Patents

Literature

119results about How to "Increase intake air temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

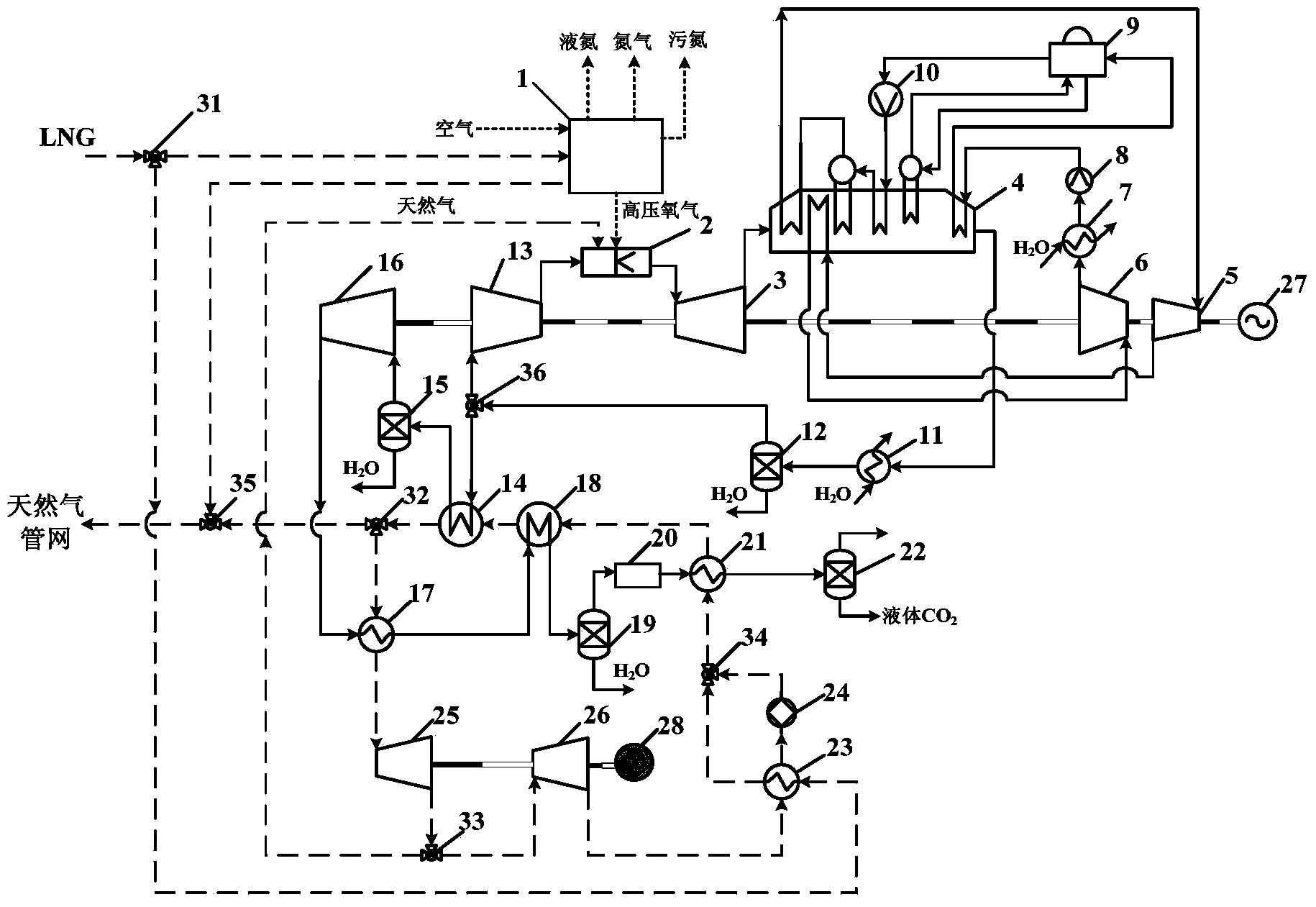

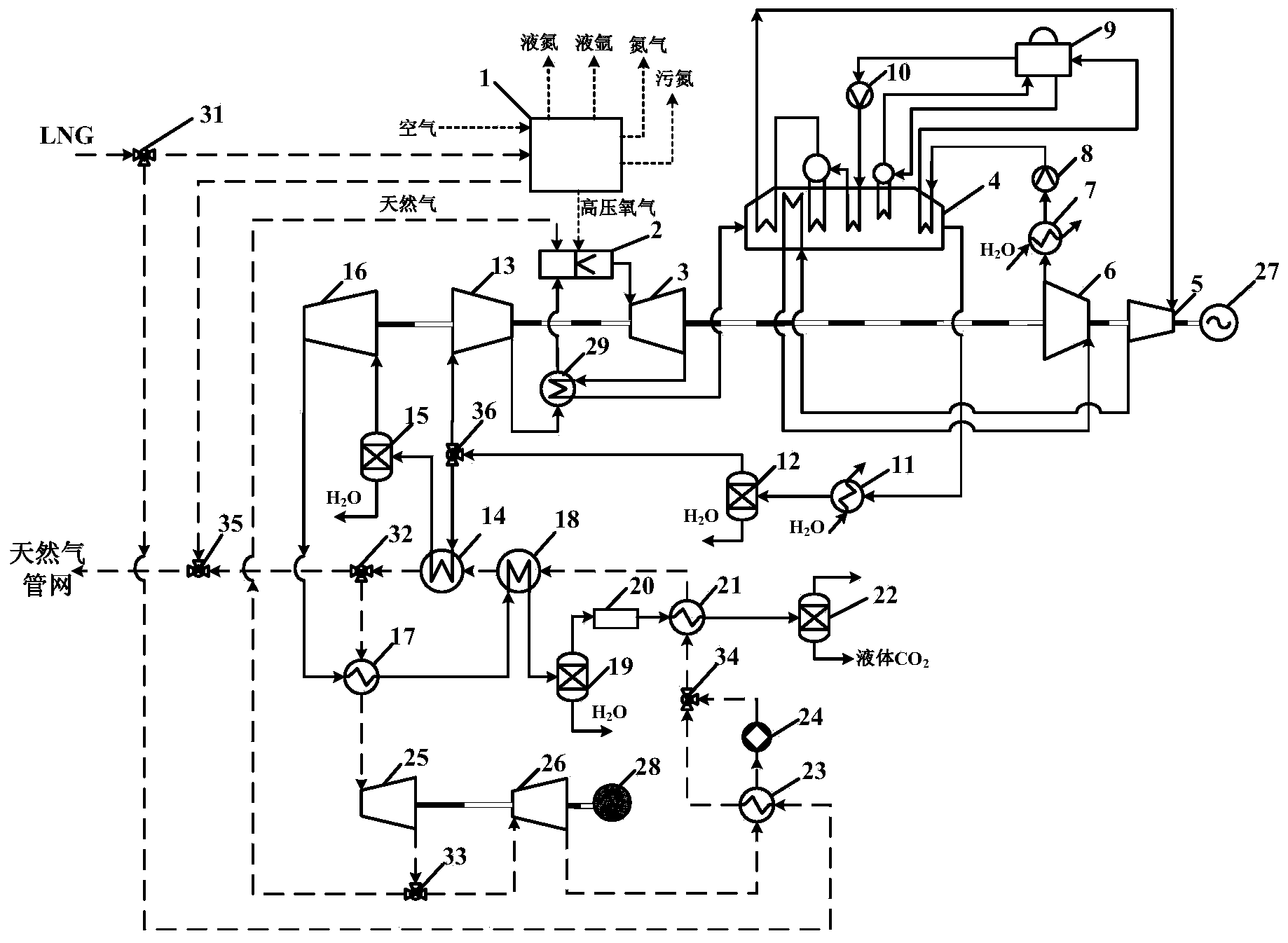

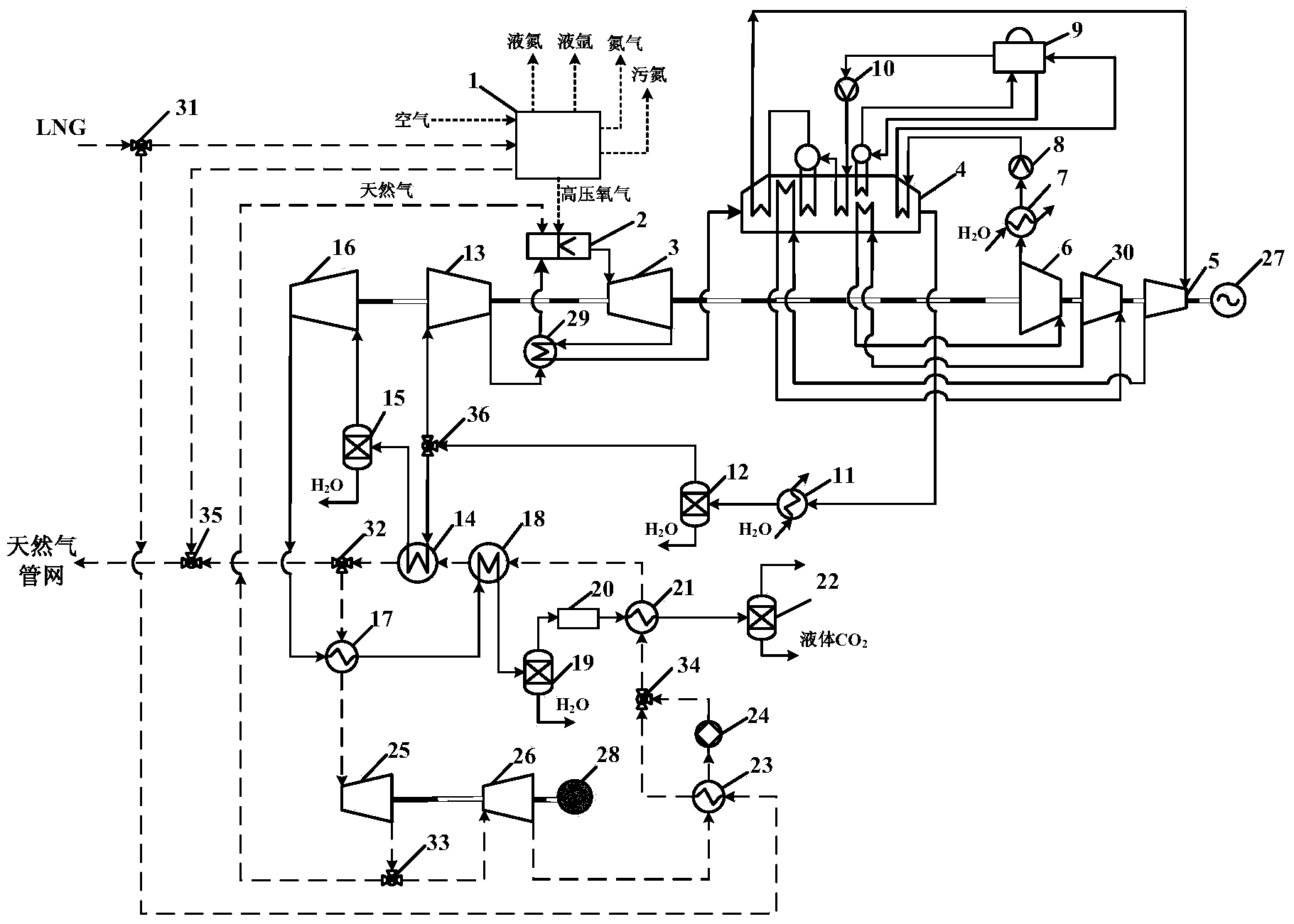

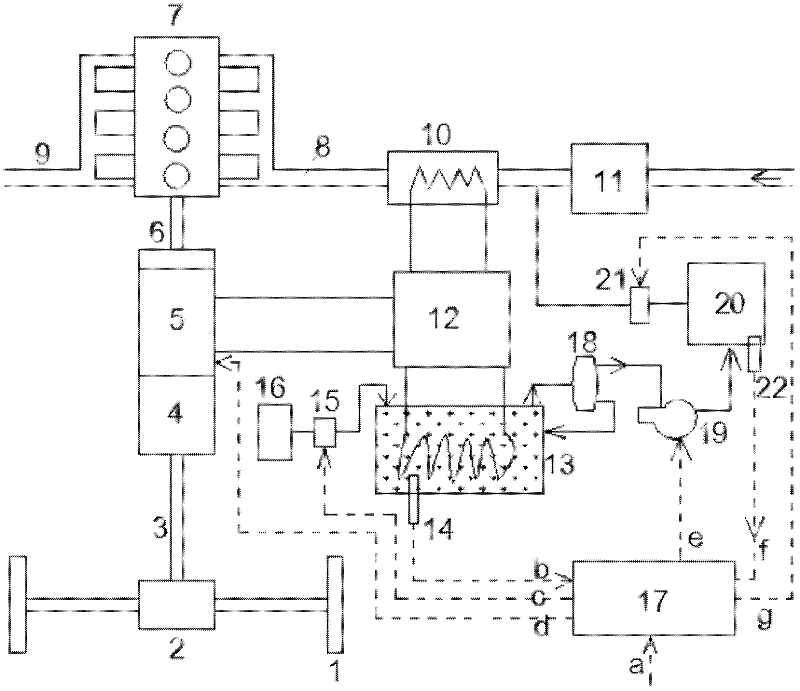

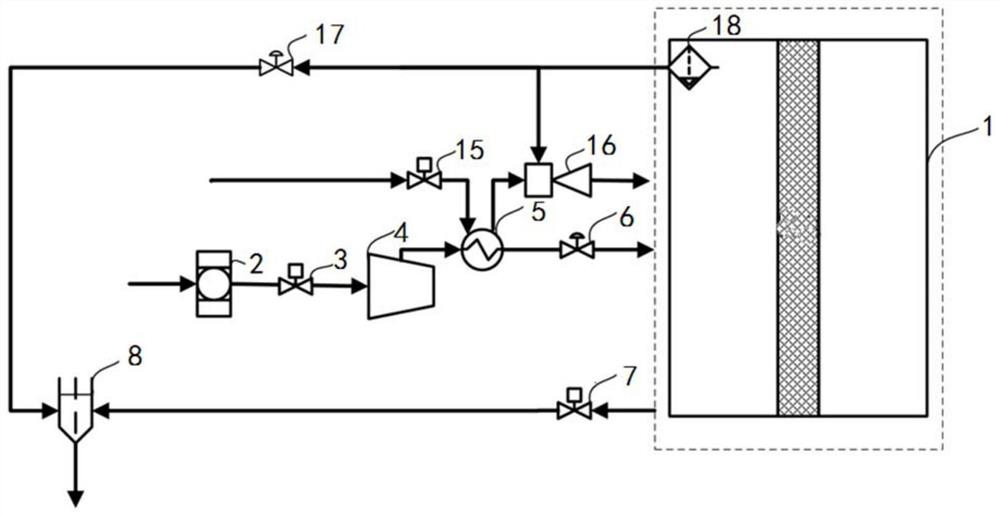

Combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and system thereof

ActiveCN103628982AImprove power generation efficiencyIncrease capture rateSolidificationLiquefactionPower cycleHigh pressure

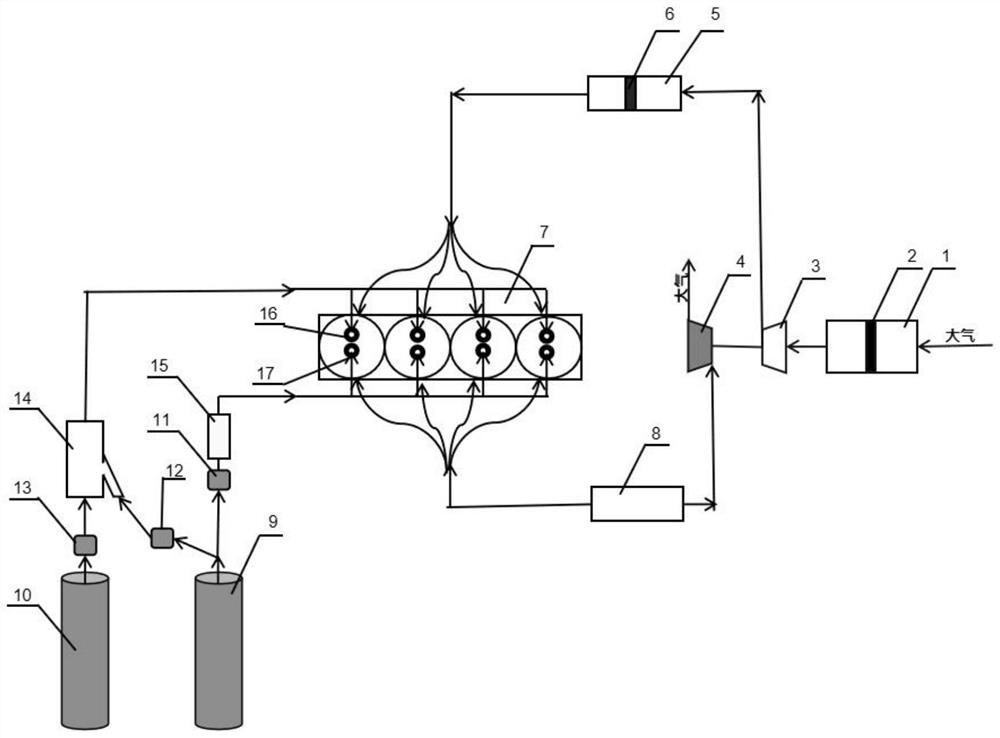

The invention discloses a combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and a system thereof. The system comprises an air separation device, an oxygen-enriched-combustion gas turbine circulation device, a high-pressure steam power circulation device, a CO2 separation and liquefaction device and an LNG cold energy power circulation device, wherein the air separation device, the oxygen-enriched-combustion gas turbine circulation device, the high-pressure steam power circulation device, the CO2 separation and liquefaction device and the LNG cold energy power circulation device utilize the LNG cold energy. According to the method and the system, electricity and high-temperature fume which is rich in CO2 and water are generated from LNG through the oxygen-enriched-combustion gas turbine circulation device, and heat is recovered from the fume through the high-pressure steam power circulation device, so as to produce high-temperature and high-pressure steam with the pressure over 18MPa and increase the power generation efficiency of natural gas; moreover, the LNG cold energy is sequentially applied to the air separation device, the LNG cold energy power circulation device and the CO2 separation and liquefaction device, and the energy consumption for CO2 catching is lowered by making full use of the LNG cold energy, so that combined power cycle has relatively high power generation efficiency and relatively high CO2 catching rate, and the efficient utilization of the LNG cold energy is realized.

Owner:JINAN UNIVERSITY

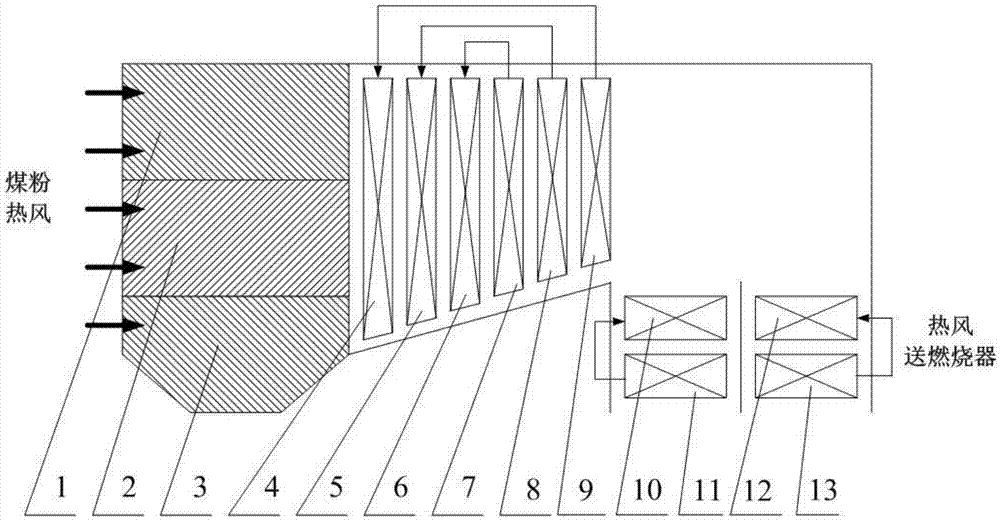

Novel supercritical carbon dioxide coal-fired boiler

ActiveCN104728823AShorten the lengthIncrease temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterGas cooler

