Low-temperature combustion and small-load stable combustion device and method for internal combustion engine

A low-temperature combustion and stable combustion technology, applied in internal combustion piston engines, combustion engines, charging systems, etc., can solve the problems of complex and complex variable valve technology, which cannot well meet the stable combustion of engines with small loads, and achieve broadening Intake temperature domain and the effect of working condition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

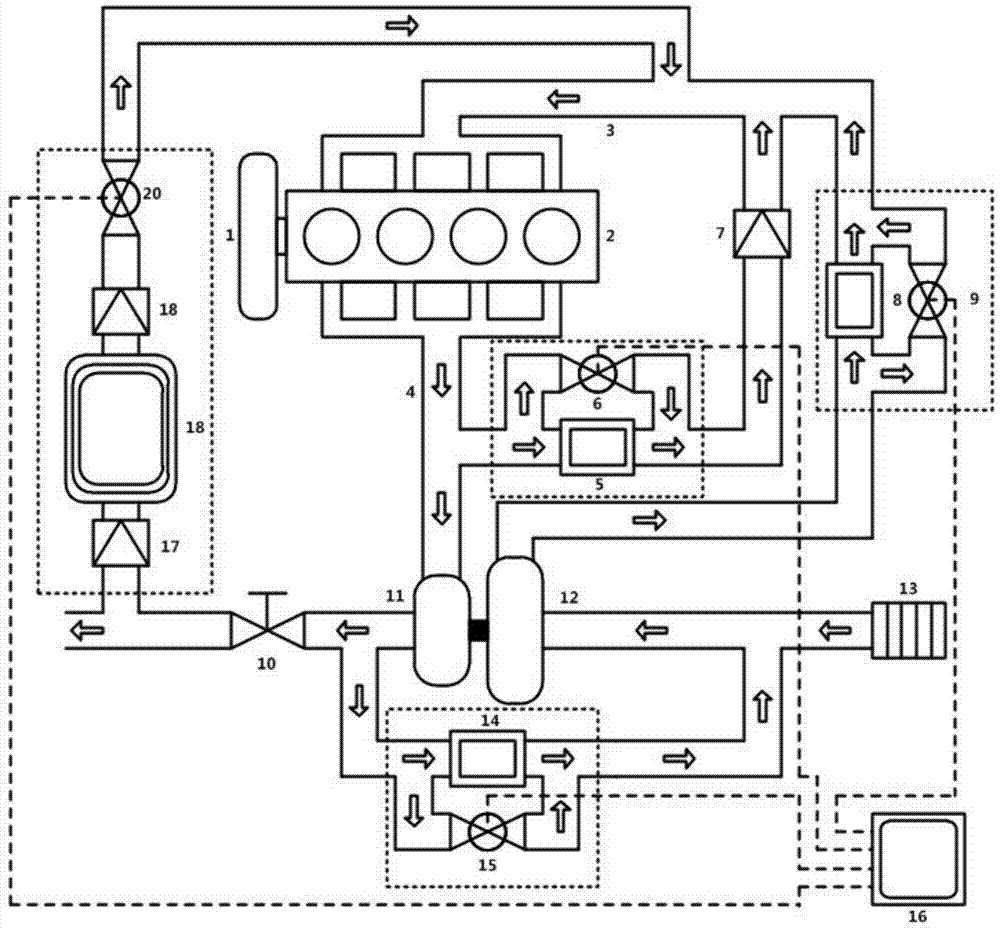

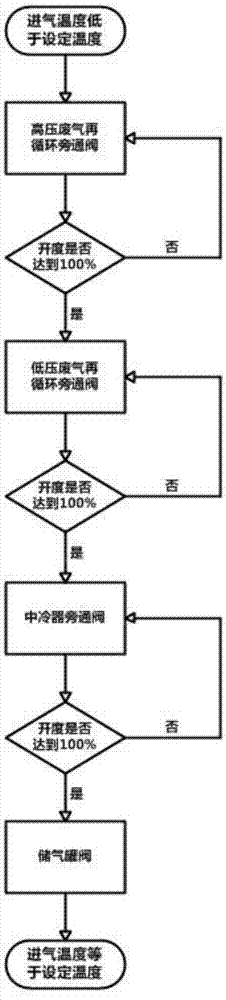

Embodiment 1

[0027] Step 1. During the running of the engine, the electronic control unit 16 reads the temperature signal of the temperature sensor installed on the intake manifold. The temperature is 25°C, and the set temperature value of the electronic control unit 16 is 45°C. Output the control signal to the high-pressure EGR control system, open the high-pressure EGR bypass valve 6 to an opening degree of 50%, so that the exhaust gas before the turbine 11 bypasses the high-pressure EGR cooler 5, thereby increasing the high-pressure EGR exhaust gas temperature, and then through the one-way valve 7, into the intake manifold 3; when it is detected that the intake air temperature is 28°C, the high-pressure exhaust gas recirculation bypass valve 6 increases the opening to 75%, 87.5%, and 100% in turn, When the intake air temperature is detected to be 30°C again, the low-pressure EGR bypass valve 15 starts to respond;

[0028] Step 2: The electronic control unit 16 sends an instruction to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com