprises the following steps of: performing melt extrusion and casting on polypropylene at the temperature of between 180 and 260 DEG C to obtain a polyolefin cast base membrane; longitudinally stretching the polyolefin cast base membrane at the temperature of between 10 and 150 DEG C to obtain a primary polyolefin microporous membrane with micropores; and performing heat setting treatment on the primary polyolefin microporous membrane at the temperature of between 110 and 150 DEG C, and transversely drawing the primary polyolefin microporous membrane to obtain the polyolefin microporous membrane. The invention also provides application of the method for forming the polyolefin microporous membrane in preparing a diaphragm or a lithium ion battery. In the method, based on the primary microporous membrane obtained by longitudinal stretching, the primary microporous membrane is transversely stretched at the predetermined temperature, and finally pores of the polyolefin microporous membrane become circular and are enlarged, so the air permeability of the polyolefin microporous membrane is improved, and the transverse strength of the microporous membrane is improved.

Owner:SHENZHEN SENIOR TECH MATERIAL

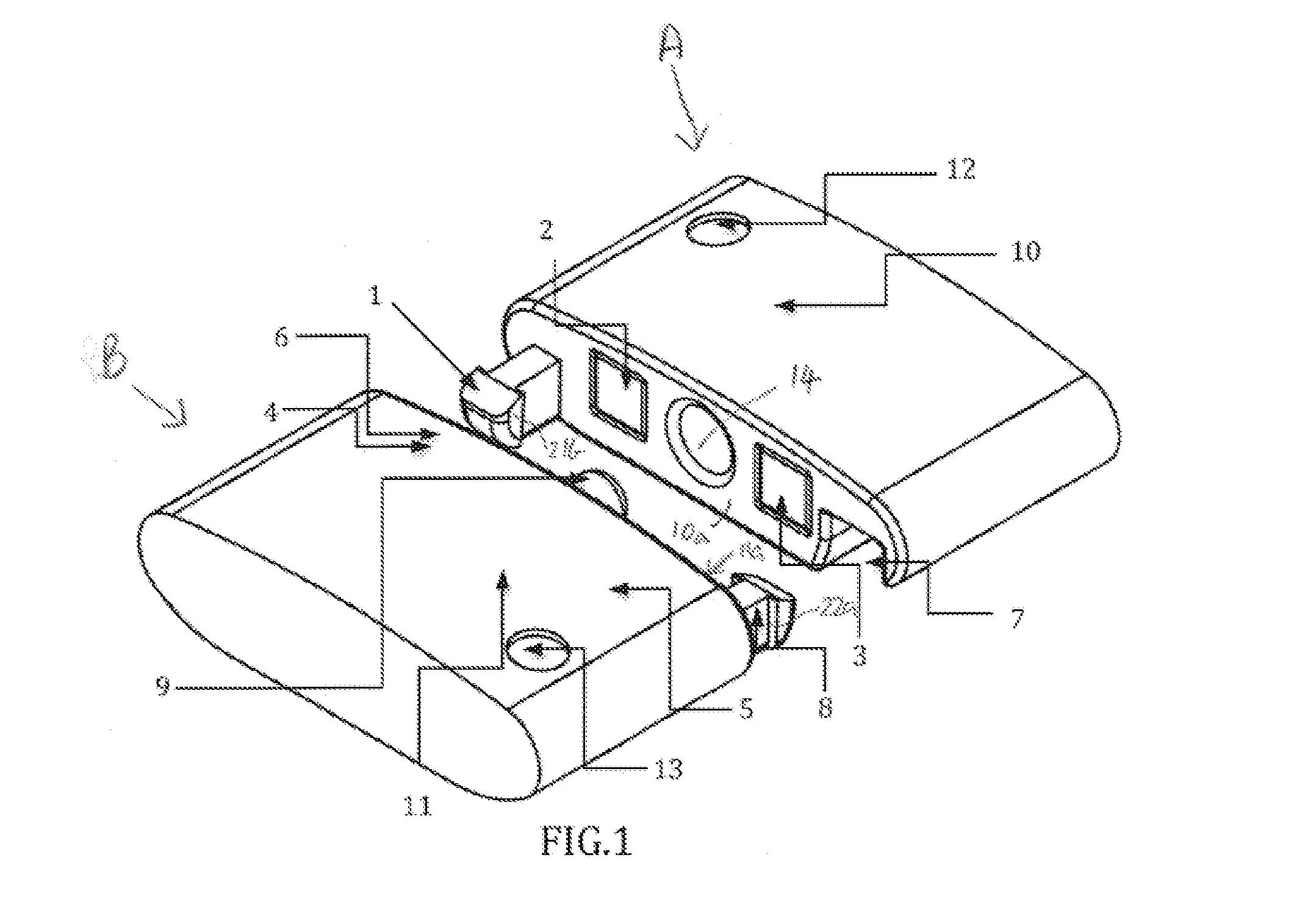

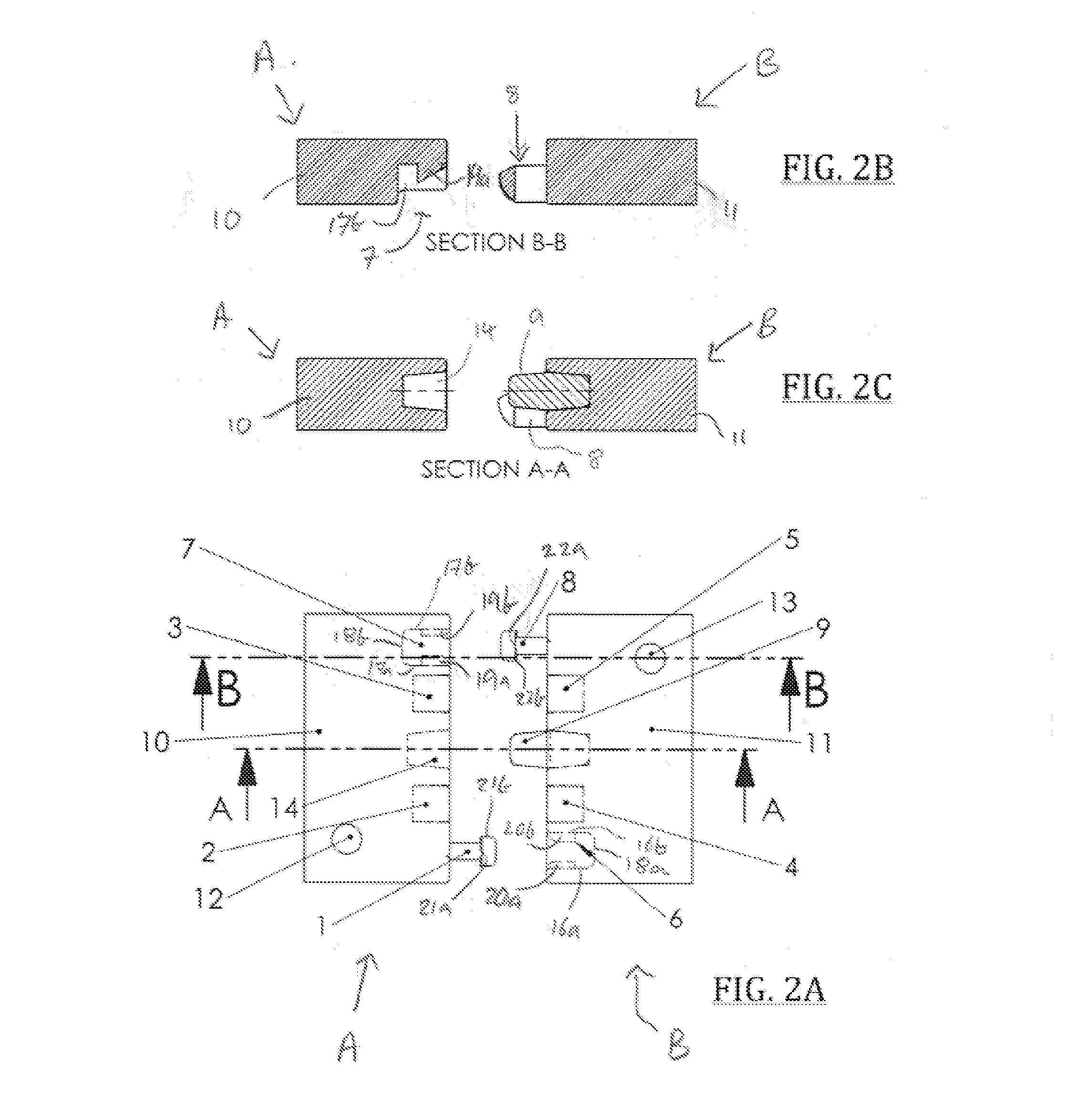

Clasp system

ActiveUS20140130544A1Avoid partialSimple to unlatchSnap fastenersClothes buttonsMechanical engineeringEngineering

A clasp system for attaching two elements, comprising first and second parts (A, B) each having a body (10, 11) for attachment to a respective one of the elements. The first and second parts having a fastening means comprising first and second fastening portions (1, 6), the first part including the first fastening portion and the second part including the second fastening portion. The first fastening portion and the second fastening portion are respectively configured for clipping engagement to fasten the first and second parts together. The unfastening comprises a relative twist movement of the first and second parts to unclip the first and second fastening portions. The first and second parts further comprise magnetic material (2, 3, 4, 5) arranged to pull the first and second parts together into the clipping engagement when the first and second parts are relatively oriented in a predetermined manner and spaced less than a predetermined maximum distance apart.

