Patents

Literature

98 results about "Polymeric MDI" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymeric MDI. Polymeric methylene diphenyl diisocyanate (PMDI) is a brown mixture of monomeric (2-ring) and polyaromatic (3-ring and higher species) methylene diphenyl diisocyanates, which is liquid at room temperature.

Processes and Manufacturing Methods to Produce an Aqueous Thermosetting Fire-Rated Fire-Retardant Polymeric Adhesive Composition for Manufacturing Interior or Exterior Fire-Rated Cellulosic Products

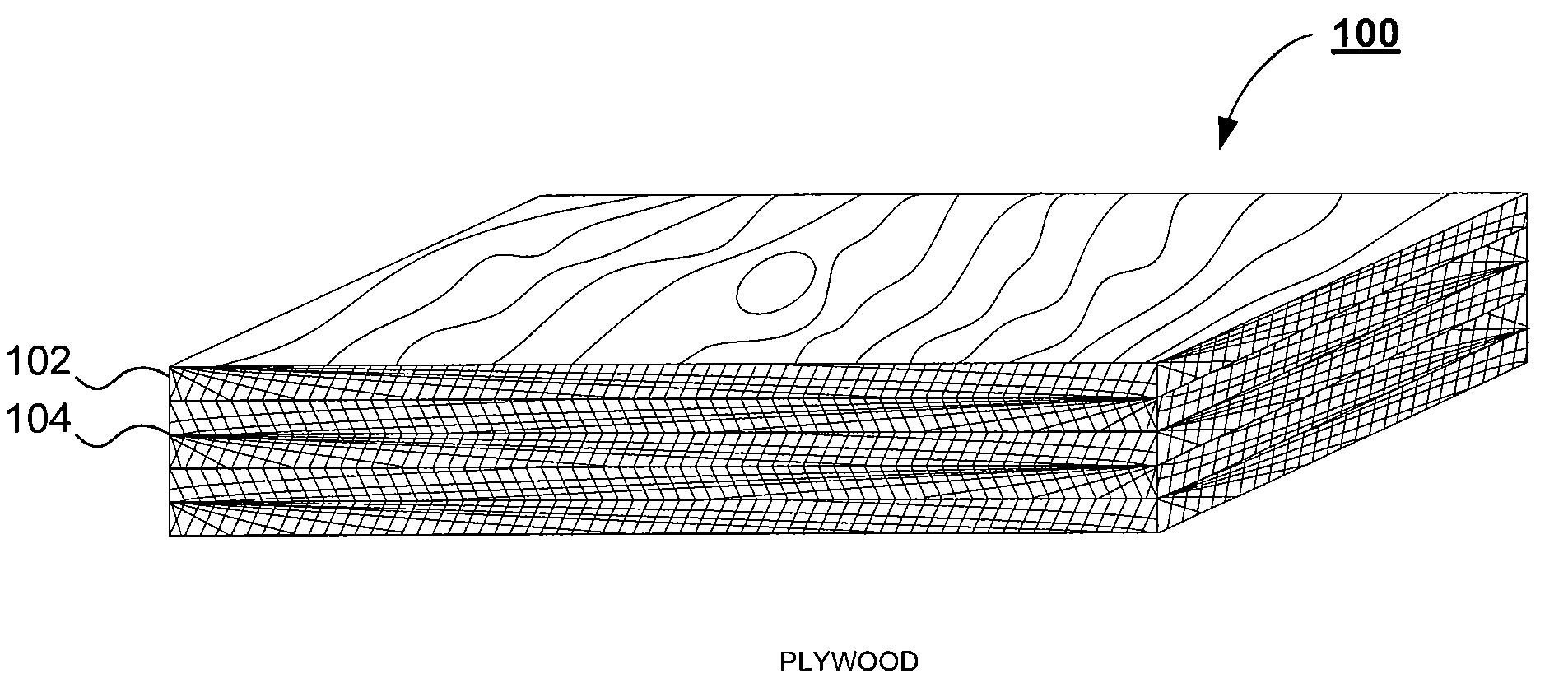

InactiveUS20080171231A1Impart resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsCellulosePolymer science

Disclosed is a fire-retardant non-corrosive composition, as well as a process for the production of porous materials, wherein the process is conducted in the presence of the said fire-retardant, non-corrosive composition. The fire-retardant, non-corrosive composition of the subject application includes a flame-retardant agent, preservative composition, casein liquid modified melamine resin adhesive, and a monomeric-polymeric MDI catalyst. The composition material and the product resulting from the process of the subject application have fire retardant, non-corrosive properties and protection from fungus and insects.

Owner:LOPEZ RICHARD A +1

Process for the production of 4,4'-diphenylmethane diisocyanate

InactiveUS20070117997A1Simple processOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4′-diphenylmethane diisocyanate (4,4′-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4′-MDI and polymeric MDI.

Owner:BAYER MATERIALSCIENCE AG

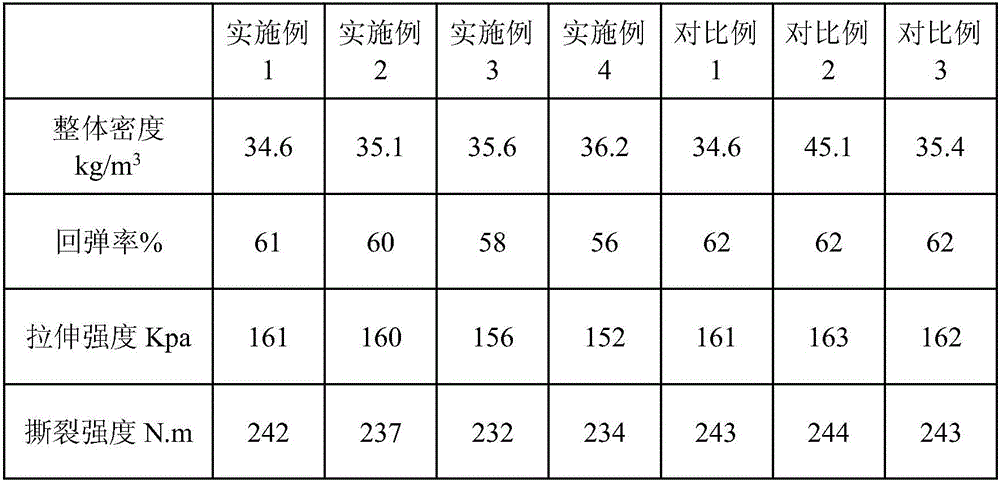

High flame-retardant polyurethane composition and preparation method thereof

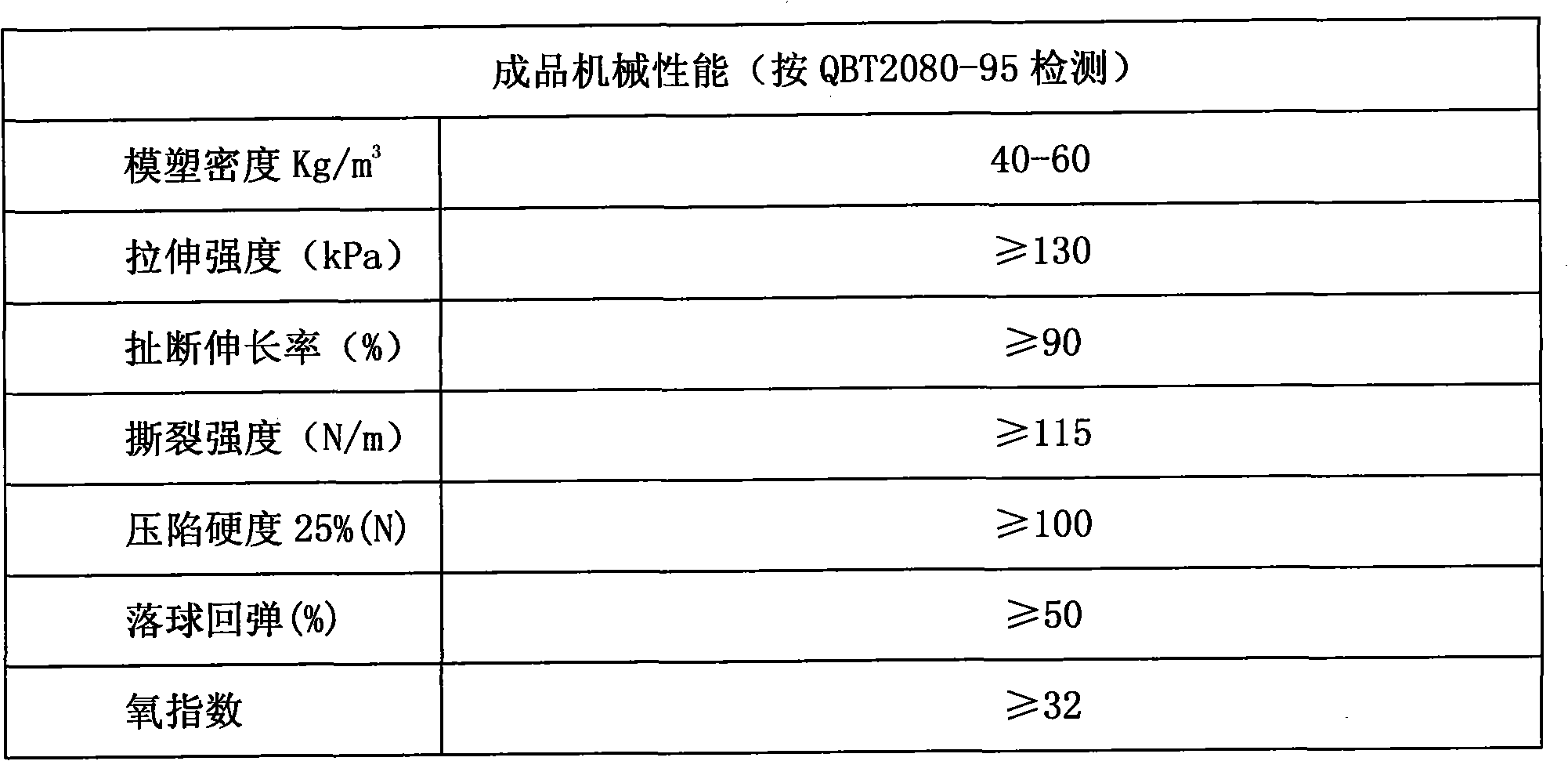

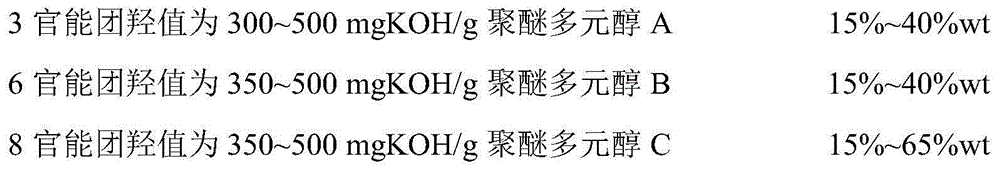

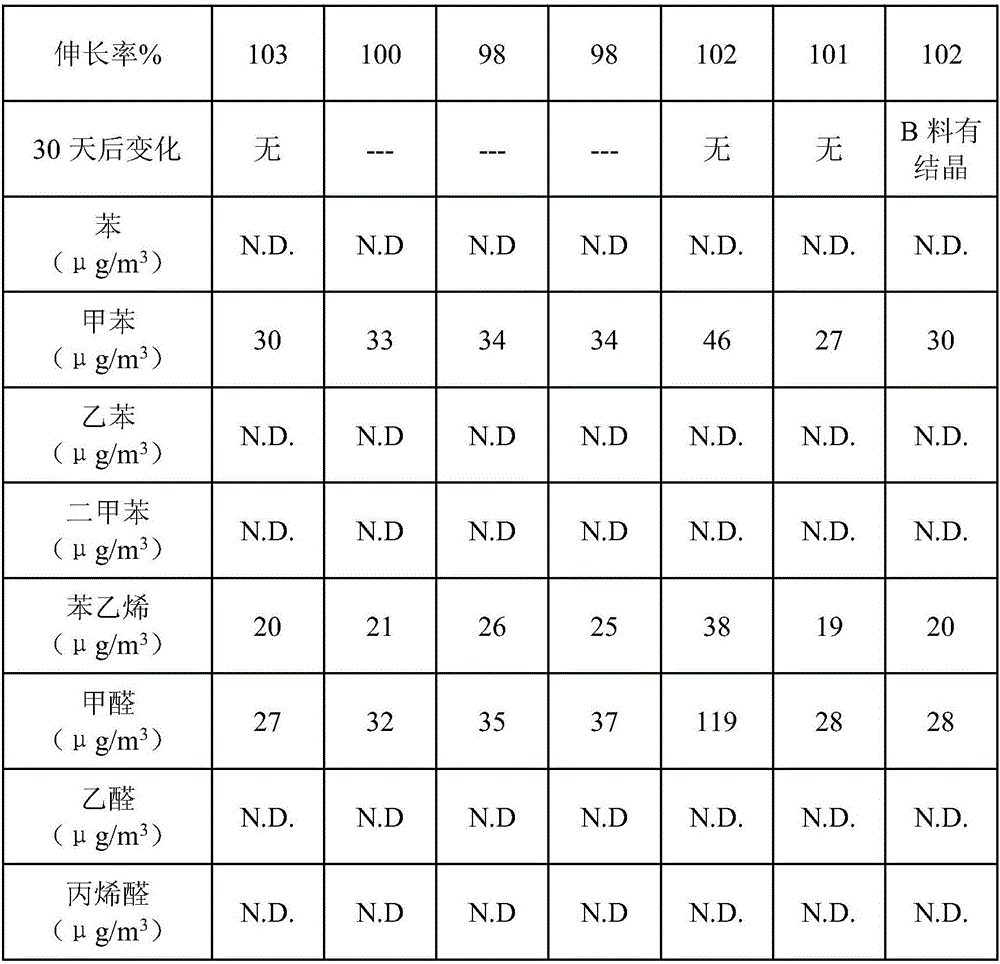

The invention provides a high flame-retardant polyurethane composition and a preparation method thereof. The high flame-retardant polyurethane composition consists of an A component and a B component, wherein the A component consists of polyether polyol, flame-retardant polyether polyol, a cross-linking agent, a foam stabilizer, water, a physical foaming agent and a catalyst; and the B component consists of the polyether polyol, a flame retardant, polymeric MDI and a toluene diisocyanate prepolymer. When in use, the A component and the B component are evenly mixed according to the weight ratio that A: B is equal to 100: 50-60 and injected into a mold at the mold temperature of 45-65 DEG C, mold-opening is carried out after 5-10 minutes, and placing is carried out for 24 hours at the normal temperature. The high flame-retardant polyurethane composition can achieve the higher flame retardance without additionally adding the flame retardant, the oxygen index is not less than 32, and the high flame-retardant polyurethane composition has the advantages of good fluidity, high storage stability and the like, thereby being very convenient to use and store by a foaming manufacturer.

