Power battery top cover and power battery using top cover

A technology of power battery and top cover, applied in battery cover/end cover, battery, battery pack components, etc., can solve the problems such as the accumulation of energy not being released, the increase of the battery, and the failure to reduce the remaining capacity of the battery in time. , to achieve the effect of excellent safety protection function and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention and its beneficial effects will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

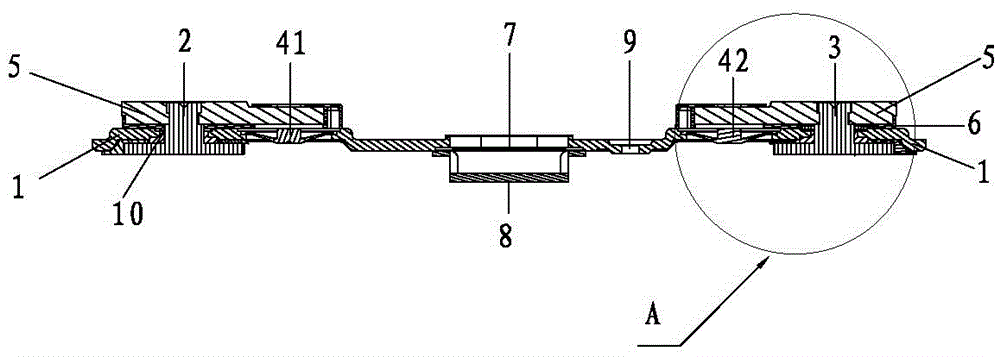

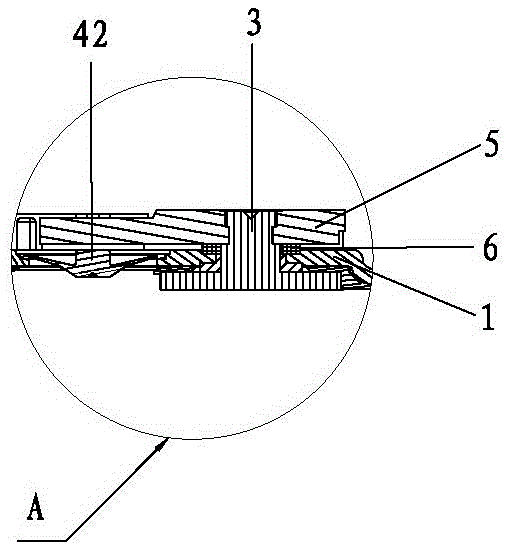

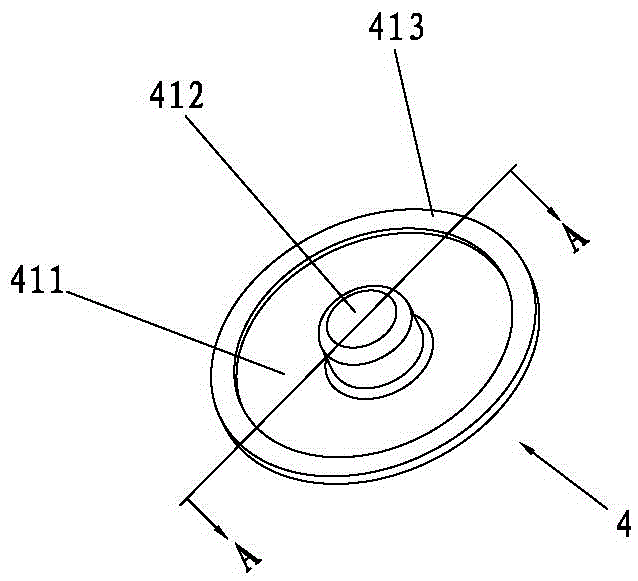

[0040] Such as Figure 1~5 As shown, a power battery top cover includes a top cover sheet 1 and a first pole 2, a second pole 3, a pressure relief valve 7, a liquid injection hole 9, and an air pressure flip sheet 4 arranged on the top cover sheet 1. And the resistance block 6, the first pole 2 is insulated and connected to the top cover sheet 1 through the insulating block 10, the second pole 3 is electrically connected to the top cover sheet 1 through the resistance block 6, and the air pressure flip sheet 4 is electrically connected to the top cover sheet 1 , a conductive block 5 is arranged above the air pressure reversing sheet 4, and the first pole 2 and the second pole 3 are electrically connected to the conductive block 5 resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com