Owner:BUDDI

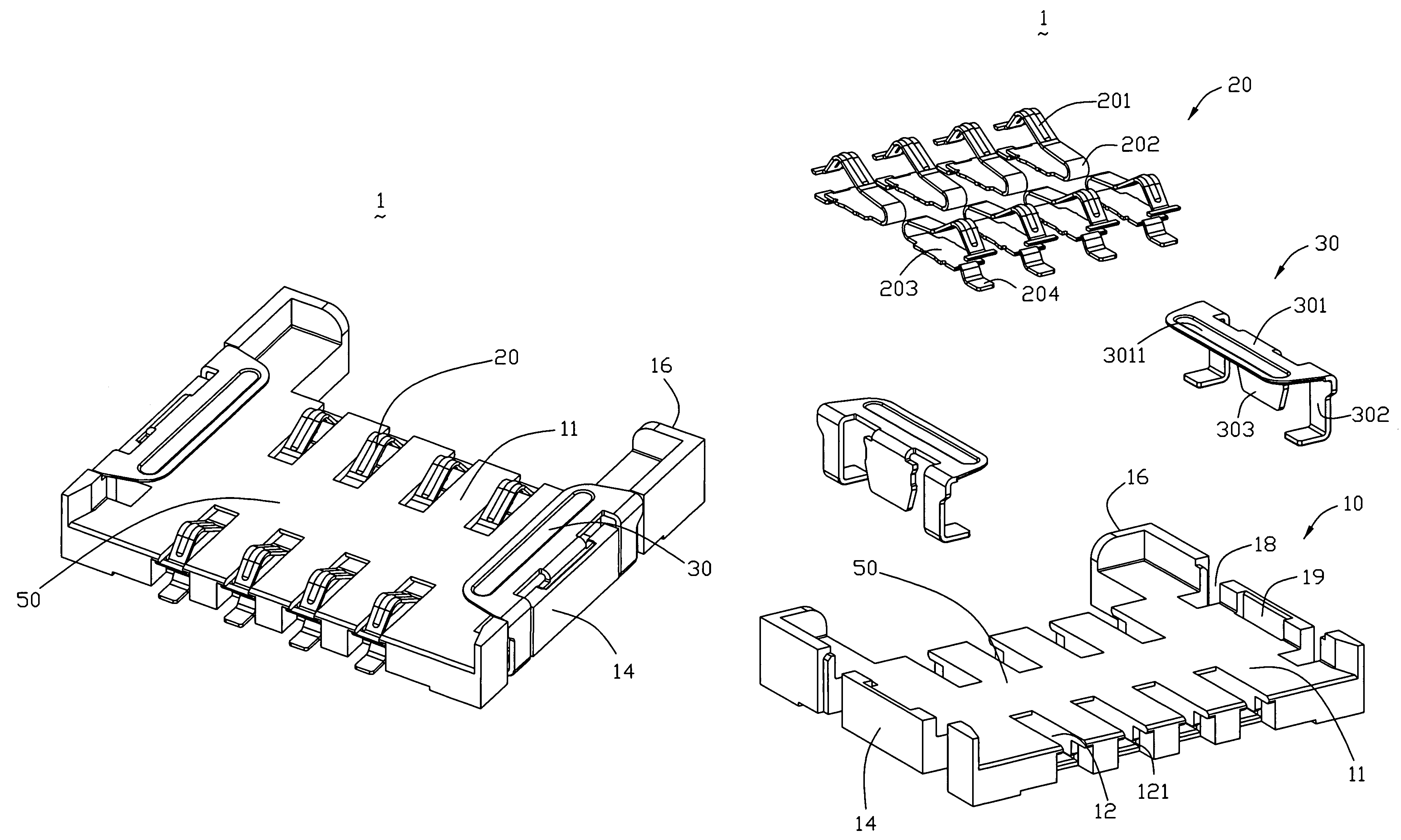

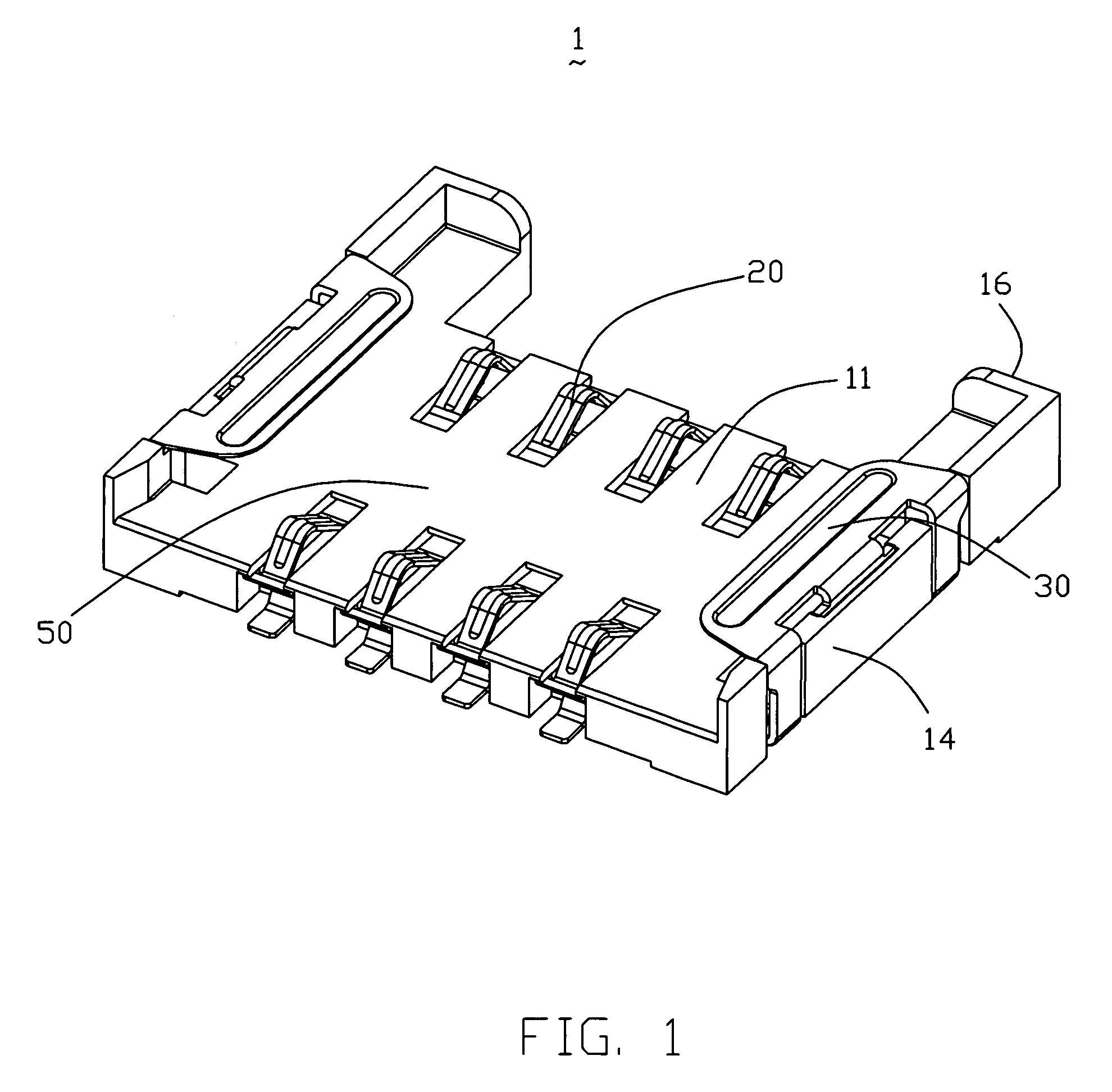

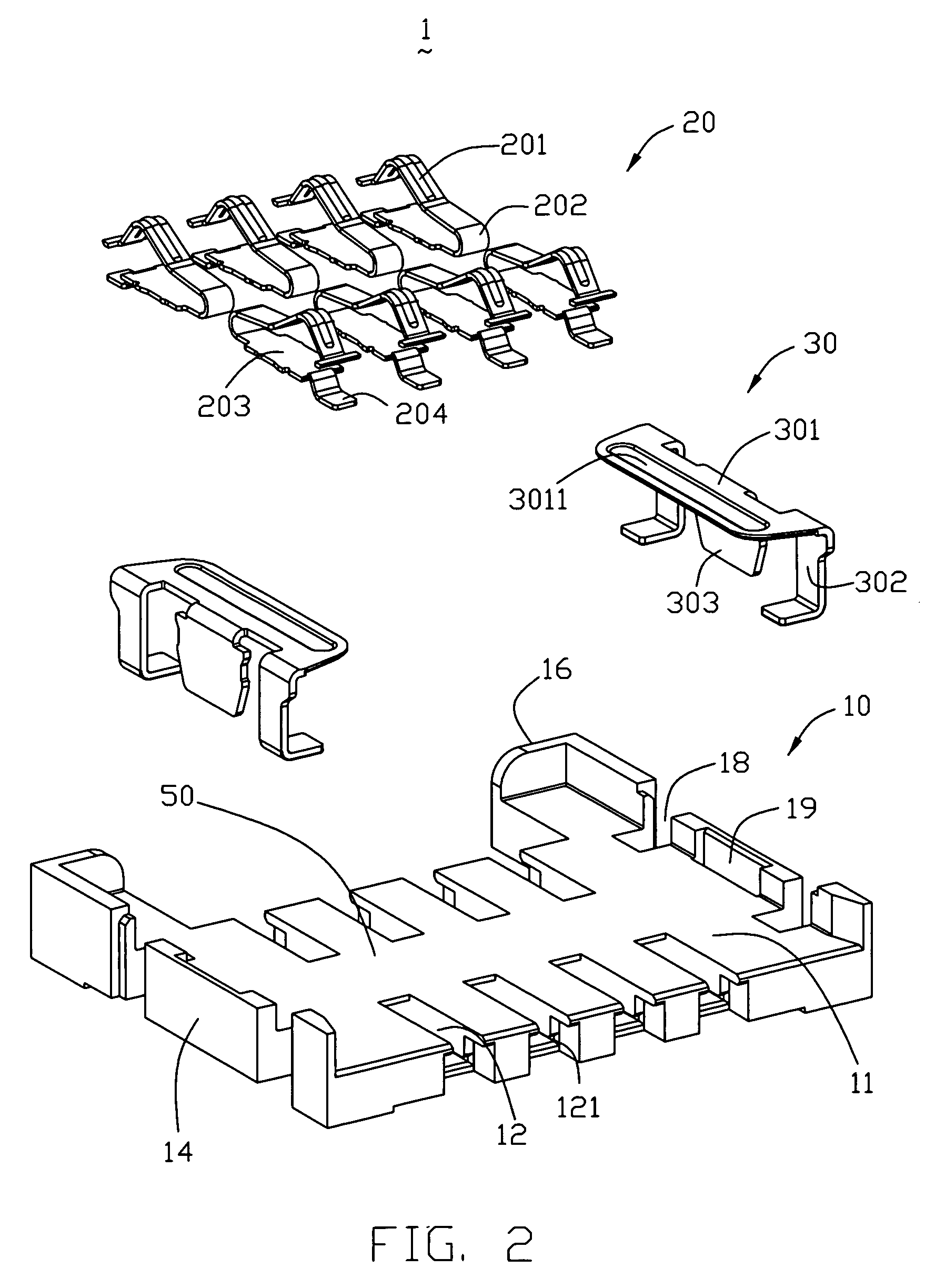

Electrical card connector

InactiveUS7442087B2Improve lateral strengthStabilize the electrical cardIncorrect coupling preventionSensing by galvanic contactsElectrical and Electronics engineeringEngineering

Owner:HON HAI PRECISION IND CO LTD

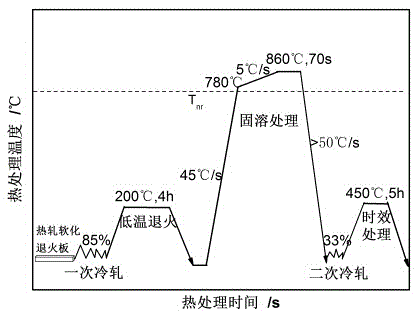

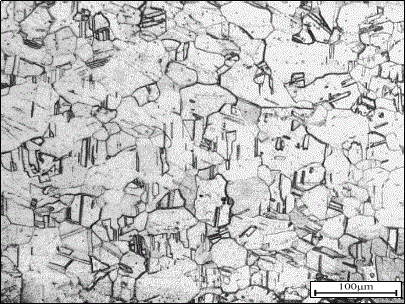

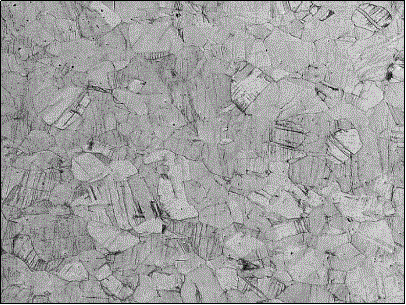

Low-anisotropic-index high-intensity Cu-Ni-Si alloy and preparing process thereof

The invention discloses a low-anisotropic-index high-intensity Cu-Ni-Si alloy and a preparing process thereof. The low-anisotropic-index high-intensity Cu-Ni-Si alloy and the preparing process are suitable for cold rolling copper-based thin panels for lead frames. The alloy comprises, by chemical mass percent, 2%-3% of Ni, 0.5%-1.0% of Si, 0.1%-0.5% of Sn, 0.05%-0.1% of Fe, 0.1%-0.3% of Mg, 0.05%-0.08% of Zn, 0.2%-0.5% of RE and