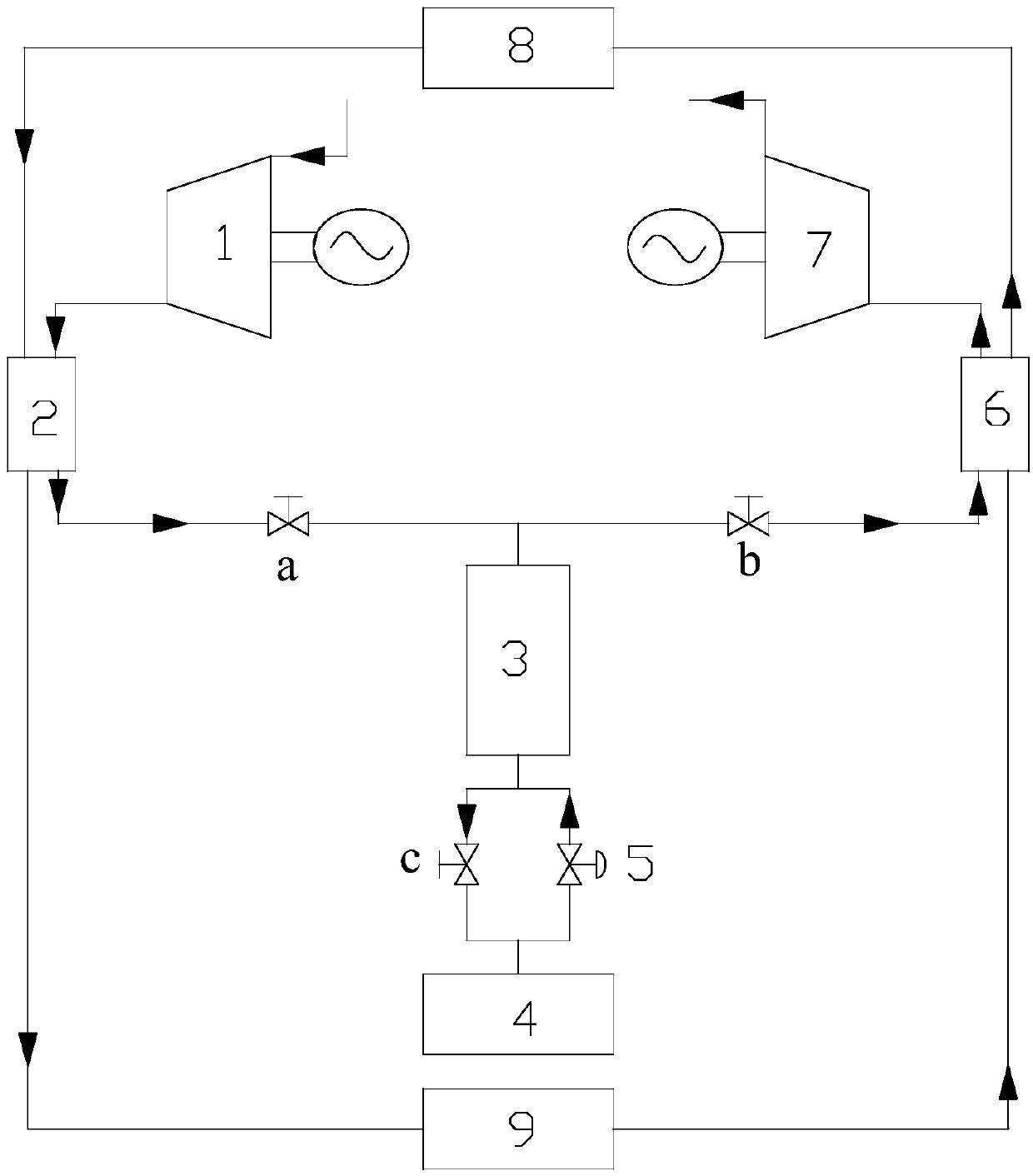

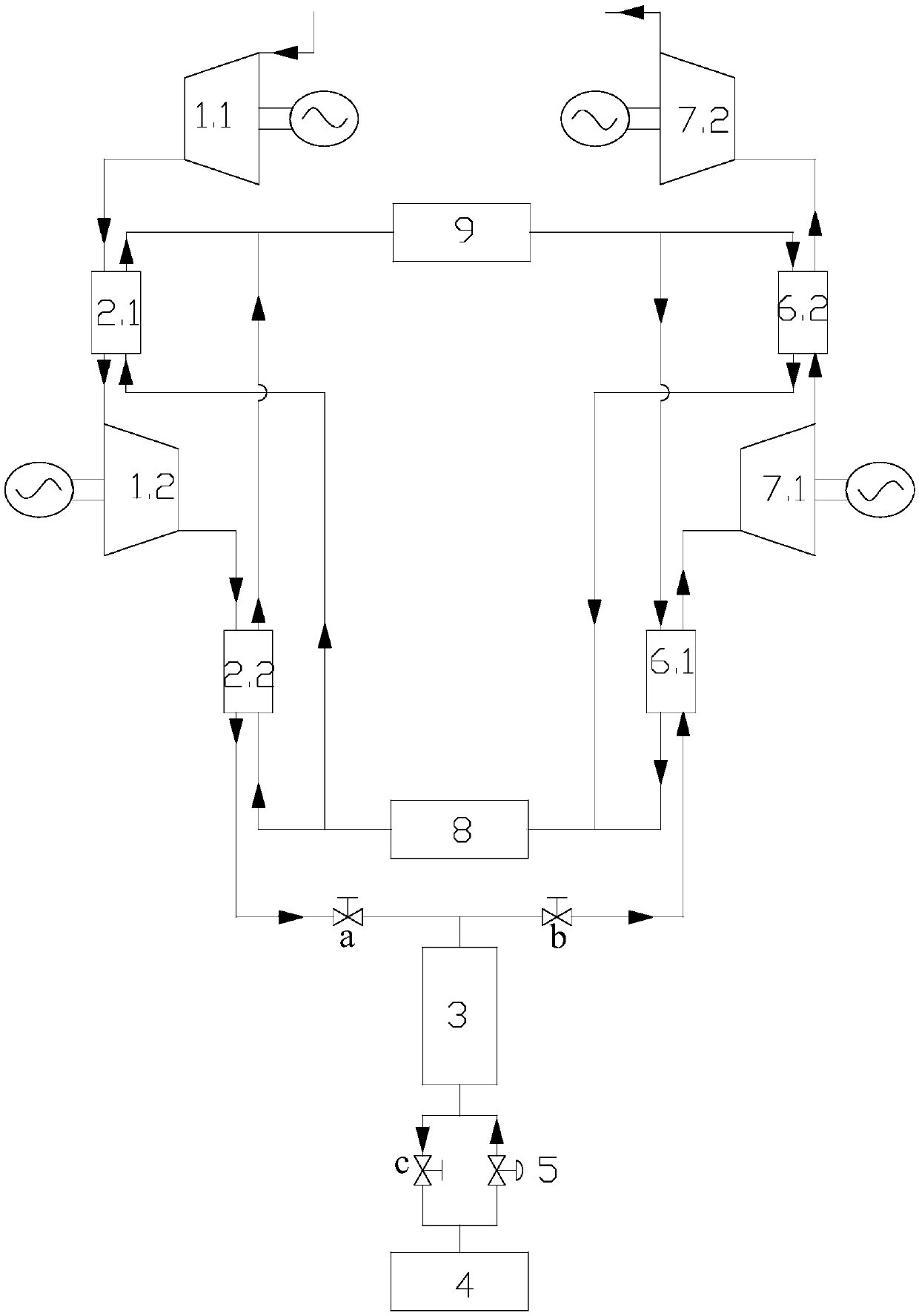

The invention discloses a novel supercritical carbon dioxide coal-fired boiler. The novel supercritical carbon dioxide coal-fired boiler comprises a horizontally arranged hearth, a wall-attached radiation cooling heating surface system, a superheater and reheater system, smoke gas coolers and air preheaters, wherein the wall-attached radiation cooling heating surface system is arranged in the hearth in a graded and segmented mode, the superheater and reheater system is arranged in a horizontal flue in a graded mode, and the smoke gas coolers and the air preheaters are arranged in a tail flue in a graded and flow-dividing mode. The wall-attached radiation cooling heating surface system greatly reduces the length of a high-temperature working medium pipeline, and reduces the number of needed high-temperature convection heating surfaces and high-temperature alloy pipelines, thereby reducing fixed investment of equipment. The superheater and reheater system combines with turbines which are arranged in a multi-stage and multi-axis mode, so the air inlet temperature and the turbine efficiency of the turbine of each grade can be improved. The tail flue comprises an upper-grade smoke gas coal economizer and a lower-grade smoke gas coal economizer which are used for heating a new working medium to meet requirements of an inlet of a primary wall-attached radiation cooling heating surface of the boiler, and the upper-grade air preheater and the lower-grade air preheater are used for heating combustion air, so that the special requirements for hearth combustion and heat transfer of the supercritical working medium circulation are met.

