Lactic acid producing transgenic hydrogenophilic bacteria

A technology of hydrogenophilic bacteria and lactate dehydrogenase, applied in the direction of bacteria, genetic engineering, plant genetic improvement, etc., can solve the problems of putting into practice the industrialized method of producing lactic acid, and achieve the effect of reducing emissions and strengthening recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

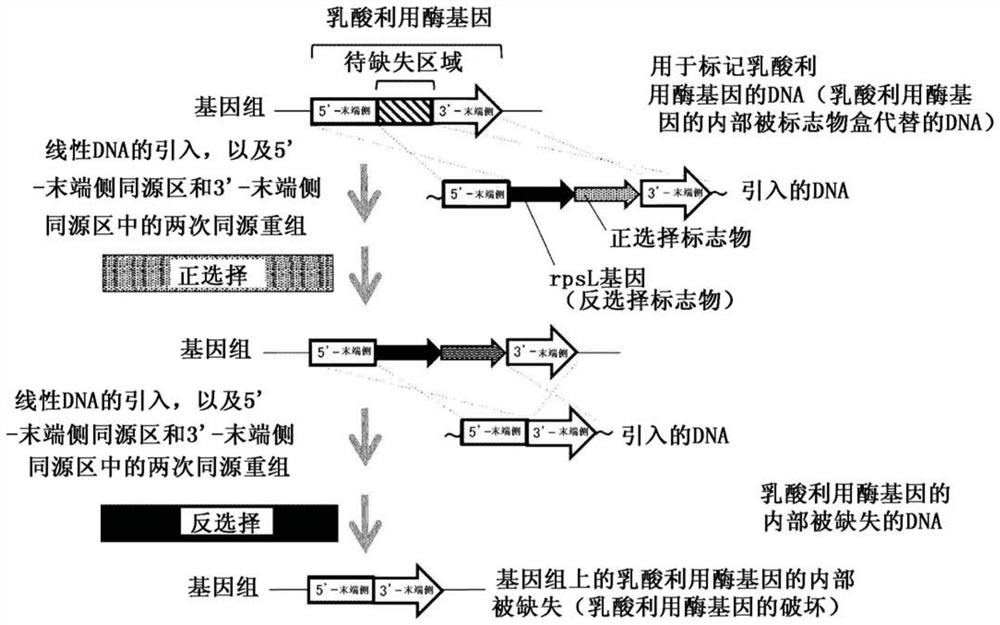

Method used

Image

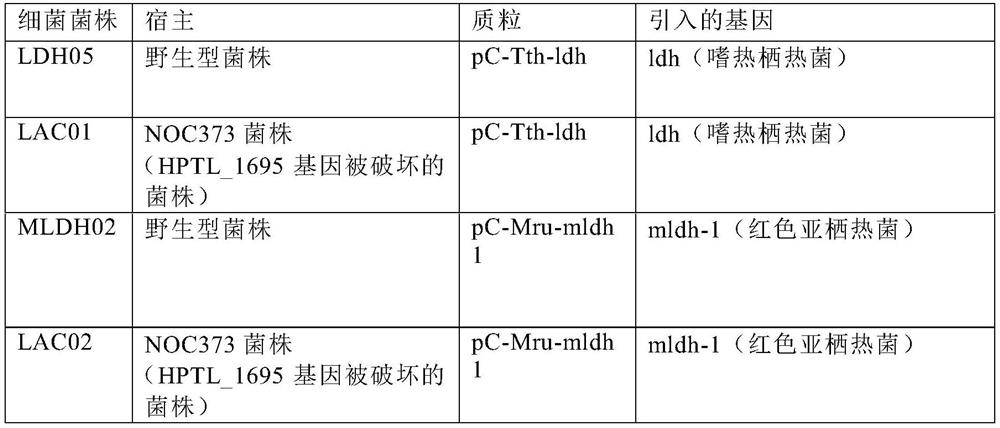

Examples

Embodiment

[0208] Next, the present invention will be described in further detail with reference to examples, but the present invention is not limited to these examples.

[0209] ( 1) Acquisition of streptomycin-resistant strains

[0210] Hydrogenophilus thermoluteolus TH-1 strain (NBRC14978) (hereinafter sometimes referred to as "TH-1 strain") was inoculated using a platinum ring into which was placed 5 mL of A liquid medium [3.0 g (NH 4 ) 2 SO 4 , 1.0g KH 2 PO 4 , 2.0g K 2 HPO 4 , 0.25g NaCl, 0.014g FeSO 4 ·7H 2 O, 0.5g MgSO 4 ·7H 2 O, 0.03g CaCl 2 , 4.0mg MoO 3 , 28mg ZnSO 4 ·7H 2 O, 2.0 mg CuSO 4 ·5H 2 O, 4.0 mg H 3 BO 3 , 4.0mgMnSO 4 ·5H 2 O and 4.0 mg CoCl 2 ·6H 2 O(pH 7.0)] in a test tube filled with H 2 :O 2 :CO 2 =7.5:1:1.5 mixed gas, and cultured with shaking at 50°C. After 24 hours, the culture solution was applied to A solid medium containing 500 μg / mL streptomycin [3.0 g (NH 4 ) 2 SO 4 , 1.0g KH 2 PO 4 , 2.0g K 2 HPO 4 , 0.25gNaCl, 0.014g Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com