the balance Cu. Yttrium-based heavy rare earth is added for purifying a copper solution, and Ni2Si precipitation is improved; meanwhile, harmful texture is effectively restrained through the process that low temperature annealing is combined with grading solid dissolving before solid dissolving; and by controlling the cold rolling reduction rate, a transverse shearing belt is obtained for a product, and anisotropism is greatly improved. The alloy has the beneficial effects that the strength of extension ranges from 650 MPa to 750 MPa, the elongation ranges from 13% to 18%, the in-plane anisotropy (IPA) of the intensity is smaller than 6%, the in-plane anisotropy (IPA) of the elongation is smaller than 8%, and defects of warping, deformation and cracking of the Cu-Ni-Si alloy in the blanking process can be effectively reduced.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

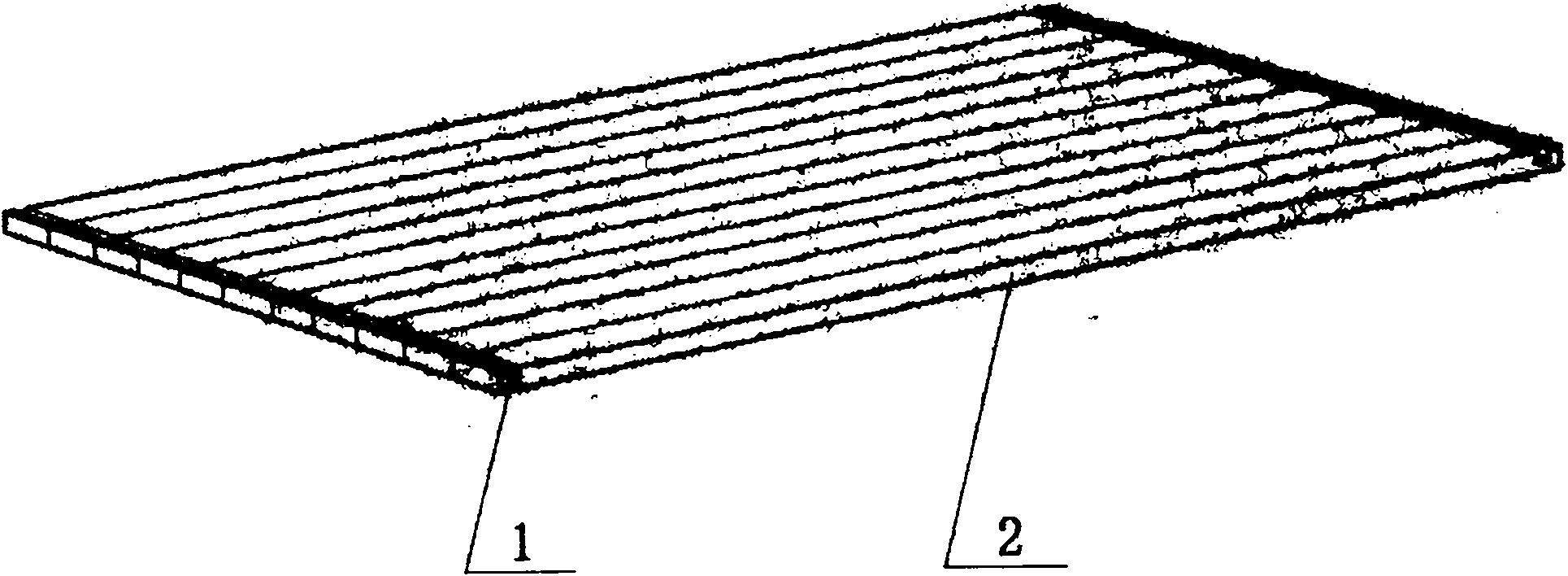

Method for manufacturing bamboo wood whole-piece assembly and bamboo composite material