Owner:XIAN THERMAL POWER RES INST CO LTD

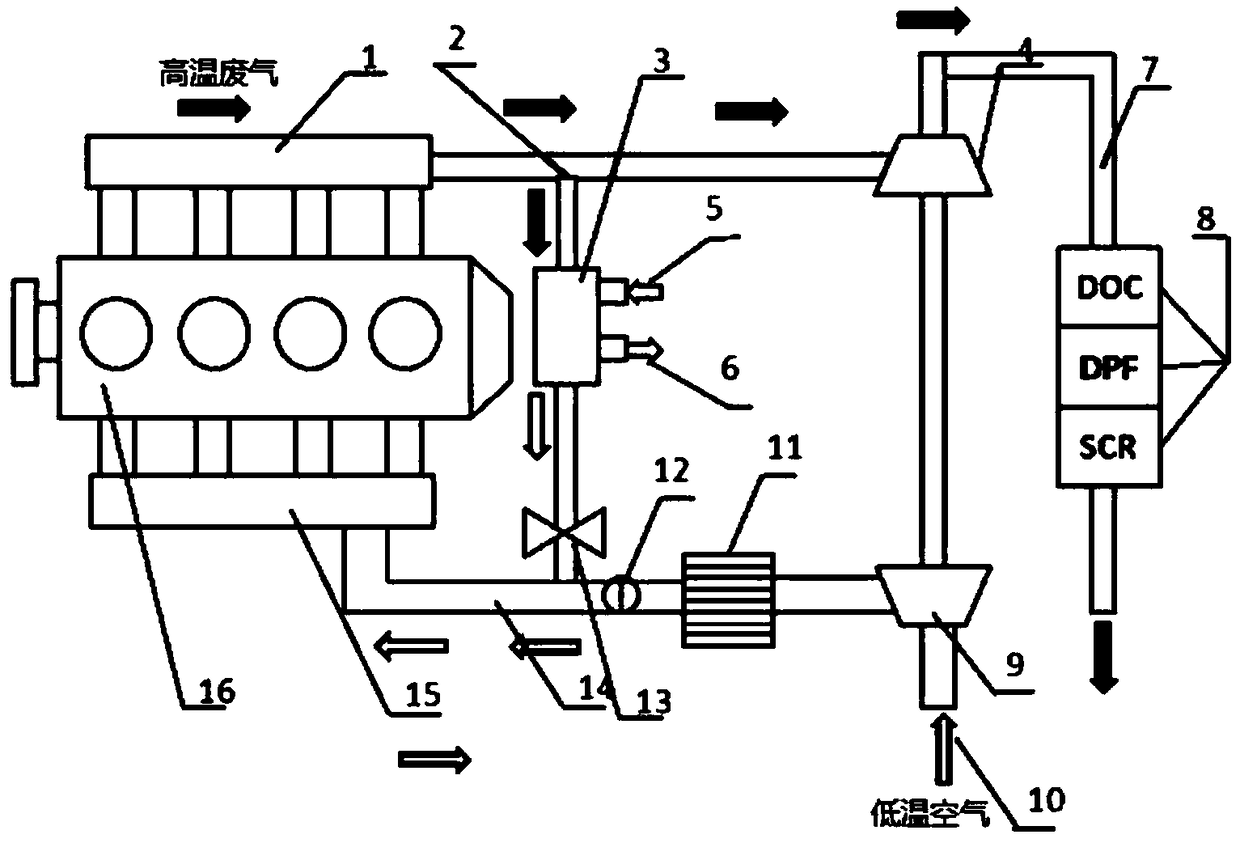

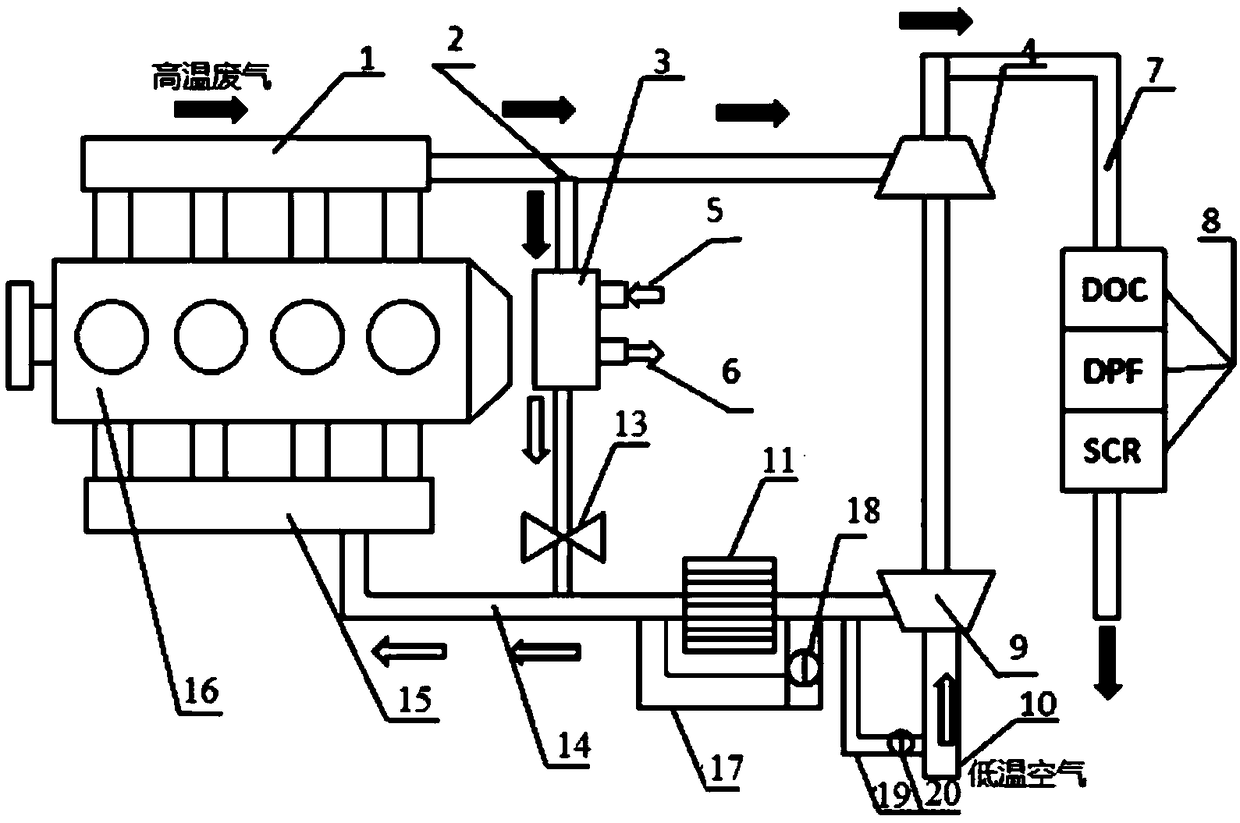

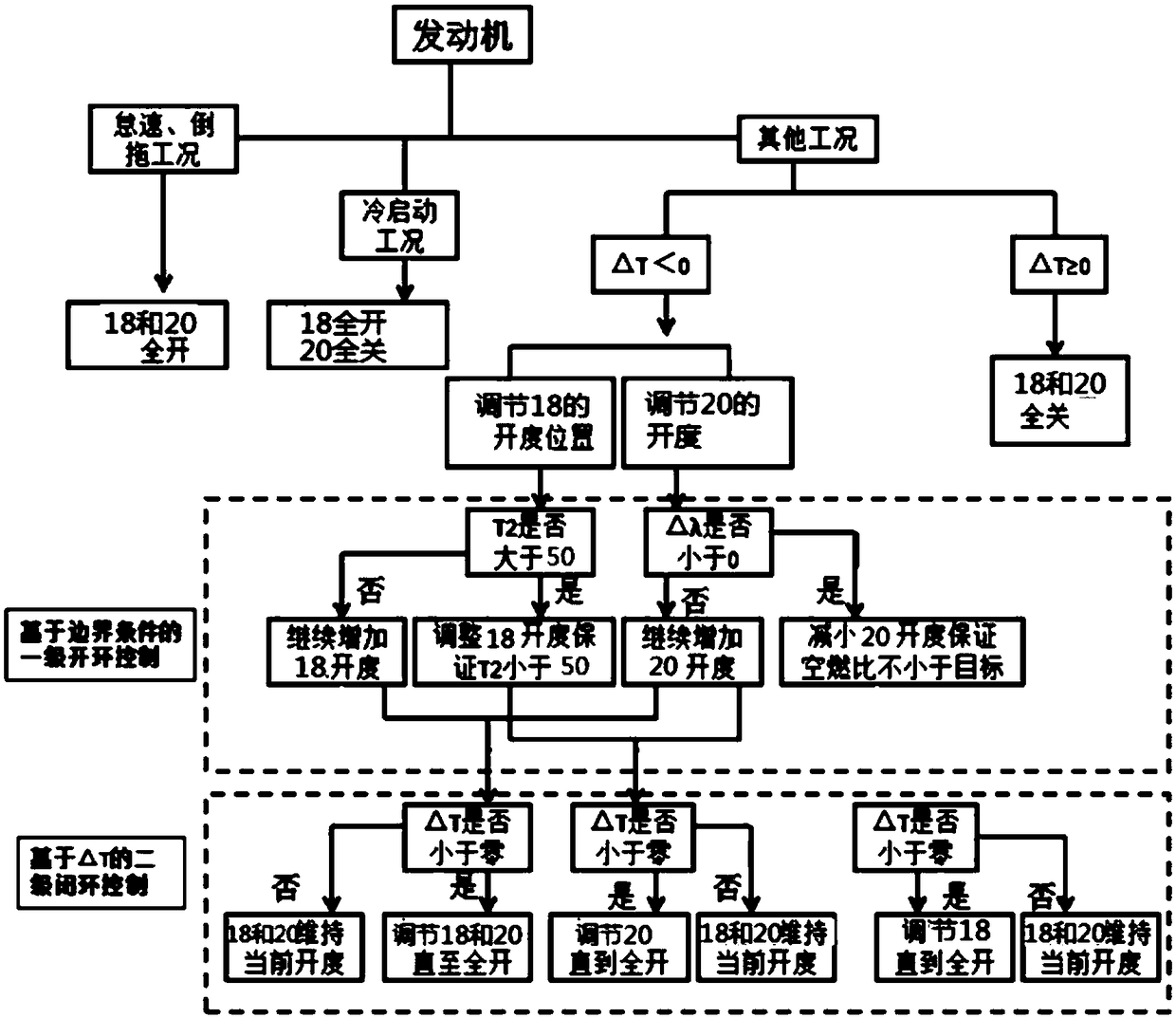

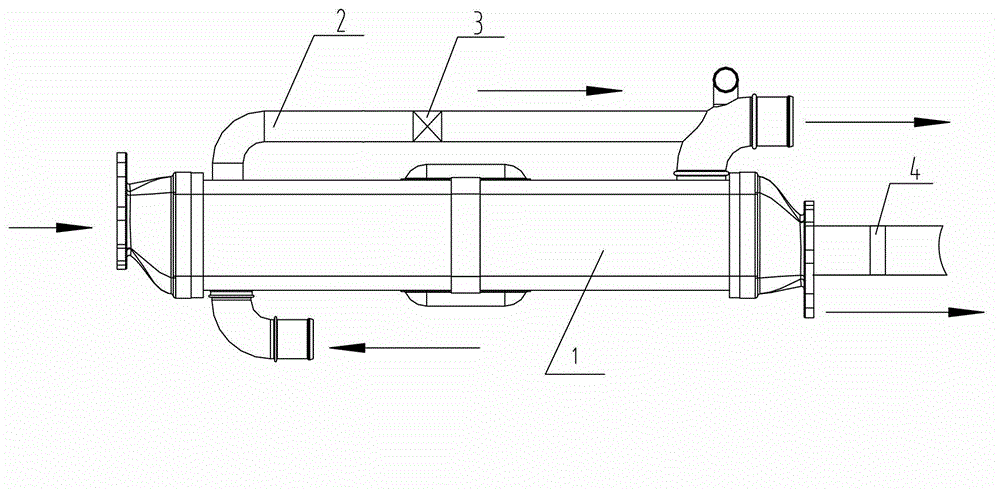

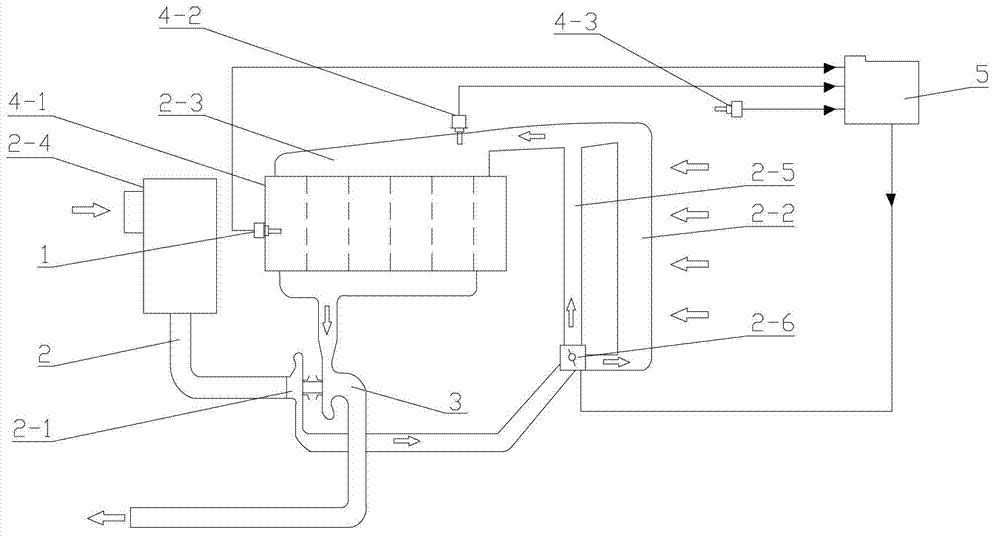

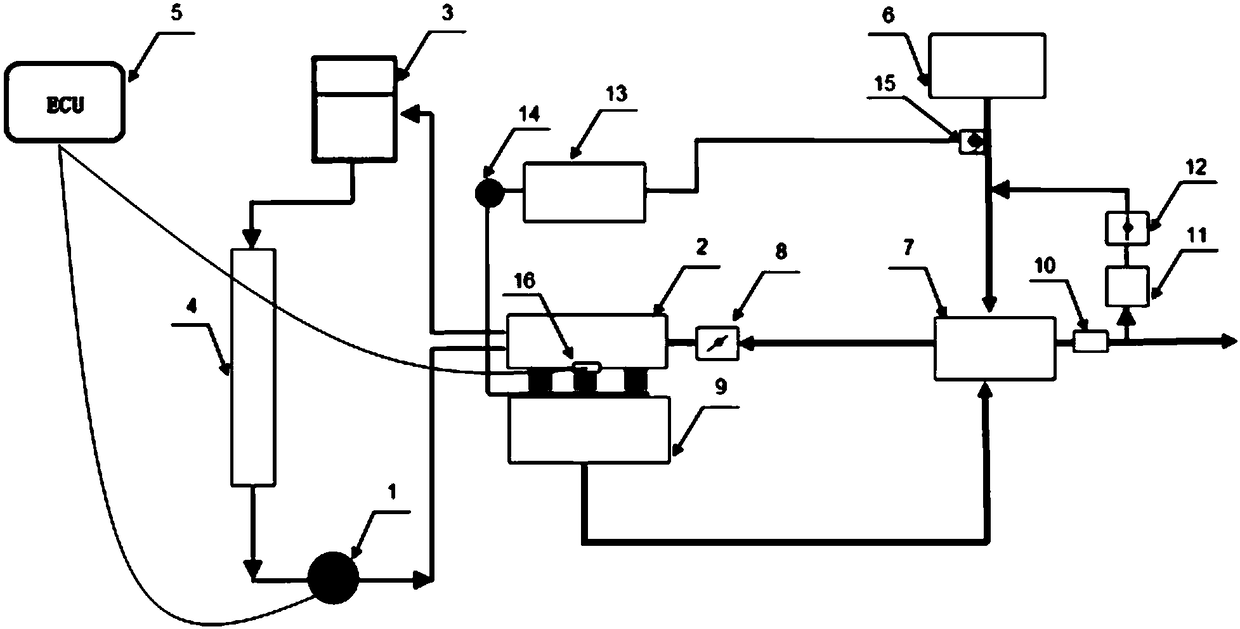

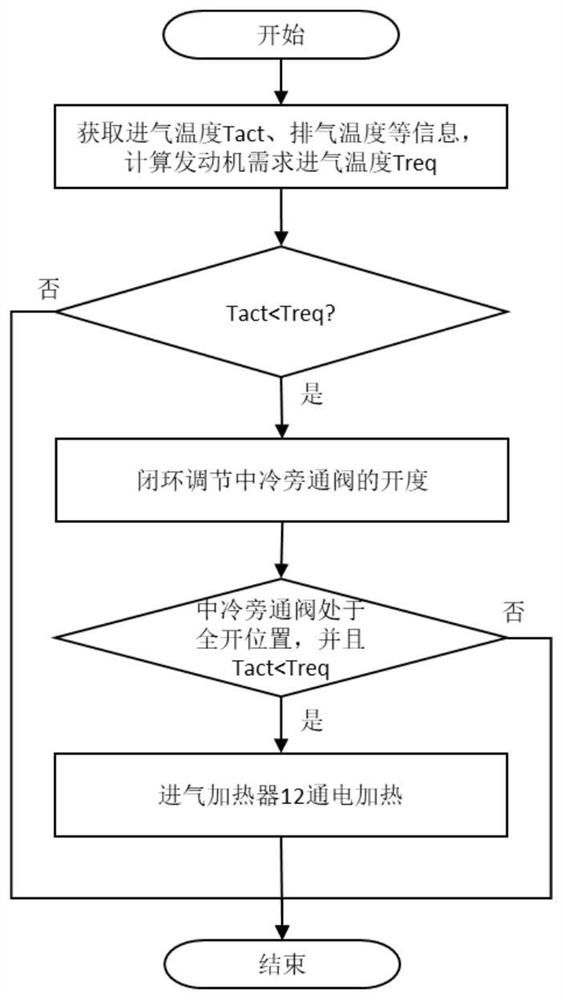

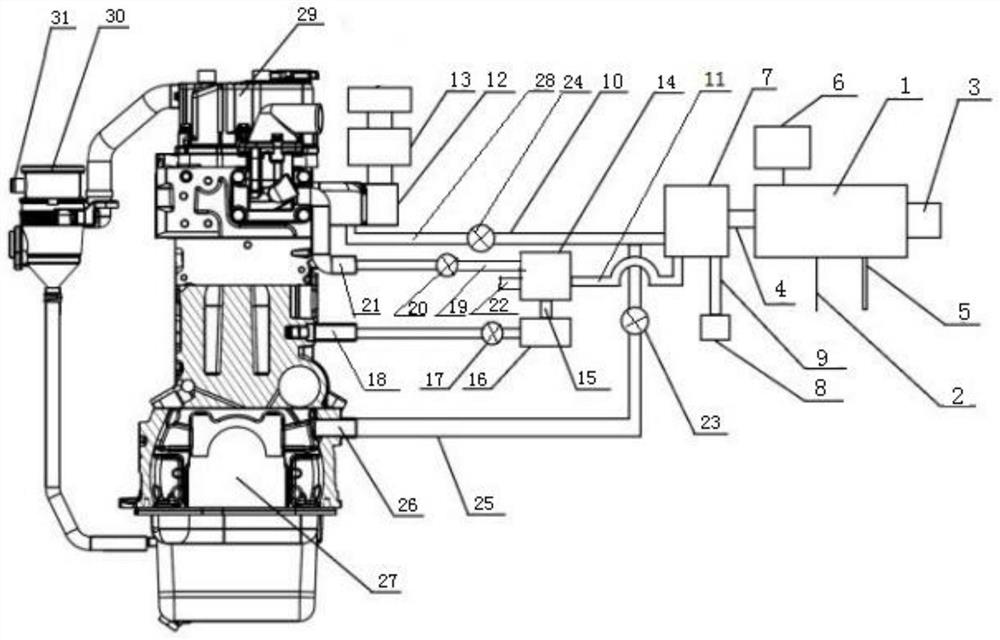

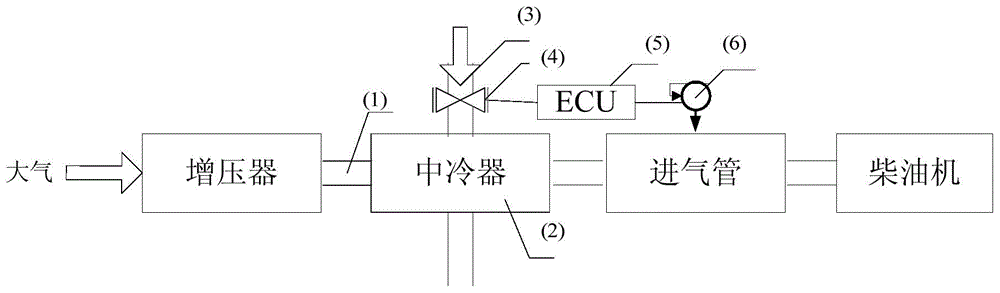

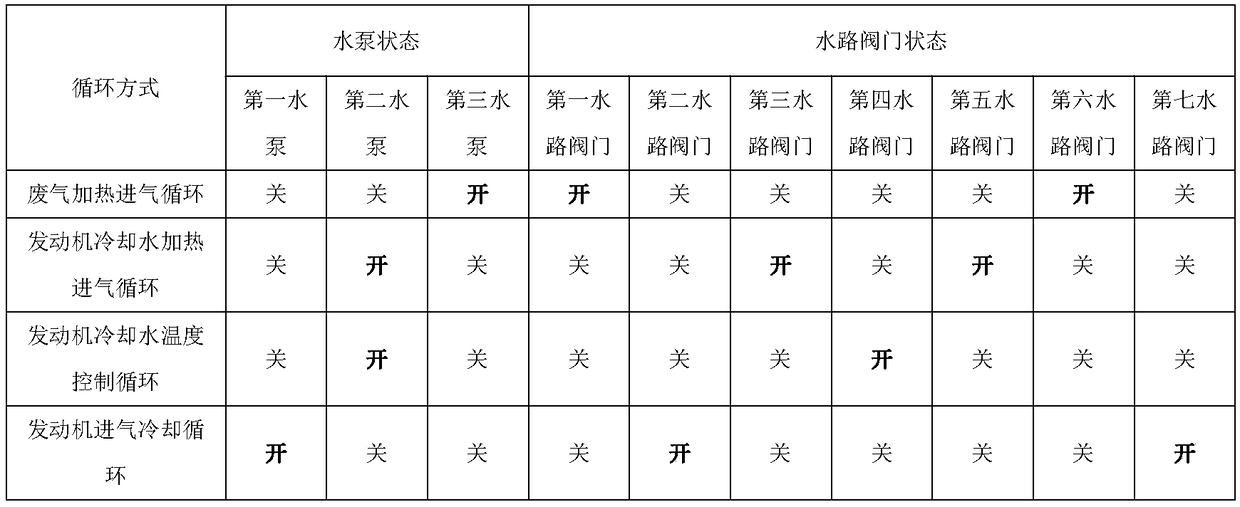

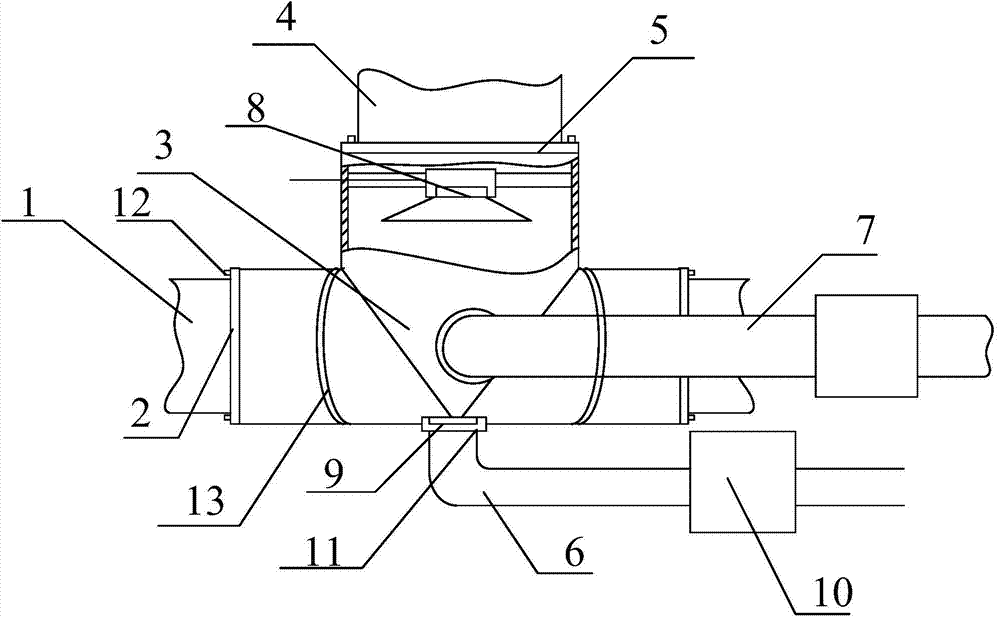

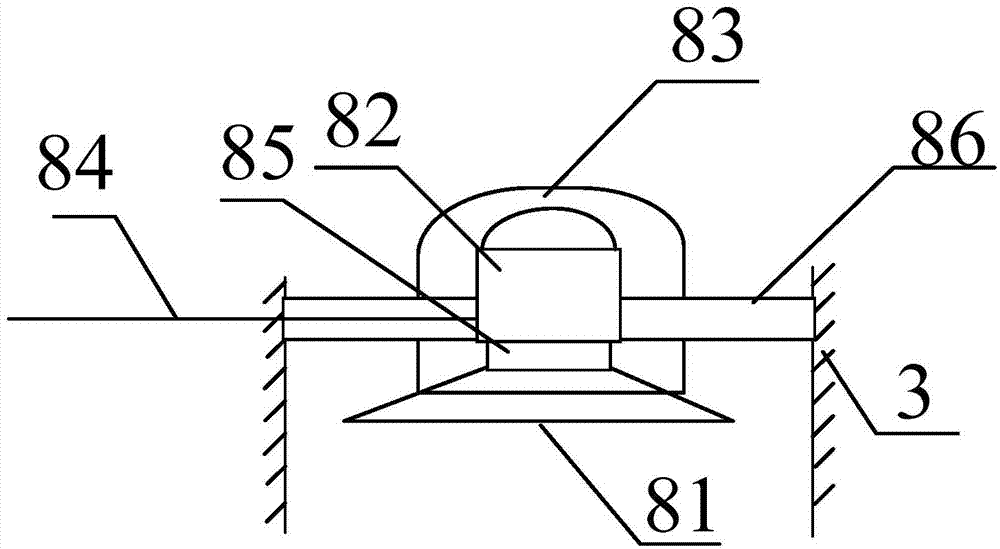

Engine thermal management system and control method thereof

ActiveCN108716433AIncrease intake air temperatureReduce fuel consumptionInternal combustion piston enginesExhaust apparatusThermal management systemIntercooler

The invention discloses an engine thermal management system. The system includes an engine air intake pipe, an engine air intake main pipe, an intercooler, and a supercharger compressor. The engine thermal management system also includes an intake air temperature control bypass pipeline, an intake air amount control bypass pipeline and a temperature sensor. The two ends of the intake air temperature control bypass pipeline are respectively connected to the inlet and outlet of the intercooler. The intake air temperature control bypass pipeline is connected in parallel with the intercooler. A first bypass proportional valve is arranged on the intake air temperature control bypass pipeline. The intake air flow bypass of different flow rates can be realized by adjusting the position ratio of the first bypass proportional valve. The two ends of the intake air amount control bypass pipeline are respectively connected to the inlet and outlet of the compressor. The intake air amount control bypass pipeline is connected in parallel with the supercharger compressor. A second bypass proportional valve is arranged on the intake air amount control bypass pipeline. The intake air flow demands ofdifferent working conditions can be met by adjusting the opening degree of the second bypass proportional valve. The temperature sensor is arranged on a pipeline of the engine air intake main pipe and is used for measuring the temperature of intake air entering the engine air intake main pipe. An EUC can collect measured values of the intake air temperature.

Owner:GUANGXI YUCHAI MASCH CO LTD

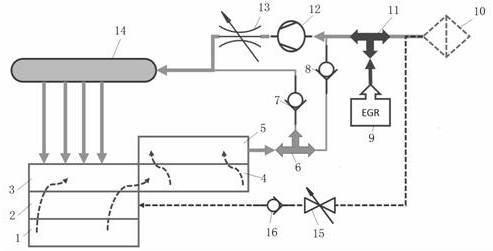

EGR (exhaust gas recirculation) gas temperature control device, EGR gas temperature control method, engine and engineering machinery

ActiveCN102913345AIncrease intake air temperatureAvoid charge factor dropNon-fuel substance addition to fuelInternal combustion piston enginesStreamflowCooling fluid

The invention discloses an EGR (exhaust gas recirculation) gas temperature control device, which comprises an EGR cooler for cooling the EGR gas exhausted from an engine exhaust pipe, a bypass pipe of which an inlet is communicated with a cooling liquid inlet of the EGR cooler, a flow regulating valve which is mounted on the bypass pipe and is used for regulating the flow of a cooling liquid in the bypass pipe. The temperature of the EGR gas is controlled by regulating the opening degree of the flow regulating valve. The EGR gas temperature control device has the advantages of simple control structure and convenience in operation, and can prevent EGR valve from being damaged due to over high / low temperature of the EGR gas and also prevent colloidal materials and carbon from being deposited in the EGR cooler and the EGR valve. The invention further discloses an engine, engineering machinery and an EGR gas temperature control method.

Owner:昆山三一动力有限公司

Apparatus and method for recycling braking energy of automobiles

InactiveCN102259596AAvoid wastingTimely consumptionInternal combustion piston enginesElectrodynamic brake systemsCatalytic reformingCombustion

The invention provides a device and method for recycling automobile braking energy, belonging to the technical field of automobile energy conservation and emission reduction. Aiming at the problem that a large number of braking energy is wasted during the frequent or long time braking procedure of an automobile, an automobile rotation shaft power generation device is added to prevent the large number of braking energy from wasting, so that mechanical energy is transformed into electric energy; and a part of the electric energy transmitted by a generator is used for fuel catalytic reforming, and the generated reformed gas is led into a gas inlet pipe of a diesel engine to be mixed with the diesel oil for combustion; and the other part of the electric energy is used for heating up the inletgas of the diesel engine. In the invention, by the combined actions of an automobile rotation shaft power generation device, a fuel catalytic reforming device, a diesel engine inlet gas heating device and a control system, the braking energy of automobiles is recycled, the combustion and emission performances of diesel engines in idling are greatly improved, and the energy conservation and emission reduction of diesel engines are realized.

Owner:BEIJING UNIV OF TECH

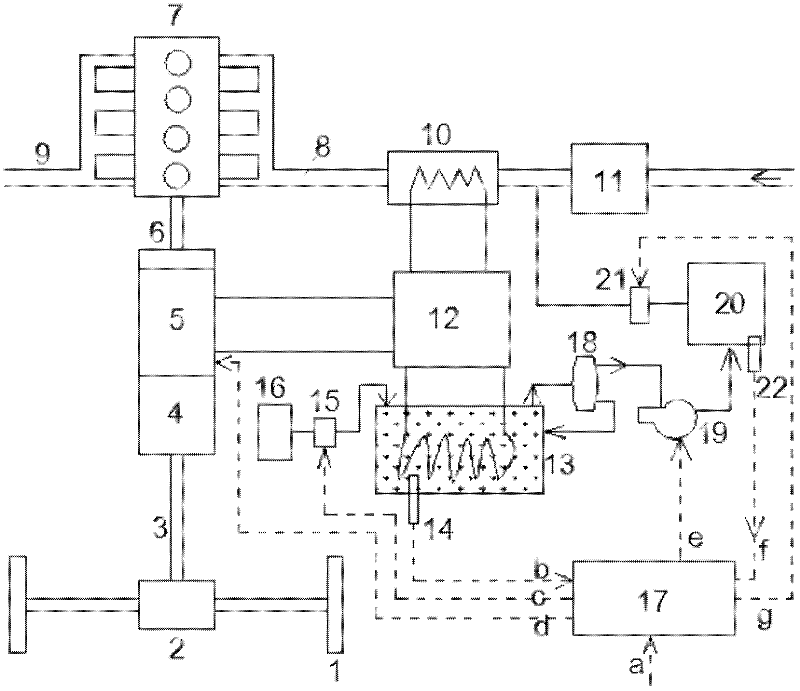

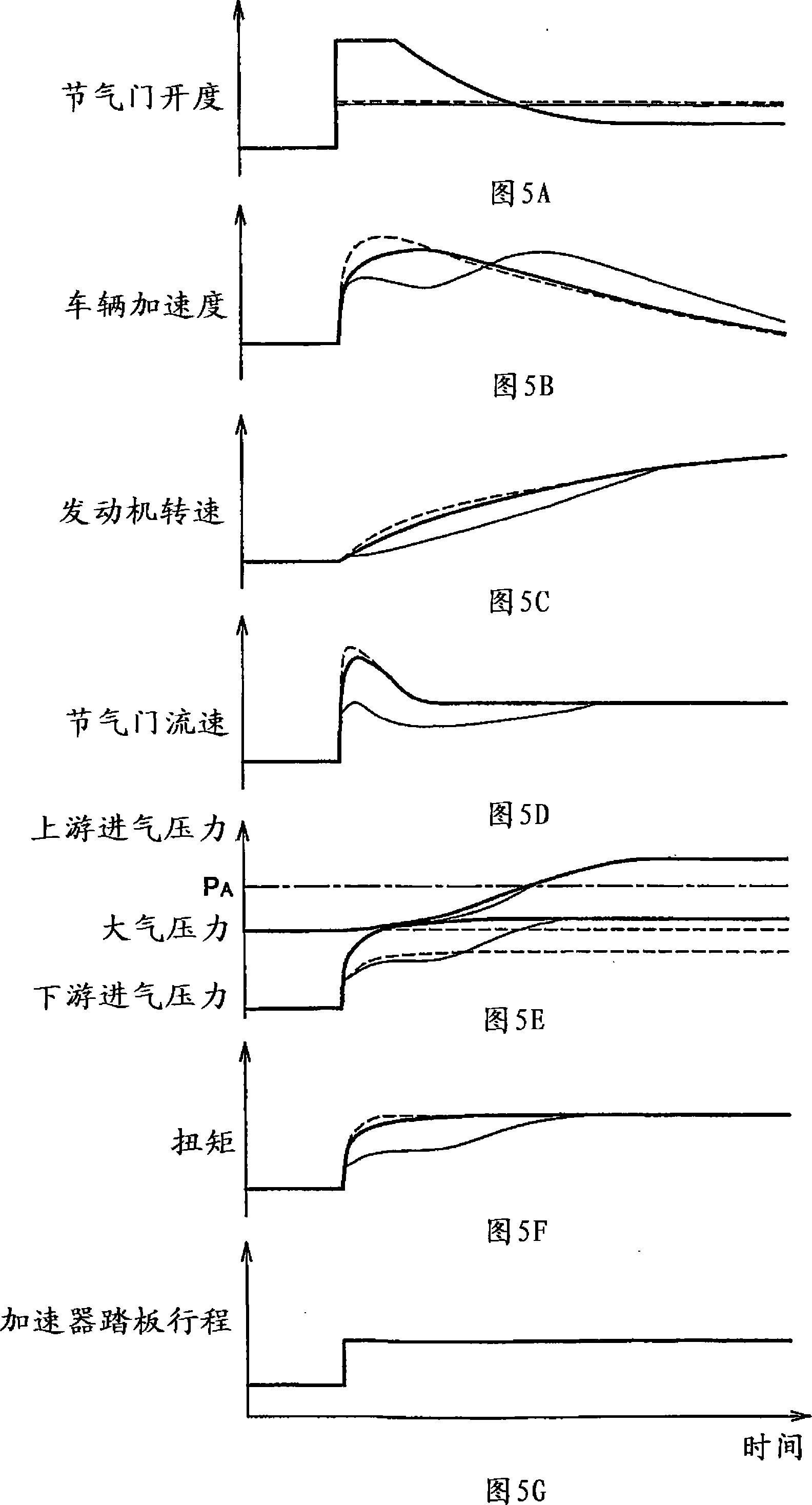

Control system and control method for internal combustion engine equipped with supercharger

InactiveCN101180460AIncrease intake air temperatureGood acceleration characteristicsElectrical controlInternal combustion piston enginesControl systemThrottle opening

A control system for an internal combustion engine equipped with a supercharger calculates a target intake mass airflow (mt') in accordance with an accelerator pedal travel (thetaA), using a virtual internal combustion engine model having a virtual upstream intake air pressure (PA). The control system then calculates a target throttle opening (thet) in accordance with a measured upstream intake pressure (PIN) so as to provide the target intake mass airflow (mt'), and controls a throttle valve based on the target throttle opening (theta).

Owner:TOYOTA JIDOSHA KK

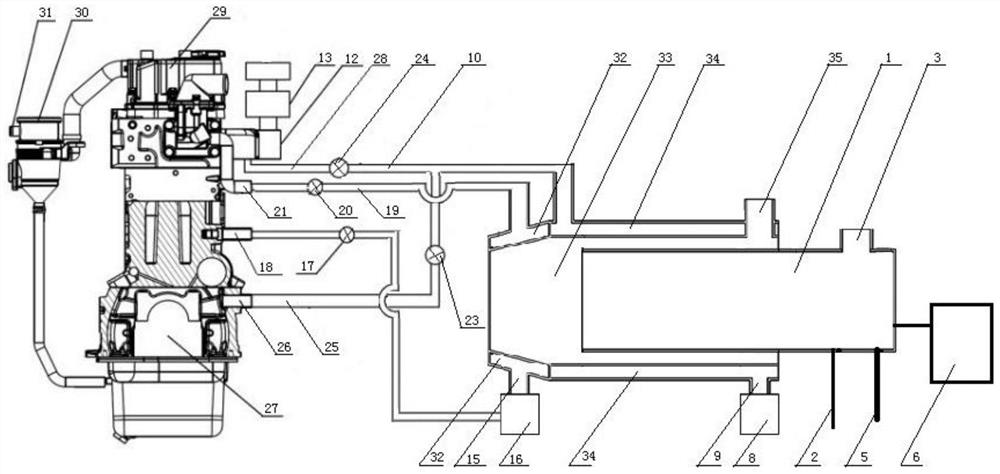

Diesel engine, and air inlet device and air inlet control method for diesel engine

ActiveCN102865167ARaise the combustion temperatureBurn fullyInternal combustion piston enginesCombustion-air/fuel-air treatmentIntercoolerControl valves

The invention discloses an air inlet device of a diesel engine. The air inlet device comprises a supercharger, an intercooler, a diesel engine air inlet tube, a temperature sensor, a diesel engine electronic control unit, an auxiliary air inlet tube and a control valve, wherein an air outlet of the supercharger is communicated with an air inlet of the control valve; a first air outlet of the control valve is communicated with an air inlet of the intercooler; a second air outlet of the control valve is communicated with an air inlet of the auxiliary air inlet tube; an air outlet of the intercooler and an air outlet of the auxiliary air inlet tube are communicated with the diesel engine air inlet tube; and the diesel engine electronic control unit adjusts the air inlet quantity of the auxiliary air inlet tube and the air inlet quantity of the intercooler through the control valve according to signals of the temperature sensor. By the air inlet device of the diesel engine, the air inlet temperature of the diesel engine can be controlled in real time, a burning environment of diesel oil can be improved, a phenomenon of white smoke is relieved, the burning efficiency of the diesel oil is improved, and accordingly the emission level and the economic performance of the diesel engine in cold regions can be improved. The invention further discloses a diesel engine air inlet control method and the diesel engine.