Owner:SHANDONG INOV POLYURETHANE

Hard polyurethane foam for ultralow-temperature insulation and preparation method thereof

InactiveCN104788642AGood dimensional stabilityThe preparation method is simple and reliableFoaming agentSteam pressure

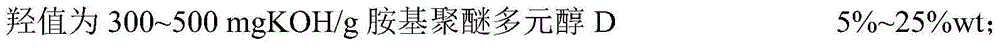

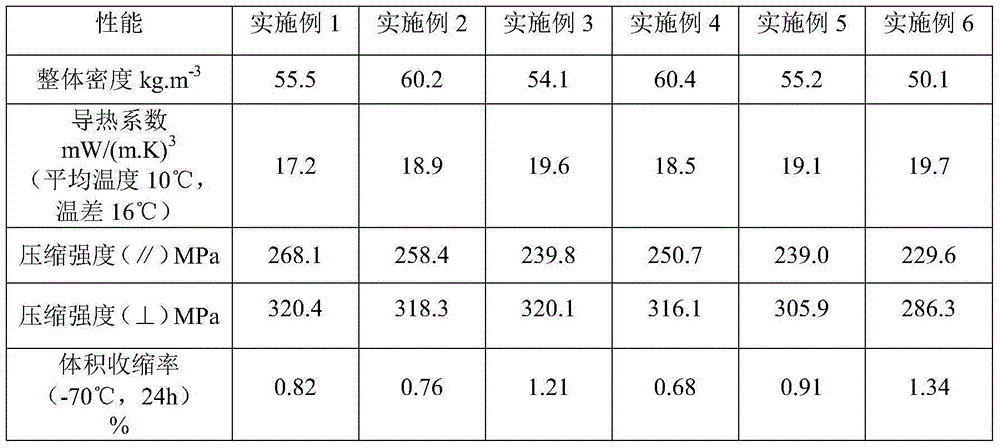

The invention discloses a hard polyurethane foam for ultralow-temperature insulation, which is prepared by independently foaming trans-1,3,3,3-tetrafluoropropylene or foaming the trans-1,3,3,3-tetrafluoropropylene with cyclopentane. By utilizing the characteristic that HFO-1234ze has higher steam pressure at low temperature, the polyurethane foam has favorable dimensional stability at ultralow temperature, and is applicable to the field of ultralow-temperature insulation. The hard polyurethane foam for ultralow-temperature insulation is prepared by mixing composite polyethers and poly MDI (methylenediphenyl diisocyanate) in a mass ratio of 1:(1.1-1.3), wherein the composite polyethers contain a physical foaming agent and a chemical foaming agent; the physical foaming agent is HFO-1234ze or an HFO-1234ze-cyclopentane mixture; and the chemical foaming agent is water.

Owner:NANJING FORESTRY UNIV

Polyurethane foam for wet-method preparation and preparation method thereof

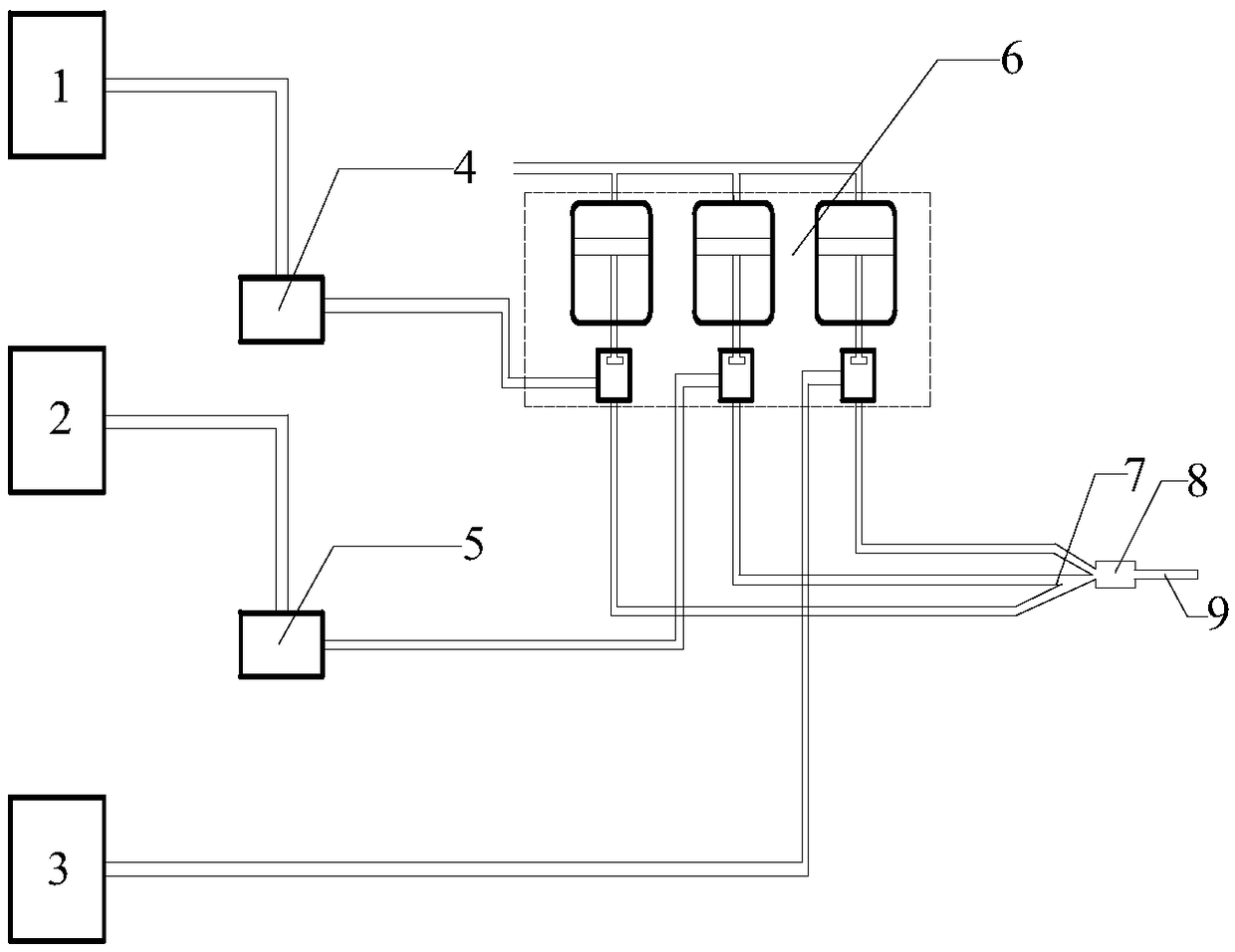

ActiveCN103275296AThe difference between the top, middle and bottom is reducedAccurate measurementProduction linePolymeric MDI

The invention relates to polyurethane foam for wet-method preparation and a preparation method thereof, and belongs to the field of polyurethane foam production. The polyurethane foam is used for wet-method preparation of an automobile skylight sun shield or an automobile top. The polyurethane foam comprises a material A composed of polyether polyol, glycerin, silicone oil, water, a catalyst 1, a reaction catalyst 2, a low-volatility catalyst, an opening agent, and an anti-oxidant, and also comprises a material B composed of a mixture of pure MDI or polymerized MDI and MDI. The material A and the material B are mixed according to the above ratio and then are foamed to form the polyurethane foam for wet-method preparation of an automobile skylight sun shield or an automobile top. The preparation method is mainly used for a foaming continuous-production line. The preparation method is suitable for large-scale multi-size production. The more yield is, the higher foaming rate is. The preparation method has the advantages that in the industry, it is recognized that continuous foaming and box type foaming have the advantages of high foaming quality, accurate raw material metering, and uniform foam apertures; difference of upper, middle and lower parts of the foam block is reduced; unavailable upper and lower parts of the foam block can be controlled; and through multiple top flattening technologies, a foam yield is improved.

Owner:WUXI GISSING AUTO PARTS CO LTD

Environmental-friendly two-component polyurethane waterproof coating and preparation method thereof

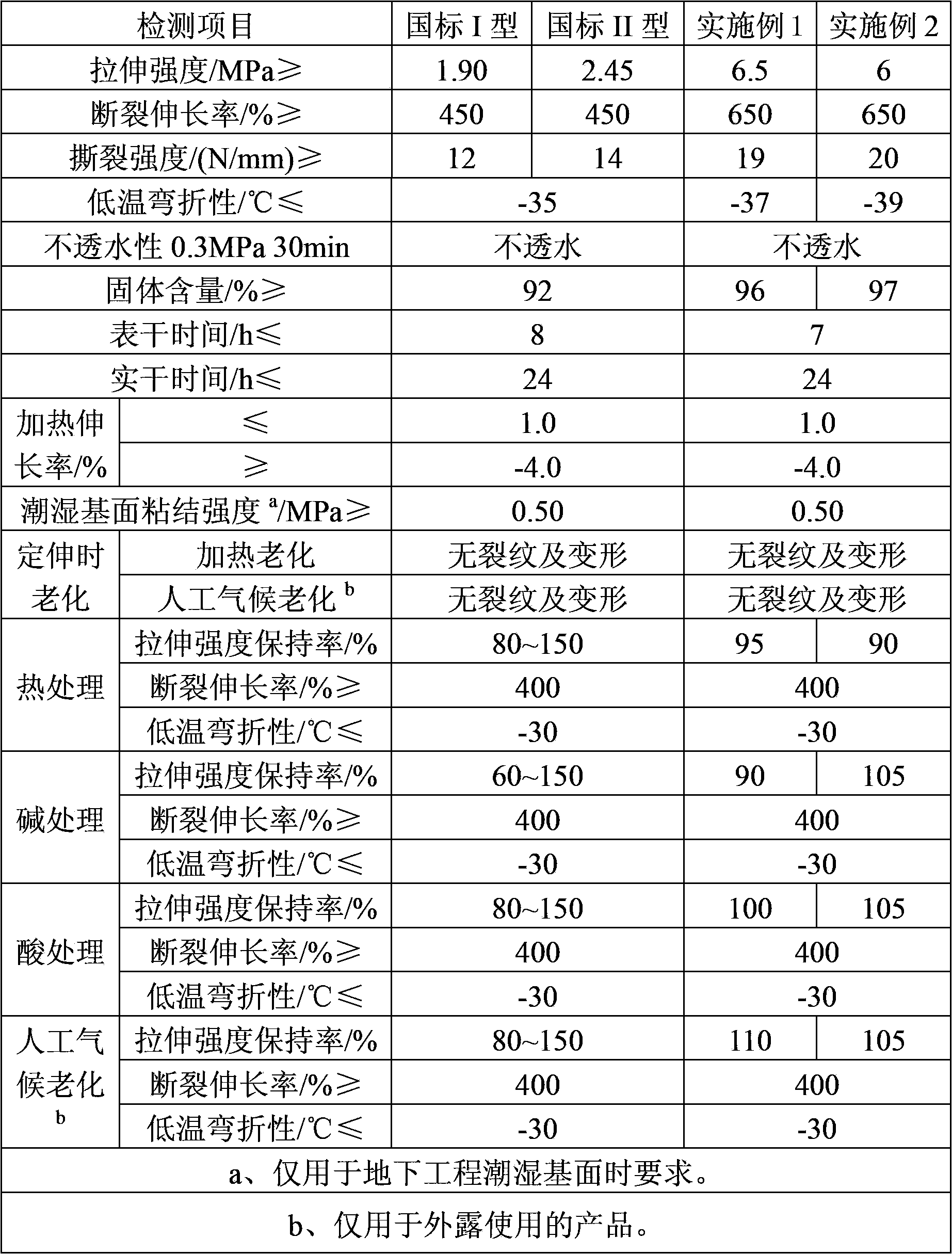

The invention discloses an environmental-friendly two-component polyurethane waterproof coating and a preparation method thereof. The environmental-friendly two-component polyurethane waterproof coating is prepared from components A and B; the component A comprises the following materials in percentage by weight: 10%-40% of polyether glycol N220, 20%-50% of polyether glycol N330, 1%-10% of dihydric alcohol, 10%-65% of isocyanate and 10 ppm of polymerization inhibitors, wherein the isocyanate is one or more than one of MDI (Diphenyl-Methane-Diisocyanate), MDI-50 and polymerized MDI; the component B comprises the following materials in percentage by weight: 10%-30% of the polyether glycol N220, 1%-20% of curing agents, 20%-50% of fillers, 10%-40% of plasticizing agents and 0.1%-2.0% of catalyst; the weight ratio of the component A to the component B is 1:2.3-1:2.8. The environmental-friendly two-component polyurethane waterproof coating disclosed by the invention can completely meet the requirement for standard of a waterproof coating used for a railway bridge in property without volatilizing a solvent or generating pungent smell or causing pollution and harmfulness to builders and a surrounding environment.