ActiveCN102172932AGet rid of densityGet rid of stabilitySynthetic resin layered productsWood veneer joiningUltimate tensile strengthSoftwood

The invention discloses a method for manufacturing a bamboo wood whole-piece assembly and bamboo composite material. A whole-piece laminated bamboo bunch and flat-sawn cork veneer serve as the main raw materials, water-proof phenolic resins serve as auxiliary materials, and an outdoor bamboo composite material with high size stability can be produced under the hot-press condition. The method comprises the following steps: carrying out rip sawing and bamboo green removal on the bamboo wood before lamination processing; carrying out whole-piece processing on a bamboo chip; then, laminating the bamboo chip into a bamboo bunch curtain with wide breadth and loose structure; and when the bamboo composite material is assembled, causing the impregnated bamboo bunch curtain with wide breadth and the impregnated cork veneer to be mutually assembled. The bamboo composite material manufactured with the method has the advantages of high bamboo wood use ratio, even distribution of the internal density of the plate blank, good size stability and excellent longitudinal and lateral strength and can be used as high-grade building templates, furniture plates and indoor and outdoor decoration materials.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Veneer for container base plate

InactiveCN101549505AReasonable structureReasonable structural designWood veneer joiningWood layered productsMechanical engineeringLongitudinal strength

The invention relates to a veneer for a container base plate, belonging to the technical field of veneers. The veneer has reasonable structural design and enhances the horizontal and longitudinal strength of floors, thereby giving full play to the maximum performance of various materials and obtaining a more reasonable compounding floor structure; with the mixed structure, the veneer for the container base plate is ensured to meet the using requirement of the container base plate; materials used by the veneer for container base plate have extensive sources and lower cost, thus the production cost of the container base plate is reduced.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Impregnated paper finished OSB composite floor and preparation method

ActiveCN105464335ALow costGood value for moneyAldehyde/ketone condensation polymer adhesivesFlooringPulp and paper industryUltimate tensile strength

The invention relates to a plate, in particular to an impregnated paper finished OSB composite floor and a preparation method. The impregnated paper finished OSB composite floor sequentially comprises an OSB base material layer, a veneer layer, a buffer paper layer, a balance paper layer and a sprayed decorative paper layer from bottom to top. The longitudinal static bending intensity of the OSB base material layer is larger than or equal to 50 MPa, and the water absorption thickness swelling rate of the OSB base material layer is smaller than or equal to 12%. The veneer layer is a poplar bleached veneer, and the thickness ranges from 0.6 mm to 1.2 mm. The buffer paper layer is impregnated kraft paper with the thickness of 0.4 mm to 0.6 mm, and the glue quantity is 80% or above. The weight of the balance paper layer ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The weight of the sprayed decorative paper ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The impregnated paper finished OSB composite floor has high environment friendliness, stability and water resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