Owner:WEICHAI POWER CO LTD

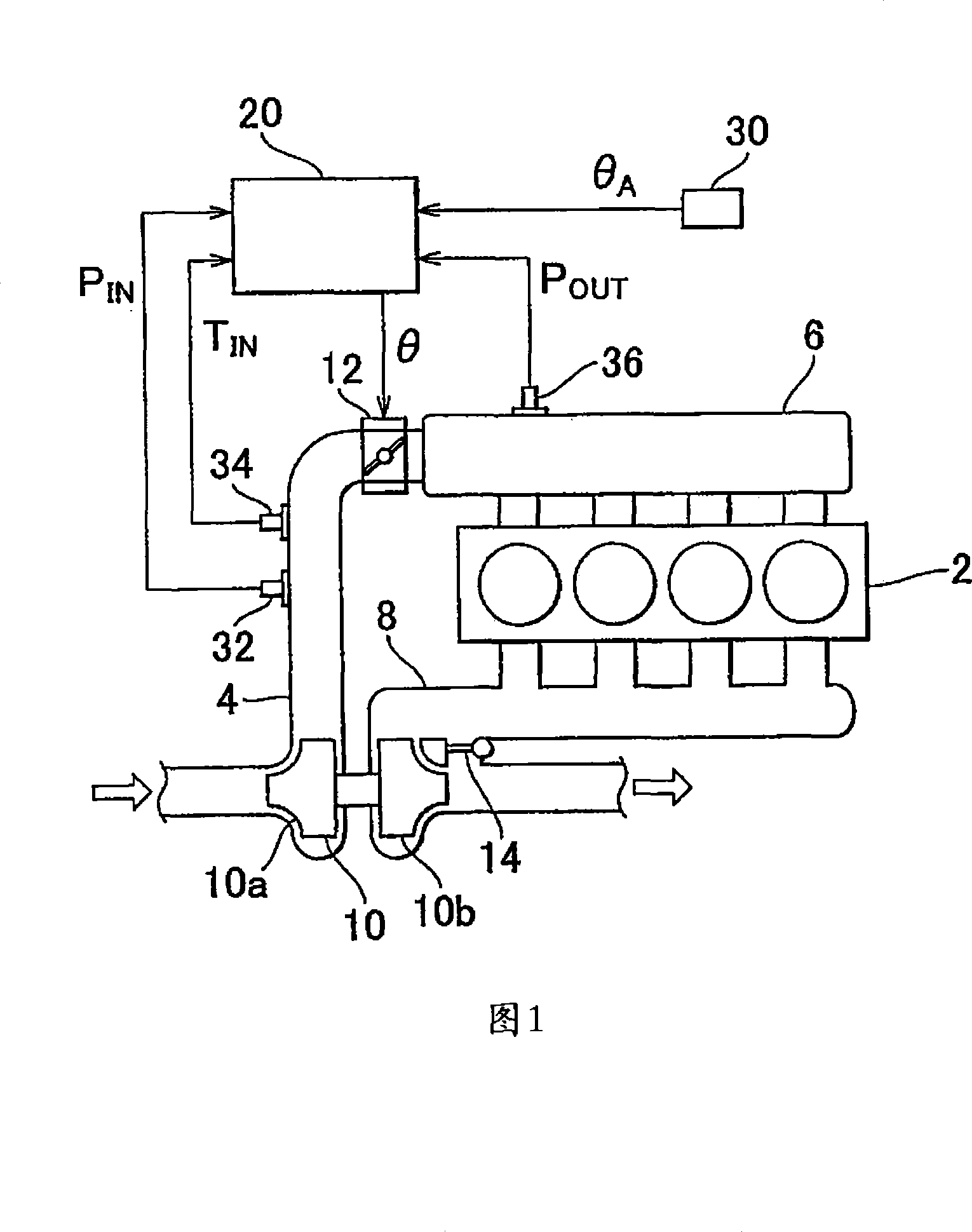

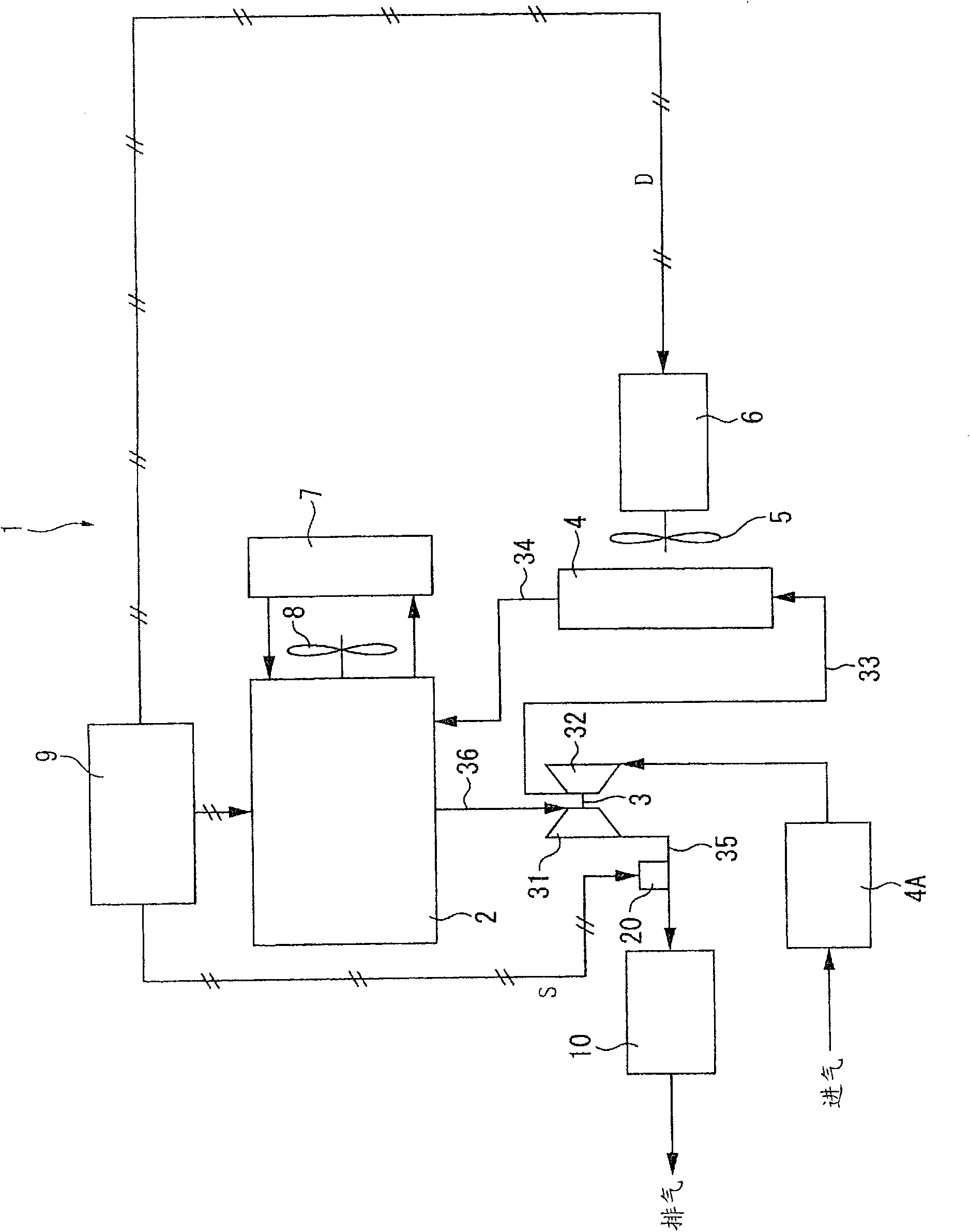

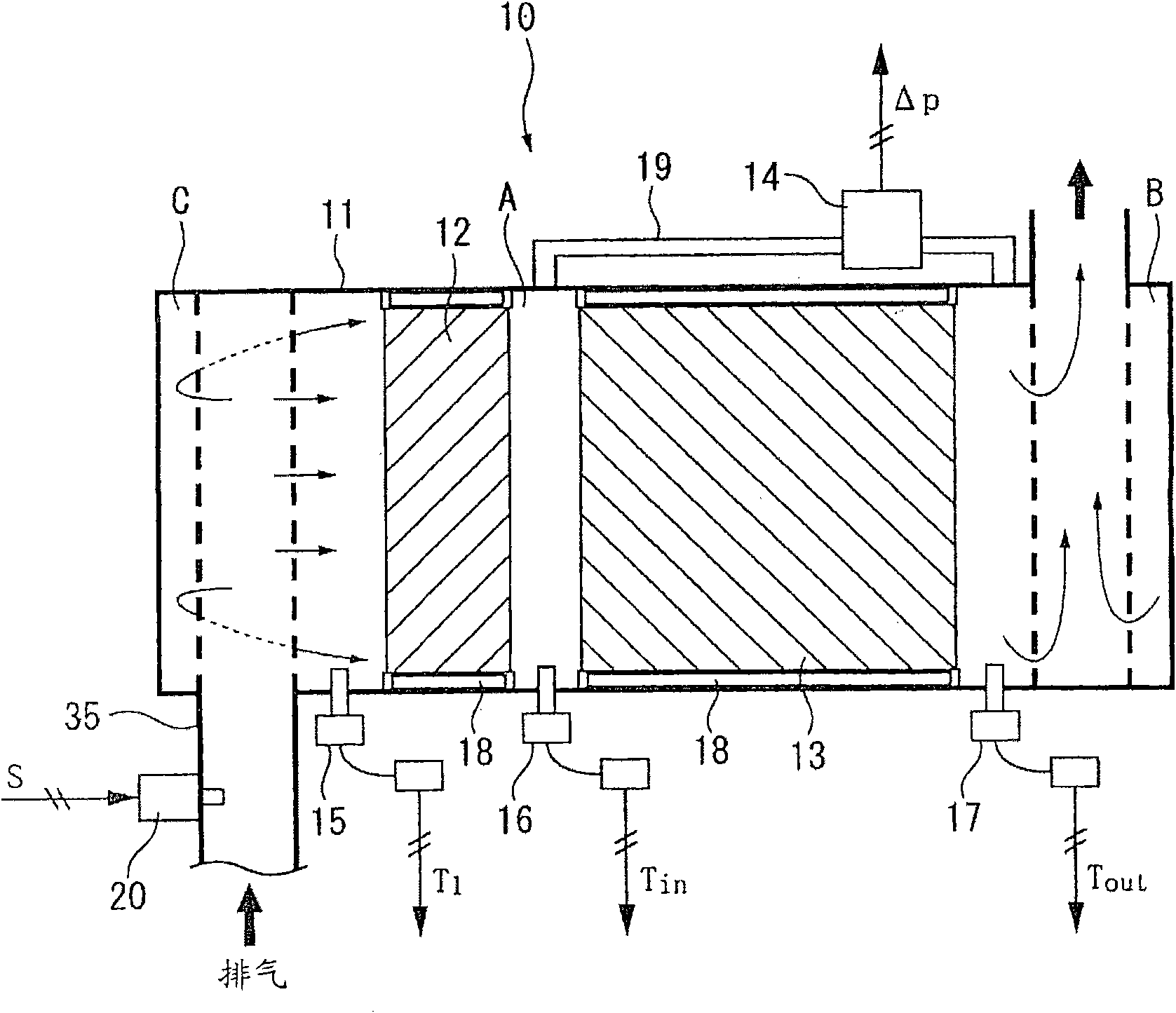

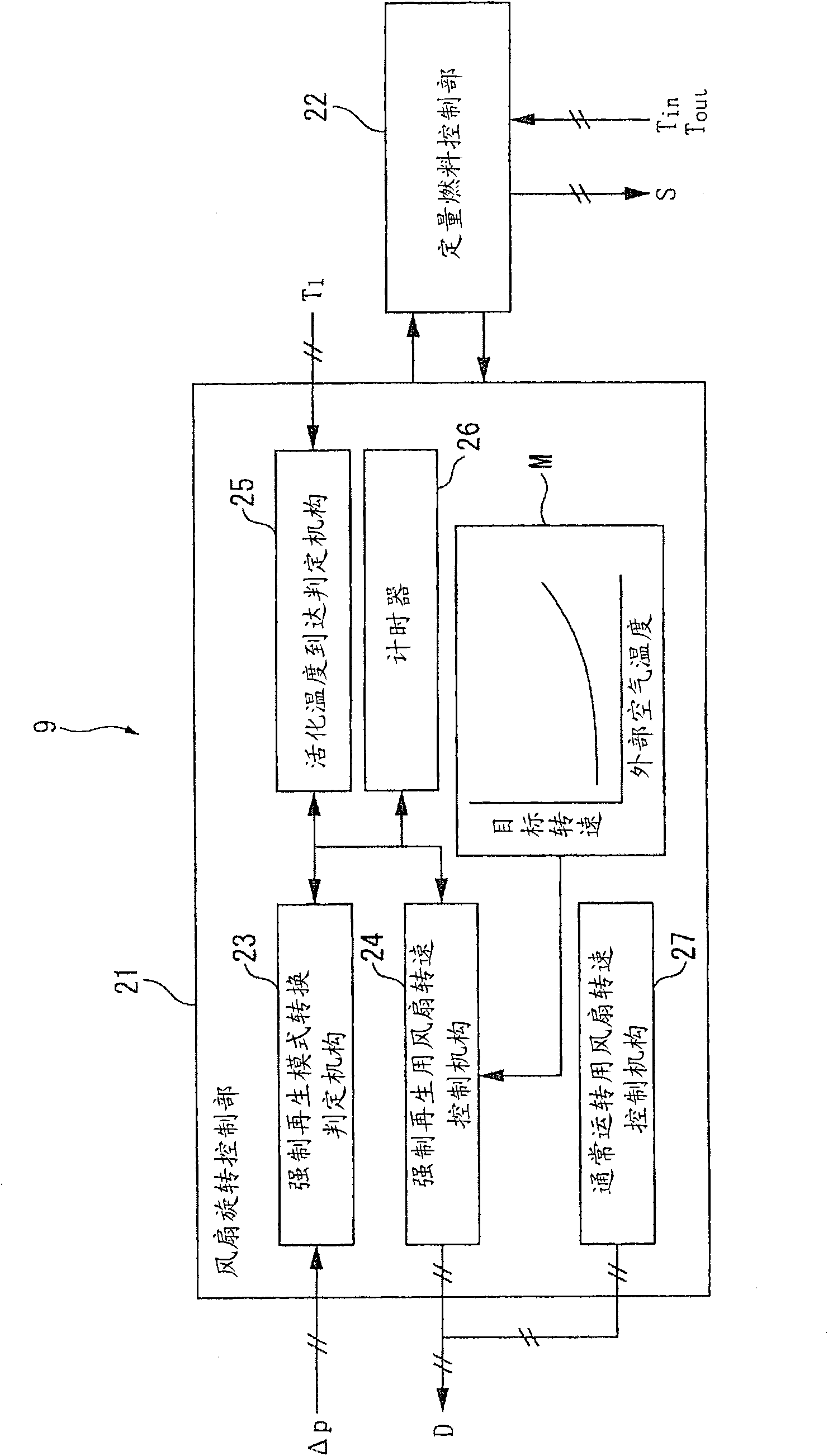

Exhaust gas purifying system for internal combustion engine and soot filter regenerating method

InactiveCN102046935ALife expectancyPrevent intake air temperature from risingGas treatmentElectrical controlExternal combustion engineTurbocharger

The invention provides an exhaust gas purifying system for an internal combustion engine and a soot filter regenerating method. An exhaust gas purifying system (1) for an engine (2) is provided with a soot filter in a PM filter device (10) for capturing PM contained in exhaust gas; a regeneration execution determining means in a control device (9), determining whether or not the soot filter is to be regenerated; an air-cooled after cooler (4) for cooling intake air supercharged by an exhaust turbine supercharger (3); a cooling fan (5) for supplying cooling air to the after cooler (4); and a fan speed control means for forcible regeneration, provided in the control device (9) and reducing the speed of the cooling fan (5) when the regeneration execution determining means determines that the soot filter is to be regenerated.

Owner:KOMATSU LTD

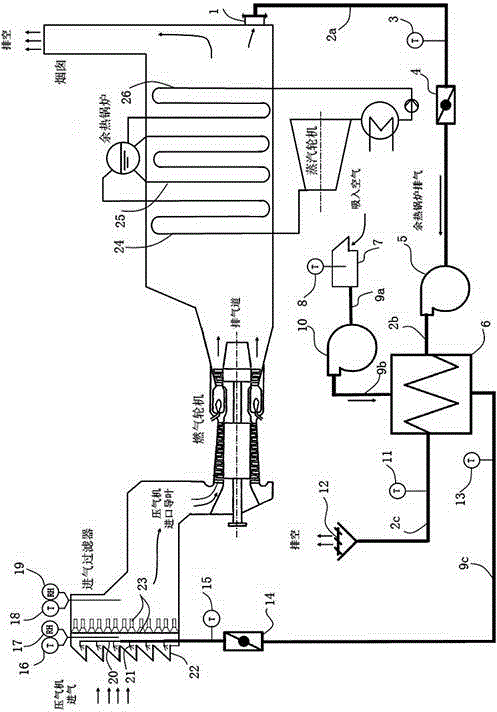

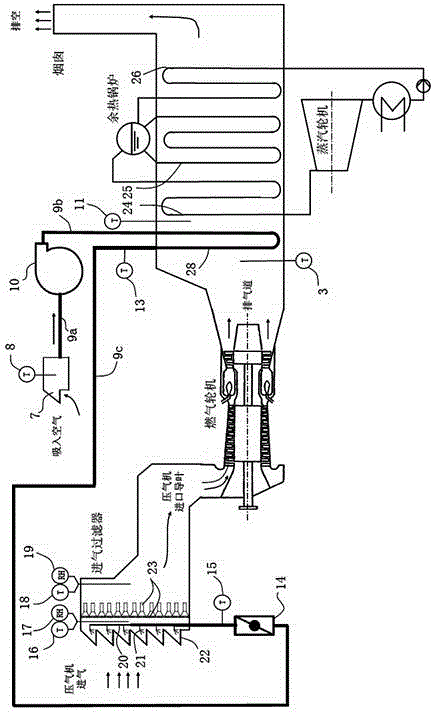

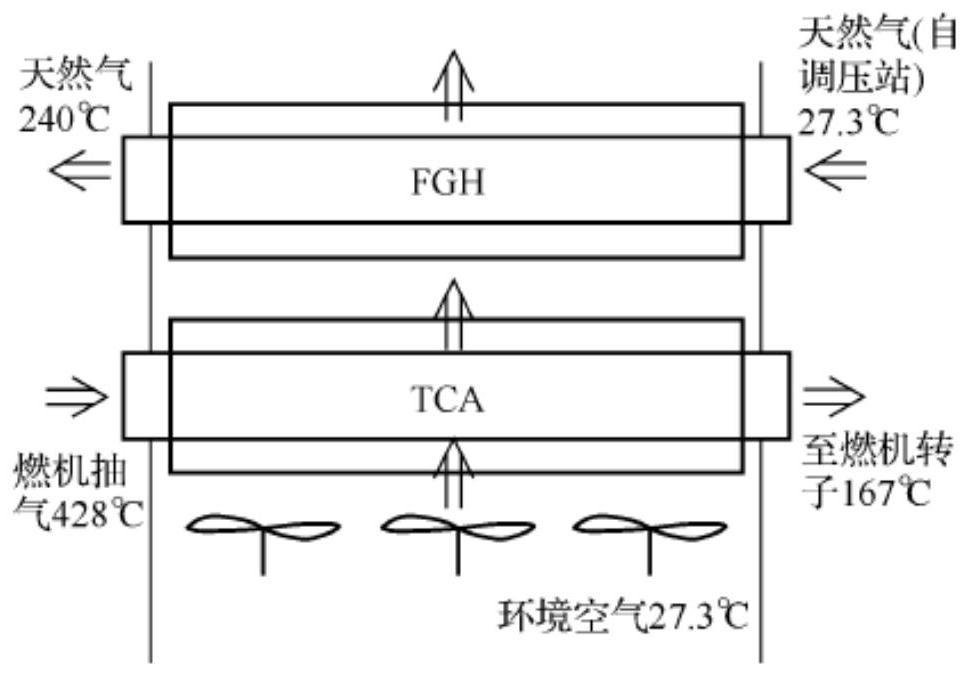

Air suction warming method and warming system of gas turbine compressor

InactiveCN104314691AReduce adverse effects of working conditionsIncrease intake air temperatureGas turbine plantsTurbine/propulsion air intakesEngineeringWarming process

The invention discloses an air suction warming heat exchanging method and an air suction warming heat exchanging system of a gas turbine compressor, and belongs to the technical field of gas turbines. The warming method comprises heating air suction of the gas turbine compressor by using exhaust gas from the gas turbine as the heat source. The warming system comprises a gas turbine unit, wherein an air inlet is provided with an air intake filter; an air vent or an air vent successive afterheat utilizing system is provided with a heat recovering device; a heating device is arranged at the air intake filter; and the heat recovering device and the heating device are combined to form a heat exchanging network. According to the air suction warming heat exchanging method and the air suction warming heat exchanging system of the gas turbine compressor, the exhaust fuel gas from the air vent of the gas turbine is used as the heat source to warm the inlet air from the compressor. The air suction warming method and the air suction warming system improve the air intake temperature of the compressor, achieve the purpose of preventing freezing of a filter element of the air intake filter or freezing of an inlet blade of the compressor, improve the economical efficiency of the warming process, and avoid unfavorable influence on the working condition of the gas turbine by the heat recover of the gas turbine body.

Owner:DONGFANG TURBINE CO LTD

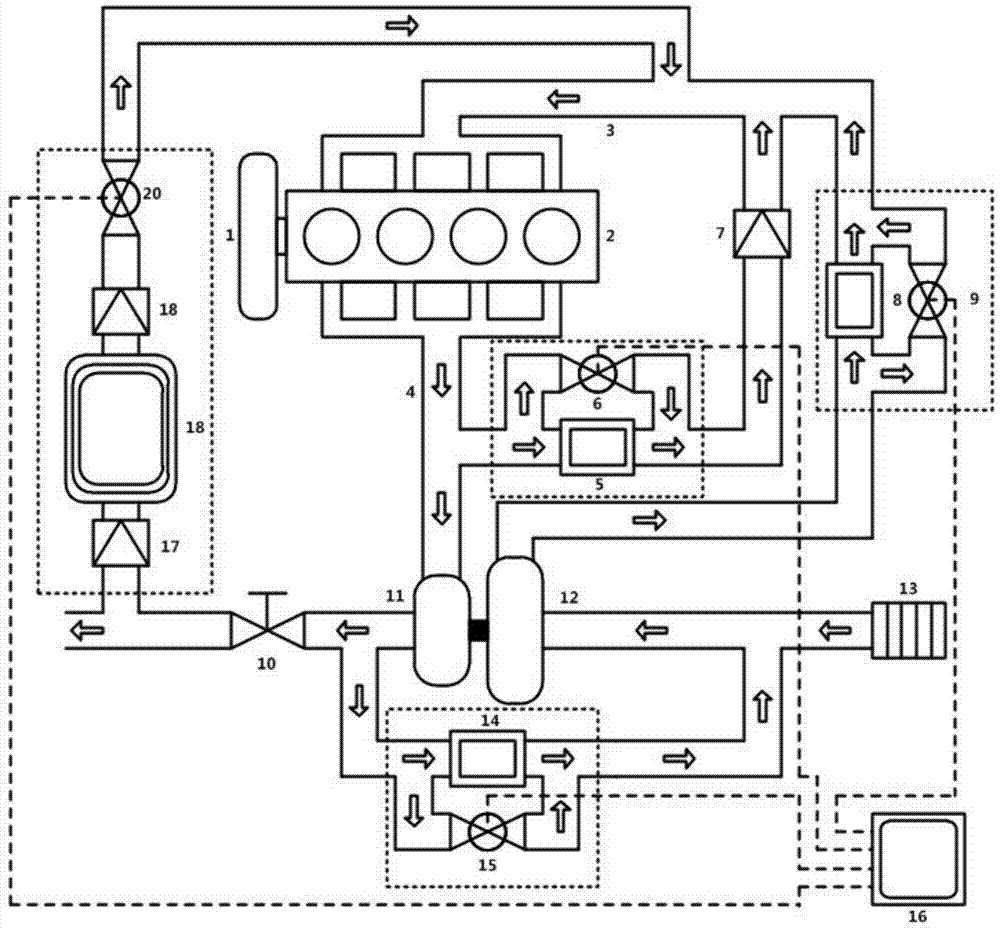

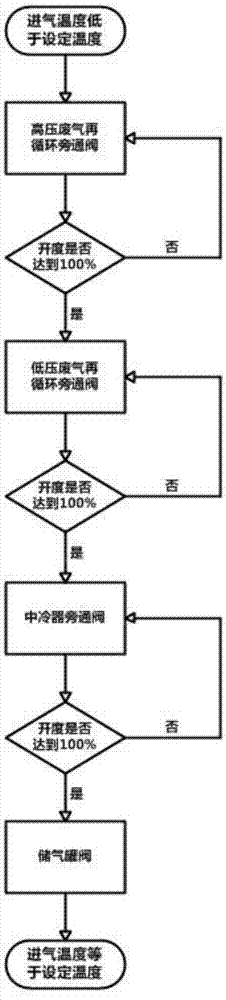

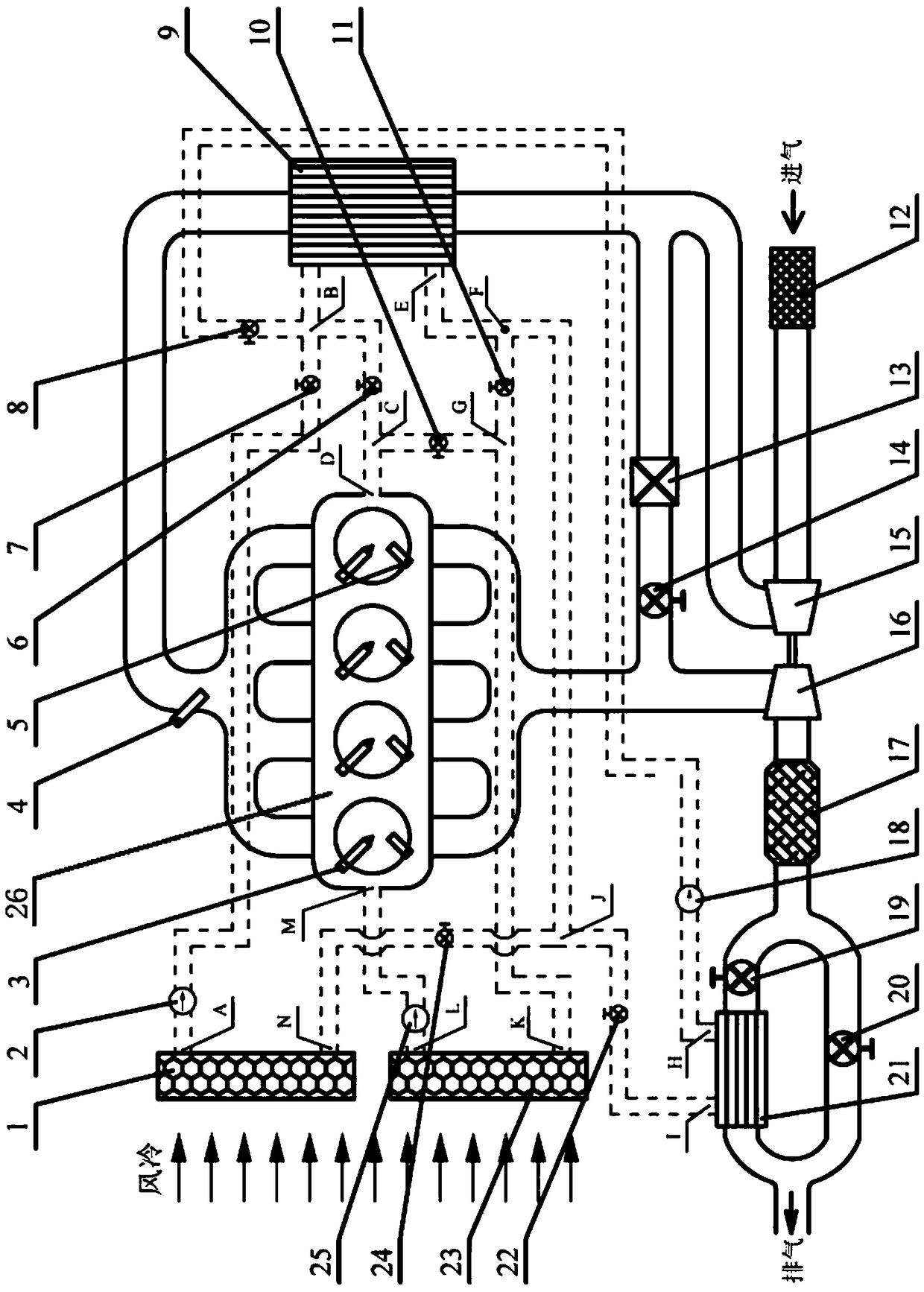

Low-temperature combustion and small-load stable combustion device and method for internal combustion engine

ActiveCN105443272AIncrease intake air temperatureEfficient and intelligent adjustable intake air temperatureElectrical controlInternal combustion piston enginesExternal combustion engineControl signal

The invention discloses a low-temperature combustion and small-load stable combustion method for an internal combustion engine. The method includes the following steps that in the running process of the engine, an electronic control unit reads temperature signals of a temperature sensor arranged on a gas inlet manifold; and when the gas inlet temperature of the engine is lower than the set temperature value of the electronic control unit, the electronic control unit sequentially sends control signals to a high-pressure waste gas recirculation bypass valve, a low-pressure waste gas recirculation bypass valve, an intercooler bypass valve and a gas storage tank valve till the set temperature is achieved. By means of the method, it is ensured that the gas inlet temperature can be efficiently and intelligently regulated.

