High-pressure natural gas pressure energy refrigeration method for junked tire cryogenic pulverization

A technology for low-temperature crushing and waste tires, which is used in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of ice blockage, inability to meet the needs of producing fine rubber powder, and high temperature of cold energy when natural gas is cooled in pipelines. The effect of saving investment and operating costs, promoting recycling, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

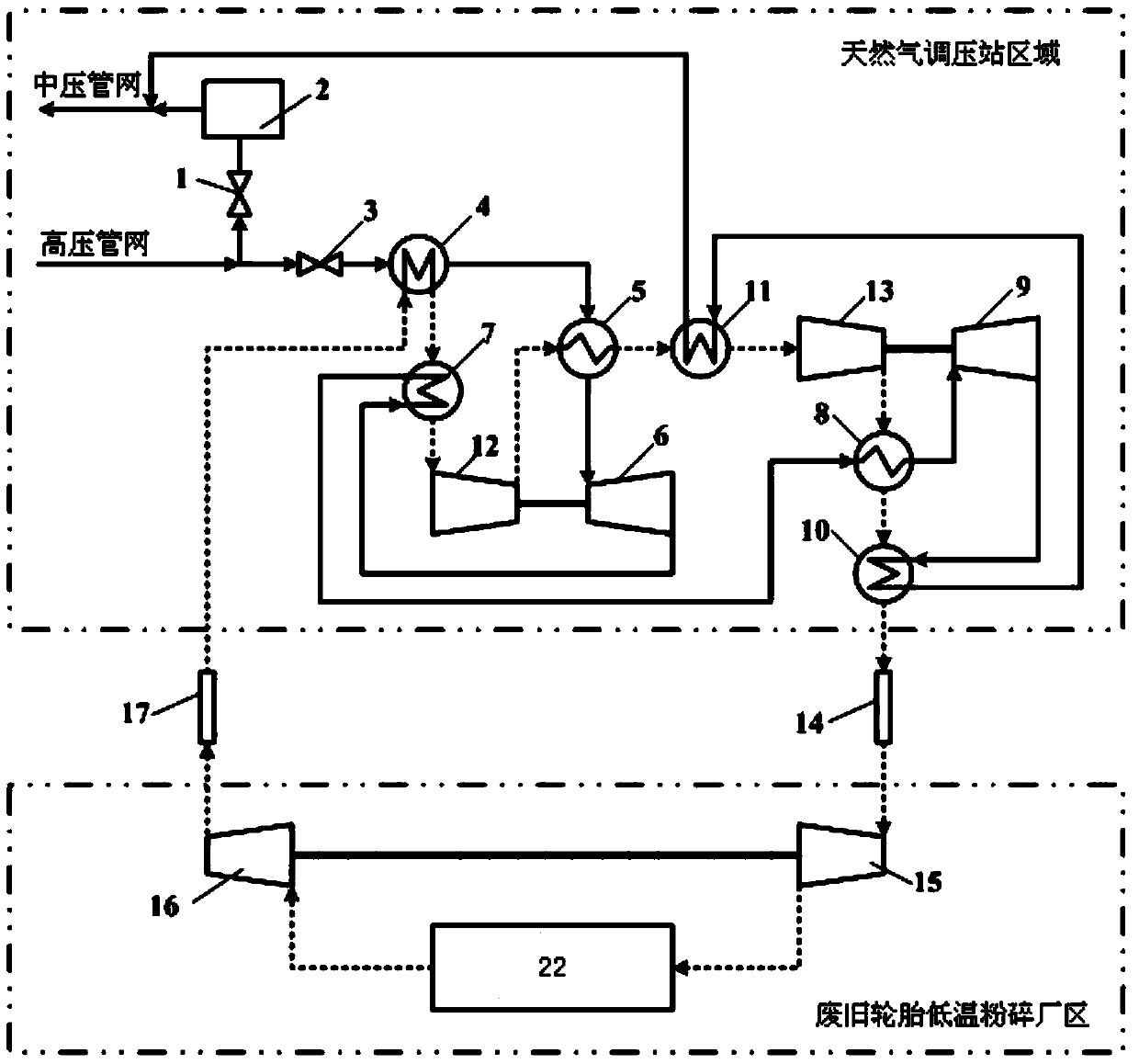

[0050] A high-pressure natural gas pressure energy refrigeration method for low-temperature crushing of waste tires, the process flow is as follows figure 1As shown, two expanders are used to realize two-stage decompression of high-pressure natural gas, and nitrogen is selected as the refrigerant.

[0051] The pressure of high-pressure natural gas transported from the main natural gas pipeline network (high-pressure pipeline network) to the urban natural gas pressure regulating station is 4.0MPa (absolute pressure), the temperature is 15.0°C, and its volume composition is: methane 94.844%, ethane 2.353%, propane 0.309 %, butane 0.079%, pentane 0.042%, hexane 0.032%, nitrogen 1.656%, carbon dioxide 0.655%, water 0.03%; the water dew point of the pipeline transported natural gas at 4.0 MPa is 5.0 ℃, the water dew point at 0.5 MPa -15.0°C. In the natural gas pressure regulating station, the 4.0MPa high-pressure natural gas needs to be reduced to 0.5MPa before entering the urban ...