Owner:SHANGHAI DONGDA CHEM

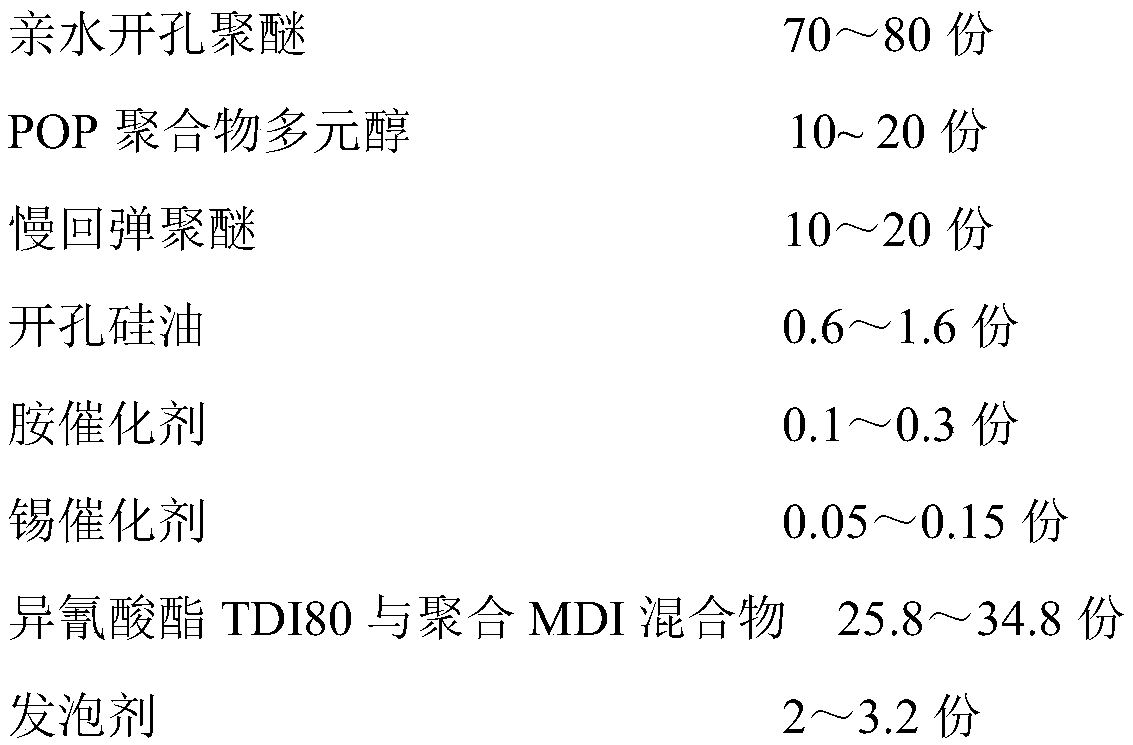

Full-open-cell high-breathable sponge and preparation method

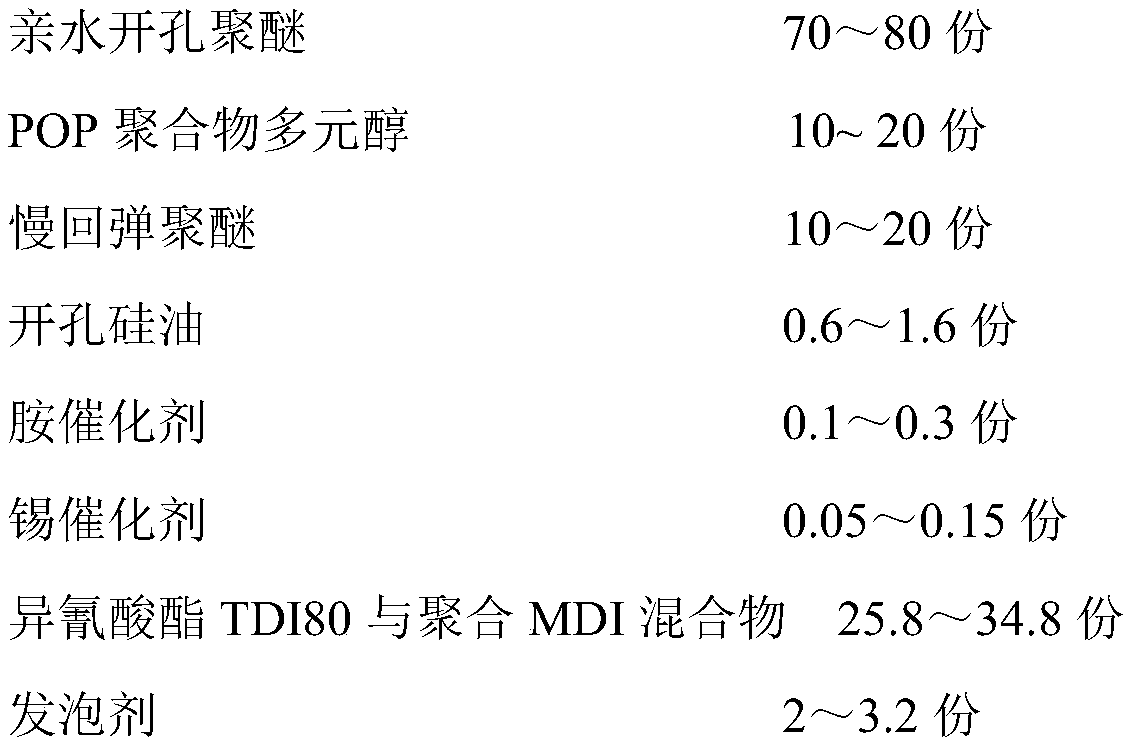

The invention discloses a full-open-cell and high-breathable sponge and a preparation method. The sponge is formed by the reaction of raw materials composed of the following components in parts by weight: 70-80 parts of hydrophilic open-cell polyether, 10-20 parts of POP polymer polyol, 10-20 parts of slow rebound polyether, 0.6-1.6 parts of open-cell silicone oil, 0.1-0.3 part of an amine catalyst, 0.05-0.15 part of a tin catalyst, 25.8-34.8 parts of a mixture of isocyanate TDI80 and polymerized MDI, and 2-3.2 parts of a foaming agent. The original density of the raw materials is 30-48 kg / m<3>, and the foaming index of the sponge is 0.84-0.98; and the hydrophilic open-cell polyether is polypropylene glycol PPG5000, the POP polymer polyol is POP2045, the slow rebound polyether is polypropylene glycol diacrylate PPG700, the foaming agent is water, the amine catalyst is A33, and the tin catalyst is tin catalyst T-9. The sponge has full open cells and excellent air permeability.

Owner:东莞市腾崴塑胶制品有限公司

Adhesives

InactiveUS20010031819A1Increase resistanceHigh strengthPolyureas/polyurethane adhesivesSpecial tyresEmulsionPolyvinyl acetate

An adhesive, comprising (A) a polymeric MDI, (B) modified polyvinyl acetate emulsion, (C) aqueous polyvinyl alcohol solution, and (D) a filler. Preferably, amass ratio of A:B:C:D is 30:(60-160):(50-160):(10-140) provided that the aqueous polyvinyl alcohol solution (C) is in a concentration of 10% by mass.

Owner:YAMAHA CORP

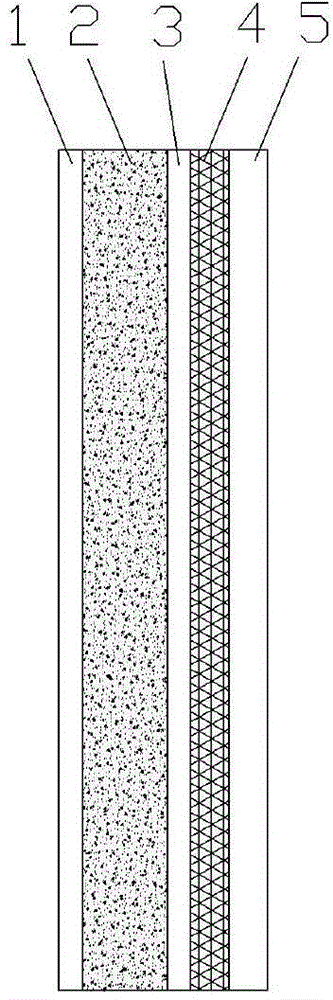

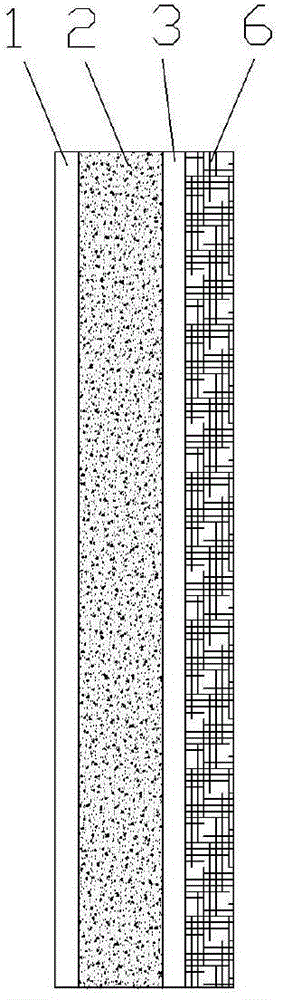

Heat-retaining and sound-insulating metal decorating plate

InactiveCN104929332AAvoid fire hazardsExtended service lifeCovering/liningsSynthetic resin layered productsSheet steelPolymeric MDI

The invention discloses a heat-retaining and sound-insulating metal decorating plate which comprises a metal heat-retaining baseplate and a sound-insulating decorating layer. The heat-retaining and sound-insulating metal decorating plate is characterized in that the metal heat-retaining baseplate comprises a first steel plate, a heat-retaining foam layer and a second steel plate sequentially from left to right, each of the first steel plate and the second steel plate is phosphorized, and the heat-retaining foam layer is formed by enabling rigid polyurethane foam premixed polyether and polymerized MDI to directly reacting between the first steel plate and the second steel plate. Compared with the prior art, the heat-retaining and sound-insulating metal decorating plate has the advantages that danger that heat-retaining materials are prone to catching fire is avoided, and the surface of each of the first steel plate and the second steel plate is phosphorized, so that corrosion resistance is realized, service life of the plate is prolonged, contact area between the heat-retaining foam layer and the steel plates can be increased, and combining is firmer while shedding is avoided; phosphorizing liquid enables films to be loose and porous in structure, so that sufficient contact area between the steel plates and the heat-retaining foam layer is guaranteed, and the plate is enabled to be firmer and more durable.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

