Compound fibre draw-winding rod and preparation method

A composite fiber and rod-wound technology, which is used in underwater operation equipment, ships, special-purpose ships, etc., can solve the problems of low lateral strength, splitting and twisting, and lack of corrosion resistance, so as to improve bending performance and improve corrosion resistance. performance, the effect of improving lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

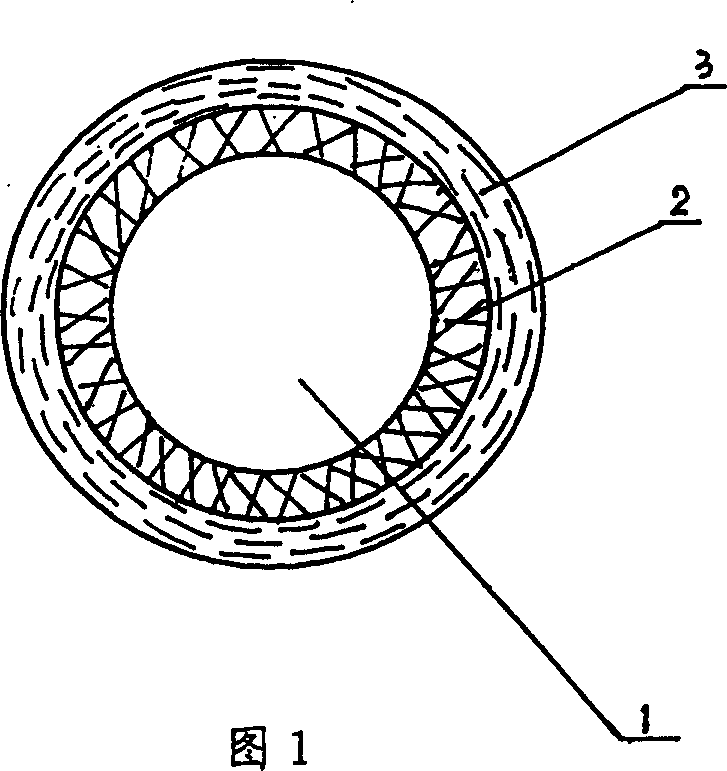

[0023] As shown in Figure 1: the draw-wound rod manufactured by the present invention is composed of a core rod 1, a winding layer 2, and an anti-corrosion layer 3. The core rod 1 is a solid rod, which is formed by mixed pultrusion of carbon fiber and resin; the selected tensile modulus is 290GPa , carbon fiber with an elongation of 1.5%; the winding layer 2 is a high-strength glass fiber with a tensile modulus of 80GPa and an elongation of 3%; the anti-corrosion layer 3 is made of alkali-free glass fiber; the resin selected is a glue-like vinyl resin, which The tensile modulus was 3.2 and the elongation was 6%.

[0024] The method for preparing a core rod comprises the steps of:

[0025] The first step: mold design: design mold according to different requirements of sample specifications

[0026] For a core rod with a diameter of 8mm, the diameter of the inner cavity of the core rod is set to 4.94mm; the number of carbon fibers required for the inner core is 37 strands, and ...

Embodiment 2

[0032] As shown in Figure 1: the draw-wound rod manufactured by the present invention is composed of a core rod 1, a winding layer 2, and an anti-corrosion layer 3. The core rod 1 is a solid rod, which is formed by mixed pultrusion of carbon fiber and resin; the selected tensile modulus is 290GPa , carbon fiber with an elongation of 1.5%; the winding layer 2 is a high-strength glass fiber with a tensile modulus of 80GPa and an elongation of 3%; the anti-corrosion layer 3 is made of alkali-free glass fiber; the resin selected is a glue-like vinyl resin, which The tensile modulus was 3.2 and the elongation was 6%.

[0033] The method for preparing a core rod comprises the steps of:

[0034] The first step: mold design: design mold according to different requirements of sample specifications

[0035] The inner cavity of the inner core with a diameter of 10mm is set to 6.17mm; the number of carbon fibers required for the inner core is 61 strands, and the number of glass fibers re...

Embodiment 3

[0041] diameter

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com