Embodiment 2

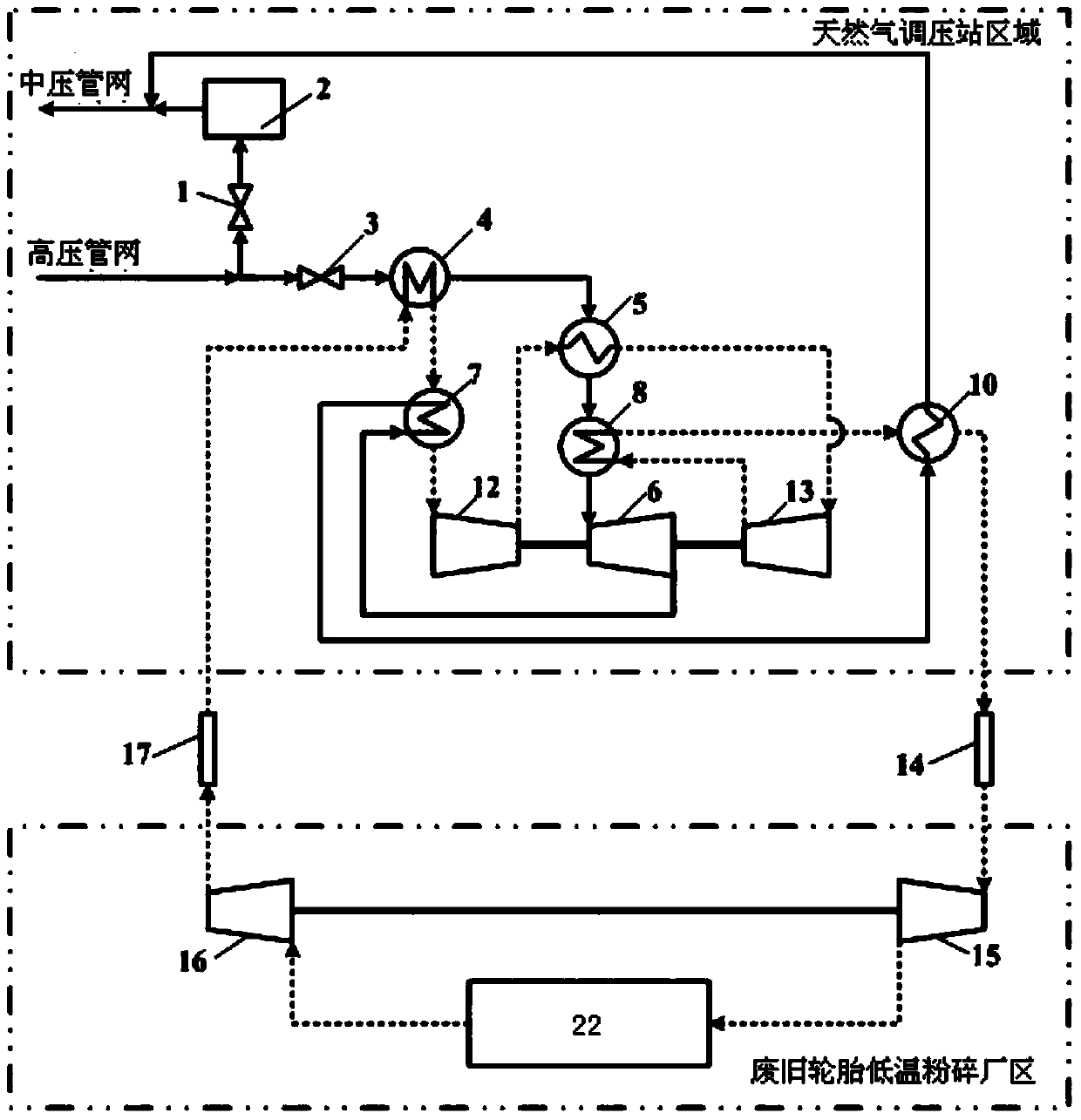

[0061] A high-pressure natural gas pressure energy refrigeration method for low-temperature crushing of waste tires, the process flow is as follows figure 2 As shown, an expander is used, and the refrigerant is nitrogen.

[0062] The pressure of the natural gas transported from the main natural gas pipeline network (high pressure pipeline network) to the urban natural gas pressure regulating station is 1.6MPa (absolute pressure), the temperature is 15.0°C, and its volume composition is: methane 94.844%, ethane 2.353%, propane 0.309% , butane 0.079%, pentane 0.042%, hexane 0.032%, nitrogen 1.656%, carbon dioxide 0.655%, water 0.03%; the water dew point of natural gas transported by this pipeline at 1.6MPa is -2.7℃, the water dew point at 0.5MPa -15.0°C. In the natural gas pressure regulating station, the 1.6MPa high-pressure natural gas needs to be reduced to 0.5MPa before entering the urban medium-pressure natural gas pipeline network (medium-pressure pipeline network). The ...

