Full-open-cell high-breathable sponge and preparation method

A technology with high air permeability and full opening, applied in the sponge field, can solve the problems of poor air permeability and open pores of the sponge, and achieve the effect of high opening rate and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

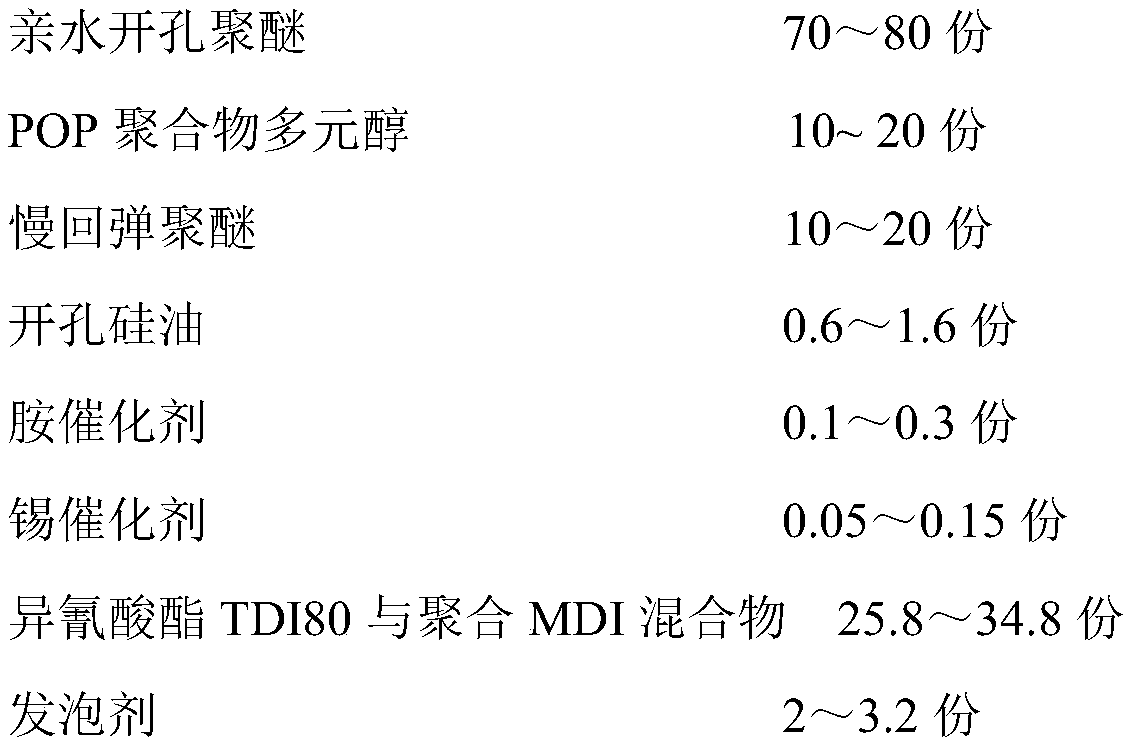

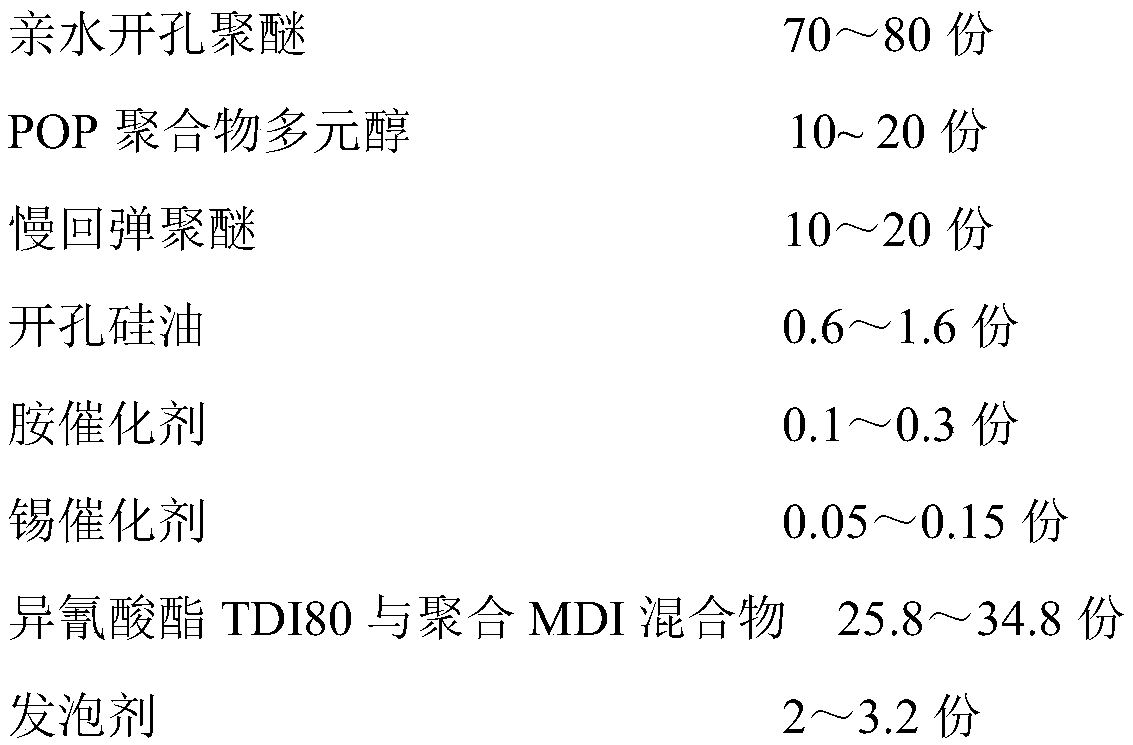

Method used

Image

Examples

Embodiment 1

[0021] A fully open-pore highly air-permeable sponge, which is produced by reacting raw materials consisting of the following components in parts by weight: 70 parts of hydrophilic open-cell polyether, 20 parts of POP polymer polyol, and 10 parts of slow-rebound polyether , 1 part of open-pore silicone oil, 0.2 parts of amine catalyst, 0.12 parts of tin catalyst, 34.8 parts of isocyanate TDI80 and polymeric MDI mixture, 3.2 parts of water; among them, the original density of the raw material is 30kg / m 3 , the foaming index of sponge is 0.84; Described hydrophilic polyether is the polypropylene glycol PPG5000 that takes glycerol as initiator, and the ethylene oxide that is 75% and the propylene oxide that content is 25% random polymerization reaction , the hydroxyl value of the hydrophilic polyether is 35mgKOH / g; the POP polymer polyol is a polyether polyol with high solid content graft-copolymerized by general-purpose polyether, styrene monomer and acrylonitrile monomer, and th...

Embodiment 2

[0027] A fully open-pore highly air-permeable sponge, which is produced by reacting raw materials consisting of the following components in parts by weight: 80 parts of hydrophilic open-cell polyether, 10 parts of POP polymer polyol, and 10 parts of slow-rebound polyether , 1 part of open-pore