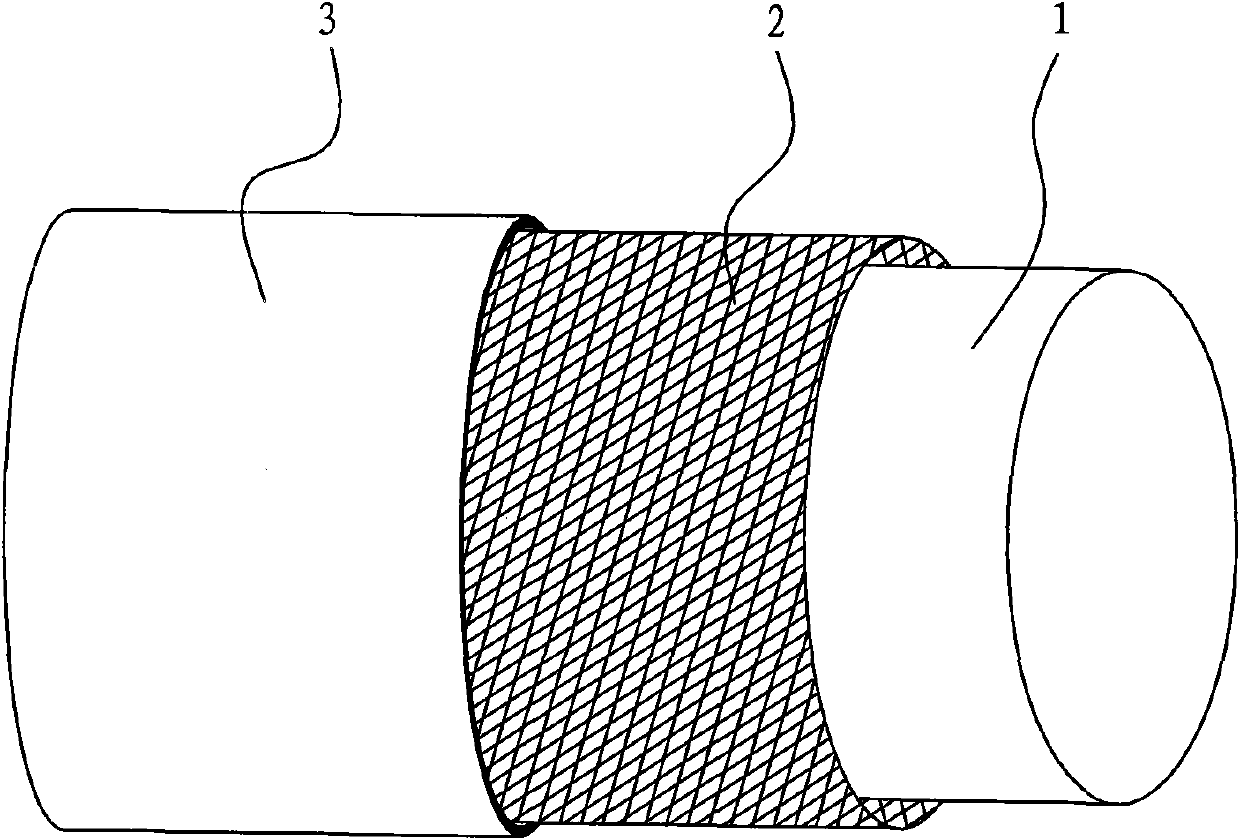

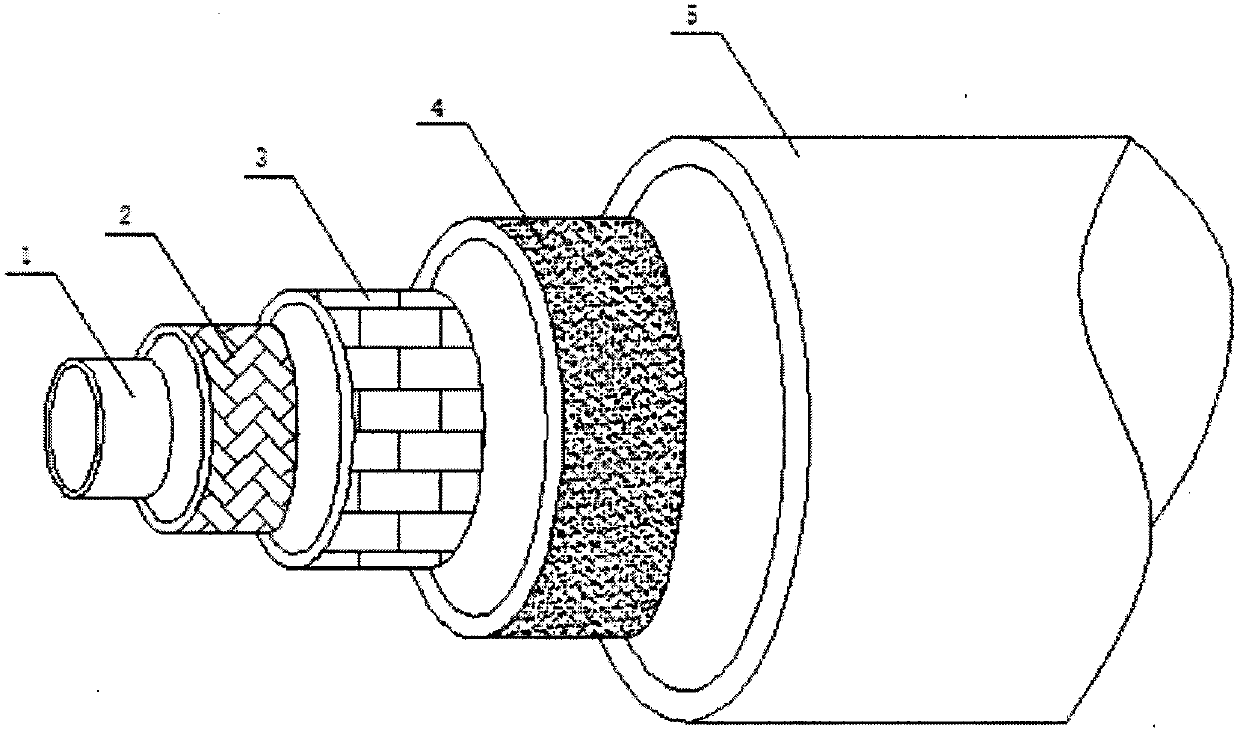

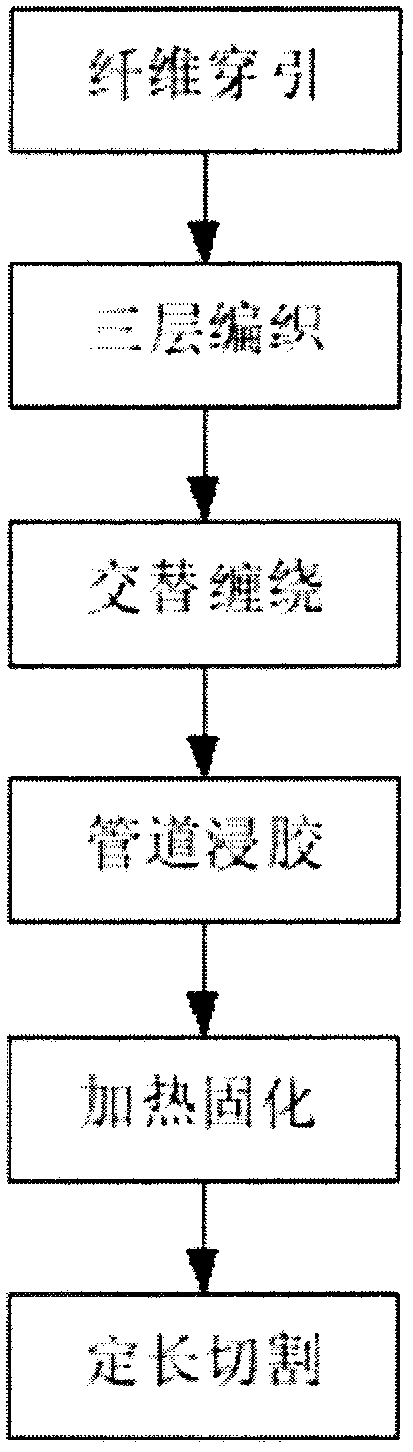

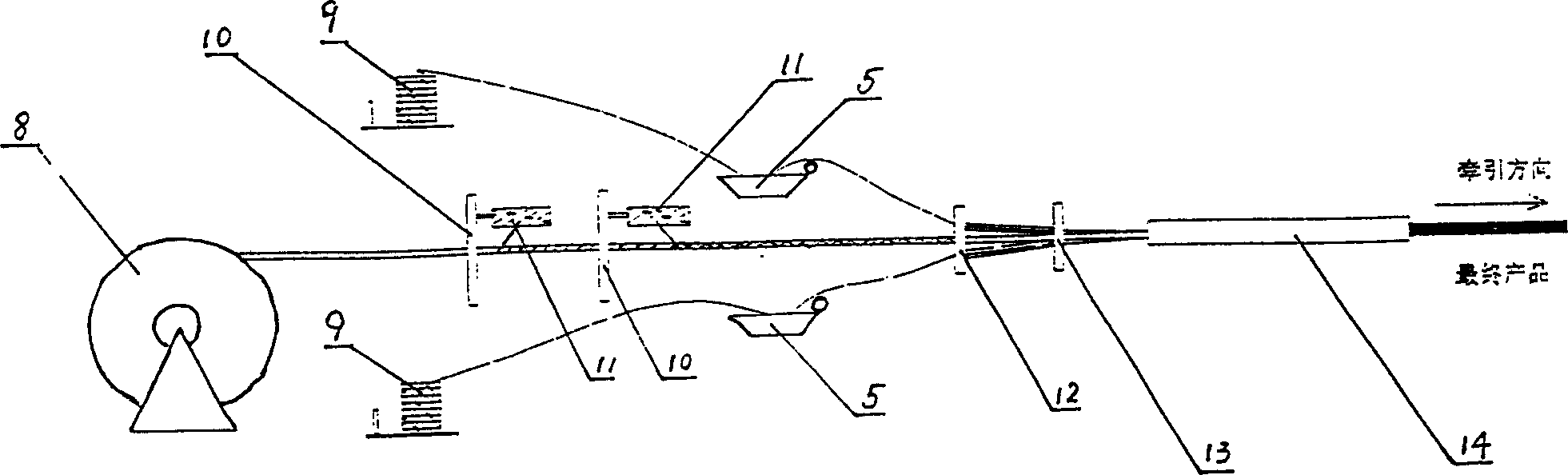

Continuous large-diameter braided fiber reinforced thermosetting pultrusion pipeline and production method

InactiveCN111055514AImprove lateral strengthEven by forceRigid pipesPipe protection against damage/wearWinding machineProcess engineering

Belonging to the technical field of pipeline forming, the invention discloses a continuous large-diameter braided fiber reinforced thermosetting pultrusion pipeline and a production method. The pipeline comprises a mandrel, a braided layer, a winding layer, a gum dipping layer and an outer protective layer. The braided layer is distributed along the axial direction of the mandrel, the winding layer 3 is wound on the surface of the braided layer through a winding machine, the layer thickness does not exceed 3mm, and the winding layer is compounded with the outer protective layer through the gumdipping layer. By changing the form and the laying mode of the fiber reinforced material, the transverse strength of the pultrusion composite material is improved, meanwhile, uniform stress can be guaranteed to the winding layer and the braided layer fiber at the same time, and good internal pressure bearing performance is achieved. The pipeline prepared through the process has excellent performance and is suitable for large-batch production.