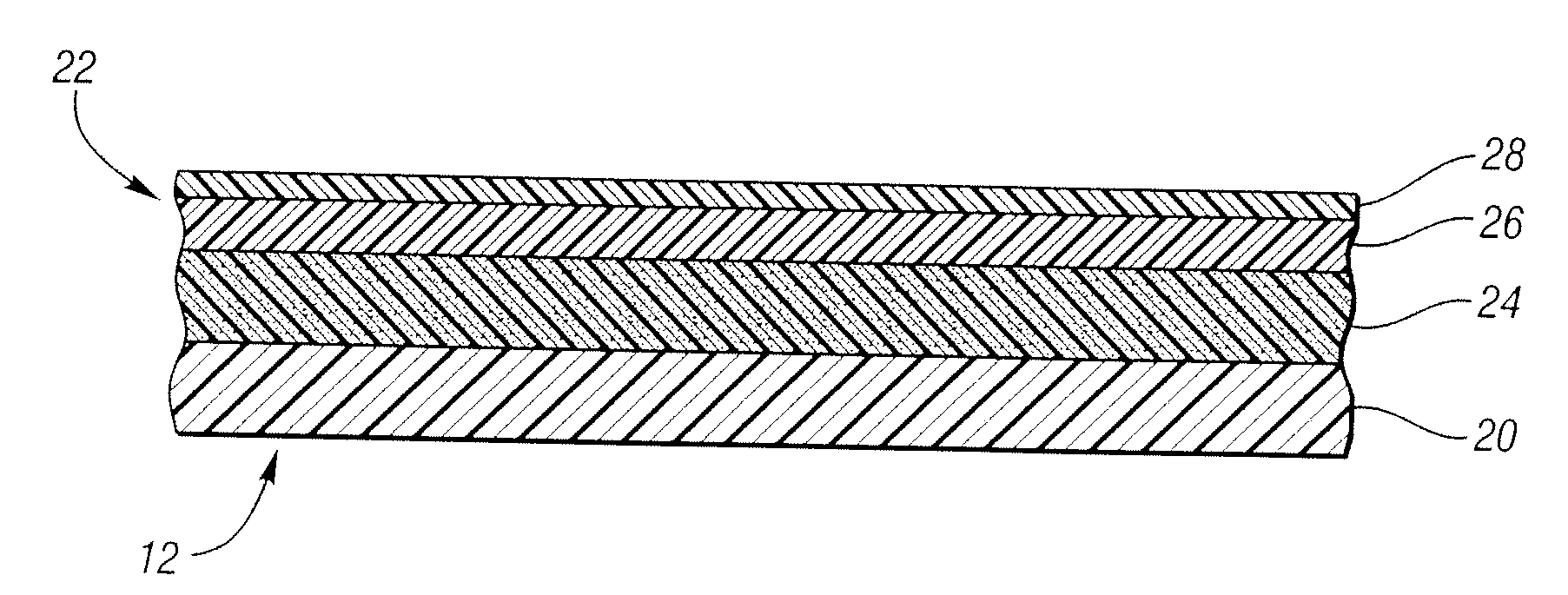

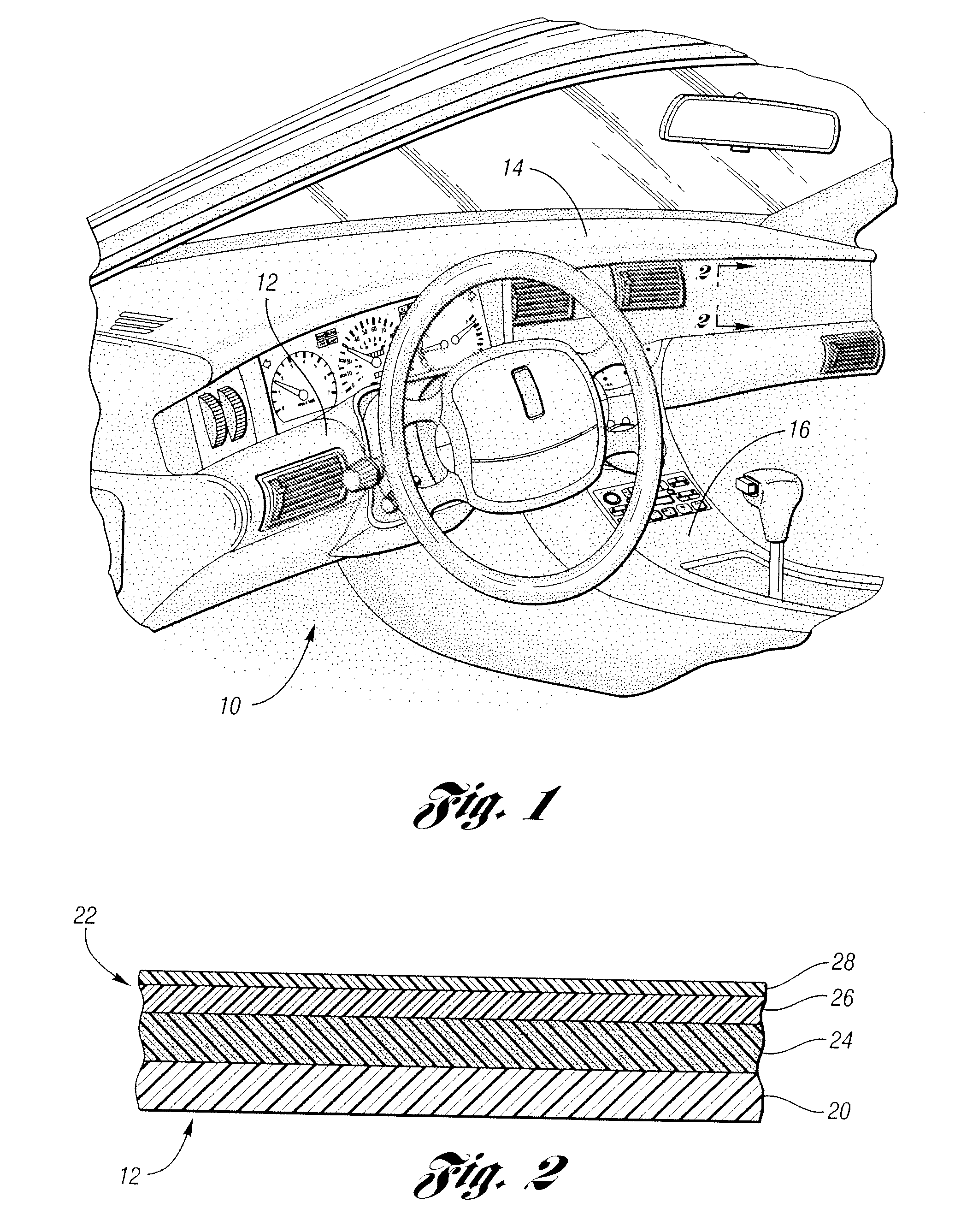

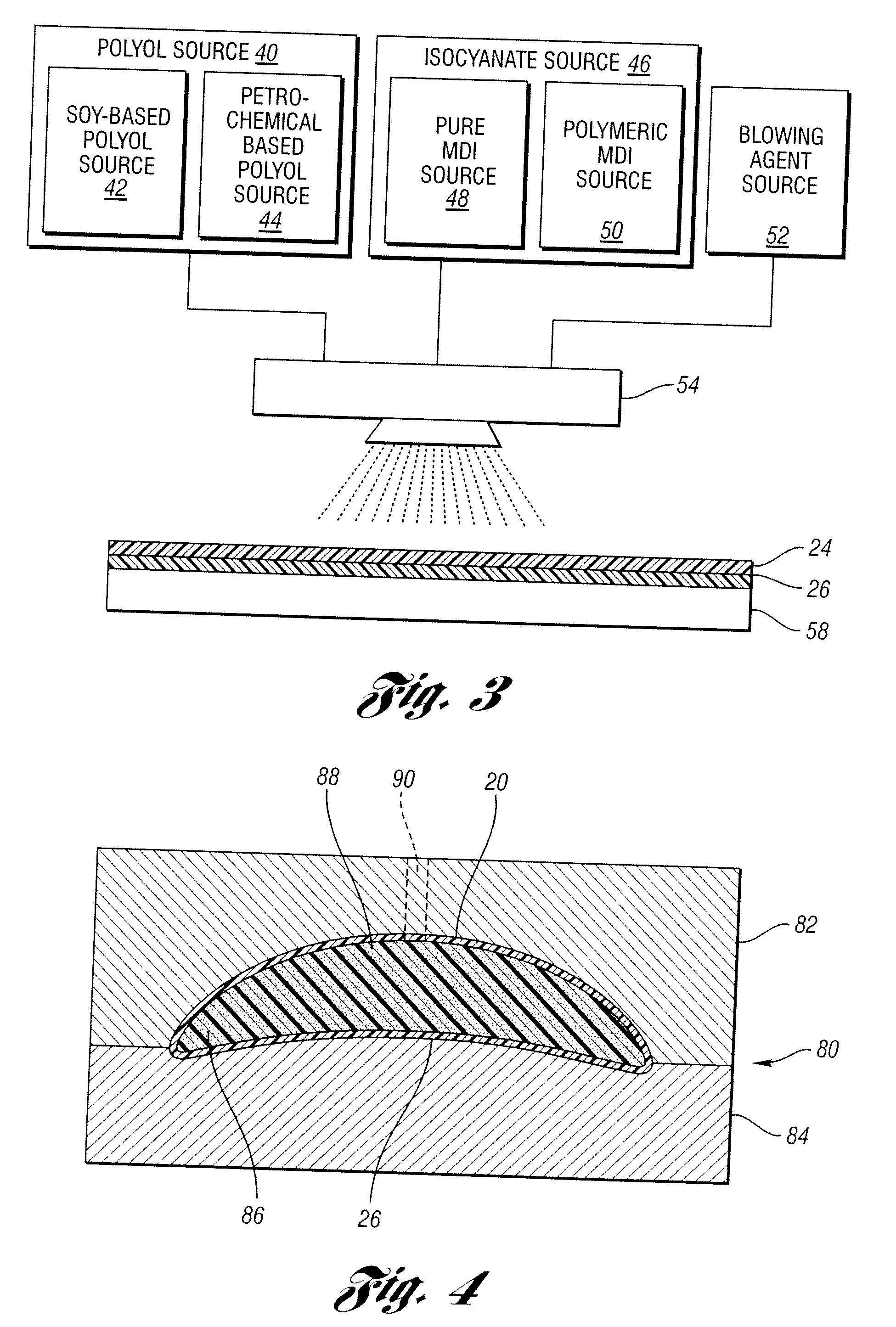

Interior panel component for use with a vehicle and method for making

InactiveUS20100151227A1Synthetic resin layered productsLaminationPolymeric MDIElectrical and Electronics engineering

The invention relates to an interior panel component and the method for making the component. The interior panel component for use with a vehicle includes a skin layer, and a resilient layer secured to the skin. The resilient layer is made from a polymeric MDI, a pure MDI, and a polyol. The polyol is less than 50 pphr of a soy-based polyol. The resilient layer is secured to a substrate to form the interior panel component.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

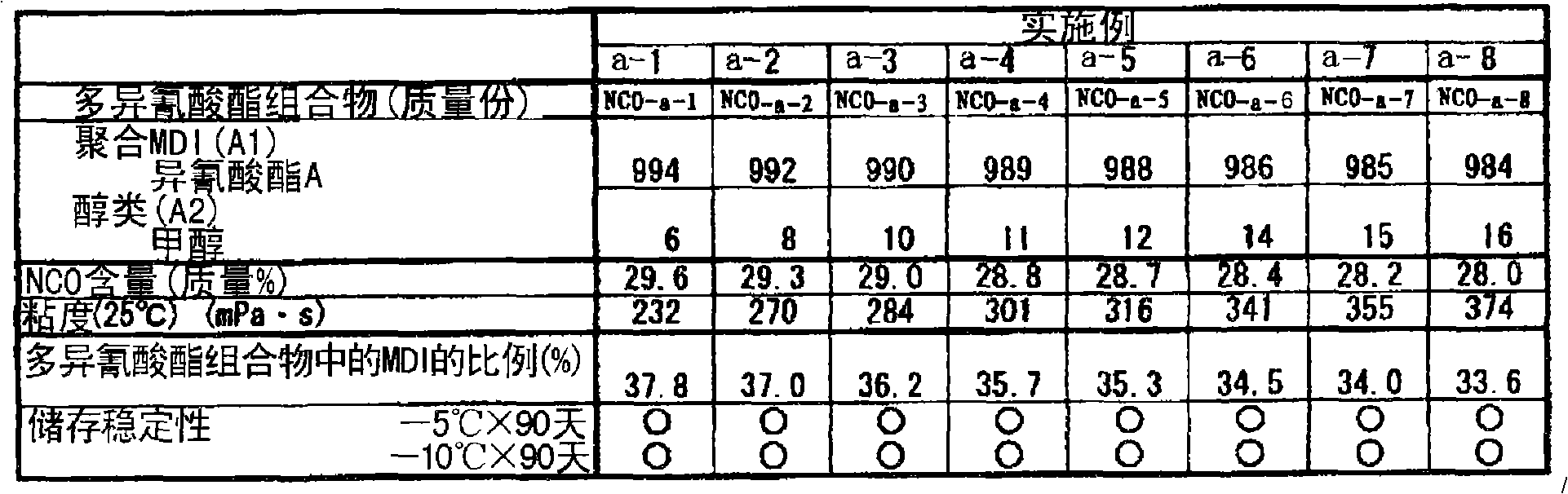

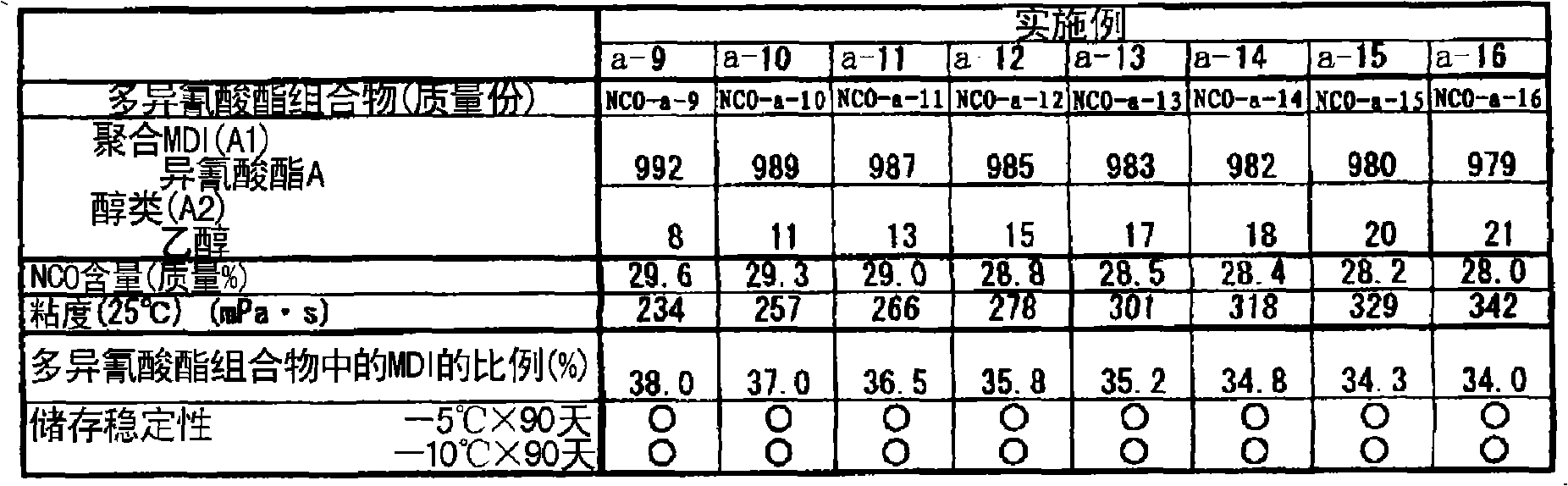

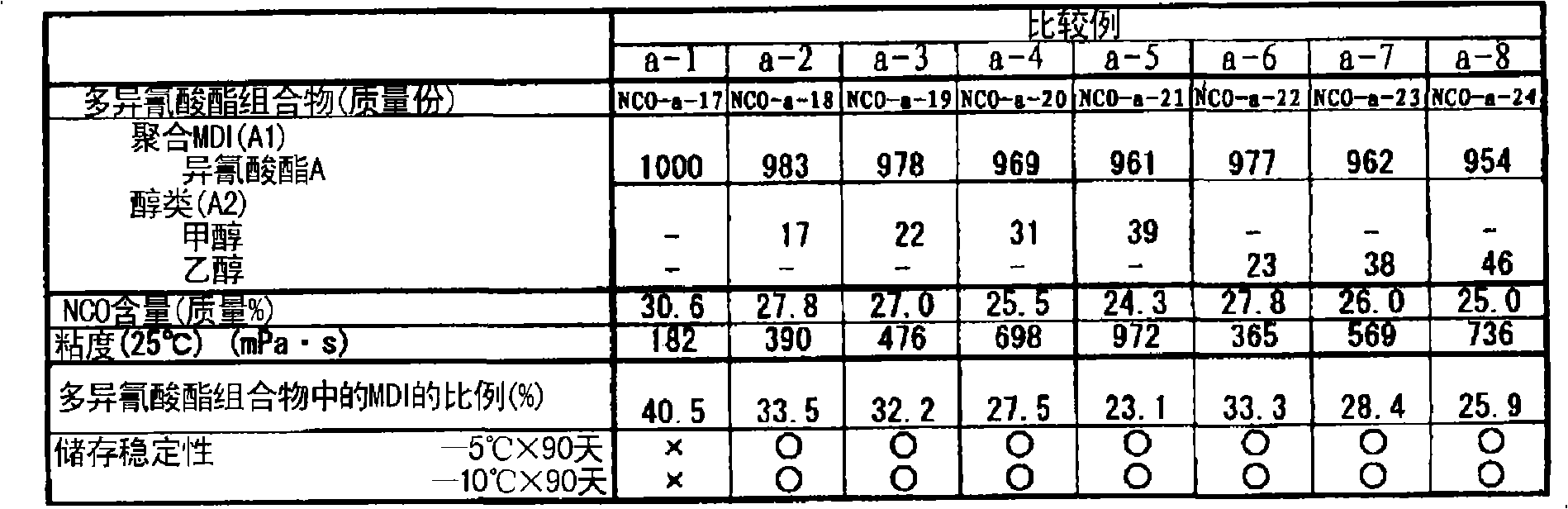

Polyisocyanate combination and method for preparing rigid isocyanurate foam using the same

The invention provides an isocyanate composite and a preparation method for scleroid polyurethane foam using the same. A preparation method for scleroid polyurethane foam using the hydrocarbon as the vesicant with independent bubbles; the scleroid polyurethane foam has a great storing stability, and the scleroid polyurethane foam can provide the heat conductive performance and great mechanical physical property (size stability and so on) for the scleroid polyurethane foam with the independent bubbles. The method uses the isocyanate composite composed by the polymerized MDI and alcohols with molecular weight less than 150 to prepare the scleroid polyurethane foam with the independent bubbles.

Owner:NIPPON POLYURETHANE IND CO LTD

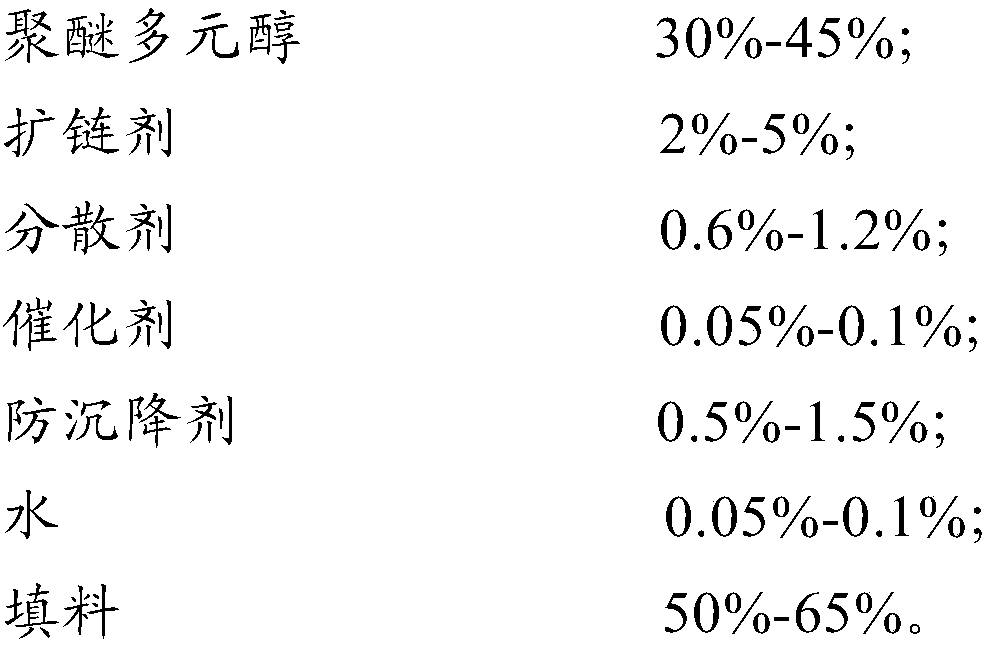

Double-component polyurethane adhesive used in construction, and preparation method thereof

ActiveCN107556962AHigh bonding strengthHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymeric MDI

