Low-heat-value high-strength polyurethane material for coal mine grouting and preparation method thereof

A polyurethane material with low calorific value, applied in the field of coal mine safety materials, can solve the problems of reducing the mechanical properties of materials, not suitable for large-scale promotion and use, and complicated preparation process, so as to eliminate safety hazards, low raw material prices, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

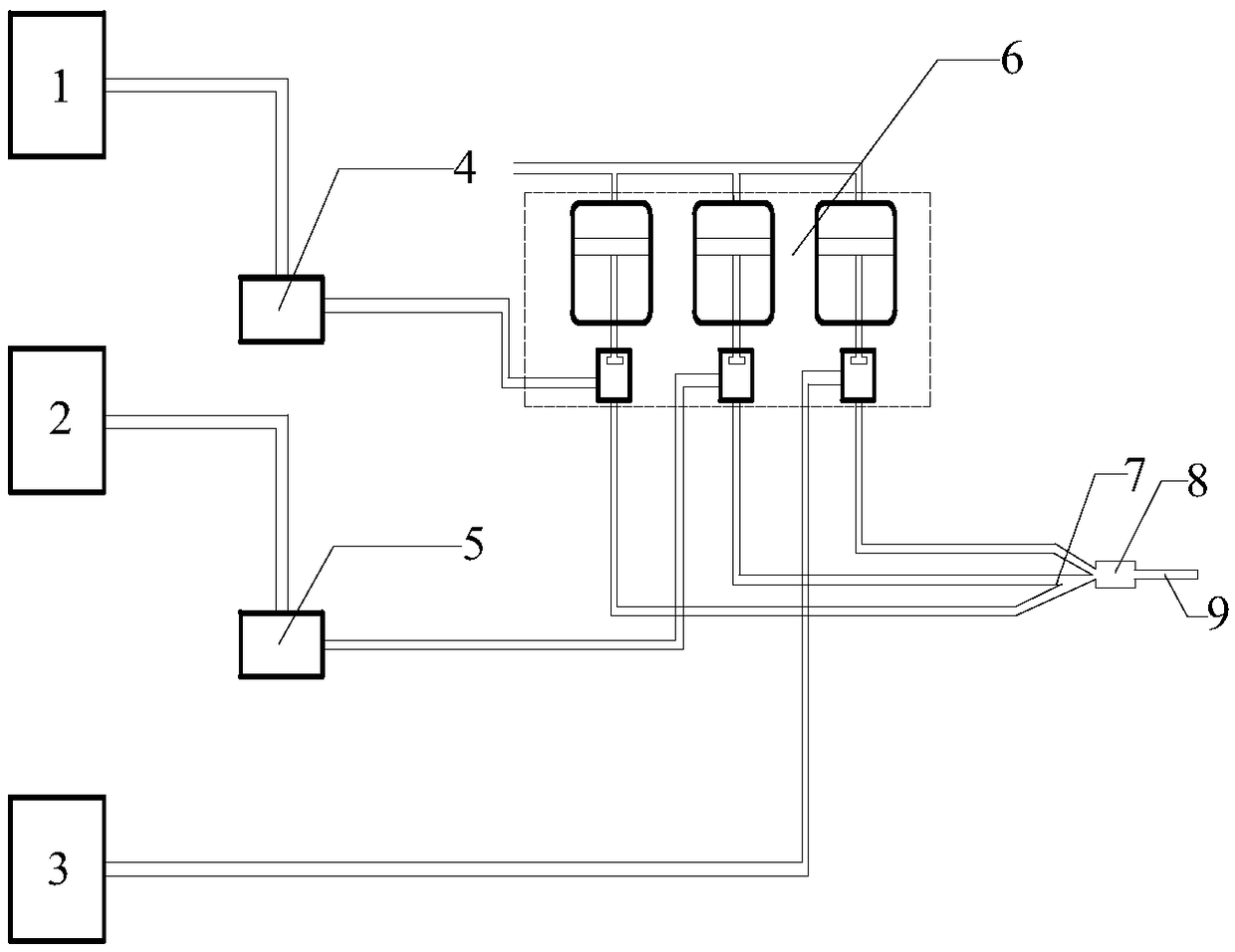

[0036] A kind of low calorific value high-strength polyurethane material for coal mine grouting, such as figure 1 Shown, prepared by the following steps:

[0037] (1) Preparation of component A: Grind 5 parts of slag micropowder several times to nanometer level, then dry at 120°C for more than two hours; pump out 30 parts of polyether polyol in container I1 (Functionality is 4, relative molecular weight 1000) to mixing kettle I4, add 5 parts of silicone oil, 5 parts of stannous octoate, 5 parts of trichloroethyl phosphate, 5 parts of ammonium aluminum sulfate dodecahydrate, 10 parts of chopped polypropylene fibers (length 3mm, diameter 8 μm), 5 parts of dried nano slag micropowder are simultaneously added in the mixing tank I4, after fully stirring, it is made into component A;

[0038] (2) Preparation of component B: pump 20 parts of polyether polyol in container II2 to mixing kettle II5, and add 5 parts of octahydrate barium hydroxide to mixing kettle II5 to form component ...

Embodiment 2

[0044] A kind of low calorific value high-strength polyurethane material for coal mine grouting, such as figure 1 Shown, prepared by the following steps:

[0045] (1) Preparation of component A: Grind 15 parts of stone powder several times to the nanometer level, then dry at 120°C for more than two hours, and pump out 60 parts of polyether polyol in container I1 ( Functionality is 4, relative molecular weight is 1000) to mixing kettle I4, and 10 parts of silicone oil, 10 parts of stannous octoate, 10 parts of trichloroethyl phosphate, 10 parts of ammonium aluminum sulfate dodecahydrate, 15 parts 1 part of chopped polypropylene fiber (length 3mm, diameter 10 μm), 15 parts of dried nano stone powder were added to mixing kettle I4 at the same time, after fully stirring, it was made into component A;

[0046] (2) Preparation of component B: pump 40 parts of polyether polyol in container II2 to mixing kettle II5, and add 10 parts of octahydrate barium hydroxide to mixing kettle II...

Embodiment 3

[0052] A kind of low calorific value high-strength polyurethane material for coal mine grouting, such as figure 1 Shown, prepared by the following steps:

[0053] (1) Preparation of component A: Grind 10 parts of fly ash several times until it reaches the nanometer level, then dry it at 120°C for more than two hours for later use, and pump out 35 parts of polyether in container I1 Add polyol (functionality: 4, relative molecular weight: 1000) to mixing tank I4, and add 5 parts of silicone oil, 5 parts of stannous octoate, 5 parts of trichloroethyl phosphate, and 5 parts of aluminum sulfate dodecahydrate into mixing tank I4 Ammonium, 10 parts of chopped polypropylene fibers (length 3mm, diameter 9 μm), 10 parts of dried nano-fly ash were added to mixing kettle I4 at the same time, after fully stirring, it was made into component A;

[0054] (2) Preparation of component B: pump 25 parts of polyether polyol in container II2 to mixing kettle II5, and add 5 parts of octahydrate ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of fusion | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com