Owner:HUNAN YIJING ENVIRONMENTAL PROTECTION TECH CO LTD

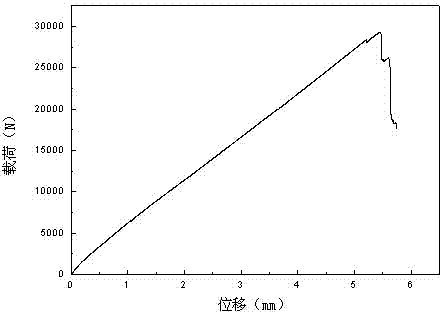

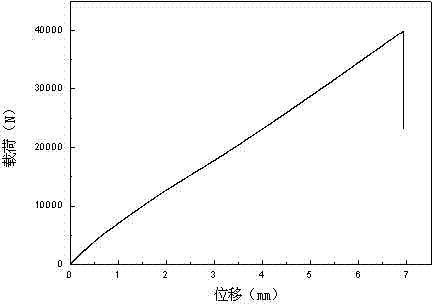

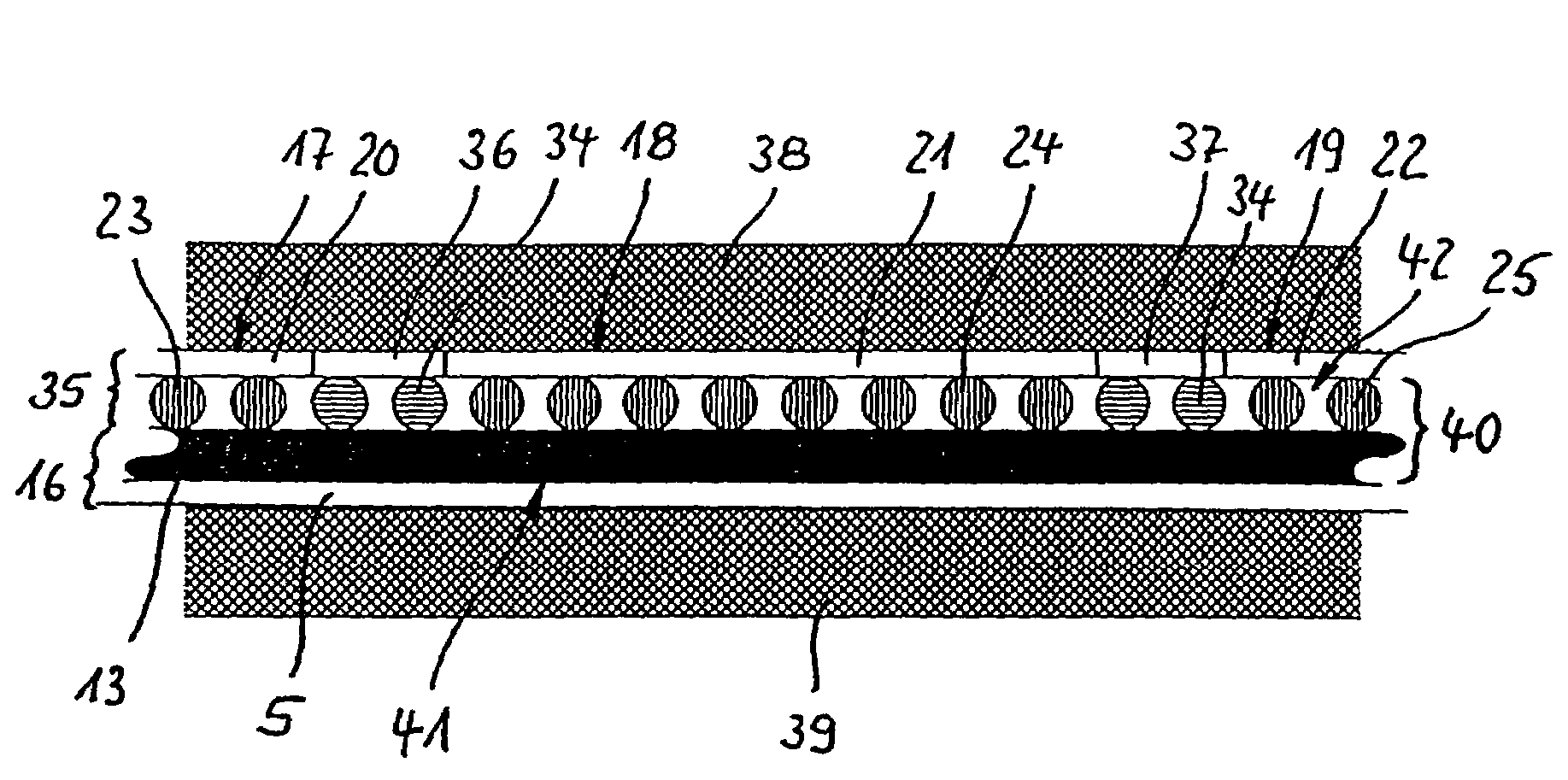

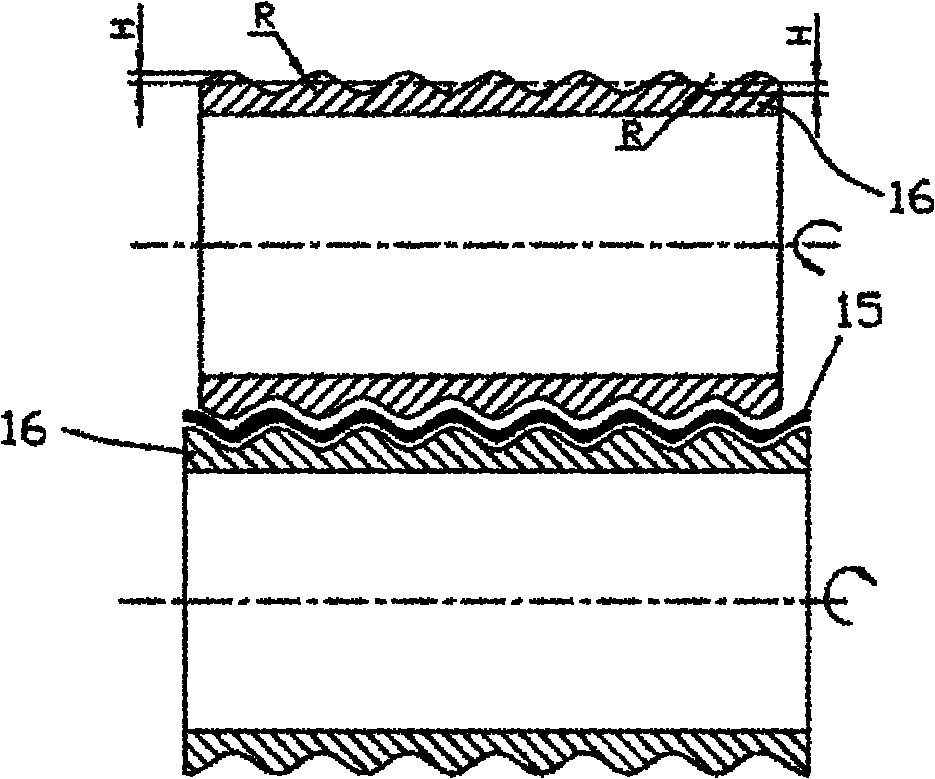

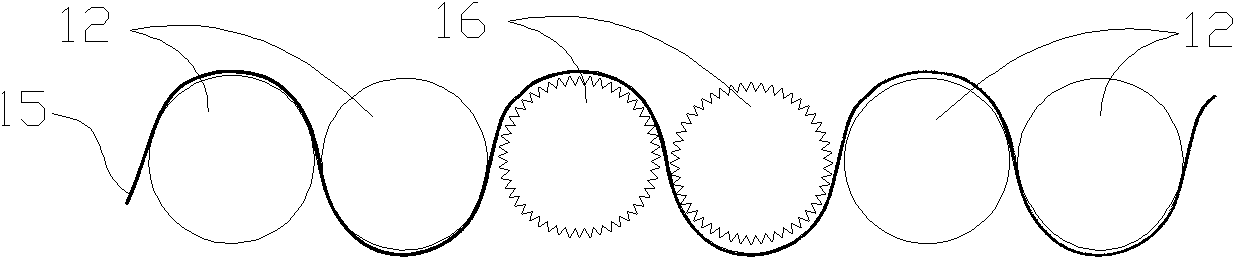

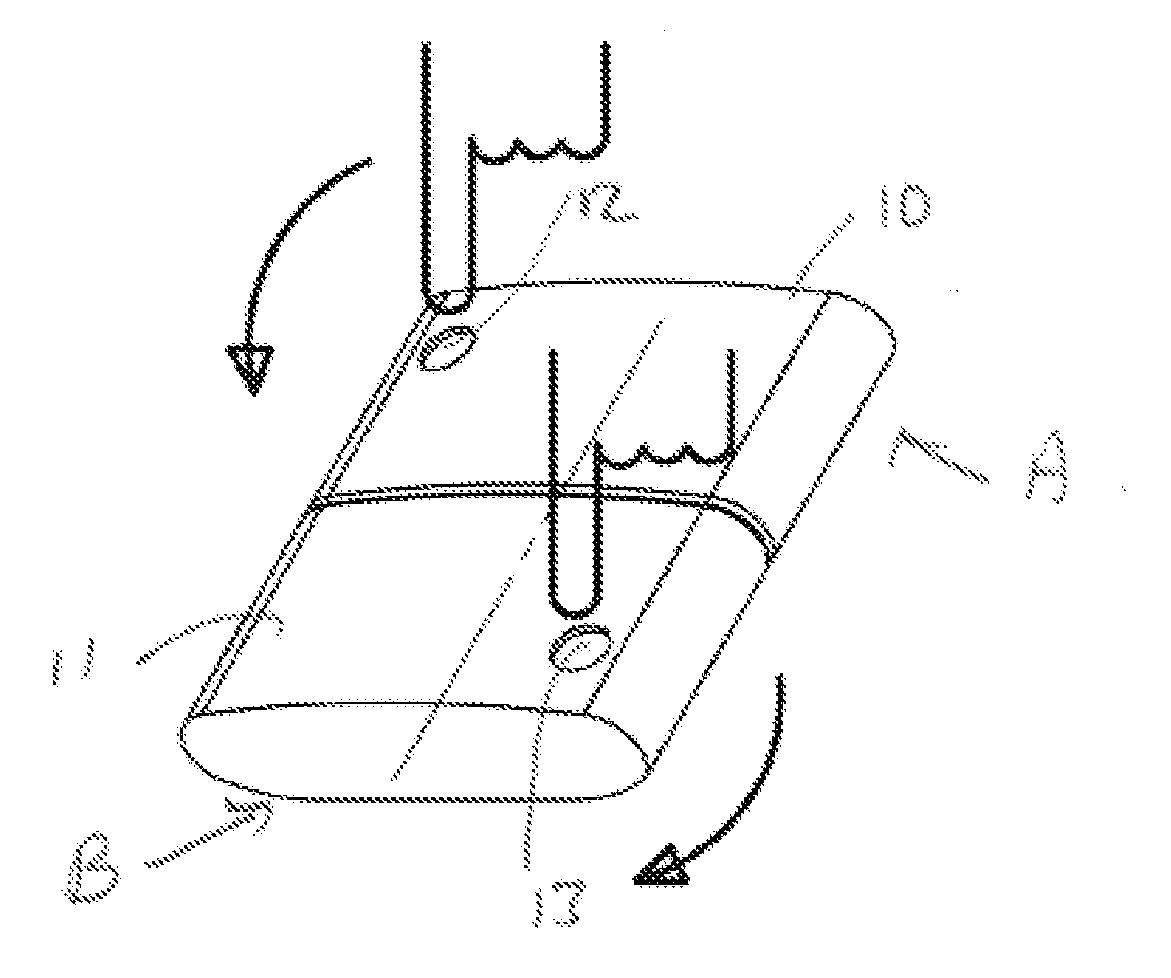

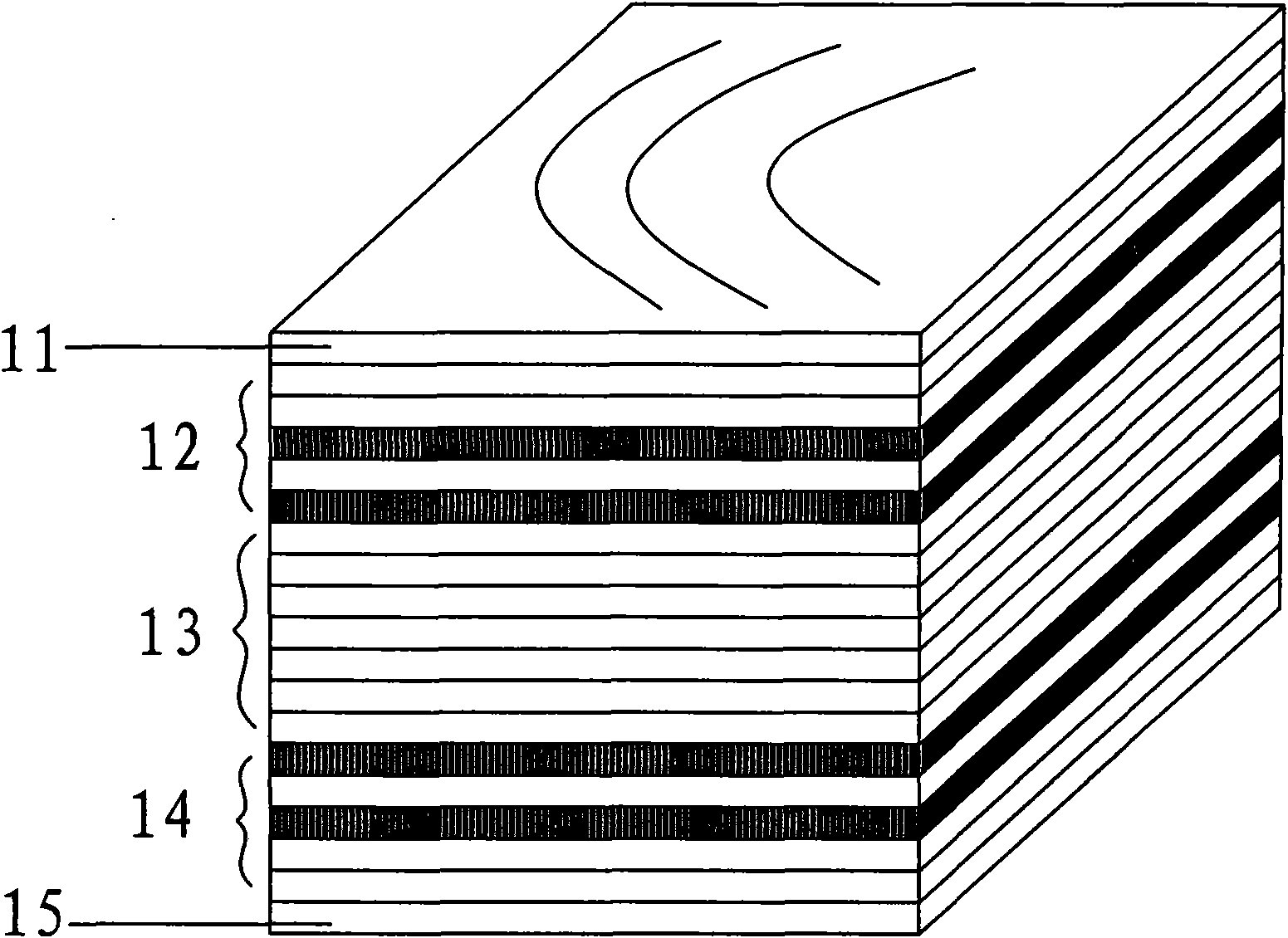

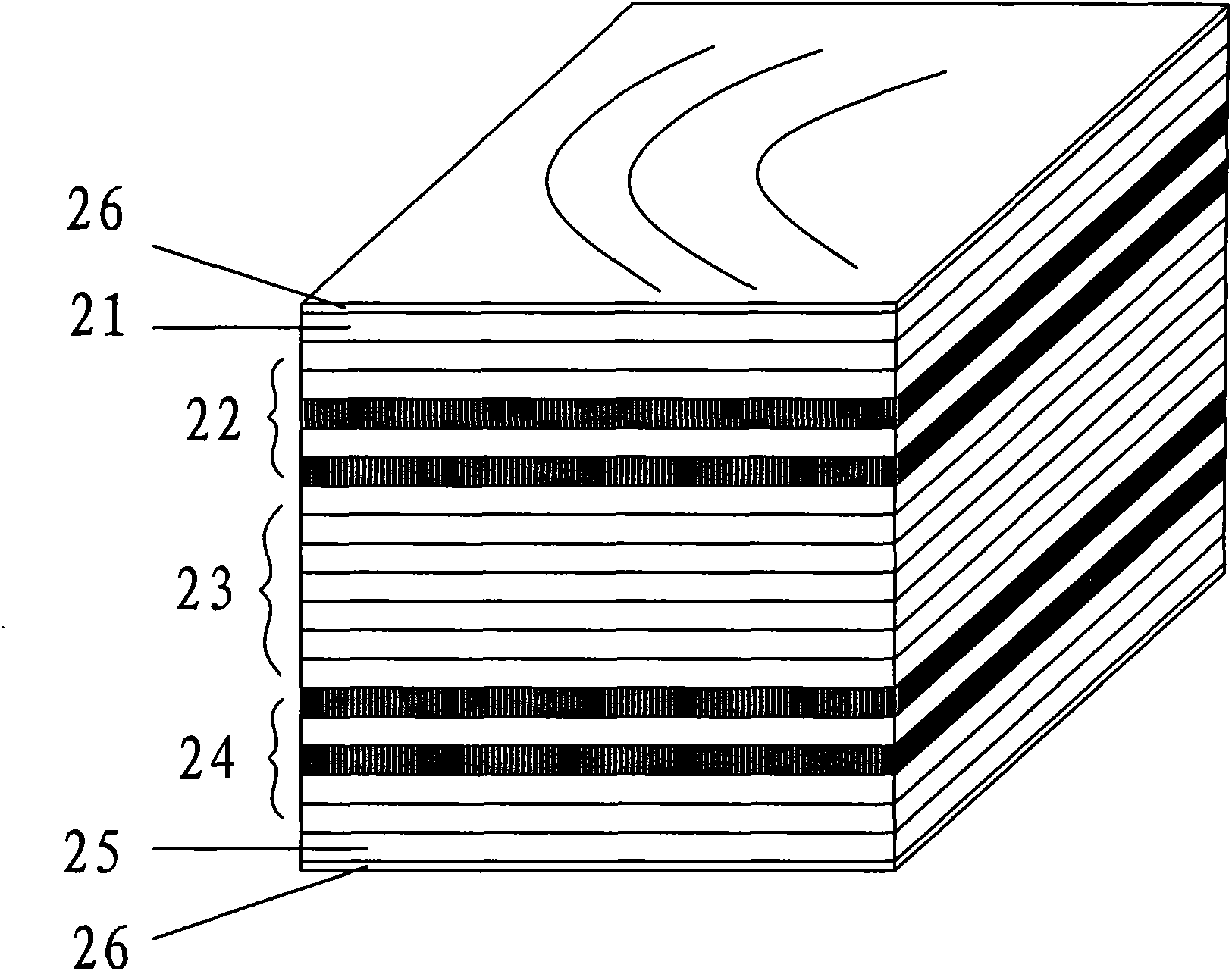

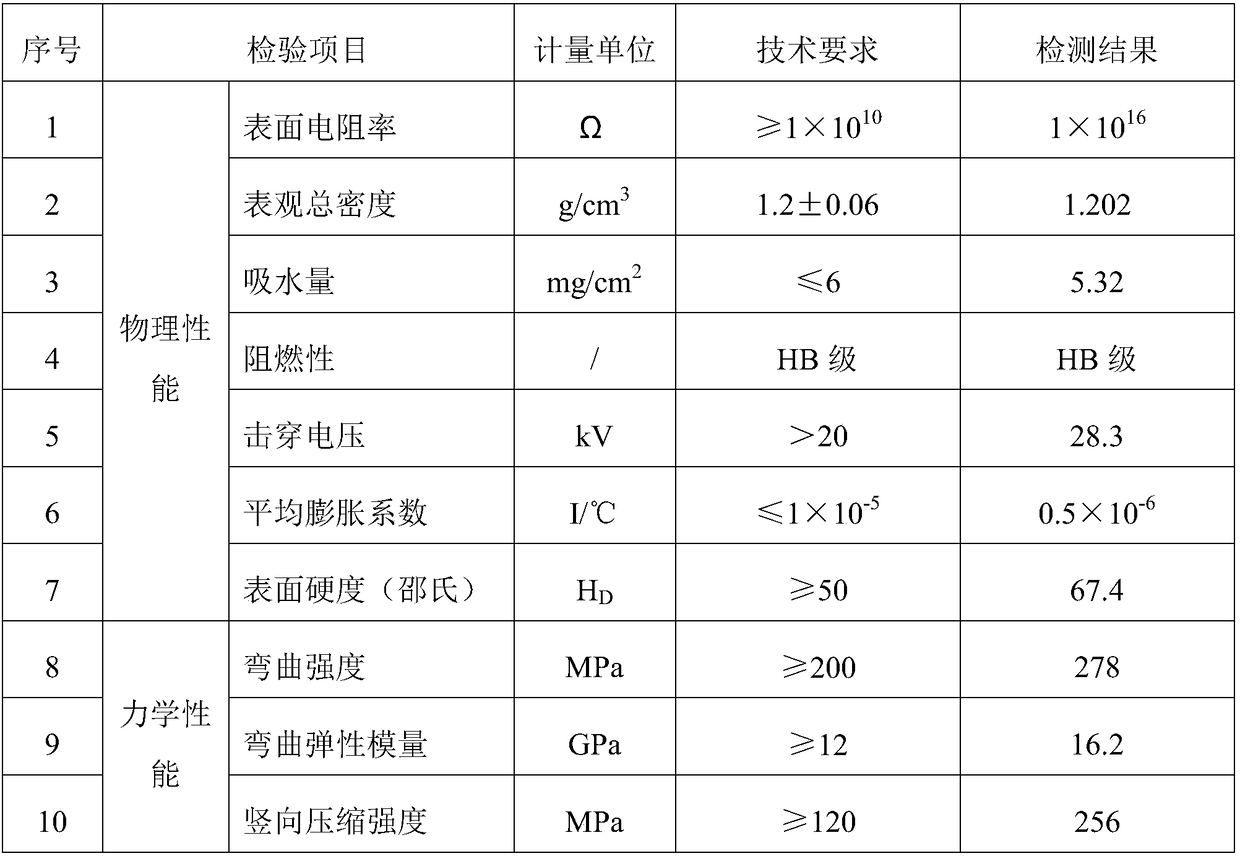

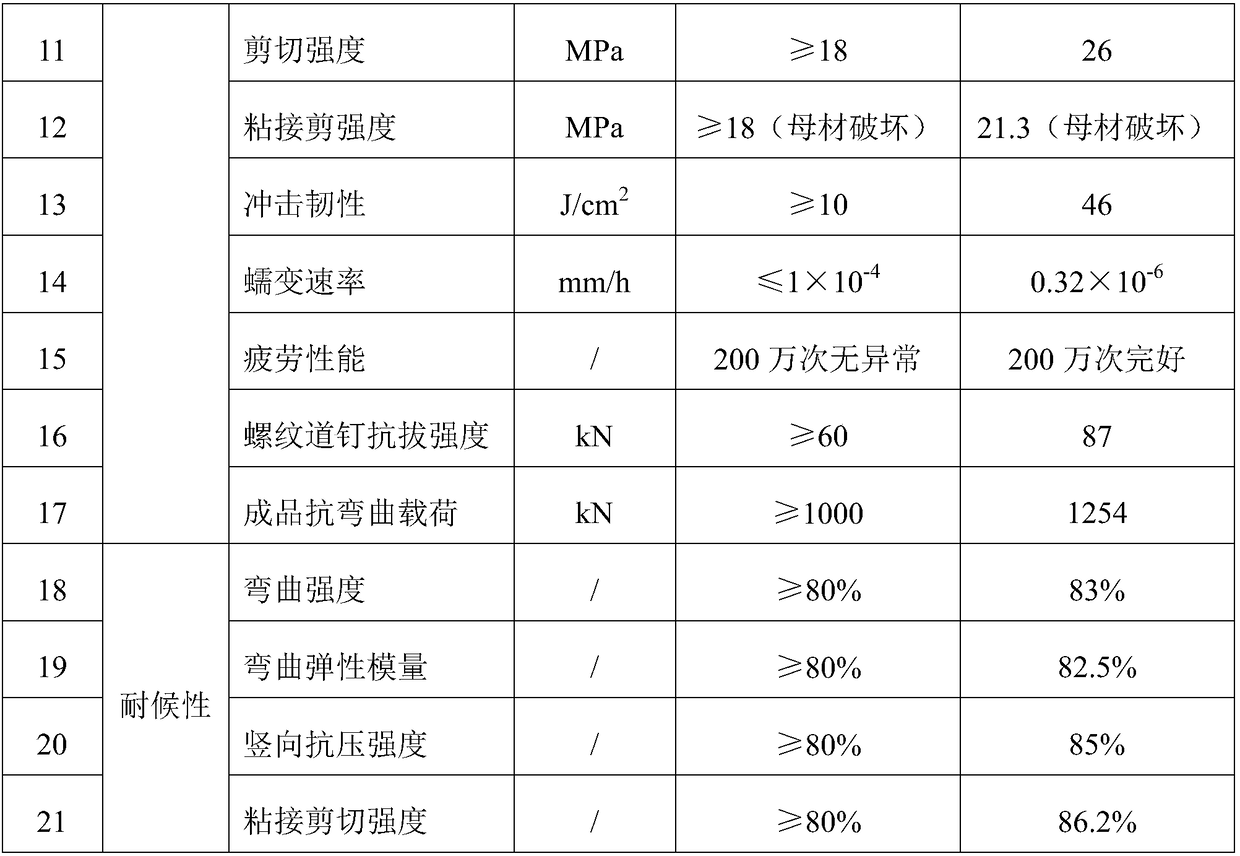

Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

The invention discloses a fiber-reinforced polyurethane foamed and synthesized sleeper and a preparation method thereof. The sleeper comprises a body formed by polyurethane resin in a one-time lamination manner, wherein multiple layers of composite felts with a transverse reinforcing effect are transversely arranged in the body, and a fiber yarn layer with a longitudinal reinforcing effect penetrates into the polyurethane resin between two adjacent composite felts; the fiber yarn layer and the composite felts account for 65%-75% of the total weight of the sleeper; the polyurethane resin accounts for 25%-35% of the total weight of the sleeper, and the density of the sleeper is 0.6g / cm<3>-1.6g / cm<3>; and the sleeper is prepared through combination of a double-steel belt laminating machine