Owner:TIANJIN UNIV

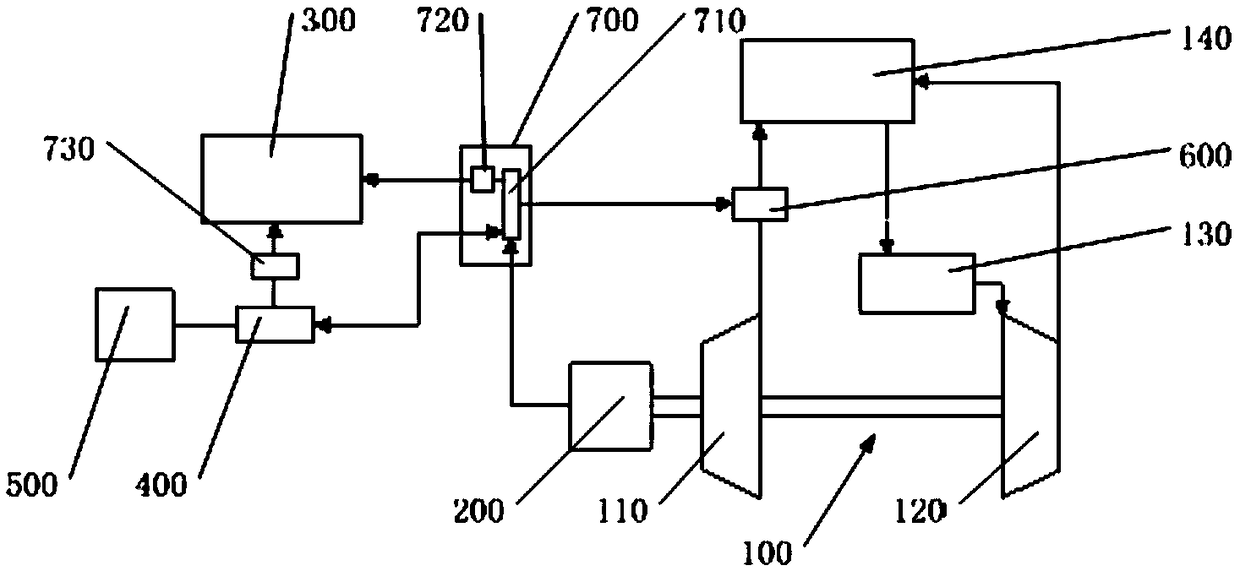

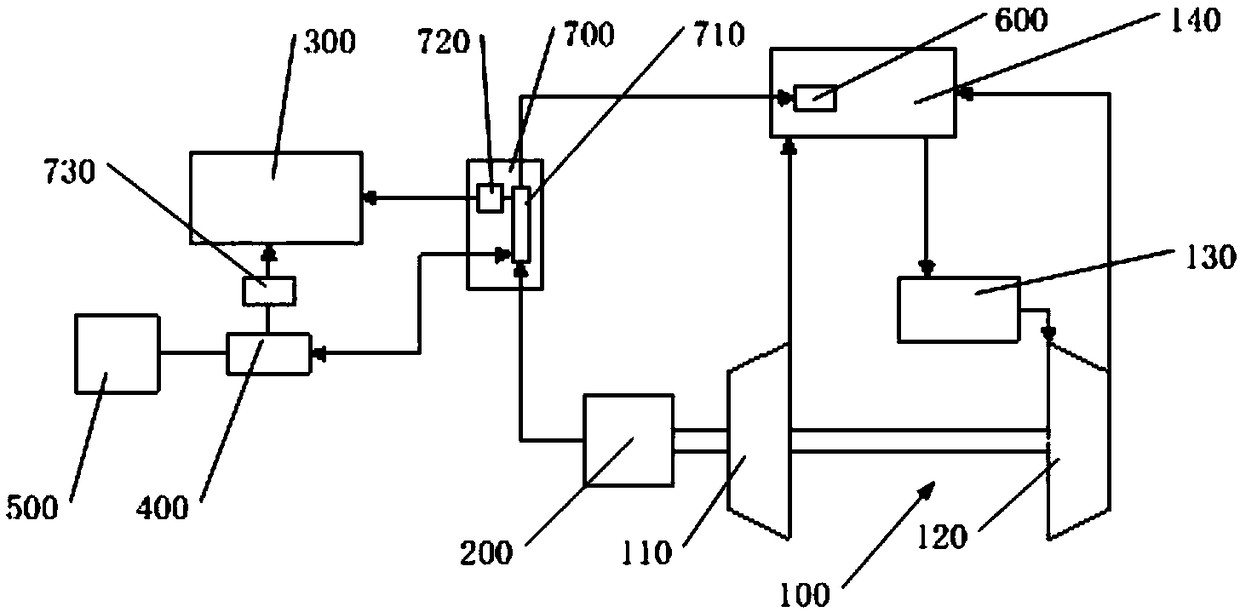

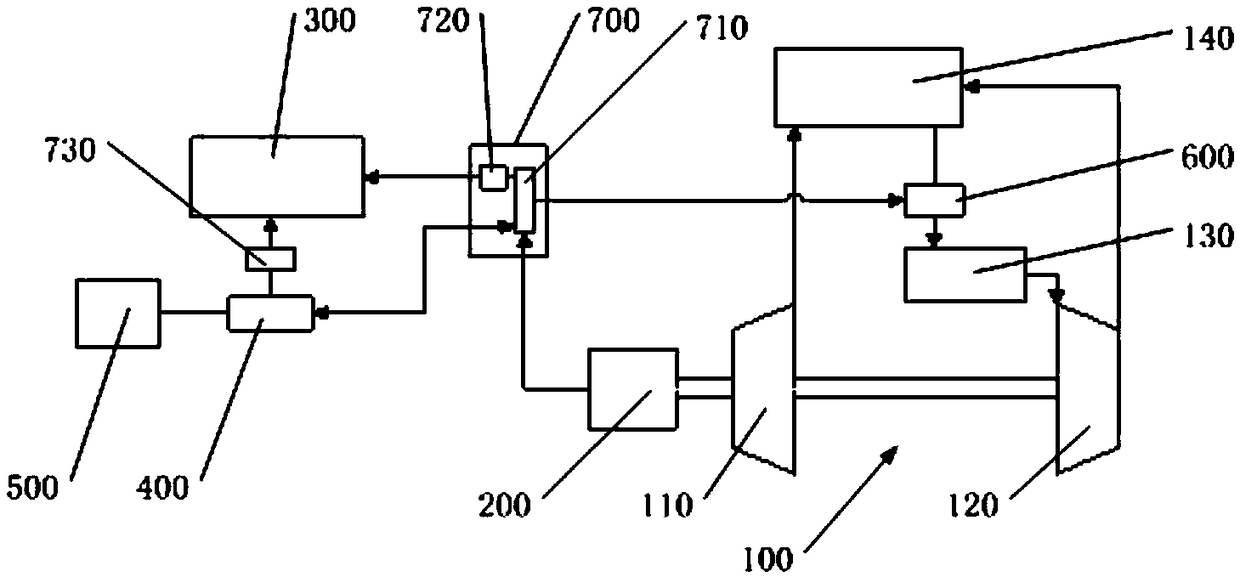

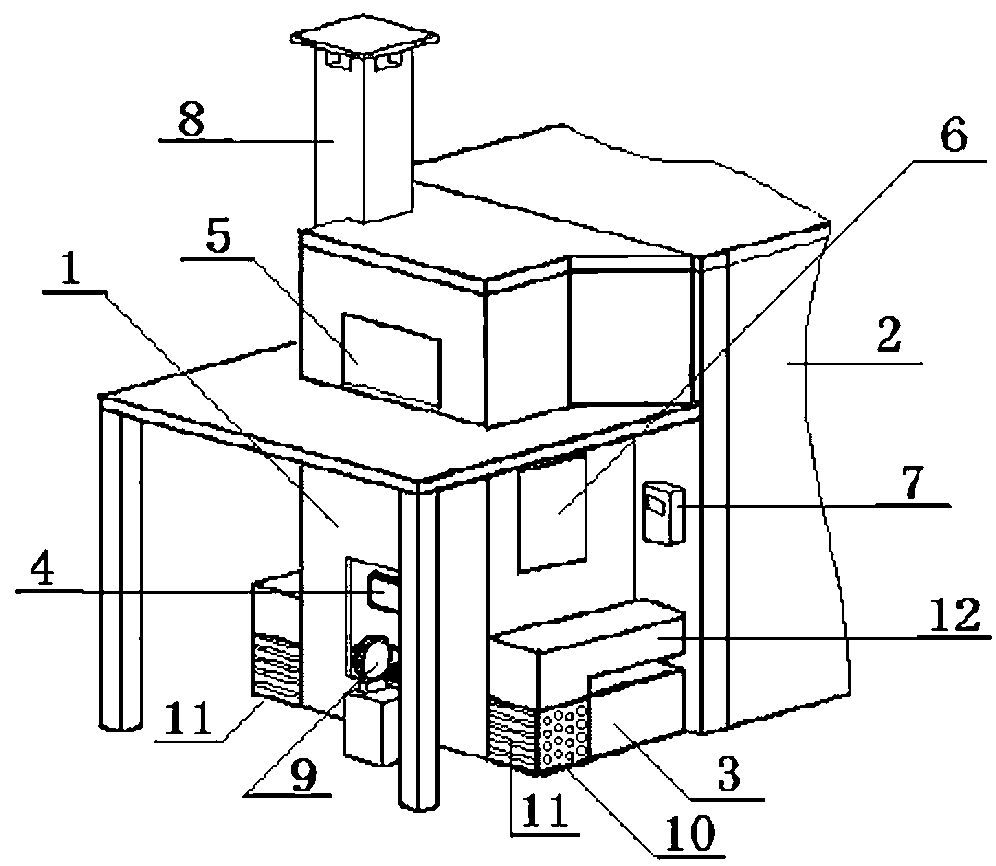

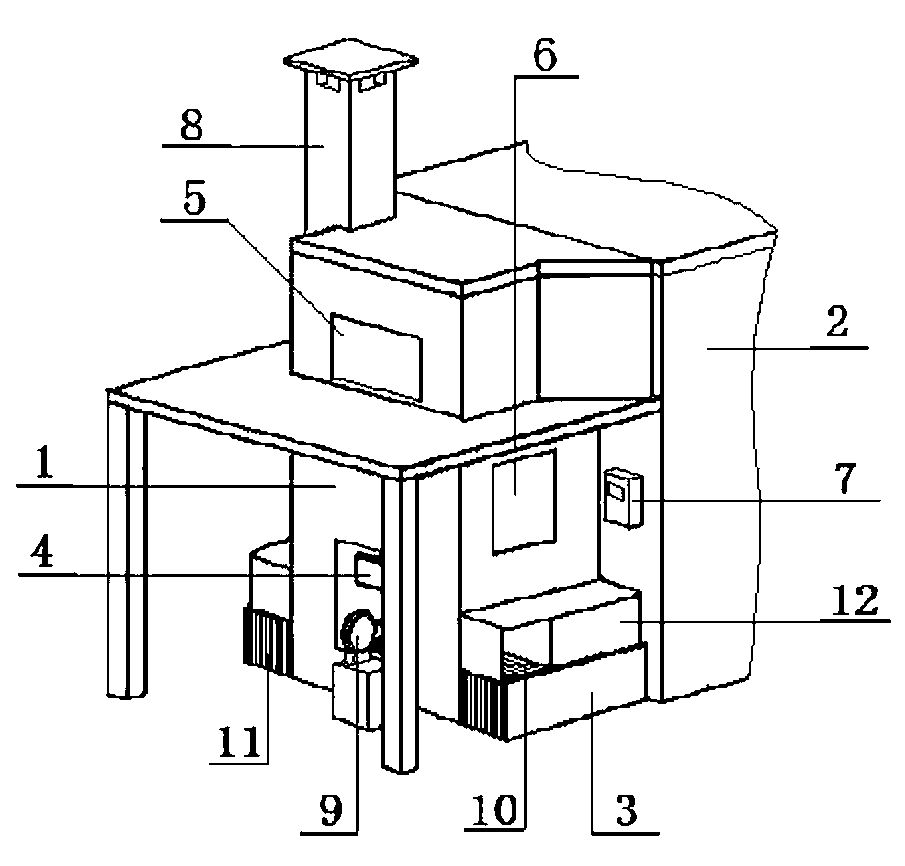

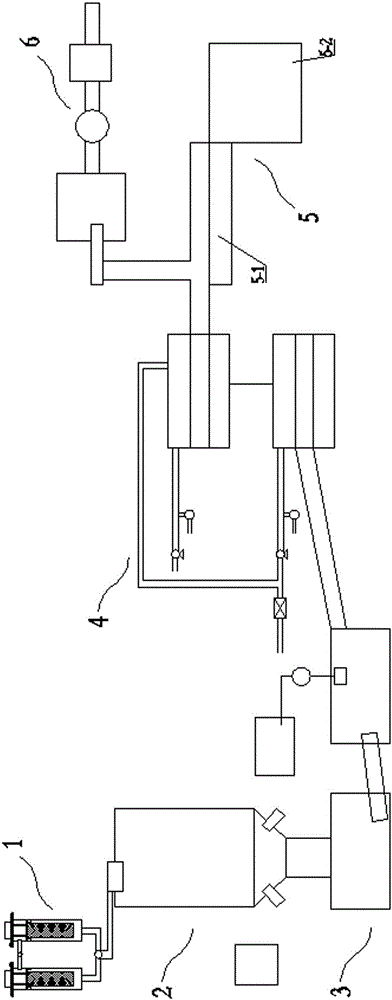

Energy recovery system for extended-range electric vehicle

PendingCN108749586AIncrease intake air temperatureImprove battery lifeElectrodynamic brake systemsPropulsion using engine-driven generatorsThermal energyCombustion chamber

The present invention belongs to the technical field of energy recovery, and in particular provides an energy recovery system for an extended-range electric vehicle. The extended-range electric vehicle includes a turbine engine (100), a generator (200), a battery pack (300), a drive motor (400), wheels (500) and a control device (700); the energy recovery system includes a thermal element (600), the thermal element (600) is connected with the control device (700) and the turbine engine (100), and used for converting braking energy of the wheels (500) into thermal energy for heating intake airof the turbine engine (100). According to the invention, the braking energy of the extended-range electric vehicle is converted into heat energy by installing the thermal element, and is used for secondary heating of the gas entering a combustion chamber, thereby improving the temperature of intake air of the combustion chamber, so as to improve the power generation of the unit fuel, the enduranceof the extended-range electric vehicle is prolonged.

Owner:刘慕华

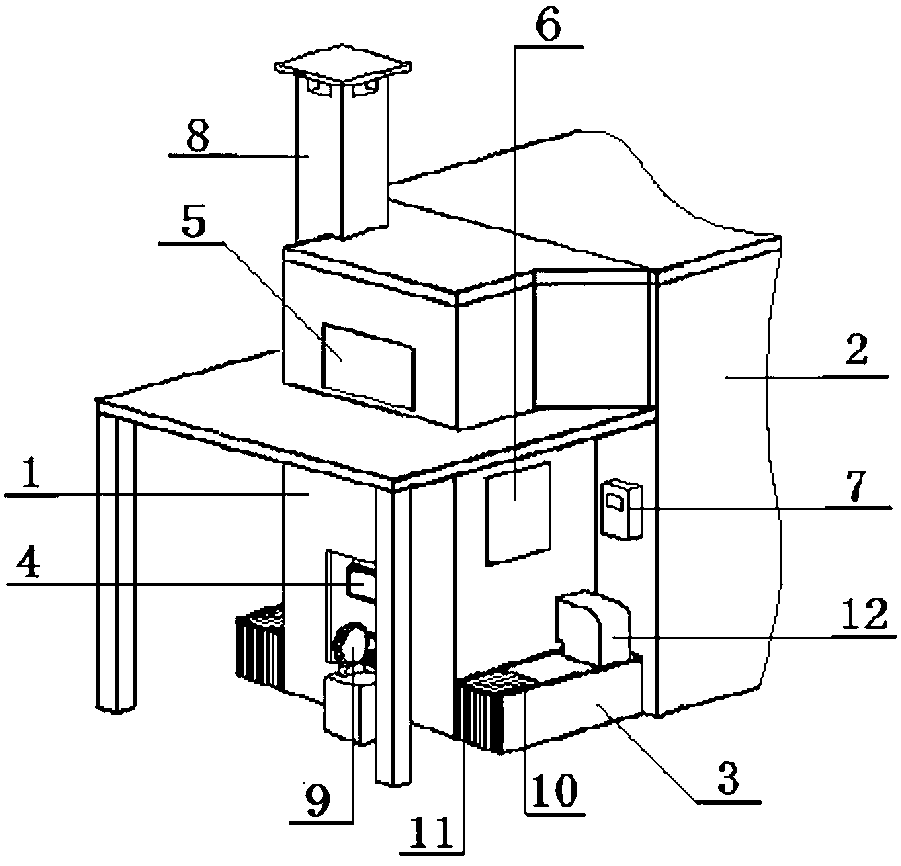

Energy-saving tobacco flue-curing house capable of effectively recycling dehumidification heat energy

ActiveCN102697160AFull recoveryReduce coal consumptionTobacco preparationStationary plate conduit assembliesCold airProcess engineering

The invention discloses an energy-saving tobacco flue-curing house capable of effectively recycling dehumidification heat energy, which comprises a heating chamber and a tobacco flue-curing chamber. The heating chamber is communicated with a chimney. A heating furnace chamber is arranged at the lower part of the heating chamber. A circulating air chamber is arranged at the upper part of the heating chamber. A furnace mouth, an ash outlet and an air blowing port are arranged at the front part of the heating furnace chamber. The air blowing port is connected with an air blower. Dehumidification passages are arranged on the two sides of the bottom of the heating furnace chamber. Cold air inlets are arranged above the dehumidification passages. A circulating fan repair passage is arranged at the front part of the circulating air chamber. High-efficiency heat exchange devices are arranged in the dehumidification passages. The dehumidification pipes of the heat exchange devices are communicated with a waste heat utilization device. The dry air pipes of the heat exchange devices are communicated with dry air inlets. The energy-saving tobacco flue-curing house capable of effectively recycling dehumidification heat energy has the advantages that since the high-efficiency heat exchange devices are directly arranged in the dehumidification passages to realize heat exchange between high-temperature moisture exhausted from the tobacco flue-curing house and normal-temperature fresh air, the heat in dehumidification air can be fully recovered and directly used as an auxiliary heat source for the tobacco flue-curing house, and the temperature of inlet air which enters the heating chamber can be increased by more than 10DEG C.

Owner:云南汇能科技有限公司

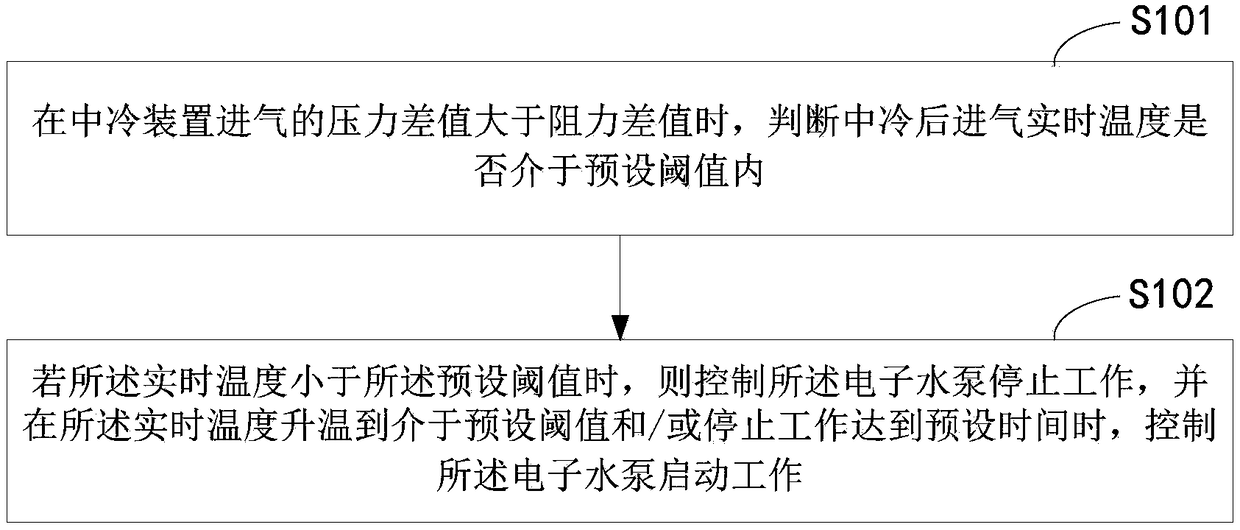

Vehicle, vehicle cooling system and electronic water pump control method of inter-cooling device of vehicle cooling system

ActiveCN108087100AMitigates increased intake pressure dropIncrease intake air temperatureInternal combustion piston enginesExhaust gas recirculationStopped workEngineering

The invention relates to a vehicle, a vehicle cooling system and an electronic water pump control method of an inter-cooling device of the vehicle cooling system. The method comprises the steps that whether the real-time air inlet temperature after inter-cooling is in the preset threshold or not is judged, and if the real-time temperature is less than the preset threshold, an electronic water pumpis controlled to stop working; and when the real-time temperature rises to the preset threshold and / or when the water pump stops working for the preset-time, the electronic water pump is controlled to start working. By controlling the running state of the electronic water pump of the inter-cooling device, the electronic water pump is controlled to stop working, the air inlet temperature is increased after the inter-cooling until the air inlet temperature after the inter-cooling is higher than a set value, and then the electronic water pump is started, so that the mixture of engine oil and condensate water in the inter-cooling device are volatilized, and the problem of the drop and increase of the front and rear air inlet pressure of the inter-cooling device is alleviated; and by controlling the electronic water pump to stop working in a cold environment, the air inlet cooling is avoided, the rise of the air inlet temperature is accelerated, and when the air inlet temperature after theinter-cooling is higher than a set value, the electronic pump is started, so that the problems of freezing and the like are solved.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS

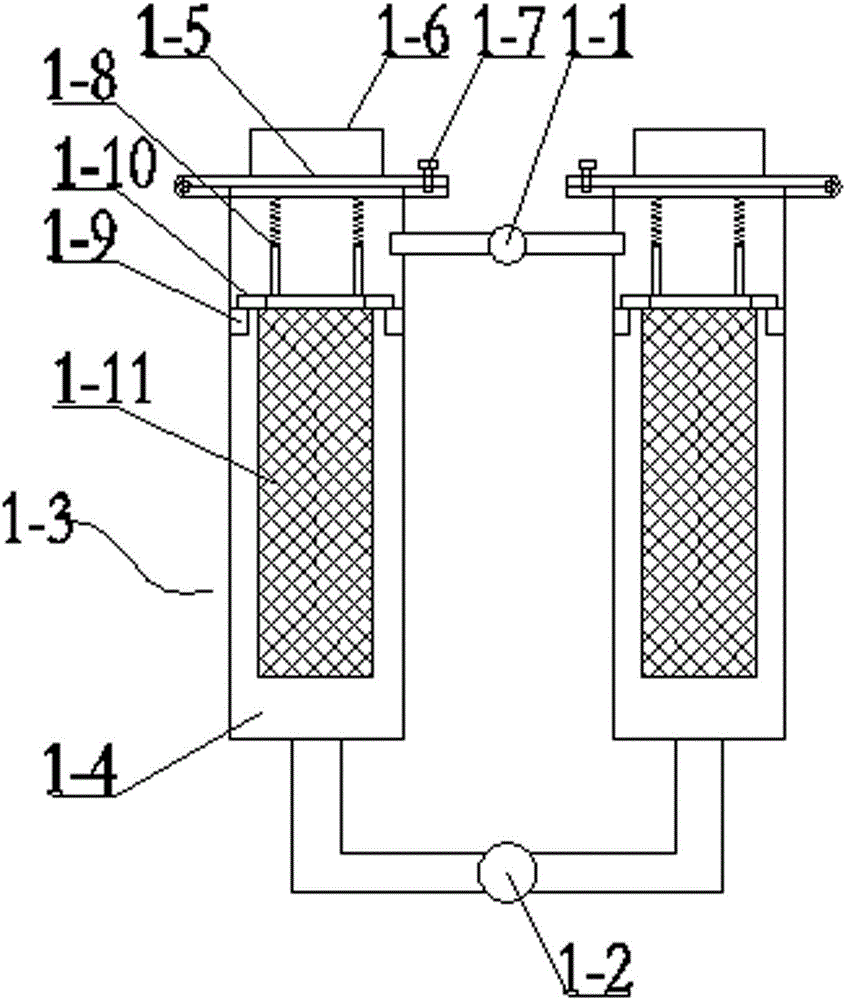

Automatic-switching heat accumulation type gas burner

InactiveCN102563653AFull heat exchangeBurn completelyIndirect carbon-dioxide mitigationGaseous fuel burnerInlet temperatureGas burner

The invention provides an automatic-switching heat accumulation type gas burner, wherein two single gas burners with the same structure are arranged at two sides of a furnace body; when one burner burns, the other burner accumulates heat; the automatic reversing of the burner is achieved by an external switching valve; the switching of a low-temperature operating mode and a high-temperature operating mode, the low-temperature high-speed burning and the high-temperature oxygen-lacking burning and smoke reflux technology are adopted, so that the heat exchange is full, the inlet temperature of the combustion-supporting air is improved greatly, the temperature of the exhausted smoke is reduced, the complete burning is achieved, and the low NOx emission, automatic switching of high and low temperature operating modes, high-efficient and energy-saving self heat accumulation function are achieved.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

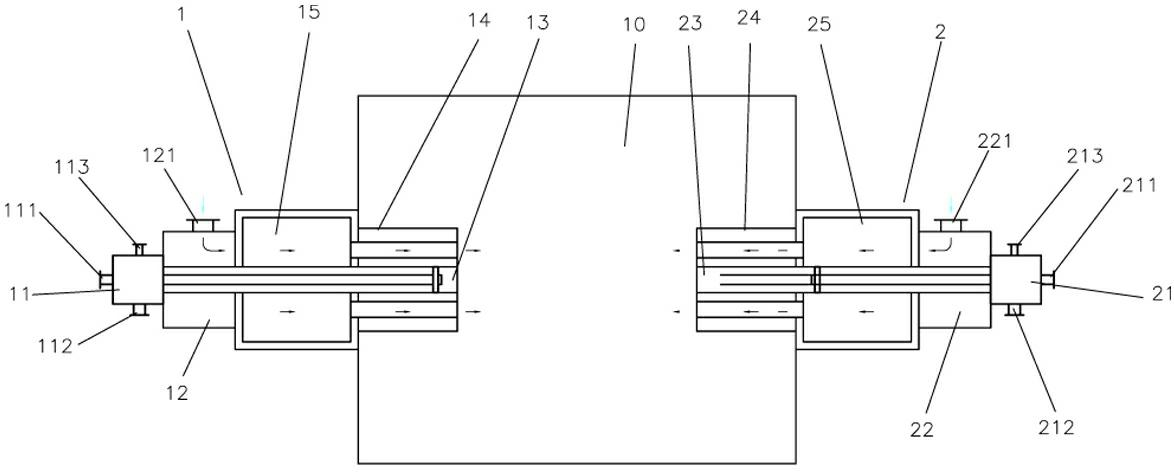

Quick cold start system and quick cold start method for fuel cell

PendingCN111682243ALower oxygen partial pressureIncrease concentration overpotentialFuel cell heat exchangeAutomotive engineeringIntercooler

The invention relates to a rapid cold start system and a rapid cold start method for a fuel cell. The system comprises a controller, and an air subsystem and a hydrogen subsystem which are respectively connected with an electric pile; the air subsystem comprises a back pressure valve, an air filter, an air compressor, an intercooler and an air inlet stop valve, wherein the air filter, the air compressor, the intercooler and the air inlet stop valve are sequentially connected. The air subsystem further comprises an air inlet adjusting valve, the air inlet adjusting valve is connected with the air filter and the air compressor, and the controller controls the air inlet adjusting valve. The method comprises the steps that the controller controls the opening degree of the air inlet adjusting valve, so the excess air coefficient is controlled to reduce the external output efficiency of the fuel cell; meanwhile, the compression ratio of the air compressor is adjusted, and the power consumption of the air compressor is increased to increase the air inlet temperature. Compared with the prior art, the method can achieve the rapid cold starting without auxiliary preheating and the success rate of cold starting.

Owner:TONGJI UNIV

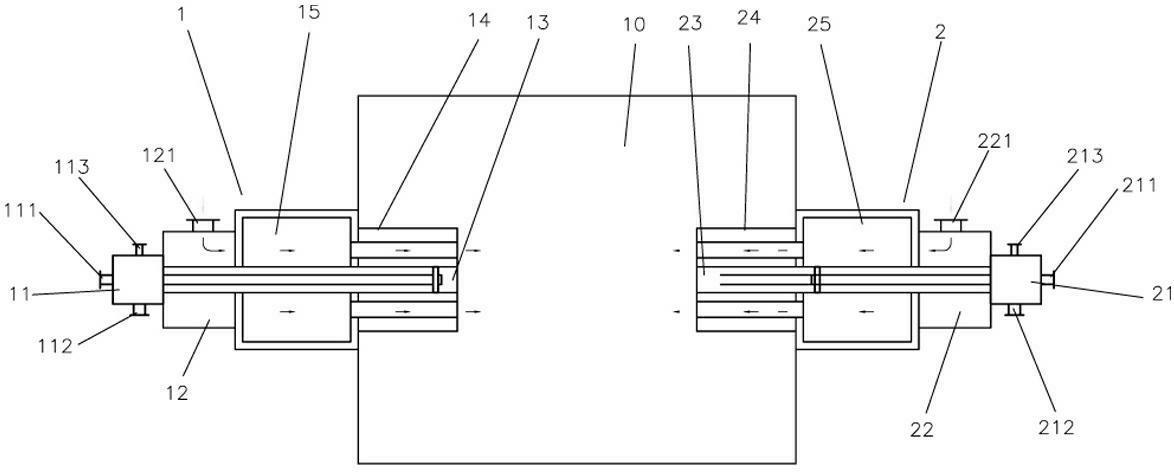

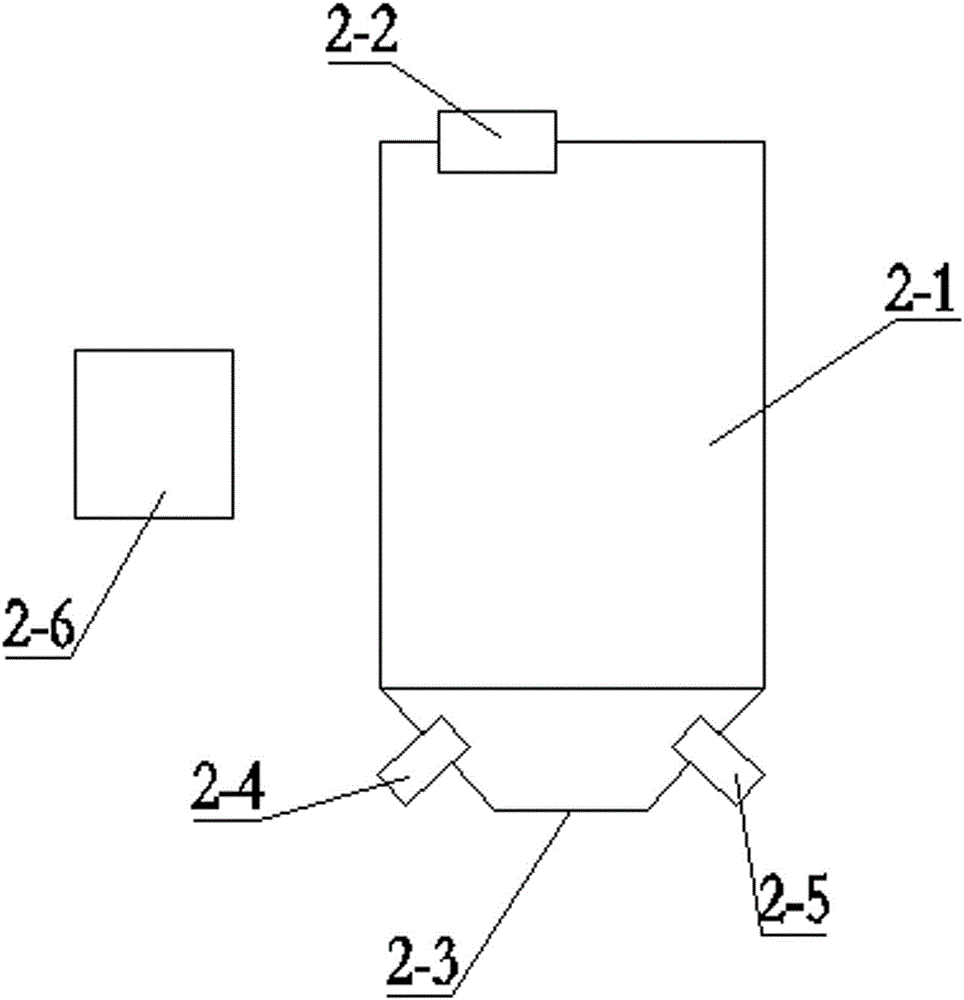

Polyacrylamide production line

ActiveCN105061646AFirmly connectedGuaranteed SolubilityDispersed particle filtrationGranulation by liquid drop formationProduction lineProcess engineering

The invention relates to a polyacrylamide production line. A reactor prefilter, an oil inlet lubrication polymerization reactor, an oil inlet lubrication smashing and pelleting device and a polyacrylamide colloid drying production line are connected in sequence, and the polyacrylamide colloid drying production line is respectively connected to a screening and grinding device and a pulse dust tail gas treatment device. The polyacrylamide production line is simple in structure, impurities in polyacrylamide production raw materials can be effectively filtered, the discharging time of a reactor is shortened, the amount of polymerization reactions is increased, colloid pelleting can be effectively lubricated, colloidal particles with the grain diameters of about 4 mm are obtained while the molecular weight of polyacrylamide is not reduced, required drying air quantity and energy consumption are reduced, the drying condition and standing time of materials are easily adjusted and controlled, the production capacity and product quality are improved, and the tail gas is effectively dedusted.

Engine crankcase ventilation system and method

InactiveCN111997710AIncrease intake air temperatureReduce the rate of oil agingNon-fuel substance addition to fuelExhaust gas recirculationAutomotive engineeringMotor oil

The invention relates to an engine crankcase ventilation system and method. The system comprises an engine crankcase, one end of a PCV valve communicates with an oil-gas separator, one end of the PCVvalve communicates with the air inlet end of an intake manifold through a first one-way valve, and one end of the PCV valve communicates with one output end of a supercharger and an EGR mixing valve through a second one-way valve, an EGR cooler communicates with the input end of the EGR mixing valve, the other output end of the EGR mixing valve communicates with an air filter, the other end of thesupercharger communicates with the air inlet end of the intake manifold, and the air outlet end of the intake manifold communicates with an engine cylinder cover. According to the system, an engine oil aging speed can be effectively reduced, engine oil emulsification risk of a valve chamber cover, an oil filling cover and the wall surface of the oil-gas separator can be reduced, and the problem of a failure of icing at the tail end of a breathing tube in winter can be solved.

Owner:KUNMING YUNNEI POWER +1

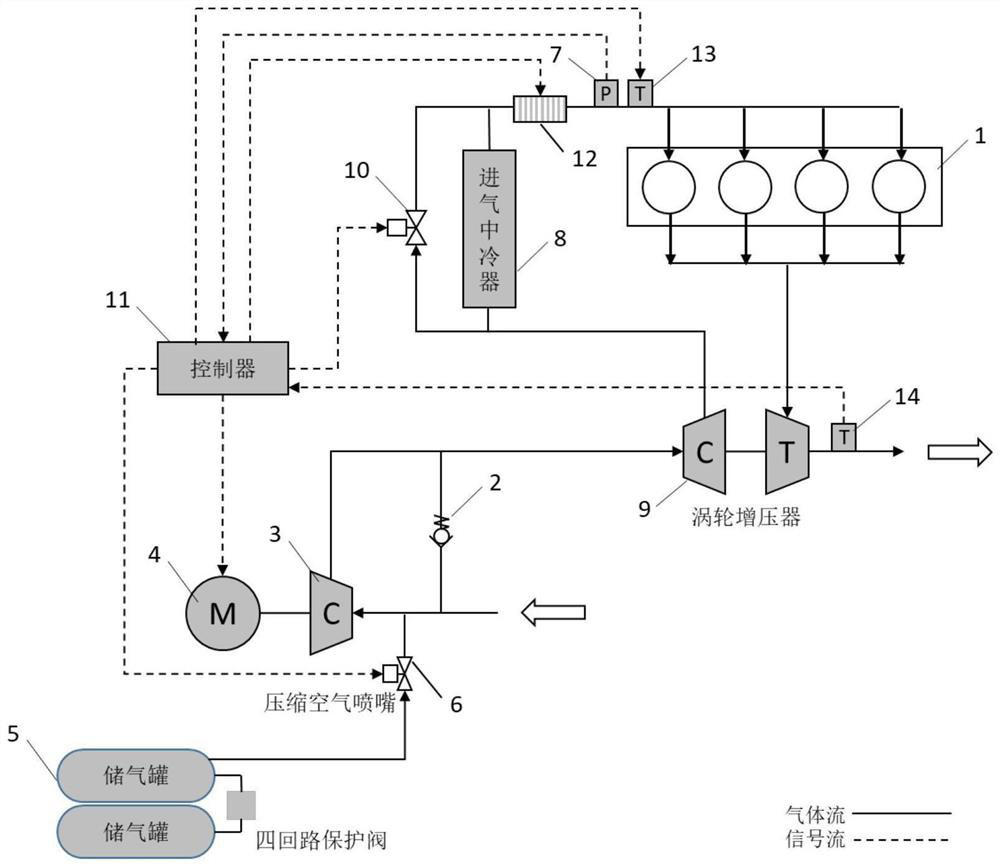

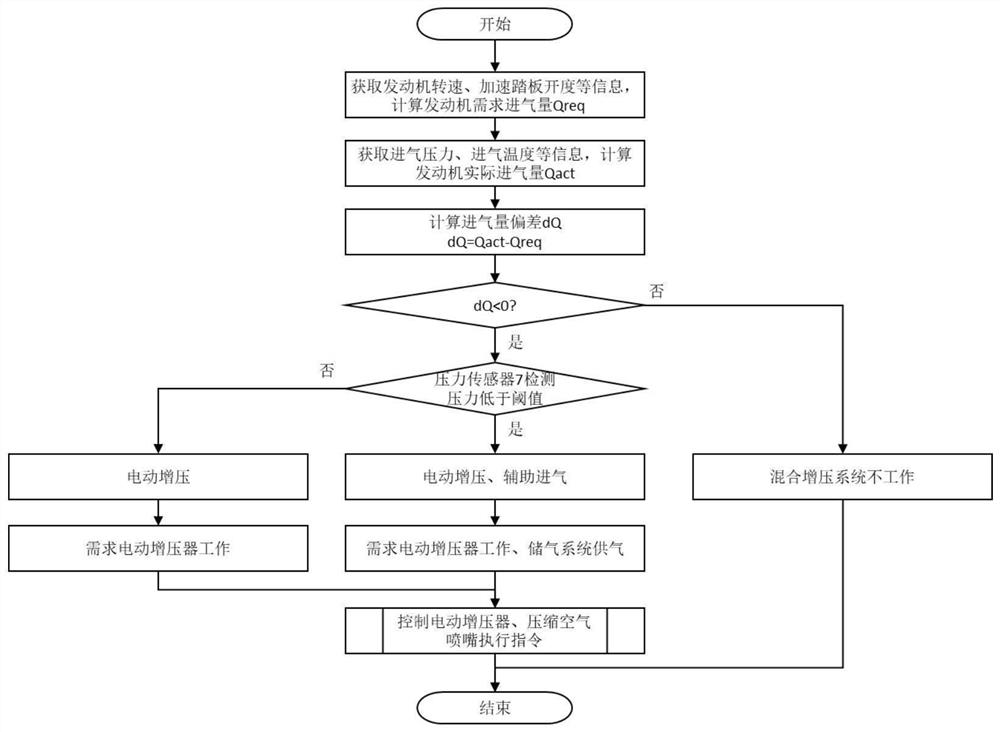

Multi-stage supercharging flexible air system with electric supercharging function for engine

ActiveCN112211717AIncrease intake air temperatureEmission reductionInternal combustion piston enginesEngine componentsIntercoolerMotronic

The invention provides a multi-stage supercharging flexible air system with an electric supercharging function for an engine. The multistage supercharging flexible air system involves an electric supercharger, the engine, a turbocharger, an air storage tank and a controller, wherein an air inlet communicates with the air inlet end of a first air compressor of the electric supercharger through a pipeline, the air inlet communicates with the air inlet end of a second air compressor of the turbocharger through a pipeline, and a one-way valve is arranged on the pipeline; the air outlet end of thefirst air compressor communicates with the air inlet end of the second air compressor through a pipeline; the air outlet end of the second air compressor communicates with an air inlet pipe of the engine through a pipeline via an air inlet intercooler and an air inlet heater; an air outlet pipe of the engine communicates with a turbine air inlet end of the turbocharger; the output end of the controller is electrically connected with a motor of the electric supercharger; the motor is used for driving the first gas compressor to operate; and a turbine of the turbocharger drives the second air compressor to operate through exhaust energy of the air outlet pipe of the engine.

Owner:DONGFENG COMML VEHICLE CO LTD

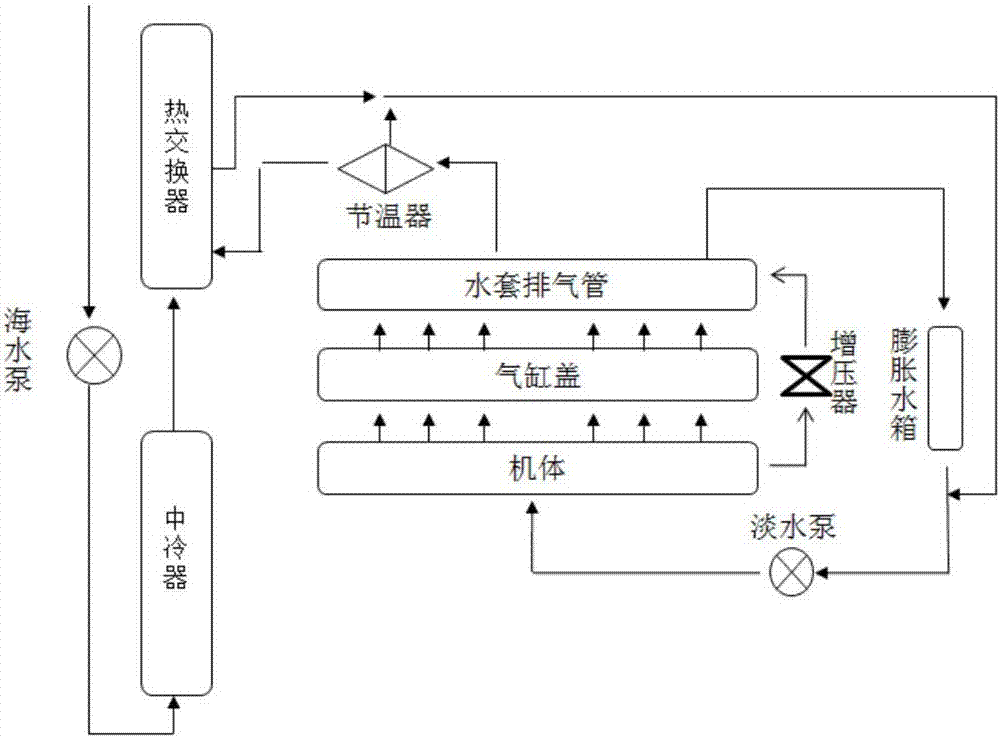

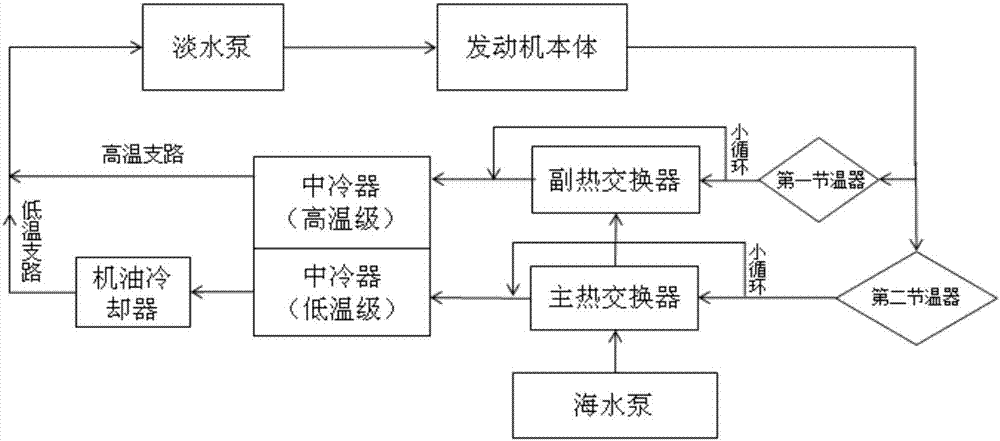

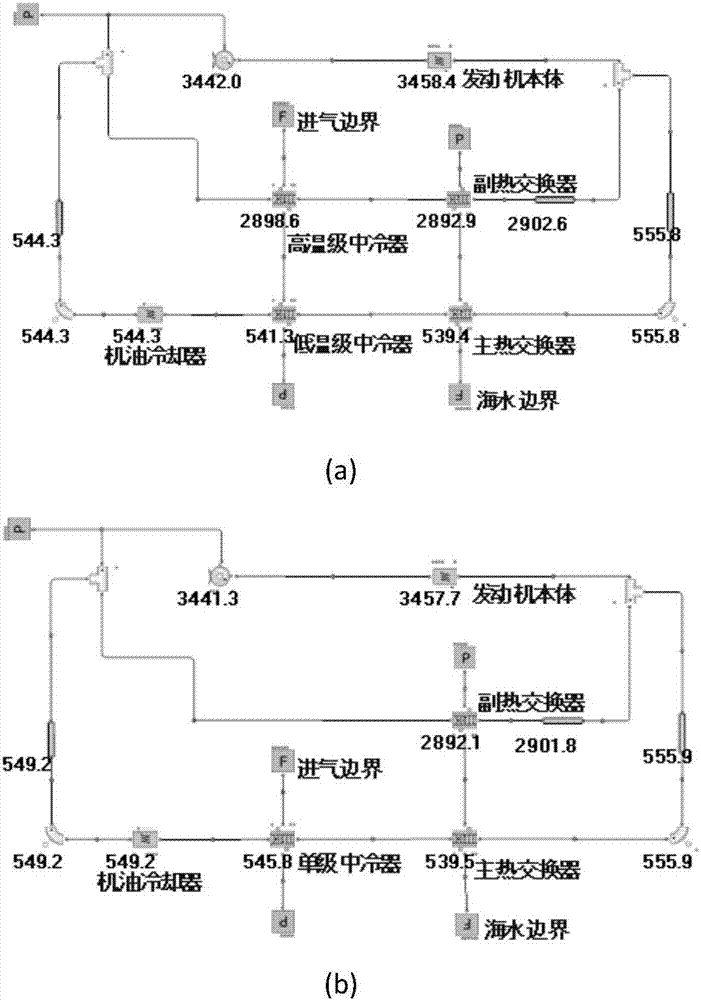

Cooling system and method of engine

ActiveCN107044332AReduced heat dissipation requirementsReduce volumeLiquid coolingInternal combustion piston enginesCombustionNuclear engineering

The invention provides a cooling system and method of an internal combustion engine, in particular to a cooling system and method of a marine diesel engine. Double heat exchangers are adopted and arranged in a high temperature branch and a low temperature branch correspondingly, internal cooling liquid are divided into a first internal cooling liquid branch and a second internal cooling liquid branch after being heated by an engine body, and the first internal cooling liquid branch comprises a first thermostat, the vice heat exchanger and a high temperature stage intercooler; the second internal cooling liquid branch comprises a second thermostat, the main heat exchanger and a lower temperature stage intercooler; and internal cooling liquid passing through the first internal cooling liquid branch and the second internal cooling liquid branch are converged and then returns to the engine body to form a closed cooling loop. According to the cooling system, size requirement of a whole engine is met, cooling system cost is lowered, the reliability of the cooling system is improved, and the combustion condition of the engine is improved.