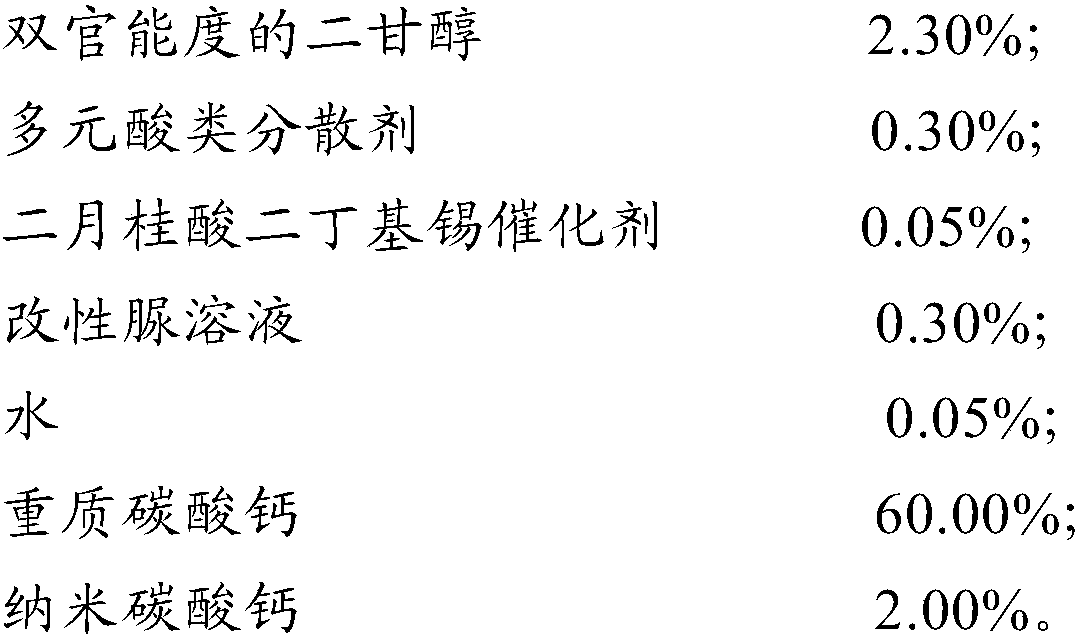

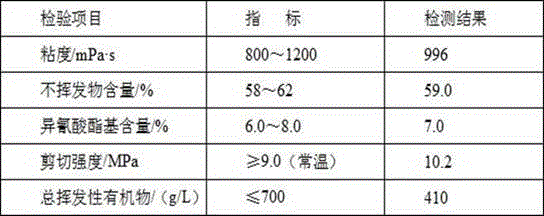

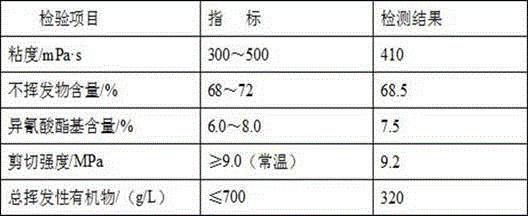

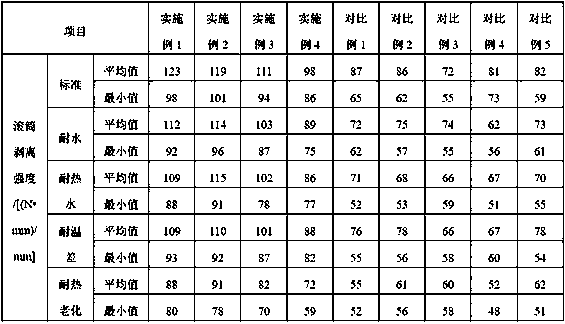

The invention discloses a double-component polyurethane adhesive used in construction, and a preparation method thereof. The double-component polyurethane adhesive used in construction is composed ofa component A and a component B at a weight ratio of 5:1; the component B is polymeric MDI; the component A comprises, by mass, 30 to 45% of a polyether polyol, 2 to 5% of a chain extender, 0.6 to 1.2% of a dispersant, 0.05 to 0.1% of a catalyst, 0.5 to 1.5% of an anti-sedimentation agent, 0.05 to 0.1% of water, and 50 to 65% of water. According to the preparation method, the polyether polyol andthe chain extender of the component A are combined, so that a three-dimensional net structure with higher crosslinking degree is formed in solidification, the content of hard segments in the three-dimensional net structure is increased, and the bonding strength of the double-component polyurethane adhesive is increased; a foaming structure is formed via reaction of water with isocyanate, so that apart of the double-component polyurethane adhesive penetrates into rock wool for solidification reaction, the strength of rock wool main body is increased, and the bonding strength of cement boards with rock wool is increased.

Owner:保光(天津)汽车零部件有限公司

Coarse TDI (toluene diisocynate) treating method

ActiveCN106753180AEasy to useImprove performancePolyureas/polyurethane adhesivesPolyurethane adhesivePolymeric MDI

The invention relates to the technical field of synthesizing of TDI (toluene diisocynate), in particular to the technical field of treatment of wastes in the synthesizing process, and discloses a coarse TDI treatment method. The method is characterized in that coarse TDI is modified through polymerized MDI (methylene diphenyl diisocyanate), and thus novel modified isocyanate can be produced and can be used as a raw material for producing a polyurethane adhesive. The production method is simple; the prepared polyurethane adhesive is high in performances. With the adoption of the method, the technical problems in the prior art that the cost of treating coarse TDI in the TDI synthesizing process is high, the generated tar solid wastes are hardly treated and the environment is polluted can be solved; the tar solid wastes can be effectively reduced, and thus the environmental pollution is reduced; and the economic benefit is high.

Owner:CANGZHOU DAHUA CO LTD

Polyisocyanates for soft polyurethane foam board and producing method for soft polyurethane foam board using same

The present invention provides a soft polyurethane foam plate with a well -operated stabilization stability of low temperature storage and well operating at low viscosity. Polycylisocyanate, as well as good productivity and formability, can be manufactured by low -density soft polyurethane bubble boards.The invention is prepared by reacting the polymerization MDI (A) and polyol (B) in the following shown below (A) / (B) = 80 / 20-95 / 5 (quality ratio), and the content of isocyanate is 25~ 32 quality %, aggregate MDI (A): The content of the dual -core component is 50 to 80 % of the mass, and 4, 4' -diophenyl nterrocyanate in dual -core components is 10~ 20 % of the polymerization MDI.Polynes (B): Polyal polymer polymiol with average official energy base of the nominal nominal is 4 and the average molecular weight of 5000 to 100,000.

Owner:NIPPON POLYURETHANE IND CO LTD

Two-component polyurethane composite adhesive and preparation method thereof

ActiveCN110184022AHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention relates to the field of production of composite adhesives, and provides a two-component polyurethane composite adhesive and a preparation method thereof. The invention aims to improve the bonding effect of the composite adhesive. The two-component polyurethane composite adhesive comprises a component A and a component B, wherein the component A comprises, in parts by mass, 15-20 parts of modified castor oil polyol, 10-15 parts of castor oil polyol, 5-10 parts of branched polyether / polyester polyol, 0.5-1 part of a nano reinforcing material, 55-60 parts of a filler, 0.5-2 parts ofa water removing agent, 1-2 parts of calcium oxide, 4-6 parts of activated alumina powder and 0.5-1 part of an auxiliary agent; and the component B comprises 20-30 parts by mass of polymerized MDI. The polyurethane adhesive still maintains good bonding strength after high-temperature aging is performed.