silicone oil, 0.2 parts of amine catalyst, 0.09 part of tin catalyst, 25.8 parts of isocyanate TDI80 and polymeric MDI mixture, 2 parts of water; among them, the original density of the raw material is 48kg / m 3, the foaming index of sponge is 0.88; Described hydrophilic polyether is the polypropylene glycol PPG5000 that takes glycerol as initiator, and the ethylene oxide that is 70% and the propylene oxide that content is 30% random polymerization reaction , the hydroxyl value of the hydrophilic polyether is 35mgKOH / g; the POP polymer polyol is a polyether polyol with high solid content graft-copolymerized by general-purpose polyether, styrene monomer and acrylonitrile monomer, and the T...

Embodiment 3

[0030] A fully open-pore highly air-permeable sponge, which is produced by reacting raw materials consisting of the following components in parts by weight: 70 parts of hydrophilic open-cell polyether, 20 parts of POP polymer polyol, and 10 parts of slow-rebound polyether , 1 part of open-pore silicone oil, 0.2 parts of amine catalyst, 0.05 part of tin catalyst, 34.6 parts of isocyanate TDI80 and polymeric MDI mixture, 2.6 parts of water; among them, the original density of the raw material is 36kg / m 3 , the foaming index of sponge is 0.98; Described hydrophilic polyether is the polypropylene glycol PPG5000 that takes glycerol as initiator, and the ethylene oxide that is 75% and the propylene oxide that content is 25% random polymerization reaction , the hydroxyl value of the hydrophilic polyether is 35mgKOH / g; the POP polymer polyol is a polyether polyol with high solid content graft-copolymerized by general-purpose polyether, styrene monomer and acrylonitrile monomer, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com