Owner:WEICHAI POWER CO LTD

Engine inlet air, crankcase and anti-freezing solution preheating combined system and preheating method thereof

PendingCN111664041AReduce starting torqueRaise the compression end temperatureMachines/enginesThermal treatment of fuelCold airThermodynamics

The invention discloses an engine inlet air, crankcase and anti-freezing solution preheating combined system. The system comprises a controller, an air heating device, an anti-freezing solution preheating assembly and a pipeline for communicating, wherein external cold air is heated through the air heating device, then high-temperature air is input into an engine air inlet pipe and a crankcase airinlet channel in a crankcase through the pipeline, the anti-freezing solution preheating assembly inputs the heated anti-freezing solution into an engine cylinder cover and an engine body, the air heating device and the anti-freezing solution preheating assembly are both electrically connected with the controller, and the controller is connected with a storage battery on a vehicle to achieve power supply. The preheating combined system is independent of a vehicle, efficient preheating of engine inlet air can be achieved only through a small amount of power supplied by a storage battery on thevehicle and a small amount of oil supplied by an oil tank, the inlet air temperature and the anti-freezing solution temperature are rapidly increased, then the engine in-cylinder temperature and thetemperatures of all friction pairs of a crankshaft are increased, the starting torque is reduced, and the engine can be smoothly started under a harsh low-temperature condition.

Owner:BEIJING GAOXIN GREAT FILTER CO LTD

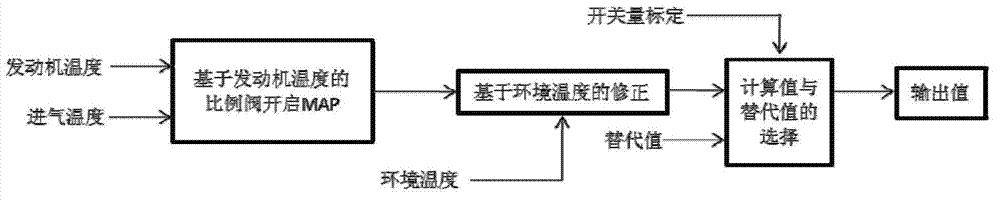

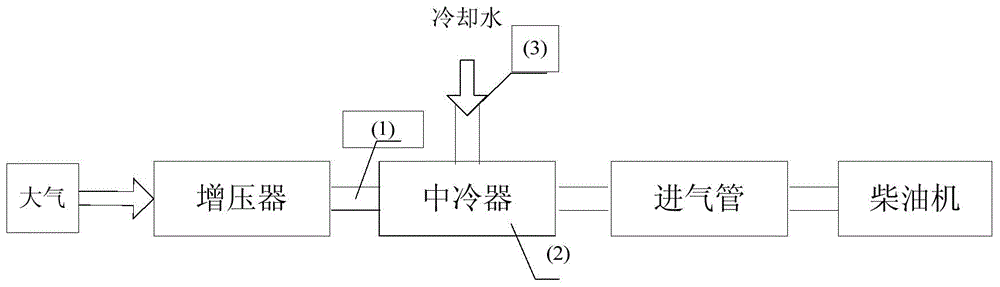

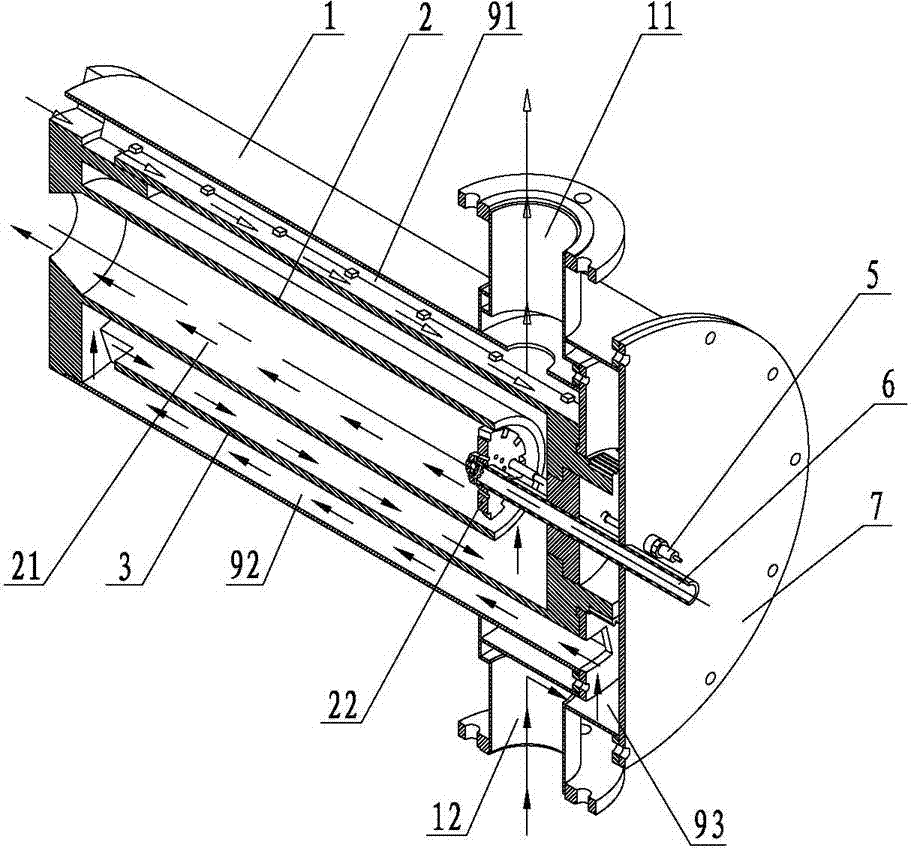

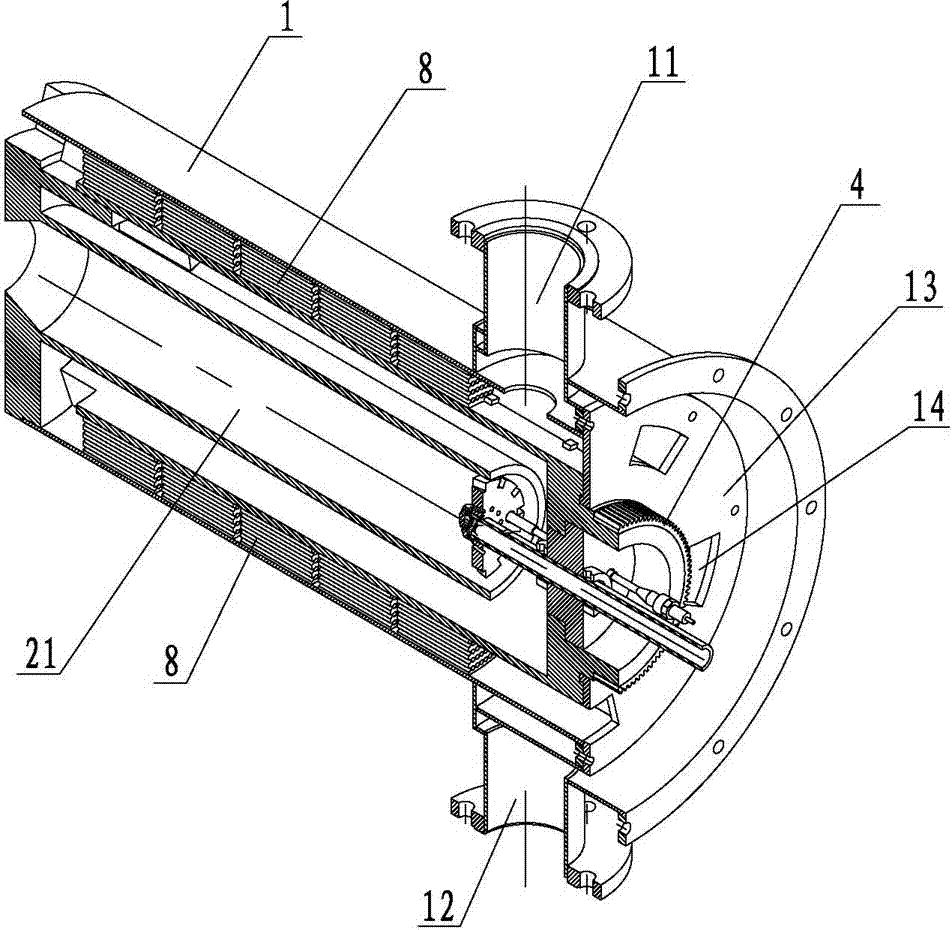

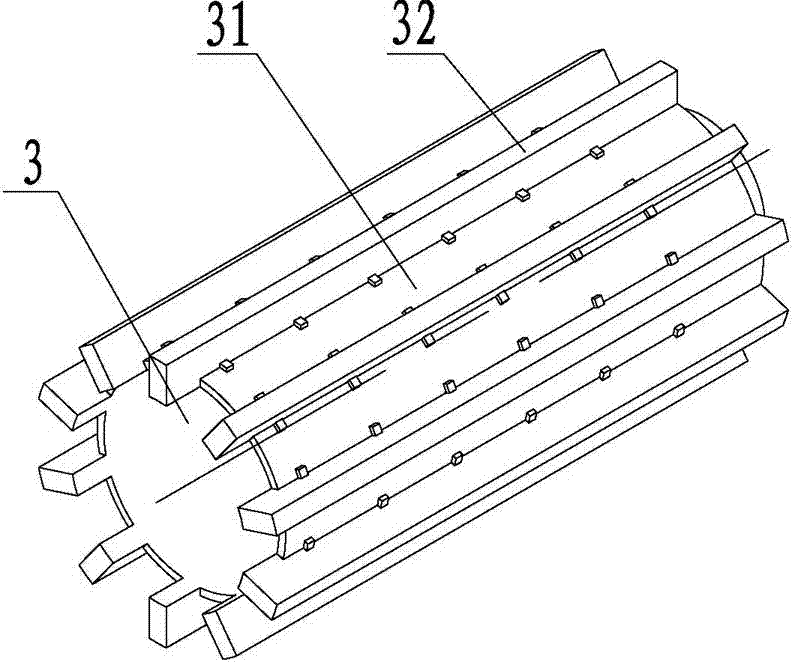

Apparatus for precisely regulating intake temperature by water cooling

InactiveCN104635794AIncrease intake air temperatureImprove performanceTemperatue controlLow loadControl signal

The invention provides an apparatus for precisely regulating intake temperature by water cooling. The apparatus comprises a compressor exhaust pipe, an intercooler, a cooling water pipe, an intake pipe, a diesel engine, a temperature sensor and an ECU (electronic control unit). An inlet of the intercooler is communicated with the compressor exhaust pipe; an outlet of the intercooler is communicated with an inlet of the intake pipe; a water cooling inlet of the intercooler is communicated with an outlet of the cooling water pipe through an electromagnetic valve; the temperature sensor is disposed within the intake pipe; an outlet of the intake pipe is connected to an intake hole of the diesel engine; the control end of the electromagnetic valve is in signal connection with the control signal output port of the ECU; the temperature sensor is in signal connection with a signal input port of the ECU. The apparatus according to the technical scheme has the advantages that the ECU and the electromagnetic valve are added, intake temperature of the diesel engine running in low-load condition at low ambient temperature is raised, performance of the diesel engine is improved, environmental adaptability of the diesel engine is improved and the apparatus is simple in structure and convenient to regulate.

Owner:CHINA NORTH ENGINE INST TIANJIN

Self-regenerative type burner

ActiveCN103090391ALower discharge temperatureIncrease intake air temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invention relates to a self-regenerative type burner. A smoke outlet, an air inlet and a baffle are arranged at the back end of a valve body and a plurality of fan-shaped windows are distributed evenly in the baffle. A burner block is contained in the valve body, a core body is sleeved on the burner block, a plurality of channels are evenly distributed in the core body, and a regenerative body is arranged in each channel. A transmission mechanism is connected with the core body and can drive the core body. A smoke channel and an air channel are formed between the core body and the valve body, wherein the smoke channel is communicated with the smoke outlet. A burning chamber is formed in the middle of the burner block, the burning chamber is communicated with the air channel, and a fire rod and a gas pipe extend into the burning chamber. An end cover is fixedly arranged at the back end of the valve body, and a back end external channel is formed between the end cover and the valve body, the back end external channel is communicated with the air channel through the fan-shaped windows, and the back end external channel is communicated with the air inlet. The self-regenerative type burner heats combustion air by means of smoke so as to greatly improve the air inlet temperature of the combustion air and reduce the smoke exhaust temperature, and therefore heat energy is completely utilized.

Owner:SHAOXING XUEERDE FURNACE IND

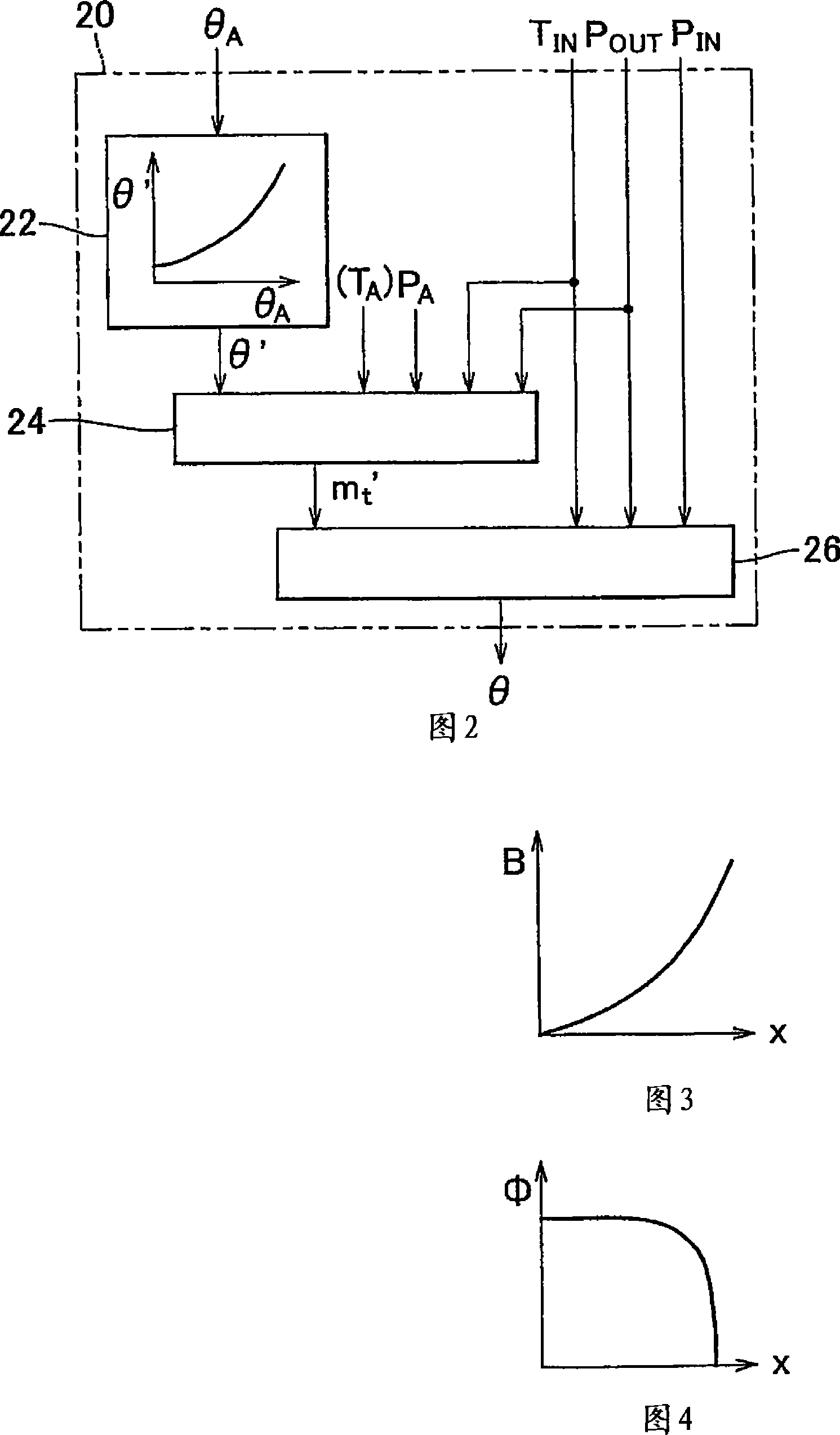

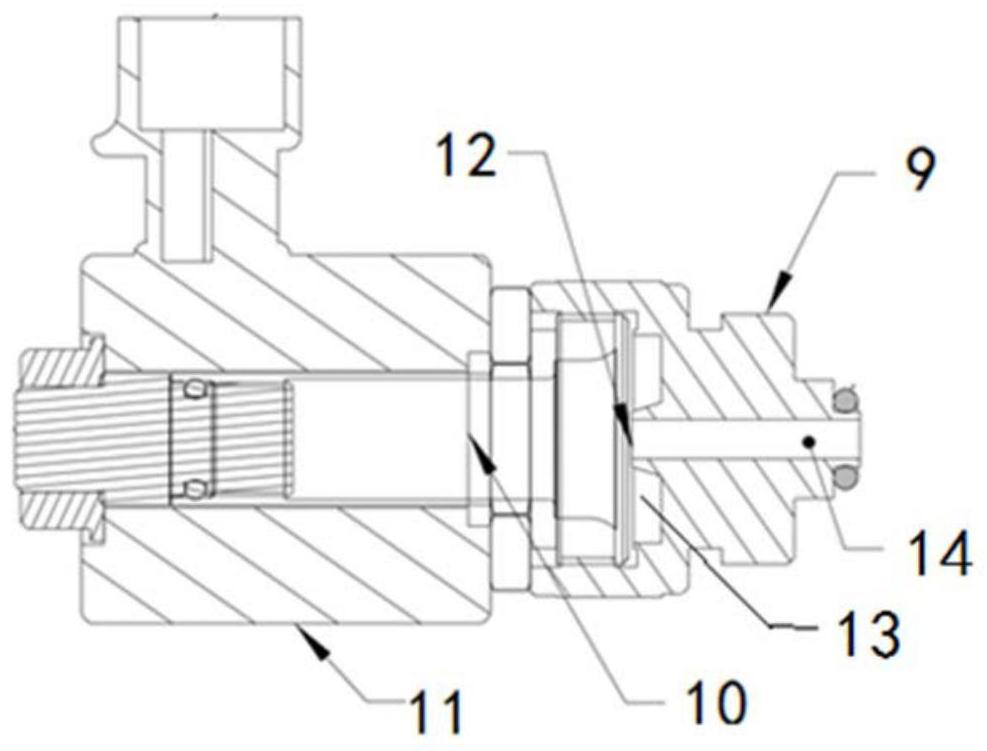

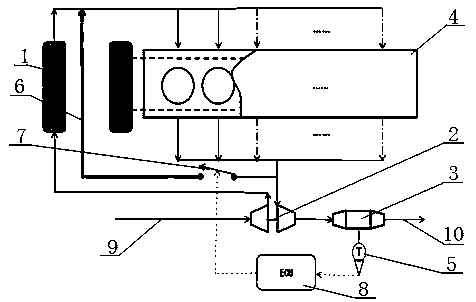

Air inlet device for controlling exhaust gas temperature by waste gas drainage

InactiveCN103775180AImprove conversion efficiencyIncrease exhaust temperatureInternal combustion piston enginesExhaust apparatusTurbochargerEngineering

The invention discloses an air inlet device for controlling exhaust gas temperature by waste gas drainage. The air inlet device comprises an intercooler (1), a turbocharger (2), a selective catalytic reduction (SCR) postprocessing device (3) and a drainage pipeline (6); a compressor outlet of the turbocharger (2) is communicated with an air inlet tube of an engine (2) through the intercooler (1); a turbine outlet of the turbocharger (2) is communicated with the SCR postprocessing device (3); an exhaust port of the SCR postprocessing device (3) is provided with a temperature sensor (5); one end of the drainage pipeline (6) is communicated with a turbine inlet of the turbocharger (2); the other end of the drainage pipeline (6) is communicated with the outlet of the intercooler (1); the drainage pipeline (6) is provided with a controlled valve (7); the temperature sensor (5) and the controlled valve (7) are respectively and electrically connected with an engine electronic control unit (ECU) (8). By the air inlet device, the conversion efficiency of a catalyst in the SCR postprocessing device (3) of the engine is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