Owner:佛山市桐立新材料科技有限公司

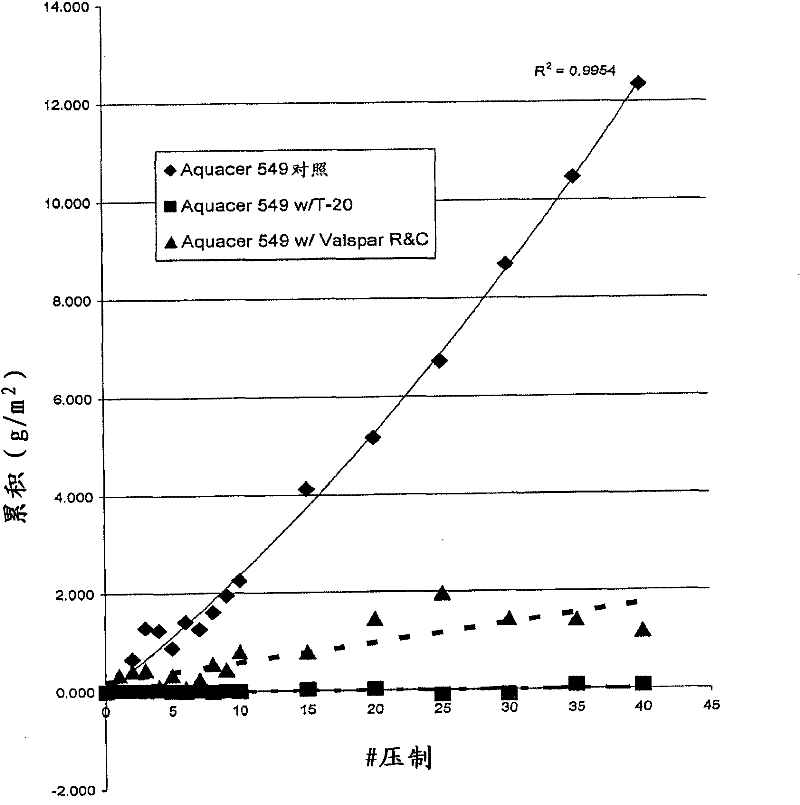

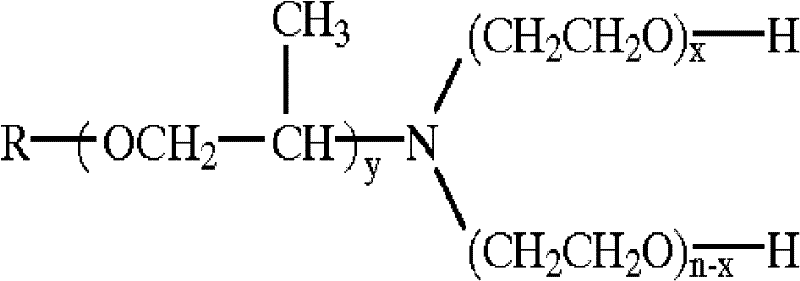

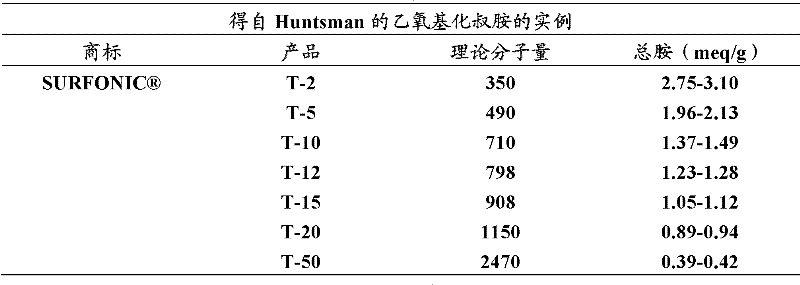

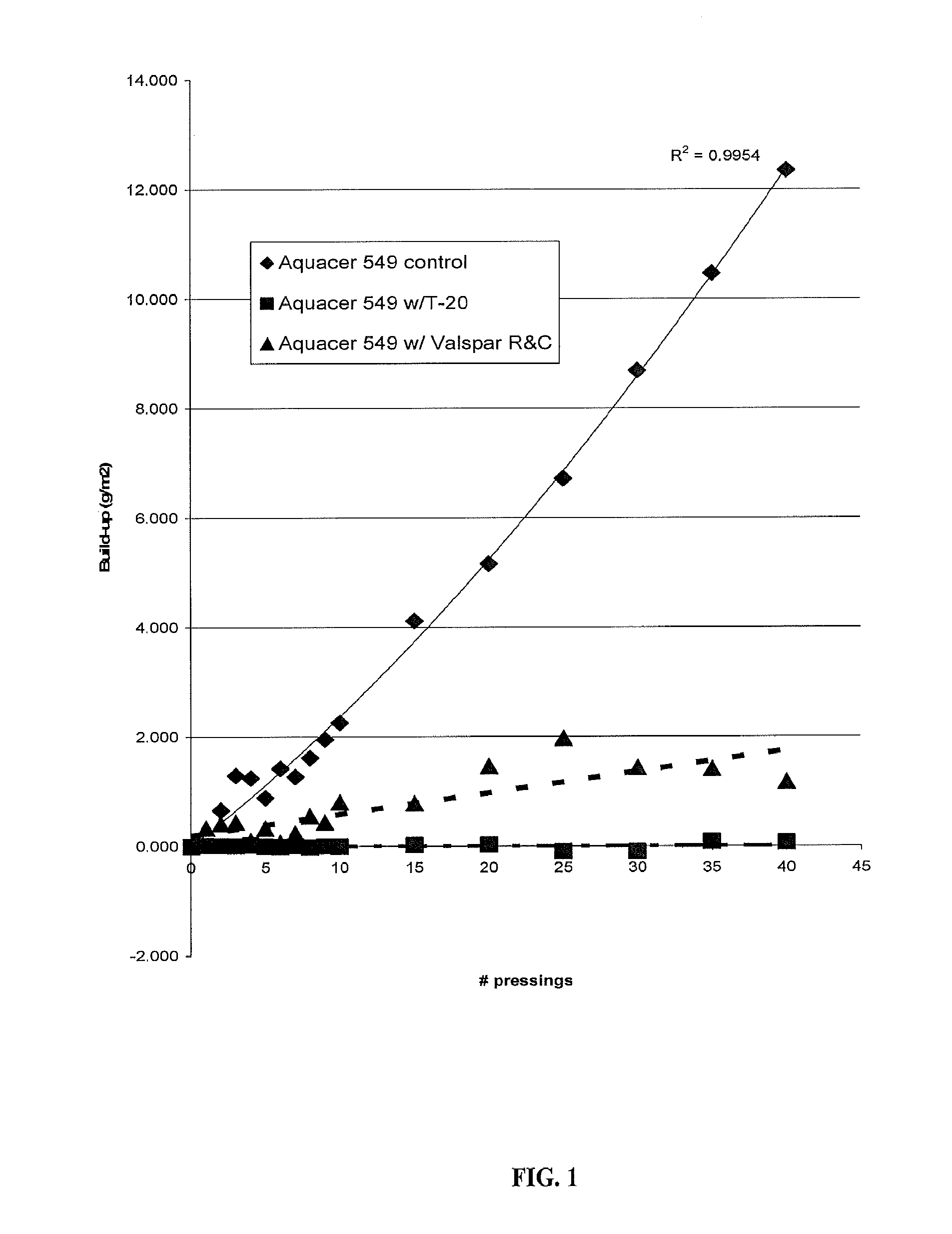

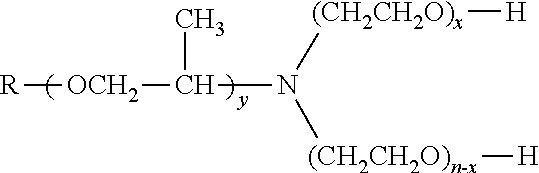

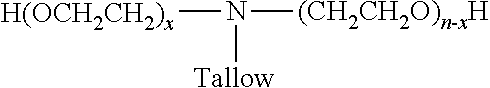

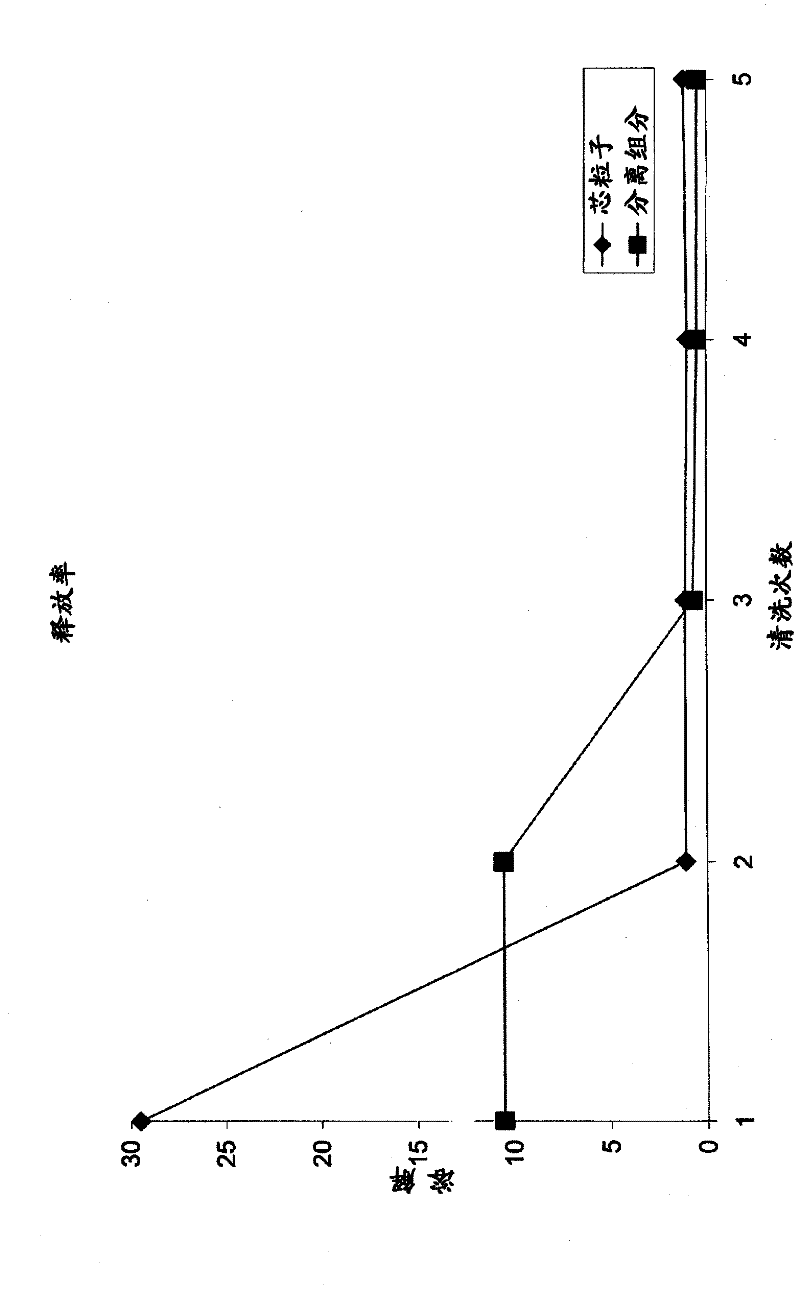

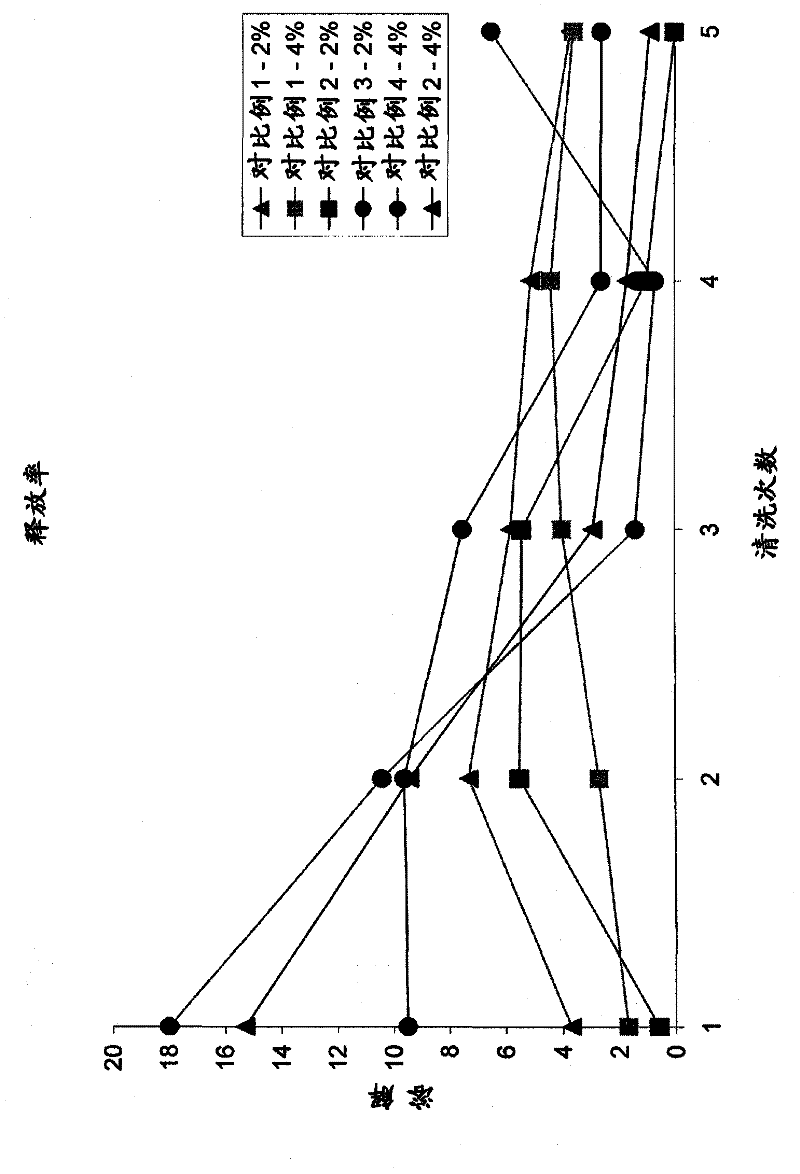

Release compositions for lignocellulosic composites

Lignocellulosic composites are made by pressing a mixture of a particulate lignocellulosic material with polymeric MDI, in the presence of a fatty amine ethoxylate anti- masking agent.

Owner:HUNTSMAN INT LLC

Method for producing 4,4'-methylene (diphenyldiisocyanate)

ActiveCN1966489AOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4'-diphenylmethane diisocyanate (4,4'-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4'-MDI and polymeric MDI.

Owner:COVESTRO DEUTSCHLAND AG

Anti-aging environment-friendly polyurethane foam combination material and preparation method thereof

The invention relates to an aging-resistant and environment-friendly polyurethane foam composite material and a preparation method thereof. It includes material A and material B; material A includes: polyether polyol, polymer polyol, foam stabilizer, catalyst, auxiliary agent, crosslinking agent and foaming agent; material B includes: toluene diisocyanate, modified diisocyanate Benzyl methane diisocyanate; the auxiliary agent is an aldehyde scavenger; the foaming agent is a composite foaming agent, which is composed of a mixture of cyclopentane and n-pentane and pure water. Preparation of material A: heat polyether polyol and polymer polyol, then mix them in the reaction container, add catalyst, auxiliary agent, crosslinking agent, then add foam stabilizer and foaming agent, and react; The preparation method comprises the following steps: mixing and stirring liquefied MDI and polymerized MDI, then adding TDI 80 / 20, and charging after passing the test. The polyurethane foam produced by the combined material has low density, is environmentally friendly and non-toxic, and has good aging resistance.

Owner:江苏向阳科技有限公司

Release Compositions for Lignocellulosic Composites

Lignocellulosic composites are made by pressing a mixture of a particulate lignocellulosic material with polymeric MDI, in the presence of a fatty amine ethoxylate anti-masking agent.