and a multilayer synchronous glue injection primary formation. According to the fiber-reinforced polyurethane foamed and synthesized sleeper, gum dipping is relatively adequate and uniform, so that thetransverse strength of the sleeper is enhanced, and the cracking phenomenon of a product during punching and indenting can be avoided; and the production process is simple, the equipment input is reduced, the production cost is lowered, and the production efficiency is improved.

Owner:铁科腾跃科技有限公司

Compound fibre draw-winding rod and preparation method

InactiveCN1465501AImprove lateral strengthImprove corrosion resistanceTextile cablesUnderwater vesselsFiberGreenhouse

The present invention discloses a composite fibre guy turnstile, and is formed from core rod and covering layer, and its core rod is a solid rod, and its covering layer is formed from wrapped layer and anticorrosive layer, and its wrapped layer is made by at least mixing two plies of fibre and resin and winding them round the core rod, and its anticorrosive layer is made up by making several plies of fibre impregnated with resin be radially attached on the wrapped layer. The tensile modulus and bending modules are over above, 100 GPa, it can be extensively used for making glass fibre reinforced plastic pipeline, supporting rod for greenhouse and antenna equipment.

Owner:北京玻钢院复合材料有限公司

Vehicle seat

InactiveUS20120025579A1Simple structureGood lateral strengthSeat framesStoolsEngineeringMechanical engineering

A vehicle seat includes a back frame including: a back frame body that is formed by bending a pipe into a rectangular form such that both ends of the pipe are located at one of four corner portions of the rectangular form; and a pair of side frames that are joined, respectively, to a first corner portion which is one of the corner portions of the back frame body and at which the both ends of the pipe are located and a second corner portion that is another of the corner portions of the back frame body and is laterally next to the first corner portion. One of the ends of the pipe is butt-welded to one of the side frames.

Owner:TOYOTA BOSHOKU KK

Integral wall base and flash cove

An integral wall base and flash cove having a wall portion, an elongated toe and a concave cove interconnecting the wall portion and the elongated toe in smooth transition. The integral wall base and flash cove can be wrapped around inside and outside corners without the need for a separate molded corner. The integral wall base and flash cove can be installed without required a cove stick or top cap moulding.

Owner:TARKETT USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com