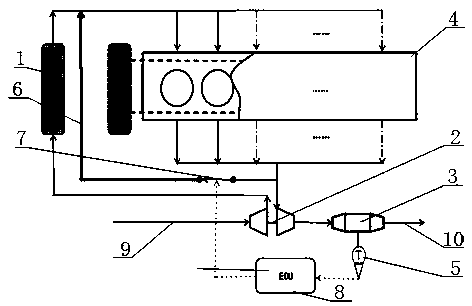

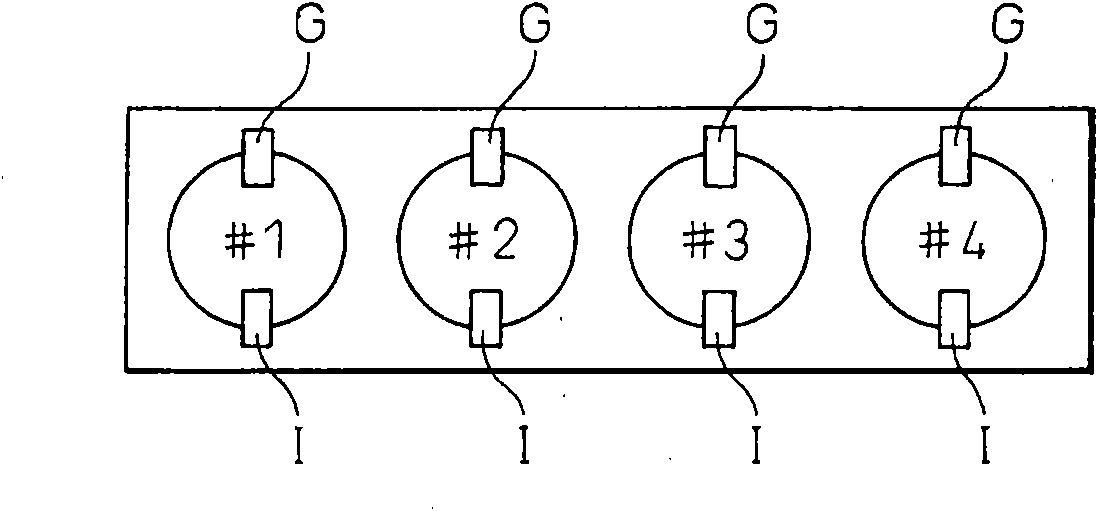

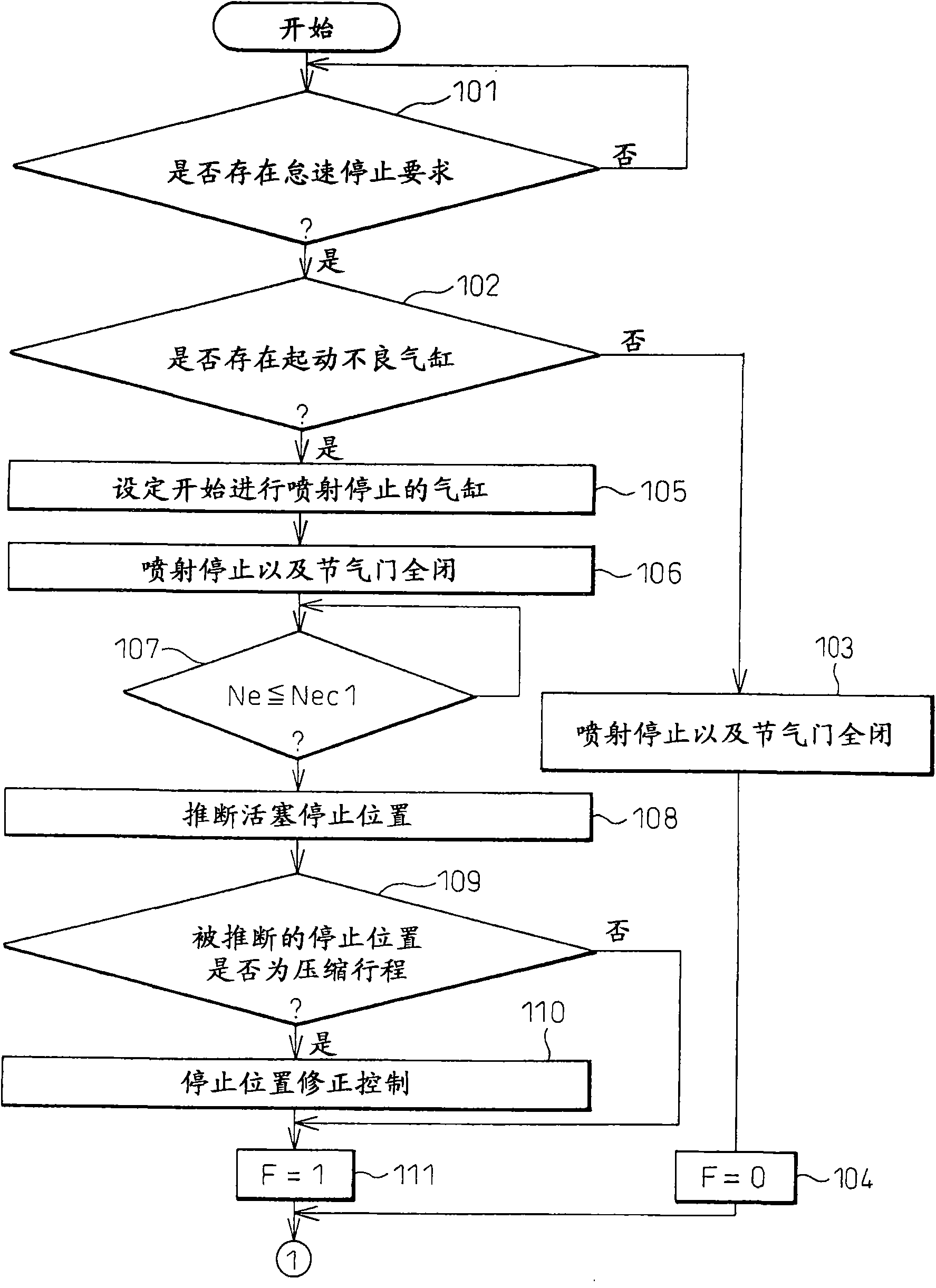

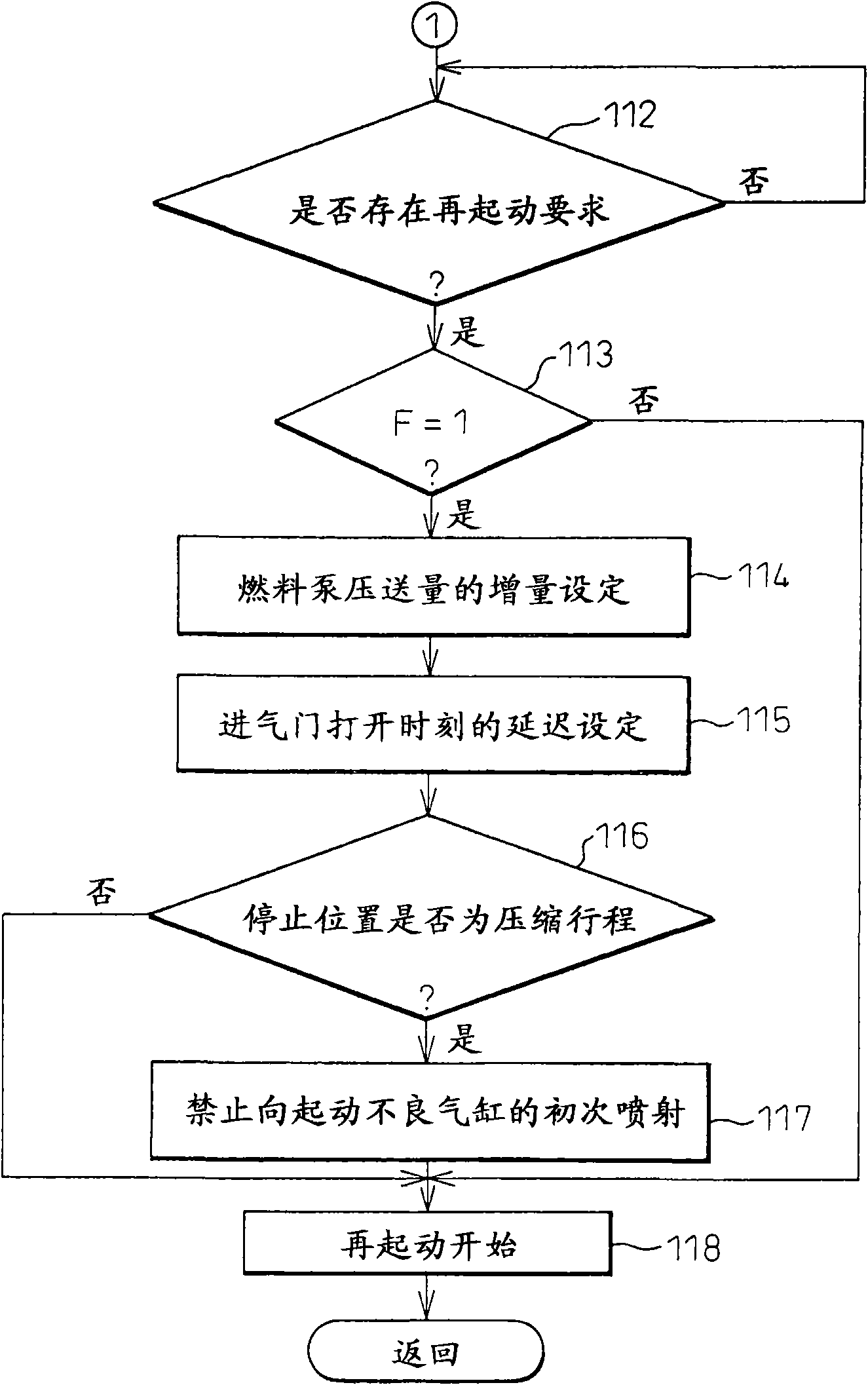

Starter for internal-combustion engine

InactiveCN101680376AInhibition of initiationAvoid dischargeElectrical controlInternal combustion piston enginesIdle speedInternal combustion engine

Owner:TOYOTA JIDOSHA KK

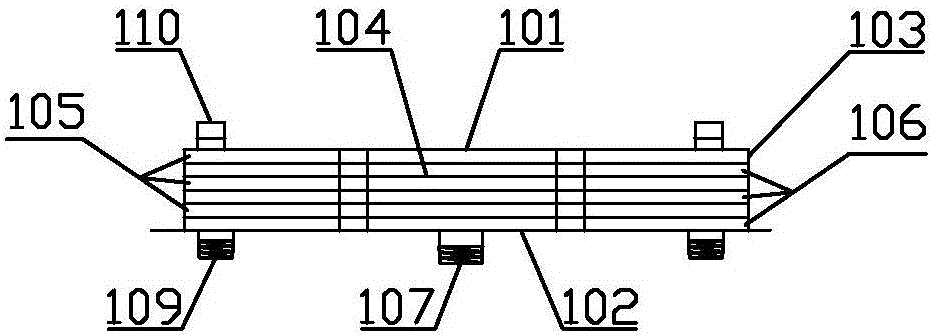

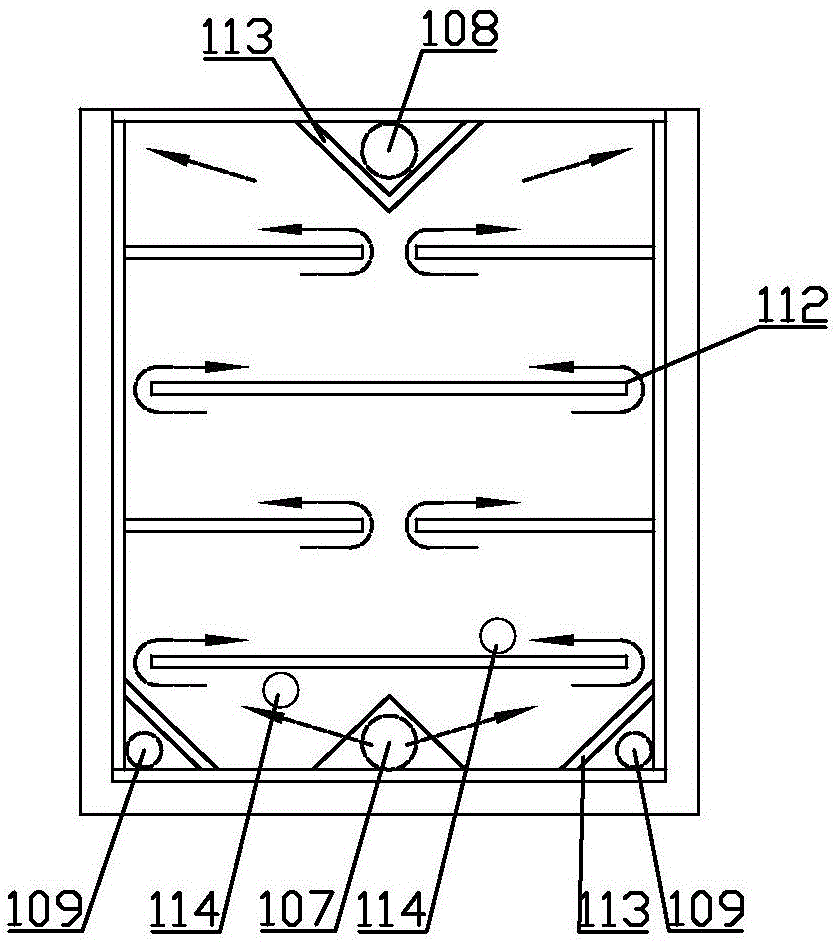

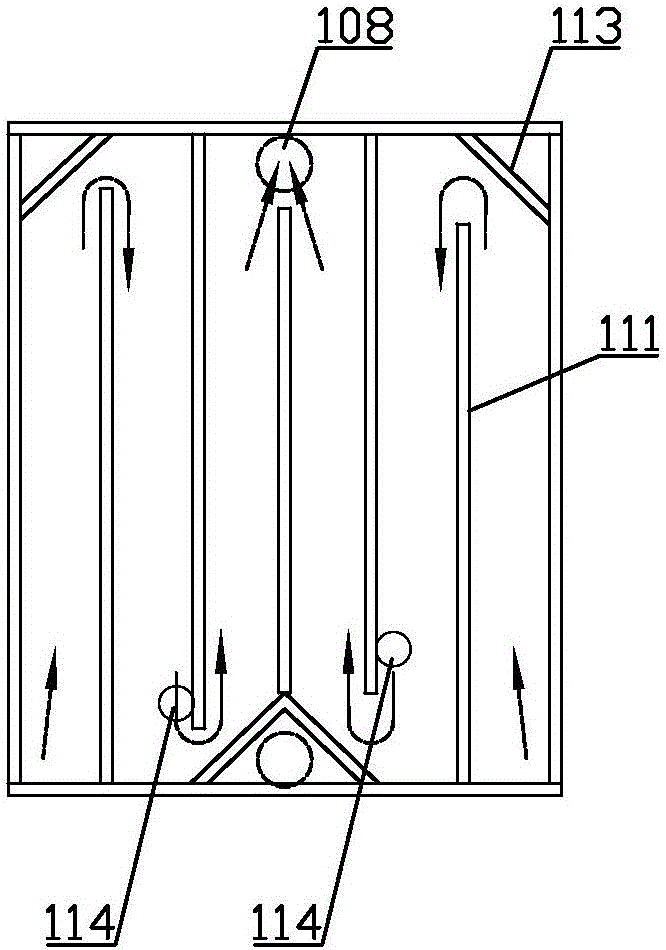

Heat exchanger for food baking and heat exchange and heat dissipation integrated preheating baking equipment

ActiveCN106440887APlay the role of thermal insulationTake advantage ofBaking vesselsHeat exchanger casingsThermal energyCooking & baking

The invention discloses a heat exchanger for food baking. The heat exchanger for food baking comprises a top plate, a baseplate, a side plate, and a heat exchange separation plate arranged between the top plate and the baseplate; the heat exchange separation plate is fixed on the side plate, and divides a space between the top plate and the baseplate into multiple medium layers; and the heat exchange separation plate is manufactured by metal foils or metal sheets. The invention further discloses heat exchange and heat dissipation integrated preheating baking equipment; the equipment comprises a baking box body; a microhole air distributor is arranged at the lower part of the internal space of the baking box body, and is connected with a refrigerant outlet; a heating medium inlet is communicated with the upper part of the internal space of the baking box body through a guide pipe; an air blower is arranged in a refrigerant inlet; and an induced draft fan is arranged in a heating medium outlet. The whole heat exchange system occupies no additional space, fully uses a shell structure, and becomes chassis heating equipment of baking equipment, thermal insulation equipment at the lower part of the baking equipment and preheater equipment for recovering heat energy by waste gas.

Owner:DALIAN SAILE ENERGY SAVING EQUIP CO LTD

Hydrogen-ignited ammonia-hydrogen mixed combustion zero-carbon engine and control method

PendingCN114738140AIncrease the speed of flame spreadEliminate ammonia slipElectrical controlInternal combustion piston enginesProcess engineeringOil supply

Owner:HARBIN ENG UNIV

Throttling and recooling adiabatic compressed-air energy storage system

InactiveCN107842399AIncrease intake air temperatureImprove working abilityEngine componentsSteam engine plantsSystem capacityThermal energy storage

The invention relates to the technical field of energy utilization, and discloses a throttling and cooling adiabatic compressed air energy storage system, including an air pipeline, which includes an air compressor, a cooler, an air storage chamber, a regenerator, and a turbine connected in sequence. Expander; heat circulation pipeline, including low-temperature heat recovery storage tank and high temperature heat recovery storage tank sequentially connected into circulation pipeline, cooler and regenerator are arranged on heat circulation pipeline; air pipeline and heat circulation pipeline pass through Cooler and regenerator heat transfer; cold accumulator, including shell and air channel, the shell is filled with cold storage medium, one end of air channel is connected with cooler and regenerator, and the other end passes through the first branch and the second branch respectively. The second branch is connected with the gas storage chamber; the second branch is provided with a throttling and pressure stabilizing valve. When deflated, the system absorbs and stores the cold energy of the throttling air through the regenerator, thereby preheating the intake air of the turbo expander; when inflating, the cold energy stored in the regenerator is used to cool the air intake of the air storage chamber, thereby increasing the air storage capacity. Chamber gas storage capacity and system capacity.

Owner:TSINGHUA UNIV

Intake temperature control system to meet intake temperature requirement of gasoline compression ignition full conditions

ActiveCN109252990AIncrease profitImprove combustion stability and combustion efficiencyInternal combustion piston enginesThermal treatment of fuelIntercoolerEngineering

The invention discloses an intake temperature control system to meet intake temperature requirement of gasoline compression ignition full conditions. An intake port of a dual-variable-valve mechanismis connected with an intake master tube that is connected with a gas compressor; an exhaust port of the dual-variable-valve mechanism is connected with an exhaust master tube; the exhaust master tubeis connected with a turbine that is connected with a post-processor; the intake master tube is provided with an intercooler; an exhaust port of the post-processor is connected with two exhaust branches; one exhaust branch is provided with a second exhaust valve, and the other exhaust branch is provided with a first exhaust valve and an exhaust heat exchanger; a shell side water outlet of the exhaust heat exchanger is connected with a shell side water inlet of the intercooler; a shell side water inlet of the exhaust heat exchanger is connected with a shell side water outlet of the intercooler;the shell side water inlet of the intercooler is connected with a water inlet of a first radiator; the shell side water outlet of the intercooler is connected with a water inlet of the first radiator;the shell side water outlet of the intercooler is connected with a water inlet of the second radiator; the shell side water inlet of the intercooler is connected with a water outlet of a cooling water passage of an engine; a water outlet of the second radiator is connected with a water inlet of the cooling water passage of the engine.

Owner:TIANJIN UNIV

Tee joint material fluidistor of improved structure

ActiveCN104760829AImprove feeding efficiencyGood fluidization effectBulk conveyorsFailure rateDischarge rate

The invention provides a tee joint material fluidistor of an improvd structure. The fluidistor comprises side discharge ports, discharge flanges, a tee joint body, a top feed port, a feed flange, a bottom air inlet pipe, a side air inlet pipe, a vibration device, an intercepter plate, a preheating device, an air pipe joint, a fixed bolt and a protection plate, and the side discharge ports are installed at the left side and the right side of the tee joint body through the discharge flanges; the top feed port is installed on the upper portion of the tee joint body through the feed flange; the bottom air inlet pipe is installed at the lower side of the tee joint body through the air pipe joint. According to the fluidistor, through the arrangements of the vibration device, the preheating device, the intercepter plate and the protection plate, it is facilitated to improve the feeding efficiency, the fluidization degree is improved, the failure rate is reduced, and the market application and popularization are facilitated.

Owner:TIANJIN SHIDA ELECTRIC POWER EQUIP

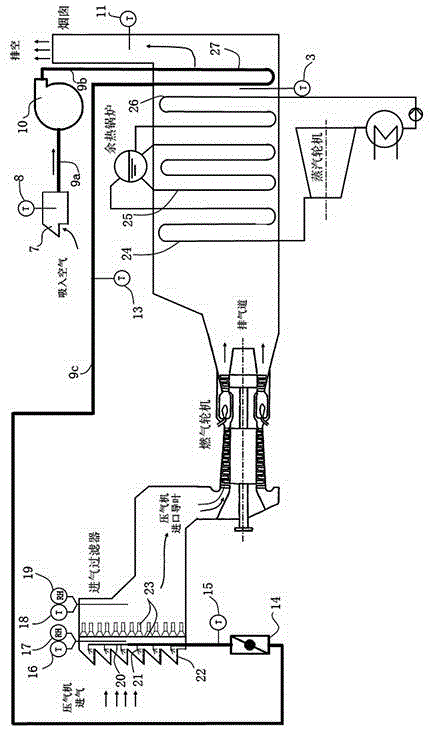

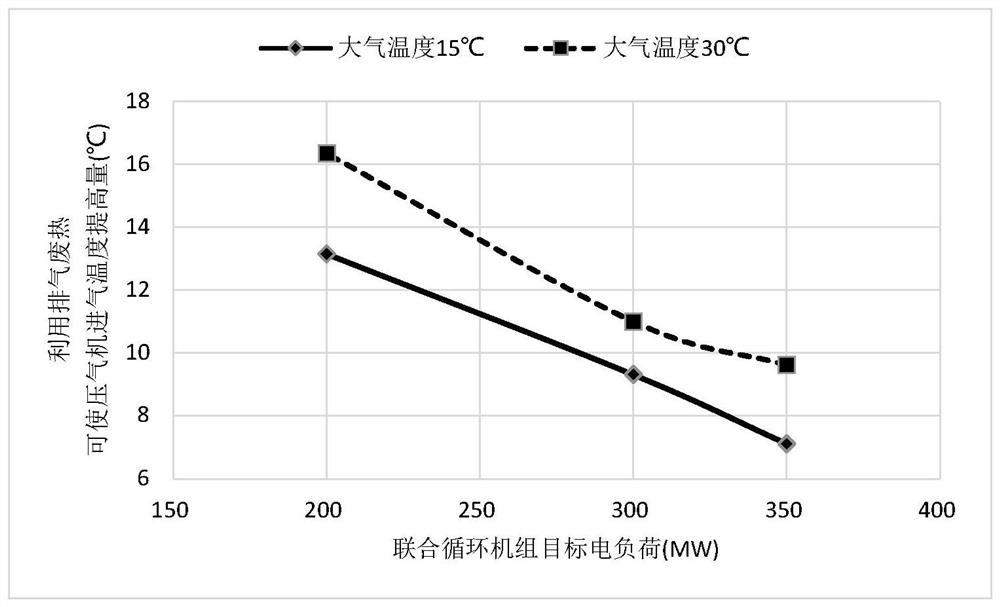

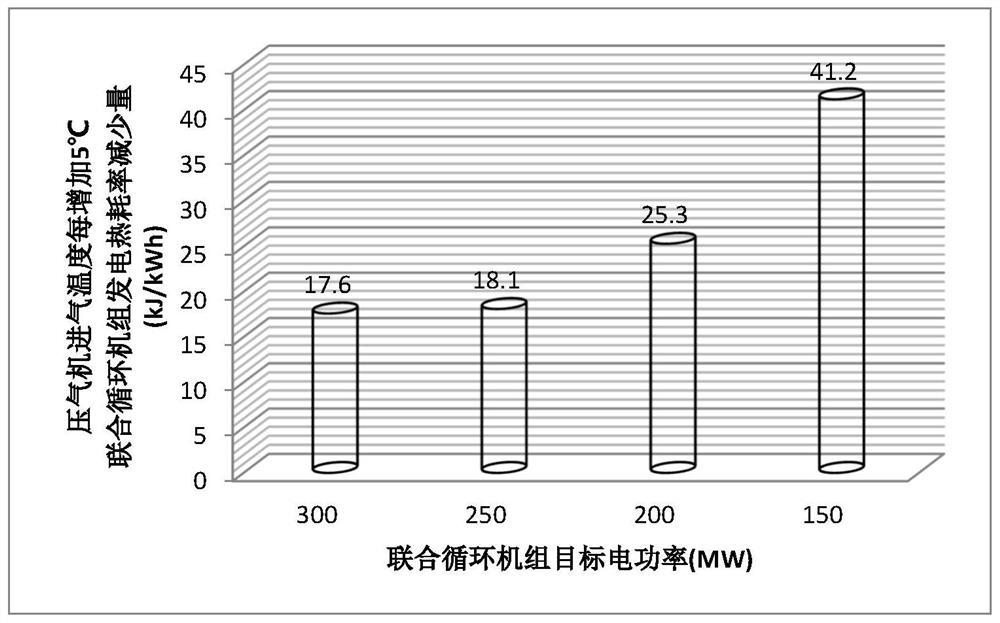

Exhaust waste heat utilization system of gas turbine heat channel cooling air heat exchanger

PendingCN112360633AIncrease intake air temperatureIncrease load factorTurbine/propulsion engine coolingTurbine/propulsion fuel heatingGas compressorProcess engineering

The invention discloses an exhaust waste heat utilization system of a gas turbine heat channel cooling air heat exchanger. The exhaust waste heat utilization system mainly comprises a gas compressor gas inlet channel, a gas turbine, a waste heat boiler, a steam turbine, the gas turbine heat channel cooling air heat exchanger and an air channel. According to the exhaust waste heat utilization system, high-temperature exhaust energy of the gas turbine heat channel cooling air heat exchanger which is originally directly exhausted to the atmosphere is used for heating gas compressor inlet gas, thegas compressor inlet gas temperature is increased, the load rate of a combined cycle unit under the partial load working condition is increased, then the power generation efficiency of the combined cycle unit is improved, and the beneficial effect of improving the running economy of the combined cycle unit under the partial load working condition is achieved.

Owner:HUANENG POWER INT INC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com