Embodiment 3

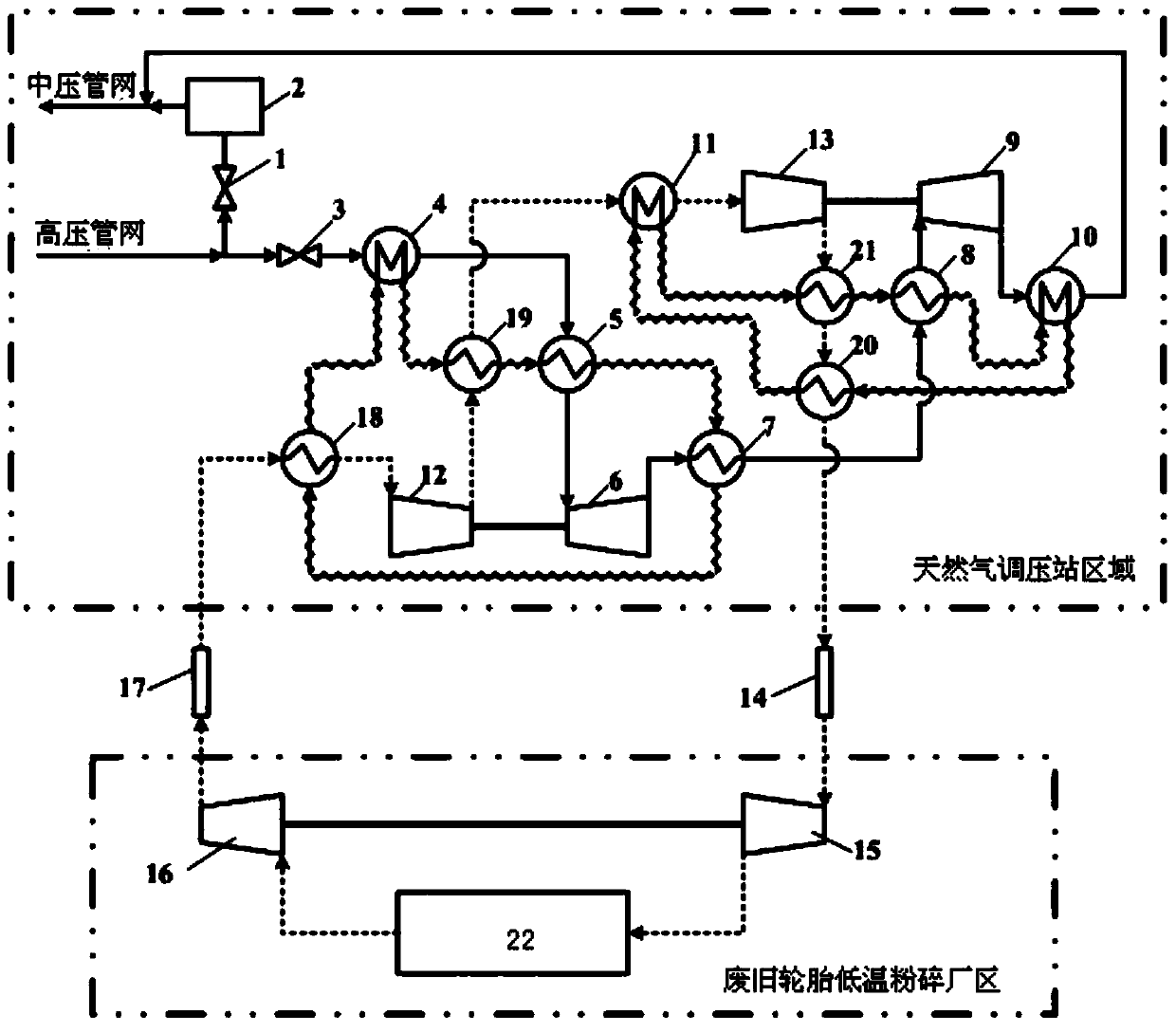

[0072] A high-pressure natural gas pressure energy refrigeration method for low-temperature crushing of waste tires, the process flow is as follows image 3 As shown, two expanders are used, and the refrigerant is air.

[0073] The pressure of the natural gas transported from the main natural gas pipeline network (high pressure pipeline network) to the urban natural gas pressure regulating station is 4.0MPa (absolute pressure), the temperature is 15.0°C, and its volume composition is: methane 94.844%, ethane 2.353%, propane 0.309% , butane 0.079%, pentane 0.042%, hexane 0.032%, nitrogen 1.656%, carbon dioxide 0.655%, water 0.03%; the water dew point of the pipeline transported natural gas at 4.0MPa is 5.0℃, and the water dew point at 0.5MPa is -15.0°C. In the natural gas pressure regulating station, the 4.0MPa high-pressure natural gas needs to be reduced to 0.5MPa before entering the urban medium-pressure natural gas pipeline network (medium-pressure pipeline network). The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com