Owner:HUNTSMAN INT LLC

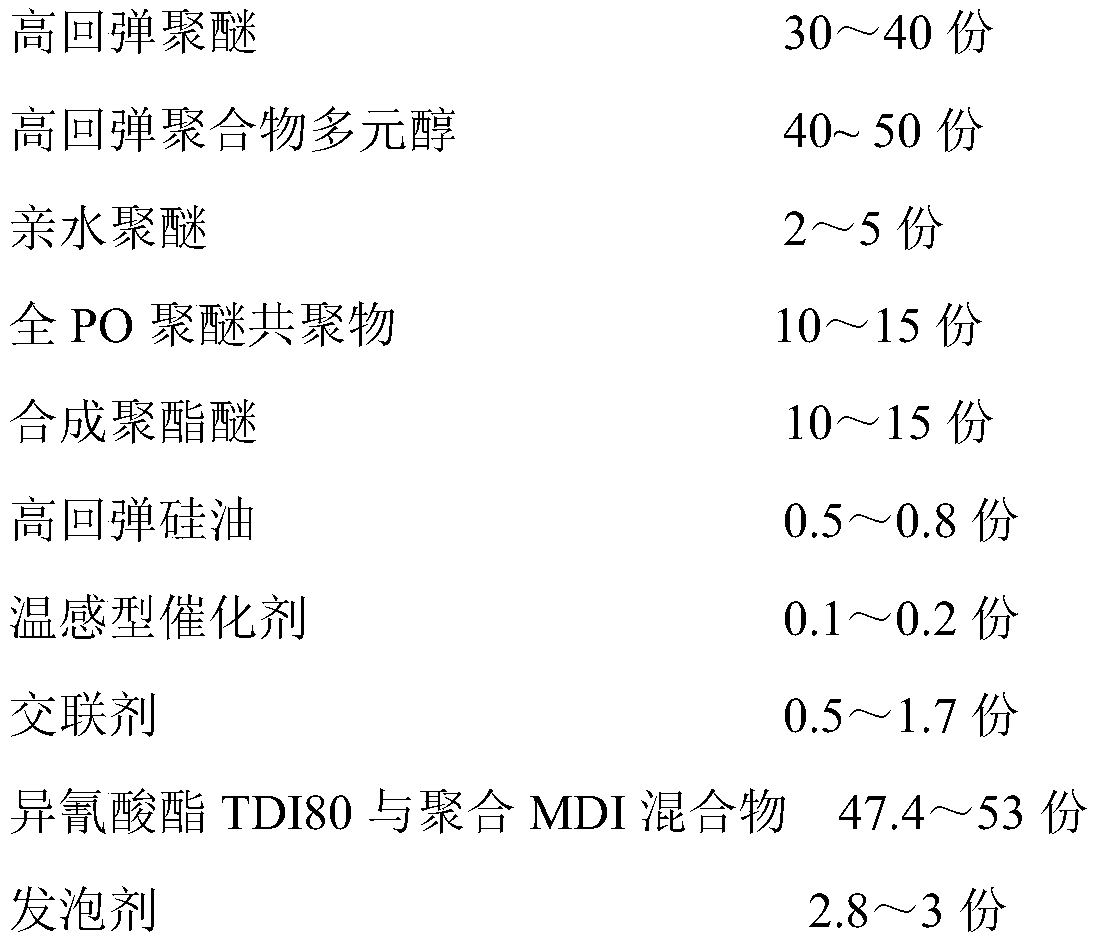

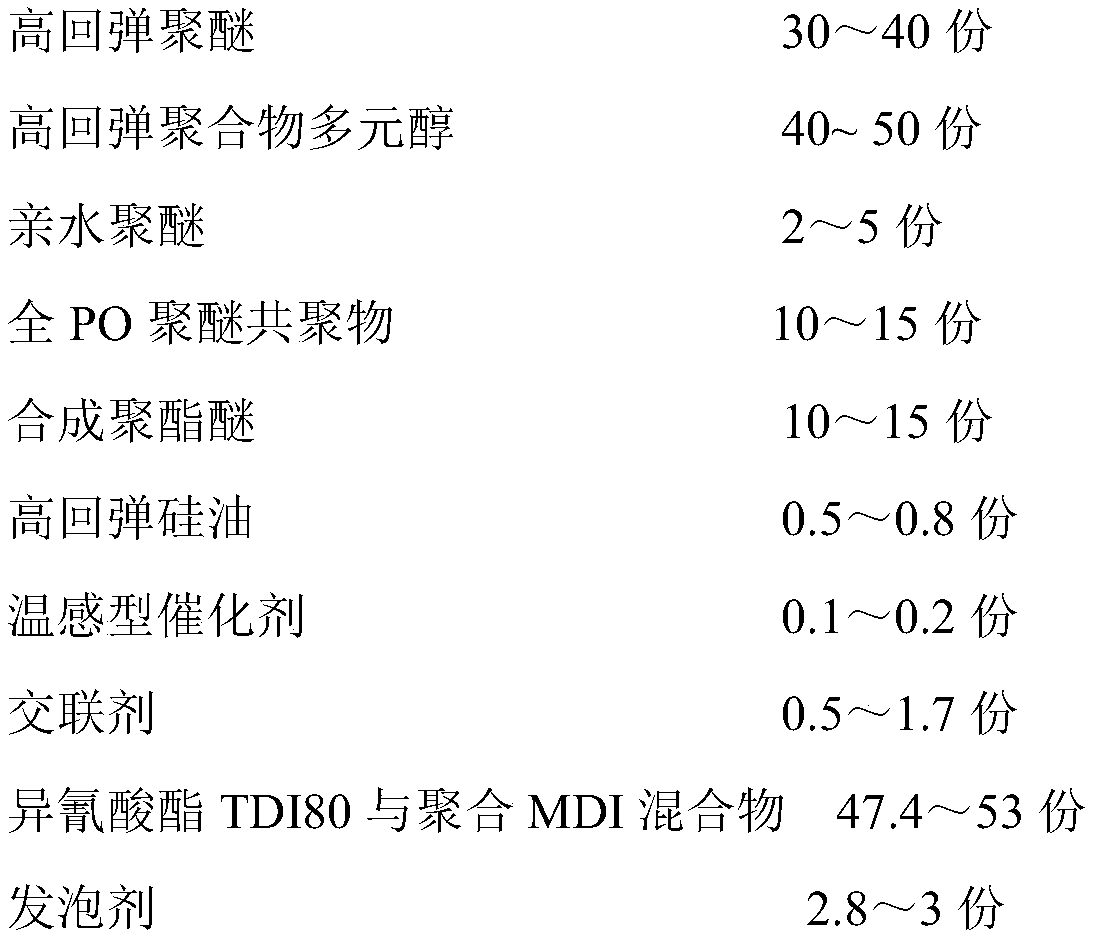

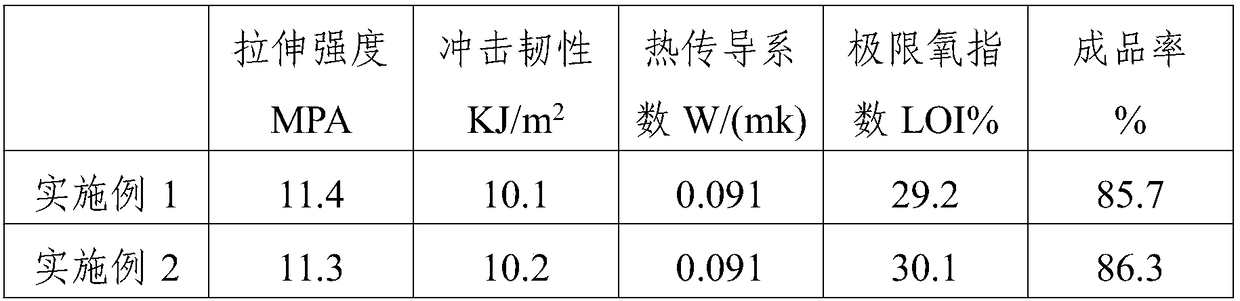

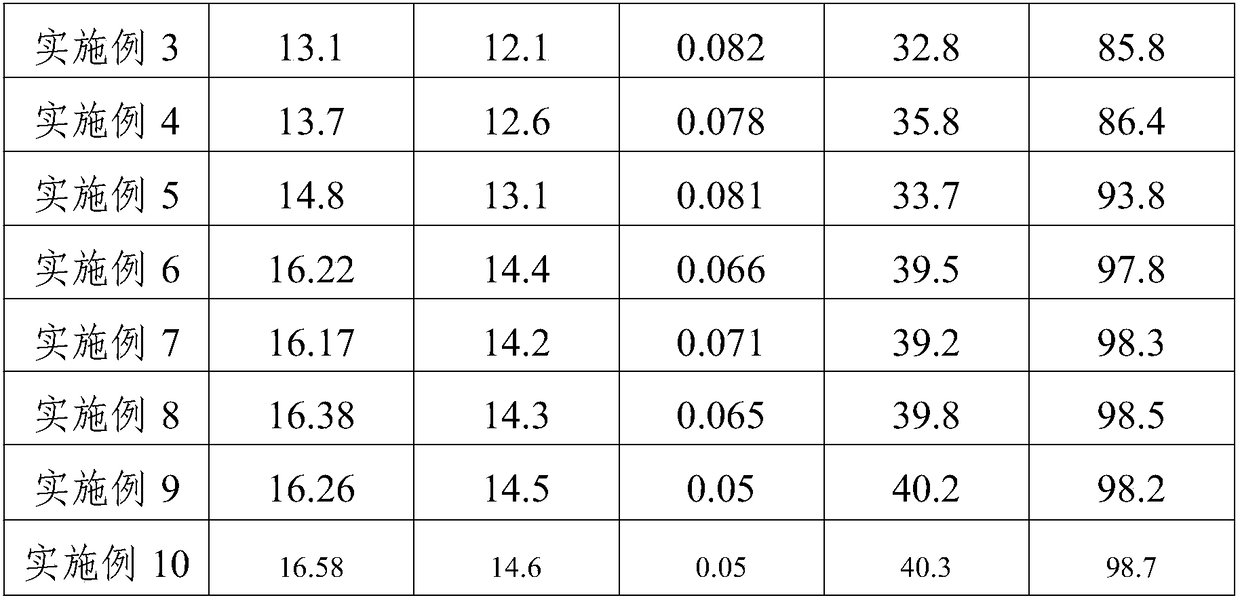

High-resilience sponge and preparing method

The invention discloses high-resilience sponge and a preparing method. The high-resilience sponge is obtained through reaction of raw materials which include, by weight, 30-40 parts of high-resiliencepolyether, 40-50 parts of high-resilience polypolyols, 2-5 parts of hydrophilic polyether, 10-15 parts of full PO polyether copolymers, 10-15 parts of synthesized polyester ether, 0.5-0.8 part of high-resilience silicone oil, 0.1-0.2 part of a temperature sensitive catalyst, 0.5-1.7 parts of a crosslinking agent, 47.4-53 parts of mixtures of isocyanate TDI80 and polyMDI and 2.8-3 parts of a foaming agent. According to the prepared sponge, at normal temperature, the resilience rate is 69-72, the resilience is good, the hardness of the sponge is within 110-130 N, and the sponge is not easily torn and long in service life.

Owner:东莞市腾崴塑胶制品有限公司

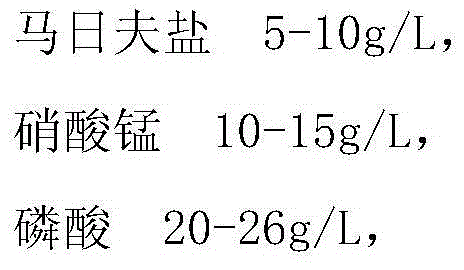

Waste textile wall thermal insulation plate and preparation method thereof

InactiveCN108440950ASolve the technical problems of difficult disposal and low recycling rateImprove insulation effectThermal insulationPolymeric MDI

The invention provides a waste textile wall thermal insulation plate and a preparation method of the waste textile wall thermal insulation plate, and relates to the technical field of thermal insulation materials. The waste textile wall thermal insulation plate comprises the following components by mass: 30-35% of waste textiles, 10-15% of waste plastic, 7-10% of thermoplastic polyurethane, 10-15%of a flame retardant, 10-15% of polyether polyol, and 20-25% of polymeric MDI (diphenylmethane diisocyanate). The provided technique for the thermal insulation plate solves the technical problems that the waste textile is difficult to process and the recovery rate is low. Due to the matching of the waste textile and the waste plastic, the strength and the hardness of a product are improved whilethe production cost is lowered. The wall thermal insulation plate is excellent in thermal insulation property, strength and flame retardant property, and the production cost is low. The idea of turning waste into wealth and being green and environmentally friendly is truly realized, and the comprehensive recovery rate of the resource is increased.

Owner:安徽职业技术学院

Reaction-curable polyurethane resin composition and two-part reaction-curable polyurethane adhesive made by using the same

ActiveCN101842406AExcellent shelf lifeHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolymeric MDI

To provide a reaction-curable polyurethane resin composition which is extremely excellent in liquid storage stability (both homogeneity and reactivity) and in reactivity (uniformity of reaction) and a solventless, two-pack, reaction-curable polyurethane adhesive composed of ''a base resin'' and ''a curing agent'' which are based on the constituents of the composition. The above problems can be solved by selecting and using a specific catalyst, by selecting and using a polymeric MDI having an acidity above a specific level as the organic polyisocyanate, and by specifying the equivalent ratio of isocyanato of the organic polyisocyanate to hydroxyl of castor oil polyol (A).

