Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

A technology of fiber reinforcement and polyurethane, which is applied in the field of rail transit, can solve the problems of uneven distribution of resin fibers on the upper and lower layers, uneven distribution on both sides and in the middle, and low efficiency, so as to achieve uniform distribution of fibers and resin, avoid pollution that is difficult to clean, and reduce The effect of waste of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a fiber-reinforced polyurethane foam synthetic sleeper, specifically comprising the following steps.

[0031] A. According to the size and density requirements of the product, arrange the fibers, thread the glass fibers in the dipping tooling, and connect them to the traction block.

[0032] B. Cut the composite felt into the same size as the width of the sleeper, sandwich the glass fiber in the middle and connect it to the traction block.

[0033] C. Preheat the double-steel belt laminator in advance, place the double-steel belt laminator in the heat preservation room, and preheat the temperature at 45-80°C.

[0034] D. Use the traction block to pull all the glass fibers and composite mats to the double steel belt laminator, press them in the middle of the upper and lower steel belts, adjust the height of the upper steel belt, so that the size between the upper and lower steel belts is 0.5mm higher than the height of the sleeper, Adjust the width ...

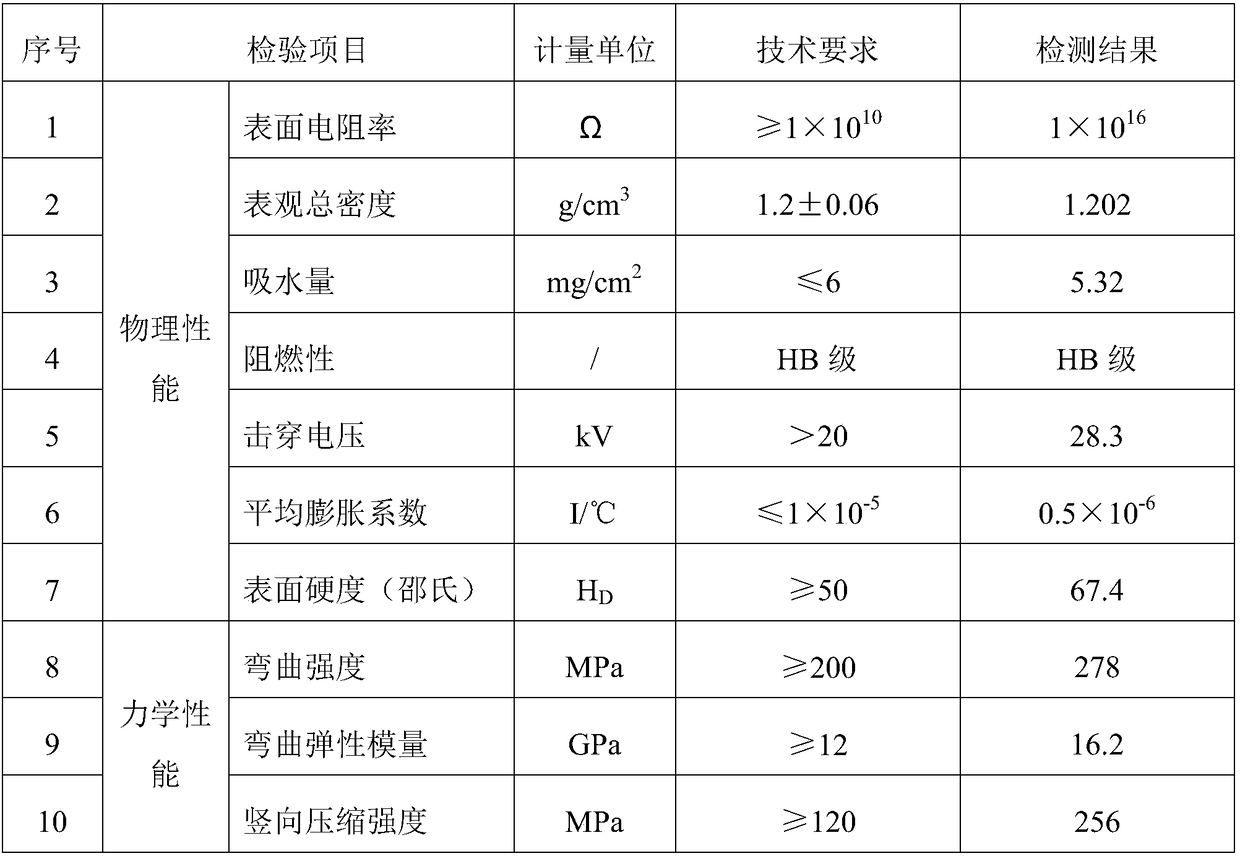

Embodiment 1

[0041] A fiber-reinforced polyurethane foam synthetic sleeper, which includes a body formed by one-time lamination of polyurethane resin, and a seven-layer composite felt for transverse reinforcement is arranged in the body, and a layer of composite felt is inserted in the polyurethane resin between adjacent composite felts. Fiber yarn layer for longitudinal reinforcement; fiber yarn layer and composite felt account for 72% of the total weight of the sleeper; polyurethane resin accounts for 28% of the total weight of the sleeper, and the density of the sleeper is 1.2±0.06g / cm 3 .

[0042] In the present embodiment, composite felt is 1000g / m 2 The fiberglass stitching mat is made of 9600TEX continuous glass fiber. Polyurethane resin is compounded by component A and component B with a weight ratio of 1:1; wherein, component A is polymeric MDI, and component B includes the following components in parts by weight: combined polyether 100 parts , 15 parts of flame retardant, 1 par...