Owner:NIPPON POLYURETHANE IND CO LTD

Bio-based polyhydric alcohol sponge and preparing method

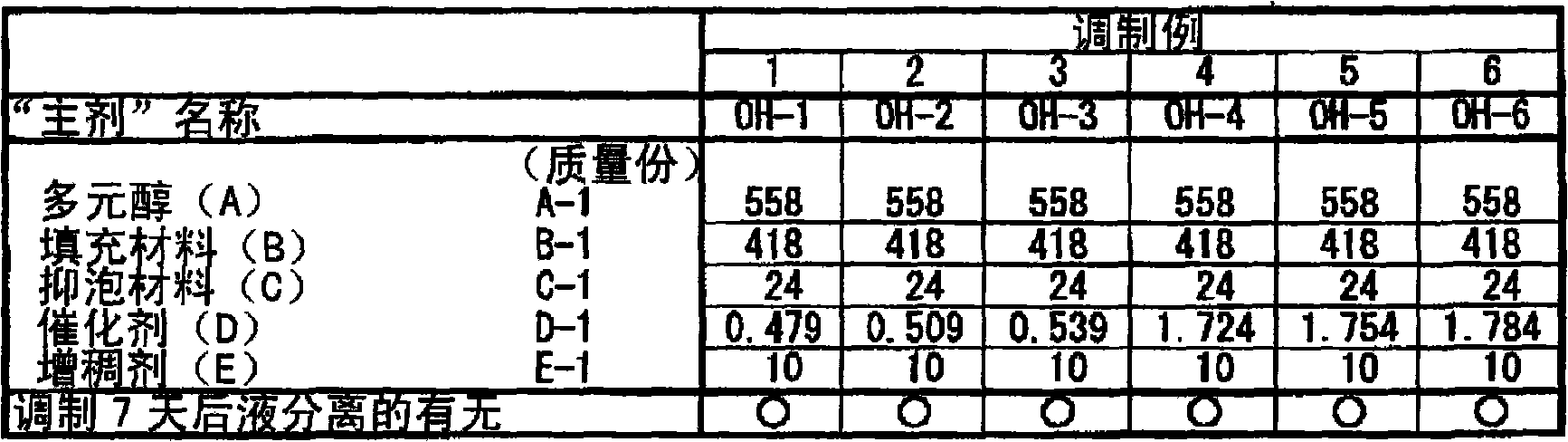

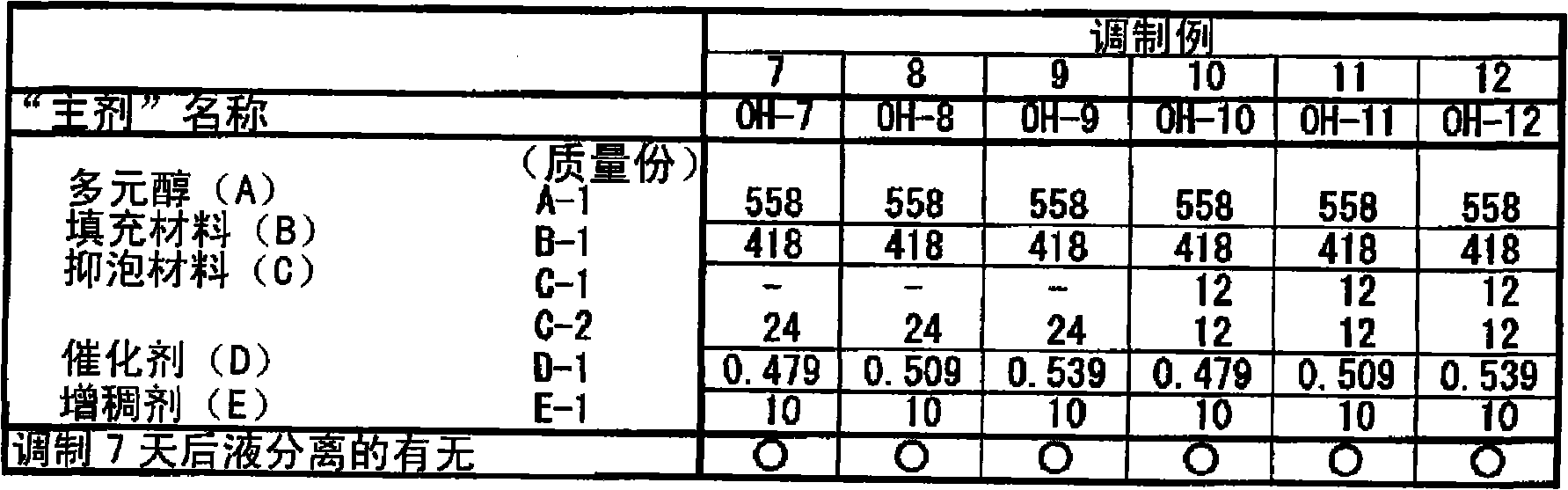

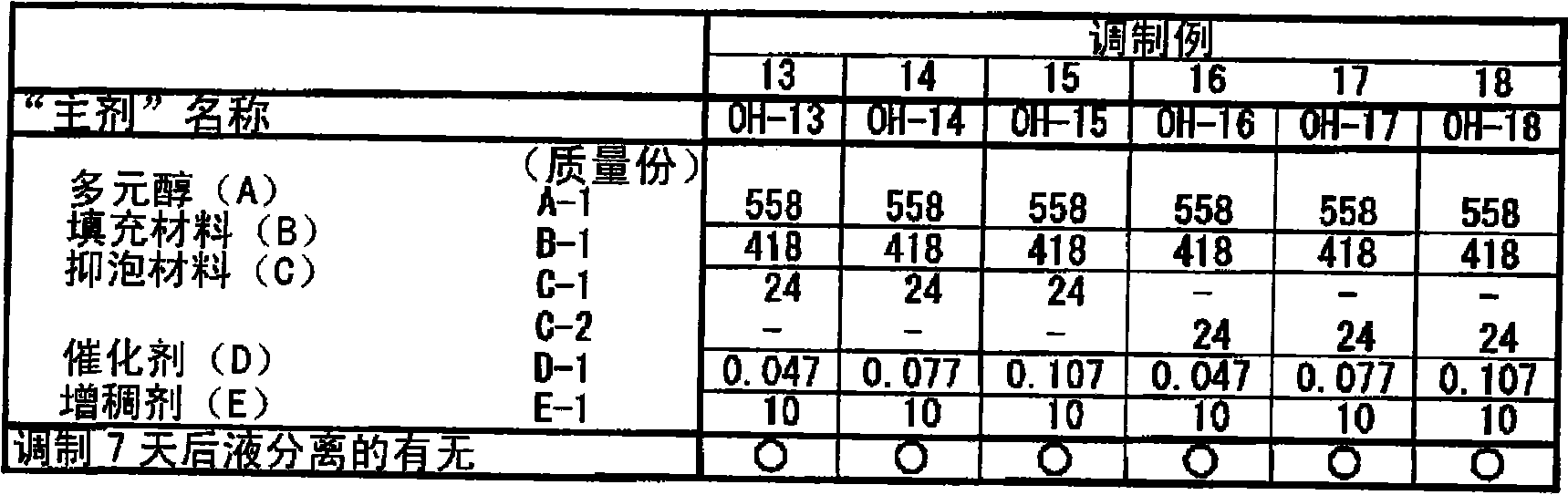

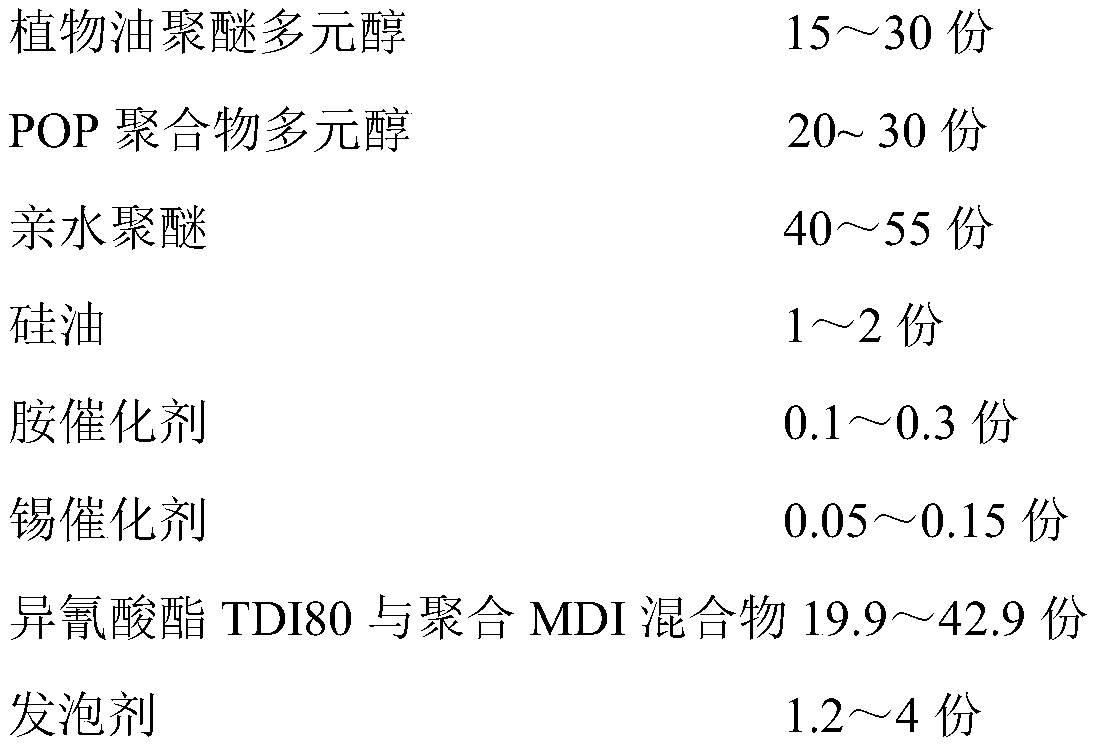

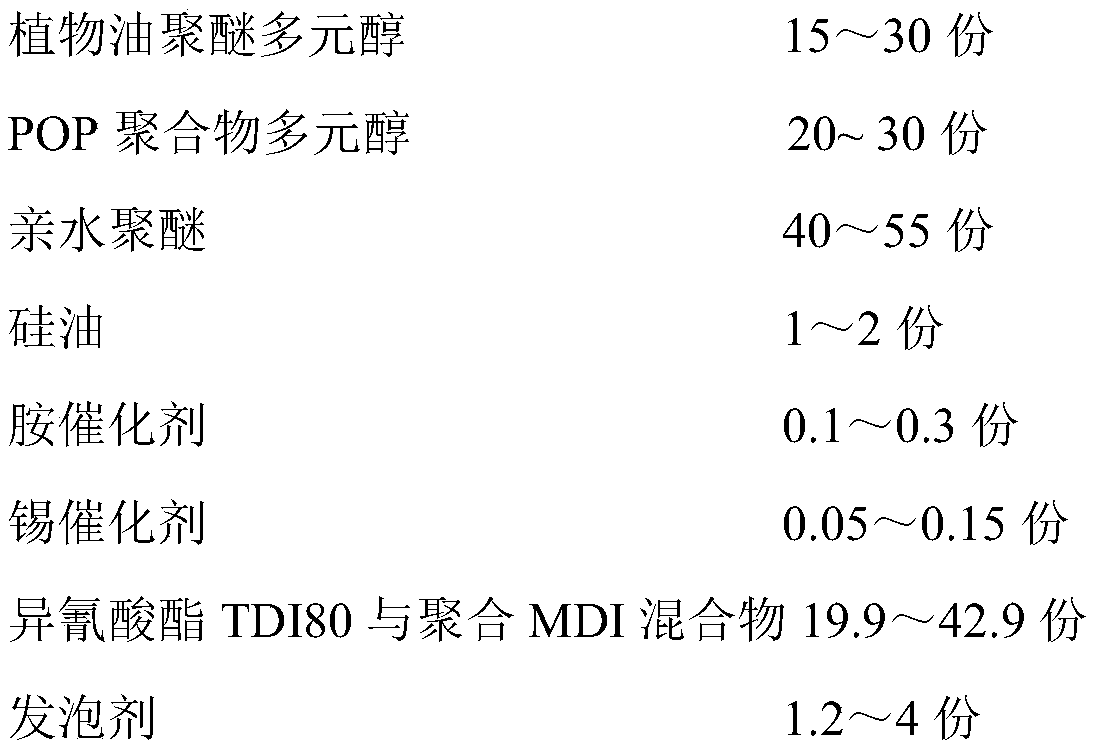

The invention discloses a bio-based polyhydric alcohol sponge and a preparing method. The sponge is prepared through reaction from, by weight, 15-30 parts of vegetable oil polyether polyol, 20-30 parts of polypolyols (POP), 40-55 parts of hydrophilic polyether, 1-2 parts of silicone oil, 0.1-0.3 part of an amine catalyst, 0.05-0.15 part of a tin catalyst, 19.9-42.9 parts of an isocyanate TDI80 polymerized MDI mixture and 1.2-4 parts of a foaming agent, wherein the original density of the raw materials is 25-80 kg / m<3>, and the foaming index of the sponge is 0.8-1.1. The bio-based polyhydric alcohol sponge prepared from the components according to the ratio through the preparing method has extremely excellent supporting force and softness.

Owner:东莞市腾崴塑胶制品有限公司

Low-heat-value high-strength polyurethane material for coal mine grouting and preparation method thereof

The invention provides a low-heat-value high-strength polyurethane material for coal mine grouting and relates to the technical field of coal mine safety materials. The low-heat-value high-strength polyurethane material comprises three components, namely, a component A, a component B and a component C, wherein the component A is mainly formed by polyether glycol, inorganic filling aggregate, foamstabilizer, tin catalyst, fire retardant, phase change additive a and polypropylene fiber; the component B is mainly formed by polyether glycol and phase change additive b; the component C is made ofpolymerized MDI. According to the invention, the phase change material with lower melting point is adopted for achieving a three-step cooling effect through chemical reaction, crystallizing water lossand phase change, so that ultrahigh temperature of the material in the use process is prevented and the potential safety hazard in the borehole operation process of coal mine is eliminated; the problems of low strength, easiness in cracking and the like of the material can be solved; the low-heat-value high-strength polyurethane material is environment-friendly and pollution-free and is high in curing rate; the preparation method is simple.

Owner:SHANDONG UNIV OF SCI & TECH

Monocomponent polyurethane foaming type adhesive

InactiveCN101676356APolyureas/polyurethane adhesivesAdhesive processes using foamed adhesivesChemical reactionOrganic solvent

The invention provides a monocomponent polyurethane foaming type adhesive, which is prepared by adding, according to the finished product containing 5 to 20% of isocyanate group, polymerized MDI, MDI0129M, polyether polyalcohol, plasticizer, color paste and dimorpholinyl diethylether into a reaction kettle, heating and reacting at the temperature of 60 to 90 DEG C for 60 to 150 minutes. The adhesive has no organic solvent, after being solidified, the adhesive is formed into a micro foam layer with good mechanical strength.

Owner:SHANGHAI HAOHAI CHEM

Polyisocyanate composition for soft polyurethane foam and process for producing soft polyurethane foam from the composition

To provide a soft polyurethane foam having a favorable storage stability and being simultaneously favorable in rebound resilience and mechanical properties. ¢MEANS FOR SOLVING PROBLEMS! There is provided a polyisocyanate composition for soft polyurethane foam obtained by performing a urethanization reaction of pure MDI (a) with an equivalent amount or less of polyol (b) under the following conditions and thereafter mixing a polymeric MDI (c) with the reaction product. (2,2'-MDI + 2,4'-MDI) / MDI = 60 to 85 mass%, and MDI / ((a) + (C)) = 50 to 90 mass% provided that the component (b) is a polyetherpolyol of 700 to 10,000 number average molecular weight, 2 to 8 functional groups on average and 10 to 40% in the content of oxyethylene in the repeating units.

Owner:NIPPON POLYURETHANE IND CO LTD

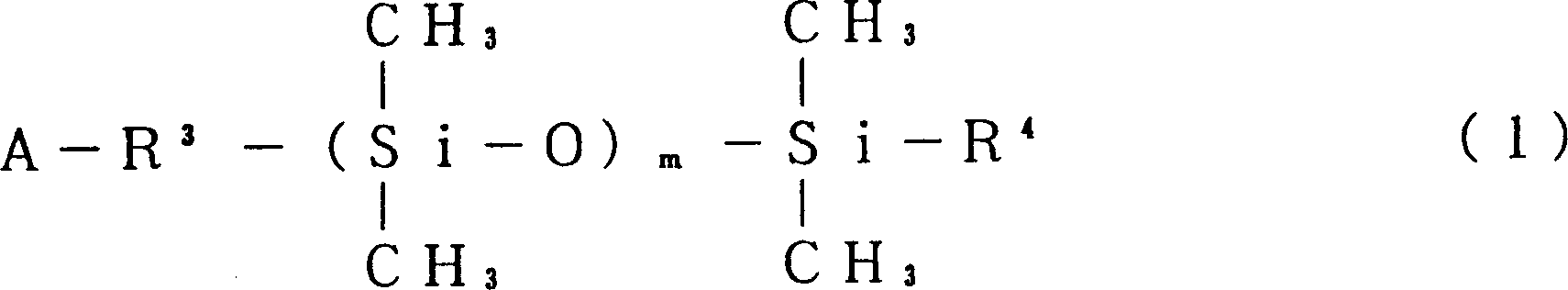

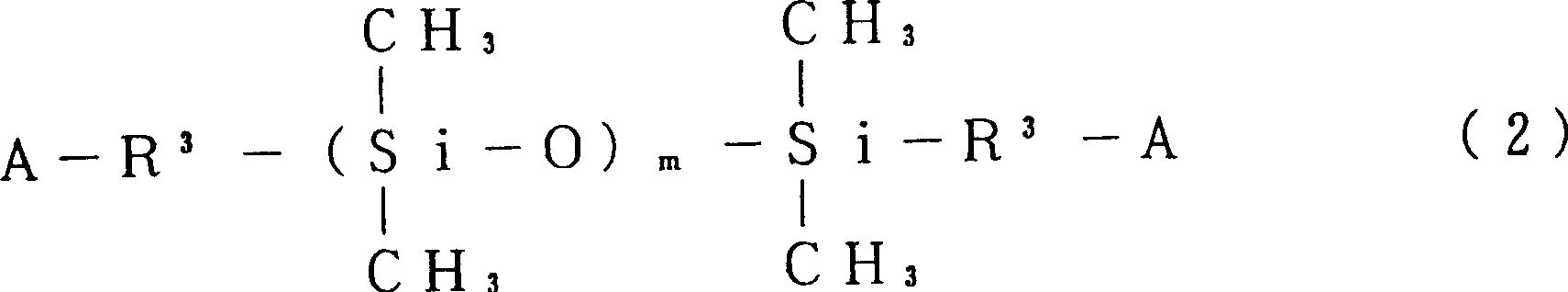

Polyisocyanate ester composition and its making method and method for preparing hard polyurethane foam

The object of this invention is to provide a polyisocyanate composition producing a rigid polyurethane foam having good adhesiveness to various kinds of adherends, a low shrinkage percentage and excellent shape stability. The polyisocyanate composition used for producing the rigid polyurethane foam comprises the following. (A0) a polymeric MDI (diphenylmethane diisocyanate), (A1) a first isocyanate group-terminated prepolymer obtained by reacting the polymeric MDI with a polyester polyol (a1) having sulfo groups or sulfonate groups in the molecular structure, (A2) a second isocyanate group-terminated prepolymer prepared by reacting the polymeric MDI with a polyether monool (a2) and (A3) a silicone foam stabilizer.

Owner:NIPPON POLYURETHANE IND CO LTD

flexible polyurethane foam

Owner:BASF SE

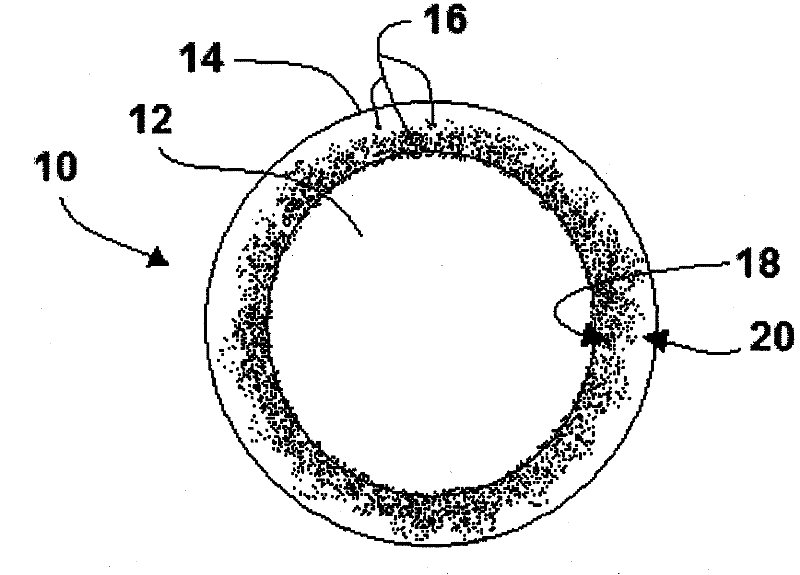

Polyurethane pouring sealant for water treatment curtain type membrane assembly and preparation method thereof

InactiveCN107629753AImprove curing hardnessSuitable mixing viscositySemi-permeable membranesPolyureas/polyurethane adhesivesEnvironmental resistanceWeather resistance

The invention provides a two-component high-hardness polyurethane pouring sealant suitable for fixing a water treatment curtain type membrane assembly, wherein the pouring sealant is prepared by mixing a component A of hydroxyl compound-modified isocyanate and a component B composed of a polymerized MDI modified hydroxyl compound according to the weight ratio of (50-90):100. The polyurethane pouring sealant has the advantages of high curing hardness, proper mixing viscosity, convenient construction, moderate curing speed, low heat release peak value, no bubbling, good bonding effect, environmental protection, no pollution, and excellent acid and alkali resistance and weather resistance. The process is simple, the condition is easy to control, and automatic production is easy to realize. The polyurethane pouring sealant is fully satisfied with technical requirements of the water treatment curtain type membrane assembly on the application process and product performance of the pouring sealant.

Owner:山东奥卓新材料有限公司

Adhesives

InactiveUS7074844B2Quickly initial bond strengthGood water and heat resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsPolymer sciencePolymer modified

An adhesive, comprising (A) a polymeric MDI, (B) modified polyvinyl acetate emulsion, (C) aqueous polyvinyl alcohol solution, and (D) a filler. Preferably, a mass ratio of A:B:C:D is 30:(60–160):(50–160):(10–140) provided that the aqueous polyvinyl alcohol solution (C) is in a concentration of 10% by mass.

Owner:YAMAHA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com