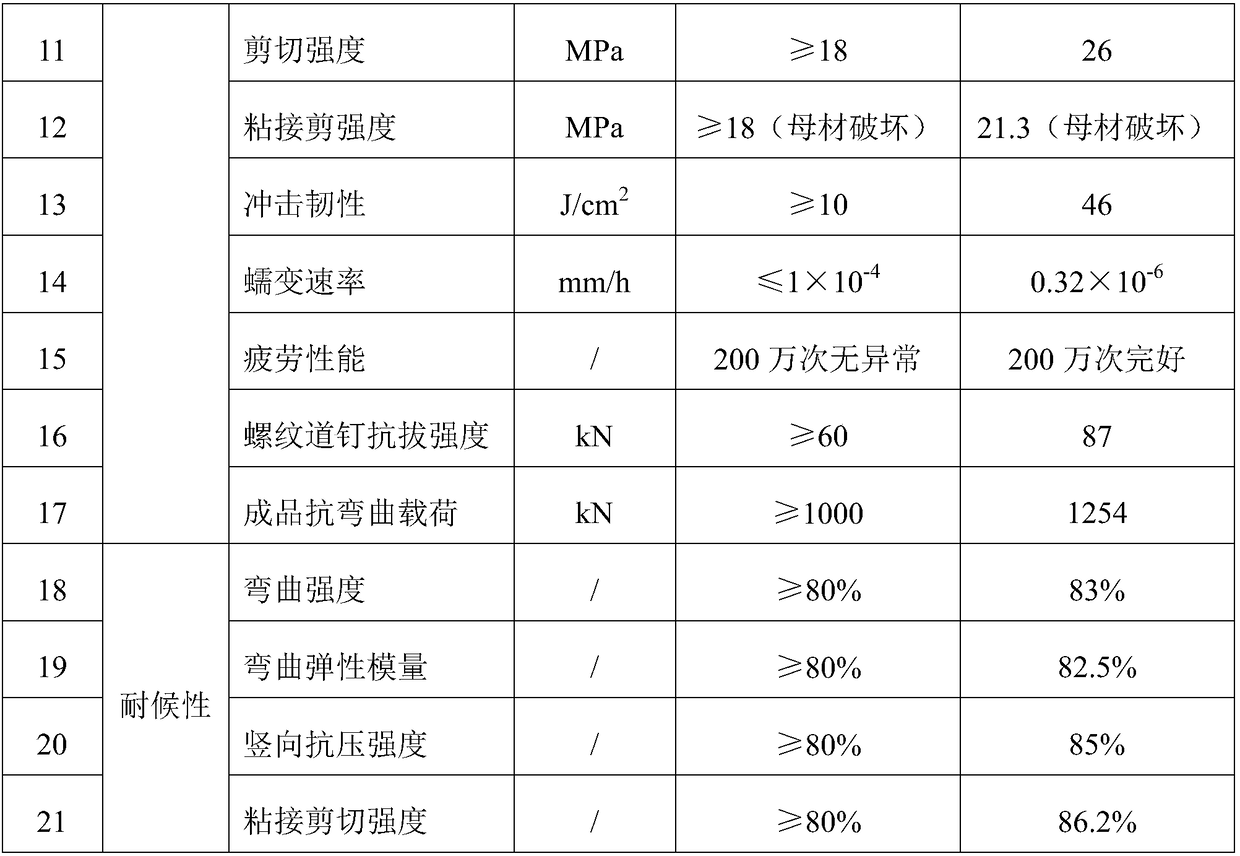

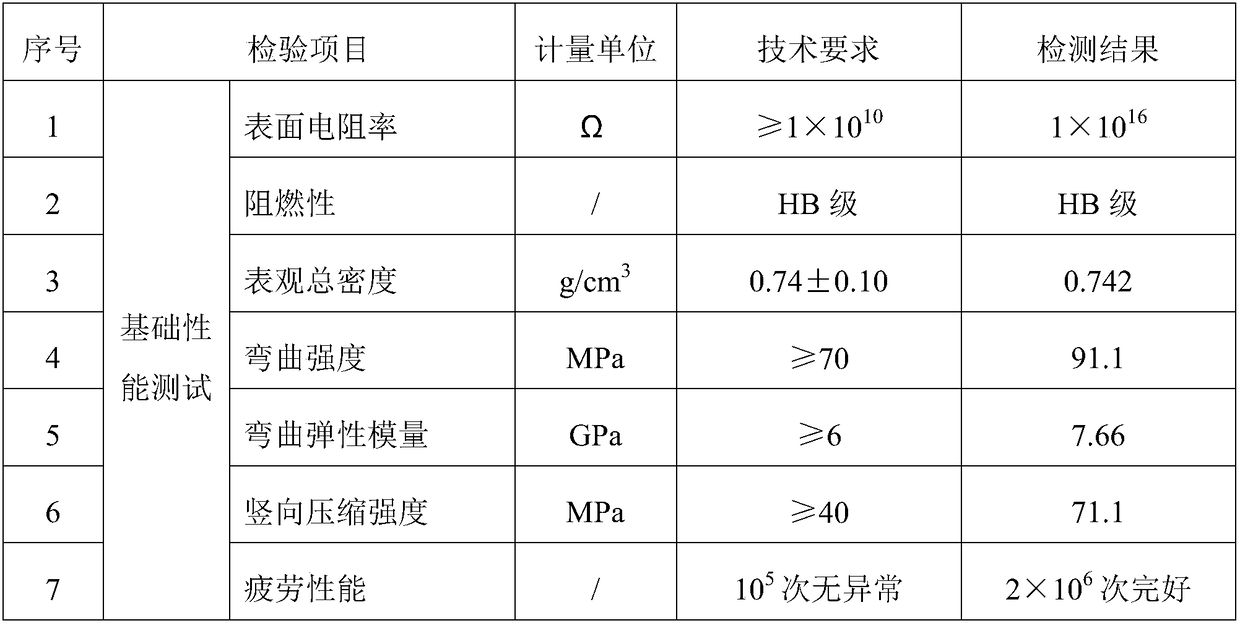

Embodiment 2

[0057] A fiber-reinforced polyurethane foam synthetic sleeper, which includes a body formed by one-time lamination of polyurethane resin, and a seven-layer composite felt for transverse reinforcement is arranged in the body, and a layer of composite felt is inserted in the polyurethane resin between adjacent composite felts. Fiber yarn layer for longitudinal reinforcement; fiber yarn layer and composite felt account for 70% of the total weight of the sleeper; polyurethane resin accounts for 30% of the total weight of the sleeper, and the density of the sleeper is 0.74±0.1g / cm 3 .

[0058] In the present embodiment, composite felt is 1100g / m 2 The fiberglass stitching mat is made of 9600TEX continuous glass fiber. Polyurethane resin is compounded by A component and B component with a weight ratio of 1.08:1; wherein, A component is polymerized MDI, and B component includes the following components in parts by weight: combined polyether 100 parts , 25 parts of flame retardant, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com